Fatigue Damage Suppression by Ply Curving Termination in Covered Composite Ply Drop-Off

Abstract

1. Introduction

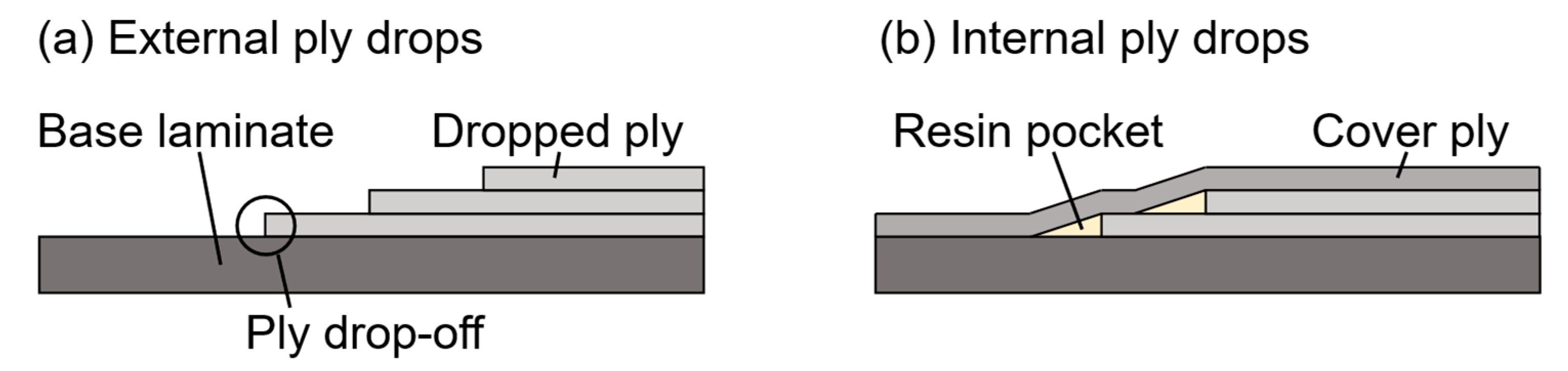

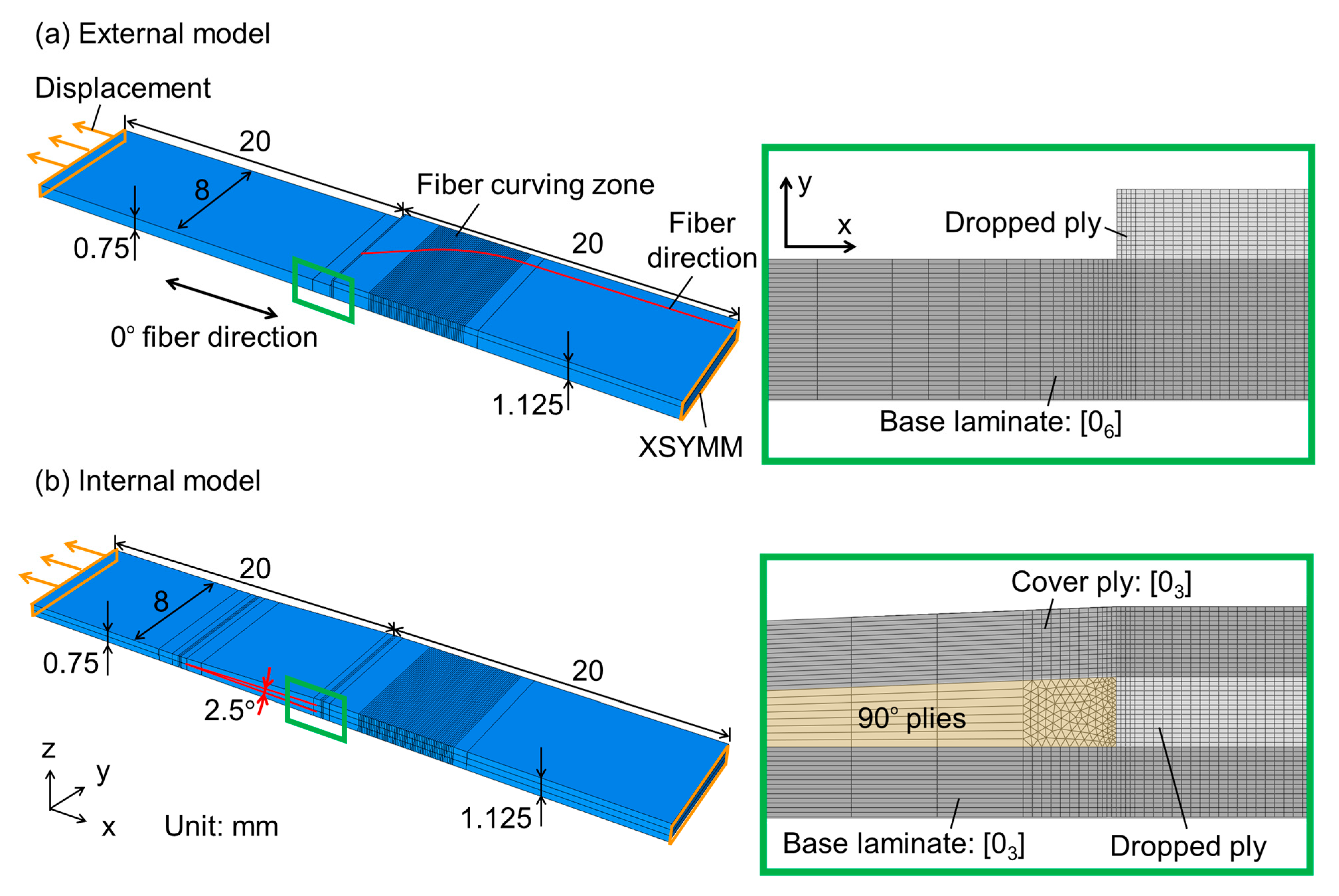

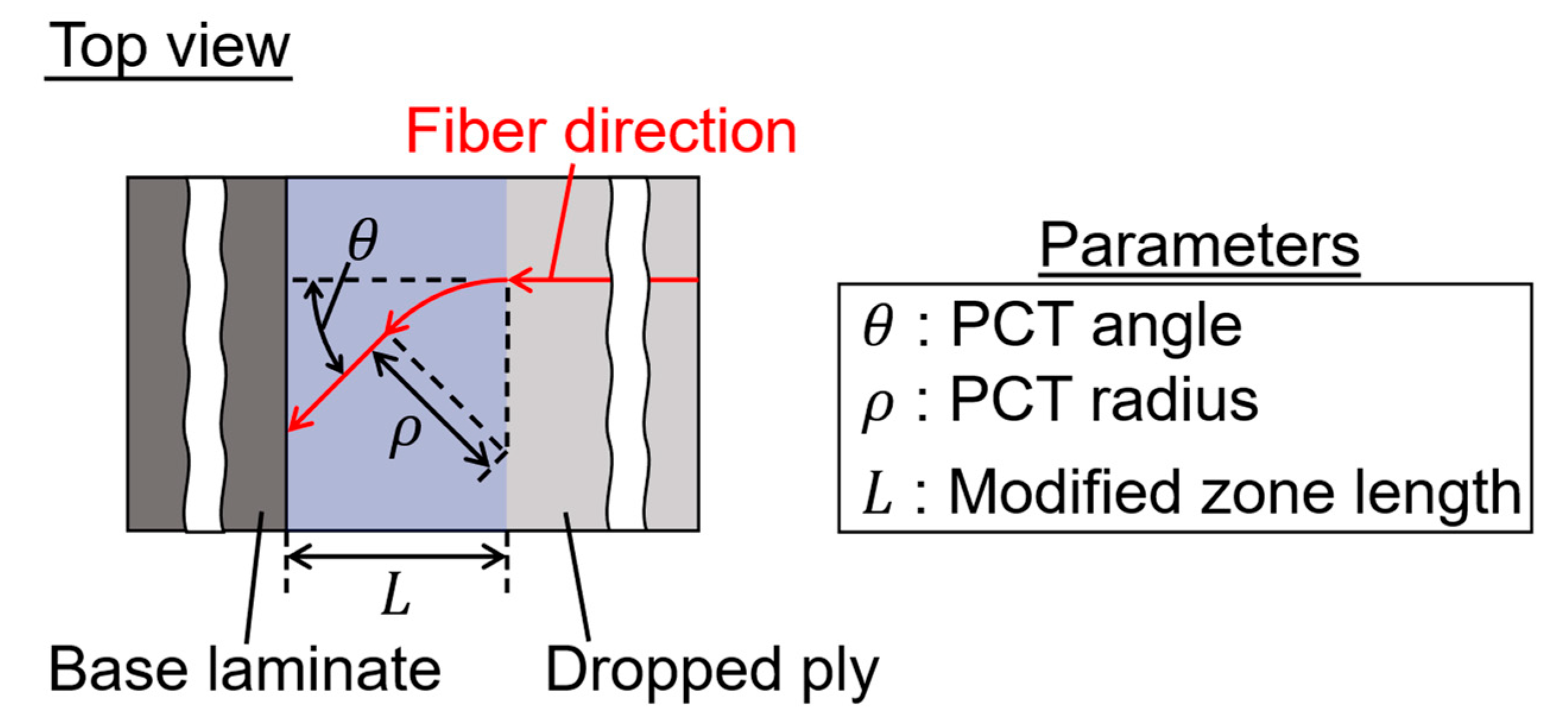

2. Finite Element Analysis

2.1. Finite Element Model

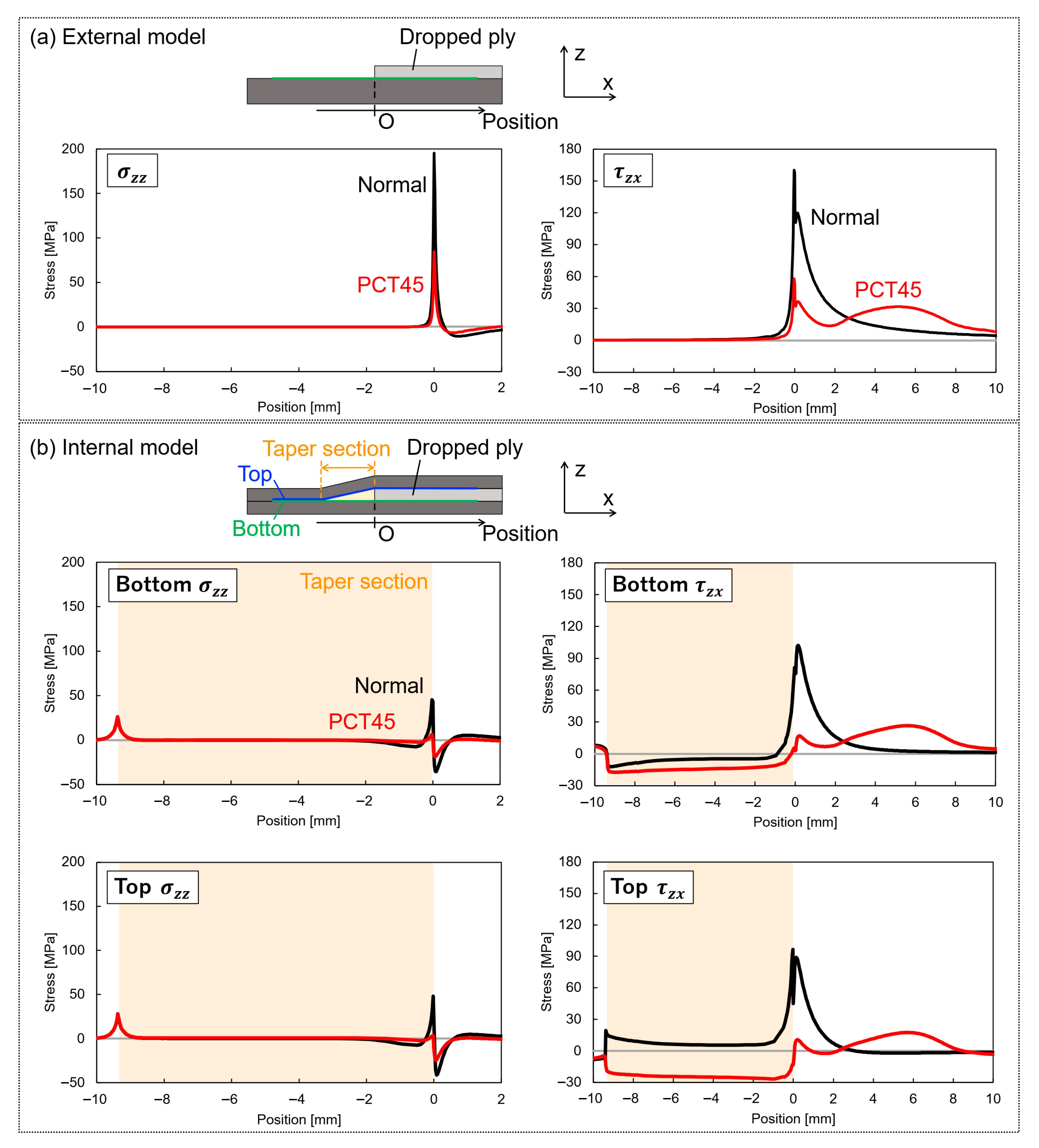

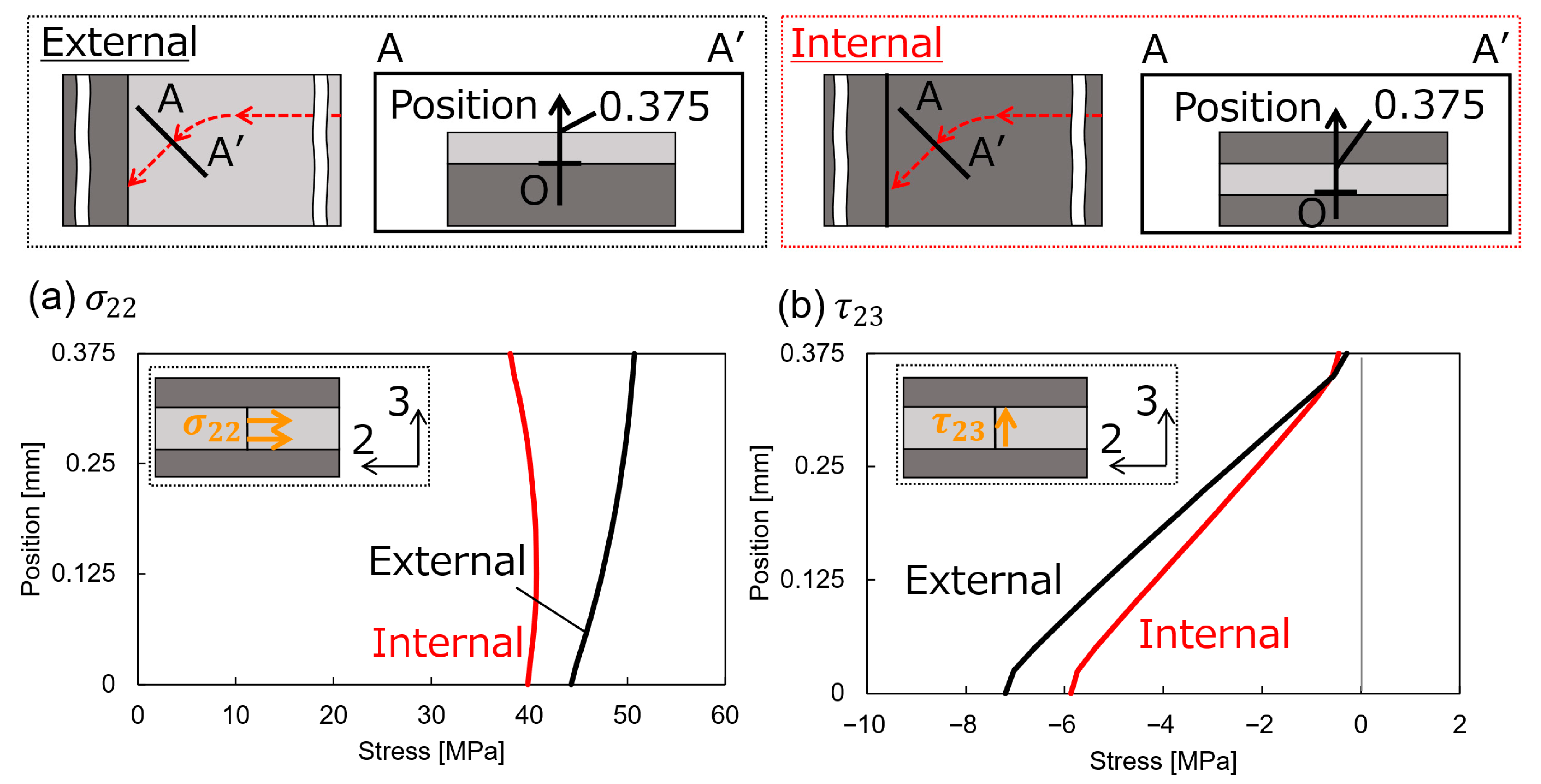

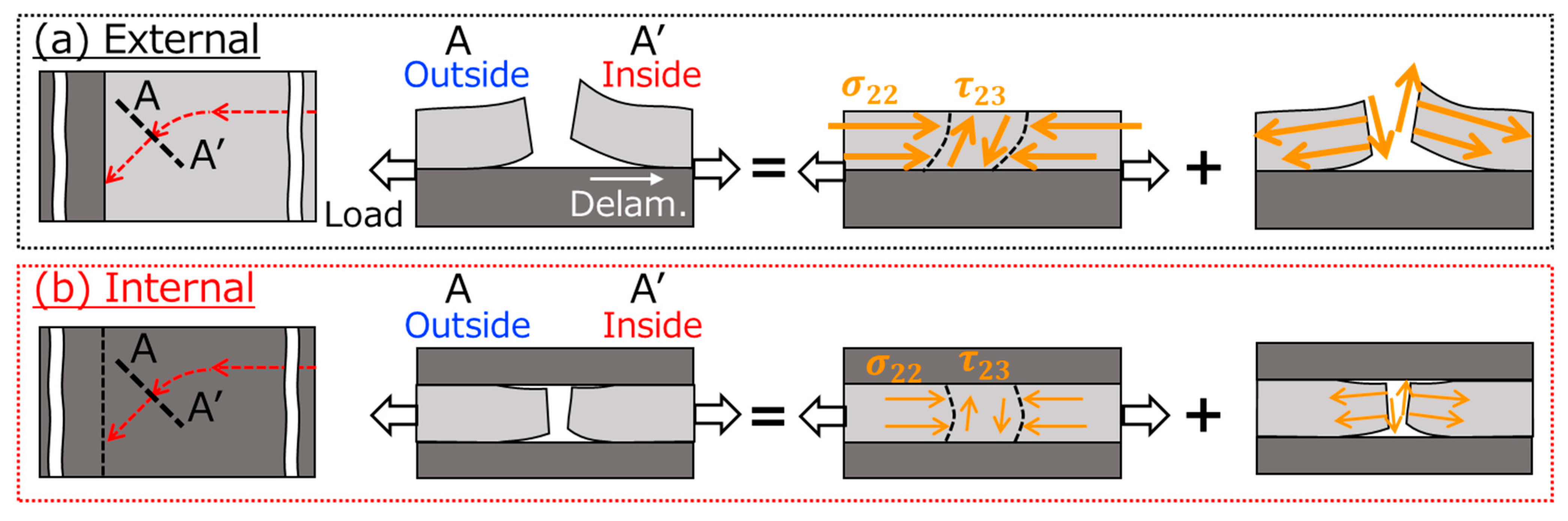

2.2. Results

3. Tensile Fatigue Test

3.1. Materials and Methods

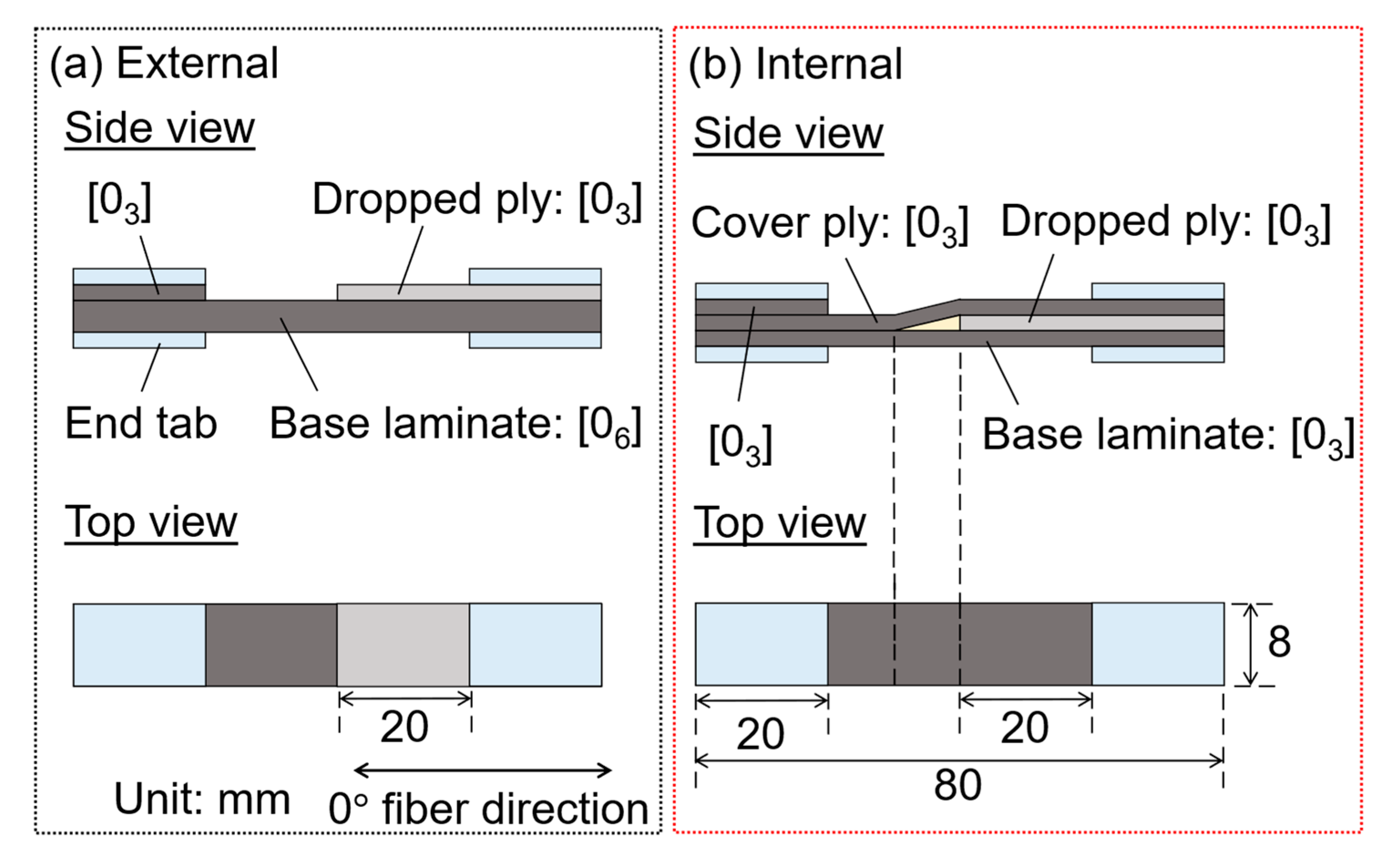

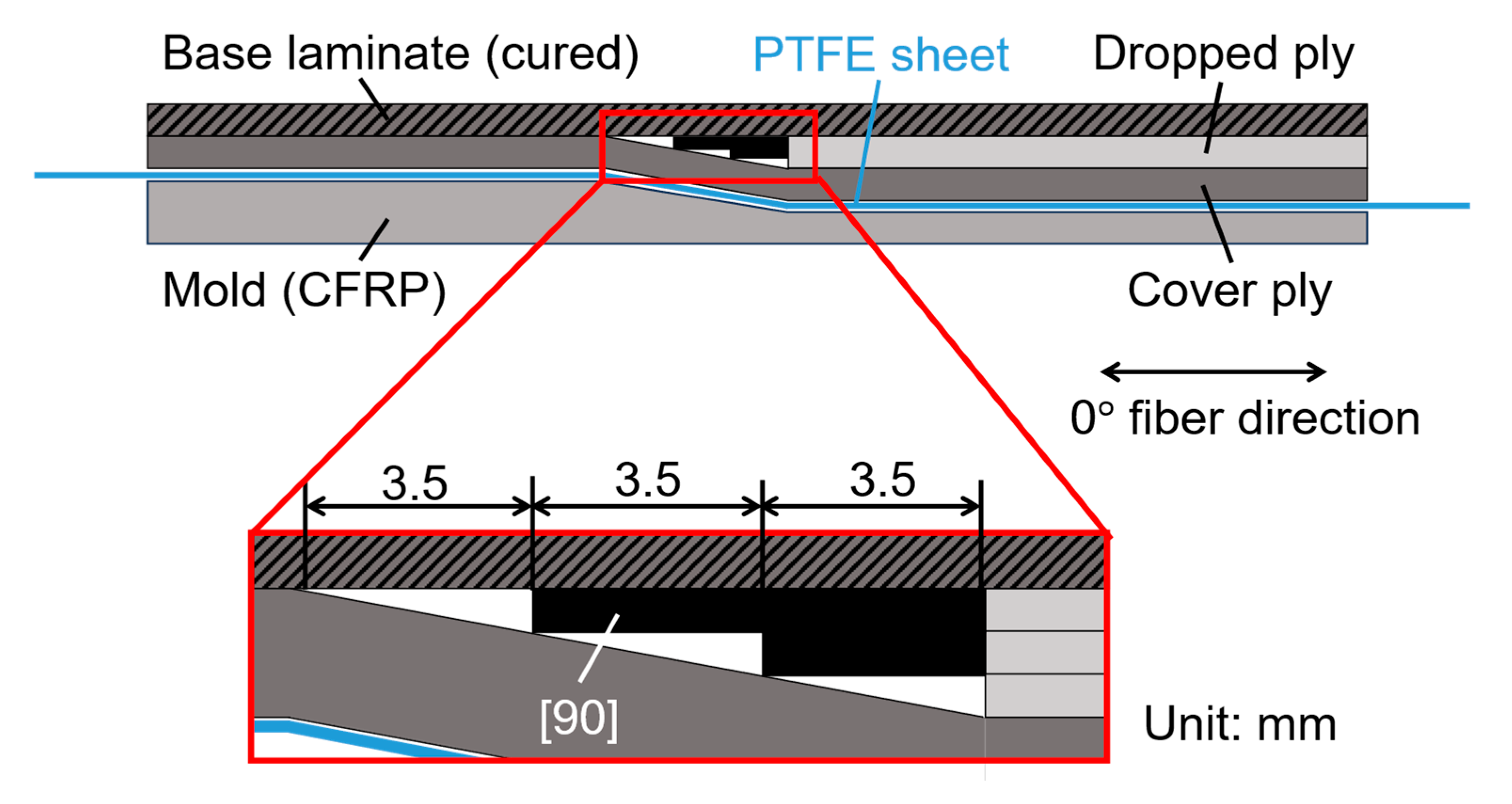

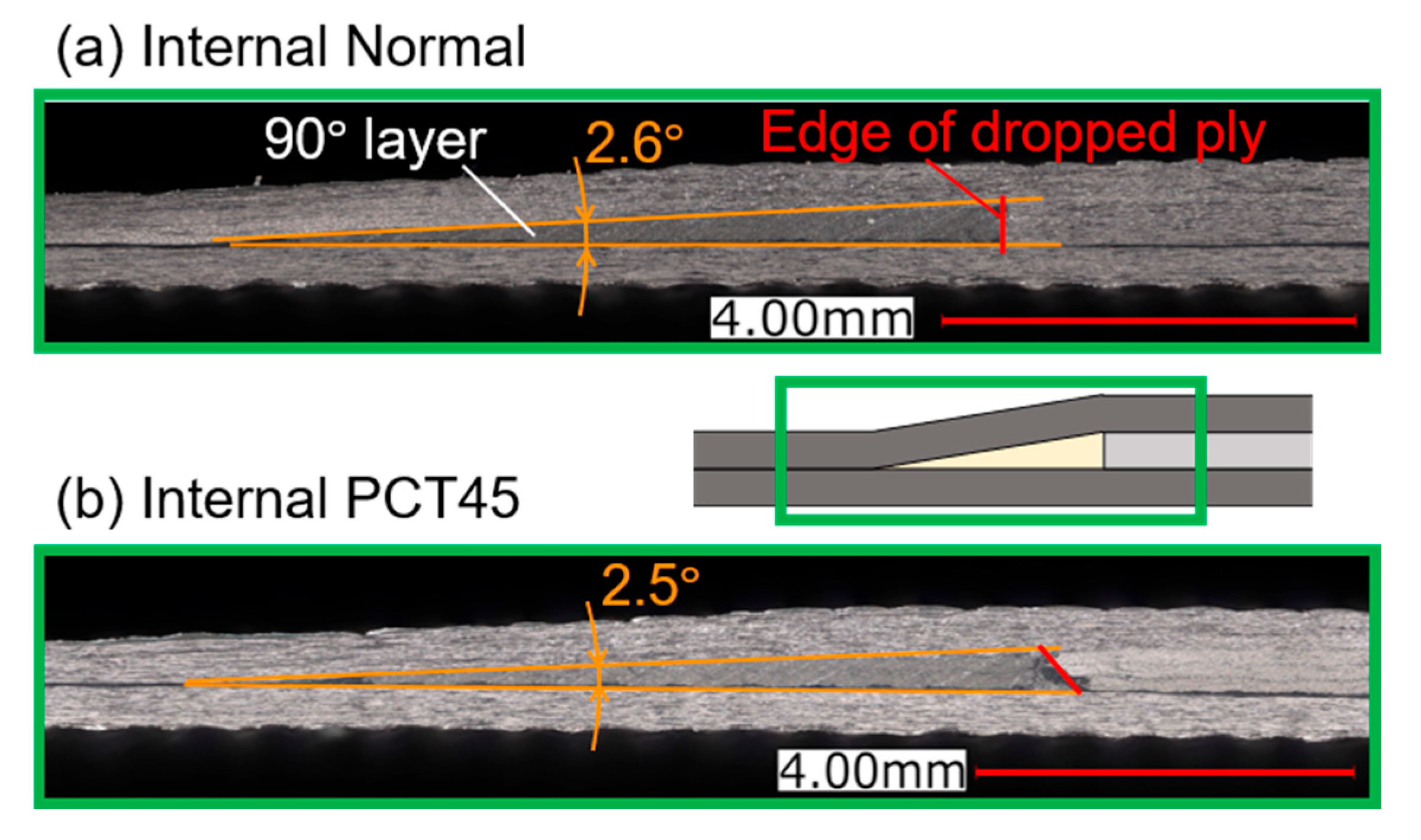

3.1.1. Specimen Preparation

3.1.2. Test Method

3.2. Results and Discussions

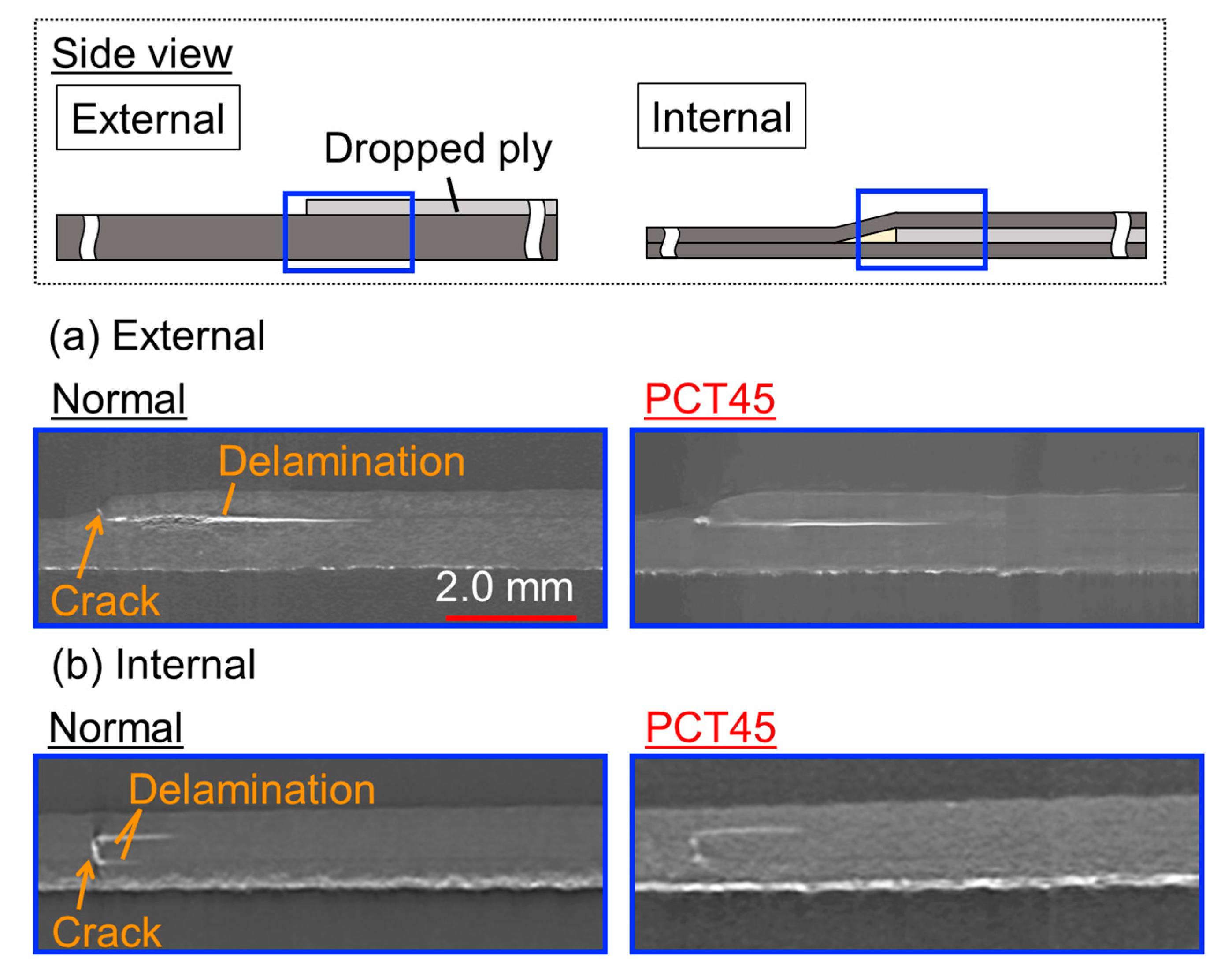

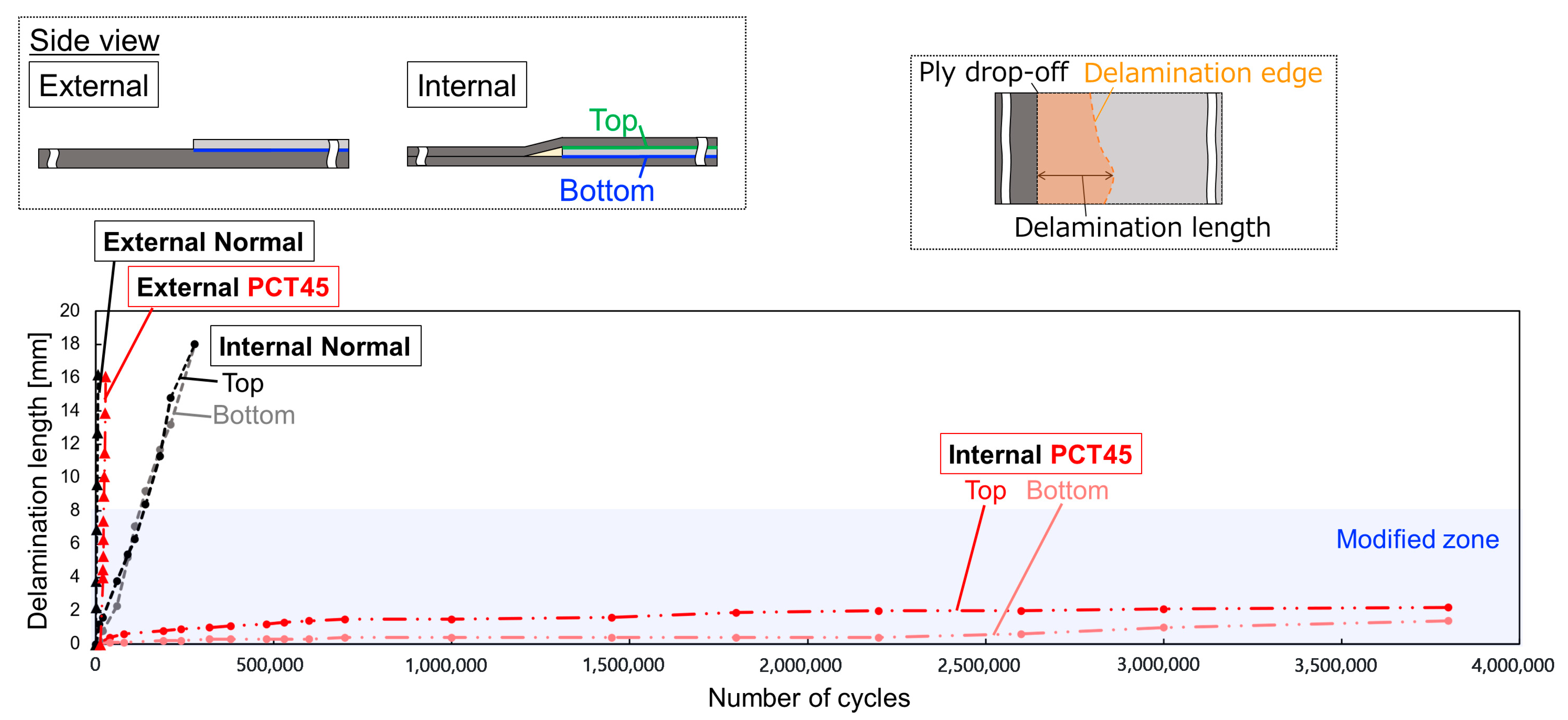

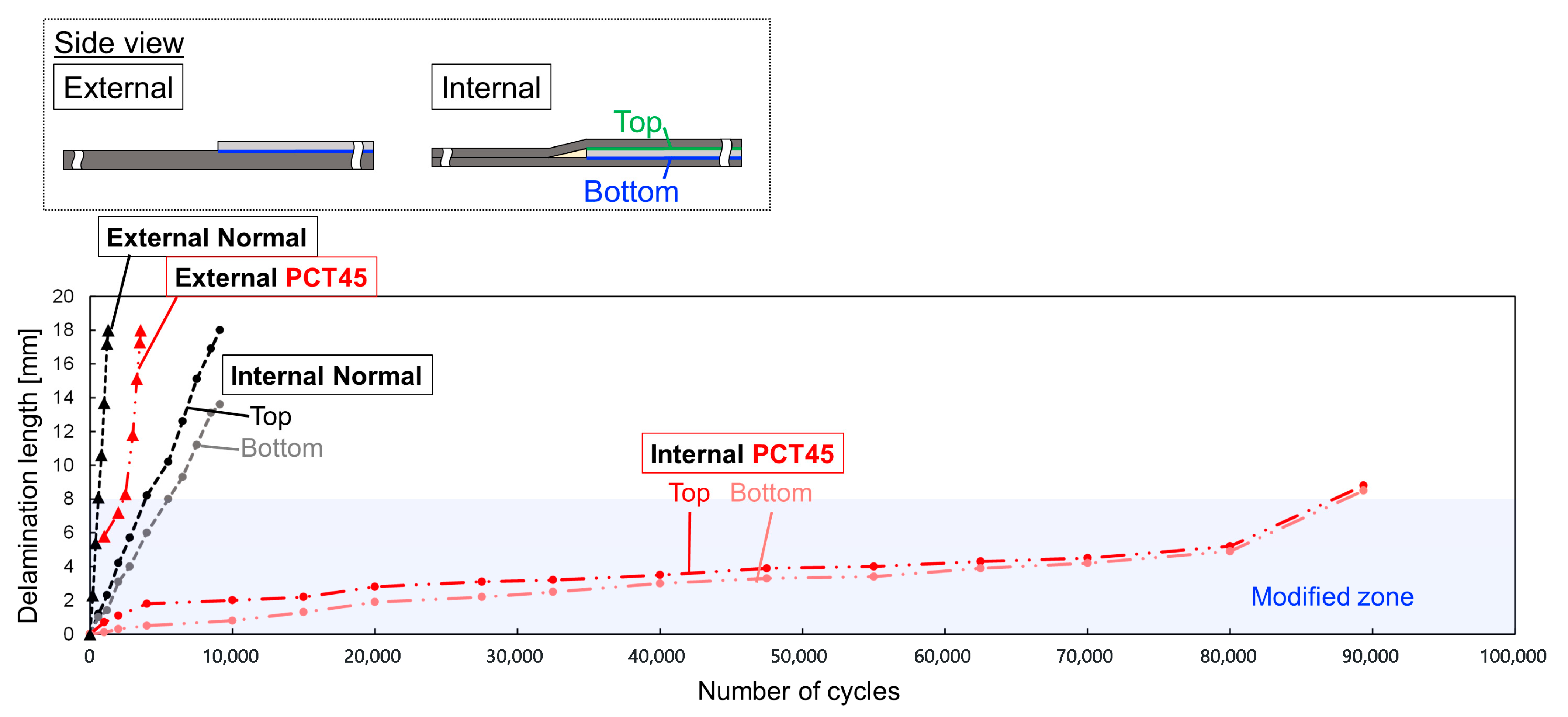

3.2.1. Low Loading Condition (Maximum Stress 680 MPa, Maximum Strain 0.5%)

3.2.2. High Loading Condition (Maximum Stress 1190 MPa, Maximum Strain 0.9%)

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Murri, G.; Schaff, J. Fatigue life methodology for tapered hybrid composite flexbeams. Compos. Sci. Technol. 2006, 66, 499–508. [Google Scholar] [CrossRef]

- Wisnom, M.R.; Dixon, R.; Hill, G. Delamination in asymmetrically tapered composites loaded in tension. Compos. Struct. 1996, 35, 309–322. [Google Scholar] [CrossRef]

- Zhang, B.; Kawashita, L.F.; Jones, M.I.; Lander, J.K.; Hallett, S.R. An experimental and numerical investigation into damage mechanisms in tapered laminates under tensile loading. Compos. Part A Appl. Sci. Manuf. 2020, 133, 105862. [Google Scholar] [CrossRef]

- Allegri, G.; Wisnom, M.R.; Hallett, S.R. A simplified approach to the damage tolerance design of asymmetric tapered laminates. Part I: Methodology development. Compos. Part A Appl. Sci. Manuf. 2010, 41, 1388–1394. [Google Scholar] [CrossRef]

- Wisnom, M.R.; Jones, M.I.; Cui, W. Delamination in composites with terminating internal plies under tension fatigue loading. Compos. Mater. Fatigue Fract. 1995, 5, 486–508. [Google Scholar]

- He, K.; Hoa, S.; Ganesan, R. The study of tapered laminated composite structures: A review. Compos. Sci. Technol. 2000, 60, 2643–2657. [Google Scholar] [CrossRef]

- Vidyashankar, B.; Murty, A.K. Analysis of laminates with ply drops. Compos. Sci. Technol. 2001, 61, 749–758. [Google Scholar] [CrossRef]

- Cui, W.; Wisnom, M.R.; Jones, M. Effect of step spacing on delamination of tapered laminates. Compos. Sci. Technol. 1994, 52, 39–46. [Google Scholar] [CrossRef]

- Fikry, M.J.M.; Iizuka, K.; Nakatani, H.; Yoneyama, S.; Vinogradov, V.; Koyanagi, J.; Ogihara, S. Suppression of Delamination in CFRP Laminates with Ply Discontinuity Using Polyamide Mesh. J. Compos. Sci. 2025, 9, 414. [Google Scholar] [CrossRef]

- Fikry, M.J.M.; Terashi, N.; Koizumi, K.; Ogihara, S. Inhibition of interlaminar damage in CFRP laminates by inserting non-woven carbon fiber interlaminar reinforced tissue. Adv. Compos. Mater. 2024, 34, 513–533. [Google Scholar] [CrossRef]

- Lu, X.; Higuchi, R.; Hua, X.; Nagashima, T.; Yokozeki, T. Experimental and numerical study on failure mechanisms of tapered laminates: Effects of ply thickness and taper ratio. Compos. Sci. Technol. 2024, 256, 110784. [Google Scholar] [CrossRef]

- Ohashi, N.; Minakuchi, S. Effect of ply curving termination geometry on fracture behavior and tensile strength of composite ply drop-off. Adv. Compos. Mater. 2025, 1–20. [Google Scholar] [CrossRef]

- Obata, S.; Takahashi, K.; Inaba, K. Laminate design for a tapered FRP structure with ply drop-off based on yielding of resin pockets. Compos. Struct. 2020, 253, 112787. [Google Scholar] [CrossRef]

- Ergin, F.; Kayran, A. Investigation of Variable Taper Angle Design in Highly Tapered Laminates for Delaying Delamination. Compos. Struct. 2025, 357, 118918. [Google Scholar] [CrossRef]

- Fish, J.C.; Vizzini, A.J. Tailoring concepts for improved structural performance of rotorcraft flexbeams. Compos. Eng. 1992, 2, 303–312. [Google Scholar] [CrossRef]

- Llanos, A.S.; Vizzini, A.J. The effect of film adhesive on the delamination strength of tapered composites. J. Compos. Mater. 1992, 26, 1968–1983. [Google Scholar] [CrossRef]

- Cairns, D.S.; Mandell, J.F.; Scott, M.E.; Maccagnano, J.Z. Design Considerations for Ply Drops in Composite Structures. In Proceedings of the 11th International Conference on Composite Materials, Gold Coast, Australia, 14–18 July 1997. [Google Scholar]

- Hua, X.; Higuchi, R.; Yokozeki, T. Enhancement of tensile strength of tapered laminates by utilizing thin-ply composites. Compos. Part B Eng. 2023, 248, 110372. [Google Scholar] [CrossRef]

- Helmy, S.; Hoa, S.V. Tensile fatigue behavior of tapered glass fiber reinforced epoxy composites containing nanoclay. Compos. Sci. Technol. 2014, 102, 10–19. [Google Scholar] [CrossRef]

- Khan, B.; Potter, K.; Wisnom, M.R. Suppression of delamination at ply drops in tapered composites by ply chamfering. J. Compos. Mater. 2006, 40, 157–174. [Google Scholar] [CrossRef]

- Gordon, T.; Xu, X.; Wisnom, M.R.; Kim, B.C. Novel tape termination method for automated fibre placement: Cutting characteristics and delamination suppression. Compos. Part A Appl. Sci. Manuf. 2020, 137, 106023. [Google Scholar] [CrossRef]

- Gordon, T.; Xu, X.; Kawashita, L.; Wisnom, M.R.; Hallett, S.R.; Kim, B.C. Delamination suppression in tapered unidirectional laminates with multiple ply drops using a tape scarfing technique. Compos. Part A Appl. Sci. Manuf. 2021, 150, 106627. [Google Scholar] [CrossRef]

- Gordon, T.; Xu, X.; Wisnom, M.R.; Hallett, S.R.; Kim, B.C. Improved impact damage resistance of tapered composite laminates using a ply scarfing technique. Compos. Part A Appl. Sci. Manuf. 2023, 166, 107391. [Google Scholar] [CrossRef]

- Gordon, T.; Wisnom, M.R.; Kim, B.C. Suppression of compression induced delamination in tapered laminated composites using a ply scarfing method. Compos. Part A Appl. Sci. Manuf. 2024, 176, 107870. [Google Scholar] [CrossRef]

- Minakuchi, S.; Takeda, N. Ply Curving Termination: Suppressing Delamination in Tapered Composites. In Proceedings of the 22nd International Conference on Composite Materials, Melbourne, Australia, 11–16 August 2019. [Google Scholar]

- Ohashi, N.; Yoshida, T.; Minakuchi, S. Ply curving termination for enhancing tensile strength of composite ply drop-off: Static evaluation and failure mechanism. Adv. Compos. Mater. 2025, 34, 307–328. [Google Scholar] [CrossRef]

- Wisnom, M.R.; Jones, M.I.; Cui, W. Failure of tapered composites under static and fatigue tension loading. AIAA J. 1995, 33, 911–918. [Google Scholar] [CrossRef]

- Goutianos, S.; Sørensen, B.F. Fatigue crack growth rate at material and geometry transitions in glass-epoxy composites. Compos. Struct. 2021, 275, 114445. [Google Scholar] [CrossRef]

- Thawre, M.M.; Verma, K.K.; Jagannathan, N.; Peshwe, D.R.; Paretkar, R.K.; Manjunatha, C.M. Effect of ply-drop on fatigue life of a carbon fiber composite under a fighter aircraft spectrum load sequence. Compos. Part B Eng. 2016, 86, 120–125. [Google Scholar] [CrossRef]

- Yoshida, T.; Minakuchi, S. Improving fatigue characteristics of ply drop-off in composite laminate with ply curving termination. Adv. Compos. Mater. 2024, 33, 1209–1223. [Google Scholar] [CrossRef]

- Hisada, S.; Minakuchi, S.; Takeda, N. Damage tolerance improvement of composite T-joint under pull-up conditions using an interlocking-fiber-based crack arrester. Compos. Struct. 2020, 253, 112792. [Google Scholar] [CrossRef]

- Varkonyi, B.; Belnoue, J.P.H.; Kratz, J.; Hallett, S.R. Predicting consolidation-induced wrinkles and their effects on composites structural performance. Int. J. Mater. Form. 2020, 13, 907–921. [Google Scholar] [CrossRef]

| Elastic Moduli [GPa] | Poisson’s Ratio | ||||

|---|---|---|---|---|---|

| E11 | E22 = E33 | G12 = G13 | G23 | 12 =13 | 23 |

| 135 | 8.5 | 4.8 | 2.7 | 0.34 | 0.49 |

| External Normal | External PCT45 | Internal Normal | Internal PCT45 | |

|---|---|---|---|---|

| Initial damage cycles | 200 | 2400 | 100 | 5000 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yoshida, T.; Minakuchi, S. Fatigue Damage Suppression by Ply Curving Termination in Covered Composite Ply Drop-Off. J. Compos. Sci. 2025, 9, 523. https://doi.org/10.3390/jcs9100523

Yoshida T, Minakuchi S. Fatigue Damage Suppression by Ply Curving Termination in Covered Composite Ply Drop-Off. Journal of Composites Science. 2025; 9(10):523. https://doi.org/10.3390/jcs9100523

Chicago/Turabian StyleYoshida, Takumu, and Shu Minakuchi. 2025. "Fatigue Damage Suppression by Ply Curving Termination in Covered Composite Ply Drop-Off" Journal of Composites Science 9, no. 10: 523. https://doi.org/10.3390/jcs9100523

APA StyleYoshida, T., & Minakuchi, S. (2025). Fatigue Damage Suppression by Ply Curving Termination in Covered Composite Ply Drop-Off. Journal of Composites Science, 9(10), 523. https://doi.org/10.3390/jcs9100523