Low Poisson’s Ratio Measurement on Composites Based on DIC and Frequency Analysis on Tensile Tests

Abstract

1. Introduction

2. Fundamentals

2.1. Lock-In Filtering

2.2. Phase Motion Magnification

3. Methodology

3.1. Materials Studied

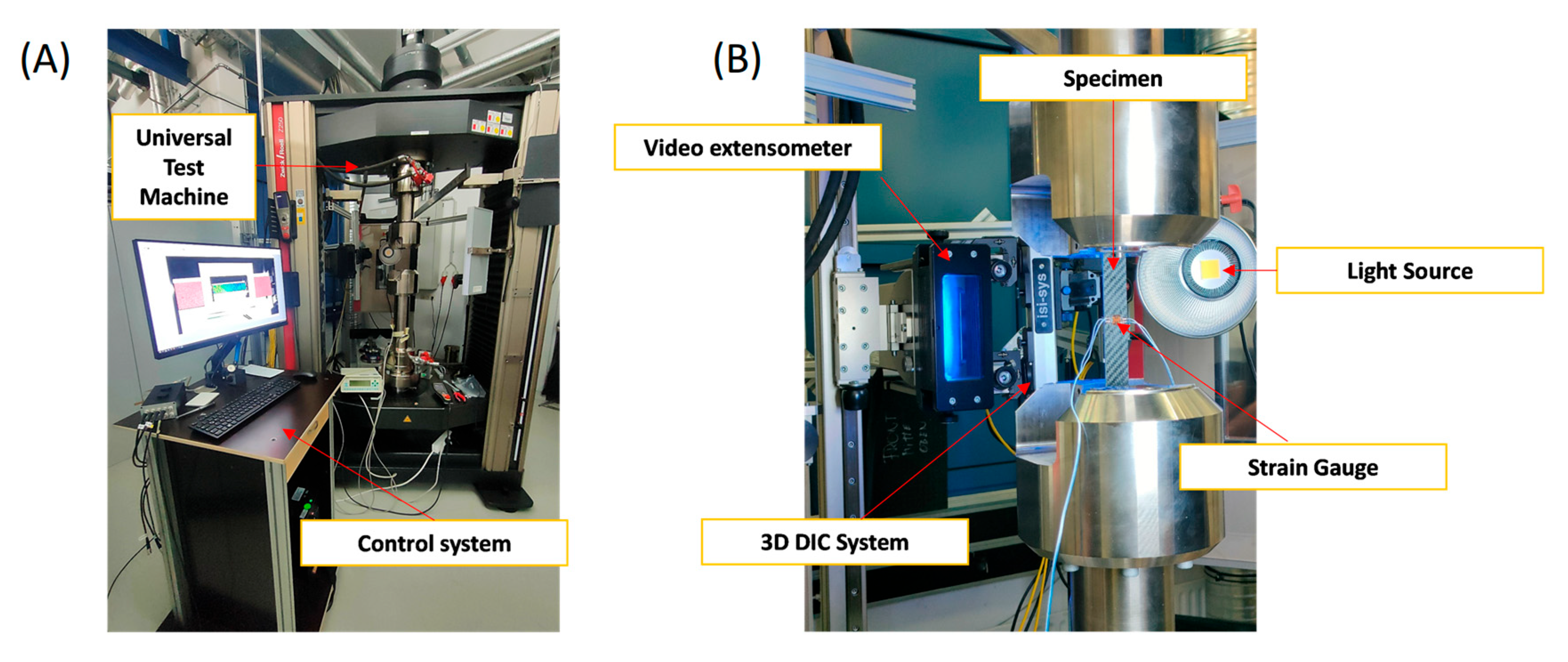

3.2. Experimental Procedure

3.3. Methodology for PBMM and Lock-In Analysis

4. Results

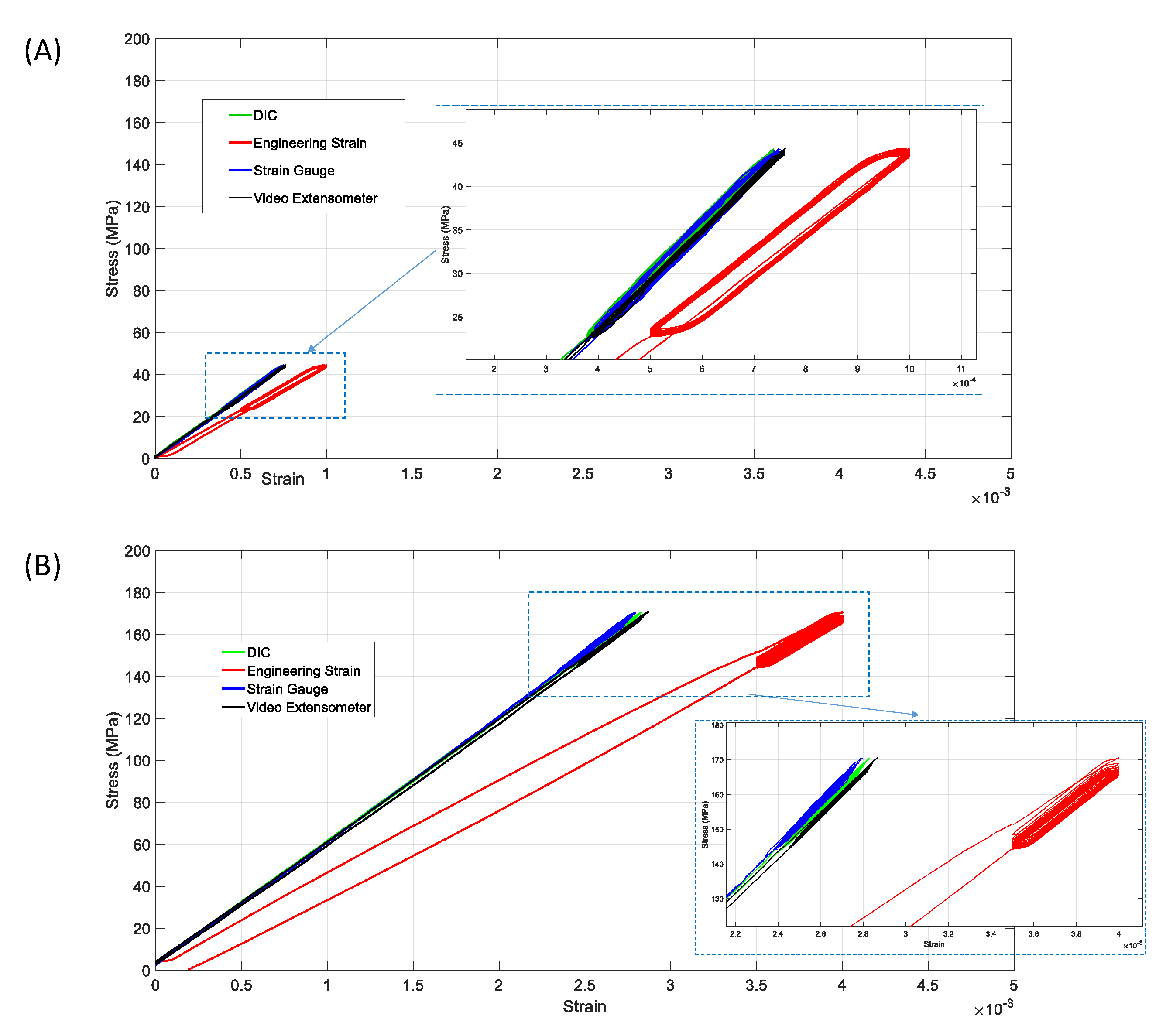

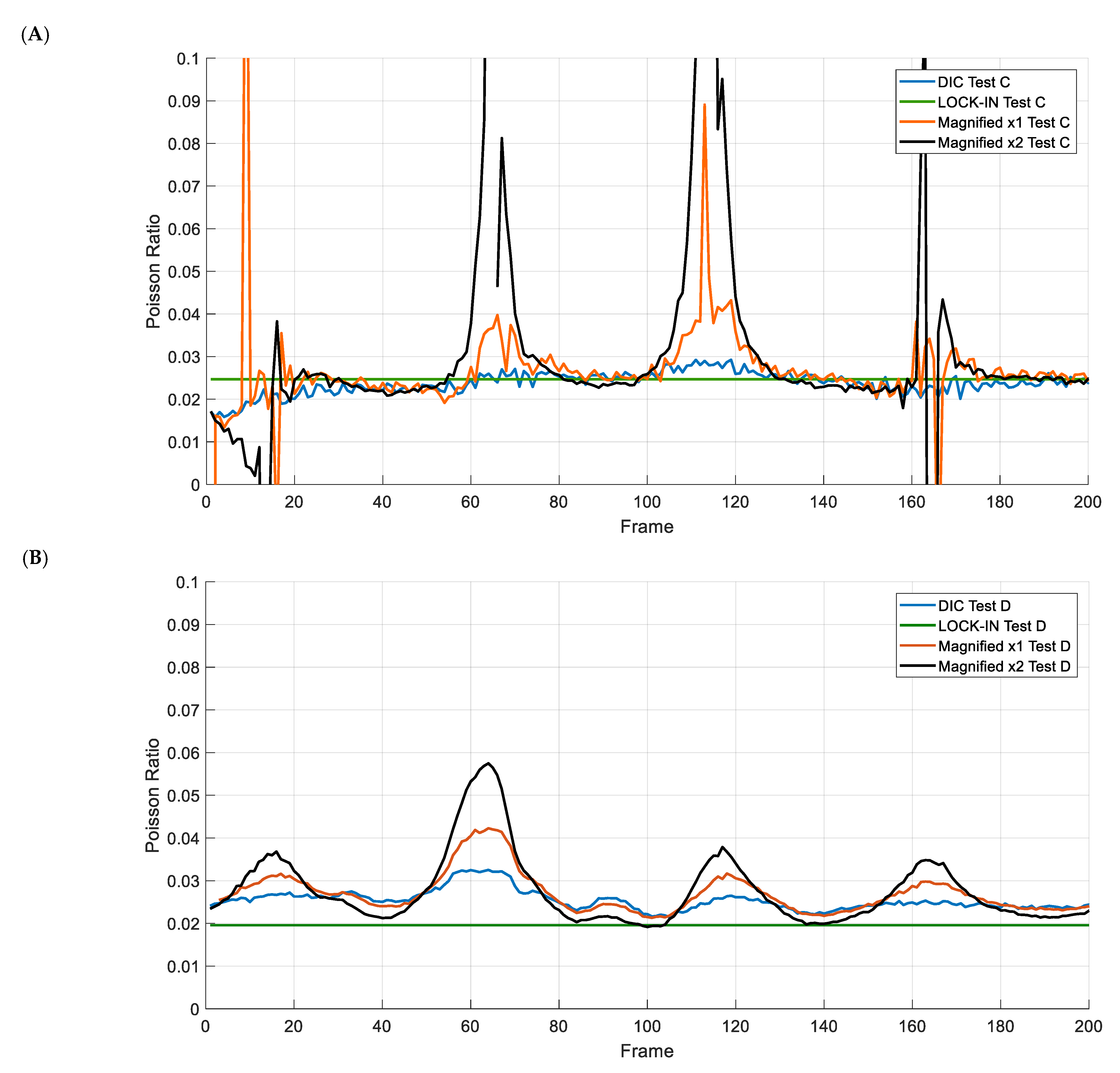

4.1. Results for GF-PA6 Material

4.2. Results for CF-PC Material

5. Conclusions

- It has uniquely employed frequency analysis techniques in conjunction with tensile testing for the precise determination of elastic properties, particularly at the challenging low strain ranges relevant to composite materials. This represents a significant methodological contribution to material characterization.

- While DIC + PBMM shows promise for magnifying subtle motions, its application for low Poisson’s ratio measurements presented notable challenges. The primary limitation arose when the low-amplitude strains, especially transverse strains, approached zero after magnification, leading to significant fluctuations and impossibly high (tending to infinity) Poisson’s ratio values. Furthermore, the computational time required for PBMM processing was considerable, making it less practical for routine analysis in this specific application.

- In contrast, the integration of DIC with Lock-in filtering emerged as a powerful and highly effective tool for accurately determining Poisson’s ratio. This methodology demonstrated no significant drawbacks and incurred negligible computational cost. It consistently provided a filtered and stable strain distribution, leading to more reliable Poisson’s ratio measurements, particularly at low strain amplitudes. In fact, the standard deviation of the measurements was reduced by up to 27.7% of the measurement of the original DIC measurements. The fidelity of Lock-in filtering, already well-established in other fields like Thermoelastic Stress Analysis (TSA) for detecting subtle periodic behaviors, is strongly supported by its successful application and performance in this study. This method offers a robust solution for capturing the elusive characteristics of low Poisson’s ratios in composites.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Pendleton, R.; Tuttle, M. Manual on Experimental Methods for Mechanical Testing of Composites; Society for Experimental Mechanic: London, UK, 1989. [Google Scholar]

- Parveez, B.; Kittur, M.I.; Badruddin, I.A.; Kamangar, S.; Hussien, M.; Umarfarooq, M.A. Scientific Advancements in Composite Materials for Aircraft Applications: A Review. Polymers 2022, 14, 5007. [Google Scholar] [CrossRef]

- Kamarudin, S.H.; Mohd Basri, M.S.; Rayung, M.; Abu, F.; Ahmad, S.; Norizan, M.N.; Osman, S.; Sarifuddin, N.; Desa, M.S.Z.M.; Abdullah, U.H.; et al. A Review on Natural Fiber Reinforced Polymer Composites (NFRPC) for Sustainable Industrial Applications. Polymers 2022, 14, 3698. [Google Scholar] [CrossRef]

- Harussani, M.M.; Sapuan, S.M.; Nadeem, G.; Rafin, T.; Kirubaanand, W. Recent Applications of Carbon-Based Composites in Defence Industry: A Review. Def. Technol. 2022, 18, 1281–1300. [Google Scholar] [CrossRef]

- Xu, D.; Cerbu, C.; Wang, H.; Rosca, I.C. Analysis of the Hybrid Composite Materials Reinforced with Natural Fibers Considering Digital Image Correlation (DIC) Measurements. Mech. Mater. 2019, 135, 46–56. [Google Scholar] [CrossRef]

- Shen, H.S.; Xiang, Y.; Reddy, J.N. Assessment of the Effect of Negative Poisson’s Ratio on the Thermal Postbuckling of Temperature Dependent FG-GRMMC Laminated Cylindrical Shells. Comput. Methods Appl. Mech. Eng. 2021, 376, 113664. [Google Scholar] [CrossRef]

- Mentrasti, L.; Molari, L.; Fabiani, M. Poisson’s Ratio Bounds in Orthotropic Materials. Application to Natural Composites: Wood, Bamboo and Arundo Donax. Compos. Part B Eng. 2021, 209, 108612. [Google Scholar] [CrossRef]

- Lempriere, B.M. Poisson’s Ratio in Orthotropic Materials. AIAA J. 1968, 6, 2226–2227. [Google Scholar] [CrossRef]

- Greaves, G.N.; Greer, A.L.; Lakes, R.S.; Rouxel, T. Poisson’s Ratio and Modern Materials. Nat. Mater. 2011, 10, 823–837. [Google Scholar] [CrossRef]

- Orell, O.; Vuorinen, J.; Jokinen, J.; Kettunen, H.; Hytönen, P.; Turunen, J.; Kanerva, M. Characterization of Elastic Constants of Anisotropic Composites in Compression Using Digital Image Correlation. Compos. Struct. 2018, 185, 176–185. [Google Scholar] [CrossRef]

- Schreier, H.; Orteu, J.-J.; Sutton, M.A. Image Correlation for Shape, Motion and Deformation Measurements; Springer: Boston, MA, USA, 2009. [Google Scholar]

- Bassir, D.; Guessasma, S.; Zheng, Y.; Cai, Y.; Salzenstein, P. Composite Characterization Using Digital Image Correlation (DIC) Approach for Stress-Strain Prediction. AIP Conf. Proc. 2024, 3094, 230003. [Google Scholar]

- Merzkirch, M. Mechanical Characterization Using Digital Image Correlation; Springer Nature: Dordrecht, The Netherlands, 2022. [Google Scholar]

- Molina-Viedma, A.J.; Felipe-Sesé, L.; López-Alba, E.; Díaz, F. High Frequency Mode Shapes Characterisation Using Digital Image Correlation and Phase-Based Motion Magnification. Mech. Syst. Signal Process. 2018, 102, 245–261. [Google Scholar] [CrossRef]

- Xu, Y.X.; Juang, J.Y. Measurement of Nonlinear Poisson’s Ratio of Thermoplastic Polyurethanes under Cyclic Softening Using 2d Digital Image Correlation. Polymers 2021, 13, 1498. [Google Scholar] [CrossRef]

- Ranjan, R.; Murthy, H. 3D-DIC for Mechanical Characterization of Composite Solid Propellant under Uniaxial Compression. Propellants Explos. Pyrotech. 2024, 49, 1–10. [Google Scholar] [CrossRef]

- Choi, J.Y.; Yanamandra, K.; Shetty, A.; Gupta, N. Simultaneous Measurement of Elastic Constants from Dynamic Mechanical Analysis with Digital Image Correlation. Polymer 2022, 242, 124562. [Google Scholar] [CrossRef]

- Fruehmann, R.K.; Dulieu-Barton, J.M.; Quinn, S.; Tyler, J.P. The Use of a Lock-in Amplifier to Apply Digital Image Correlation to Cyclically Loaded Components. Opt. Lasers Eng. 2015, 68, 149–159. [Google Scholar] [CrossRef]

- Wadhwa, N.; Rubinstein, M.; Durand, F.; Freeman, W.T. Phase-Based Video Motion Processing. ACM Trans. Graph. 2013, 32, 80. [Google Scholar] [CrossRef]

- Molina-Viedma, A.J.; Felipe-Sesé, L.; López-Alba, E.; Díaz, F.A. Comparison of Lock-in Correlation and a Novel Periodogram Method for Experimental Multi-Harmonic Thermoelastic Analysis. Mech. Syst. Signal Process. 2022, 164, 108235. [Google Scholar] [CrossRef]

- Gdoutos, E.E. Thermoelastic Stress Analysis (TSA). In Experimental Mechanics; Solid Mechanics and Its Applications; Springer: Cham, Switzerland, 2022; pp. 261–267. [Google Scholar]

- Molina-Viedma, A.J.; Felipe-Sesé, L.; López-Alba, E.; Díaz, F.A. 3D Mode Shapes Characterisation Using Phase-Based Motion Magnification in Large Structures Using Stereoscopic DIC. Mech. Syst. Signal Process. 2018, 108, 140–155. [Google Scholar] [CrossRef]

- Felipe-Sesé, L.; Molina-Viedma, A.J.; Pastor-Cintas, M.; López-Alba, E.; Díaz, F.A. Exploiting Phase-Based Motion Magnification for the Measurement of Subtle 3D Deformation Maps with FP + 2D-DIC. Meas. J. Int. Meas. Confed. 2022, 195, 111122. [Google Scholar] [CrossRef]

- Scofield, J.H. Frequency-Domain Description of a Lock-in Amplifier. Am. J. Phys. 1994, 62, 129–133. [Google Scholar] [CrossRef]

- Sarrafi, A.; Mao, Z.; Niezrecki, C.; Poozesh, P. Vibration-Based Damage Detection in Wind Turbine Blades Using Phase-Based Motion Estimation and Motion Magnification. J. Sound Vib. 2018, 421, 300–318. [Google Scholar] [CrossRef]

- Wadhwa, N.; Wu, H.Y.; Davis, A.; Rubinstein, M.; Shih, E.; Mysore, G.J.; Chen, J.G.; Buyukozturk, O.; Guttag, J.V.; Freeman, W.T.; et al. Eulerian Video Magnification and Analysis. Commun. ACM 2017, 60, 87–95. [Google Scholar] [CrossRef]

- DIN EN ISO 527-4; Plastics—Determination of Tensile Properties—Part 4: Test Conditions for Isotropic and Orthotropic Fibre-reinforced Plastic Composites. DIN Deutsches Institut für Normung e.V.: Berlin, Germany, 2023.

| Strain Gauge | DIC | DIC + PBMM | DIC + Lock-In | ||||

|---|---|---|---|---|---|---|---|

| Average | Average | STD | Average | STD | Average | STD | |

| Test A | 0.0307 | 0.0528 | 0.0668 | 0.1423 | 0.415 | 0.0479 | 0.0225 |

| Test B | 0.0373 | 0.0456 | 0.0391 | 0.0444 | 0.0302 | 0.0346 | 0.0210 |

| Average | 0.0333 | 0.0493 | 0.0530 | 0.0471 | 0.216 | 0.0433 | 0.01275 |

| DIC | DIC + PBMM ×2 | DIC + PBMM ×1 | DIC + Lock-In | |||||

|---|---|---|---|---|---|---|---|---|

| Average | STD | Average | STD | Average | STD | Average | STD | |

| Test C | 0.0237 | 0.0231 | 0.0286 | 0.6806 | 0.0173 | 0.4483 | 0.0247 | 0.0036 |

| Test D | 0.0254 | 0.0097 | 0.0277 | 0.0235 | 0.0190 | 0.1012 | 0.0196 | 0.0055 |

| Average | 0.0246 | 0.0164 | 0.0282 | 0.352 | 0.0182 | 0.275 | 0.0217 | 0.00455 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Felipe-Sesé, L.; Kenf, A.; Schmeer, S.; López-Alba, E.; Díaz, F.A. Low Poisson’s Ratio Measurement on Composites Based on DIC and Frequency Analysis on Tensile Tests. J. Compos. Sci. 2025, 9, 570. https://doi.org/10.3390/jcs9100570

Felipe-Sesé L, Kenf A, Schmeer S, López-Alba E, Díaz FA. Low Poisson’s Ratio Measurement on Composites Based on DIC and Frequency Analysis on Tensile Tests. Journal of Composites Science. 2025; 9(10):570. https://doi.org/10.3390/jcs9100570

Chicago/Turabian StyleFelipe-Sesé, Luis, Andreas Kenf, Sebastian Schmeer, Elías López-Alba, and Francisco Alberto Díaz. 2025. "Low Poisson’s Ratio Measurement on Composites Based on DIC and Frequency Analysis on Tensile Tests" Journal of Composites Science 9, no. 10: 570. https://doi.org/10.3390/jcs9100570

APA StyleFelipe-Sesé, L., Kenf, A., Schmeer, S., López-Alba, E., & Díaz, F. A. (2025). Low Poisson’s Ratio Measurement on Composites Based on DIC and Frequency Analysis on Tensile Tests. Journal of Composites Science, 9(10), 570. https://doi.org/10.3390/jcs9100570