Abstract

In the search for eco-friendly and resource-efficient alternatives to conventional building materials, agricultural residues are gaining increasing attention as reinforcements in cement-based composites. This study investigates the potential of walnut shell particles (WSPs), a lignocellulosic bio-product, as a sustainable reinforcing agent in walnut shell cement boards (WSCBs). Using super white cement (SWC) as a binder, boards were manufactured with WSP content ranging from 10% to 50% by weight, targeting a density of 1300 kg/m3, a 10 mm thickness, and a water-to-cement ratio of 0.6:1. The mixtures were cold-pressed at ambient temperature using a hydraulic press at 3 MPa for 24 h, followed by curing for 28 days under ambient conditions. Physical properties such as density, water absorption, and thickness swelling were assessed, along with mechanical performance, through flexural testing. Fracture surfaces and internal microstructures were examined using scanning electron microscopy (SEM) and energy-dispersive spectroscopy (EDS). Functional groups and chemical reactions were monitored using FTIR, while thermal analysis (TGA and DSC), as well as measurements of thermal conductivity and resistance, provided comprehensive insights into the thermal behavior, insulating performance, and energy efficiency potential of the boards. Results demonstrate that the board with 30% WSP exhibited an optimal balance of physical and mechanical properties, achieving a 24 h water absorption of 14.05% and a modulus of rupture (MOR) of 6.53 MPa, making it suitable for non-structural applications. The board with 50% WSP exhibited the best thermal insulation performance, with a low thermal conductivity of 0.079 W/m·K. These findings highlight the potential of recycled agricultural materials in enhancing building materials’ performance, contributing to sustainable, eco-friendly construction practices.

1. Introduction

The construction industry, as one of the most resource-intensive sectors globally, exerts a profound impact on the environment. The rising demand for infrastructure, largely driven by rapid urbanization, underscores the urgency of adopting more sustainable construction practices [1]. The circular economy has emerged as a strategic approach to address these challenges, focusing on waste minimization, emission reduction, and decreased reliance on virgin resources. Over recent years, this framework has gained significant attention among policymakers, academics, and businesses as a transformative strategy for sustainable development [2]. Practical solutions within this approach include reducing energy consumption during construction, developing thermal insulation materials, and recycling waste from industrial, agricultural, and household sources [3,4]. Furthermore, the transition towards sustainability is increasingly recognized not only as an environmentally imperative goal but also as a cornerstone of business success. Companies are recognizing the strong interplay between customer satisfaction, corporate responsibility, and environmental consciousness. Consequently, many industries are shifting away from conventional materials toward “green” substitutes, thereby reducing environmental footprint and enhancing social accountability [5].

In this context, significant attention has been given to innovative construction materials, particularly cementitious composites incorporating natural fibers, which enhance sustainability and energy efficiency. Among these, materials such as cement-bonded wood wool (CBWW), cement-bonded particleboard (CBPB), and fiber-reinforced cement board have emerged as sustainable alternatives [6]. CBPB, for instance, integrates 10–70% by weight of wood or non-wood particles, fibers, or other biomaterials into an inorganic matrix such as Ordinary Portland Cement (OPC), offering enhanced properties, including improved mechanical properties, thermal insulation, and acoustic performance [7,8]. Additionally, these composites demonstrate superior resistance to fire, termites, and moisture compared to conventional wood-based products [6].

Ongoing research efforts have focused on enhancing the sustainability of cementitious composites by incorporating various types of waste materials, including construction residues, post-consumer plastics, and animal-derived by-products. For instance, recycled powder (RP) obtained from construction and demolition waste has been shown to reduce cement consumption while supporting the development of ductile and environmentally friendly composites [9]. Similarly, recycled plastic fibers (RPFs) have emerged as a promising alternative to conventional disposal methods such as landfilling. Their integration into mortar and concrete not only reduces greenhouse gas emissions but also enhances crack resistance and provides economic benefits [10]. In addition, animal-derived residues such as waste eggshells [11], bone powder [12], and waste chicken feathers [13] have been investigated as bio-based additives or partial cement replacements, contributing to improved mechanical performance and a reduced environmental footprint in cementitious materials.

Since the 1920s, wood fibers have been extensively used in cementitious composites [14]. However, the increasing demand for wood has exacerbated forest depletion, necessitating the exploration of alternative raw materials. Numerous lignocellulosic materials, including coir pith particles [15], palm particles [16], Arhar flakes [17], sugar cane bagasse, bamboo [18], coconut shell, coffee husk, banana pseudostem [19], nutshell [20], cedar sawdust [21], and rice stalk with husk [22], have shown promise as substitutes for wood in cementitious composites. Among these, walnut shells (Juglans regia L.) stand out as a viable alternative due to their high lignin and polysaccharide content, which forms the thin endocarp of the walnut fruit [23].

Walnuts are a valuable crop in the food industry, prized for their nutritional value, health benefits, and sensory qualities [24]. In recent years, Morocco has witnessed substantial growth in walnut cultivation, producing approximately 12,467 tons of unshelled walnuts in 2018, thereby contributing to the global production of 3.66 million tons [25,26]. The country has over 7600 hectares of walnut trees [27], cultivated across diverse agro-ecosystems ranging from the humid, warm regions of the Rif and Atlas Mountains (High and Middle Atlas) to the arid areas in the southeast [26,28]. However, the rising global demand for walnuts has led to the generation of substantial agricultural waste, with an estimated 0.8 to 1.7 million tons of shells discarded annually [29]. Despite the significant potential of organic waste from Morocco’s agricultural and food sectors, its utilization remains limited, and no comprehensive investigations or data exist to quantify the exact volume of waste generated [30]. Walnut shells, in particular, are often underutilized and predominantly disposed of through environmentally harmful practices such as incineration. Adopting waste recovery initiatives could unlock the untapped economic potential of these shells while aligning with circular economy principles, thereby mitigating environmental degradation, combating climate change, and reducing pressure on forest resources. Furthermore, such initiatives could create employment opportunities, improve farmers’ incomes, and provide a range of additional social and economic benefits [31].

In recent years, walnut shells have attracted increasing attention for their potential applications in sustainable construction [32,33,34]. They can be incorporated into structural elements and insulating concrete, with particle contents of up to 30% and 50%, respectively [35]. Using walnut shells to produce cement boards represents an economically viable and eco-friendly solution for recycling agricultural waste. Walnut shell-based composites will hold substantial potential in the construction industry, given their cost-effectiveness and the local abundance of raw materials. Moreover, incorporating waste materials into cementitious products, either as aggregate substitutes or cement replacements, will help reduce cement demand and significantly lower CO2 emissions associated with cement production [1].

Moisture content is a key factor influencing the performance of cementitious composites reinforced with lignocellulosic materials such as walnut shell particles. The mechanical properties and thermal conductivity of these materials are particularly sensitive to their moisture content [36,37,38]. Due to the hydrophilic nature of these agricultural reinforcements, such composites tend to absorb and retain water, which can negatively impact mechanical strength, dimensional stability, and thermal performance. Therefore, a thorough understanding of moisture-related behavior is essential to assess the suitability of such materials for insulation and structural applications under varying environmental conditions.

This study focuses on the fabrication of cement boards reinforced with untreated walnut shell particles (WSPs), investigating how varying WSP content influences the boards’ physical, mechanical, thermal, and morphological properties. By investigating the reinforcing potential of walnut shells, this research seeks to advance sustainable building materials that minimize environmental impact, optimize resource efficiency, and promote forest conservation. A clear understanding of WSP-reinforced cement boards will facilitate enhanced design and optimization for applications such as wall cladding and partitions, aligning with broader goals to transform agricultural waste into valuable resources for eco-friendly construction materials.

2. Materials and Methods

2.1. Materials

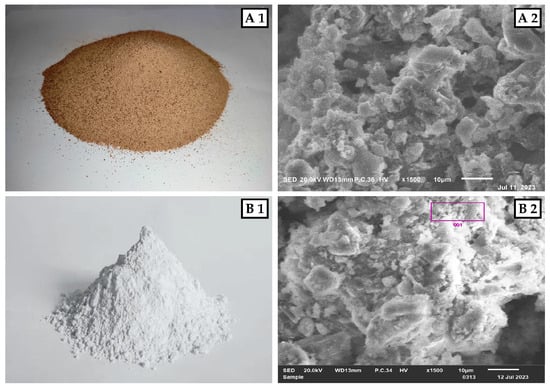

The cement boards were fabricated using walnut shell particles (WSPs) as the reinforcing material, super white cement (SWC) as the binder, and a suitable amount of water. Figure 1 presents the SEM images and morphological aspects of both the WSP and SWC, highlighting their surface structure and textural features.

Figure 1.

Appearance of WSP (A1) and SWC (B1); SEM images of WSP (A2) and SWC (B2).

2.1.1. Walnut Shell Particles (WSPs)

The walnut shells (Juglans regia) used as raw material were sourced from farmers in the village of Ait M’goun (Azilal, Morocco). These shells, considered agricultural bio-waste from the walnut harvesting season, were initially cleaned with cold water to remove dust and impurities and then air-dried for seven days under ambient conditions. After drying, the shells were crushed into small pieces approximately 1 cm in size using a mortar and subsequently ground into finer particles using a commercial grinder.

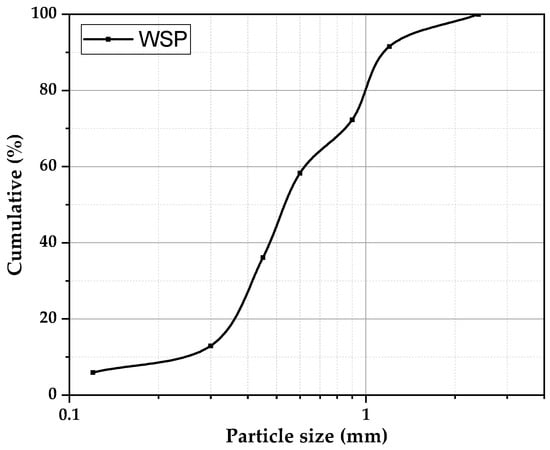

Following the grinding process, the WSP was oven-dried for 12 h to reduce moisture content to around 5%. The particle size distribution was then analyzed using a set of sieves with mesh sizes of 2.4, 1.2, 0.9, 0.6, 0.45, 0.3, and 0.12 mm. Three samples, each weighing 10 g, were placed in a sieve shaker for five minutes, and the mass of particles retained on each sieve was measured as a percentage of the total sample weight (Figure 2). The density of the WSP was subsequently determined, and the processed particles were then stored in plastic bags for future use.

Figure 2.

Particle size distribution of walnut shell particles.

The chemical composition of walnut shells, summarized in Table 1, highlights lignin and cellulose as the predominant components, with a relatively high extractive content (10.2%). This is comparable to other agricultural residues used in cement-bonded boards, such as Bagasse (12.5%) and Pinus sawdust (10.8%) [18]. The WSPs were used without any previous treatment, reducing energy consumption and expediting the production process. This approach differs from the production of wood-cement boards, where inhibiting water-soluble extractives must be removed by soaking the wood particles in water [20].

Table 1.

Walnut shell’s chemical composition found by Domingos et al. [23].

2.1.2. Super White Cement (SWC)

The super white cement (SWC, CEM 52.5R) used in this study was a commercially available product supplied by Çimsa, based in Ataşehir, Turkey. The cement was thoroughly characterized in a previous study [21], where its chemical composition was determined using X-ray fluorescence (XRF) spectroscopy, and key physical properties, including Blaine-specific surface area, density, fineness, and setting time, were reported. The main components are SiO2, Al2O3, and CaO representing 20.43%, 4.21%, and 66.03%, respectively.

2.2. Production of Walnut Shell Cement Boards (WSCBs)

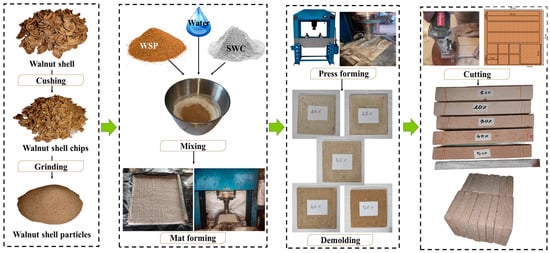

The manufacturing process for WSCB, as shown in Figure 3, involved determining the mass proportions for each component. Walnut shell particles (WSPs) and cement were mixed in five ratios, 10:90, 20:80, 30:70, 40:60, and 50:50 (WSP to cement by weight), with a fixed water-to-cement ratio of 0.6:1. These ratios were chosen to achieve a target board density of 1300 kg/m3, with each board measuring 28 cm × 28 cm × 1 cm. A total of 20 boards were produced, with four replicates for each composition level. The quantities of the components and the corresponding board designations are summarized in Table 2.

Figure 3.

The production process of WSCB.

Table 2.

The production plan of WSCB.

The cement and WSPs were mixed in a metal container until a uniform distribution was achieved. Water was gradually added to the mixture, which was continuously stirred for approximately 10 min to obtain a homogeneous paste. The prepared mixture was subsequently poured into a metal mold lined with plastic film to facilitate easy demolding after pressing.

The boards were formed using a cold pressing process at ambient temperature with a hydraulic press applying a pressure of 3 N/mm2 for 24 h, resulting in a final board thickness of 1 cm. After pressing, the boards were demolded and placed in plastic bags to cure under ambient conditions for 28 days, ensuring complete cement hydration.

Once the curing process was completed, the boards were finished by sanding the surfaces and edges to achieve a smooth finish surface. Testing samples were cut from the boards for the evaluation of physical, mechanical, and thermal properties.

2.3. Physical Characterization of the Boards

The physical properties of the WSCBs, including density, water absorption (WA), and thickness swelling (TS), were evaluated using test specimens measuring 50 × 50 mm2. In accordance with the EN 325 (2012) standard [39], the dimensions of specimen were recorded using a digital caliper with 0.01 mm accuracy, and their weights were measured using a precision balance with an accuracy of 0.01 g. Density was calculated by dividing the recorded mass by the measured volume, following the EN 323 (1993) standard [40].

Water absorption was evaluated after 2 h (WA 2 h) and 24 h (WA 24 h) of immersion time, while thickness swelling was measured over the same time intervals (TS 2 h and TS 24 h), following the EN 317 (1993) standard [41]. Specimens were immersed in water and maintained at 25 °C for the specified durations, then removed and gently wiped to eliminate any excess of surface water.

For each board type, eight samples were tested for water absorption and thickness swelling, which were calculated using the following equations:

where W2 is the weight of the wet sample, and W1 is the weight of the dry sample.

where T2 is the thickness of the wet sample, and T1 is the thickness of the dry sample.

Water absorption = (W2 − W1)/W1 × 100.

Thickness swelling = (T2 − T1)/T1 × 100.

2.4. Mechanical Characterization of the Boards

The mechanical properties of the WSCB were evaluated through a three-point bending test on specimens measuring 250 × 50 mm2, in accordance with the EN 310 (1993) standard [42]. Testing was conducted using a Lloyd LS5 high-precision testing machine (Lloyd Instruments Ltd., Bognor Regis, UK) equipped with a 5 kN load cell. The load was applied at a speed of 10 mm/min, perpendicular to the specimen’s center, until failure occurred. Six specimens were tested for each board type, and the modulus of rupture (MOR) was calculated according to the following equation:

where Fmax is the maximum load applied (N); l1 is the distance between the centers of the supports (mm); b is the width of the test specimen (mm); t is the thickness of the test specimen (mm).

Modulus of rupture = 3Fmax I1/2bt2 × 100.

Similarly, the modulus of elasticity (MOE) was determined using the equation:

where l1, b, and t are as defined above; F2 − F1 is the increment of load on the straight-line portion of the load–deflection curve, where F1 is approximately 10% and F2 is approximately 40% of the maximum load; a2 − a1 is the corresponding increment of deflection at the mid-length of the specimen.

2.5. Microstructural Analysis

The fracture surface morphology of the WSCBs was examined using scanning electron microscopy (SEM) coupled with energy-dispersive X-ray spectroscopy (EDS). A Jeol JSM-IT-100 microscope (JEOL, Tokyo, Japan) was employed to analyze the elemental composition and surface features of the fracture zones. Samples with varying WSP content were mounted on carbon tape and coated with a thin layer of platinum to improve conductivity. The analysis was conducted at an accelerating voltage of 20 kV, a working distance of 14 mm, and under low-vacuum conditions (7 kPa).

2.6. Fourier Transform Infrared Spectroscopy Analysis

FTIR was used to identify chemical interactions and functional groups in both raw materials and the WSCB. The analysis was performed using a Nicolet iS10 FTIR spectrophotometer (Thermo Fisher Scientific, Waltham, MA, USA) with an Attenuated Total Reflectance (ATR) technique for improved accuracy. Finely ground samples (300 mg) were compressed into pellets to ensure uniform consistency. Spectra were recorded over a wavelength range of 500–4000 cm−1 with a resolution of 4 cm−1 and 32 scans, allowing the precise detection of chemical bands and peaks corresponding to different functional groups.

2.7. Thermal Analysis

Thermal properties and stability were assessed for both WSP and WSCB3 (30% WSP) using thermogravimetric analysis (TGA) and differential scanning calorimetry (DSC). A Netzsch STA 449 F5 Jupiter simultaneous thermal analyzer (NETZSCH-Gerätebau GmbH, Selb, Germany) was used for testing. Approximately 20 mg of each sample was placed in 85 µL alumina (Al2O3) crucibles and analyzed under an argon atmosphere. The temperature systematically increased from 25 °C to 800 °C at a constant heating rate of 10 °C per minute. This approach provides detailed insights into the thermal stability and the behavior of both WSP and the WSCB3 board over the specified temperature ranges.

2.8. Thermal Conductivity and Thermal Resistance of the Boards

The thermal conductivity and resistance of the boards were evaluated to determine their suitability for insulation applications. Testing was performed using a Netzsch HFM 446 Lambda heat flow meter (NETZSCH-Gerätebau GmbH, Selb, Germany) on specimens measuring 102 × 102 mm2, following the ASTM C518 standard [43]. The tests were conducted at a mean temperature of 10.0 °C with a temperature difference (ΔT) of 20.0 K. Six samples with varying WSP content were tested, and the thermal conductivity (λ) and thermal resistance (R) were calculated using the equations below:

where λ is the thermal conductivity (W/(m·K)); R is the thermal resistance (m2·K/W); Q is the heat transferred through the material (W); L is the distance between the two isothermal planes (m); A is the surface area (m2); ΔT is the temperature difference (K).

λ = (Q × L)/(A × ΔT).

R = L/(A × λ).

2.9. Data Analysis

The experimental data were subjected to statistical analysis, including one-way analysis of variance (ANOVA), to evaluate the relative significance of variations in the physical and mechanical properties. When the ANOVA indicated statistically significant differences, Tukey’s test was applied at a 95% confidence level to compare the mean values.

3. Results and Discussion

3.1. Physical Properties

The effect of walnut shell particle (WSP) content on the physical properties of walnut shell cement boards (WSCBs) was investigated, with the obtained results summarized in Table 3. The analysis of variance (ANOVA) for these properties is presented in Table 4.

Table 3.

Average and standard deviation of the physical and mechanical properties of the WSCB.

Table 4.

Summary of ANOVA results indicating the significance of WSP content on the physical and mechanical properties of WSCB.

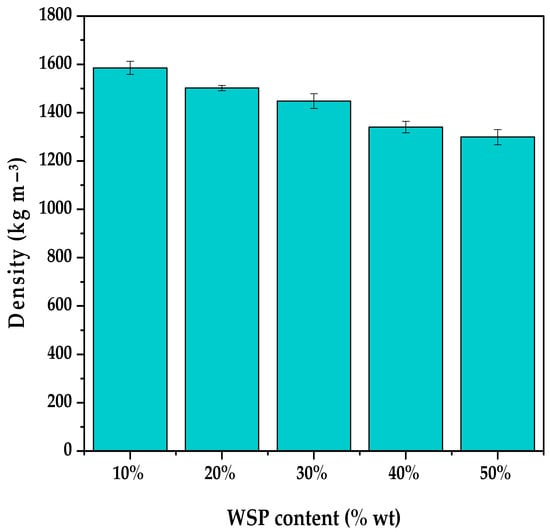

3.1.1. Density

Density is a crucial parameter in composite materials, as it directly correlates with various properties, including mechanical strength and thermal performance. Typically, composites with higher densities (greater or equal to 1300 kg/m3) demonstrate superior mechanical strength [45]. Although the target density for the boards was initially set at 1300 kg/m3, the actual measured densities ranged from 1298.95 to 1585.21 kg/m3 (Figure 4). Variance analysis revealed statistically significant differences in density across all WSP content levels, highlighting the substantial impact of WSP on the board’s density. Increasing WSP content generally resulted in density reduction, attributed to the lower density of WSP (685 kg/m3) compared to cement (3047 kg/m3). These observations align with previous studies on cement-based composites incorporating various lignocellulosic materials [46,47,48].

Figure 4.

Variation in density with WSP content.

Alternatively, higher density values were also associated with stronger adhesion between fibers and cement within the matrix, contributing to improved composite compactness [49]. The WSCB1, WSCB2, and WSCB3 exhibited the highest densities, corresponding to superior modulus of rupture (MOR) values. Conversely, the reduced mechanical properties observed in WSCB4 and WSCB5 can be attributed to their lower density. Despite these variations, the densities of all boards produced in this study meet the Bison standards for HZ-type cement boards, which require a minimum density of 1200 kg/m3 [44].

3.1.2. Water Absorption and Thickness Swelling

One of the main challenges in using lignocellulosic materials in composite boards is their high sensitivity to water, which can adversely affect the mechanical performance [50]. To address this issue, it is important to evaluate the stability of WSP–cement boards, particularly their water absorption (WA) and thickness swelling (TS). These parameters are critical for assessing the dimensional stability of the boards under high-humidity conditions, especially when used for external applications [51].

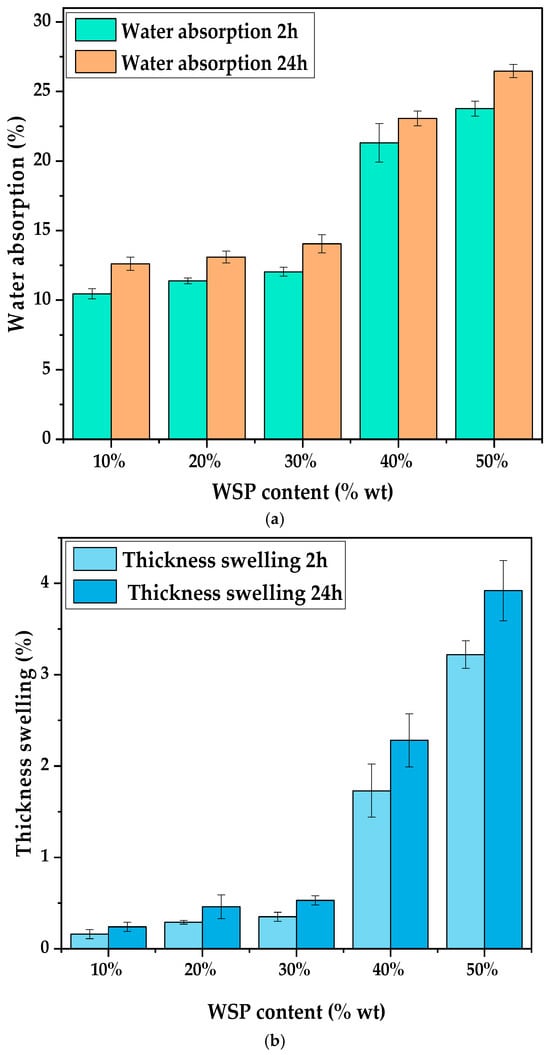

Figure 5 illustrates the WA and TS of WSCB manufactured with varying WSP content. The results indicate that WA values increased with prolonged immersion time. Specifically, after 2 h of soaking, WA values ranged from 10.46% to 23.77%, rising to between 12.62% and 26.47% after 24 h. A similar trend was observed for TS, which ranged from 0.16% to 3.22% after 2 h and from 0.24% to 3.92% after 24 h. Boards with 10% WSP (WSCB1) exhibited the lowest WA and TS values, while those with 50% WSP (WSCB5) showed the highest value.

Figure 5.

(a) Variation in WA with WSP content; (b) variation in TS with WSP content.

The increase in WA and TS can be attributed to the hygroscopic nature and chemical composition of lignocellulosic materials [52]. These materials contain hydroxyl and other oxygen-containing groups in their cell wall polymers (mainly cellulose and hemicellulose), which readily form hydrogen bonds with water molecules [29]. Furthermore, water molecules can diffuse into the interface between the reinforcement and the matrix, exacerbating moisture uptake [53]. Statistical analysis (Table 4) confirmed the significant effect of WSP content on the physical properties of the boards. However, Table 3 shows no statistically significant differences in WA values (both at 2 and 24 h) among WSCB1, WSCB2, and WSCB3. This indicates that increasing the WSP content from 10% to 30% has a minimal effect on water absorption, with only a slight increase of approximately 1.5% and 1.4% after 2 and 24 h of immersion time, respectively. Similarly, no significant differences in TS were observed for boards with WSP content up to 30%, regardless of immersion time.

In contrast, boards with WSP content exceeding 30% (WSCB4 and WSCB5) exhibited significant increases for both WA and TS. These results align with previous studies investigating the effects of various lignocellulosic residue content on WA or/and TS of cement-based composites. For example, studies involving nut shell flour with content ranging from 30% to 50% [20], poplar chopped strands (30–60%) [54], and Arhar flakes (0–32%) [17]. The high WA and TS values observed in boards with 40% and 50% WSP content are likely due to particle agglomeration and insufficient compaction, which create pores that facilitate water penetration and reduce the board’s apparent density. High lignocellulosic content in cement boards typically leads to lower density and inefficient compaction [47].

According to Bison’s specifications for HZ-type boards, TS values after 24 h immersion should range between 1.2% and 1.8% [44]. Based on the results obtained in this study, boards containing 10% to 30% WSP meet these requirements and are suitable for applications involving exposure to humidity. Conversely, boards with WSP content above 30% exceed the recommended specifications, limiting their suitability for such applications.

Overall, the physical properties of WSCB were significantly affected by WSP content. Boards with up to 30% WSP maintained acceptable density, water absorption, and thickness swelling values, indicating this as the optimal threshold for physical performance.

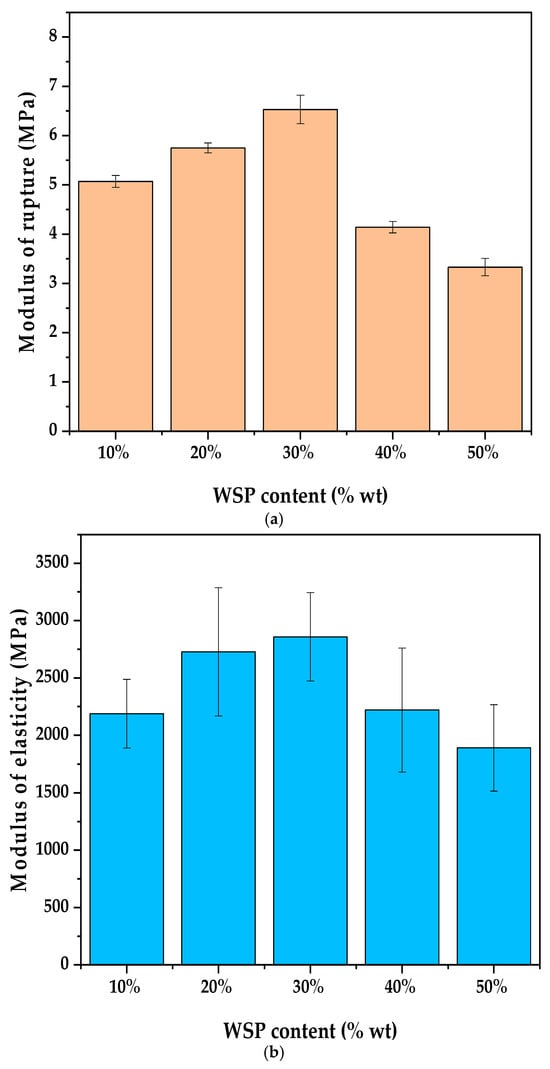

3.2. Mechanical Properties

The flexural properties of WSCB reinforced with varying amounts of WSP, including modulus of rupture (MOR) and modulus of elasticity (MOE), are presented in Figure 6. The MOR values ranged from 3.33 to 6.53 MPa, while the MOE values varied between 1891.06 and 2858.32 MPa. The highest MOR and MOE values were observed in WSCB3 boards containing 30% WSP, whereas the lowest values were recorded for WSCB5 boards containing 50% WSP content. The statistical analysis, as shown in Table 4, revealed a significant influence of WSP content on the mechanical properties of the boards. Up to 30% WSP content (WSCB1, WSCB2, and WSCB3), the increasing WSP amount positively impacted the flexural performance of the boards. This enhancement can be attributed to effective particle dispersion within the cement matrix, strong adhesion between the WSP and the cement, and the applied pressing cycle, which minimizes internal voids during production [55].

Figure 6.

(a) Variation in MOR with WSP content; (b) variation in MOE with WSP content.

However, boards containing more than 30% WSP (WSCB4 and WSCB5) exhibited a clear decline in flexural properties. This trend aligns with findings from previous studies on cement boards reinforced with lignocellulosic materials such as nutshells [20], poplar chopped strands [54], and a mixture of hardwood with rice stalks [22]. In each case, optimal flexural properties were observed at specific reinforcement content levels (30%, 40%, and 25%, respectively), with higher reinforcement contents resulting in significant reductions in mechanical performance.

The decline in flexural properties at higher WSP content can be attributed to several factors. Excessive WSP content affects the uniformity of the reinforcement–matrix interface, leading to particle clustering and reduced bonding strength. Increased particle-to-particle interactions further weaken the composite structure by impeding the efficient transfer of stress between the cement matrix and the reinforcement. Pirayesh and Saadatnia [20] noted that at higher loadings, particle aggregation leads to increased filler-to-filler contact, ultimately reducing overall material strength due to the inefficient transfer of stress within the composite. Moreover, based on the findings of Ashori et al. [54], the low specific gravity of lignocellulosic materials, like WSP, could cause particles to migrate to the surface of the slurry, resulting in uneven distribution within the composite. Applying this to our results, the lack of homogeneity likely led to particle accumulation in the top layers of WSCB4 and WSCB5, disrupting the uniform dispersion of reinforcement and increasing the porosity of the boards. Consequently, exceeding the optimal WSP content increases the porosity of the boards.

This increase in porosity, as evidenced by the decreased densities in WSCB4 and WSCB5, weakened the bonding within the matrix, ultimately contributing to reduced MOE and MOR values.

Despite these limitations, the flexural properties observed in this study are comparable to those reported in prior research. For instance, Ayrilmis et al. [16] demonstrated that cement boards reinforced with palm lignocellulosic particles achieved MOR values between 4.58 and 6.55 MPa in the absence of CaCl2. However, studies such as Aras et al. [56] reported higher MOR values (6.69 to 13.87 MPa) and MOE values (3979 to 7080 MPa) when using olive mill solid waste in cement-bonded particleboard. Similarly, Mendes et al. observed MOR and MOE values of up to 12.2 and 3452 MPa, respectively, for cement-bonded boards reinforced with various lignocellulosic residues [18].

The discrepancies between this study and previous findings may be attributed to differences in reinforcement characteristics. For instance, the small particle size of nutshell flour, owing to its non-fibrous nature, results in low aspect ratios and predominantly spherical shapes. These shapes do not align well within the mixture, leading to reduced physical contact between particles, as observed by Pirayesh et al. [20]. In contrast, Sotannde et al. found that boards containing a mix of flakes and sawdust exhibited higher MOR values, attributed to the random distribution of particles within the composite [57]. This suggests that using a heterogeneous mix of particle sizes enhances the mechanical properties of the composites compared to the use of uniformly sized particles.

Based on the findings of this study, none of the WSCB produced met the minimum requirements for HZ-type boards, which specify an MOR of 9 MPa and a MOE of 3000 MPa [44]. Nonetheless, these boards may still be suitable for non-structural applications, such as interior ceiling installations, where their thermal and acoustic insulation properties offer significant advantages.

The mechanical performance of WSCB peaked at 30% WSP content, with the highest MOR and MOE values observed. Beyond this level, increased WSP content led to reduced strength due to poor particle dispersion, increased porosity, and weaker matrix bonding.

3.3. Microstructural Analysis

3.3.1. Scanning Electron Microscopy (SEM)

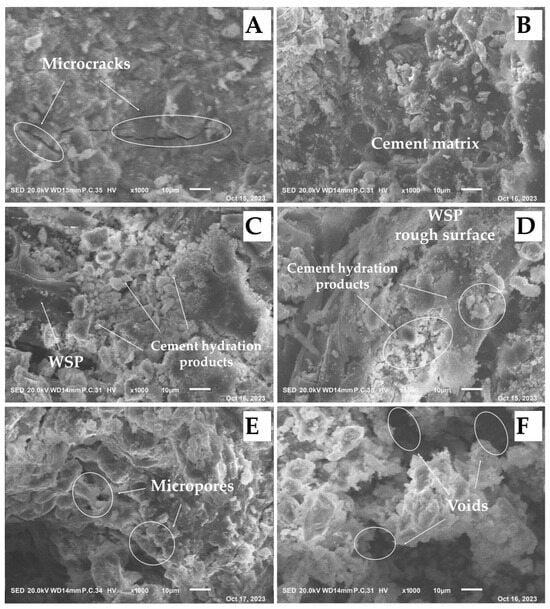

Scanning electron microscopy (SEM) was performed to investigate the fracture surface morphology of the walnut shell cement boards (WSCBs) manufactured with varying WSP contents (10%, 20%, 30%, 40%, and 50%). Figure 7 displays SEM images of the pure cement board and WSCB with different reinforcement levels.

Figure 7.

SEM micrographs at fractured surfaces of boards at different WSP content: (A) cement paste; (B) 10%; (C) 20%; (D) 30%; (E) 40%; and (F) 50%.

In Figure 7A, the pure cement board displays a microcracked surface characterized by shallow cracks running perpendicular to the surface. These microcracks, typically less than 50 µm wide, primarily result from internal stresses that develop during the drying process. As the cement dries, moisture gradients form across the sample, leading to uneven shrinkage [58]. Enhancing the water retention capacity of the cement matrix is essential to mitigate such shrinkage. This is because the cement paste absorbs significant amounts of water during hydration, contributing to volumetric changes and chemical shrinkage [59].

Figure 7B shows the SEM image of a WSCB with a low WSP content (10%). The microstructure is dominated by the cement matrix, with limited visible reinforcement particles compared to boards with higher WSP content (Figure 7C,D). At this reinforcement level, the insufficient amount of WSP limits the ability to effectively support the load from the matrix, explaining the lower mechanical properties observed in boards with 10% WSP content.

In contrast, Figure 7C, depicting the board with 20% WSP, reveals a well-defined interface between the cement matrix and the reinforcement particles, alongside the visible presence of cement hydration products. In this case, the cement paste effectively fills the voids within the WSP, aided by the lignocellulosic properties of the reinforcement, which enhances the water retention capacity of the matrix. This improved particle–matrix interface reduces the formation of microcracks, thereby enhancing the board’s physical and mechanical properties. This observation aligns with previous research, which indicates that incorporating agricultural and forestry residues into cement-bonded composites improves fracture toughness and crack resistance within the cement matrix [18,59,60].

The SEM image in Figure 7D, corresponding to a board with 30% WSP, shows reinforcement particles embedded and coated with a layer of the cement matrix. This tight integration results from the significant accumulation of cement hydration products at the WSP–cement interface. Lignocellulosic materials, such as WSPs, stabilize calcium ions on their surfaces, which are highly mobile in the cement hydration solution [15]. This stabilization promotes strong bonding at the reinforcement–matrix interface, eliminating cracks and voids, which justifies the superior mechanical properties observed for this composition.

However, SEM images in Figure 7E,F, representing boards with 40% and 50% WSP, respectively, reveal numerous voids and distinct micropores within the cement matrix, along with signs of debonding at the WSP–cement interface. At higher WSP contents, the insufficient availability of cementitious material to adequately bond the particles leads to freely dispersed reinforcement particles and voids left behind after particle pull-out. These structural discontinuities contribute to increased porosity, reduced density, and higher water absorption and ultimately result in lower mechanical properties compared to boards with the optimal 30% WSP content.

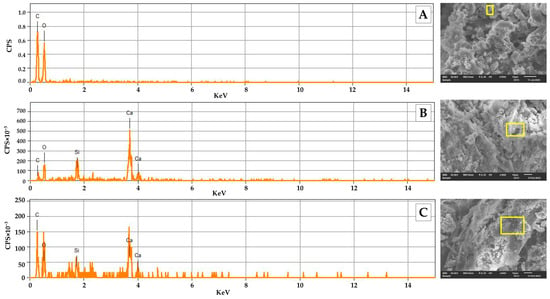

3.3.2. Energy Dispersive Spectroscopy (EDS)

Energy-dispersive X-ray spectroscopy (EDS) was conducted to analyze the elemental composition of walnut shell particles (WSPs) and the fractured surface of the cement board containing 30% WSP (WSCB3). The analysis focused on two regions of the fractured surface: the cement matrix and the WSP reinforcement. The resulting EDS spectra are shown in Figure 8, and the corresponding chemical compositions are detailed in Table 5. This analysis provides interesting insights into the elemental interaction between the WSP and the cement matrix.

Figure 8.

Energy-dispersive X-ray spectroscopy at walnut shell particles (A); cement paste (B); and fractured surfaces of the board at 30% WSP content (C).

Table 5.

Estimated elemental chemical composition for the composites.

The EDS analysis of WSP (Figure 8A) reveals that they are predominantly composed of carbon (C) and oxygen (O), which are typical of lignocellulosic materials. These results align with the chemical composition outlined in Table 1, where cellulose, hemicellulose, and lignin are the major components of walnut shells.

In Figure 8B, the cement matrix surrounding the reinforcement shows significant amounts of calcium (Ca) and silicon (Si), key components of super white cement (SWC). These findings are consistent with the X-ray fluorescence (XRF) results previously reported [21], confirming the dominance of Ca from lime (CaO) and Si from silica (SiO2). Trace amounts of other minerals, such as magnesium (Mg), aluminum (Al), and iron (Fe), were undetectable due to lower concentrations of their metal oxides in SWC, which is known for its minimal impurities compared to Ordinary Portland Cement (OPC). The detected carbon content (8.54%) is attributed to the lignocellulosic nature of the WSP embedded in the matrix.

The EDS spectrum in Figure 8C reveals that the surface of the reinforcement contains not only carbon (C) and oxygen (O) but also significant amounts of calcium (13.32%) and silicon (3.06%). These findings suggest the presence of cement hydration products, such as calcium hydroxide (Ca(OH)2) and calcium silicate hydrate (C-S-H), adhered to the reinforcement surface. This observation corroborates the earlier SEM analyses of WSCB3, which demonstrated that hydration products contribute to mechanical interlocking and improve the bond strength between WSP and the cement matrix. Similarly, Ranachowski et al. reported that chemical analysis of fibers in cement boards revealed both fibrous and cementitious elements, which they attributed to a thin layer of cement paste and hydration products coating the fiber surfaces [61]. Comparable findings have been reported in studies involving other lignocellulosic reinforcements, such as coir pith particles [15] and Pinus spp. particles [62], where the presence of hydration products on fibers’ surfaces improved mechanical properties by strengthening the matrix–reinforcement interface.

Rossen and Scrivener [63] highlighted the significance of the calcium-to-silicate ratio (Ca/Si) in C-S-H phases, which generally ranges from 1.5 to 2.0 in cement pastes (pure cement board). However, the WSCB3 board exhibited higher Ca/Si ratios of 3.71 at the cement matrix surface and 4.35 at the WSP reinforcement surface. This increased Ca/Si ratio suggests that incorporating 30% WSP promotes the formation of additional Ca-based phases, such as (CH) crystals, which contribute to the creation of interlocking structures at the interface [21]. These interlocked structures enhance the bond strength and result in the superior mechanical performance of the composite, as reported in previous studies involving vine shoot waste [64] and wood strands [65].

Furthermore, the higher CaO and SiO2 content in SWC promotes the formation of additional hydration products, as noted by Aras et al. [56]. This increased CaO and SiO2 content enhances the interfacial bond, thereby improving both the mechanical and physical properties of the boards.

SEM analysis confirmed enhanced particle–matrix interaction and reduced microcracking at 20–30% WSP content, while EDS analysis revealed favorable elemental composition and Ca/Si ratios at the WSP–cement interface. These microstructural features support the superior performance observed at this reinforcement level.

3.4. Fourier Transform Infrared Spectroscopy (FTIR)

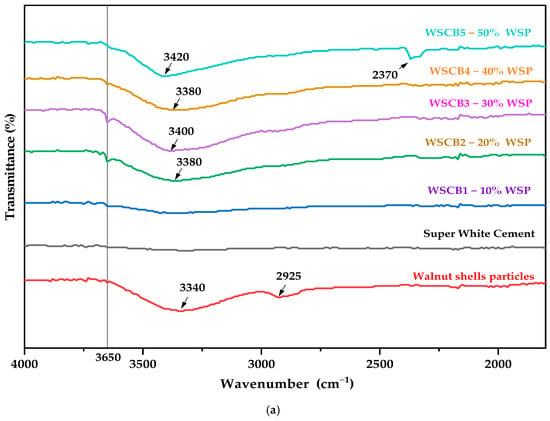

Figure 9 displays the FTIR spectra for the raw materials, including super white cement (SWC) and walnut shell particles (WSPs), as well as for the cement boards produced with varying WSP contents (10%, 20%, 30%, 40%, and 50%). These spectra identify key absorption bands and peaks that support the findings from the SEM, EDS, physical, and mechanical analyses.

Figure 9.

Fourier transform infrared spectroscopy spectra of samples: (a) 4000–1750 cm−1, (b) 1750–500 cm−1.

In the FTIR spectrum of SWC, several distinct bands reflect specific chemical bonds. Prominent bands at 1420 cm−1 and 875 cm−1 correspond to the C–O bond in carbonate groups (CO32−), arising from asymmetric stretching and out-of-plane bending vibrations, respectively [64,66]. A band near 1140 cm−1 is linked to the S–O bond stretching in sulfate groups (SO42−). Additionally, bands detected at 522 cm−1 and 920 cm−1 represent the out-of-plane bending and asymmetric stretching vibrations of the Si–O bond within silicate tetrahedral (SiO44−) [67]. A smaller band around 713 cm−1 corresponds to the symmetric stretching of the Si–O–Si linkage in the silicate network, while bands between 600 and 660 cm−1 represent Si–O–Si bending vibrations typical of silicate minerals [66].

The FTIR spectrum of WSP reveals several notable features consistent with the findings of Li et al. [68]. The prominent band at 530 cm−1 indicates O–H bending vibrations, suggesting the presence of hydroxyl groups, potentially from hydroxyl-containing compounds present in WSP or absorbed water. A broad band centered at 1041 cm−1 corresponds to C–O vibrations characteristic of primary and secondary alcohols, confirming the presence of R-OH groups [69]. The band at 1243 cm−1 reflects C–O stretching vibrations, indicative of various organic functionalities, such as alcohols, ethers, esters, and carboxylic acids [68]. The band at 1620 cm−1 is attributed to C=C stretching vibrations in aromatic carboxyl groups [70], while the band at 2925 cm−1 corresponds to C-H sp3 stretching vibrations in alkanes [71]. A broad band at 3340 cm−1 represents O-H stretching vibrations, further confirming the presence of hydroxyl groups, likely from water or alcohol [68,72]. These features collectively underscore the complex organic composition of WSP.

The FTIR spectra of the produced boards show prominent absorption bands around 875 cm−1 and 1420 cm−1, corresponding to calcium carbonate. The intensity of the 1420 cm−1 band is directly related to the extent and depth of carbonation [73], resulting from the reaction of free lime (Ca(OH)2) with CO2. This band peaks in WSCB2 and WSCB3 (20% and 30% WSP content, respectively), indicating enhanced calcium carbonate formation, driven by interactions between WSP organic compounds and the calcium in the SWC. Based on the findings of Petkova et al. [67], the small band at 856 cm−1 in WSCB1 and WSCB2 corresponds to Al–O vibrations in the AlO69− complex. However, this peak becomes less visible in higher WSP contents due to potential overlapping caused by other bands. Meanwhile, bands near 1450 cm−1 are generally attributed to C–O bending in carbonates [67]. Alongside the 1420 cm−1 band, they reach peak intensity in WSCB2 and WSCB3, further confirming substantial carbonate formation.

Bands around 540 cm−1 and 975 cm−1 are linked to Si–O vibrations, confirming the presence of calcium silicate hydrate (C-S-H) gel, a critical compound for the mechanical strength of cement composites [74]. Previous studies show that the band at 975 cm−1 reflects a shift from the typical silicate band, which was previously observed at 923 cm−1 in neat cement [64,75,76]. Mollah et al. [77] attribute this shift to the polymerization of silicate units (SiO44−) as C-S-H gel forms, suggesting that higher calcium concentrations influence the extent of polymerization and enhance the stability of the C-S-H structure.

The WSP content significantly affects the stretching and bending vibrations of bonded –OH groups observed at 1650 cm−1 and around 3400 cm−1. The intensities of these vibrations increase proportionally with the rising WSP content, reflecting the hydrophilic nature of walnut shells, as confirmed by physical tests. The increase in carbonate and water-related bands further confirms the ongoing carbonation process during hydration [64]. The band near 1100 cm−1 corresponds to sulfate (SO₄2−) vibrations in ettringite, while a sharp band at 3650 cm−1 reflects the stretching vibrations of free hydroxide ions in Ca(OH)2 [78]. Additionally, a doublet around 2350 cm−1 is attributed to traces of gaseous CO2 in the spectrometer’s sample compartment [79]. The well-defined bands at 3650 cm−1 and 975 cm−1, corresponding to calcium hydroxide and C-S-H gel in WSCB2 and WSCB3, indicate that incorporating 20–30% WSP into the cement composites significantly promotes CH and C-S-H formation, thus enhancing the mechanical properties of the boards.

FTIR analysis confirmed the development of key hydration products at optimal WSP levels (20–30%), while the increasing intensity of –OH group bands reflected the hydrophilic nature of WSP and its influence on the hydration and carbonation behavior of the cement matrix.

3.5. Thermal Analysis

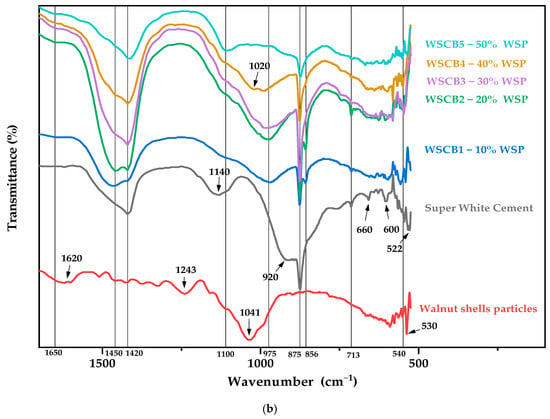

The thermal characteristics of super white cement (SWC) have been previously documented in our previous study [21]. This section presents the thermogravimetric (TG/DTG) and differential scanning calorimetry (DSC) analyses for walnut shell particles (WSPs) and the WSCB3 containing 30% WSP, as depicted in Figure 10.

Figure 10.

Thermal analysis curves (TG/DTG and DSC) of (a) walnut shell particles and (b) WSCB3 (30% WSP).

The thermal behavior of WSP, shown in Figure 10a, reveals four distinct stages beginning at 39 °C, with a total mass loss exceeding 76.66%. The initial stage, from 39 °C to 116 °C, exhibits a minor weight loss of 2.47%, accompanied by an endothermic peak at 89.5 °C. This is likely due to the evaporation of moisture and volatile organic compounds from the walnut shell [72,80].

The second stage, characterized by a weight loss of 5.54%, occurs between 116 °C and 226 °C, featuring a low-intensity peak at 186.5 °C. This is attributed to the pyrolytic breakdown of hemicellulose, sugars, organic acids, and extractives. The third stage, from 226 °C to 403 °C, shows the most significant weight loss (54.21%) with a pronounced peak at 358.6 °C due to the thermal degradation of cellulose and hemicellulose, as well as the early decomposition of lignin, marking the structural collapse of the walnut shell. This aligns with the findings of Shah et al., who observed that different lignocellulosic biomasses exhibit distinct thermogravimetric behaviors, with hemicellulose decomposing between 210 °C and 325 °C, cellulose between 310 °C and 400 °C, and lignin over a broader range from 160 °C to 900 °C [80].

The final stage, with a weight loss of 14.44% occurring above 400 °C, corresponds to the continued breakdown of lignin and the high-temperature calcination of residues [72]. This phase, commonly known as the passive zone, reflects the complex structure of lignin and its slow degradation over a wide temperature range, highlighting its resistance to thermal decomposition [80,81]. These thermal profiles align with the decomposition patterns of lignocellulosic materials, providing valuable insights into the thermal stability and degradation behavior of walnut shells.

The thermal analysis of WSCB3, shown in Figure 10b, demonstrates an overall mass loss of 25%, beginning at 68 °C and occurring in four distinct stages. The first stage, marked by a mass loss of 5.12% and a high-intensity endothermic peak at 108 °C, is primarily attributed to evaporation of free water and adsorbed moisture, typical of lignocellulosic composites due to their hygroscopic nature. The decomposition of C-S-H gel, ettringite (AFt), and monosulphate (AFm) may also contribute to this mass loss [82].

The second stage, resulting in a mass loss of 7.88% and a moderate-intensity endothermic peak at 300 °C, is associated with the decomposition of organic components from WSP reinforcement, along with minor contributions from volatile organic compounds and residual water. This is consistent with findings from walnut shells analysis in Figure 10a. FTIR analysis further supports this, with characteristic bands indicating the breakdown of organic compounds and the formation of C-S-H gel.

The third stage, occurring between 412 °C and 485 °C, involves further lignin decomposition, which occurs at a higher temperature than cellulose and hemicellulose [56]. Additionally, according to previous research [53,82,83], this stage coincides with the dehydration of calcium hydroxide (Ca(OH)2), as represented by the following reaction:

Ca(OH)2 → CaO + H2O,

The observed mass loss of 2.64% at this stage is lower than reported in other studies [7,84], indicating a lower presence of portlandite crystals, leading to higher amounts of C-S-H phases, enhancing the strength properties of the samples [67], as indicated by the well-defined FTIR bands corresponding to C-S-H in these samples. The final stage shows the largest mass loss of 9.24%, marked by two successive peaks. The first, a low-intensity peak at 623 °C, corresponds to the initial breakdown of CaCO3, while the more intense peak at 737 °C indicates the complete decomposition of calcium carbonate (decarbonization process), as indicated by the following reaction:

CaCO3 → CaO + CO2,

This mass loss (9.24%) significantly exceeds the 4% observed in SWC in our previous work [21], suggesting that the walnut shells considerably enhance CaCO3 formation. The FTIR analysis of the WSCB3 samples confirms this substantial carbonation, with strong absorption bands at 1450 cm−1 and 1420 cm−1. Previous studies suggest that calcium carbonate is not a hydration product like calcium hydroxide or calcium silicate hydrate. Instead, it forms through the reaction of calcium hydroxide with carbon dioxide [49,56]. The incorporation of lignocellulosic materials, such as WSP, further promotes this carbonation process. This enhancement likely results from the increased permeability of the cement matrix, allowing CO2 to penetrate deeper and react more effectively with Ca(OH)2. The presence of WSP provides channels for air and moisture to circulate within the composite, facilitating the natural carbonation process. Combined with the moisture-retaining properties of the lignocellulosic materials, this creates ideal conditions for carbonation, promoting the formation of additional calcium carbonate and thereby improving the composite’s durability.

Thermal analysis confirmed the thermal stability of WSP and its contribution to increased carbonation, especially at higher contents, leading to increased CaCO3 formation.

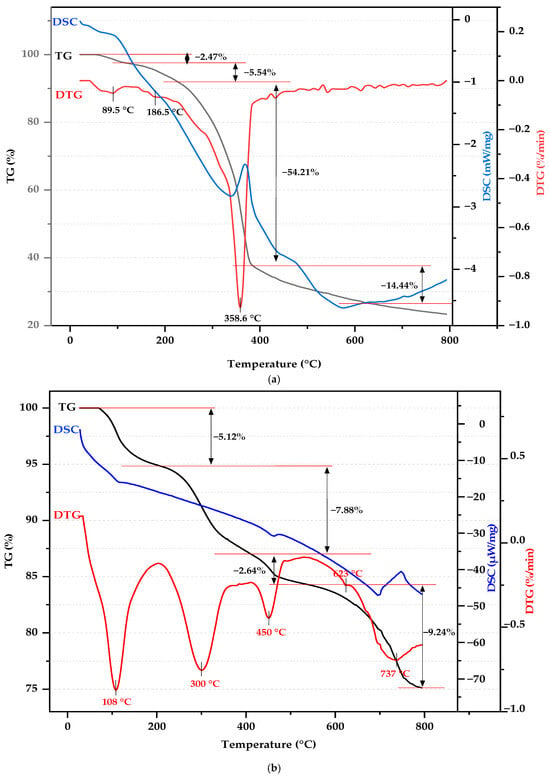

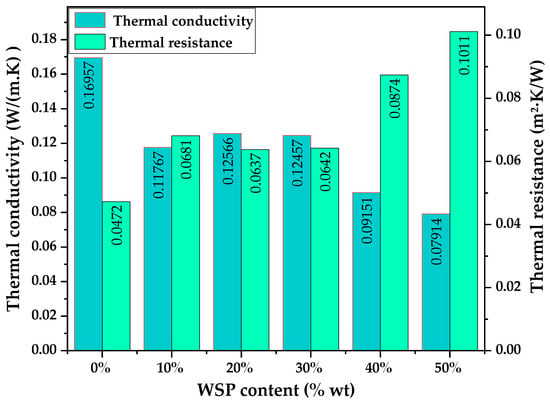

3.6. Thermal Conductivity and Thermal Resistance

The thermal behavior of cement-based materials is crucial in construction applications, particularly for buildings, foundations, walls, and other structural elements in regions with high solar radiation and elevated ambient temperatures [85]. Thermal conductivity and thermal resistance are among the critical properties, with low-conductivity materials being valued for their effective insulation, energy efficiency, and enhanced comfort in built environments [86,87].

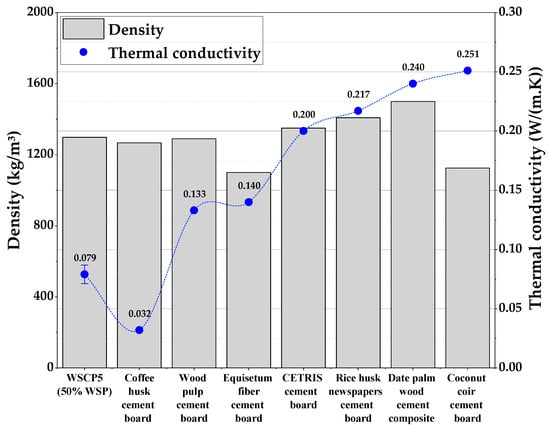

The incorporation of lignocellulosic materials into cement composites offers a promising approach due to their porosity, lightweight nature, and exceptional thermal insulating properties [38,88]. This section examines the effect of walnut shell particles (WSPs) content, ranging from 10% to 50%, on the thermal properties of walnut shell-based cement boards (WSCB). Figure 11 illustrates the thermal performance of the fabricated boards compared to a pure cement board (0% WSP), which serves as the reference.

Figure 11.

Variation in thermal conductivity and thermal resistance with WSP content.

Results indicate a significant reduction in thermal conductivity with the incorporation of 10% WSP, decreasing from 0.16957 W/(m·K) for pure cement boards to 0.11767 W/(m·K) for WSCB1 boards. In contrast, thermal resistance increased by 44.3% compared to pure cement boards, highlighting the intrinsic insulating properties of walnut shells. These enhancements are attributed to the low thermal conductivity of lignocellulosic reinforcements and increased porosity, which reduces the overall density of the boards, as shown in Figure 4. This increased porosity limits heat propagation through the porous network, with trapped air acting as a thermal insulator due to its low thermal conductivity (0.024–0.026 W/m·K) [87,89,90].

As the WSP content increases from 10% to 30%, variations in thermal properties remain relatively modest, with an average reduction of about 6% in thermal conductivity and a corresponding increase in thermal resistance. This behavior likely results from changes in the cement matrix microstructure, where denser aggregation of particles forms thermal bridges and interconnected pores, thereby mitigating the insulating effect.

At higher WSP contents (40% and 50%), thermal conductivity decreases substantially, achieving a reduction of approximately 53% compared to pure cement boards. This corresponds to an enhancement in thermal resistance, reaching 0.1011 m2·K/W, which further elevates the thermal performance of the WSCB.

Studies by Jannat et al. [90] and Zhou & Kamdem [49] suggest that the incorporation of lignocellulosic materials into composites promotes the fragmentation of large air bubbles into smaller, closed bubbles due to the action of fine fibers during the mixing process. These closed bubbles play a critical role in limiting heat transfer, thereby reducing the material’s thermal conductivity and enhancing its heat conservation performance. Additionally, the inclusion of fibers amplifies internal porosity, further reducing thermal conductivity and improving thermal insulation.

The observed patterns align with previous research on bio-based composites incorporating various lignocellulosic reinforcements. For instance, Khedari et al. demonstrated that incorporating coconut shell waste (10–30%) and durian fibers (10–40%) reduced the thermal conductivity of cement composites, achieving values of approximately 85% and 79% lower than ordinary mortar, respectively [91]. Similarly, Hafidh et al. reported comparable improvements in cement elements containing 10% to 30% sawdust particles [85], while Touloum et al. showed that adding up to 10% palm oil fibers significantly improved thermal insulation [92]. Similar conclusions were drawn for rubber cement composites [4], fiber–gypsum-based composites [93,94], and clay–cement–wood composites [95]. In aggregate, these findings corroborate the effectiveness of lignocellulosic residues in reducing thermal conductivity and enhancing thermal resistance in cement composites.

Figure 12 compares the thermal conductivity of WSCB5 boards with commercial boards and results from other studies on cement-based boards of similar density reinforced with various lignocellulosic materials. The WSCB5s produced in this study exhibit superior thermal performance compared to most values reported in the literature, achieving notable thermal insulation for a material classified as high-density. These results highlight the potential of WSCB as an innovative and high-performance solution for improving thermal insulation in construction applications while simultaneously addressing environmental and energy efficiency challenges.

Figure 12.

Thermal conductivity of walnut shell cement boards (WSCB5) in comparison to similar cement boards [38,92,96,97,98,99].

Thermal conductivity decreased with increasing WSP content, reaching a minimum of 50% WSP, while thermal resistance improved significantly. These results confirm the potential of WSCB as an effective insulating material.

4. Conclusions

This research highlights the considerable benefits of incorporating walnut shell particles (WSPs) into cement composites, demonstrating significant enhancements in physical, mechanical, and thermal properties. Key findings from the study of varying WSP content in walnut shell cement boards (WSCBs) are summarized as follows:

- The incorporation of WSP significantly influenced both the physical and mechanical properties of WSCB. At WSP contents up to 30%, the boards maintained acceptable density, water absorption (WA), and thickness swelling (TS), meeting Bison standards while also exhibiting improved flexural performance. WSCB3 achieved the highest modulus of rupture (MOR) and modulus of elasticity (MOE), attributed to good dispersion and strong particle–matrix bonding. Beyond 30% WSP, performance declined due to increased porosity, water uptake, and void formation caused by poor workability and particle agglomeration.

- Microstructural analysis (SEM/EDS) revealed improved particle bonding and reduced microcracks at 20–30% WSP, while higher WSP content introduced porosity and voids that compromised integrity. Elevated calcium and silicon levels, along with a favorable Ca/Si ratio at the WSP–cement interface, suggested the formation of interlocking structures that further strengthened the composite.

- FTIR analysis identified chemical transformations within WSCB, particularly at 20–30% WSP content, including the formation of calcium carbonate and C-S-H gel, which contributed to enhanced mechanical properties. The increased intensity of –OH group bands reflected the hydrophilic nature of WSP, influencing hydration and carbonation processes.

- TG/DSC analysis confirmed the high-temperature resistance of WSP and distinct thermal behaviors of WSCB3 boards. The porous structure of WSP promoted natural carbonation within the cement matrix, enhancing CO2 permeability and facilitating CaCO3 formation. These processes improved durability and supported additional C-S-H phase formation.

- Thermal conductivity was significantly reduced from 0.16957 W/(m·K) in pure cement boards to 0.07914 W/(m·K) in WSCB5 (50% WSP), with a corresponding increase in thermal resistance. These improvements are attributed to lower density and higher porosity, as trapped air within the porous structure disrupts heat transfer pathways, enhancing thermal insulation.

The findings confirm the potential of WSP as a sustainable and efficient reinforcing agent in cement composites, offering substantial improvements in physical, mechanical, and thermal performance. These results underscore the feasibility of recycling agricultural bio-waste into eco-friendly construction materials. Future studies should focus on evaluating the long-term durability, environmental impact, and practical application of WSP composites in real-world construction settings, thereby advancing sustainable and innovative building solutions.

Author Contributions

Conceptualization, A.E.H., H.C. and N.-E.E.M.; methodology, A.E.H., H.C. and N.-E.E.M.; software, A.E.H. and O.O.; validation, Y.M. and H.C.; formal analysis, A.E.H., Y.M. and H.C.; investigation, A.E.H.; resources, A.E.H., Y.M., H.C., O.O., M.C. and N.-E.E.M.; data curation, A.E.H. and Y.M.; writing—original draft preparation, A.E.H.; writing—review and editing, Y.M. and N.-E.E.M.; visualization, Y.M. and O.O.; supervision, M.C. and N.-E.E.M.; project administration, M.C. and N.-E.E.M.; funding acquisition, A.E.H. and N.-E.E.M. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

Data are contained within the article.

Acknowledgments

The authors extend their sincere appreciation to the CETEMCO center, RADACO company, and “Faculty of Science and Technology (FST) of Beni Mellal” for their continuous support.

Conflicts of Interest

The authors declare no conflicts of interest.

Abbreviations

The following abbreviations are used in this manuscript:

| CBPB | Cement-Bonded Particleboard |

| WSP | Walnut Shell Particles |

| WSCB | Walnut Shell Cement Boards |

| SWC | Super White Cement |

| WA | Water Absorption |

| TS | Thickness Swelling |

| SEM | Scanning Electron Microscopy |

| EDS | Energy Dispersive Spectroscopy |

| XRF | X-Ray Fluorescence |

| TG | Thermogravimetric Analysis |

| DSC | Differential Scanning Calorimetry |

| FTIR | Fourier Transformed Infrared |

| WSCB 1 | Boards with 10% Walnut Shell Particles |

| WSCB 2 | Boards with 20% Walnut Shell Particles |

| WSCB 3 | Boards with 30% Walnut Shell Particles |

| WSCB 4 | Boards with 40% Walnut Shell Particles |

| WSCB 5 | Boards with 50% Walnut Shell Particles |

| C–S–H | Calcium silicate hydrate |

References

- Li, X.; Qin, D.; Hu, Y.; Ahmad, W.; Ahmad, A.; Aslam, F.; Joyklad, P. A Systematic Review of Waste Materials in Cement—Based Composites for Construction Applications. J. Build. Eng. 2022, 45, 103447. [Google Scholar] [CrossRef]

- Tura, N.; Hanski, J.; Ahola, T.; Ståhle, M.; Piiparinen, S.; Valkokari, P. Unlocking Circular Business: A Framework of Barriers and Drivers. J. Clean. Prod. 2019, 212, 90–98. [Google Scholar] [CrossRef]

- Fan, Y.V.; Lee, C.T.; Lim, J.S.; Klemeš, J.J.; Le, P.T.K. Cross-Disciplinary Approaches towards Smart, Resilient and Sustainable Circular Economy. J. Clean. Prod. 2019, 232, 1482–1491. [Google Scholar] [CrossRef]

- Benazzouk, A.; Douzane, O.; Mezreb, K.; Laidoudi, B.; Quéneudec, M. Thermal Conductivity of Cement Composites Containing Rubber Waste Particles: Experimental Study and Modelling. Constr. Build. Mater. 2008, 22, 573–579. [Google Scholar] [CrossRef]

- Bonnet-Masimbert, P.-A.; Gauvin, F.; Brouwers, H.J.H.; Amziane, S. Study of Modifications on the Chemical and Mechanical Compatibility between Cement Matrix and Oil Palm Fibres. Results Eng. 2020, 7, 100150. [Google Scholar] [CrossRef]

- Frybort, S.; Mauritz, R.; Teischinger, A.; Müller, U. Cement Bonded Composites—A Mechanical Review. BioResources 2008, 3, 602–626. [Google Scholar] [CrossRef]

- Cabral, M.R.; Nakanishi, E.Y.; Dos Santos, V.; Gauss, C.; Dos Santos, S.F.; Fiorelli, J. Evaluation of Accelerated Carbonation Curing in Cement-Bonded Balsa Particleboard. Mater. Struct. 2018, 51, 1–14. [Google Scholar] [CrossRef]

- Nasser, R.A.; Salem, M.Z.M.; Al-Mefarrej, H.A.; Aref, I.M. Use of Tree Pruning Wastes for Manufacturing of Wood Reinforced Cement Composites. Cem. Concr. Compos. 2016, 72, 246–256. [Google Scholar] [CrossRef]

- Liang, C.; Zhang, Y.; Wu, R.; Yang, D.; Ma, Z. The Utilization of Active Recycled Powder from Various Construction Wastes in Preparing Ductile Fiber-Reinforced Cementitious Composites: A Case Study. Case Stud. Constr. Mater. 2021, 15, e00650. [Google Scholar] [CrossRef]

- Duan, Z.; Deng, Q.; Liang, C.; Ma, Z.; Wu, H. Upcycling of Recycled Plastic Fiber for Sustainable Cementitious Composites: A Critical Review and New Perspective. Cem. Concr. Compos. 2023, 142, 105192. [Google Scholar] [CrossRef]

- Yang, D.; Zhao, J.; Ahmad, W.; Nasir Amin, M.; Aslam, F.; Khan, K.; Ahmad, A. Potential Use of Waste Eggshells in Cement-Based Materials: A Bibliographic Analysis and Review of the Material Properties. Constr. Build. Mater. 2022, 344, 128143. [Google Scholar] [CrossRef]

- Kotb, M.; Assas, M.; Abd-Elrahman, H. Effect of Grounded Bone Powder Addition on the Mechanical Properties of Cement Mortar. WIT Trans. Ecol. Environ. 2010, 138, 201–212. [Google Scholar]

- Acda, M.N. Waste Chicken Feather as Reinforcement in Cement-Bonded Composites. Philipp. J. Sci. 2010, 139, 161–166. [Google Scholar]

- Islam, M.R.; Rahman, F.; Islam, M.N.; Rana, M.N.; Nath, S.K.; Ashaduzzaman, M.; Shams, M.I. Cement-Bonded Lignocellulosic Panel (CLP): A Promising Environmental Friendly Construction Material for Conservation of Forest Resources. In Handbook of Ecomaterials; Martínez, L.M.T., Kharissova, O.V., Kharisov, B.I., Eds.; Springer International Publishing: Cham, Germany, 2018; pp. 1–13. ISBN 978-3-319-48281-1. [Google Scholar]

- Brasileiro, G.A.M.; Vieira, J.A.R.; Barreto, L.S. Use of Coir Pith Particles in Composites with Portland Cement. J. Environ. Manag. 2013, 131, 228–238. [Google Scholar] [CrossRef]

- Ayrilmis, N.; Hosseinihashemi, S.K.; Karimi, M.; Kargarfard, A.; Ashtiani, H.S. Technological Properties of Cement-Bonded Composite Board Produced with the Main Veins of Oil Palm (Elaeis guineensis) Particles. BioResources 2017, 12, 3583–3600. [Google Scholar] [CrossRef][Green Version]

- Aggarwal, L.K.; Agrawal, S.P.; Thapliyal, P.C.; Karade, S.R. Cement-Bonded Composite Boards with Arhar Stalks. Cem. Concr. Compos. 2008, 30, 44–51. [Google Scholar] [CrossRef]

- Mendes, R.F.; Vilela, A.P.; Farrapo, C.L.; Mendes, J.F.; Denzin Tonoli, G.H.; Mendes, L.M. Lignocellulosic Residues in Cement-Bonded Panels. In Sustainable and Nonconventional Construction Materials Using Inorganic Bonded Fiber Composites; Elsevier: Amsterdam, The Netherlands, 2017; pp. 3–16. ISBN 978-0-08-102001-2. [Google Scholar]

- Ferraz, P.F.P.; Mendes, R.F.; Marin, D.B.; Paes, J.L.; Cecchin, D.; Barbari, M. Agricultural Residues of Lignocellulosic Materials in Cement Composites. Appl. Sci. 2020, 10, 8019. [Google Scholar] [CrossRef]

- Pirayesh, H.; Saadatnia, M.A. Effects of Accelerating Agent and SiO2 Nano-Powder on the Mechanical and Physical Characteristics of Nut Shell–Cement Based Composites. Mater. Struct. 2016, 49, 3435–3443. [Google Scholar] [CrossRef]

- El Hamri, A.; Mouhib, Y.; Ourmiche, A.; Chigr, M.; El Mansouri, N.-E. Study of the Effect of Cedar Sawdust Content on Physical and Mechanical Properties of Cement Boards. Molecules 2024, 29, 4399. [Google Scholar] [CrossRef]

- Ghofrani, M.; Mokaram, K.N.; Ashori, A.; Torkaman, J. Fiber-Cement Composite Using Rice Stalk Fiber and Rice Husk Ash: Mechanical and Physical Properties. J. Compos. Mater. 2015, 49, 3317–3322. [Google Scholar] [CrossRef]

- Domingos, I.; Ferreira, J.; Cruz-Lopes, L.P.; Esteves, B. Liquefaction and Chemical Composition of Walnut Shells. Open Agric. 2022, 7, 249–256. [Google Scholar] [CrossRef]

- Martínez, M.L.; Labuckas, D.O.; Lamarque, A.L.; Maestri, D.M. Walnut (Juglans regia, L.): Genetic Resources, Chemistry, by-Products. J. Sci. Food Agric. 2010, 90, 1959–1967. [Google Scholar] [CrossRef]

- FAO. FAOSTAT—Crops and Livestock Products. Food and Agriculture Organization of the United Nations. Available online: https://www.fao.org/faostat/en/#data/QCL (accessed on 14 September 2024).

- Houmanat, K.; Abdellah, K.; Hssaini, L.; Razouk, R.; Hanine, H.; Jaafary, S.; Charafi, J. Molecular Diversity of Walnut (Juglans regia, L.) Among Two Major Areas in Morocco in Contrast with Foreign Varieties. Int. J. Fruit. Sci. 2021, 21, 180–192. [Google Scholar] [CrossRef]

- Lansari, A.; El Hassani, A.; Nabil, D.; Germain, E. Preliminary Results on Walnut Germplasm Evaluation in Morocco. IV Int. Walnut Symp. 2001, 544, 27–35. [Google Scholar] [CrossRef]

- Kabiri, G.; Bouda, S.; Elhansali, M.; Haddioui, A. Morphological and Pomological Variability Analysis of Walnut (Juglans regia, L.) Genetic Resources from the Middle and High Atlas of Morocco. Atlas J. Biol. 2018, 575–582. [Google Scholar] [CrossRef]

- Pirayesh, H.; Khanjanzadeh, H.; Salari, A. Effect of Using Walnut/Almond Shells on the Physical, Mechanical Properties and Formaldehyde Emission of Particleboard. Compos. Part. B Eng. 2013, 45, 858–863. [Google Scholar] [CrossRef]

- Dahchour, A.; Hajjaji, S.E. Management of Solid Waste in Morocco. In Waste Management in MENA Regions; Negm, A.M., Shareef, N., Eds.; Springer Water; Springer International Publishing: Cham, Germany, 2020; pp. 13–33. ISBN 978-3-030-18349-3. [Google Scholar]

- Babatunde, A. Durability Characteristics of Cement-Bonded Particleboards Manufactured from Maize Stalk Residue. J. For. Res. 2011, 22, 111–115. [Google Scholar] [CrossRef]

- Abdolhosseini Sarsari, N.; Pourmousa, S.; Tajdini, A. Physical and Mechanical Properties of Walnut Shell Flour-Filled Thermoplastic Starch Composites. BioResources 2016, 11, 6968–6983. [Google Scholar] [CrossRef]

- Jannat, N.; Latif Al-Mufti, R.; Hussien, A. Eggshell and Walnut Shell in Unburnt Clay Blocks. CivilEng 2022, 3, 263–276. [Google Scholar] [CrossRef]

- Peng, S.; Qiu, K.; Yang, B.; Ai, J.; Zhou, A. Experimental Study on the Durability Performance of Sustainable Mortar with Partial Replacement of Natural Aggregates by Fiber-Reinforced Agricultural Waste Walnut Shells. Sustainability 2024, 16, 824. [Google Scholar] [CrossRef]

- Abdulwahid, M.Y.; Akinwande, A.A.; Kamarou, M.; Romanovski, V.; Al-Qasem, I.A. The Production of Environmentally Friendly Building Materials out of Recycling Walnut Shell Waste: A Brief Review. Biomass Convers. Biorefinery 2024, 14, 24963–24972. [Google Scholar] [CrossRef]

- Melichar, T.; Meszarosova, L.; Bydzovsky, J.; Ledl, M.; Vasas, S. The Effect of Moisture on the Properties of Cement-Bonded Particleboards Made with Non-Traditional Raw Materials. J. Wood Sci. 2021, 67, 75. [Google Scholar] [CrossRef]

- Francioso, V.; Moro, C.; Velay-Lizancos, M. Effect of Recycled Concrete Aggregate (RCA) on Mortar’s Thermal Conductivity Susceptibility to Variations of Moisture Content and Ambient Temperature. J. Build. Eng. 2021, 43, 103208. [Google Scholar] [CrossRef]

- Ferraz, P.F.P.; Mendes, R.F.; Ferraz, G.A.S.; Carvalho, V.R.; Avelino, M.R.C.; Narciso, C.R.P.; Eugênio, T.M.C.; Cadavid, V.G.; Bambi, G. Thermal Analysis of Cement Panels with Lignocellulosic Materials for Building. Agron. Res. 2020, 18, 797–805. [Google Scholar] [CrossRef]

- PNM EN 325; Panneaux à Base de Bois—Détermination Des Dimensions Des Éprouvettes. Public Service Company of New Mexico: Rabat, Morocco, 2012.

- EN 323; Wood-Based Panels—Determination of Density. The European Committee for Standardization: Brussels, Belgium, 1993.

- EN 317; Particleboards and Fibreboards—Determination of Swelling in Thickness after Immersion in Water. The European Committee for Standardization: Brussels, Belgium, 1993.

- EN 310; Wood-Based Panels—Determination of Modulus of Elasticity in Bending and of Bending Strength. The European Committee for Standardization: Brussels, Belgium, 1993.

- ASTM-C518; Standard Test Method for Steady-State Thermal Transmission Properties by Means of the Heat Flow Meter Apparatus (C 518). American Society of Testing and Materials (ASTM): West Conshohocken, PA, USA, 2010.

- Okino, E.Y.A.; de Souza, M.R.; Santana, M.A.E.; da Alves, M.V.S.; Sousa, M.E.D.; Teixeira, D.E. Cement-Bonded Wood Particleboard with a Mixture of Eucalypt and Rubberwood. Cem. Concr. Compos. 2004, 26, 729–734. [Google Scholar] [CrossRef]

- Antwi-Boasiako, C.; Ofosuhene, L.; Boadu, K.B. Suitability of Sawdust from Three Tropical Timbers for Wood-Cement Composites. J. Sustain. For. 2018, 37, 414–428. [Google Scholar] [CrossRef]

- Ali, I.M.; Nasr, M.S.; Naje, A.S. Enhancement of Cured Cement Using Environmental Waste: Particleboards Incorporating Nano Slag. Open Eng. 2020, 10, 273–281. [Google Scholar] [CrossRef]

- He, P.; Hossain, U.; Poon, C.S.; Tsang, D.C.W. Mechanical, Durability and Environmental Aspects of Magnesium Oxychloride Cement Boards Incorporating Waste Wood. J. Clean. Prod. 2019, 207, 391–399. [Google Scholar] [CrossRef]

- Odeyemi, S.O.; Abdulwahab, R.; Adeniyi, A.G.; Atoyebi, O.D. Physical and Mechanical Properties of Cement-Bonded Particle Board Produced from African Balsam Tree (Populous balsamifera) and Periwinkle Shell Residues. Results Eng. 2020, 6, 100126. [Google Scholar] [CrossRef]

- Zhou, Y.; Kamdem, D.P. Effect of Cement/Wood Ratio on the Properties of Cement-Bonded Particleboard Using CCA-Treated Wood Removed from Service (Composites and Manufactured Products). For. Prod. J. 2002, 52, 77–82. [Google Scholar]

- Farag, E.; Alshebani, M.; Elhrari, W.; Klash, A.; Shebani, A. Production of Particleboard Using Olive Stone Waste for Interior Design. J. Build. Eng. 2020, 29, 101119. [Google Scholar] [CrossRef]

- Mancera, C.; El Mansouri, N.-E.; Pelach, M.A.; Francesc, F.; Salvadó, J. Feasibility of Incorporating Treated Lignins in Fiberboards Made from Agricultural Waste. Waste Manag. 2012, 32, 1962–1967. [Google Scholar] [CrossRef]

- Bilcati, G.K.; Matoski, A.; Trianoski, R.; Lengowski, E. Potential Use of Curaua Fiber (Ananas erectifolius) for Cementitious Production Composite Uso Potencial de La Fibra de Curauá (Ananas acutifolius) Para La Fabricación de Compuestos Cementicios. Rev. Ing. Constr. 2018, 33, 155–160. [Google Scholar] [CrossRef]

- Hasan, K.M.F.; Horváth, P.G.; Alpár, T. Development of Lignocellulosic Fiber Reinforced Cement Composite Panels Using Semi-Dry Technology. Cellulose 2021, 28, 3631–3645. [Google Scholar] [CrossRef]

- Ashori, A.; Tabarsa, T.; Sepahvand, S. Cement-Bonded Composite Boards Made from Poplar Strands. Constr. Build. Mater. 2012, 26, 131–134. [Google Scholar] [CrossRef]

- Mahzabin, M.S.; Hamid, R.; Badaruzzaman, W.H.W. Evaluation of Chemicals Incorporated Wood Fibre Cement Matrix Properties. J. Eng. Sci. Technol. 2013, 8, 385–398. [Google Scholar] [CrossRef]

- Aras, U.; Kalaycıoğlu, H.; Yel, H.; Kuştaş, S. Utilization of Olive Mill Solid Waste in the Manufacturing of Cement-Bonded Particleboard. J. Build. Eng. 2022, 49, 104055. [Google Scholar] [CrossRef]

- Sotannde, O.A.; Oluwadare, A.O.; Ogedoh, O.; Adeogun, P.F. Evaluation of Cement-Bonded Particle Board Produced Fromafzelia Africanawood Residues. J. Eng. Sci. Technol. 2012, 7, 732–743. [Google Scholar]

- Bisschop, J.; Van Mier, J.G.M. Effect of Aggregates on Drying Shrinkage Microcracking in Cement-Based Composites. Mat. Struct. 2002, 35, 453–461. [Google Scholar] [CrossRef]

- Wen, J.; Wang, B.; Dai, Z.; Shi, X.; Jin, Z.; Wang, H.; Jiang, X. New Insights into the Green Cement Composites with Low Carbon Footprint: The Role of Biochar as Cement Additive/Alternative. Resour. Conserv. Recycl. 2023, 197, 107081. [Google Scholar] [CrossRef]

- Dias, S.; Tadeu, A.; Almeida, J.; Humbert, P.; António, J.; De Brito, J.; Pinhão, P. Physical, Mechanical, and Durability Properties of Concrete Containing Wood Chips and Sawdust: An Experimental Approach. Buildings 2022, 12, 1277. [Google Scholar] [CrossRef]

- Ranachowski, Z.; Ranachowski, P.; Dębowski, T.; Gorzelańczyk, T.; Schabowicz, K. Investigation of Structural Degradation of Fiber Cement Boards Due to Thermal Impact. Materials 2019, 12, 944. [Google Scholar] [CrossRef] [PubMed]

- Miranda De Lima, A.J.; Iwakiri, S.; Satyanarayana, K.G.; Lomelí-Ramírez, M.G. Studies on the Durability of Wood-Cement Particleboards Produced with Residues of Pinus Spp., Silica Fume, and Rice Husk Ash. BioResources 2020, 15, 3064–3086. [Google Scholar] [CrossRef]

- Rossen, J.E.; Scrivener, K.L. Optimization of SEM-EDS to Determine the C–A–S–H Composition in Matured Cement Paste Samples. Mater. Charact. 2017, 123, 294–306. [Google Scholar] [CrossRef]

- Scurtu, D.A.; Kovacs, E.; Senila, L.; Levei, E.A.; Simedru, D.; Filip, X.; Dan, M.; Roman, C.; Cadar, O.; David, L. Use of Vine Shoot Waste for Manufacturing Innovative Reinforced Cement Composites. Appl. Sci. 2022, 13, 134. [Google Scholar] [CrossRef]

- Wei, Y.M.; Fujii, T.; Hiramatsu, Y.; Miyatake, A.; Yoshinaga, S.; Fujii, T.; Tomita, B. A Preliminary Investigation on Microstructural Characteristics of Interfacial Zone between Cement and Exploded Wood Fiber Strand by Using SEM-EDS. J. Wood Sci. 2004, 50, 327–336. [Google Scholar] [CrossRef]

- Tawfik, A.; Mohammed, M.S.; Abd-El-Raoof, F.; Aggor, F.S.; Ahmed, E.M. Heat-Treated Portland Cement Pastes Incorporating Superabsorbent Hydrogels for Precast Applications. Interceram—Int. Ceram. Rev. 2018, 67, 30–37. [Google Scholar] [CrossRef]

- Petkova, V.; Stoyanov, V.; Kostova, B.; Kostov-Kytin, V.; Kalinkin, A.; Zvereva, I.; Tzvetanova, Y. Crystal—Chemical and Thermal Properties of Decorative Cement Composites. Materials 2021, 14, 4793. [Google Scholar] [CrossRef]

- Li, X.; Qiu, J.; Hu, Y.; Ren, X.; He, L.; Zhao, N.; Ye, T.; Zhao, X. Characterization and Comparison of Walnut Shells-Based Activated Carbons and Their Adsorptive Properties. Adsorpt. Sci. Technol. 2020, 38, 450–463. [Google Scholar] [CrossRef]

- Fan, L.; Chen, J.; Guo, J.; Jiang, X.; Jiang, W. Influence of Manganese, Iron and Pyrolusite Blending on the Physiochemical Properties and Desulfurization Activities of Activated Carbons from Walnut Shell. J. Anal. Appl. Pyrolysis 2013, 104, 353–360. [Google Scholar] [CrossRef]

- Hashemian, S.; Salari, K.; Salehifar, H.; Atashi Yazdi, Z. Removal of Azo Dyes (Violet B and Violet 5R) from Aqueous Solution Using New Activated Carbon Developed from Orange Peel. J. Chem. 2013, 2013, 283274. [Google Scholar] [CrossRef]

- Azmi, N.H.; Ali, U.F.; Muhammad Ridwan, F.; Isa, K.M.; Zulkurnai, N.Z.; Aroua, M.K. Preparation of Activated Carbon Using Sea Mango (Cerbera odollam) with Microwave-Assisted Technique for the Removal of Methyl Orange from Textile Wastewater. Desalination Water Treat. 2016, 57, 29143–29152. [Google Scholar] [CrossRef]

- Gallardo, K.; Castillo, R.; Mancilla, N.; Remonsellez, F. Biosorption of Rare-Earth Elements From Aqueous Solutions Using Walnut Shell. Front. Chem. Eng. 2020, 2, 4. [Google Scholar] [CrossRef]

- Haris Javed, M.; Ali Sikandar, M.; Ahmad, W.; Tariq Bashir, M.; Alrowais, R.; Bilal Wadud, M. Effect of Various Biochars on Physical, Mechanical, and Microstructural Characteristics of Cement Pastes and Mortars. J. Build. Eng. 2022, 57, 104850. [Google Scholar] [CrossRef]

- Jain, B.; Sancheti, G.; Jain, V. FTIR Analysis of Silica Fume and Iron Dust Added Concrete. Mater. Today Proc. 2022, 60, 777–781. [Google Scholar] [CrossRef]

- Peschard, A.; Govin, A.; Grosseau, P.; Guilhot, B.; Guyonnet, R. Effect of Polysaccharides on the Hydration of Cement Paste at Early Ages. Cem. Concr. Res. 2004, 34, 2153–2158. [Google Scholar] [CrossRef]

- Bensted, J.; Varma, S.P. Some Applications of Infrared and Raman Spectroscopy in Cement Chemistry. Part 3-Hydration of Portland Cement and Its Constituents. Cem. Technol. 1974, 5, 440–445. [Google Scholar]

- Mollah, M.Y.A.; Yu, W.; Schennach, R.; Cocke, D.L. A Fourier Transform Infrared Spectroscopic Investigation of the Early Hydration of Portland Cement and the Influence of Sodium Lignosulfonate. Cem. Concr. Res. 2000, 30, 267–273. [Google Scholar] [CrossRef]

- Luo, D.; Wei, J. Hydration Kinetics and Phase Evolution of Portland Cement Composites Containing Sodium-Montmorillonite Functionalized with a Non-Ionic Surfactant. Constr. Build. Mater. 2022, 333, 127386. [Google Scholar] [CrossRef]

- Scurtu, D.A.; David, L.; Levei, E.A.; Simedru, D.; Filip, X.; Roman, C.; Cadar, O. Developing Innovative Cement Composites Containing Vine Shoot Waste and Superplasticizers. Materials 2023, 16, 5313. [Google Scholar] [CrossRef]

- Shah, M.A.; Khan, M.N.S.; Kumar, V. Biomass Residue Characterization for Their Potential Application as Biofuels. J. Therm. Anal. Calorim. 2018, 134, 2137–2145. [Google Scholar] [CrossRef]

- Eseyin, A.E.; Steele, P.H.; Pittman, C.U.; Ekpenyong, K.I.; Soni, B. TGA Torrefaction Kinetics of Cedar Wood. J. Biofuels 2016, 7, 20. [Google Scholar] [CrossRef]

- Kamasamudram, K.S.; Ashraf, W.; Landis, E.N.; Khan, R.I. Effects of Ligno– and Delignified– Cellulose Nanofibrils on the Performance of Cement-Based Materials. J. Mater. Res. Technol. 2021, 13, 321–335. [Google Scholar] [CrossRef]

- Yel, H.; He, C.; Urun, E. Performance of Cement-Bonded Wood Particleboards Produced Using Fly Ash and Spruce Planer Shavings. Maderas. Cienc. Y Tecnol. 2022, 24, 1–10. [Google Scholar] [CrossRef]