Enhancing the Sustainability of Concrete by Adding Recycled Sand and Silica Fume Along with Human Hair Fibers

Abstract

1. Introduction

2. Materials and Methods

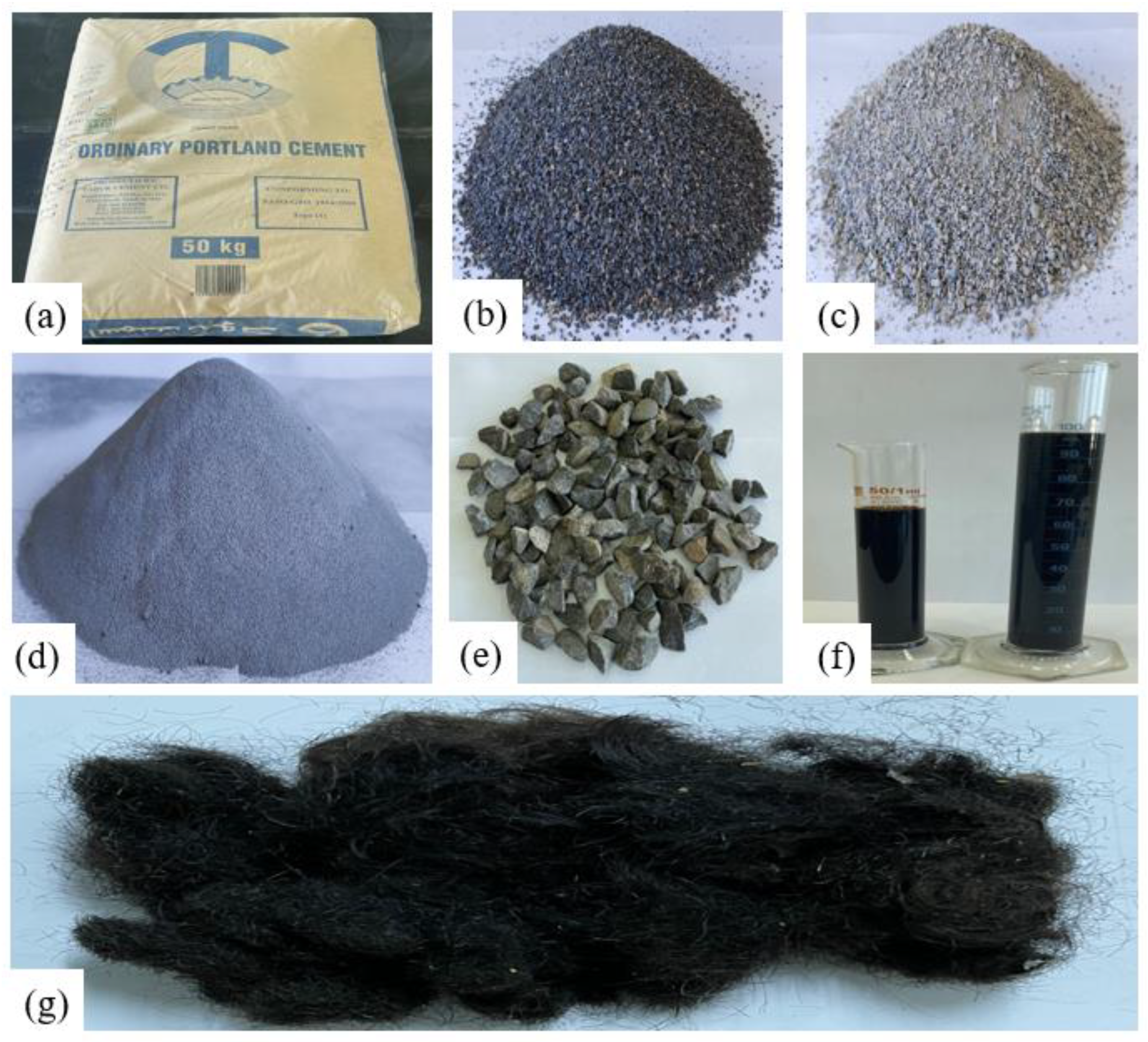

2.1. Materials

Materials for Producing Concrete

2.2. Methods

3. Results and Discussion

3.1. Chemical Characterization of Developed Sand

3.1.1. SEM-EDS Instrumentation

3.1.2. Characterization of Developed Modified Sand Using SEM-EDS

3.2. Strength Characteristics

3.2.1. Compressive Strength Evaluation

3.2.2. Splitting Tensile Strength

3.3. Durability Characteristics in Terms of Density and Porosity of Prepared Samples at Hardened Stage

3.3.1. Experimental Method

3.3.2. Density and Porosity Results of Hardened Concrete Samples

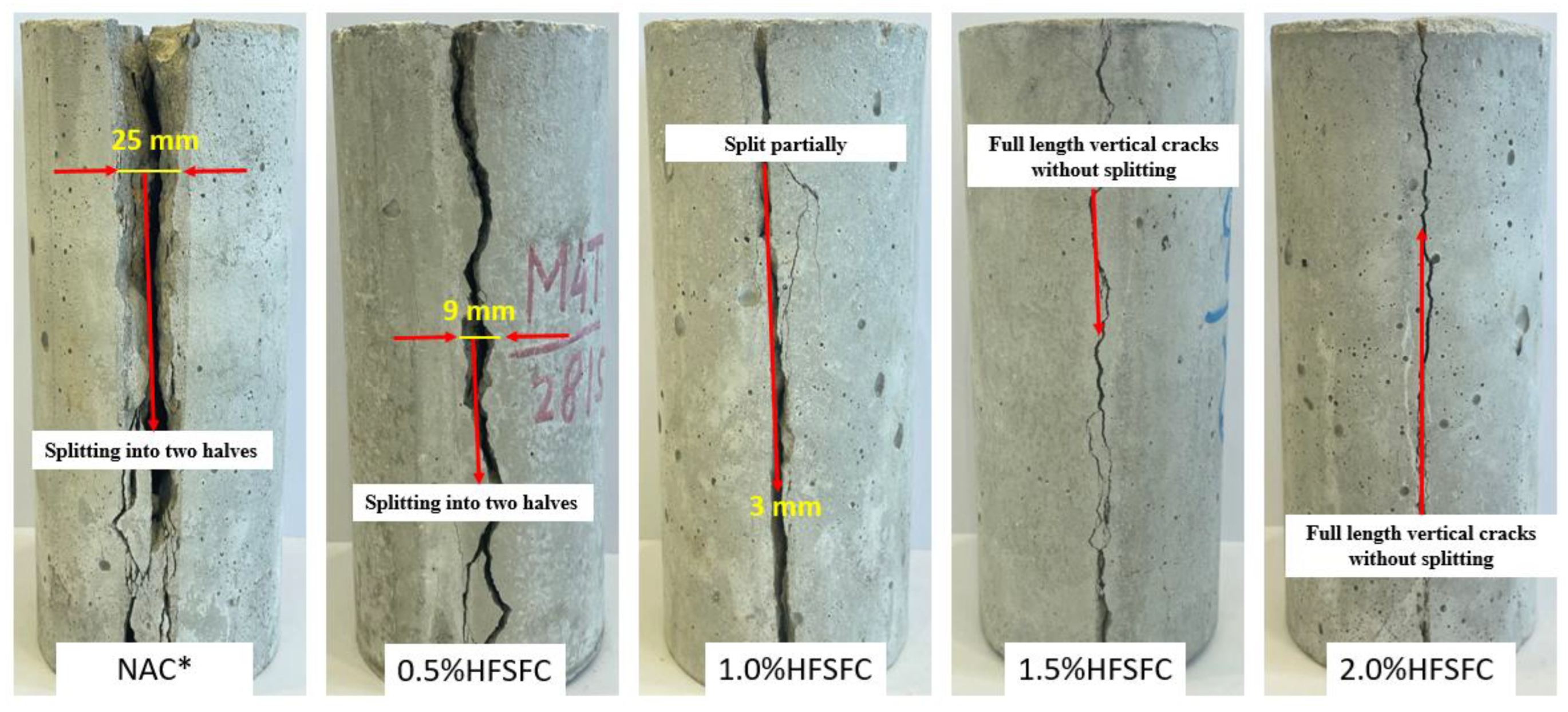

3.4. Crack Pattern

4. Conclusions

- A slump of 100 mm was successfully attained in the mixes NAC*, 0.5% HFSFC, 1.0% HFSFC, 1.5% HFSFC, and 2.0% HFSFC, achieved by adding 0.5%, 1%, 1.4%, 1.9%, and 2.6% admixture by weight of cement, respectively.

- The compressive strength of the developed mixes containing hair fibers, i.e., 0.5% HFSFC, 1.0% HFSFC, 1.5% HFSFC, and 2.0% HFSFC, met the target compressive strength requirement (f’cr) of 38 MPa. The control mix NAC*, which utilized 100% ordinary Portland cement (OPC), exhibited a compressive strength of 36.104 MPa, falling short of the target strength but demonstrating proximity to it. This indicates that including hair fibers positively enhances the compressive strength of the concrete mixes.

- The splitting tensile strength (STS) values for the mixes NAC*, 0.5% HFSFC, 1.0% HFSFC, 1.5% HFSFC, and 2.0% HFSFC were recorded to be 15.4%, 15.8%, 16%, 18.7%, and 18.8% (f’c), respectively. All tested mixes surpassed the established criterion of 10–15% (f’c), indicating satisfactory performance.

- The bulk density measurements of the dry mixes 0.5% HFSFC, 1.0% HFSFC, 1.5% HFSFC, and 2.0% HFSFC, which included hair fibers and silica fume, were determined to be 2.518, 2.644, 2.708, and 2.792 g/cm3, respectively. In contrast, the reference mix NAC*, which contained 100% OPC and did not contain any hair fibers or silica fume, exhibited a bulk density of 2.360 g/cm3. These results signify that adding hair fibers and silica fume increased the bulk density of the concrete mixes, with the mixes 0.5% HFSFC, 1.0% HFSFC, 1.5% HFSFC, and 2.0% HFSFC showing increments in bulk density of 6.69%, 12.03%, 14.75%, and 18.30% compared to the reference mix. Moreover, the utilization of a 50% blend of recycled sand and manufactured sand as a fine aggregate was identified as a significant factor for pore reduction and density enhancement.

- The combination of 50% recycled sand and 50% manufactured sand is an effective alternative to 100% natural river sand. Furthermore, the optimal incorporation of 10% silica fume alongside 0.5% to 2% hair fibers emerged as the most favorable combination in terms of the strength and durability of the newly developed concrete mixes. Notably, all specified parameters of the 1.5% HFSFC mix complied with the required parameter values, making it the best concrete mix developed in this study.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- UN. Translation Division. Documentation, Reference and Terminology Section. Environment and Development; United Nations: New York, NY, USA, 1992; Volume 2. [Google Scholar]

- Gallagher, L.; Peduzzi, P. Sand and Sustainability: Finding New Solutions for Environmental Governance of Global Sand Resources; University of Geneva: Geneva, Switzerland, 2019. [Google Scholar]

- Bhatawdekar, R.M.; Singh, T.N.; Tonnizam Mohamad, E.; Armaghani, D.J.; Binti Abang Hasbollah, D.Z. River sand mining vis a vis manufactured sand for sustainability. In Proceedings of the International Conference on Innovations for Sustainable and Responsible Mining: ISRM 2020; Springer: Berlin/Heidelberg, Germany; Volume 1, pp. 143–169.

- Kisku, N.; Joshi, H.; Ansari, M.; Panda, S.; Nayak, S.; Dutta, S.C. A critical review and assessment for usage of recycled aggregate as sustainable construction material. Constr. Build. Mater. 2017, 131, 721–740. [Google Scholar] [CrossRef]

- Torres, A.; Simoni, M.U.; Keiding, J.K.; Müller, D.B.; zu Ermgassen, S.O.; Liu, J.; Jaeger, J.A.; Winter, M.; Lambin, E.F. Sustainability of the global sand system in the Anthropocene. One Earth 2021, 4, 639–650. [Google Scholar] [CrossRef]

- Safinia, S.; Al-Hinai, Z.; Yahia, H.A.; Abushammala, M.F. Sustainable construction in sultanate of Oman: Factors effecting materials utilization. Procedia Eng. 2017, 196, 980–987. [Google Scholar] [CrossRef]

- Zhong, X.; Deetman, S.; Tukker, A.; Behrens, P. Increasing material efficiencies of buildings to address the global sand crisis. Nat. Sustain. 2022, 5, 389–392. [Google Scholar] [CrossRef]

- Fanijo, E.O.; Kolawole, J.T.; Babafemi, A.J.; Liu, J. A comprehensive review on the use of recycled concrete aggregate for pavement construction: Properties, performance, and sustainability. Clean. Mater. 2023, 9, 100199. [Google Scholar] [CrossRef]

- Bolden, J.; Abu-Lebdeh, T.; Fini, E. Utilization of recycled and waste materials in various construction applications. Am. J. Environ. Sci. 2013, 9, 14–24. [Google Scholar] [CrossRef]

- Sormunen, P.; Kärki, T. Recycled construction and demolition waste as a possible source of materials for composite manufacturing. J. Build. Eng. 2019, 24, 100742. [Google Scholar] [CrossRef]

- Mistri, A.; Bhattacharyya, S.K.; Dhami, N.; Mukherjee, A.; Barai, S.V. A review on different treatment methods for enhancing the properties of recycled aggregates for sustainable construction materials. Constr. Build. Mater. 2020, 233, 117894. [Google Scholar] [CrossRef]

- Akhtar, M.N.; Bani-Hani, K.A.; Malkawi, D.A.H.; Albatayneh, O. Suitability of sustainable sand for concrete manufacturing-A complete review of recycled and desert sand substitution. Results Eng. 2024, 23, 102478. [Google Scholar] [CrossRef]

- Akhtar, M.N.; Albatayneh, O.; Bani-Hani, K.A.; Malkawi, A.I.H. Performance of modified desert sand concrete: An experimental case study. Case Stud. Constr. Mater. 2024, 21, e03465. [Google Scholar] [CrossRef]

- Bajpai, R.; Choudhary, K.; Srivastava, A.; Sangwan, K.S.; Singh, M. Environmental impact assessment of fly ash and silica fume based geopolymer concrete. J. Clean. Prod. 2020, 254, 120147. [Google Scholar] [CrossRef]

- Sáez, P.V.; Merino, M.; Porras-Amores, C. Managing construction and demolition (C&D) waste—A European perspective. In International Conference on Petroleum and Sustainable Development; IACSIT Press: Singapore, 2011; pp. 27–31. [Google Scholar]

- Fischer, C.; Werge, M.; Reichel, A. EU as a Recycling Society. European Topic Centre on Resource Waste Management, Working Paper 2/2009; European Environment Agency: Copenhagen, Denmark, 2009. [Google Scholar]

- Monier, V.; Mudgal, S.; Hestin, M.; Trarieux, M.; Mimid, S. Service contract on management of construction and Demolition Waste–SR1. Final Rep. Task 2011, 2, 240. [Google Scholar]

- Akhtar, J.; Akhtar, M. Enhancement in properties of concrete with demolished waste aggregate. GE-Int. J. Eng. Res. 2014, 2, 73–83. [Google Scholar]

- Halahla, A.M.; Akhtar, M.; Almasri, A.H. Utilization of demolished waste as coarse aggregate in concrete. Civ. Eng. J. 2019, 5, 540–551. [Google Scholar] [CrossRef]

- Monish, M.; Srivastava, V.; Agarwal, V.; Mehta, P.; Kumar, R. Demolished waste as coarse aggregate in concrete. J. Acad. Indus. Res 2013, 1, 540–542. [Google Scholar]

- Akhtar, M.N.; Ibrahim, Z.; Bunnori, N.M.; Jameel, M.; Tarannum, N.; Akhtar, J. Performance of Sustainable sand Concrete at Ambient and Elevated Temperature; Elsevier: Amsterdam, The Netherlands, 2021. [Google Scholar]

- Akhtar, M.N.; Jameel, M.; Ibrahim, Z.; Bunnori, N.M. Incorporation of recycled aggregates and silica fume in concrete: An environmental savior-a systematic review. J. Mater. Res. Technol. 2022, 20, 4525–4544. [Google Scholar] [CrossRef]

- Tang, Y.; Chen, Z.; Feng, W.; Nong, Y.; Li, C.; Chen, J. Combined effects of nano-silica and silica fume on the mechanical behavior of recycled aggregate concrete. Nanotechnol. Rev. 2021, 10, 819–838. [Google Scholar] [CrossRef]

- Feng, W.; Tang, Y.; Zhang, Y.; Qi, C.; Ma, L.; Li, L. Partially fly ash and nano-silica incorporated recycled coarse aggregate based concrete: Constitutive model and enhancement mechanism. J. Mater. Res. Technol. 2022, 17, 192–210. [Google Scholar] [CrossRef]

- Williams, K.C.; Partheeban, P. An experimental and numerical approach in strength prediction of reclaimed rubber concrete. Adv. Concr. Constr. 2018, 6, 87. [Google Scholar]

- Ashish, D.K.; Verma, S.K. Effect on permeability of concrete made with successive recycled aggregate and silica fume. In Urbanization Challenges in Emerging Economies: Resilience and Sustainability of Infrastructure; American Society of Civil Engineers: Reston, VA, USA, 2018; pp. 196–205. [Google Scholar]

- Alhajiri, A.M.; Akhtar, M.N. Enhancing Sustainability and Economics of Concrete Production through Silica Fume: A Systematic Review. Civ. Eng. J. 2023, 9, 2612–2629. [Google Scholar] [CrossRef]

- Mehta, A.; Ashish, D.K. Silica fume and waste glass in cement concrete production: A review. J. Build. Eng. 2020, 29, 100888. [Google Scholar] [CrossRef]

- Ashish, D.K.; Verma, S.K. An overview on mixture design of self-compacting concrete. Struct. Concr. 2019, 20, 371–395. [Google Scholar] [CrossRef]

- Ashish, D.K. Concrete made with waste marble powder and supplementary cementitious material for sustainable development. J. Clean. Prod. 2019, 211, 716–729. [Google Scholar] [CrossRef]

- Srivastava, K.S.; Verma, N.; Singh, K. A Comparative Study of Mechanical Characteristics of Normal Concrete with Human Hair Fiber Fabricated Concrete. IOP Conf. Ser. Earth Environ. Sci. 2013, 1110, 012057. [Google Scholar] [CrossRef]

- Akbar, M.; Umar, T.; Hussain, Z.; Pan, H.; Ou, G. Effect of human hair fibers on the performance of concrete incorporating high dosage of silica fume. Appl. Sci. 2022, 13, 124. [Google Scholar] [CrossRef]

- Kumar, S.; Kumar, A. Effect of human hair fiber On mechanical properties of concrete. J. Sci. Res. Teach. 2024, 3, 199–207. [Google Scholar]

- Bheel, N.; Awoyera, P.; Aluko, O.; Mahro, S.; Viloria, A.; Sierra, C.A.S. Sustainable composite development: Novel use of human hair as fiber in concrete. Case Stud. Constr. Mater. 2020, 13, e00412. [Google Scholar] [CrossRef]

- ASTM-C-494/C-494M; High-Range, G Water-Reducing and Retarding Admixture. ASTM: West Conshohocken, PA, USA, 2005.

- Kleiner, F.; Decker, M.; Rößler, C.; Hilbig, H.; Ludwig, H.-M. Combined LA-ICP-MS and SEM-EDX analyses for spatially resolved major, minor and trace element detection in cement clinker phases. Cem. Concr. Res. 2022, 159, 106875. [Google Scholar] [CrossRef]

- McCrone, W.C.; Skirius, C. Light microscopical study of theTurin Shroud. I. Microsc. 1980, 28, 105–113. [Google Scholar]

- Moser, R.D.; Allison, P.G.; Chandler, M.Q. Characterization of impact damage in ultra-high performance concrete using spatially correlated nanoindentation/SEM/EDX. J. Mater. Eng. Perform. 2013, 22, 3902–3908. [Google Scholar] [CrossRef]

- ACI-318; Building Code Requirements for Structural Concrete (ACI 318-08) and Commentary. American Concrete Institute: Farmington Hills, MI, USA, 2008.

- ACI-214R-11; Guide to Evaluation of Strength Test Results of Concrete. American Concrete Institute: Farmington Hills, MI, USA, 2011.

- ASTM-C496/C496M-11; Standard Test Method for Splitting Tensile Strength of Cylindrical Concrete Specimens. American Concrete Institute: Farmington Hills, MI, USA, 2011.

- ASTM-C642-13; C642-13, Standard Test Method for Density, Absorption, and Voids in Hardened Concrete. ASTM International: West Conshohocken, PA, USA, 2013.

- Akhtar, M.N.; Jameel, M.; Ibrahim, Z.; Bunnori, N.M.; Bani-Hani, K.A. Development of sustainable modified sand concrete: An experimental study. Ain Shams Eng. J. 2023, 15, 102331. [Google Scholar] [CrossRef]

| Mixes Designations | Binding Materials | HF by Weight of Cement (%) | Concrete Sand | NCA (%) | Slump (mm) | Admixture by Weight of Cement (%) | Mix Temperature (°C) | Mix Air Temperature (°C) | ||

|---|---|---|---|---|---|---|---|---|---|---|

| OPC (%) | SF (%) | M-Sand | R-Sand | |||||||

| NAC* | 100 | 0 | 0 | 100 | 0 | 100 | 100 | 0.5 | 26 | 20 |

| 0.5%HFSFC | 90 | 10 | 0.5 | 50 | 50 | 100 | 100 | 1.0 | 26 | 20 |

| 1.0%HFSFC | 90 | 10 | 1.0 | 50 | 50 | 100 | 100 | 1.4 | 25 | 20 |

| 1.5%HFSFC | 90 | 10 | 1.5 | 50 | 50 | 100 | 100 | 1.9 | 24 | 20 |

| 2.0%HFSFC | 90 | 10 | 2.0 | 50 | 50 | 100 | 100 | 2.6 | 25 | 20 |

| Mix Designation | Measurement of Masses as per ASTM C642-13 Procedure | Dry Bulk Density | Apparent Density | Void Percentage | |||

|---|---|---|---|---|---|---|---|

| A | B | C | D | Equation (2) | Equation (3) | Equation (4) | |

| = g1 | = g2 | × 100 | |||||

| g | g | g | g | g/cm3 | % | ||

| NAC* | 1025 | 1108 | 1110 | 645.7 | 2.208 | 2.702 | 18.28 |

| 0.5%HFSFC | 1005 | 1065 | 1067 | 638.4 | 2.345 | 2.741 | 14.45 |

| 1.0%HFSFC | 1048 | 1109 | 1108 | 669.6 | 2.390 | 2.769 | 13.68 |

| 1.5%HFSFC | 1130 | 1170 | 1172 | 724.8 | 2.527 | 2.788 | 9.36 |

| 2.0%HFSFC | 1109 | 1148 | 1151 | 702.3 | 2.471 | 2.727 | 9.39 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shbeeb, N.I.; Akhtar, M.N. Enhancing the Sustainability of Concrete by Adding Recycled Sand and Silica Fume Along with Human Hair Fibers. J. Compos. Sci. 2025, 9, 216. https://doi.org/10.3390/jcs9050216

Shbeeb NI, Akhtar MN. Enhancing the Sustainability of Concrete by Adding Recycled Sand and Silica Fume Along with Human Hair Fibers. Journal of Composites Science. 2025; 9(5):216. https://doi.org/10.3390/jcs9050216

Chicago/Turabian StyleShbeeb, Nadim I., and Mohammad Nadeem Akhtar. 2025. "Enhancing the Sustainability of Concrete by Adding Recycled Sand and Silica Fume Along with Human Hair Fibers" Journal of Composites Science 9, no. 5: 216. https://doi.org/10.3390/jcs9050216

APA StyleShbeeb, N. I., & Akhtar, M. N. (2025). Enhancing the Sustainability of Concrete by Adding Recycled Sand and Silica Fume Along with Human Hair Fibers. Journal of Composites Science, 9(5), 216. https://doi.org/10.3390/jcs9050216