Abstract

The development of sustainable insulation materials plays a crucial role in creating energy-efficient and environmentally responsible buildings. This study investigates eco-friendly composite materials based on plaster and wood shavings for insulation purposes. Incorporating wood shavings into plaster improves thermal insulation and mechanical behavior by enhancing porosity, reducing density, and improving bonding. As the wood shaving content increases from 5% to 15%, the thermal conductivity decreases from 0.252 W/mK to 0.099 W/mK, reflecting superior insulating performance. Concurrently, thermal resistance rises, showcasing enhanced insulation. The material also demonstrates increased flexibility, with the Young’s modulus decreasing at higher wood shaving proportions. Numerical simulations confirm these observations, indicating a 12 K temperature drop for composites with 15% wood shavings compared to a 6 K drop for pure plaster. This study suggests that an insulation thickness of 6–7 cm for the 15% composite strikes the optimal balance between performance and cost-efficiency. The findings underscore the potential of wood shavings to significantly enhance the thermal efficiency and mechanical adaptability of plaster composites, promoting sustainable and effective building insulation solutions.

1. Introduction

Energy consumption in buildings represents a substantial share of global energy demand, driven primarily by heating, cooling, lighting, and the operation of electrical appliances. This significant energy usage, predominantly reliant on fossil fuel sources, plays a critical role in the increase of greenhouse gas emissions, thereby intensifying the impacts of climate change [1]. The energy inefficiency of buildings results in a heightened reliance on fossil fuels, leading to the release of carbon dioxide (CO2) and other greenhouse gases into the atmosphere. These emissions contribute to the greenhouse effect by trapping heat, thereby raising global temperatures and triggering climatic disturbances such as heatwaves, storms, and floods. Consequently, the environmental impact of buildings is twofold: they not only consume substantial amounts of non-renewable energy but also directly contribute to global warming through their emissions [2]. To mitigate this impact, implementing measures such as adopting energy-efficient heating and cooling technologies, integrating renewable energy sources, and enhancing thermal insulation is essential. These strategies contribute to a significant reduction in energy consumption and associated emissions while fostering more sustainable and climate-resilient built environments [3,4,5].

Thermal and wall insulation in buildings is fundamental to enhancing energy efficiency and mitigating environmental impact. Effective thermal insulation minimizes heat loss during winter and helps to maintain cooler indoor temperatures in summer, thereby reducing the reliance on heating and air conditioning systems. Well-insulated walls are key to this performance, as they significantly limit heat exchange between the interior and exterior environments [6,7,8]. In addition to lowering energy consumption, thermal insulation also reduces associated greenhouse gas emissions. The effectiveness of thermal insulation depends on the specific properties of the materials employed. Insulating materials are characterized by low thermal conductivity, which inhibits the transfer of heat. This low conductivity is attributed to the material’s structure, which traps air or other gases within small pockets. Since air is a poor conductor of heat, the greater the amount of trapped air within the material, the more effective its insulating capacity becomes [9,10].

Furthermore, certain insulating materials reduce heat transfer by radiation through reflective surfaces that deflect heat radiation. The capacity of a material to resist heat transfer is quantified by its thermal resistance, or R-value: a higher R-value indicates superior insulating performance [11]. While air pockets significantly enhance thermal insulation, other factors also contribute to overall thermal performance. These include the material’s density, specific heat capacity, and thickness [12]. For instance, materials with higher density and specific heat capacity can effectively store and release heat, thereby contributing to thermal inertia and stabilizing indoor temperatures. Additionally, multi-layered insulation systems can enhance performance by combining different materials to exploit their complementary properties [11,13,14].

The selection of insulation materials requires careful consideration of their thermal properties, environmental impact, durability, and cost-effectiveness—key factors for the development of sustainable and energy-efficient buildings [15]. Insulation materials for building applications can be classified into three main categories: conventional materials, state-of-the-art insulation technologies, and sustainable insulation solutions. Conventional materials include inorganic insulators, such as fibrous types (e.g., fiberglass) and cellular types, alongside organic fibrous materials like polystyrene and polyurethane, which are widely used due to their affordability and effective thermal insulation properties. State-of-the-art insulation materials encompass advanced options such as transparent insulation materials (e.g., aerogels), which combine exceptional insulating performance with light transmission. Closed-cell foam offers superior moisture resistance and structural integrity, making it suitable for diverse applications. Vacuum insulation panels (VIPs) stand out for their extremely low thermal conductivity, delivering high performance in thin profiles. Additionally, reflective insulation utilizes metallic or reflective surfaces to minimize radiant heat transfer, thereby improving energy efficiency in regions with significant solar radiation [16].

The building and construction sector, which accounts for substantial natural resource consumption and more than 45% of global waste production, is increasingly adopting sustainable insulation materials to address environmental challenges. While inorganic materials are effective insulators, they pose environmental risks, and organic options such as expanded polystyrene (EPS) and extruded polystyrene (XPS) can release hazardous emissions when exposed to high temperatures. Bio-based insulation materials, derived from renewable resources such as coconut fibers, wood, hemp, and rice husks, offer eco-friendly alternatives with promising thermal and acoustic properties. However, concerns related to durability and flame resistance require further investigation. Agricultural waste by-products, such as corncobs and pineapple leaves, present low-cost, resource-abundant options that have demonstrated favorable thermal performance [17]. Recycled insulation materials, including those made from reclaimed plastic, polystyrene, and cellulose fibers, provide cost-effective, high-performance solutions by repurposing waste, thereby contributing to circular economy initiatives and reducing the environmental footprint of construction [10,18,19,20].

Sustainable construction materials prioritize environmental sustainability, addressing the rising demand for eco-friendly building solutions. Natural plaster, produced from abundant and renewable resources, contributes to reducing the carbon footprint of buildings. It offers effective moisture regulation, promoting a comfortable and healthy indoor environment by balancing ambient humidity and minimizing condensation issues. Additionally, natural plaster provides moderate thermal insulation and can enhance the overall energy efficiency of walls when combined with other insulating materials, such as recycled insulation additives [21].

Natural composite materials derived from wood waste for building insulation have garnered significant interest among researchers. The use of wood shavings in this context is primarily driven by their low-cost availability and their prevalence as a form of municipal solid waste that often lacks adequate disposal methods. Wood shavings are a by-product generated in large volumes by the woodworking industry, with a significant proportion of raw wood transformed into residues during processing. The volume of waste produced varies according to factors such as population growth, socio-economic conditions, and urbanization levels, all of which are increasing at an exponential rate, reinforcing concerns that municipal solid waste volumes will rise in the coming years. In many developing and least-developed countries, effective solid waste management remains challenging. Consequently, wood shavings are often incinerated in open spaces, producing ash with no commercial value. This practice has considerable negative impacts on the environment and public health due to the release of harmful emissions [21,22].

Among the sustainable composite systems under current investigation, plaster/wood shaving composites present a compelling alternative for eco-friendly insulation. Plaster, a mineral binder derived from gypsum, is widely used in construction due to its affordability, ease of application, and hygroscopic properties. However, in its pure form, plaster has limited insulating capability due to its relatively high thermal conductivity and density [22]. To overcome this, recycled lignocellulosic fillers such as wood shavings can be introduced, offering a dual benefit of improved thermal resistance and enhanced sustainability [23].

Wood shavings, primarily composed of cellulose, hemicellulose, and lignin, exhibit low thermal conductivity due to their porous structure, which traps air and impedes heat flow. When combined with plaster, they introduce micro-voids and discontinuities in the matrix, significantly lowering the composite’s thermal conductivity while also reducing overall density [24]. The resulting composite material achieves improved thermal insulation and mechanical adaptability. Furthermore, the incorporation of wood waste into plaster addresses environmental concerns by valorizing industrial by-products and minimizing landfill waste. This synergy not only enhances the composite’s performance but also supports the principles of the circular economy and low-impact construction practices.

Recent studies have reported that plaster-based composites reinforced with wood particles or fibers can exhibit thermal conductivity values as low as 0.1 W/m·K, depending on formulation and density [25]. Such performance positions them as viable candidates for interior wall insulation, especially in regions seeking low-cost and bio-based solutions to reduce building energy consumption. Building on this context, our study investigates the optimized combination of natural Moroccan plaster and recycled wood shavings, aiming to quantify the effect of wood shaving content on the thermal and mechanical behavior of the composite through both experimental and numerical analysis.

This study aims to develop and evaluate sustainable composite materials based on natural Moroccan plaster and recycled wood shavings. Experimental investigations were carried out to identify the optimal proportion of wood shavings that can be incorporated into plaster to enhance its thermal and mechanical properties. The originality of this research lies in its dual approach, which combines experimental analysis with numerical simulations to assess the impact of both composition and material thickness on the performance of these eco-friendly composites. By focusing on the integration of abundant wood waste into traditional plaster, this study contributes to the development of cost-effective, high-performance insulation materials that support sustainability and effective waste management. The findings will provide valuable insights into enhancing building energy efficiency while reducing environmental impacts, offering practical solutions for sustainable construction practices.

2. Materials and Methods

2.1. Materials Used

The following materials were used for making the different mixtures.

2.1.1. Plaster

In Morocco, plaster is commonly used in construction for interior wall cladding, ceilings, decorative elements such as cornices and moldings, and the manufacture of plasterboard for interior partitions. In addition to its decorative applications, it is used to improve the thermal and acoustic insulation of buildings, often in combination with other materials [21,26]. Plaster, usually purchased locally (as is our case), is available in building supply stores, making it an accessible and versatile material for a variety of residential and commercial construction projects. Plasterers and construction companies frequently use it for its ease of application and aesthetic finishing properties.

2.1.2. Wood Shavings

The wood used in this work is sourced from waste generated by local carpentry activities (Figure 1). Wood shavings are an abundant waste product generated by wood processing industries. They offer interesting potential as a component in the manufacture of insulating composite materials. As a natural material, wood shavings are not only economical but also readily available, making them an attractive option for sustainable and environmentally friendly applications. Their incorporation into a plaster-based composite improves the thermal and mechanical properties of the final material. They also enable this waste material to be recycled in a useful way, thereby reducing its environmental impact. The use of wood shavings in building materials contributes to more efficient waste management, while improving the performance of composites, making them lighter and sometimes more resistant to cracking.

Figure 1.

The used wood sourced from waste generated by local carpentry activities.

2.2. Sample Preparation

To guarantee the optimum quality and performance of plaster- and wood shavings-based composite materials, particular attention was paid to pre-drying the components. Wood shavings had been cleaned before use. Plaster was dried in an oven at a temperature of 50 °C for 24 h. Wood shavings were dried at a temperature of 70 °C for 48 h. This drying process is essential to improve the mechanical and thermal properties of the final composite, ensure better adhesion between components, and prevent mold formation, thus guaranteeing the durability and efficiency of the insulating material.

Formulation refers to the ingredients used to create plasterboard with wood shavings. This involves determining the quantity and type of raw materials required, as well as the mixing method, to produce the desired end product.

The percentages of plaster and wood shavings depend on the desired mechanical and thermal properties of the final material. To achieve the desired properties for the insulation material, the percentages of plaster and wood shavings in the formulation must be carefully selected and adjusted. A well-balanced formulation can provide sufficient thermal insulation as well as adequate mechanical strength for final material. In this work, four formulations of insulation composites were experimentally evaluated, comprising 0%, 5%, 10%, and 25% wood shavings in the plaster matrix (percentage by weight of plaster). Table 1 shows the composition of each mixture per gram of plaster.

Table 1.

The prepared samples.

2.3. Characterization

2.3.1. Thermal Properties Measurement

The thermal conductivity of the insolation composites was measured using the “thermal house” device as described in previous research [21]. This method allows the study of thermal behavior under steady-state heat flow conditions by measuring the temperatures on both sides of the material. A square specimen of 250 × 250 × 40 mm3 was used for each composite.

By establishing a steady-state heat transfer and recording the temperatures, the following formulas allow for the precise calculation of the composite’s thermal conductivity for each composition of the composites.

The heat input is provided by a controlled heating element, while the resulting temperature distribution across the sample is recorded using an HD32.8.16 temperature data logger.

After establishing a steady state, temperatures were recorded. The heat flow produced by the heating element (Φres) is given by

where V is the voltage and R is the resistance. Heat conduction through the sample (Φcon) is determined using

where is the thermal conductivity, S is the surface area, e is the thickness, and T1 and T2 are the internal and external face temperatures.

Heat losses (φlos) are evaluated with

where c is the thermal coefficient of loss, T3 is the box temperature, and T4 is the ambient temperature.

The heat balance equation

allows the calculation of the sample’s thermal conductivity () using

Thermal conductivity (λ) measures a material’s ability to conduct heat. Low thermal conductivity means better thermal insulation. Thermal resistance (R), defined as the ratio between material thickness (e) and its thermal conductivity (λ), is expressed in m2K/W. High thermal resistance indicates a greater ability to reduce heat loss through structures such as walls, ceilings, and floors.

2.3.2. Sample Preparation for Measurement

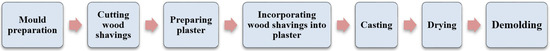

Figure 2 outlines a scientific protocol for the fabrication of a wood shaving and plaster-based composite, involving several key stages, each crucial to the quality of the final product. Initially, molds with specific dimensions (25 × 25 × 4 cm) are prepared, meticulously cleaned, and dried to remove any dust or debris. Each mold is inspected to ensure its structural integrity and stability. A release agent, such as a uniform layer of soap, is applied to the mold to facilitate easy demolding and prevent the composite from adhering to the mold walls. The wood shavings are then cut or calibrated to ensure a homogeneous particle size, which is essential for achieving a uniform distribution within the plaster matrix. The preparation of the plaster consists of mixing plaster powder with water in precise proportions to obtain a smooth, homogeneous paste with optimal rheological properties. The wood shavings are gradually incorporated into the mixture to prevent clumping and ensure an even dispersion. The resulting mixture is poured into the mold under controlled conditions to minimize air entrapment and ensure the cohesion of the composite. The composite is then subjected to a drying phase to allow the complete evaporation of residual water and the full hardening of the material. Finally, the composite is demolded after complete curing, resulting in a lightweight and durable product ready for further testing or application. This process exemplifies an eco-friendly approach by valorizing lignocellulosic by-products and optimizing the composite fabrication method.

Figure 2.

Sample preparation process for thermal property measurement.

Figure 3 illustrates the different stages involved in preparing samples for thermal properties measurement. The process begins with sieving the wood shavings to remove large pieces and ensure a uniform texture for even distribution within the composite. For each formulation, a specific ratio of plaster and wood shavings is used. The plaster is prepared by measuring the required amount and mixing it with water in a bucket, ensuring that it is added first to prevent lumps. The mixture is stirred until a smooth liquid paste is obtained. The wood shavings are then mixed into the plaster to achieve a balanced integration. The plaster–wood shavings mixture is poured into the mold in successive layers. The first layer is allowed to dry partially, promoting the impregnation of the wood shavings into the plaster matrix. A second layer is then added to ensure uniform distribution throughout the mold. The sample is left to dry for several days, with the mold placed in an oven at around 60 °C to facilitate complete moisture evaporation and enhance structural strength. Once the drying phase is complete, the sample is carefully demolded to achieve the desired finish. The figure shows various final samples with different wood shaving concentrations (e.g., 0%, 5%, 10%, 15%) prepared for subsequent thermal property testing. This stepwise approach ensures a consistent composite structure, optimizing thermal performance evaluation.

Figure 3.

Steps of composite sample preparation: cutting wood shavings, plaster mixing, casting, and final dried samples.

2.3.3. Mechanical Properties

For each composite formulation, a mechanical compression test was conducted to assess the impact of wood shavings on the plaster’s properties. The samples used for this mechanical testing had dimensions of 4 × 4 × 4 cm. A universal mechanical testing machine (criterion MTS model 43) was used for the tests with a load capacity of 20 kN and a precision measurement according to the type of control. Using data on the displacement and load increase during the compression tests on the samples within their elastic range, the elastic modulus (E) of the composites was determined using the following expression:

where Δσ represents the change in compressive stress measured in megapascals (MPa) and Δε denotes the corresponding change in strain between two points on the stress–strain curve.

2.4. Numerical Investigation

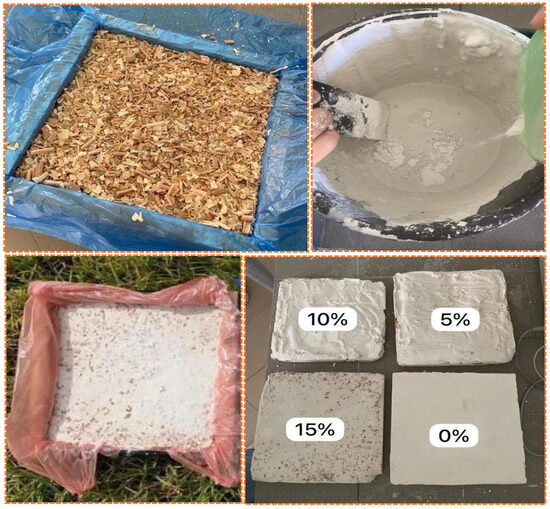

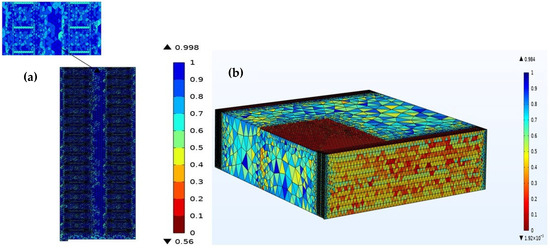

The numerical study includes two geometric models (a two-dimensional plane model and a three-dimensional model). The first is a wall with 6 transverse layers, made up, respectively, of concrete, 18 bricks separated by thin layers of concrete, insulating material, air, brick, and concrete. The second is made up of two walls separated by a volume of air containing an equipped chamber occupying 0.25% of the air volume, as shown in Figure 4.

Figure 4.

(a): Cross-sectional view of the multilayer wall assembly in 2D, (b): Side view of the 3D geometric model showing the multilayer wall and room in perspective, (c): Interior perspective of the simulated room environment of the numerical modeling.

Numerical simulation was used to take into account heat transfer between the wall and the external environment on the one side, and between the wall and the interior of the house on the other. The solid and fluid heat transfer physics available in the software are exploited for this purpose. To minimize calculation errors, a fine mesh (Figure 5) is customized in the software interface. The study is carried out in two regimes: static and dynamic.

Figure 5.

(a): Meshing scheme of the 2D plane model, illustrating the discretization of the multilayer structure, (b): The meshing of the 3D model used for heat transfer simulation, where mesh refinement is applied around thermal boundaries and air cavity zones of the numerical modeling.

In the static or stationary regime, heat transfer between wall layers is described by the equation

where k is the thermal conductivity and φ is the flux density received by conduction along the normal direction of the wall.

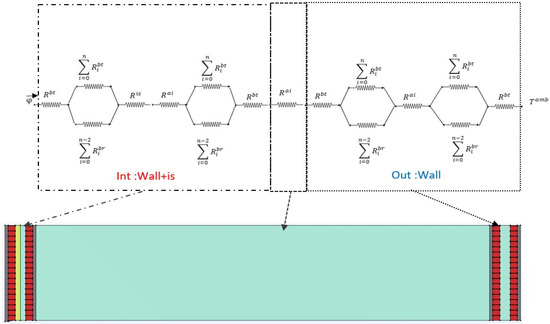

Under static conditions, the equivalent diagram of the studied system is shown in Figure 6.

Figure 6.

Equivalent diagram of the studied model under static conditions.

Similarly, the thermal behavior of the investigated system as a function of time follows the transient heat transfer equation

where ρ is the density and c is the heat capacity of the layer i.

2.4.1. Initial and Boundary Conditions

In this study, we employed specific initial and boundary conditions to model the heat transfer through insulating materials. The details are as follows:

Steady-State Regime

- 2D Modeling:

Initial Temperature: The initial temperature of the entire domain is set to T(x,z) = 298.15 °K

Boundary Conditions:

At x = 0 (surface exposed to heat):

−k.dT(x,z)dz|x = 0 = φ − h(Text − T(x = 0,z))

This condition represents a time-dependent heat flux applied to the surface, where φ(t) is the time-dependent heat flux, h is the convective heat transfer coefficient, and Text is the external temperature.

At the boundaries z = 0 and z = L1 (lateral boundaries),

These conditions indicate no heat flux through the lateral boundaries, representing adiabatic boundaries.

- 3D Modeling:

Initial Temperature: The initial temperature of the entire domain is set to T(x,y,z) = 298.15 K.

This complex condition accounts for both the applied heat flux to the surface and the convective heat transfer.

At the boundaries z = 0 and z = L (lateral boundaries):

These conditions indicate no heat flux through the lateral boundaries.

At the boundaries y = 0 and y = 5L,

These conditions indicate no heat flux through the boundaries in y, representing adiabatic boundaries.

These boundary conditions model the thermal behavior of insulating materials under continuous heat flux and after the cessation of this flux. The equations describe the heat transfer by conduction and convection within the material.

Dynamic Regime

- 2D Modeling:

Initial Temperature: T(x, z, 0) = 298.15 K

Boundary Conditions: At x = 0 (surface exposed to heat),

where φ(t) is the time-dependent heat flux, defined as

h is the convective heat transfer coefficient, and Text is the external temperature.

At the boundaries z = 0 and z = L1 (lateral boundaries):

indicating no heat flux through the lateral boundaries, representing adiabatic boundaries.

- 3D Modeling

Initial Temperature T(x, y, z, t) = 298.15 K

Boundary Conditions:

At x = 0 (surface exposed to heat):

where φ(t) is the time-dependent heat flux, defined as

At the boundaries z = 0 and z = L (lateral boundaries):

These conditions indicate no heat flux through the lateral boundaries, representing adiabatic boundaries.

3. Results and Discussion

3.1. Thermal Properties of the Elaborated Samples

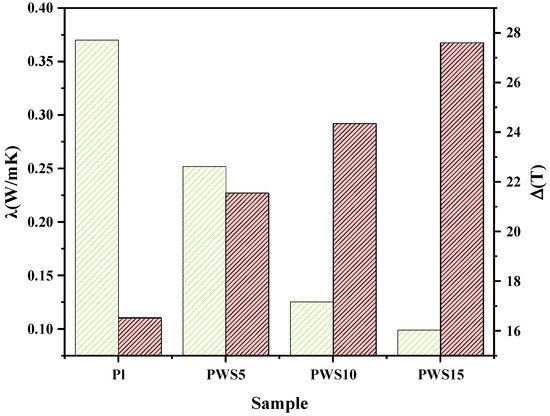

The thermal behavior of the composite materials, as listed in Table 2, demonstrates the impact of adding wood shavings to plaster on the thermal conductivity and overall insulation performance.

Table 2.

Thermal behavior of the samples.

For the pure plaster sample (Pl), the thermal conductivity (λ) is 0.370 W/mK, indicating a relatively high rate of heat transfer compared to the other samples. The temperatures recorded (T1 and T2) show a significant temperature gradient across the sample, which correlates with the higher density power per area (P/A) value of 152.92 W/m2. This indicates that the pure plaster allows more heat to pass through. As wood shavings are added to the plaster, the thermal conductivity decreases significantly. For PWS5 (5% wood shavings), the thermal conductivity drops to 0.252 W/mK, and the P/A value decreases to 135.84 W/m2. This shows that the composite with 5% wood shavings is a better insulator than pure plaster. This trend continues with higher percentages of wood shavings. For PWS10 (10% wood shavings), the thermal conductivity further decreases to 0.126 W/mK, and the P/A value is reduced to 90.54 W/m2. The composite with 10% wood shavings demonstrates even better insulation properties, with a lower rate of heat transfer.

Thermal behavior enhancement is justified in that increasing porosity introduces more air pockets within the material, which act as thermal barriers, slowing down the transfer of heat [26]. Additionally, the lower density means there is less solid material to conduct heat, further decreasing thermal conductivity. This combination of lower density and higher porosity makes the composite more effective at resisting heat flow, thus improving its overall thermal insulation performance (Figure 7). The most substantial improvement is seen in PWS15 (15% wood shavings), where the thermal conductivity is the lowest at 0.099 W/mK, and the P/A value is significantly reduced to 68.58 W/m2. This indicates that the composite with 15% wood shavings provides the best thermal insulation among the tested samples.

Figure 7.

Thermal conductivity and temperature variation of the insulation composites.

The calculated thermal resistance values presented in Table 2, indicate that, as the percentage of wood shavings in the plaster increases, the thermal resistance of the material also increases.

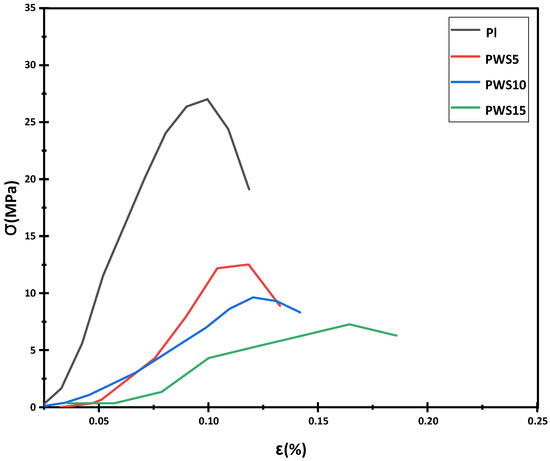

3.2. Mechanical Properties of the Elaborated Samples

Figure 8 shows the stress–strain behavior of the four different composite materials subjected to a compression test: PL, PWS5, PWS10, and PWS15. Using the data on position change and load increase during compression tests within the elastic range, the Young’s modulus (E) of the composites was determined (Table 3). For each material, the Young’s modulus was calculated from the slope of the linear portion of the stress–-strain curve. Adding wood shavings to plaster decreases the stiffness of the composite material, making it more flexible.

Figure 8.

Stress–strain behavior of the different composite materials subjected to a compression test.

Table 3.

Young’s modulus of Pl, PWS5, PWS10, and PWS15.

In addition to increased flexibility, the mechanical properties influence the effectiveness of the material as thermal insulation. A more flexible composite can better absorb shocks and vibrations, beneficial for structures subjected to load variations. Furthermore, the addition of wood shavings enhances the thermal resistance of the composite material. The lower density and increased porosity from the wood shavings reduce the thermal conductivity, thereby enhancing the material’s insulation properties. This means that materials with higher flexibility and lower Young’s modulus, such as PWS15 (plaster with 15% wood shavings), are likely to exhibit better thermal insulation performance compared to stiffer materials like Pl (100% plaster). The combination of mechanical flexibility and low thermal conductivity makes such composites highly effective in reducing heat transfer, improving energy efficiency in buildings by minimizing heat loss through walls, ceilings, and floors.

3.3. Numerical Results

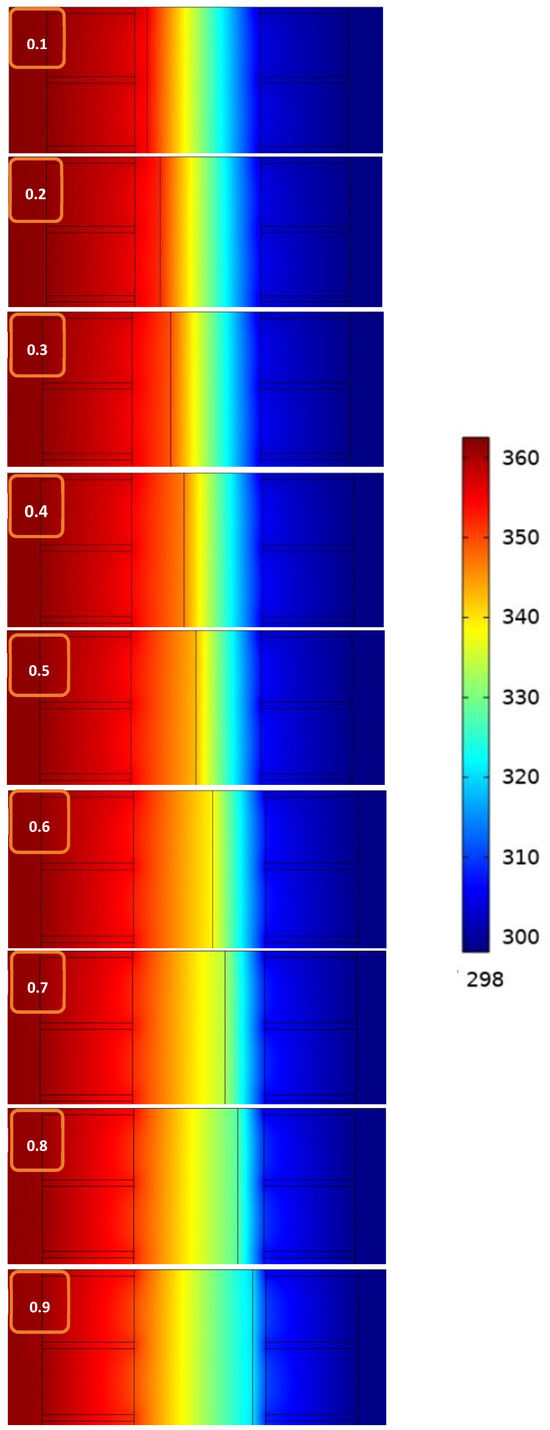

In this numerical study, we investigate the effect of incorporating wood shavings into plaster on the thermal properties of the resulting composite material. The objective is to evaluate how varying filler percentages (5%, 10%, and 15% wood shavings) influence the thermal insulation performance of plaster/wood shaving composites. Using a multilayer wall model that includes concrete, brick, the composite insulation layer, an air gap, and additional layers of brick and concrete, we simulate the temperature distribution across the wall and the entire building structure in steady-state and dynamic conditions. This analysis provides insights into the thermal behavior of the composites and helps to identify the optimal filler content and thickness for enhanced insulation properties in building applications.

3.3.1. Effect of the Composite Composition Plaster/Wood Shavings on Thermal Properties

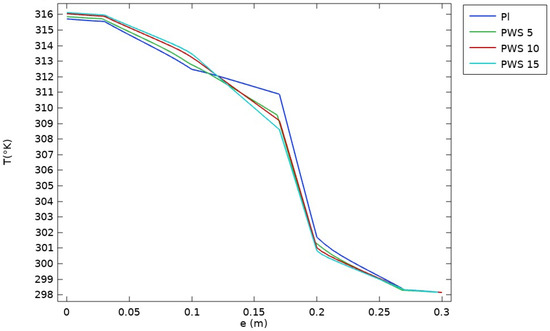

In this numerical study, we investigate the effect of incorporating wood shavings into plaster on the thermal properties of the resulting composite material, building on experimental investigations previously conducted. The temperature profile indicates the thermal behavior of these materials when subjected to a steady-state thermal condition. Figure 9 presents the temperature evolution across different composite materials (Pl, PWS5, PWS10, and PWS15) in a steady-state condition. The x-axis represents the thickness of the wall (e), while the y-axis represents the temperature (T) in Kelvin.

Figure 9.

Temperature evolution across the different composites at steady state.

Within the insulating materials, which are positioned between 0.1 m and 0.17 m on the x-axis, we observe distinct temperature behaviors for each composite. All samples show a similar temperature gradient, but with varying degrees of thermal resistance. By increasing the percentage of wood shavings in the plaster composite results in an enhancement of the insulation properties. The addition of wood shavings reduces the thermal conductivity of the material, leading to a greater temperature drop across the insulating layer. This improved performance is particularly evident in the segment from 0.1 m to 0.17 m, where the composites with higher wood shavings content (PWS 10 and PWS 15) show superior insulation compared to plain plaster. PWS 15 shows the highest temperature drop of 12 K, while the plaster shows the lowest temperature drop of 6 K. This is in good agreement with the experimental results presented above (Figure 7, delta T).

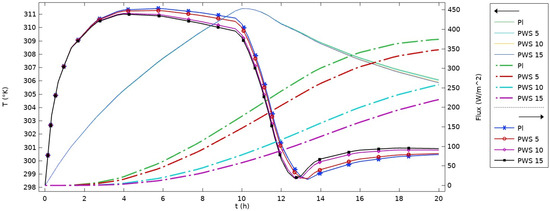

In Figure 10, a continuous heat flow was applied to the wall for 10 h and then measured the wall’s response during the application of the heat flow and for an additional 10 h to understand the post-application behavior for different compositions. The weighted mean wall temperature is represented by solid lines, and the temperature of the inside face of the insulating materials over 20 h is shown by dashed lines. Additionally, the heat flow of each composition is represented by lines with symbols.

Figure 10.

Incoming heat flux, weighted mean wall temperature, and temperature of the inside face of insulating materials over 20 h.

Heat flow decreases as the percentage of wood shavings increases. PI has the highest heat flow, meaning greater heat transfer through the material. PWS15 has the lowest heat flow. This correlation between lower heat flow and reduced thermal conductivity is consistent with the increased porosity and insulating capacity of wood shaving composites. Heat flow also decreases more rapidly for composites with higher percentages of wood shavings after heat flow has stopped. PI shows a slow reduction in heat flow, while PWS 5, PWS 10, and PWS 15 show increasingly rapid decreases in heat flow.

During the first ten hours of heat flow, the weighted average wall temperature rises progressively. For Pl, the temperature peaks at around 311 K. This behavior reflects a uniform temperature rise across the wall, illustrating constant thermal conduction. PWS5 shows a slightly lower temperature peak than Pl, indicating better thermal insulation. The composite PWS10 shows an even lower peak temperature, suggesting a significant improvement in insulating performance. The composite PWS15 has the lowest peak temperature, demonstrating the highest insulation efficiency of the materials tested. After the heat flow has stopped, the weighted average temperature of the wall begins to fall. For Pl, this decrease is gradual, indicating slow heat dissipation. PWS 5 shows a slightly faster cooling rate than Pl, suggesting more efficient heat dissipation. PWS10 and PWS15 show even faster cooling rates, with PWS15 showing the fastest temperature decrease, reflecting better heat retention and dissipation thanks to improved insulation.

The temperature of the inside surface of the insulating materials does not follow a similar trend to that of the weighted average wall temperature. The weighted average wall temperature for the different compositions rises gradually until reaching a peak after 10 h, then drops rapidly once the heat flow has stopped. The temperature of the internal face, however, shows a different response. For Pl, the temperature reaches around 309 K; for PWS5, around 308 K; for PWS10, around 306 K; and, for PWS15, around 304 K. These values indicate that composites with higher percentages of wood shavings show a slower temperature rise and faster heat dissipation after the heat flow had stopped.

The continued rise in temperature on the inside surface of insulating materials for 10 h after the heat flow has stopped can be explained by the phenomenon of heat dissipation and the thermal inertia of the materials. When heat flow is applied for the first 10 h, a large amount of heat is accumulated in the insulating materials. This heat is not immediately dissipated once the heat flow stops, due to the thermal capacity of the materials. The thermal inertia of materials means that they continue to transfer the accumulated heat inwards, even after the external flow has stopped. As a result, the temperature on the inside continues to rise for some time, until thermal equilibrium is reached.

3.3.2. Effect of Insulation Composite Layer Thickness

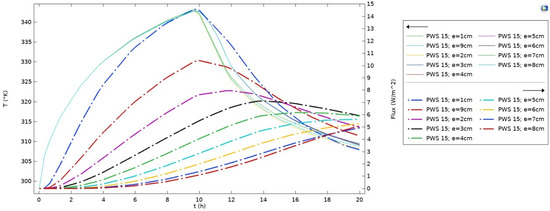

After determining that a 15% wood shavings content (PWS15) provided the best thermal insulation, the next phase of the study involved examining the impact of the insulating material’s thickness on its thermal performance. This was conducted through a numerical investigation, where the thickness of the PWS15 material was varied from 1 cm to 9 cm in increments of 1 cm, resulting in nine different materials with varying thicknesses.

Figure 11 illustrates the incoming heat flux and the weighted average temperature of these different thicknesses of the PWS15 insulating material over a 20 h period under dynamic conditions. The heat flux was applied for the first 10 h at a constant value of 400 W/m2. The temperature of the material increased significantly during this period, with thicker materials showing a slower rate of temperature increase compared to thinner materials. This is due to the higher thermal mass and resistance of thicker materials, which can absorb more heat before reaching thermal equilibrium.

Figure 11.

Incoming heat flux and weighted average temperature of different thicknesses of insulating material over 20 h.

After the heat flux was removed, the materials began to cool down. Thicker materials retained heat for a longer duration, leading to a slower decrease in temperature. This behavior is expected as thicker insulating layers provide better thermal resistance, slowing down the rate of heat dissipation.

The variation in the temperature profiles with different material thicknesses highlights the impact of insulation thickness on thermal performance. The material with the smallest thickness (1 cm) quickly reached a higher temperature and cooled down rapidly once the heat source was removed. Conversely, the material with the greatest thickness (9 cm) exhibited a more gradual temperature rise and fall, indicating better insulation properties.

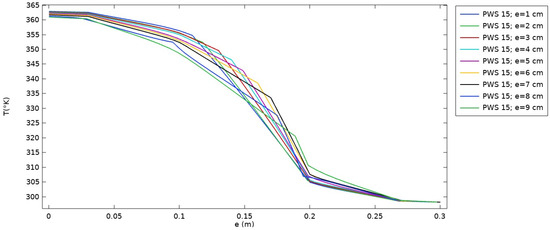

Figure 12 shows the temperature evolution across all layers of the wall, for different thicknesses of the PWS15 insulating material in a steady-state regime. The temperature decreases from the heated exterior surface through the various layers of the wall to the interior surface. This gradient reflects the thermal resistance provided by each layer, including the insulation material.

Figure 12.

Temperature variation as a function of wall length at steady state.

The walls with thinner insulation (1 cm to 2 cm) exhibit a steeper temperature gradient. The heat passes more quickly through the insulation, resulting in less effective thermal resistance. The inner layers closer to the heated surface maintain higher temperatures. The walls with thicker insulation (7 cm to 9 cm) show a more gradual temperature gradient. The thicker insulation effectively slows the heat transfer, resulting in lower temperatures for the inner layers closer to the interior surface (Figure 13). Thicker insulation layers show a significant temperature drop across them, indicating their role as the primary barrier to heat flow. Other wall layers also contribute but to a lesser extent.

Figure 13.

Heat flow temperature through PWS15 with different thicknesses.

Selecting the appropriate thickness of insulation material in wall assemblies is crucial for energy efficiency and maintaining comfortable indoor temperatures. Thicker insulation layers provide better thermal performance, reducing energy costs associated with heating and cooling. The optimal thickness for insulation would balance the material cost and the desired thermal performance. In this study, a thickness of around 6–7 cm appears to provide a significant improvement in insulation without excessively prolonging the temperature retention period. The primary reason for the observed behavior is the principle of thermal conductivity. Thicker insulation materials increase the path length for heat transfer, thereby reducing the heat flux and resulting in a more significant temperature drop across the wall. This aligns with Fourier’s law of heat conduction, which states that the heat flux is inversely proportional to the thickness of the material.

The steady-state temperature evolution graph for the wall layers confirms that increasing the thickness of the PWS15 insulating material significantly enhances the thermal resistance of the wall. This results in a more gradual temperature gradient, better insulating the interior environment from external temperature changes. This reinforces the importance of selecting an appropriate insulation thickness for optimizing energy efficiency and maintaining comfortable indoor temperatures in building design.

4. Conclusions

This study highlights the potential of wood-shavingsplaster-based composites as sustainable thermal insulation materials. Through a rigorous experimental approach complemented by numerical modeling, the effects of the progressive addition of wood chips on thermal and mechanical performance have been clearly demonstrated.

The main results are as follows:

- -

- Improved thermal insulation: thermal conductivity drops from 0.370 W/m-K (pure gypsum) to 0.099 W/m-K for 15% wood chips, a reduction of more than 70%, due to the increased porosity and low intrinsic conductivity of wood;

- -

- Increased mechanical flexibility: the modulus of elasticity drops from 3965 MPa to 1808 MPa, giving the composite greater flexibility and impact resistance, making it suitable for structures subject to load variations;

- -

- Numerical validation: simulations in stationary and transient regimes confirm experimental observations, with a temperature drop of 12 K in the PWS15 composite compared, with 6 K for plaster alone;

- -

- Thickness optimization: the numerical study shows that a PWS15 composite thickness of 6 to 7 cm achieves good energy efficiency while remaining economically viable.

Over and above technical performance, this research makes several significant contributions to the field of sustainable building materials:

- Valorization of lignocellulosic waste: using wood chips from local carpentry activities offers a concrete recycling solution for waste that is often burnt or landfilled;

- Alternative to synthetic insulation: although slightly less thermally efficient, these composites offer a more environmentally friendly, biobased alternative to conventional insulation materials such as polystyrene or glass wool;

- Reproducible methodology: the preparation protocol (drying, dosing, molding, curing) is accessible and can be transposed to a craft or semi-industrial context, particularly in countries with warm climates;

- Combined approach: the complementary nature of experimental characterization and numerical simulation provides an in-depth understanding of the thermal behavior of materials, paving the way for future optimization.

In conclusion, the wood-chip–plaster-based composites studied represent a promising solution for the development of low-energy buildings, integrating local, recycled resources that have low environmental impact.

Author Contributions

Conceptualization, R.M.B., R.M., D.M., E.C., E.A., C.Y., M.H., E.K.M. and B.F.; methodology, R.M.B., R.M., D.M., E.C., E.A., C.Y., M.H., E.K.M. and B.F.; software, R.M.B., R.M., D.M., E.C., E.A., C.Y., M.H., E.K.M. and B.F.; validation, R.M.B., R.M., D.M., E.C., E.A., C.Y., M.H., E.K.M. and B.F.; formal analysis, R.M.B., R.M., D.M., E.C., E.A., C.Y., M.H., E.K.M. and B.F.; investigation, R.M.B., R.M., D.M., E.C., E.A., C.Y., M.H., E.K.M. and B.F.; resources, R.M.B., R.M., D.M., E.C., E.A., C.Y., M.H., E.K.M. and B.F.; data curation, R.M.B., R.M., D.M., E.C., E.A., C.Y., M.H., E.K.M. and B.F.; writing—original, R.M.B., R.M., D.M. and E.C.; writing—review and editing, E.A. and C.Y.; supervision, E.C. and C.Y. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

Data available on request.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Santamouris, M.; Vasilakopoulou, K. Present and Future Energy Consumption of Buildings: Challenges and Opportunities towards Decarbonisation. e-Prime—Adv. Electr. Eng. Electron. Energy 2021, 1, 100002. [Google Scholar] [CrossRef]

- Pérez-Lombard, L.; Ortiz, J.; Pout, C. A Review on Buildings Energy Consumption Information. Energy Build. 2008, 40, 394–398. [Google Scholar] [CrossRef]

- Colmenar-Santos, A.; Terán de Lober, L.N.; Borge-Diez, D.; Castro-Gil, M. Solutions to Reduce Energy Consumption in the Management of Large Buildings. Energy Build. 2013, 56, 66–77. [Google Scholar] [CrossRef]

- Belussi, L.; Barozzi, B.; Bellazzi, A.; Danza, L.; Devitofrancesco, A.; Fanciulli, C.; Ghellere, M.; Guazzi, G.; Meroni, I.; Salamone, F.; et al. A Review of Performance of Zero Energy Buildings and Energy Efficiency Solutions. J. Build. Eng. 2019, 25, 100772. [Google Scholar] [CrossRef]

- Cozza, S.; Chambers, J.; Brambilla, A.; Patel, M.K. In Search of Optimal Consumption: A Review of Causes and Solutions to the Energy Performance Gap in Residential Buildings. Energy Build. 2021, 249, 111253. [Google Scholar] [CrossRef]

- Dylewski, R.; Adamczyk, J. Economic and Environmental Benefits of Thermal Insulation of Building External Walls. Build. Environ. 2011, 46, 2615–2623. [Google Scholar] [CrossRef]

- Al-Homoud, M.S. The Effectiveness of Thermal Insulation in Different Types of Buildings in Hot Climates. J. Therm. Envel. Build. Sci. 2004, 27, 235–247. [Google Scholar] [CrossRef]

- Al-Sanea, S.A.; Zedan, M.F.; Al-Hussain, S.N. Effect of Thermal Mass on Performance of Insulated Building Walls and the Concept of Energy Savings Potential. Appl. Energy 2012, 89, 430–442. [Google Scholar] [CrossRef]

- Dong, Y.; Kong, J.; Mousavi, S.; Rismanchi, B.; Yap, P.-S. Wall Insulation Materials in Different Climate Zones: A Review on Challenges and Opportunities of Available Alternatives. Thermo 2023, 3, 38–65. [Google Scholar] [CrossRef]

- Kumar, D.; Alam, M.; Zou, P.X.W.; Sanjayan, J.G.; Memon, R.A. Comparative Analysis of Building Insulation Material Properties and Performance. Renew. Sustain. Energy Rev. 2020, 131, 110038. [Google Scholar] [CrossRef]

- Al-Sanea, S.A.; Zedan, M.F. Improving Thermal Performance of Building Walls by Optimizing Insulation Layer Distribution and Thickness for Same Thermal Mass. Appl. Energy 2011, 88, 3113–3124. [Google Scholar] [CrossRef]

- Hung Anh, L.D.; Pásztory, Z. An Overview of Factors Influencing Thermal Conductivity of Building Insulation Materials. J. Build. Eng. 2021, 44, 102604. [Google Scholar] [CrossRef]

- Al-Sanea, S.A. Evaluation of Heat Transfer Characteristics of Building Wall Elements. J. King Saud Univ.-Eng. Sci. 2000, 12, 285–312. [Google Scholar] [CrossRef]

- Stazi, F.; Vegliò, A.; Di Perna, C.; Munafò, P. Experimental Comparison between 3 Different Traditional Wall Constructions and Dynamic Simulations to Identify Optimal Thermal Insulation Strategies. Energy Build. 2013, 60, 429–441. [Google Scholar] [CrossRef]

- Asdrubali, F.; D’Alessandro, F.; Schiavoni, S. A Review of Unconventional Sustainable Building Insulation Materials. Sustain. Mater. Technol. 2015, 4, 1–17. [Google Scholar] [CrossRef]

- Abu-Jdayil, B.; Mourad, A.-H.; Hittini, W.; Hassan, M.; Hameedi, S. Traditional, State-of-the-Art and Renewable Thermal Building Insulation Materials: An Overview. Constr. Build. Mater. 2019, 214, 709–735. [Google Scholar] [CrossRef]

- Building Insulating Materials from Agricultural By-Products: A Review | SpringerLink. Available online: https://link.springer.com/chapter/10.1007/978-981-32-9868-2_26 (accessed on 29 July 2024).

- Pargana, N.; Pinheiro, M.D.; Silvestre, J.D.; De Brito, J. Comparative Environmental Life Cycle Assessment of Thermal Insulation Materials of Buildings. Energy Build. 2014, 82, 466–481. [Google Scholar] [CrossRef]

- Rabhi, A.; Ennawaoui, A.; Radoine, H.; Hammoumi, I.; Assif, S.; Chhiti, Y.; Laasri, S.; Ennawaoui, C. Thermal and Mechanical Performances Optimization of Plaster–Polystyrene Bio-Composites for Building Applications. CivilEng 2024, 5, 1172–1184. [Google Scholar] [CrossRef]

- Ennawaoui, A.; Lalam, K.; Harmen, Y.; El Morabit, A.; Chhiti, Y.; Chebak, A.; Benssitel, M. Cactus Cladode Juice as Bioflocculant in the Flocculation-Thickening Process for Phosphate Washing Plant: A Comparative Study with Anionic Polyacrylamide. Sustainability 2022, 14, 8054. [Google Scholar] [CrossRef]

- Pedreño-Rojas, M.A.; Morales-Conde, M.J.; Pérez-Gálvez, F.; Rodríguez-Liñán, C. Eco-Efficient Acoustic and Thermal Conditioning Using False Ceiling Plates Made from Plaster and Wood Waste. J. Clean. Prod. 2017, 166, 690–705. [Google Scholar] [CrossRef]

- Mehrez, I.; Hachem, H.; Jemni, A. Thermal Insulation Potential of Wood-Cereal Straws/Plaster Composite. Case Stud. Constr. Mater. 2022, 17, e01353. [Google Scholar] [CrossRef]

- Karawi, R.J.A.; Borhan, T.M.; Karawi, M.Q.A.; Al-Hassnawi, N.; Karawi, R.J.A.; Borhan, T.M.; Karawi, M.Q.A.; Al-Hassnawi, N. Study the Effect of Sawdust Content and Temperature on Fundamental Properties of Plaster Mortars. J. Southwest. Jiaotong Univ. 2019, 54, 1–8. [Google Scholar] [CrossRef]

- Saad Azzem, L.; Bellel, N. Thermal and Physico-Chemical Characteristics of Plaster Reinforced with Wheat Straw for Use as Insulating Materials in Building. Buildings 2022, 12, 1119. [Google Scholar] [CrossRef]

- Lakrafli, H.; Sennoune, M.; Lakrafli, L. Measuring Thermal Conductivity of Certain Solid Industrial Waste by Box Method. J. Anal. Sci. Appl. Biotechnol. 2019, 1. [Google Scholar]

- Robert, U.W.; Etuk, S.E.; Agbasi, O.E.; Ekong, S.A.; Abdulrazzaq, Z.T.; Anonaba, A.U. Investigation of Thermal and Strength Properties of Composite Panels Fabricated with Plaster of Paris for Insulation in Buildings. Int. J. Thermophys. 2021, 42, 25. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).