The In-Plane Compression Response of Thermoplastic Composites: Effects of High Strain Rate and Type of Thermoplastic Matrix

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials of Specimens

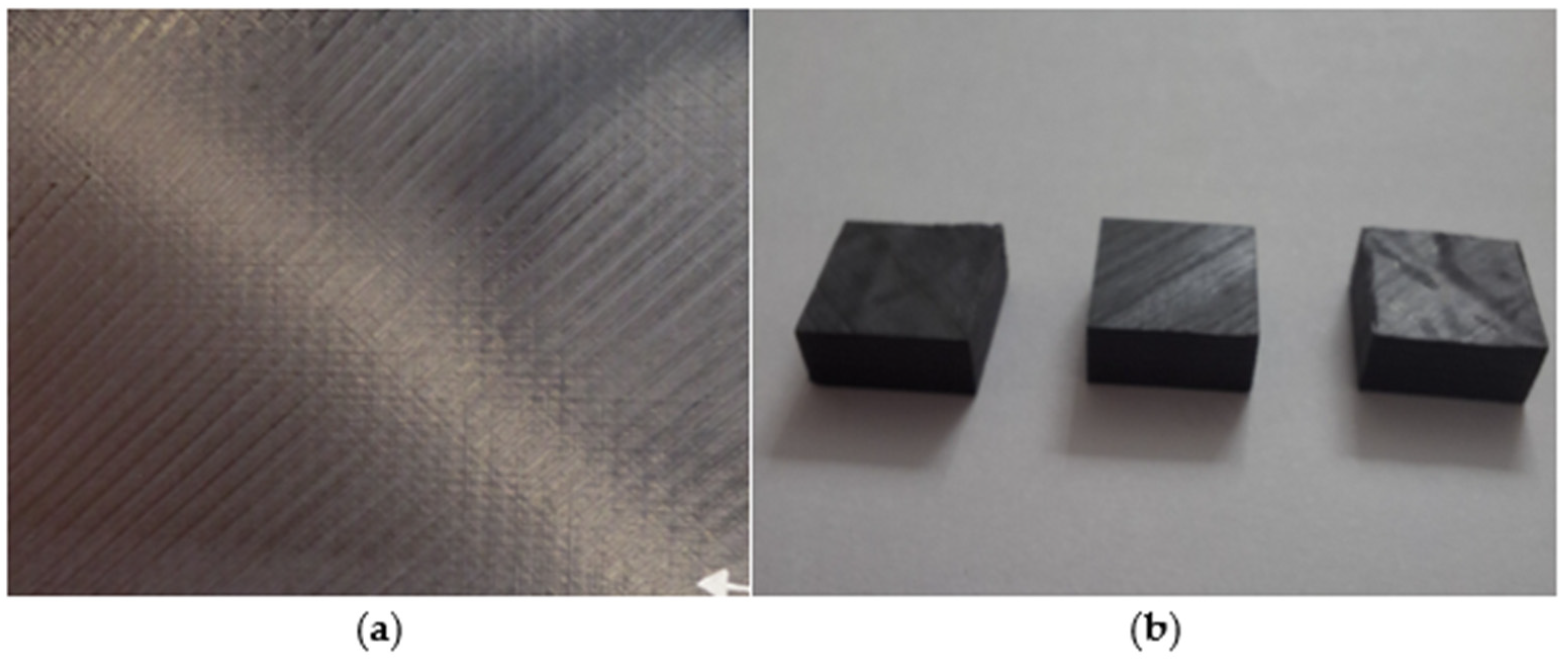

2.2. Manufacturing of Specimens

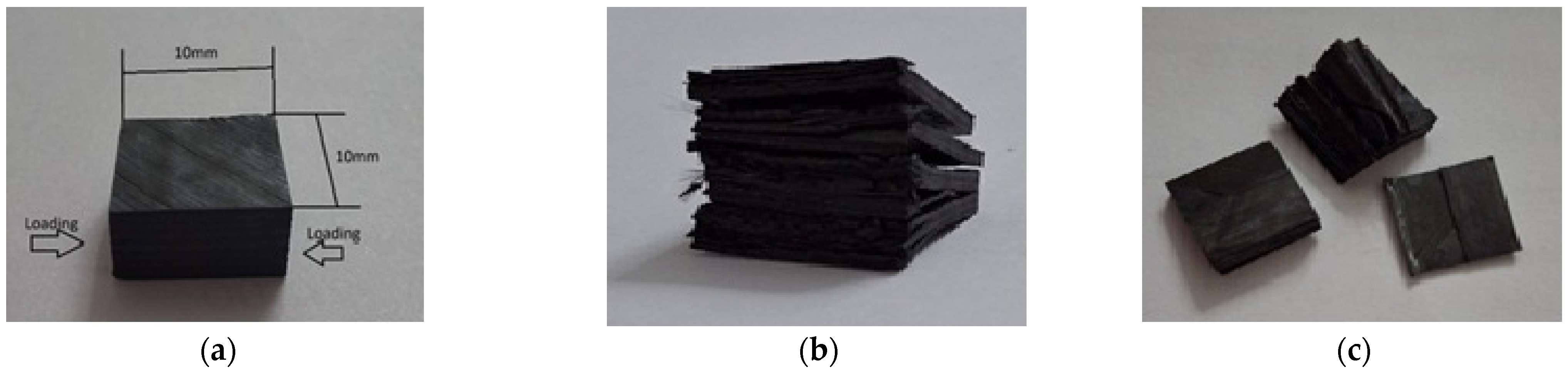

2.3. Machine for Testing

2.3.1. Servo-Hydraulic Testing Machine

2.3.2. SHPB for High Strain Rate Testing

3. Results

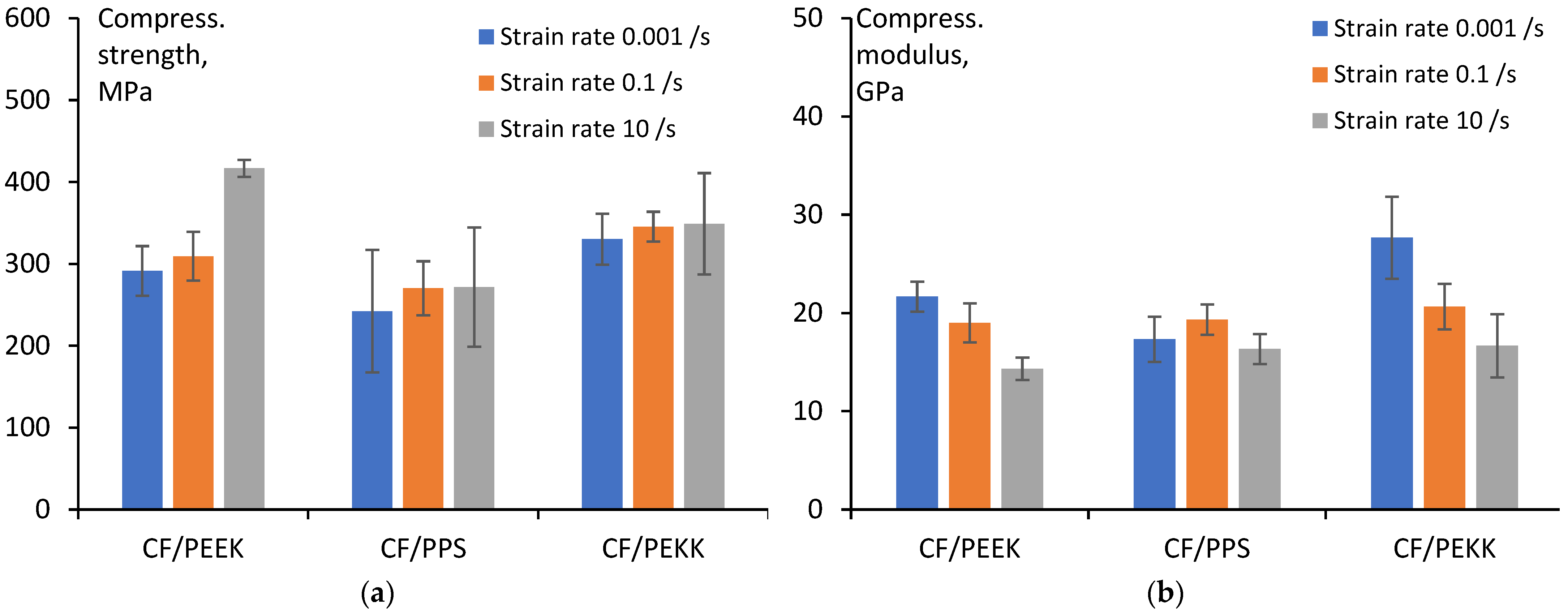

3.1. Compression Tests

3.1.1. Compressive Testing by Servo-Hydraulic Testing Machine

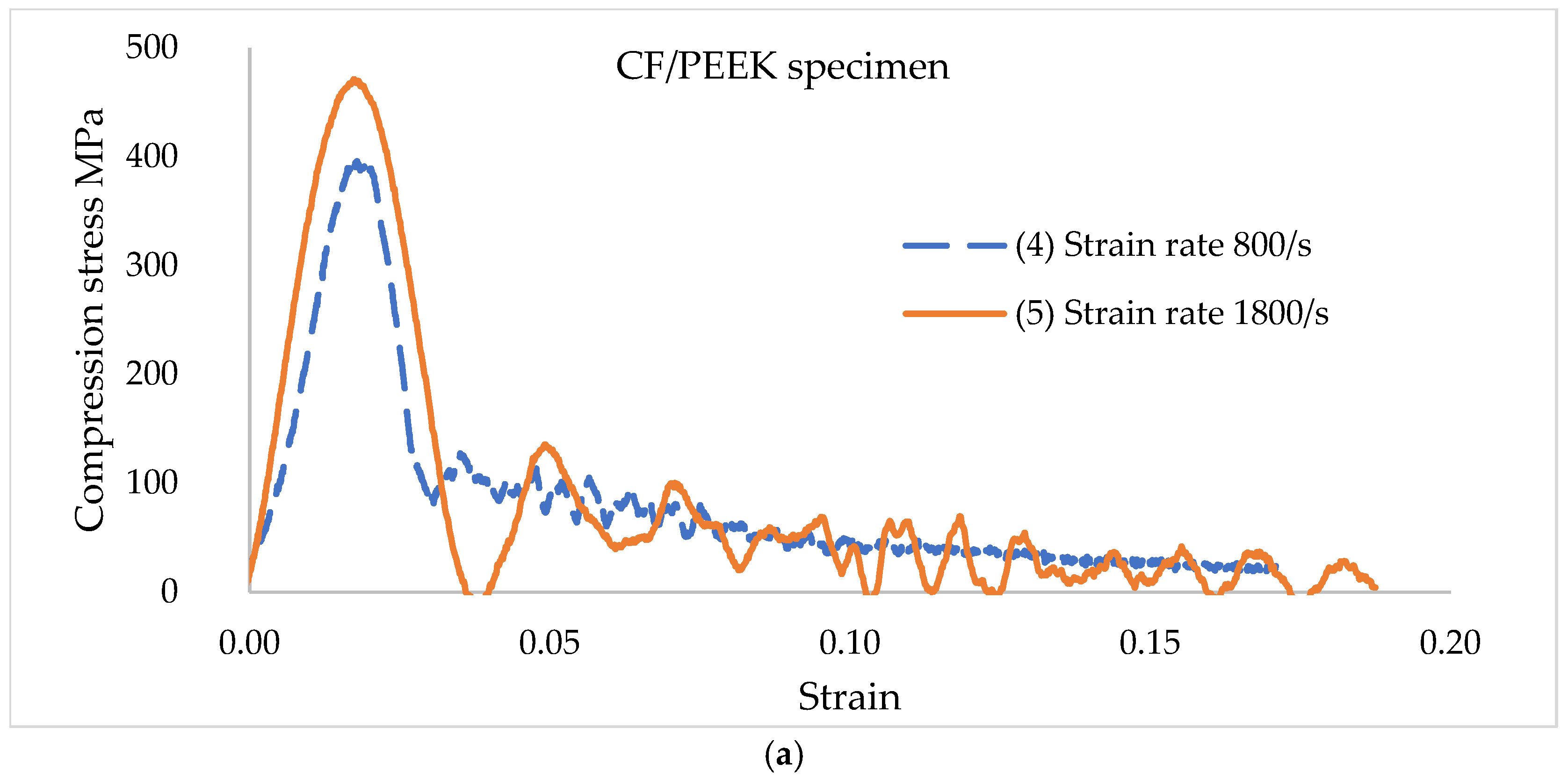

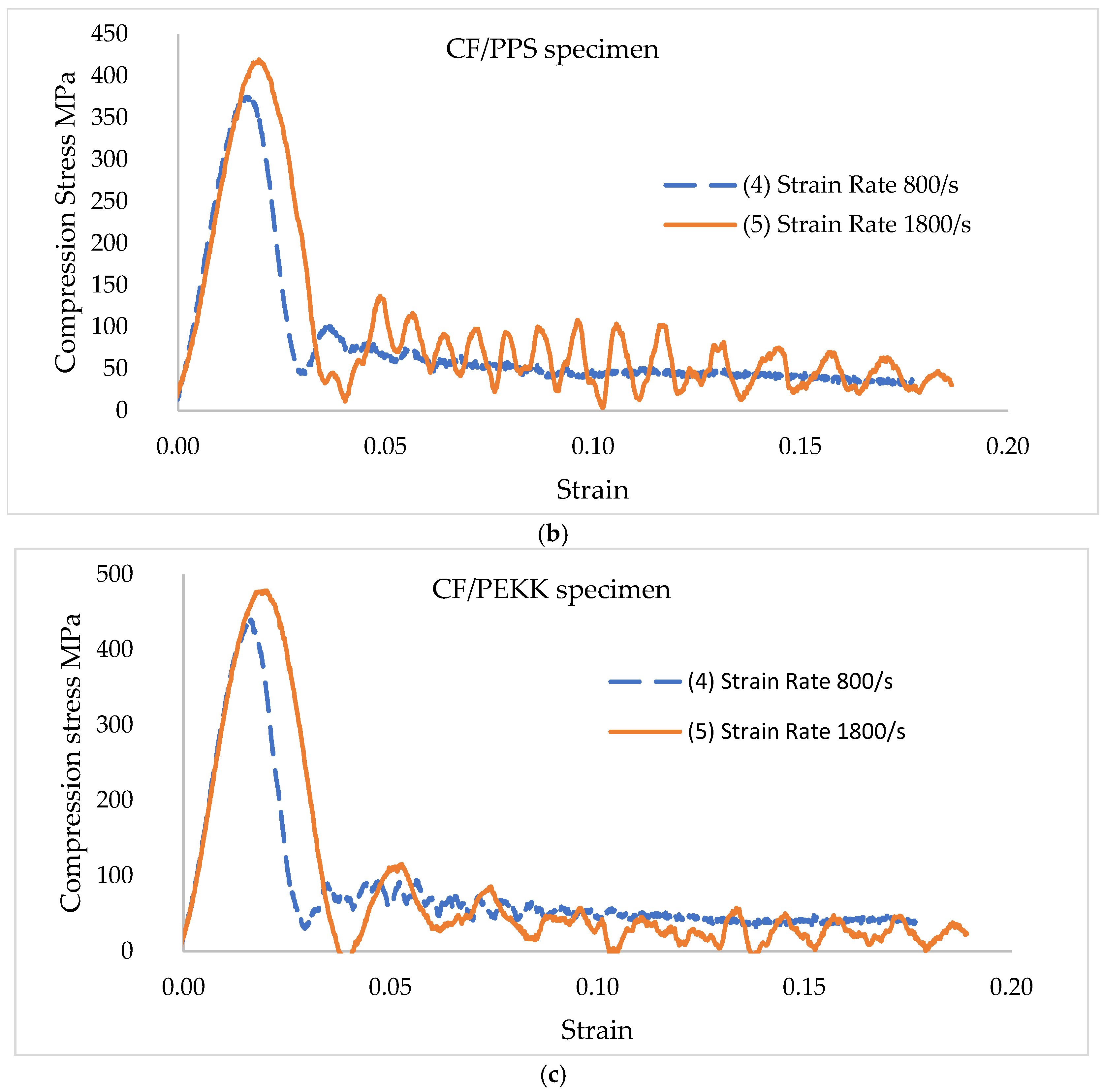

3.1.2. SHPB Apertures for High Strain Rate Testing (800/s and 1800/s)

4. Discussion

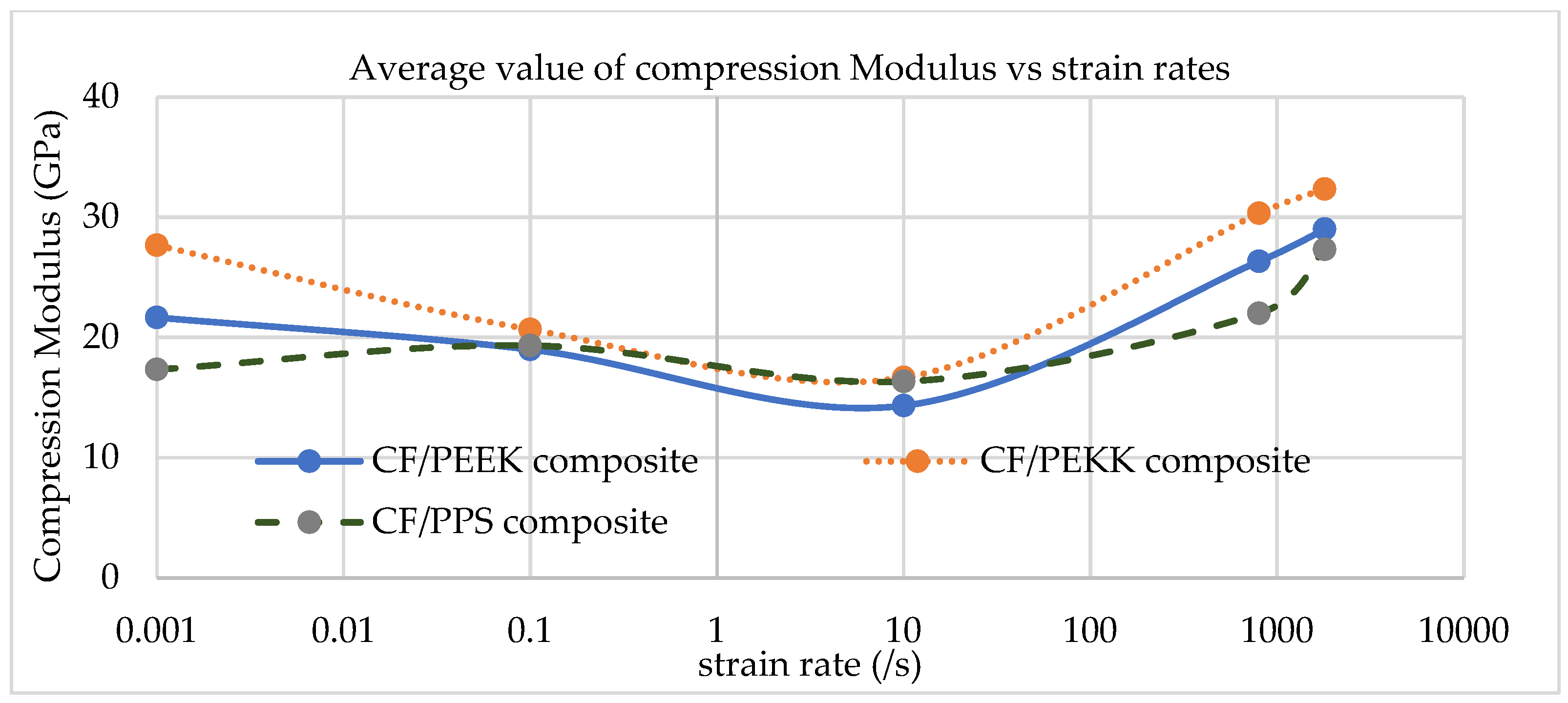

4.1. Influence of All Strain Rates on Composite Samples

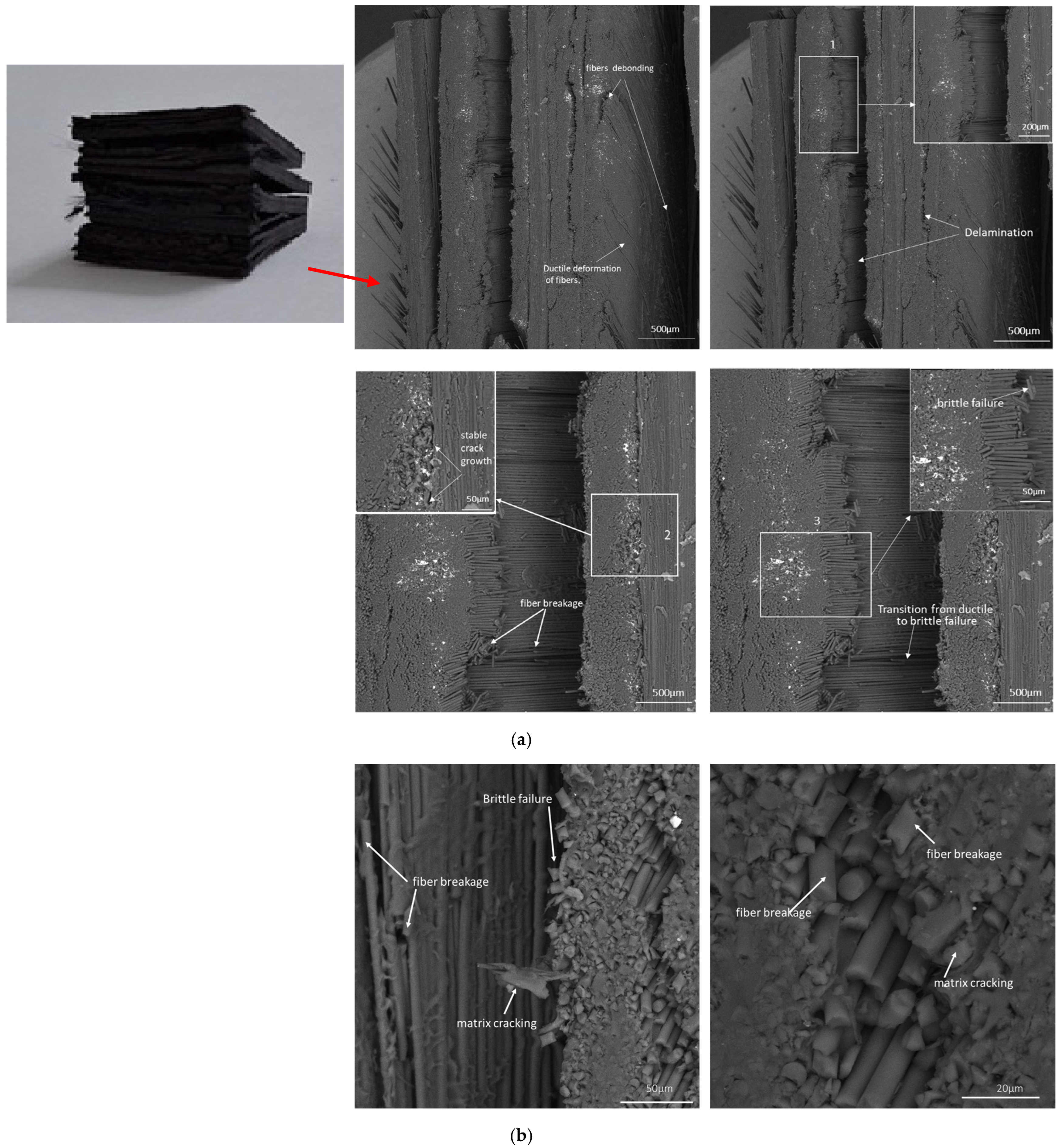

4.2. Failure Mode and Damage Mechanism

4.2.1. SEM and Optical Images

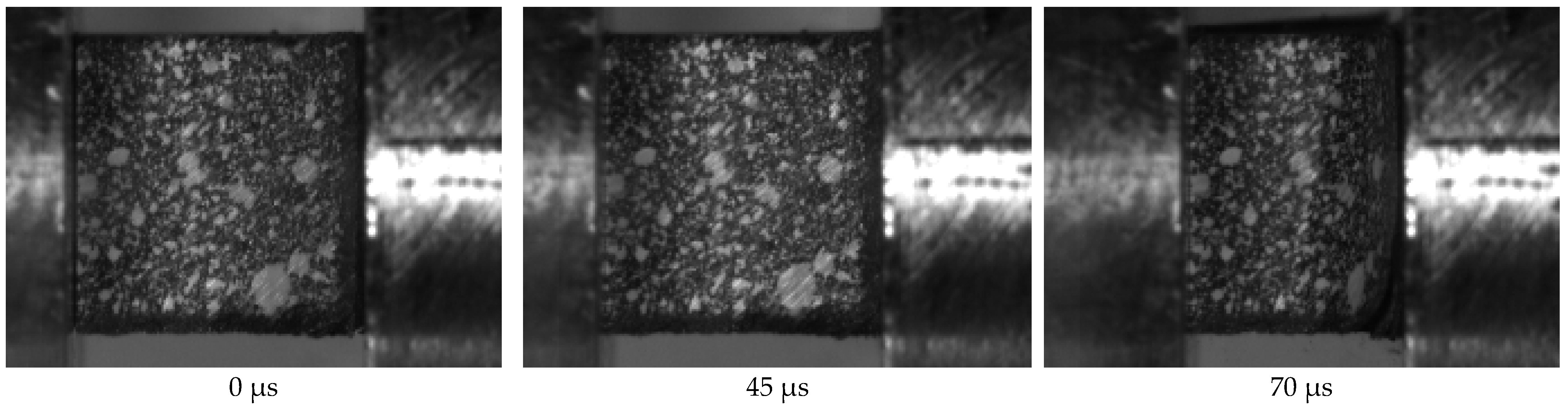

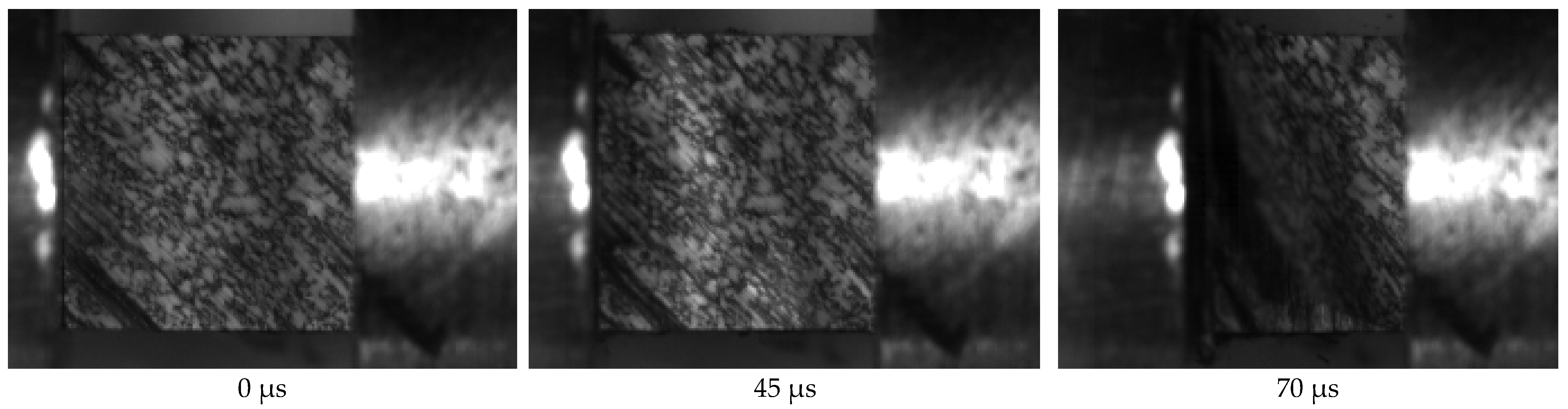

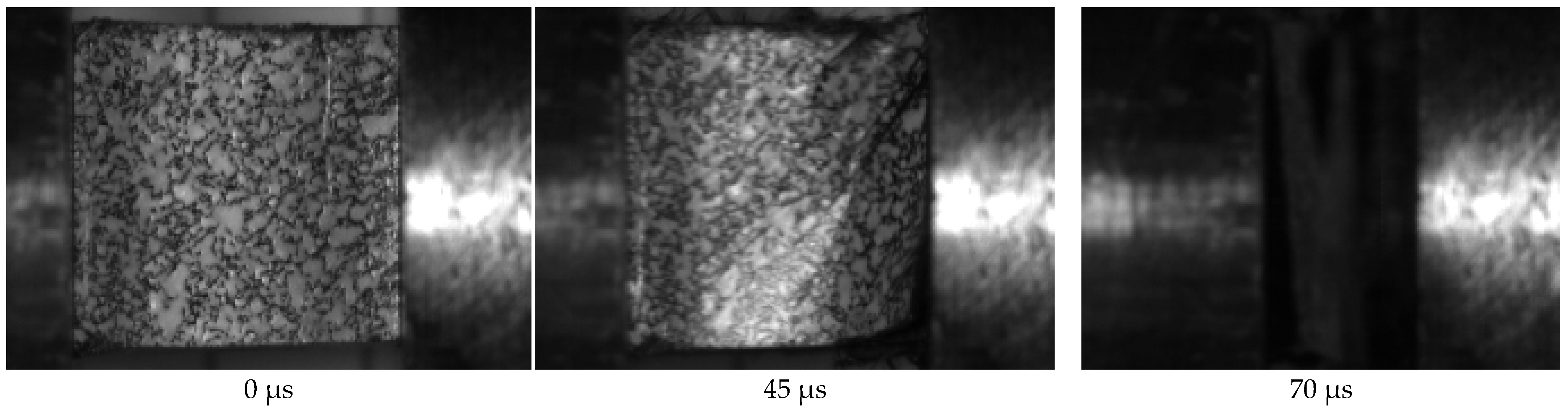

4.2.2. Images from the DIC Camera During Testing

4.2.3. Failure Mechanism Evolution Across Strain Rates

5. Conclusions

- The stress–strain curves steepen with the strain-rate increase, which is further reflected by the quasi-linear increase in dynamic strength and modulus.

- Thermoplastic composites show significant strain rate sensitivity. At low to moderate strain rates (0.001–0.1/s), PEKK composites exhibit the highest compression strength, while PPS composites perform the weakest.

- At medium strain rates (10/s), PEEK composites outperform PEKK and PPS, showing the highest compression strength and best resistance to dynamic loading.

- At high strain rates (800–1800/s), PEKK-linked composites again outperform PEEK and PPS, showing the highest compressive strength.

- PPS consistently demonstrates the lowest strength and highest susceptibility to fibre–matrix debonding and brittle failure across all strain rates.

- The results can guide the development of more efficient composite materials and improve the design of components that must perform under dynamic loading.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| Abbreviation | Description |

| SHPB | Split Hopkinson pressure bar |

| FRP | Fibre-reinforced polymeric |

| LAFP | Laser-assisted automated fibre placement |

| PAW | Prepreg areal weight |

| PEEK/PEKK | Polyether ether ketone/Polyetherketoneketone |

| PPS | Polyphenylene sulfide |

| CF | Carbon fibre |

| UD prepreg | Unidirectional prepreg |

| SEM | Scanning electron microscope |

| DIC | Digital Image Correlation |

References

- Eriksen, R.N.W. High Strain Rate Characterisation of Composite Materials. DTU Mechanical Engineering. DCAMM Special Report No. S179, 2014. Available online: https://backend.orbit.dtu.dk/ws/files/113893873/High_Strain_Rate_characterisation.pdf (accessed on 1 January 2020).

- Kolsky, H. An Investigation of the Mechanical Properties of Materials at very High Rates of Loading. Proc. Phys. Soc. Sect. B 1949, 62, 676. [Google Scholar] [CrossRef]

- Meyers, M.A. Dynamic Behavior of Materials; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 1994; pp. 323–447. [Google Scholar]

- Sierakowski, R.L. Strain rate effects in composites. Appl. Mech. Rev. 1997, 50, 741–761. [Google Scholar] [CrossRef]

- Jacob, G.C.; Starbuck, J.M.; Fellers, J.F.; Simunovic, S.; Boeman, R.G. Strain Rate Effects on the Mechanical Properties of Polymer Composite Materials. J. Appl. Polym. Sci. 2004, 94, 296–301. [Google Scholar] [CrossRef]

- Barré, S.; Chotard, T.; Benzeggagh, M.L. Damage mechanisms in low energy impact of glass–fibre–reinforced thermoplastic. Compos. Part A Appl. Sci. Manuf. 1996, 27, 1169–1181. [Google Scholar] [CrossRef]

- Wood, P.K.C.; Schley, C.A. Strain Rate Testing of Metallic Materials and Their Modelling for Use in CAE Based Automotive Crash Simulation Tools: Recommendations and Procedures; iSmithers: Shrewsbury, UK, 2009; ISBN 978-1-84735-374-0. [Google Scholar]

- Zou, H.; Yin, W.; Cai, C.; Wang, B.; Liu, A.; Yang, Z.; Li, Y.; He, X. The out-of-plane compression behavior of cross-ply AS4/PEEK thermoplastic composite laminates at high strain rates. Materials 2018, 11, 2312. [Google Scholar] [CrossRef]

- Wang, S.; Wen, L.; Xiao, J.; Lei, M.; Liang, J. Influence of strain rate and temperature on mechanical properties of carbon woven-ply PPS thermoplastic laminates Under dynamic compression. Polym. Test. 2020, 89, 106725. [Google Scholar] [CrossRef]

- Wood, P.; Schley, C.A.; Smith, G.F.; Buckley, M. A new test procedure to validate dynamic tensile mechanical properties of sheet metals and alloys in light weight automotive crash applications. SAE Tech. Pap. 2008, 28, 0019. [Google Scholar] [CrossRef]

- Stasicki, B.; Charvat, A.; Faubel, M.; Abel, B. Visualization of laser-induced liquid micro-jet disintegration by means of high-speed video stroboscopy. In Proceedings of the 26th International Congress on High-Speed Photography and Photonics, Alexandria, VA, USA, 19–24 September 2004; Volume 5580. [Google Scholar] [CrossRef]

- Eriksen, R.N.W.; Berggreen, C.; Boyd, S.W.; Dulieu-Barton, J.M. Towards high velocity deformation characterisation of metals and composites using Digital Image Correlation. EPJ Web Conf. 2010, 6, 31013. [Google Scholar] [CrossRef]

- Bardenheier, R.; Rogers, G. Dynamic impact testing with servohydraulic testing machines. J. Phys. IV Fr. 2006, 134, 693–699. [Google Scholar] [CrossRef]

- Hamouda, A.M.S.; Hashmi, M.S.J. Testing of composite materials at high rates of strain: Advances and challenges. J. Mater. Process. Technol. 1998, 77, 327–336. [Google Scholar] [CrossRef]

- Hosur, M.V.; Alexander, J.; Jeelani, S.; Vaidya, U.K.; Mayer, A. High strain compression responses of affordable woven carbon/epoxy composites. J. Reinf. Plast. Compos. 2003, 22, 271–296. [Google Scholar] [CrossRef]

- Bandaru, A.K.; Chouhan, H.; Bhatnagar, N. High strain rate compression testing of intra-ply and inter-ply hybrid thermoplastic composites reinforced with Kevlar/basalt fibers. Polym. Test. 2020, 84, 106407. [Google Scholar] [CrossRef]

- Dash, K.; Sukumaran, S.; Ray, B.C. Effect of loading speed on deformation of composite materials: A critical review. J. Adv. Res. Manuf. Mater. Sci. Metall. Eng. 2014, 1, 1–22. Available online: https://dspace.nitrkl.ac.in/dspace/handle/2080/2126 (accessed on 3 June 2025).

- Brown, K.A.; Brooks, R.; Warrior, N.A. The static and high strain rate behavior of a commingled E-glass/polypropylene woven fabric composite. Compos. Sci. Technol. 2010, 70, 272–283. [Google Scholar] [CrossRef]

- Nemat-Nasser, S. Introduction to high strain rate testing. In ASM Handbook Volume 8 Mechanical Testing and Evaluation; ASM International: Novelty, OH, USA, 2000. [Google Scholar]

- Qian, X.; Wang, H.; Zhang, D.; Wen, G. High strain rate out-of-plane compression properties of aramid fabric reinforced polyamide composite. Polym. Test. 2016, 53, 314–322. [Google Scholar] [CrossRef]

- Woo, S.C.; Kim, T.W. High strain rate failure in carbon/Kevlar hybrid woven composites via a novel SHPB-AE coupled test. Compos. Part B Eng. 2016, 97, 317–328. [Google Scholar] [CrossRef]

- Gray, G.T., III. Classic split-Hopkinson pressure bar testing. In ASM Handbook Volume 8 Mechanical Testing and Evaluation; ASM International: Novelty, OH, USA, 2000. [Google Scholar]

- Gray, G.T., III; Blumenthal, W.R. Split-Hopkinson pressure bar testing of soft materials. In ASM Handbook Volume 8 Mechanical Testing and Evaluation; ASM International: Novelty, OH, USA, 2000. [Google Scholar]

- Chen, W.W.; Song, B. Split Hopkinson (Kolsky) Bar: Design, Testing and Applications; Springer: New York, NY, USA, 2011. [Google Scholar]

- Hou, J.P.; Ruiz, C. Measurement of the properties of woven CFRP T300/914 at different strain rates. Compos. Sci. Technol. 2000, 60, 2829–2834. [Google Scholar] [CrossRef]

- Gama, B.A.; Lopatnikov, S.L.; Gillespie, J.W., Jr. Hopkinson bar experimental technique: A critical review. Appl. Mech. Rev. 2004, 57, 223–250. [Google Scholar] [CrossRef]

- Reis, V.L.; Marini, L.F.; Donadon, M.V.; Dutra, T.A.; Baldo Junior, J.E.; Nunes de Mello, W.L. Experimental investigation on the influence of the geometry of carbon fiber specimen used in split Hopkinson pressure bar tests. In Proceedings of the 23rd ABCM International Congress of Mechanical Engineering, Rio de Janeiro, Brazil, 6–11 December 2015. [Google Scholar]

- Koerber, H.; Xavier, J.; Camanho, P.P.; Essa, Y.E.; Martín de la Escalera, F. High strain rate behaviour of 5-harness satin weave fabric carbon–epoxy composite under compression and combined compression–shear loading. Int. J. Solids Struct. 2015, 54, 172–182. [Google Scholar] [CrossRef]

- Jerabek, M.; Major, Z.; Lang, R.W. Strain determination of polymeric materials using digital image correlation. Polym. Test. 2010, 29, 407–416. [Google Scholar] [CrossRef]

- Ploeckl, M.; Kuhn, P.; Koerber, H. Characterization of unidirectional carbon fiber reinforced polyamide-6 thermoplastic composite under longitudinal compression loading at high strain rate. EPJ Web Conf. 2015, 94, 01041. [Google Scholar] [CrossRef]

- Ramirez, C.; Reis, V.; Opelt, C.; Santiago, R.; Almeraya, F.; Donadon, M.V.; Gaona, C.; Croche, R.; Baltazar, M.A. High strain rate characterisation of thermoplastic fiber-reinforced composites under compressive loading. In Fiber-Reinforced Plastic; Intech Open: London, UK, 2018. [Google Scholar] [CrossRef]

- Hopkinson, B. A method of measuring the pressure produced in the detonation of high explosives or by the impact of bullets. Proc. R. Soc. Lond. Ser. A 1914, 89, 411–413. [Google Scholar]

- Davies, R.M. A critical study of the Hopkinson pressure bar. Philos. Trans. R. Soc. Lond. Ser. A Math. Phys. Sci. 1948, 240, 375–457. [Google Scholar] [CrossRef]

- Kordas, P.D.; Lampeas, G.N.; Fotopoulos, K.T. Numerical Investigation of an Experimental Setup for Thermoplastic Fuselage Panel Testing in Combined Loading. Aerospace 2024, 11, 175. [Google Scholar] [CrossRef]

- Sitohang, R.D.R.; Grouve, W.J.B.; Warnet, L.L.; Koussios, S.; Akkerman, R. An experimental approach to reproduce in-plane fiber waviness in thermoplastic composites test coupons using a reverse forming method. J. Compos. Mater. 2022, 56, 561–574. [Google Scholar] [CrossRef]

- Samak, S.; Risteska, S.; Dukovski, V.; Trajkoski, S. Some experimental investigation of products from thermoplastic composite materials manufactured with robot and LAFP. Int. J. Eng. Res. Technol. 2020, 9, 1082–1088. [Google Scholar]

- Pheysey, J.; De Cola, F.; Pellegrino, A.; Martinez-Hergueta, F. Strain rate and temperature dependence of short/unidirectional carbon fibre PEEK hybrid composites. Compos. Part B Eng. 2024, 268, 111080. [Google Scholar] [CrossRef]

- Mohsin, M.A.A.; Iannucci, L.; Greenhalgh, E.S. On the dynamic tensile behaviour of thermoplastic composite carbon/polyamide 6.6 using split Hopkinson pressure bar. Materials 2021, 14, 1653. [Google Scholar] [CrossRef]

- Perry, J.I.; Walley, S.M. Measuring the effect of strain rate on deformation and damage in fibre-reinforced composites: A review. J. Dyn. Behav. Mater. 2020, 8, 178–213. [Google Scholar] [CrossRef]

- Mario, R.R. Experimental and Computational Micromechanics of Fiber-Reinforced Polymer Composites at High Strain Rate. Ph.D. Thesis, Universidad Politecnica de Madrid, Madrid, Spain, 2021. [Google Scholar]

- Ma, L.L.; Liu, F.; Liu, D.; Liu, Y. Review of Strain Rate Effects of Fiber-Reinforced Polymer Composites. Polymers 2021, 13, 2839. [Google Scholar] [CrossRef]

- Marina, P. Effect of Strain Rate on the Tensile, Compressive, and Shear Response of Carbon-Fiber-Reinforced Thermoplastic Composites. Ph.D. Thesis, Technische Universität München, München, Germany, 2019. [Google Scholar]

- Hosur, M.V.; Alexander, J.; Vaidya, U.K.; Jeelani, S. High strain rate compression response of carbon/epoxy laminate composites. J. Compos. Struct. 2001, 52, 405–417. [Google Scholar] [CrossRef]

- Risteska, S. Unidirectional carbon fiber reinforced thermoplastic tape in automated tape placement process. In Fiber-Reinforced Plastic; Intech Open: London, UK, 2021; pp. 1–16. [Google Scholar] [CrossRef]

- Ma, H.; Bandaru, A.K.; Weaver, P.M. The effect of laser assisted tape placement processing conditions on microstructural evolution, residual stress and interlaminar shear strength of carbon fibre/PEEK laminates. Compos. Part B Eng. 2024, 276, 111293. [Google Scholar] [CrossRef]

- Srebrenkoska, S.; Dukovski, V.; Risteska, S. Influence of the process parameters on laser-assisted automated tape placement process. Int. J. Eng. Res. Technol. 2020, 9, 638–644. [Google Scholar]

- Risteska, S.; Trajkovska Petkoska, A.; Samak, S.; Drienovsky, M. Annealing effects on the crystallinity of carbon fiber-reinforced polyether ether ketone and polyphenylene laminate composites manufactured by laser automatic tape placement. Mater. Sci. (Medžiagotyra) 2020, 26, 314–322. [Google Scholar] [CrossRef]

- Pourahmadi, E.; Ganesan, R.; Shadmehri, F. Effect of in-situ consolidation on the in-plane elastic moduli of Carbon/PEEK thermoplastic composites made by Automated Fiber Placement (AFP) process. In Proceedings of the 21st European Conference on Composite Materials (ECCM21), Nantes, France, 2–5 July 2024. [Google Scholar]

- Stelter, C.J.; Sreekantamurthy, T.; Hudson, T.B.; Grimsley, B.W. Thermal modelling of the in-situ consolidation of automated fiber placement of thermoplastic composites. In Proceedings of the Society for the Advancement of Material and Process Engineering (SAMPE), Long Beach, CA, USA, 20–23 May 2024. [Google Scholar] [CrossRef]

- Saffar, F.; Sonnenfeld, C.; Beauchêne, P.; Park, C.H. In-situ monitoring of the out-of-autoclave consolidation of carbon/poly-ether-ketone-ketone prepreg laminate. Front. Mater. 2020, 7, 195. [Google Scholar] [CrossRef]

- Thor, M.; Sause, M.G.R.; Hinterhölzl, R.M. Mechanisms of origin and classification of out-of-plane fiber waviness in composite materials—A review. J. Compos. Sci. 2020, 4, 130. [Google Scholar] [CrossRef]

- Celik, O.; Peeters, D.; Dransfeld, C.; Teuwen, J. Intimate contact development during laser assisted fiber placement: Microstructure and effect of process parameters. Compos. Part A Appl. Sci. Manuf. 2020, 134, 105888. [Google Scholar] [CrossRef]

- Baho, O.; Ausias, G.; Grohens, Y.; Férec, J. Simulation of laser heating distribution for a thermoplastic composite: Effects of AFP head parameters. Int. J. Adv. Manuf. Technol. 2020, 110, 2105–2117. [Google Scholar] [CrossRef]

- Croft, K.; Lessard, L.; Pasini, D.; Hojjati, M.; Chen, J.; Yousefpour, A. Experimental study of the effect of automated fiber placement induced defects on performance of composite laminates. Compos. Part A Appl. Sci. Manuf. 2011, 42, 484–491. [Google Scholar] [CrossRef]

- Hoang, M.D. Procedure for Making Flat Thermoplastic Composite Plates by Automated Fiber Placement and Their Mechanical Properties. Master’s Thesis, Concordia University Montreal, Montreal, QC, Canada, 2015. [Google Scholar]

- Feuillerat, L.; De Almeida, O.; Fontanier, J.C.; Schmidt, F. Effect of poly (ether-ether ketone) degradation on commingled fabrics consolidation. J. Compos. Part A 2021, 149, 106482. [Google Scholar] [CrossRef]

- ASTM Standard D 2734-11; Standard Test Methods for Void Content of Reinforced Plastics. ASTM International: West Con shohocken, PA, USA, 2011.

- ASTM Standard D5229-14; Standard Test Method for Moisture Absorption Properties and Equilibrium Conditioning of Polymer Matrix Composite Materials. ASTM International: West Con shohocken, PA, USA, 2014.

- Yang, Y.; Li, Q.; Qiao, L. Review of SHPB dynamic load impact test characteristics and energy analysis methods. Processes 2023, 11, 3029. [Google Scholar] [CrossRef]

- Pankow, M.; Attard, C.; Waas, A.M. Specimen size and shape effect in split Hopkinson pressure bar testing. J. Strain Anal. Eng. Des. 2009, 44, 689–698. [Google Scholar] [CrossRef]

- Tarfaoui, M. Dynamic composite materials characterization with Hopkinson bars: Design and development of new dynamic compression systems. J. Compos. Sci. 2023, 7, 33. [Google Scholar] [CrossRef]

- Hannes, K. Mechanical Response of Advanced Composites Under High Strain Rates; Faculdade de Engenharia da Universidade do Porto Departamento de Engenharia Mechanica: Porto, Portugal, 2010; p. 262. [Google Scholar]

- Xiao, D.; Li, Y.; Hu, S. Study of small dimension specimens on SHPB test. J. Appl. Phys. 2007, 955, 1151. [Google Scholar] [CrossRef]

- Wang, S.; Wen, L.; Xiao, J.; Lei, M.; Hou, X.; Liang, J. The out-of-plane compression response of woven thermoplastic composites: Effects of strain rates and temperature. Polymers 2021, 13, 264. [Google Scholar] [CrossRef]

- Chouhan, H.; Bhalla, N.A.; Bandaru, A.K.; Bhatnagar, N. Influence of conditioning on the high strain rate compression response of Kevlar thermoplastic composites. Polym. Compos. 2020, 41, 191–204. [Google Scholar] [CrossRef]

- Massaq, A.; Rusinek, A.; Klosak, M.; Bahi, S.; Arias, A. Strain rate effect on the mechanical behavior of polyamide composites under compression loading. Compos. Struct. 2019, 214, 114–122. [Google Scholar] [CrossRef]

- Afrough, M.; Pandya, T.S.; Daryadel, S.S.; Mantena, P.R. Dynamic response of pultruded glass-graphite/epoxy hybrid composites subjected to transverse high strain-rate compression loading. Mater. Sci. Appl. 2015, 6, 953–962. [Google Scholar] [CrossRef][Green Version]

- Chen, X.; Li, Y.; Zhi, Z.; Guo, Y.; Ouyang, N. The compressive and tensile behavior of a 0/90 C fiber woven composite at high strain rates. J. Carbon 2013, 61, 97–104. [Google Scholar] [CrossRef]

- Kim, W.; Argento, A.; Lee, E.; Flanigan, C.; Houston, D.; Harris, A.; Mielewski, D.F. High strain-rate behavior of natural fiber-reinforced polymer composites. J. Compos. Mater. 2011, 45, 1051–1065. [Google Scholar] [CrossRef]

- Tarfaoui, M.; Choukri, S.; Neme, A. Effect of fiber orientation on mechanical properties of the laminated polymer composites subjected to out-of-plane high strain rate compressive loadings. Compos. Sci. Technol. 2008, 68, 477–485. [Google Scholar] [CrossRef]

| Applicable Strain Rate, /s | Testing Technique |

|---|---|

| Compression tests | |

| <0.1 | Conventional load frames |

| 0.1–500 | High-speed servo-hydraulic test machine |

| 0.1–500 | Cam plastometer |

| 200–104 | Split Hopkinson PressureBar |

| 103–105 | Taylor impact test |

| Tension test | data |

| <0.1 | Conventional load frames |

| 0.1–500 | High-speed servo-hydraulic test machine |

| 200–5 × 103 | Split Hopkinson Tension Bar |

| 104 | Expanding ring |

| >105 | Flyer plate |

| Shear and multi-axial tests | |

| <0.1 | Conventional load frames |

| 0.1–500 | High-speed servo-hydraulic test machine |

| 10–103 | Torsional impact |

| 100–104 | Split Hopkinson PressureBar (Shear/Torsion) |

| 103–104 | Double-notch shear and punch |

| 104–107 | Pressure-shear plate impact |

| Materials | CF/PEKK UD Prepreg | CF/PEEK UD Prepreg | CF/PPS UD Prepreg |

|---|---|---|---|

| Matrix glass transition temperature (Tg), °C | 160 | 143 | 85 |

| Matrix melting temperature (Tm), °C | 360 | 345 | 285 |

| Specimens | Thermoplastic Resin | Velocity mm/s | Strain Rates (/s) |

|---|---|---|---|

| a01, a02, a03 | 0.01 | 0.001 | |

| a11, a12, a13 | 1 | 0.1 | |

| a21, a22, a23 | PEEK | 100 | 10 |

| a31, a32, a33 | 8000 | 800 | |

| a41, a42, a43 | 18,000 | 1800 | |

| b01, b02, b03 | 0.01 | 0.001 | |

| b11, b12, b13 | 1 | 0.1 | |

| b21, b22, b23 | PPS | 100 | 10 |

| b31, b32, b33 | 8000 | 800 | |

| b41, b42, b43 | 18,000 | 1800 | |

| c01, c02, c03 | 0.01 | 0.001 | |

| c11, c12, c13 | 1 | 0.1 | |

| c21, c22, c23 | PEKK | 100 | 10 |

| c31, c32, c33 | 8000 | 800 | |

| c41, c42, c43 | 18,000 | 1800 |

| Strain Rate | CF/PPS Composite | CF/PEEK Composite | CF/PEKK Composite |

|---|---|---|---|

| Low (0.001/s–0.1/s) | Matrix cracking, fibre–matrix debonding | Ductile deformation, stable crack growth | Similar to PEEK but slightly stiffer |

| Medium (0.1/s–10/s) | Increased fibre pull-out, brittle fracture | Transition from ductile to brittle failure | Delamination and matrix cracking increase |

| High (10/s–100/s) | Brittle failure, fibre breakage, delamination | Brittle failure, fibre-dominated failure | Similar to PEEK, but slightly better energy absorption |

| Extreme (800/s–1800/s) | Sudden fracture, significant delamination | Highest stress, best performance under dynamic loading | Weaker than PEEK at extreme strain rates |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Risteska, S.; Peroni, M.; Srebrenkoska, S.; Srebrenkoska, V.; Glaskova-Kuzmina, T.; Hornig, A. The In-Plane Compression Response of Thermoplastic Composites: Effects of High Strain Rate and Type of Thermoplastic Matrix. J. Compos. Sci. 2025, 9, 293. https://doi.org/10.3390/jcs9060293

Risteska S, Peroni M, Srebrenkoska S, Srebrenkoska V, Glaskova-Kuzmina T, Hornig A. The In-Plane Compression Response of Thermoplastic Composites: Effects of High Strain Rate and Type of Thermoplastic Matrix. Journal of Composites Science. 2025; 9(6):293. https://doi.org/10.3390/jcs9060293

Chicago/Turabian StyleRisteska, Svetlana, Marco Peroni, Sara Srebrenkoska, Vineta Srebrenkoska, Tatjana Glaskova-Kuzmina, and Andreas Hornig. 2025. "The In-Plane Compression Response of Thermoplastic Composites: Effects of High Strain Rate and Type of Thermoplastic Matrix" Journal of Composites Science 9, no. 6: 293. https://doi.org/10.3390/jcs9060293

APA StyleRisteska, S., Peroni, M., Srebrenkoska, S., Srebrenkoska, V., Glaskova-Kuzmina, T., & Hornig, A. (2025). The In-Plane Compression Response of Thermoplastic Composites: Effects of High Strain Rate and Type of Thermoplastic Matrix. Journal of Composites Science, 9(6), 293. https://doi.org/10.3390/jcs9060293