Mechanical Properties of Dispersion-Strengthened Iron-Based W+WC(Ni) Composite Produced by Combined Wire Electron-Beam Manufacturing with Powder Addition

Abstract

1. Introduction

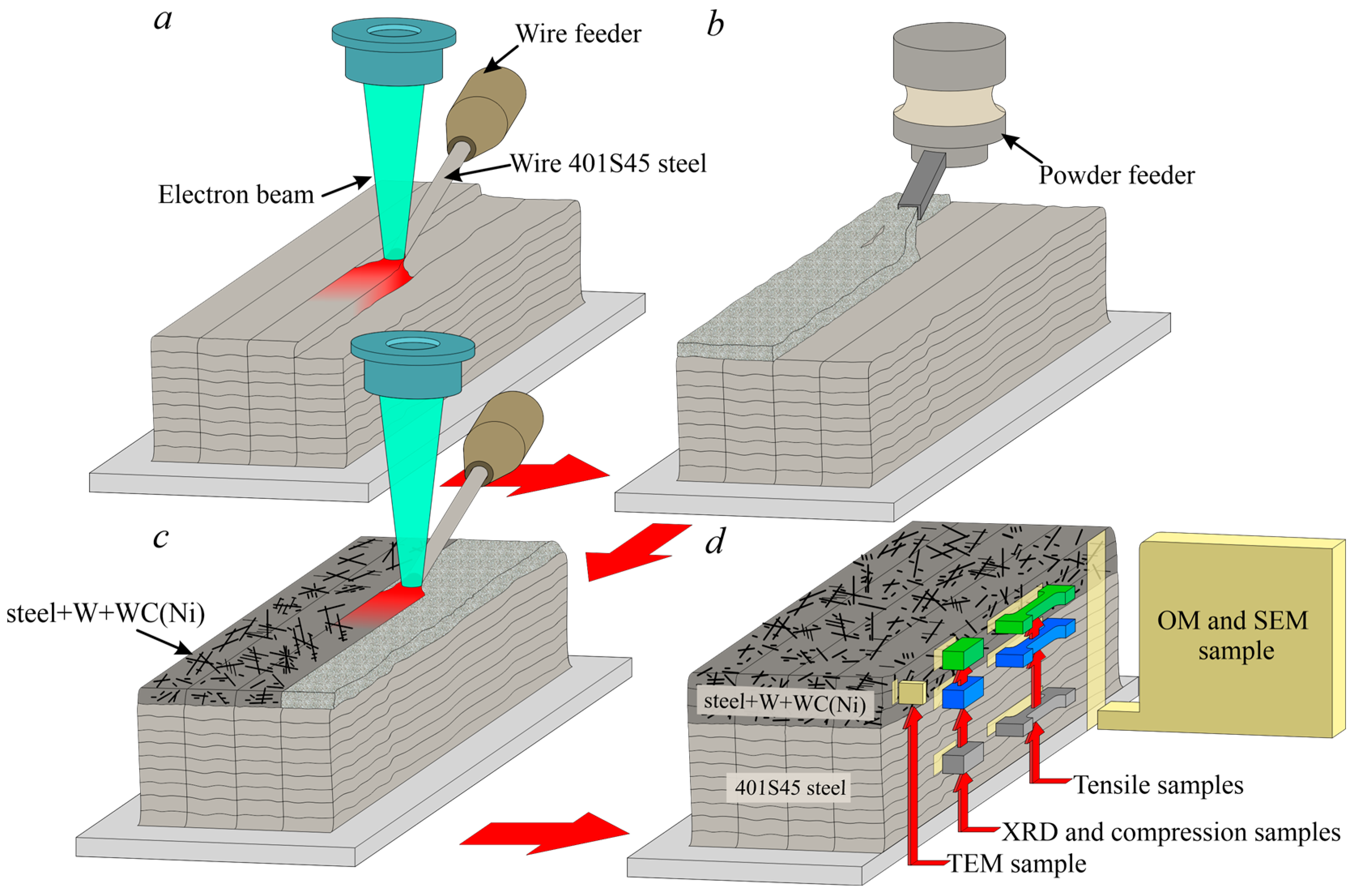

2. Materials and Methods

3. Results

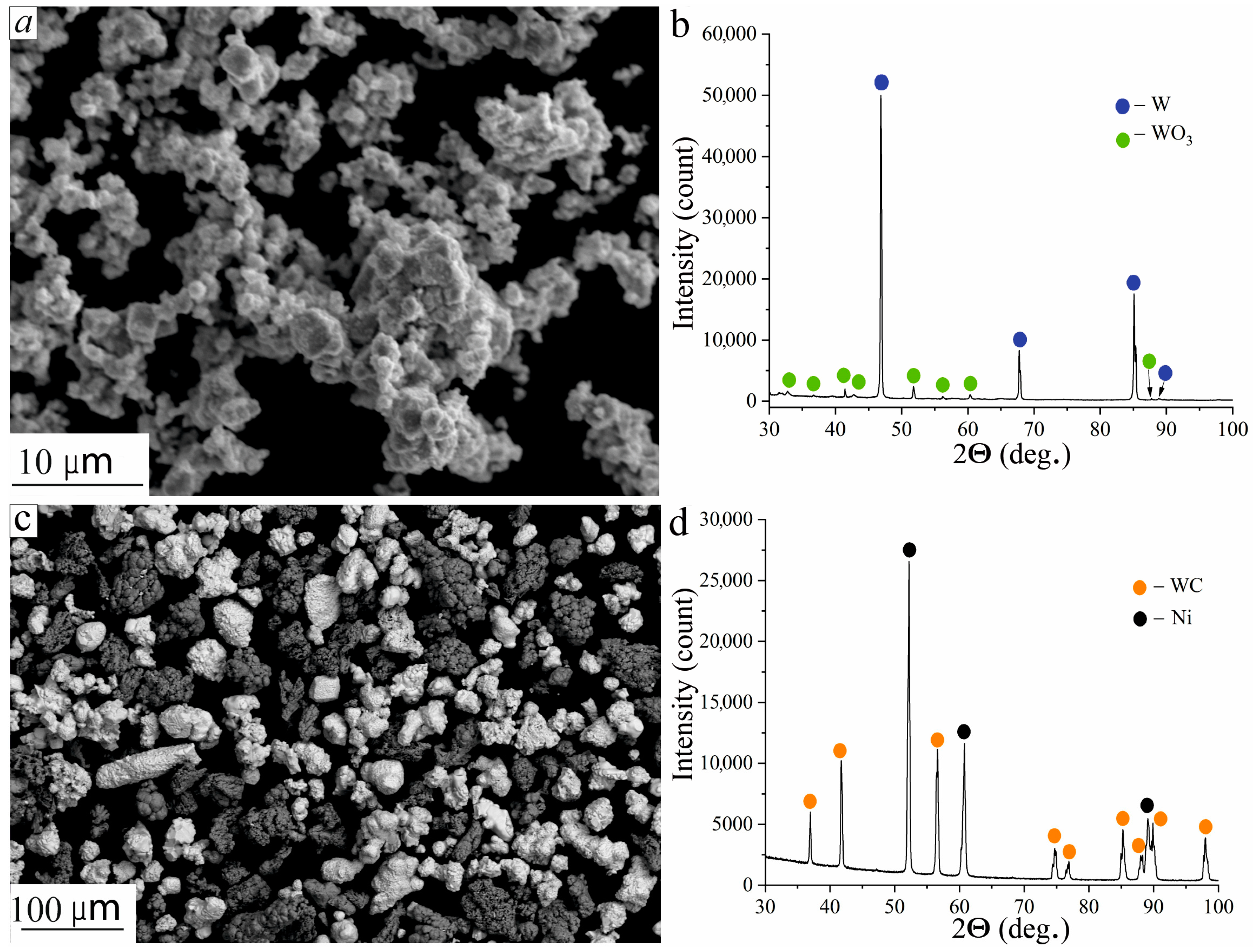

3.1. Initial Powders W and WC(Ni)

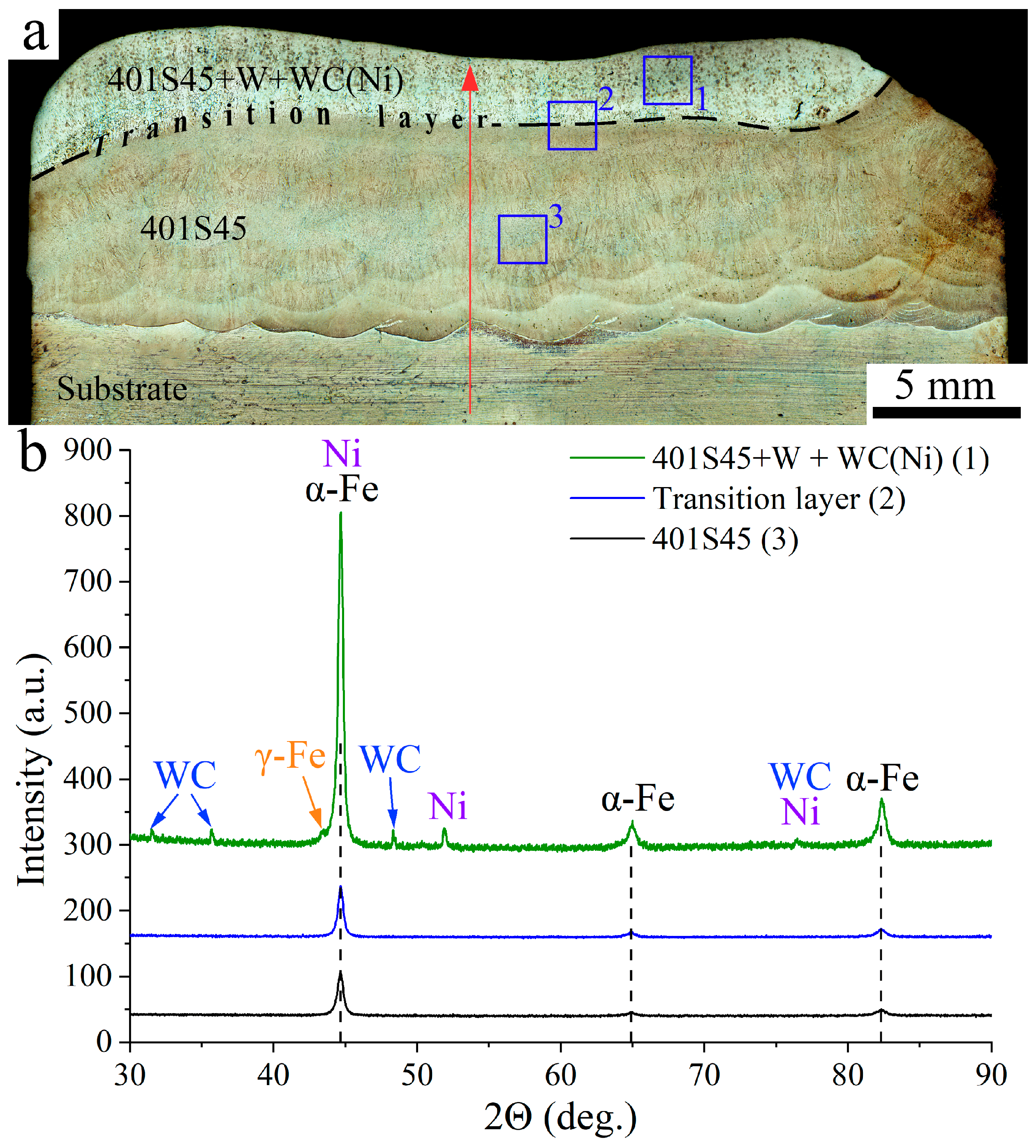

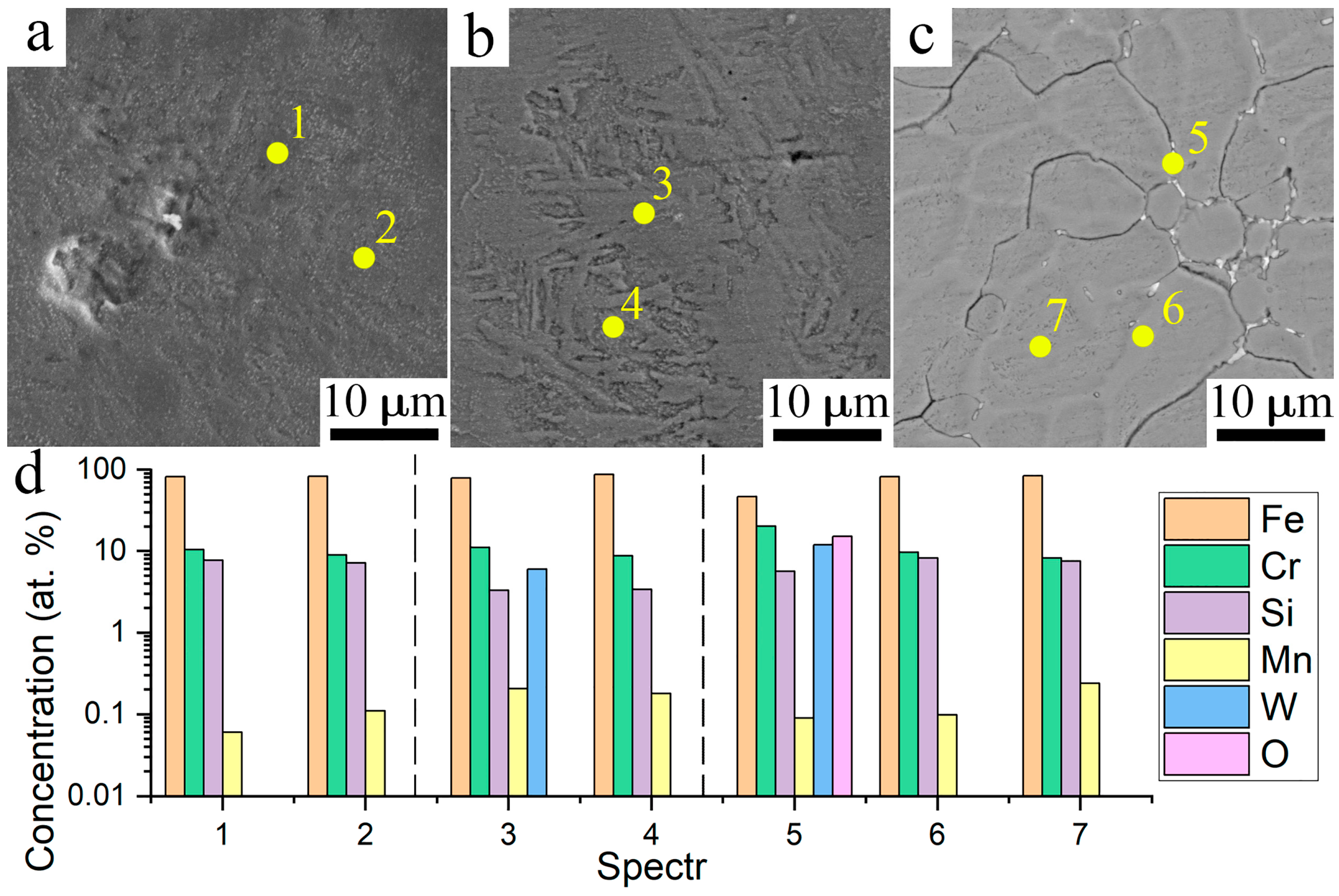

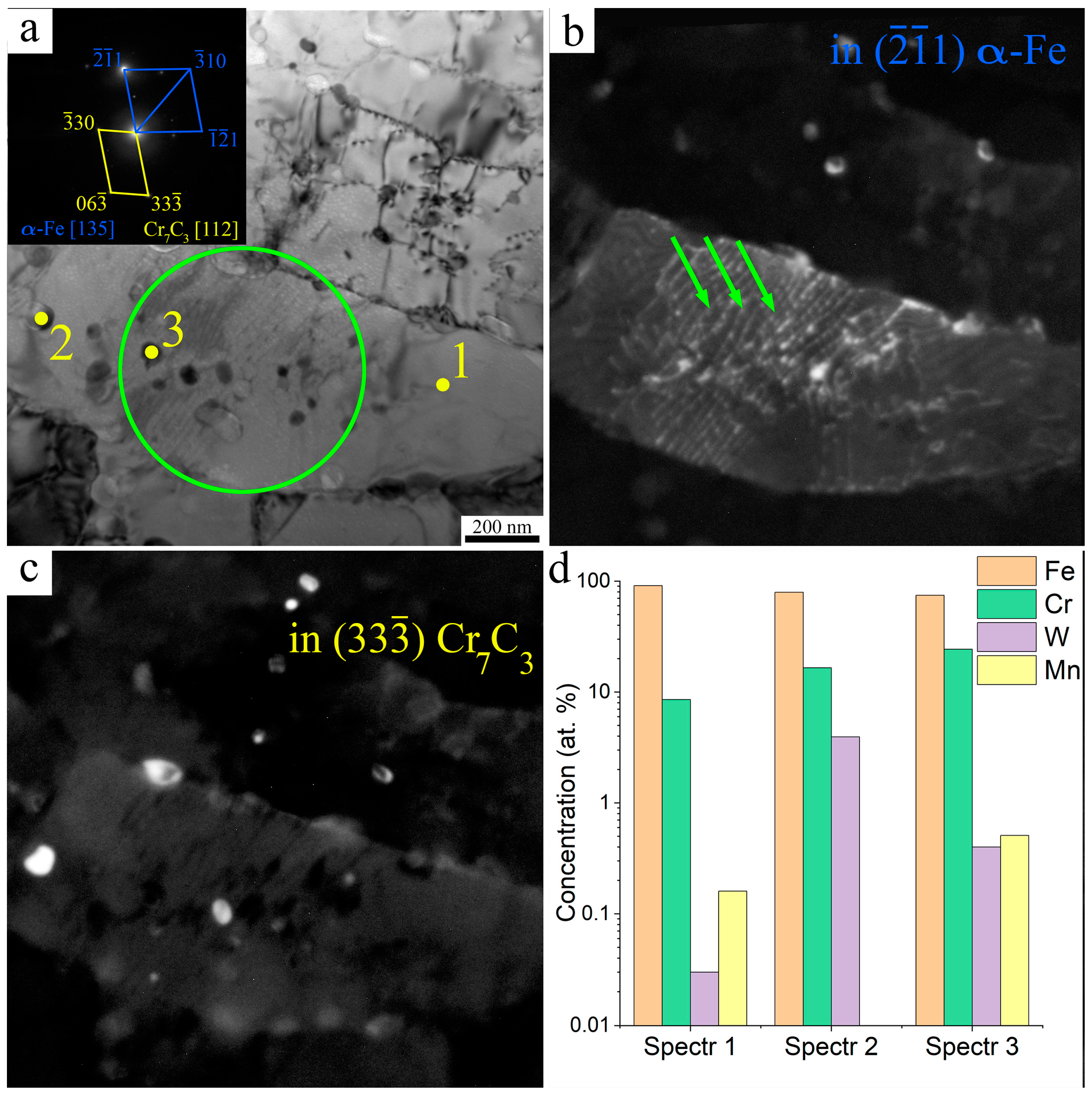

3.2. Structure of Composite Steel+W+WC(Ni)

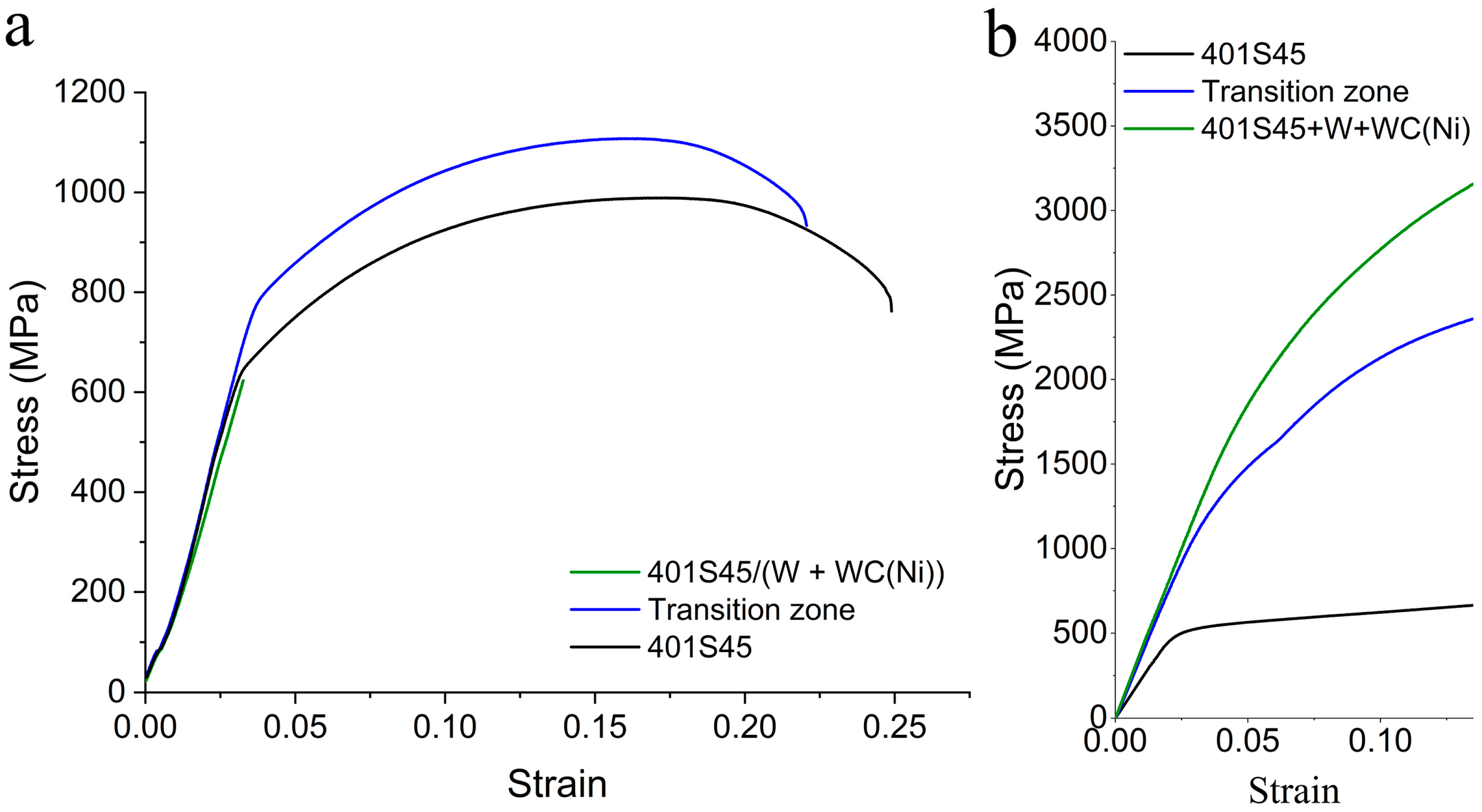

3.3. Mechanical Properties of Steel+W+WC(Ni) Composite

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Bhowmik, A.; Kumar, R.; Beemkumar, N.; Kumar, A.V.; Singh, G.; Kulshreshta, A.; Mann, V.S.; Johnson Santhosh, A. Casting of particle reinforced metal matrix composite by liquid state fabrication method: A review. Results Eng. 2024, 24, 103152. [Google Scholar] [CrossRef]

- Kumar Yadav Nartu, M.S.K.; Agrawal, P. Additive manufacturing of metal matrix composites. Mater. Des. 2025; in press. [Google Scholar] [CrossRef]

- Tjong, S.C. Recent progress in the development and properties of novel metal matrix nanocomposites reinforced with carbon nanotubes and graphene nanosheets. Mater. Sci. Eng. R Rep. 2013, 74, 281–350. [Google Scholar] [CrossRef]

- Radhamani, A.V.; Lau, H.C.; Ramakrishna, S. CNT-reinforced metal and steel nanocomposites: A comprehensive assessment of progress and future directions. Compos. Part A Appl. Sci. Manuf. 2018, 114, 170–187. [Google Scholar] [CrossRef]

- AlMangour, B.; Grzesiak, D.; Yang, J.-M. Selective laser melting of TiC reinforced 316L stainless steel matrix nanocomposites: Influence of starting TiC particle size and volume content. Mater. Des. 2016, 104, 141–151. [Google Scholar] [CrossRef]

- Enrici, T.M.; Dedry, O.; Boschini, F.; Tchuindjang, J.T.; Mertens, A. Microstructural and thermal characterization of 316L+WC composite coatings obtained by laser cladding. Adv. Eng. Mater. 2020, 22, 2000291. [Google Scholar] [CrossRef]

- Yan, X.C.; Chen, C.Y.; Zhao, R.X.; Ma, W.Y.; Bolot, R.; Wang, J.; Ren, Z.M.; Liao, H.L.; Liu, M. Selective laser melting of WC reinforced maraging steel 300: Microstructure characterization and tribological performance. Surf. Coat. Technol. 2019, 371, 355–365. [Google Scholar] [CrossRef]

- Gu, D.D.; Ma, J.; Chen, H.; Lin, K.; Xi, L. Laser additive manufactured WC reinforced Fe-based composites with gradient reinforcement/matrix interface and enhanced performance. Compos. Struct. 2018, 192, 387–396. [Google Scholar] [CrossRef]

- Wang, J.D.; Li, L.Q.; Tao, W. Crack initiation and propagation behavior of WC particles reinforced Fe-based metal matrix composite produced by laser melting deposition. Opt. Laser Technol. 2016, 82, 170–182. [Google Scholar] [CrossRef]

- Kang, N.; Ma, W.; Heraud, L.; El Mansori, M.; Li, F.; Liu, M.; Liao, H. Selective laser melting of tungsten carbide reinforced maraging steel composite. Addit. Manuf. 2018, 22, 104–110. [Google Scholar] [CrossRef]

- Chen, H.; Gu, D.; Kosiba, K.; Lu, T.; Deng, L.; Xi, L.; Kühn, U. Achieving high strength and high ductility in WC-reinforced iron-based composites by laser additive manufacturing. Addit. Manuf. 2020, 35, 101195. [Google Scholar] [CrossRef]

- Olumor, I.D.; Wisniewska, M.; Torresani, E.; Olevsky, E.A. Additive manufacturing and spark plasma sintering as effective routes for manufacturing of AISI 316L austenitic stainless steel—WC composites. J. Mater. Res. Technol. 2023, 26, 3234–3244. [Google Scholar] [CrossRef]

- Zhang, T.; Yang, K.; Zhu, Z.; Xu, L.; Chen, G.; Fang, N.; Kou, S. Effect of Cr and W on microstructure and wear resistance of arc additive manufactured flux-cored wire for railway wheels. J. Mater. Res. Technol. 2024, 30, 3438–3447. [Google Scholar] [CrossRef]

- Li, H.; Hu, Y.; Di, R.; Yuan, R.; Shi, C.; Lei, J. Effects of WC particles on microstructure and mechanical properties of 316L steel obtained by laser melting deposition. Ceram. Int. 2022, 48, 20388–20399. [Google Scholar] [CrossRef]

- Varun Kumar, K.; Kalyan Phani, M. Microstructural and mechanical characterization of parallel layered WC- NiCr weld overlay on 080 M40 steel substrate prepared using additive manufacturing. Mater. Today Proc. 2022, 67, 501–506. [Google Scholar] [CrossRef]

- Kang, N.; Ma, W.; Lib, F.; Liao, H.; Liu, M.; Coddet, C. Microstructure and wear properties of selective laser melted WC reinforced 18Ni-300 steel matrix composite. Vacuum 2018, 154, 69–74. [Google Scholar] [CrossRef]

- Yu, X.; Bai, X.; Shi, X.; Zhou, X.; Zhang, H. Microstructures and properties of wire and arc additively manufactured steel matrix composites with addition of WC by gravity-driven side powder feeding. J. Manuf. Process. 2022, 81, 236–249. [Google Scholar] [CrossRef]

- Farahmand, P.; Kovacevic, R. Corrosion and wear behavior of laser cladded Ni–WC coatings. Surf. Coat. Technol. 2015, 276, 121–135. [Google Scholar] [CrossRef]

- Liu, W.; Gao, D. Microstructure and wear of Ni-WC hardfacing used for steel-body PDC bits. Int. J. Refract. Met. Hard Mater. 2021, 101, 105683. [Google Scholar] [CrossRef]

- Tahaei, A.; Bagheri Vanani, B.; Abbasi, M.; Arizmendi-Morquecho, A. A different attempt to investigate the influence of PTA parameters on microstructure evolution and mechanical characteristics of nickel base powder (Ni-WC) deposited tool steel. J. Mater. Res. Technol. 2023, 27, 7970–7985. [Google Scholar] [CrossRef]

- Ding, H.; Yuan, Z.; Liu, T.; Chen, L.; Zhou, Y.; Cao, Y.; Cao, F.; Luo, R.; Cheng, X. Microstructure and high-temperature tensile behavior of modified H13 steel with the addition of tungsten, molybdenum, and lowering of chromium. Mater. Sci. Eng. A 2023, 866, 144655. [Google Scholar] [CrossRef]

- Won, Y.J.; Kwon, Y.J.; You, J.S.; Park, S.S.; Cho, K.S. Role of W addition in reducing heat checking and enhancing the mechanical properties of hot work tool steel. J. Mater. Res. Technol. 2023, 24, 3413–3422. [Google Scholar] [CrossRef]

- Xiang, S.; Wu, R.; Li, W.; Hu, T.; Huang, S. Improved red hardness and toughness of hot work die steel through tungsten alloying. J. Mater. Eng. Perform. 2021, 30, 6146–6159. [Google Scholar] [CrossRef]

- Hong, S.G.; Lee, W.B.; Park, C.G. The effects of tungsten addition on the microstructural stability of 9Cr–Mo Steels. J. Nucl. Mater. 2001, 288, 202–207. [Google Scholar] [CrossRef]

- Matějíček, J.; Boldyryeva, H.; Brožek, V.; Sachr, P.; Chráska, T.; Pala, Z. W–steel and W–WC–steel composites and FGMs produced by hot pressing. Fusion Eng. Des. 2015, 100, 364–370. [Google Scholar] [CrossRef]

- Bolt, H.; Barabash, V.; Krauss, W.; Linke, J.; Neu, R.; Suzuki, S.; Yoshida, N.; Team, A.U. Materials for the plasma-facing components of fusion reactors. J. Nucl. Mater. 2004, 329–333, 66–73. [Google Scholar] [CrossRef]

- Odegard, B.C.; Cadden, C.H.; Watson, R.D.; Slattery, K.T. A review of the US joining technologies for plasma facing components in the ITER fusion reactor. J. Nucl. Mater. 1998, 258–263, 329–334. [Google Scholar] [CrossRef]

- Merola, M.; Akiba, M.; Barabash, V.; Mazul, I. Overview on fabrication and joining of plasma facing and high heat flux materials for ITER. J. Nucl. Mater. 2002, 307–311, 1524–1532. [Google Scholar] [CrossRef]

- Hamilton, N.R.; Wood, J.; Galloway, A.; Robbie, M.B.O.; Zhang, Y. The metallurgy, mechanics, modelling and assessment of dissimilar material brazed joints. J. Nucl. Mater. 2013, 432, 42–51. [Google Scholar] [CrossRef]

- Filippov, A.V.; Khoroshko, E.S.; Shamarin, N.N.; Savchenko, N.L.; Moskvichev, E.N.; Utyaganova, V.R.; Kolubaev, E.A.; Smolin, A.Y.; Tarasov, S.Y. Characterization of gradient CuAl–B4C composites additively manufactured using a combination of wire-feed and powder-bed electron beam deposition methods. J. Alloys Compd. 2021, 859, 157824. [Google Scholar] [CrossRef]

- Zykova, A.; Chumaevskii, A.V.; Vorontsov, A.; Shamarin, N.; Panfilov, A.; Knyazhev, E.; Moskvichev, E.; Gurianov, D.; Savchenko, N.; Kolubaev, E.; et al. Microstructural evolution of AA5154 layers intermixed with Mo powder during electron beam wire-feed additive manufacturing (EBAM). Metals 2022, 12, 109. [Google Scholar] [CrossRef]

- Utyaganova, V.R.; Chumaevskii, A.V.; Shamarin, N.N.; Moskvichev, E.N.; Vorontsov, A.V.; Gurianov, D.A.; Knyazhev, E.O.; Savchenko, N.L. Regularities of structure formation and properties of composite materials based on aluminum–manganese bronze produced by electron beam additive manufacturing with the addition of iron, nickel, and tungsten powders during printing. Russ. Phys. J. 2023, 65, 1584–1591. [Google Scholar] [CrossRef]

- Holzweissig, M.J.; Taube, A.; Brenne, F.; Schaper, M.; Niendorf, T. Microstructural characterization and mechanical performance of hot work tool steel processed by selective laser melting. Metall. Mater. Trans. B 2015, 46, 545–549. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vorontsov, A.; Zykova, A.; Gurianov, D.; Shamarin, N.; Panfilov, A.; Chumaevskii, A.; Kalashnikov, K.; Kolubaev, E.; Savchenko, N. Mechanical Properties of Dispersion-Strengthened Iron-Based W+WC(Ni) Composite Produced by Combined Wire Electron-Beam Manufacturing with Powder Addition. J. Compos. Sci. 2025, 9, 144. https://doi.org/10.3390/jcs9040144

Vorontsov A, Zykova A, Gurianov D, Shamarin N, Panfilov A, Chumaevskii A, Kalashnikov K, Kolubaev E, Savchenko N. Mechanical Properties of Dispersion-Strengthened Iron-Based W+WC(Ni) Composite Produced by Combined Wire Electron-Beam Manufacturing with Powder Addition. Journal of Composites Science. 2025; 9(4):144. https://doi.org/10.3390/jcs9040144

Chicago/Turabian StyleVorontsov, Andrey, Anna Zykova, Denis Gurianov, Nikolay Shamarin, Aleksandr Panfilov, Andrey Chumaevskii, Kirill Kalashnikov, Evgeny Kolubaev, and Nikolai Savchenko. 2025. "Mechanical Properties of Dispersion-Strengthened Iron-Based W+WC(Ni) Composite Produced by Combined Wire Electron-Beam Manufacturing with Powder Addition" Journal of Composites Science 9, no. 4: 144. https://doi.org/10.3390/jcs9040144

APA StyleVorontsov, A., Zykova, A., Gurianov, D., Shamarin, N., Panfilov, A., Chumaevskii, A., Kalashnikov, K., Kolubaev, E., & Savchenko, N. (2025). Mechanical Properties of Dispersion-Strengthened Iron-Based W+WC(Ni) Composite Produced by Combined Wire Electron-Beam Manufacturing with Powder Addition. Journal of Composites Science, 9(4), 144. https://doi.org/10.3390/jcs9040144