Pultrusion and Vitrimer Composites: Emerging Pathways for Sustainable Structural Materials

Abstract

1. Introduction

1.1. Overview of Composite Materials

1.2. Introduction to Vitrimers

1.3. Manufacturing of Polymer Composites

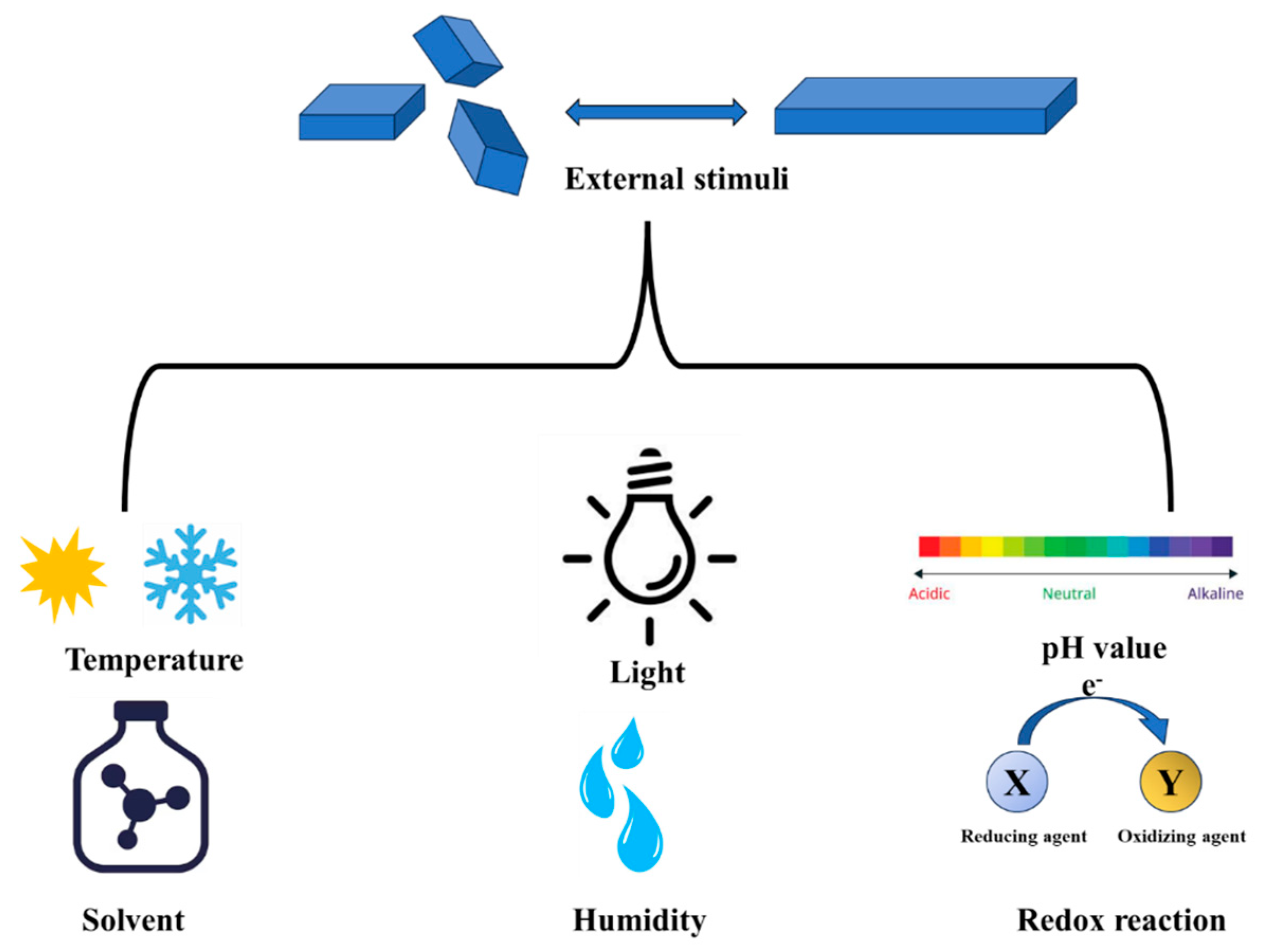

1.4. Pultrusion Process: Overview

2. Pultrusion Process

2.1. Preparation of Resin

2.2. Impregnation of Fiber

2.3. Curing Process and Die Shaping

2.4. Pulling and Cutting of the Prepared Sample

3. Factors Affecting the Quality of the Pultruded Product

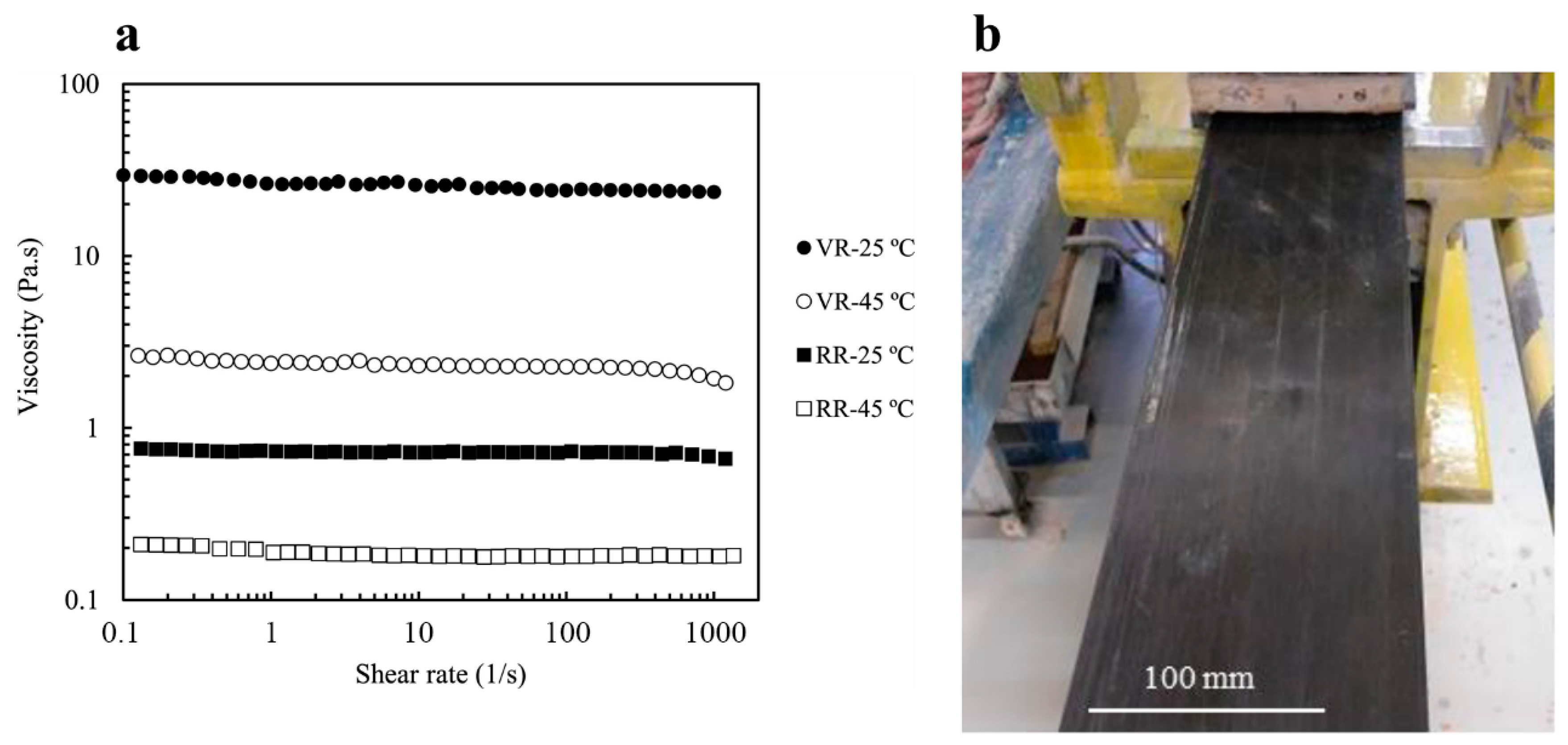

3.1. Type of Resin Used and Their Viscosity

3.2. Type of Fiber, Volume of Fiber, and Fiber Orientation

3.3. Die Geometry and Its Temperature

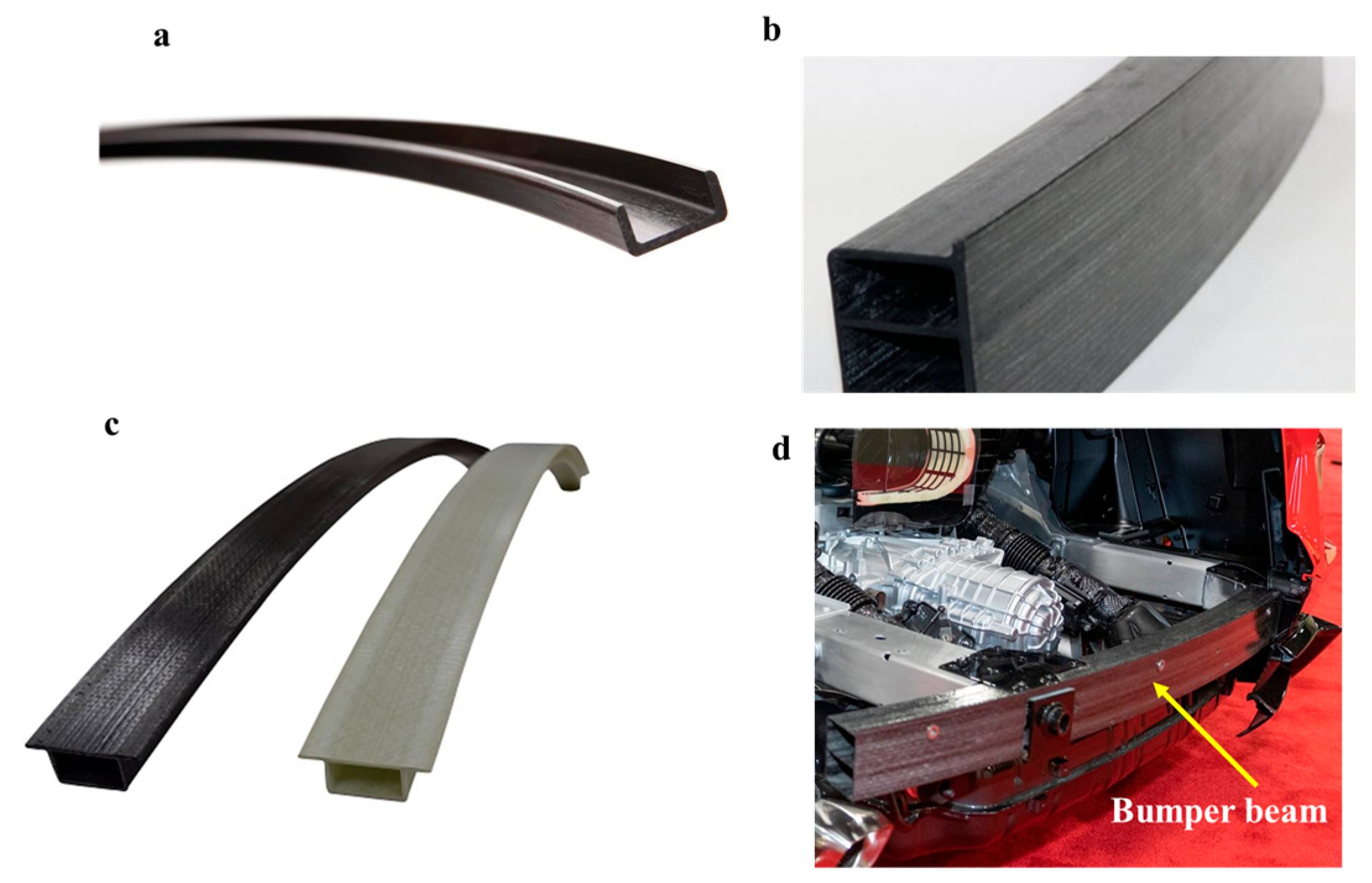

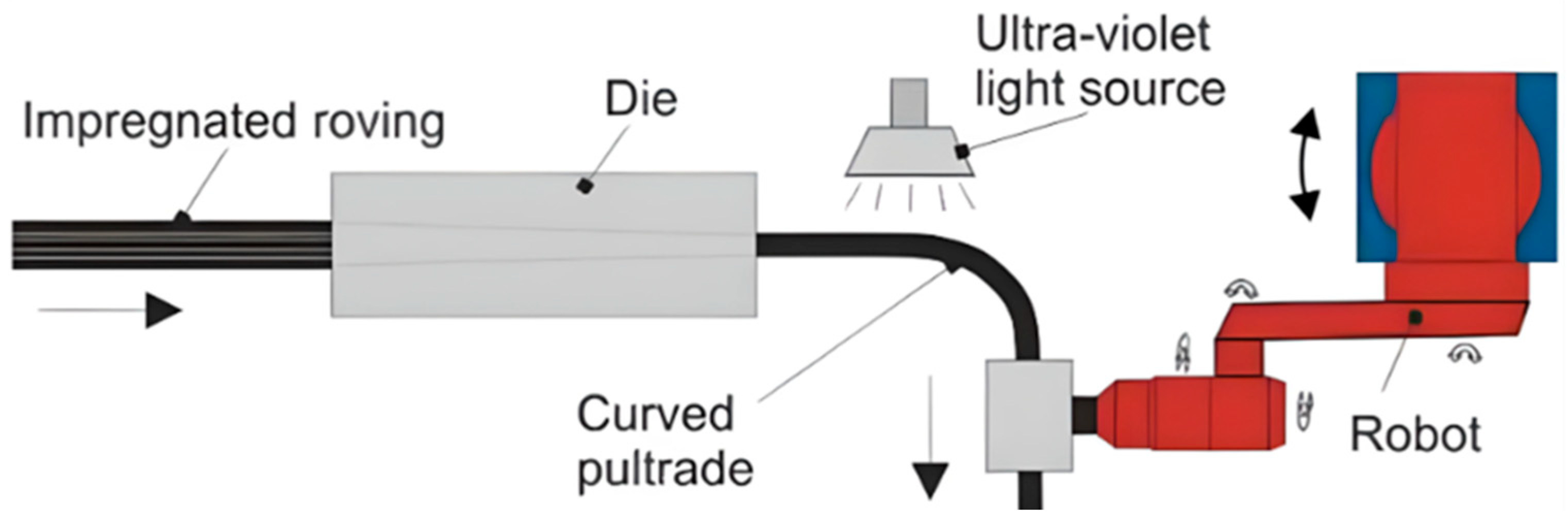

4. Pultrusion of Curved Components

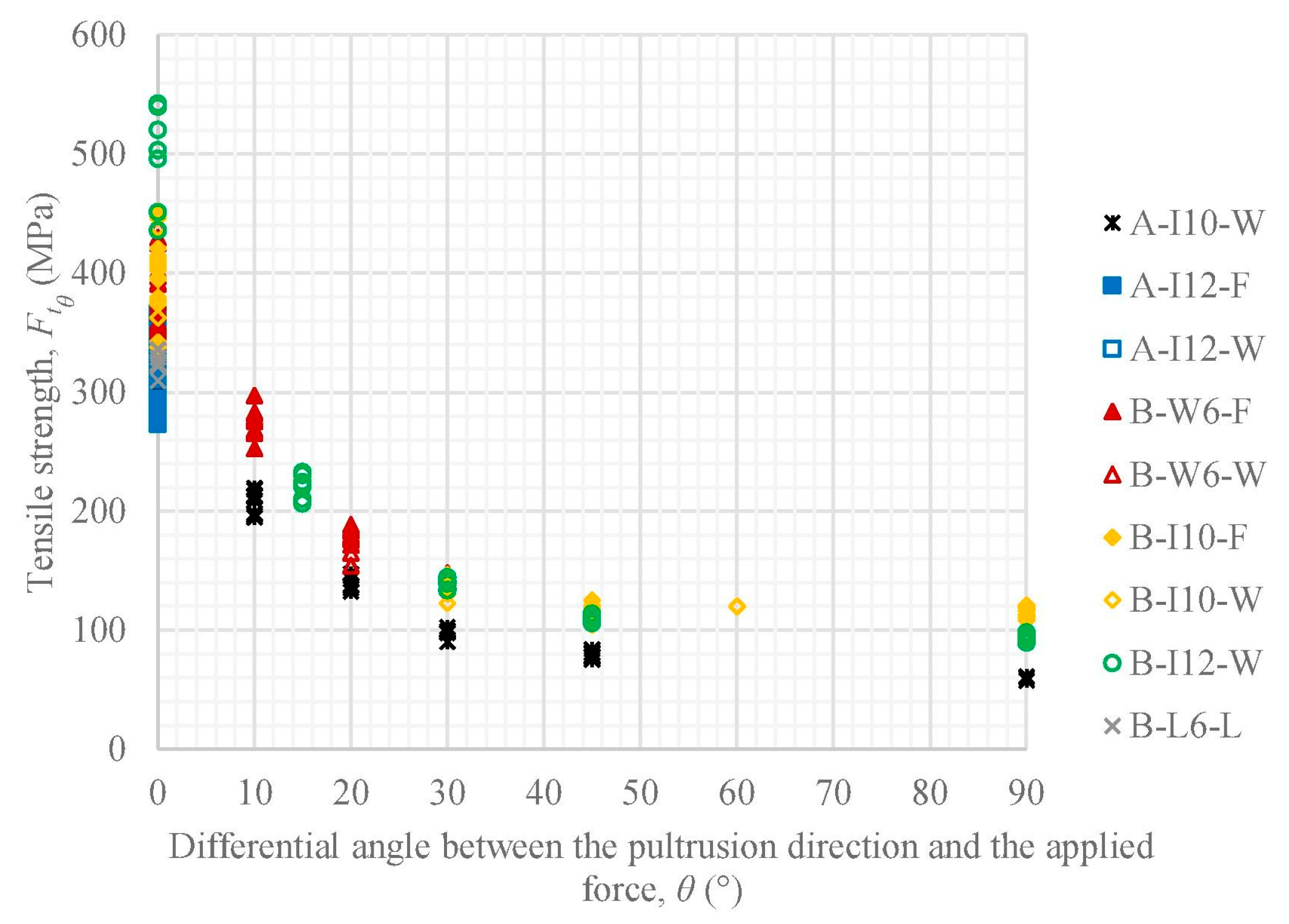

5. Properties of Pultruded Composites

6. Vitrimers: A New Class of Polymer

6.1. Vitrimer Chemistry and Its Key Properties

6.2. Key Properties of Vitrimer

- Tv Above Tg: The material behaves in a rubbery or viscoelastic state between Tg and Tv. As the temperature reaches Tv, it transitions into a viscoelastic liquid, following Arrhenius behavior.

- Tv Below Tg: The polymer chains remain rigid until reaching Tg, after which bond exchange initiates. Initially, the material exhibits WLF behavior for a specific period before shifting to Arrhenius behavior as the temperature increases.

6.3. Mechanism

6.4. Bond Exchange Mechanism

6.4.1. Transesterification

6.4.2. Disulfide Bond

6.4.3. Imine Bond

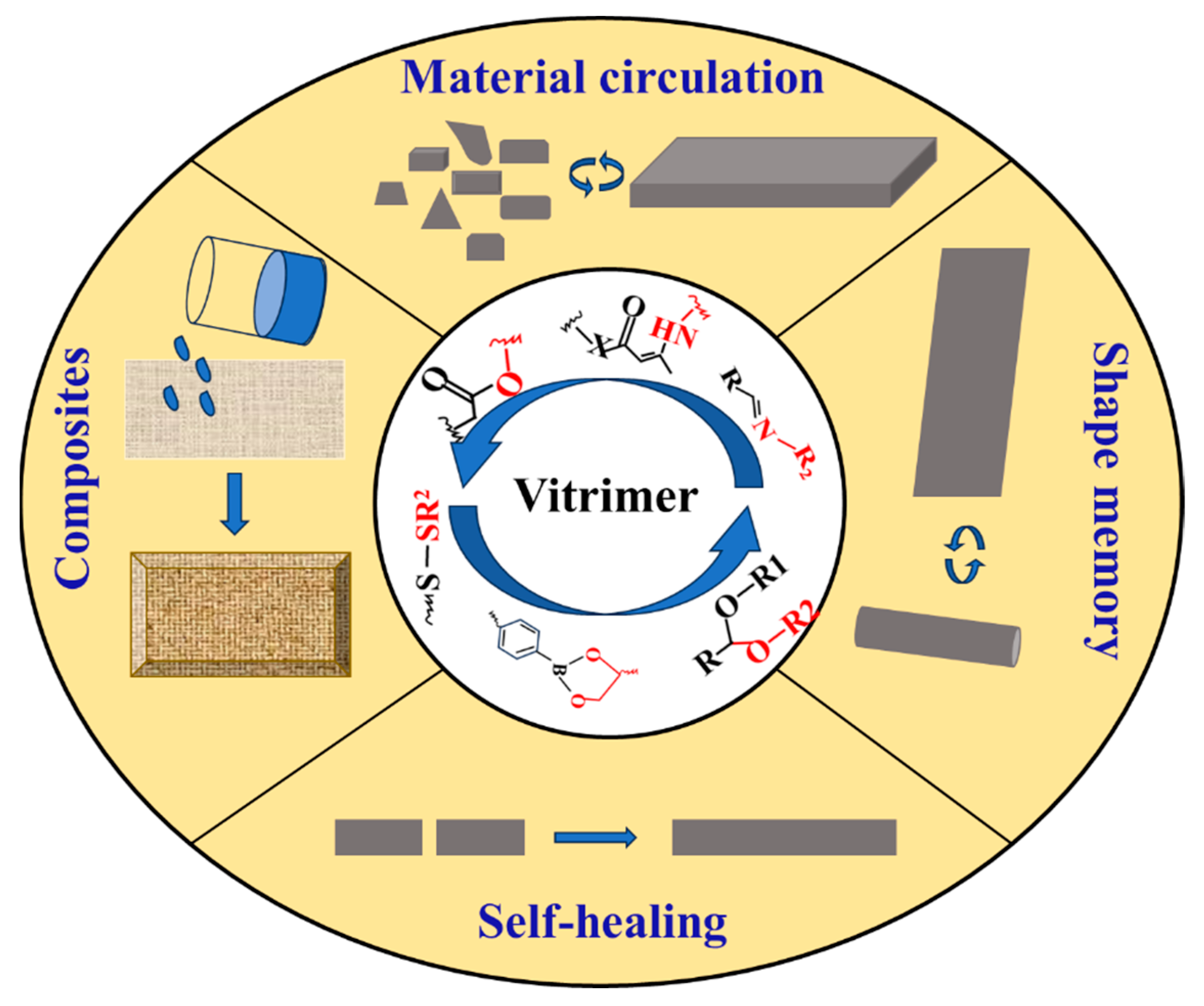

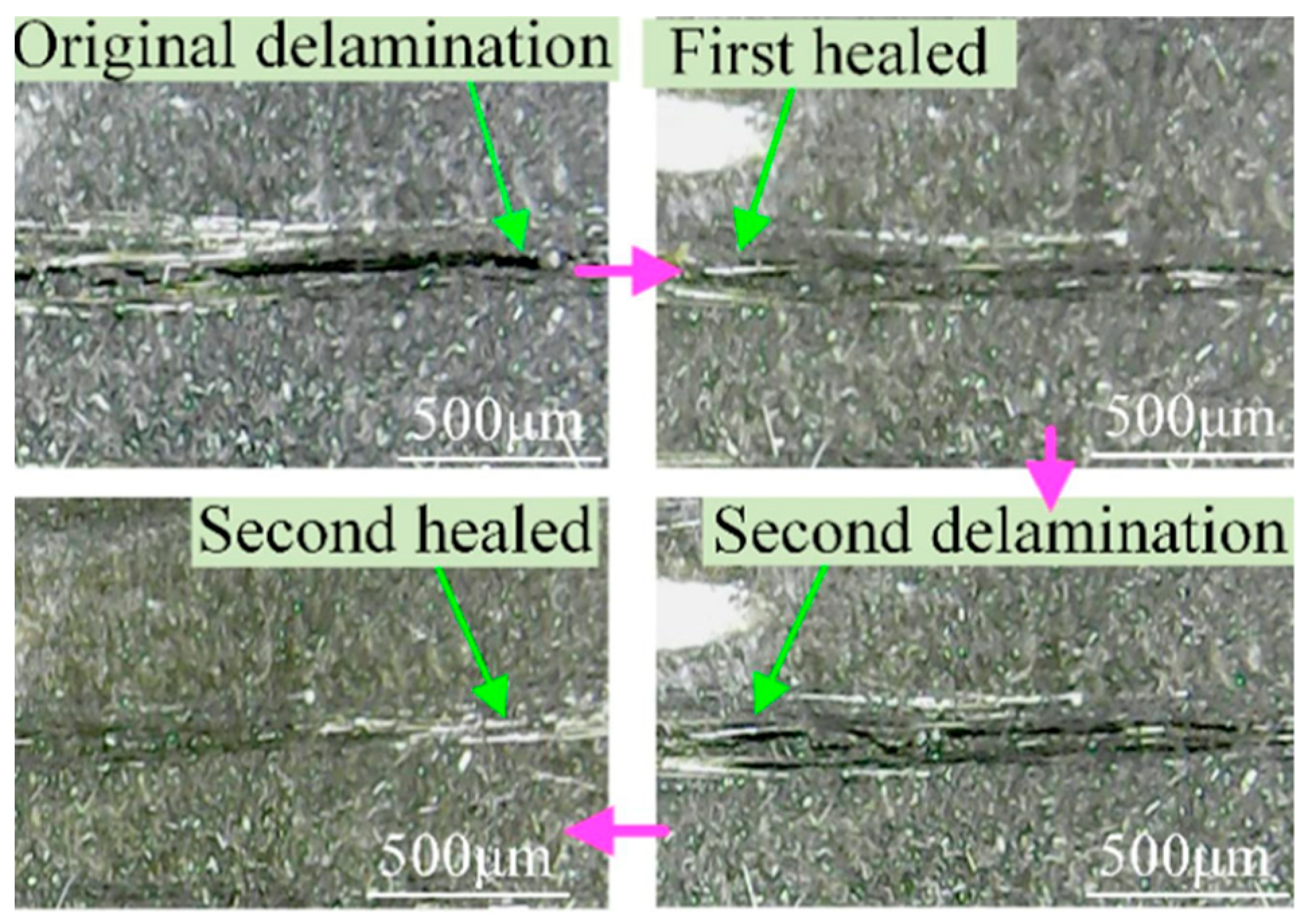

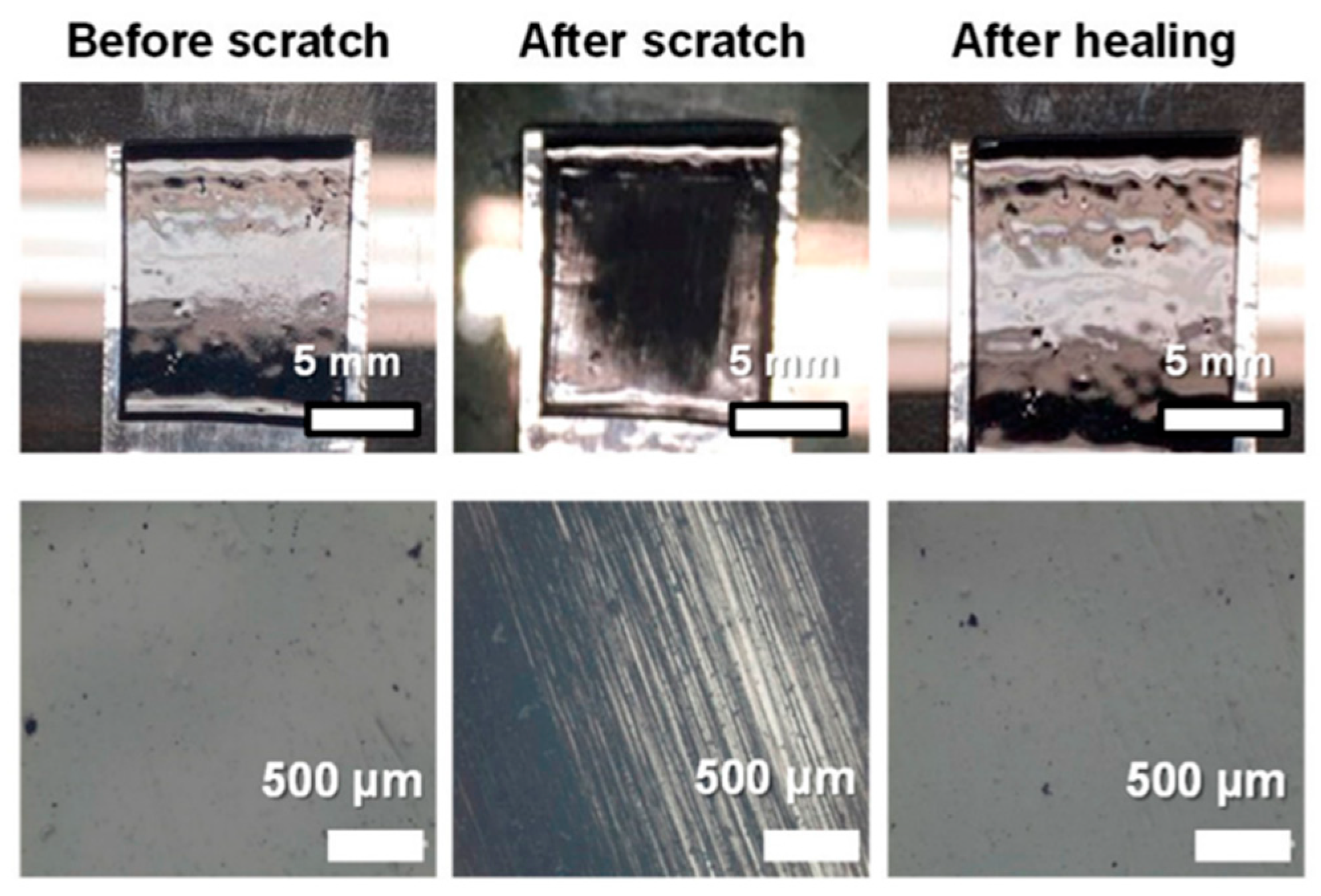

6.5. Vitrimer Composites: Key Characteristics and Properties

6.6. Recyclability and Repairability of Fiber-Reinforced Vitrimer Composites

6.6.1. Physical Recycling Technique

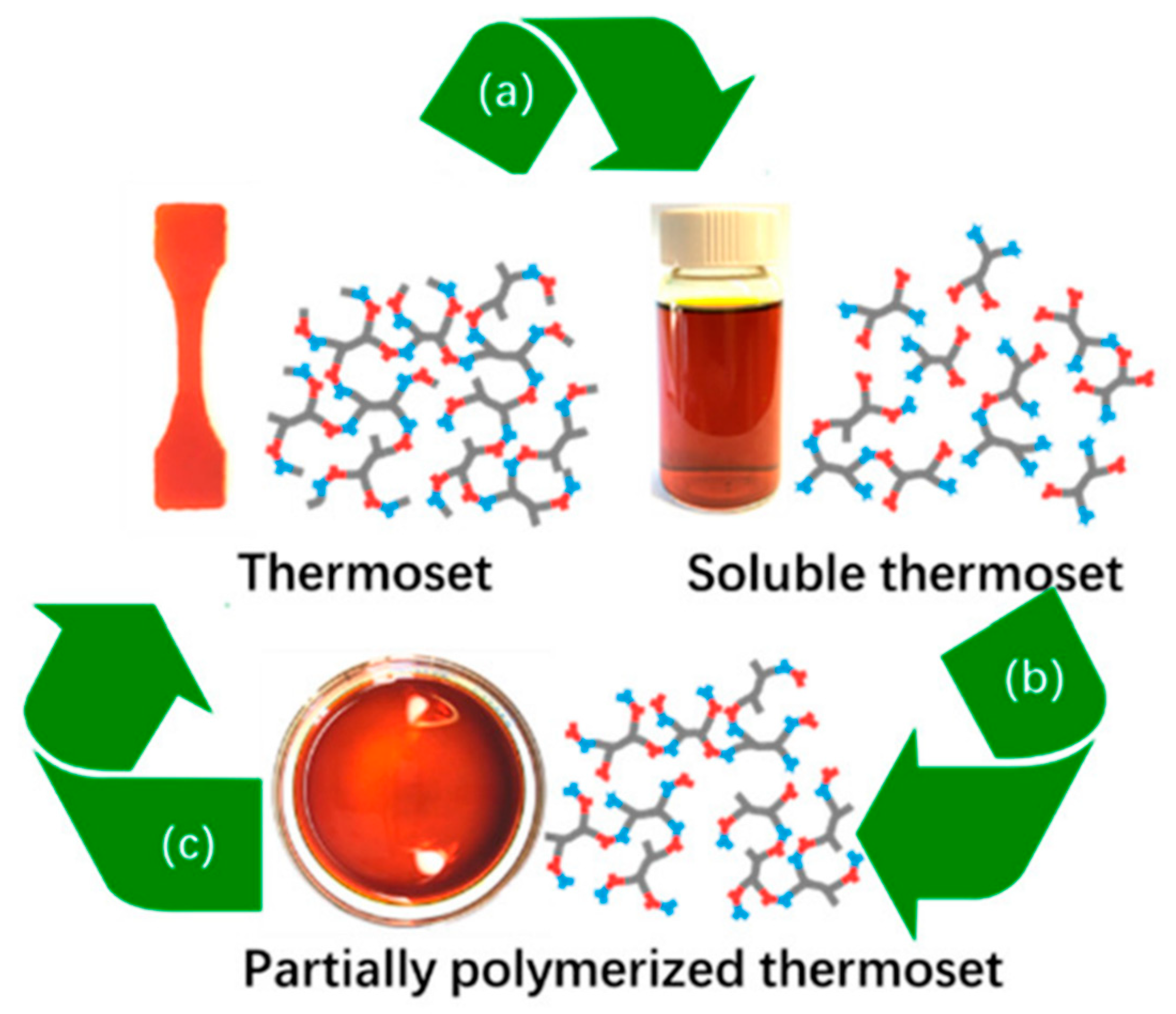

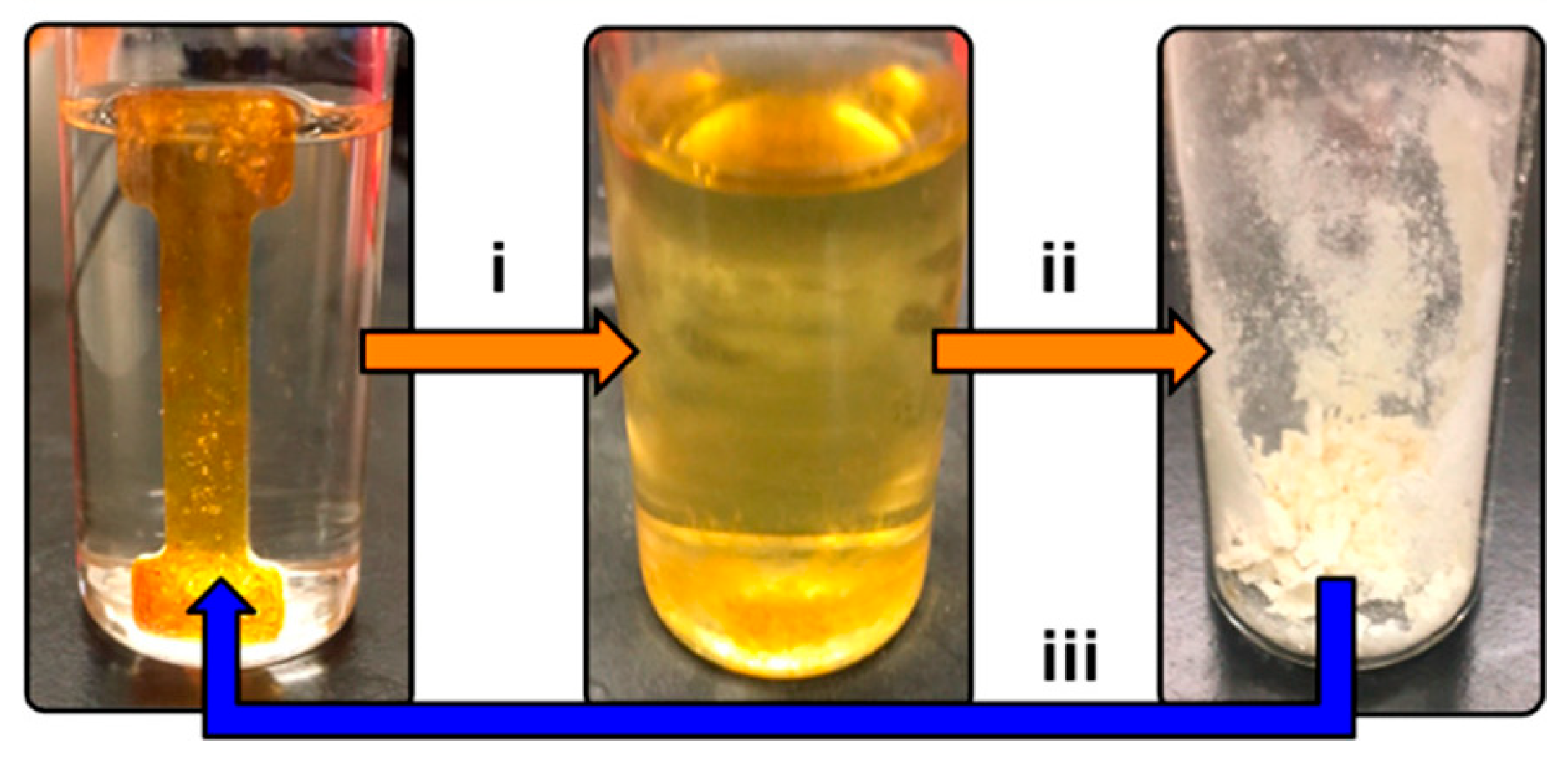

6.6.2. Chemical Recycling of Vitrimer

Imine Exchange-Based Recycling

Transesterification-Based Recycling

Disulfide Exchange-Based Recycling

7. Pultrusion of Fiber-Reinforced Vitrimer Composites

8. Applications of Pultruded Fiber-Reinforced Composites—Vitrimer

9. Challenges and Future Directions

9.1. Challenges

9.2. Future Directions

10. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Campbell, F.C. Chapter 1: Introduction to Composite Materials. In Structural Composite Materials; ASM International: Almere, The Netherlands, 2010. [Google Scholar] [CrossRef]

- Karak, N. PHI Learning Private Limited. In Fundamentals of Polymers; Cambridge University Press: Cambridge, UK, 2009; ISBN 9789354432996. [Google Scholar]

- Gowariker, V.; Viswanathan, N.V.; Sreedhar, J. New Age International. In Polymer Science; New Age International: New Delhi, India, 1986; ISBN 0-85226-307-4. [Google Scholar]

- Billmeyer, F.W. Textbook of Polymer Science; John Wiley & Sons: Hoboken, NJ, USA, 2007. [Google Scholar]

- Bakis, C.E.; Bank, L.C.; Brown, V.L.; Cosenza, E.; Davalos, J.F.; Lesko, J.J.; Triantafillou, T. Fiber-Reinforced Polymer Composites for Construction—State-of-the-Art Review. J. Compos. Constr. 2002, 6, 73–87. [Google Scholar] [CrossRef]

- Rajak, D.K.; Wagh, P.H.; Linul, E. Manufacturing Technologies of Carbon/Glass Fiber-Reinforced Polymer Composites and Their Properties: A Review. Polymers 2021, 13, 3721. [Google Scholar] [CrossRef]

- Karataş, M.A.; Gökkaya, H. A Review on Machinability of Carbon Fiber Reinforced Polymer (CFRP) and Glass Fiber Reinforced Polymer (GFRP) Composite Materials. Def. Technol. 2018, 14, 318–326. [Google Scholar] [CrossRef]

- DiBenedetto, A.T. Tailoring of Interfaces in Glass Fiber Reinforced Polymer Composites: A Review. Mater. Sci. Eng. A 2001, 302, 74–82. [Google Scholar] [CrossRef]

- Sathishkumar, T.P.; Satheeshkumar, S.; Naveen, J. Glass Fiber-Reinforced Polymer Composites—A Review. J. Reinf. Plast. Compos. 2014, 33, 1258–1275. [Google Scholar] [CrossRef]

- Karim, M.A.; Abdullah, M.Z.; Ahmed, T. An Overview: The Processing Methods of Fiber-Reinforced Polymers (FRPs). Int. J. Mech. Eng. Technol. 2021, 12, 10–24. [Google Scholar] [CrossRef]

- Rajhi, A.A. Mechanical Characterization of Hybrid Nano-Filled Glass/Epoxy Composites. Polymers 2022, 14, 4852. [Google Scholar] [CrossRef]

- Han, W.; Zhou, J.; Shi, Q. Research Progress on Enhancement Mechanism and Mechanical Properties of FRP Composites Reinforced with Graphene and Carbon Nanotubes. Alex. Eng. J. 2023, 64, 541–579. [Google Scholar] [CrossRef]

- Qiu, Y.; Yang, H.; Tong, L.; Wang, L. Research Progress of Cryogenic Materials for Storage and Transportation of Liquid Hydrogen. Metals 2021, 11, 1101. [Google Scholar] [CrossRef]

- Islam, M.S.; Benninger, L.F.; Pearce, G.; Wang, C.H. Toughening Carbon Fibre Composites at Cryogenic Temperatures Using Low-Thermal Expansion Nanoparticles. Compos. Part A 2021, 150, 106613. [Google Scholar] [CrossRef]

- Tihin, G.L.; Wang, C.H.; Islam, M.S. Use of Nanoparticles to Produce Multiscale Carbon-Epoxy Composite Laminates for Cryogenic Liquid Hydrogen Fuel Tank. In Proceedings of the 10th Australasian Congress on Applied Mechanics (ACAM10), Online, 1–3 December 2021. [Google Scholar]

- Oliveux, G.; Dandy, L.O.; Leeke, G.A. Current Status of Recycling of Fibre Reinforced Polymers: Review of Technologies, Reuse and Resulting Properties. Prog. Mater. Sci. 2015, 72, 61–99. [Google Scholar] [CrossRef]

- Ribeiro, M.C.S.; Fiúza, A.; Ferreira, A.; Dinis, M.D.L.; Castro, A.C.M.; Meixedo, J.P.; Alvim, M.R. Recycling Approach towards Sustainability Advance of Composite Materials’ Industry. Recycling 2016, 1, 178–193. [Google Scholar] [CrossRef]

- Pickering, S.J. Recycling Technologies for Thermoset Composite Materials—Current Status. Compos. Part A 2006, 37, 1206–1215. [Google Scholar] [CrossRef]

- Ogden, W.A.; Guan, Z. Recyclable, Strong and Highly Malleable Thermosets Based on Boroxine Networks. J. Am. Chem. Soc. 2018, 140, 6217–6220. [Google Scholar] [CrossRef]

- Job, S. Recycling Composites Commercially. Reinf. Plast. 2014, 58, 32–38. [Google Scholar] [CrossRef]

- Yang, Y.; Xu, Y.; Ji, Y.; Wei, Y. Functional Epoxy Vitrimers and Composites. Prog. Mater. Sci. 2021, 120, 100710. [Google Scholar] [CrossRef]

- Liu, C.; Fang, W.; Cheng, Q.; Qiu, B.; Shangguan, Y.; Shi, J. Revolutionizing elastomer technology: Advances in reversible crosslinking, reprocessing, and self-healing applications. Poly Rev. 2025, 65, 483–526. [Google Scholar] [CrossRef]

- Zhou, F.; Guo, Z.; Wang, W.; Lei, X.; Zhang, B.; Zhang, H.; Zhang, Q. Preparation of Self-Healing, Recyclable Epoxy Resins and Low-Electrical Resistance Composites Based on Double-Disulfide Bond Exchange. Compos. Sci. Technol. 2018, 167, 79–85. [Google Scholar] [CrossRef]

- Zhao, S.; Abu-Omar, M.M. Recyclable and Malleable Epoxy Thermoset Bearing Aromatic Imine Bonds. Macromolecules 2018, 51, 9816–9824. [Google Scholar] [CrossRef]

- Saheb, D.N.; Jog, J.P. Natural Fiber Polymer Composites: A Review. Adv. Polym. Technol. 1999, 18, 351–363. [Google Scholar] [CrossRef]

- Bongarde, U.S.; Shinde, V.D. Review on Natural Fiber Reinforcement Polymer Composites. Int. J. Eng. Sci. Innov. Technol. 2014, 3, 431–436. [Google Scholar]

- Thiruchitrambalam, M.; Athijayamani, A.; Sathiyamurthy, S.; Thaheer, A.S.A. A Review on the Natural Fiber-Reinforced Polymer Composites for the Development of Roselle Fiber-Reinforced Polyester Composite. J. Nat. Fibers 2010, 7, 307–323. [Google Scholar] [CrossRef]

- Chandramohan, D.; Bharanichandar, J. Natural Fiber Reinforced Polymer Composites for Automobile Accessories. Am. J. Environ. Sci. 2013, 9, 494–504. [Google Scholar] [CrossRef]

- Taj, S.; Munawar, M.A.; Khan, S. Natural Fiber-Reinforced Polymer Composites. Proc. Pak. Acad. Sci. 2007, 44, 129–144. [Google Scholar]

- Mahesha, G.T.; Subrahmanya, B.K.; Padmaraja, N.H. Biodegradable Natural Fiber Reinforced Polymer Matrix Composites: Technical Updates. AIP Conf. Proc. 2019, 2166, 020001. [Google Scholar] [CrossRef]

- Ramanan, G.; RS, R.I.; Suresh, S.; Singh, P.; Paavana, M.; Sneha, S.K.; Vinodhini, A.; Arputharaj, B.S.; Singh, S.; Varshney, D.; et al. Exploration and Characterization of Biodegradable Hybrid Composites Reinforced with Areca Leaf Sheath Fiber and Tamarind Seed Powder. Results Eng. 2025, 25, 104474. [Google Scholar]

- Capelot, M.; Unterlass, M.M.; Tournilhac, F.; Leibler, L. Catalytic Control of the Vitrimer Glass Transition. ACS Macro Lett. 2012, 1, 789–792. [Google Scholar] [CrossRef] [PubMed]

- Röttger, M.; Domenech, T.; van Der Weegen, R.; Breuillac, A.; Nicolaÿ, R.; Leibler, L. High-Performance Vitrimers from Commodity Thermoplastics through Dioxaborolane Metathesis. Science 2017, 356, 62–65. [Google Scholar] [CrossRef]

- Van Zee, N.J.; Nicolaÿ, R. Vitrimers: Permanently Crosslinked Polymers with Dynamic Network Topology. Prog. Polym. Sci. 2020, 104, 101233. [Google Scholar] [CrossRef]

- Zheng, J.; Png, Z.M.; Ng, S.H.; Tham, G.X.; Ye, E.; Goh, S.S.; Loh, X.J.; Li, Z. Vitrimers: Current Research Trends and Their Emerging Applications. Mater. Today 2021, 51, 586–625. [Google Scholar] [CrossRef]

- Taynton, P.; Ni, H.; Zhu, C.; Yu, K.; Loob, S.; Jin, Y.; Qi, H.J.; Zhang, W. Repairable Woven Carbon Fiber Composites with Full Recyclability Enabled by Malleable Polyimine Networks. Adv. Mater. 2016, 28, 2904–2909. [Google Scholar] [CrossRef] [PubMed]

- Ueda, M.; Ui, N.; Ohtani, A. Lightweight and Anti-Corrosive Fiber Reinforced Thermoplastic Rivet. Compos. Struct. 2018, 188, 356–362. [Google Scholar] [CrossRef]

- Fiberline. Data Sheet for Structural Profiles. Available online: https://fiberline.cloud1.structpim.com/media/r0inbu2w/fact_sheet_sp_profiles_uk.pdf (accessed on 23 December 2022).

- Röchling. Composite Profiles. Available online: https://www.roechling.com/fileadmin/downloads/Roechling_Industrial/Brochures/EN/Durostone/Durostone-Glastic-Composite_Profiles-DE-EN-FR.pdf (accessed on 28 December 2022).

- Bedford. Structural Shapes. Available online: https://bedfordreinforced.com/wp-content/uploads/2017/07/Bedford_PROForms-v05042020.pdf (accessed on 28 December 2022).

- Vedernikov, A.; Safonov, A.; Tucci, F.; Carlone, P.; Akhatov, I. Pultruded materials and structures: A review. J. Compos. Mater. 2020, 54, 4081–4117. [Google Scholar] [CrossRef]

- Zoghi, M. The International Handbook of FRP Composites in Civil Engineering; CRC Press: Boca Raton, FL, USA, 2013. [Google Scholar]

- Kandelbauer, A.; Tondi, G.; Zaske, O.C.; Goodman, S.H. Chapter 6—Unsaturated Polyesters and Vinyl Esters. In Handbook F41 of Thermoset Plastics, 4th ed.; Dodiuk, H., Ed.; William Andrew Publishing: Boston, MA, USA, 2022; pp. 97–158. [Google Scholar]

- Gao, H.; Sun, Y.; Jian, J.; Dong, Y.; Liu, H. Study on Mechanical Properties and Application in Communication Pole Line Engineering of Glass Fiber Reinforced Polyurethane Composites (GFRP). Case Stud. Constr. Mater. 2023, 18, e01942. [Google Scholar] [CrossRef]

- Vedernikov, A.; Nasonov, Y.; Korotkov, R.; Gusev, S.; Akhatov, I.; Safonov, A. Effects of Additives on the Cure Kinetics of Vinyl Ester Pultrusion Resins. J. Compos. Mater. 2021, 55, 2921–2937. [Google Scholar] [CrossRef]

- Cho, B.-G.; McCarthy, S.P.; Fanucci, J.P.; Nolet, S.C. Fiber Reinforced Nylon-6 Composites Produced by the Reaction Injection Pultrusion Process. Polym. Compos. 1996, 17, 673–681. [Google Scholar] [CrossRef]

- Clarke, C. Glass Fibre-Reinforced Polyurethane Composites: Catalyst Selection, Pultrusion Processing and Mechanical Performance. Master’s Thesis, The University of Canterbury, Christchurch, New Zealand, 2020; pp. 1–84. [Google Scholar]

- Chen, K.; Jia, M.; Sun, H.; Xue, P. Thermoplastic Reaction Injection Pultrusion for Continuous Glass Fiber-Reinforced Polyamide-6 Composites. Materials 2019, 12, 463. [Google Scholar] [CrossRef]

- Vemuganti, S.; Chennareddy, R.; Riad, A.; Taha, M.M.R. Pultruded GFRP Reinforcing Bars Using Nanomodified Vinylester. Materials 2020, 13, 5710. [Google Scholar] [CrossRef]

- Chen, K.; Jia, M.; Hua, S.; Xue, P. Optimization of Initiator and Activator for Reactive Thermoplastic Pultrusion. J. Polym. Res. 2019, 26, 40. [Google Scholar] [CrossRef]

- Johari, A.; Ishak, M.R.; Leman, Z.; Yusoff, M.Z.M.; Asyraf, M.R.M. Influence of CaCO3 in Pultruded Glass Fiber/Unsaturated Polyester Resin Composite on Flexural Creep Behavior Using Conventional and Time Temperature Superposition Principle Methods. Polimery 2020, 65, 792–800. [Google Scholar] [CrossRef]

- Manjunath, M.; Renukappa, N.M.; Suresha, B. Influence of Micro and Nanofillers on Mechanical Properties of Pultruded Unidirectional Glass Fiber Reinforced Epoxy Composite Systems. J. Compos. Mater. 2015, 50, 1109–1121. [Google Scholar] [CrossRef]

- Gupta, A.; Singh, H.; Walia, R. Effect of Fillers on Tensile Strength of Pultruded Glass Fiber Reinforced Polymer Composite. Indian J. Eng. Mater. Sci. 2015, 22, 62–70. [Google Scholar]

- Romanovskaia, N.; Minchenkov, K.; Gusev, S.; Klimova-Korsmik, O.; Safonov, A. Effects of Additives on the Mechanical and Fire Resistance Properties of Pultruded Composites. Polymers 2023, 15, 3581. [Google Scholar] [CrossRef]

- Nasonov, Y.; Safonov, A.; Gusev, S.; Akhatov, I. Effect of Additives on Cure Kinetics of Pultrusion Resins. Procedia Manuf. 2020, 47, 920–924. [Google Scholar] [CrossRef]

- Kang, B.; Lee, C.; Kim, S.-M.; Yoo, H.-M. Processing and Evaluation of a Carbon Fiber Reinforced Composite Bar Using a Closed Impregnation Pultrusion System with Improved Production Speed. Appl. Sci. 2022, 12, 4906. [Google Scholar] [CrossRef]

- Sandberg, M.; Yuksel, O.; Comminal, R.B.; Sonne, M.R.; Jabbari, M.; Larsen, M.; Salling, F.B.; Baran, I.; Spangenberg, J.; Hattel, J.H. 6—Numerical Modeling of the Mechanics of Pultrusion. In Mechanics of Materials in Modern Manufacturing Methods and Processing Techniques; Silberschmidt, V.V., Ed.; Elsevier: Amsterdam, The Netherlands, 2020; pp. 173–195. [Google Scholar]

- Kenny, J.M.; Nicolais, L. 18—Science and Technology of Polymer Composites. In Comprehensive Polymer Science and Supplements; Allen, G., Bevington, J.C., Eds.; Pergamon: Amsterdam, The Netherlands, 1989; pp. 471–525. [Google Scholar]

- Ann, G.C. Effect of Manufacturing Process Conditions on the Durability of Pultruded Vinyl Ester/Glass Composites. In Department of Chemical Engineering; West Virginia University: Morgantown, WV, USA, 2000. [Google Scholar]

- Raper, K.S.; Roux, J.; McCarty, T.; Vaughan, J. Investigation of the Pressure Behavior in a Pultrusion Die for Graphite/Epoxy Composites. Compos. Appl. Sci. Manuf. 1999, 30, 1123–1132. [Google Scholar] [CrossRef]

- Gadam, S.U.K.; Roux, J.; McCarty, T.; Vaughan, J. The Impact of Pultrusion Processing Parameters on Resin Pressure Rise Inside a Tapered Cylindrical Die for Glass-Fibre/Epoxy Composites. Compos. Sci. Technol. 2000, 60, 945–958. [Google Scholar] [CrossRef]

- Volk, M.; Yuksel, O.; Baran, I.; Hattel, J.H.; Spangenberg, J.; Sandberg, M. Cost-Efficient, Automated, and Sustainable Composite Profile Manufacture: A Review of the State of the Art, Innovations, and Future of Pultrusion Technologies. Compos. Part B Eng. 2022, 246, 110135. [Google Scholar] [CrossRef]

- Dubé, M.G.; Batch, G.L.; Vogel, J.G.; Macosko, C.W. Reaction Injection Pultrusion of Thermoplastic and Thermoset Composites. Polym. Compos. 1995, 16, 378–385. [Google Scholar] [CrossRef]

- Bai, Y.; Tian, J.; Li, C.; Wang, J.; Xian, G. Experimental and numerical analysis of a new thermoplastic pultrusion technology of CF/PA6 rod using prepreg tapes. Polym. Compos. 2025, 46, 9858–9871. [Google Scholar] [CrossRef]

- Ding, X.; He, Q.; Yang, Q.; Wang, S.; Chen, K. Numerical Simulation of Impregnation Process of Reactive Injection Pultrusion for Glass Fiber/PA6 Composites. Polymers 2022, 14, 666. [Google Scholar] [CrossRef]

- Dias, R.D.C.C.; de Sousa Santos, L.; Ouzia, H.; Schledjewski, R. Improving degree of cure in pultrusion process by optimizing die-temperature. Mater. Today Commun. 2018, 17, 362–370. [Google Scholar] [CrossRef]

- Black, S. Pultruding Cost Out of Aerospace Parts. In Composites World; Composites World: Cincinnati, OH, USA, 2009. [Google Scholar]

- Patrawala, T.B. Decision Support Tool for Costing of the Pultrusion Process. In College of Engineering and Mineral Resources; West Virginia University: Morgantown, WV, USA, 1999; p. 162. [Google Scholar]

- Valente, M.; Rossitti, I.; Sambucci, M. Different Production Processes for Thermoplastic Composite Materials: Sustainability versus Mechanical Properties and Process Parameters. Polymers 2023, 15, 242. [Google Scholar] [CrossRef] [PubMed]

- Vedernikov, A.; Tucci, F.; Carlone, P.; Gusev, S.; Konev, S.; Firsov, D.; Akhatov, I.; Safonov, A. Effects of Pulling Speed on Structural Performance of L-Shaped Pultruded Profiles. Compos. Struct. 2021, 255, 112967. [Google Scholar] [CrossRef]

- Ma, C.-C.M.; Yn, M.-S.; Chen, C.-H.; Chiang, C.-L. Processing and Properties of Pultruded Thermoplastic Composites (I). Compos. Manuf. 1990, 1, 191–196. [Google Scholar] [CrossRef]

- Wang, D.H.; Ramulu, M.; Arola, D. Orthogonal Cutting Mechanisms of Graphite/Epoxy Composite. Part. I: Unidirectional Laminate. Int. J. Mach. Tools Manuf. 1995, 35, 1623–1638. [Google Scholar] [CrossRef]

- Mukherji, A.; Njuguna, J. An Assessment on Effect of Process Parameters on Pull Force during Pultrusion. Int. J. Adv. Des. Manuf. Technol. 2022, 121, 3419–3438. [Google Scholar] [CrossRef]

- Aranberri, I.; Landa, M.; Elorza, E.; Salaberria, A.M.; Rekondo, A. Thermoformable and Recyclable CFRP Pultruded Profile Manufactured from an Epoxy Vitrimer. Polym. Test. 2021, 93, 106931. [Google Scholar] [CrossRef]

- Tayde, S.; Bhagwan, T.; Chatterjee, A. Polyester Resins and Their Use as Matrix Material in Polymer Composites. In Polyester-Based Biocomposites; Senthilkumar, K.C.M., Muthu, K.T.S., Siengchin, S., Eds.; CRC Press: Boca Raton, FL, USA, 2023. [Google Scholar]

- Irfan, M.S.; Shotton-Gale, N.; Paget, M.A.; Machavaram, V.R.; Leek, C.; Wootton, S.; Hudson, M.; Helsmans, S.; Bogonez, F.N.; Pandita, S.D.; et al. A Modified Pultrusion Process. J. Compos. Mater. 2016, 51, 1925–1941. [Google Scholar] [CrossRef]

- Yuksel, O.; Sandberg, M.; Baran, I.; Ersoy, N.; Hattel, J.H.; Akkerman, R. Material Characterization of a Pultrusion-Specific and Highly Reactive Polyurethane Resin System: Elastic Modulus, Rheology, and Reaction Kinetics. Compos. B Eng. 2021, 207, 108543. [Google Scholar] [CrossRef]

- Baran, I.; Akkerman, R.; Hattel, J.H. Material Characterization of a Polyester Resin System for the Pultrusion Process. Compos. B Eng. 2014, 64, 194–201. [Google Scholar] [CrossRef]

- Broyles, N.; Verghese, K.N.; Davis, R.M.; Lesko, J.J.; Riffle, J.S. Pultruded Carbon Fiber/Vinyl Ester Composites Processed with Different Fiber Sizing Agents. Part I: Processing and Static Mechanical Performance. J. Mater. Civ. Eng. 2005, 17, 320–333. [Google Scholar] [CrossRef]

- Verghese, K.; Broyles, N.S.; Case, S.W.; Lesko, J.J.; Davis, R.M.; Riffle, J.S. Pultruded Carbon Fiber/Vinyl Ester Composites Processed with Different Fiber Sizing Agents. Part III: Theoretical Aspects. J. Mater. Civ. Eng. 2005, 17, 343–352. [Google Scholar] [CrossRef]

- Zhao, J.; Liebscher, M.; Tzounis, L.; Mechtcherine, V. Role of sizing agent on the microstructure morphology and mechanical properties of mineral-impregnated carbon-fiber (MCF) reinforcement made with geopolymers. Appl. Surf. Sci. 2021, 567, 150740. [Google Scholar] [CrossRef]

- Cui, H. Glass fiber reinforced biorenewable polymer composites and the fabrication with pultrusion process. In Materials Science and Engineering; Iowa State University: Ames, IA, USA, 2013. [Google Scholar]

- Zamri, M.H.; Akil, H.M.; Ishak, Z.M.; Abu Bakar, A. Effect of different fiber loadings and sizes on pultruded kenaf fiber reinforced unsaturated polyester composites. Polym. Compos. 2015, 36, 1224–1229. [Google Scholar] [CrossRef]

- Peng, X.; Fan, M.; Hartley, J.; Al-Zubaidy, M. Properties of natural fiber composites made by pultrusion process. J. Compos. Mater. 2011, 46, 237–246. [Google Scholar] [CrossRef]

- Gupta, A.; Vaishya, R.O.; A Khan, K.L.; Walia, R.S.; Singh, H. Multi-response optimization of the mechanical properties of pultruded glass fiber composite using optimized hybrid filler composition by the gray relation grade analysis. Mater. Res. Express 2019, 6, 125322. [Google Scholar] [CrossRef]

- Duernberger, E.; MacLeod, C.; Lines, D. Fibre volume fraction screening of pultruded carbon fibre reinforced polymer panels based on analysis of anisotropic ultrasonic sound velocity. Compos. Part B Eng. 2023, 254, 110577. [Google Scholar] [CrossRef]

- Baran, I. Analysis of the local fiber volume fraction variation in pultrusion process. In AIP Conference Proceedings; AIP Publishing: Melville, NY, USA, 2017. [Google Scholar]

- Zamri, M.H.; Akil, H.M.; Abu Bakar, A.; Ishak, Z.A.M.; Cheng, L.W. Effect of water absorption on pultruded jute/glass fiber-reinforced unsaturated polyester hybrid composites. J. Compos. Mater. 2012, 46, 51–61. [Google Scholar] [CrossRef]

- Ferreira, F.; Fernandes, P.; Correia, N.; Marques, A.T. Development of a pultrusion die for the production of thermoplastic composite filaments to be used in additive manufacture. J. Compos. Sci. 2021, 5, 120. [Google Scholar] [CrossRef]

- Joshi, S.C.; Lam, Y.C.; Tun, U.W. Improved cure optimization in pultrusion with pre-heating and die-cooler temperature. Compos. Part A Appl. Sci. Manuf. 2003, 34, 1151–1159. [Google Scholar] [CrossRef]

- Izadi, R.; Wagner, D.; Michel, A.; Albrechtsen, Y.; Löpitz, D.; Zopp, C.; Drossel, W.G.; Lies, C.; Basaran, M.; Belouettar, S.; et al. Experimental and numerical investigation of cure kinetics in pultrusion of Elium®-based thermoplastic fibre reinforced composites. Compos B Eng. 2025, 307, 112828. [Google Scholar] [CrossRef]

- Volk, M.; Wong, J.; Arreguin, S.; Ermanni, P. Pultrusion of large thermoplastic composite profiles up to Ø 40 mm from glass-fibre/PET commingled yarns. Compos. Part B Eng. 2021, 227, 109339. [Google Scholar] [CrossRef]

- Yuksel, O.; Baran, I.; Ersoy, N.; Akkerman, R. Investigation of transverse residual stresses in a thick pultruded composite using digital image correlation with hole drilling. Compos. Struct. 2019, 223, 110954. [Google Scholar] [CrossRef]

- Lessard, F.; Dubé, M.; Laberge Lebel, L. A model of multi-die thermoplastic pultrusion. Compos. Part B Eng. 2022, 247, 110319. [Google Scholar] [CrossRef]

- Sandberg, M.; Yuksel, O.; Baran, I.; Spangenberg, J.; Hattel, J.H. Steady-state modelling and analysis of process-induced stress and deformation in thermoset pultrusion processes. Compos. Part B Eng. 2021, 216, 108812. [Google Scholar] [CrossRef]

- Talabi, S.I.; Tobin, J.R.; Strom, B.; Brownstein, I.; Kunc, V.; Hassen, A.A. Recent and Future Developments in Pultrusion Technology with Consideration for Curved Geometries: A Review. Compos. Part B Eng. 2024, 283, 111678. [Google Scholar] [CrossRef]

- Fu, H.; Qin, Y.; He, X.; Meng, X.; Zhong, Y.; Zou, Z. Effect of curing degree on mechanical and thermal properties of 2.5D quartz fiber reinforced boron phenolic composites. e-Polymers 2019, 19, 462–469. [Google Scholar] [CrossRef]

- Kim, D.; Nutt, S.R. Effective cure cycle development via flow optimization and advanced cure environments. Adv. Manuf. Polym. Compos. Sci. 2020, 6, 164–172. [Google Scholar] [CrossRef]

- Hofmann, M.; Machado, M.; Shahid, A.; Dourado, F.; Garrido, M.; Bordado, J.C.; Correia, J.R. Pultruded carbon fibre reinforced polymer strips produced with a novel bio-based thermoset polyester for structural strengthening. Compos. Sci. Technol. 2023, 234, 109936. [Google Scholar] [CrossRef]

- Brandt, G.W.; Fred, L. Glastrusions Inc. Apparatus for Feeding Plastic Bars, Tubes and Like Elongated Stock. U.S. Patent Application No. 2,990,091, 27 June 1961. [Google Scholar]

- Xia, Z.Y.; Jiang, T.; Yu, T. Innovating arch structures with fiber-reinforced polymer composites: A review. Adv. Struct. Eng. 2023, 26, 2341–2358. [Google Scholar] [CrossRef]

- Liu, T.; Feng, P.; Bai, Y.; Bai, S.; Yang, J.Q.; Zhao, F. Flexural performance of curved-pultruded GFRP arch beams subjected to varying boundary conditions. Eng. Struct. 2024, 308, 117962. [Google Scholar] [CrossRef]

- Liu, W.; Feng, P.; Huang, J. Bilinear softening model and double K fracture criterion for quasi-brittle fracture of pultruded FRP composites. Compos. Struct. 2017, 160, 1119–1125. [Google Scholar] [CrossRef]

- Estep, D.D.; GangaRao, H.V.; Dittenber, D.B.; Qureshi, M.A. Response of pultruded glass composite box beams under bending and shear. Compos. Part B Eng. 2016, 88, 150–161. [Google Scholar] [CrossRef]

- Britnell, D.J.; Tucker, N.; Smith, G.F.; Wong, S.S.F. Bent pultrusion—A method for the manufacture of pultrudate with controlled variation in curvature. J. Mater. Process. Technol. 2003, 138, 311–315. [Google Scholar] [CrossRef]

- Arrabiyeh, P.A.; May, D.; Eckrich, M.; Dlugaj, A.M. An overview on current manufacturing technologies: Processing continuous rovings impregnated with thermoset resin. Polym. Compos. 2021, 42, 5630–5655. [Google Scholar] [CrossRef]

- Struzziero, G.; Maistros, G.M.; Hartley, J.; Skordos, A.A. Materials modelling and process simulation of the pultrusion of curved parts. Compos. Part A Appl. Sci. Manuf. 2021, 144, 106328. [Google Scholar] [CrossRef]

- Tena, I.; Esnaola, A.; Sarrionandia, M.; Ulacia, I.; Torre, J.; Aurrekoetxea, J. Out of die ultraviolet cured pultrusion for automotive crash structures. Compos. Part B Eng. 2015, 79, 209–216. [Google Scholar] [CrossRef]

- Gertner, Y.; Miller, A.K. Die-less forming of large and variable-radii of curvature in continuous-fiber thermoplastic-matrix composite materials. J. Thermoplast. Compos. Mater. 1996, 9, 151–182. [Google Scholar] [CrossRef]

- Heimbucher, C.; Seeßelberg, L.; Giese, E.; Boysen, S.; Herrmann, A.S. Investigation of Quality Related Process Variables in Pultrusion by Correlation of Numerical and Experimental Data with Application of an Inline Data Acquisition System. J. Compos. Mater. 2024, 58, 867–891. [Google Scholar] [CrossRef]

- Klimovski, A.; Lai, K.K.T.; Zielinski, B.S. Pultrusion Systems That Apply Lengthwise Curvature to Composite Parts. U.S. Patent Application No. 11,065,830, 20 July 2021. [Google Scholar]

- Corwin, C.C.; Jacobson, T.K.; Matecki, J.R.; Pendergrass, E.C. Pultruded Beam, and Apparatus and Methods for Manufacturing. U.S. Patent Application No. 9,682,674, 20 June 2017. [Google Scholar]

- Pirchio, D.; Althouse, J.A.; Madlem, T.A.; Denavit, M.D.; Weldon, B.D.; Walsh, K.Q. Tensile strength and modulus of FRP pultruded composites at varying load angles relative to the pultrusion direction. Constr. Build. Mater. 2023, 385, 131477. [Google Scholar] [CrossRef]

- Landesmann, A.; Seruti, C.A.; Batista, E.D.M. Mechanical properties of glass fiber reinforced polymers members for structural applications. Mater. Res. 2015, 18, 1372–1383. [Google Scholar] [CrossRef]

- Hashemi, F.; Tahir, P.M.; Madsen, B.; Jawaid, M.; Majid, D.L.; Brancheriau, L.; Juliana, A.H. Volumetric composition and shear strength evaluation of pultruded hybrid kenaf/glass fiber composites. J. Compos. Mater. 2016, 50, 2291–2303. [Google Scholar] [CrossRef]

- Irfan, M.S.; Harris, D.; Paget, M.A.; Ma, T.; Leek, C.; Machavaram, V.R.; Fernando, G.F. On-site evaluation of a modified pultrusion process: Fibre spreading and resin injection-based impregnation. J. Compos. Mater. 2021, 55, 77–93. [Google Scholar] [CrossRef]

- Balakrishnan, T.S.; Sultan, M.T.H.; Shahar, F.S.; Basri, A.A.; Shah, A.U.M.; Sebaey, T.A.; Łukaszewicz, A.; Józwik, J.; Grzejda, R. Fatigue and impact properties of kenaf/glass-reinforced hybrid pultruded composites for structural applications. Materials 2024, 17, 302. [Google Scholar] [CrossRef] [PubMed]

- Luo, Y.; Zhang, P.; Yu, T. On characterization of transverse tensile properties of pultruded glass fiber-reinforced polymer (PGFRP) profiles based on non-standard short coupons. Compos. Struct. 2024, 338, 118128. [Google Scholar] [CrossRef]

- Liu, T.; Feng, P.; Wu, Y.; Liao, S.; Meng, X. Developing an innovative curved-pultruded large-scale GFRP arch beam. Compos. Struct. 2021, 256, 113111. [Google Scholar] [CrossRef]

- Struzziero, G.; Barbezat, M.; Skordos, A.A. Consolidation of continuous fibre reinforced composites in additive processes: A review. Addit. Manuf. 2021, 48, 102458. [Google Scholar] [CrossRef]

- Vidil, T.; Tournilhac, F.; Musso, S.; Robisson, A.; Leibler, L. Control of reactions and network structures of epoxy thermosets. Prog. Polym. Sci. 2016, 62, 126–179. [Google Scholar] [CrossRef]

- Post, W.; Susa, A.; Blaauw, R.; Molenveld, K.; Knoop, R.J. A review on the potential and limitations of recyclable thermosets for structural applications. Polym. Rev. 2020, 60, 359–388. [Google Scholar] [CrossRef]

- Bowman, C.; Du Prez, F.; Kalow, J. Introduction to chemistry for covalent adaptable networks. Polym. Chem. 2020, 11, 5295–5296. [Google Scholar] [CrossRef]

- Alabiso, W.; Schlögl, S. The impact of vitrimers on the industry of the future: Chemistry, properties and sustainable forward-looking applications. Polymers 2020, 12, 1660. [Google Scholar] [CrossRef] [PubMed]

- Elling, B.R.; Dichtel, W.R. Reprocessable cross-linked polymer networks: Are associative exchange mechanisms desirable? ACS Cent. Sci. 2020, 6, 1488–1496. [Google Scholar] [CrossRef] [PubMed]

- Yoon, S.; Joshi, S.S.; Aracri, S.; Ospina-Yepes, Y.; Sathe, D.; Foster, M.D.; Wang, J.; Eagan, J.M. Chemically and Mechanically Recyclable Vitrimers from Carbon Dioxide-Based Polycarbonates. ACS Appl. Polym. Mater. 2025, 7, 4561–4571. [Google Scholar] [CrossRef]

- Zhou, Z.; Su, X.; Liu, J.; Liu, R. Synthesis of vanillin-based polyimine vitrimers with excellent reprocessability, fast chemical degradability, and adhesion. ACS Appl. Polym. Mater. 2020, 2, 5716–5725. [Google Scholar] [CrossRef]

- Liu, T.; Hao, C.; Zhang, S.; Yang, X.; Wang, L.; Han, J.; Li, Y.; Xin, J.; Zhang, J. A self-healable high glass transition temperature bioepoxy material based on vitrimer chemistry. Macromolecules 2018, 51, 5577–5585. [Google Scholar] [CrossRef]

- Chen, Q.; Wei, Y.; Ji, Y. Photo-responsive liquid crystalline vitrimer containing oligoanilines. Chin. Chem. Lett. 2017, 28, 2139–2142. [Google Scholar] [CrossRef]

- Kumar, S.; Krishnan, S.; Prabakaran, K. Renewable Resource-Based Epoxy Vitrimer Composites for Future Application: A Comprehensive Review. ACS Sustain. Resour. Manag. 2024, 1, 2086–2107. [Google Scholar] [CrossRef]

- Liu, Y.Y.; He, J.; Li, Y.D.; Zhao, X.L.; Zeng, J.B. Biobased epoxy vitrimer from epoxidized soybean oil for reprocessable and recyclable carbon fiber reinforced composite. Compos. Commun. 2020, 22, 100445. [Google Scholar] [CrossRef]

- Denissen, W.; Rivero, G.; Nicolaÿ, R.; Leibler, L.; Winne, J.M.; Du Prez, F.E. Vinylogous urethane vitrimers. Adv. Funct. Mater. 2015, 25, 2451–2457. [Google Scholar] [CrossRef]

- Wang, Z.; Li, Z.; Wei, Y.; Ji, Y. Gold nanospheres dispersed light-responsive epoxy vitrimers. Polymers 2018, 10, 65. [Google Scholar] [CrossRef]

- Hendriks, B.; Waelkens, J.; Winne, J.M.; Du Prez, F.E. Poly(thioether) vitrimers via transalkylation of trialkylsulfonium salts. ACS Macro Lett. 2017, 6, 930–934. [Google Scholar] [CrossRef] [PubMed]

- Fortman, D.J.; Brutman, J.P.; Cramer, C.J.; Hillmyer, M.A.; Dichtel, W.R. Mechanically activated, catalyst-free polyhydroxyurethane vitrimers. J. Am. Chem. Soc. 2015, 137, 14019–14022. [Google Scholar] [CrossRef] [PubMed]

- Xue, B.; Tang, R.; Xue, D.; Guan, Y.; Sun, Y.; Zhao, W.; Tan, J.; Li, X. Sustainable alternative for bisphenol a epoxy resin: High-performance and recyclable lignin-based epoxy vitrimers. Ind. Crops Prod. 2021, 168, 113583. [Google Scholar] [CrossRef]

- Huang, Z.; Wang, Y.; Zhu, J.; Yu, J.; Hu, Z. Surface engineering of nanosilica for vitrimer composites. Compos. Sci. Technol. 2018, 154, 18–27. [Google Scholar] [CrossRef]

- de Luzuriaga, A.R.; Martin, R.; Markaide, N.; Rekondo, A.; Cabañero, G.; Rodríguez, J.; Odriozola, I. Epoxy resin with exchangeable disulfide crosslinks to obtain reprocessable, repairable, and recyclable fiber-reinforced thermoset composites. Mater. Horiz. 2016, 3, 241–247. [Google Scholar] [CrossRef]

- Fortman, D.J.; Snyder, R.L.; Sheppard, D.T.; Dichtel, W.R. Rapidly reprocessable cross-linked polyhydroxyurethanes based on disulfide exchange. ACS Macro Lett. 2018, 7, 1226–1231. [Google Scholar] [CrossRef]

- Zheng, H.; Liu, Q.; Lei, X.; Chen, Y.; Zhang, B.; Zhang, Q. A conjugation polyimine vitrimer: Fabrication and performance. J. Polym. Sci. Part A Polym. Chem. 2018, 56, 2531–2538. [Google Scholar] [CrossRef]

- Krishnakumar, B.; Sanka, R.P.; Binder, W.H.; Parthasarthy, V.; Rana, S.; Karak, N. Vitrimers: Associative dynamic covalent adaptive networks in thermoset polymers. Chem. Eng. J. 2020, 385, 123820. [Google Scholar] [CrossRef]

- Denissen, W.; Winne, J.M.; Du Prez, F.E. Vitrimers: Permanent organic networks with glass-like fluidity. Chem. Sci. 2016, 7, 30–38. [Google Scholar] [CrossRef]

- Chakma, P.; Konkolewicz, D. Dynamic covalent bonds in polymeric materials. Angew. Chem. Int. Ed. 2019, 58, 9682–9695. [Google Scholar] [CrossRef] [PubMed]

- Fang, X.; Zheng, N.; Yan, J.; Chen, Q.; Xie, H.; Wu, C. High-Performance Vitrimer Composites: Recent Advances and Future Directions. Compos. Sci. Technol. 2024, 247, 110544. [Google Scholar]

- Chung, C.M.; Roh, Y.S.; Cho, S.Y.; Kim, J.G. Crack healing in polymeric materials via photochemical [2+2] cycloaddition. Chem. Mater. 2004, 16, 3982–3984. [Google Scholar] [CrossRef]

- Montarnal, D.; Capelot, M.; Tournilhac, F.; Leibler, L. Silica-like malleable materials from permanent organic networks. Science 2011, 334, 965–968. [Google Scholar] [CrossRef] [PubMed]

- Kissounko, D.A.; Taynton, P.; Kaffer, C. New material: Vitrimers promise to impact composites. Reinf. Plast. 2018, 62, 162–166. [Google Scholar] [CrossRef]

- Fang, M.; Liu, X.; Feng, Y.; Huang, M.; Liu, C.; Shen, C. Reprocessable and repairable carbon fiber reinforced vitrimer composites based on thermoreversible dynamic covalent bonding. Compos. Sci. Technol. 2024, 255, 110731. [Google Scholar] [CrossRef]

- Lucherelli, M.A.; Duval, A.; Avérous, L. Biobased vitrimers: Towards sustainable and adaptable performing polymer materials. Prog. Polym. Sci. 2022, 127, 101515. [Google Scholar] [CrossRef]

- Zhang, Y.; Ma, F.; Shi, L.; Lyu, B.; Ma, J. Recyclable, repairable and malleable bio-based epoxy vitrimers: Overview and future prospects. Curr. Opin. Green Sustain. Chem. 2023, 39, 100726. [Google Scholar] [CrossRef]

- Vidil, T.; Llevot, A. Fully Biobased Vitrimers: Future Direction toward Sustainable Cross-Linked Polymers. Macromol. Chem. Phys. 2022, 223, 2100494. [Google Scholar] [CrossRef]

- Taynton, P.; Yu, K.; Shoemaker, R.K.; Jin, Y.; Qi, H.J.; Zhang, W. Heat- or water-driven malleability in a highly recyclable covalent network polymer. Adv. Mater. 2014, 26, 3938–3942. [Google Scholar] [CrossRef]

- Memon, H.; Wei, Y.; Zhang, L.; Jiang, Q.; Liu, W. An imine-containing epoxy vitrimer with versatile recyclability and its application in fully recyclable carbon fiber reinforced composites. Compos. Sci. Technol. 2020, 199, 108314. [Google Scholar] [CrossRef]

- Denissen, W.; De Baere, I.; Van Paepegem, W.; Leibler, L.; Winne, J.; Du Prez, F.E. Vinylogous urea vitrimers and their application in fiber reinforced composites. Macromolecules 2018, 51, 2054–2064. [Google Scholar] [CrossRef]

- Zhou, Z.; Kim, S.; Bowland, C.C.; Li, B.; Ghezawi, N.; Lara-Curzio, E.; Hassen, A.; Naskar, A.K.; Rahman, M.A.; Saito, T. Unraveling a path for multi-cycle recycling of tailored fiber-reinforced vitrimer composites. Cell Rep. Phys. Sci. 2022, 3, 101036. [Google Scholar] [CrossRef]

- Liu, X.; Zhang, E.; Feng, Z.; Liu, J.; Chen, B.; Liang, L. Degradable bio-based epoxy vitrimers based on imine chemistry and their application in recyclable carbon fiber composites. J. Mater. Sci. 2021, 56, 15733–15751. [Google Scholar] [CrossRef]

- Zhao, Y.; Zhang, Y.; Bai, X.; Wang, Y.; Li, Y.; Yang, S. Sustainable Epoxy Vitrimer Materials with Imine and Disulfide Bonds Prepared from Epoxidized Soybean Oils. Ind. Crops Prod. 2025, 225, 120435. [Google Scholar] [CrossRef]

- Zhang, B.; Yuan, C.; Zhang, W.; Dunn, M.L.; Qi, H.J.; Liu, Z.; Yu, K.; Ge, Q. Recycling of vitrimer blends with tunable thermomechanical properties. RSC Adv. 2019, 9, 5431–5437. [Google Scholar] [CrossRef]

- Yu, K.; Taynton, P.; Zhang, W.; Dunn, M.L.; Qi, H.J. Reprocessing and recycling of thermosetting polymers based on bond exchange reactions. RSC Adv. 2014, 4, 10108–10117. [Google Scholar] [CrossRef]

- Zhang, B.; Li, H.; Yuan, C.; Dunn, M.L.; Qi, H.J.; Yu, K.; Shi, Q.; Ge, Q. Influences of processing conditions on mechanical properties of recycled epoxy-anhydride vitrimers. J. Appl. Polym. Sci. 2020, 137, 49246. [Google Scholar] [CrossRef]

- Zheng, N.; Xu, Y.; Zhao, Q.; Xie, T. Dynamic covalent polymer networks: A molecular platform for designing functions beyond chemical recycling and self-healing. Chem. Rev. 2021, 121, 1716–1745. [Google Scholar] [CrossRef]

- Lessard, J.J.; Garcia, L.F.; Easterling, C.P.; Sims, M.B.; Bentz, K.C.; Arencibia, S.; Savin, D.A.; Sumerlin, B.S. Catalyst-free vitrimers from vinyl polymers. Macromolecules 2019, 52, 2105–2111. [Google Scholar] [CrossRef]

- Zamani, P.; Zabihi, O.; Ahmadi, M.; Mahmoodi, R.; Kannangara, T.; Joseph, P.; Naebe, M. Biobased carbon fiber composites with enhanced flame retardancy: A cradle-to-cradle approach. ACS Sustain. Chem. Eng. 2021, 10, 1059–1069. [Google Scholar] [CrossRef]

- Zhao, Q.; Zou, W.; Luo, Y.; Xie, T. Shape memory polymer network with thermally distinct elasticity and plasticity. Sci. Adv. 2016, 2, e1501297. [Google Scholar] [CrossRef] [PubMed]

- Hao, C.; Liu, T.; Liu, W.; Fei, M.E.; Shao, L.; Kuang, W.; Simmons, K.L.; Zhang, J. Recyclable CFRPs with extremely high T g: Hydrothermal recyclability in pure water and upcycling of the recyclates for new composite preparation. J. Mater. Chem. A 2022, 10, 15623–15633. [Google Scholar] [CrossRef]

- Zhang, B.; Cui, T.; Jiao, X.; Ma, Y.; Gao, L.; Hu, J. Reprocessable and recyclable high-performance carbon fiber-reinforced composites enabled by catalyst-free covalent adaptable networks. Chem. Eng. J. 2023, 476, 146625. [Google Scholar] [CrossRef]

- Xu, Y.; Zhang, H.; Dai, S.; Xu, S.; Wang, J.; Bi, L.; Jiang, J.; Chen, Y. Hyperbranched polyester catalyzed self-healing bio-based vitrimer for closed-loop recyclable carbon fiber-reinforced polymers. Compos. Sci. Technol. 2022, 228, 109676. [Google Scholar] [CrossRef]

- Yu, K.; Shi, Q.; Dunn, M.L.; Wang, T.; Qi, H.J. Carbon fiber reinforced thermoset composite with near 100% recyclability. Adv. Funct. Mater. 2016, 26, 6098–6106. [Google Scholar] [CrossRef]

- Si, H.; Zhou, L.; Wu, Y.; Song, L.; Kang, M.; Zhao, X.; Chen, M. Rapidly reprocessable, degradable epoxy vitrimer and recyclable carbon fiber reinforced thermoset composites relied on high contents of exchangeable aromatic disulfide crosslinks. Compos. Part B Eng. 2020, 199, 108278. [Google Scholar] [CrossRef]

- Qin, B.; Liu, S.; Xu, J.F. Reversible Amidation Chemistry Enables Closed-Loop Chemical Recycling of Carbon Fiber Reinforced Polymer Composites to Monomers and Fibers. Angew. Chem. Int. Ed. 2023, 62, e202311856. [Google Scholar] [CrossRef]

- Wu, P.; Liu, L.; Wu, Z. A transesterification-based epoxy vitrimer synthesis enabled high crack self-healing efficiency to fibrous composites. Compos. A Appl. Sci. Manuf. 2022, 162, 107170. [Google Scholar] [CrossRef]

- Patel, T.; Kim, M.P.; Park, J.; Lee, T.H.; Nellepalli, P.; Noh, S.M.; Jung, H.W.; Ko, H.; Oh, J.K. Self-healable reprocessable triboelectric nanogenerators fabricated with vitrimeric poly(hindered urea) networks. ACS Nano 2020, 14, 11442–11451. [Google Scholar] [CrossRef]

- Yu, L.; Lei, Z.; Sun, X.; Ding, P.; Wesche, A.; Jin, Y.; Zhang, W.; Long, R. Rapid fabrication of fiber-reinforced polyimine composites with reprocessability, repairability, and recyclability. ACS Appl. Polym. Mater. 2021, 3, 5808–5817. [Google Scholar] [CrossRef]

- Kamble, M.; Vashisth, A.; Yang, H.; Pranompont, S.; Picu, C.R.; Wang, D.; Koratkar, N. Reversing fatigue in carbon-fiber reinforced vitrimer composites. Carbon 2022, 187, 108–114. [Google Scholar] [CrossRef]

- Chen, Y.; Fang, J.; Zhu, S.; Liu, X.; Wang, Z. Tailoring Epoxy Vitrimers for Advanced Composites: Challenges and Opportunities. Prog. Polym. Sci. 2022, 128, 101528. [Google Scholar]

- Rybicka, J.; Tiwari, A.; Leeke, G.A. A Generic Cost Estimating Approach for a Composite Manufacturing Process Assessment. Sustainability 2021, 13, 10005. [Google Scholar]

| Types of Mechanism | Types of Materials | Types of Catalyst | Transition Temperature (Tg) | Healing Conditions | Healing Efficiency | Mechanical Strength (MPa) | References |

|---|---|---|---|---|---|---|---|

| Transesterification | Biobased triepoxy | [Zn (Ac)2] | 187 °C | 220 °C, slight pressure | 90% | 62.8–69.2 | [128] |

| Transesterification | Epoxy | Tributylamine (TBA) | 130 °C | 160 °C, 3 h | 57% | 20 | [129] |

| Transesterification | Liquid crystalline vitrimer with amino-capped trimer | Triazobicyclodecene (TBD) | 58 °C | IR laser | 100% | 41.4 | [131] |

| Transesterification | Polydopamine-modified gold nanosheet epoxy vitrimer | Triazobicyclodecene (TBD) | 42 °C | Light, 120 min | 90–100% | 90 | [132] |

| Transamination | Poly(vinylogous urethane) | Catalyst free | 87 °C | 150 °C, 30 min | 76% | 25 | [133] |

| Transalkylation | Poly(1,2,3-triazolium ionic liquid) | Catalyst free | −8, −23 °C | - | - | 15 | [134] |

| Transalkylation | Poly(thioether) | Catalyst free | −20 °C | 160 °C, 45 min | 100% | 80 | [135] |

| Transcarbamoylation | Polyhydroxy urethane | Catalyst free | 54 °C | 160 °C, 4 MPa for 8 h | 76% | 2.2 ± 0.4 | [136] |

| Disulfide | Epoxy with silica nanoparticles | Catalyst free | 151–155 °C | 180 °C, 30–120 min | 36.8–78.1% | 58.5 ± 1.3 | [137] |

| Disulfide | Polyhydroxy urethane | Catalyst free | 66 °C | 150 °C, 510 MPa for 30 min | 65% | 35 | [138] |

| Disulfide | Epoxy with FRP | Catalyst free | 127 °C | 200 °C,100 bar for 5 min | - | 43 ± 7 | [139] |

| Imine | Polyimine | Catalyst free | 102 °C | 110 °C for 30 min | - | Dry and wet samples, 49 and 32 | [140] |

| Matrix Type | Reinforcement | Tensile Strength (MPa) | Flexural Strength (MPa) | Modulus (GPa) | ILSS (MPa) | Retention After Recycling | Test Standard | Ref. |

|---|---|---|---|---|---|---|---|---|

| Polyimine vitrimer | Neat polymer | ~40 | – | 1.0 | Significant recovery after reprocessing | ASTM D3039/ASTM D790 | [36] | |

| Polyimine vitrimer | Carbon fiber (single ply woven) | ~400 | ~150 | 14.2 | Excellent recovery after reprocessing | ASTM D3039/ASTM D790 | [36] | |

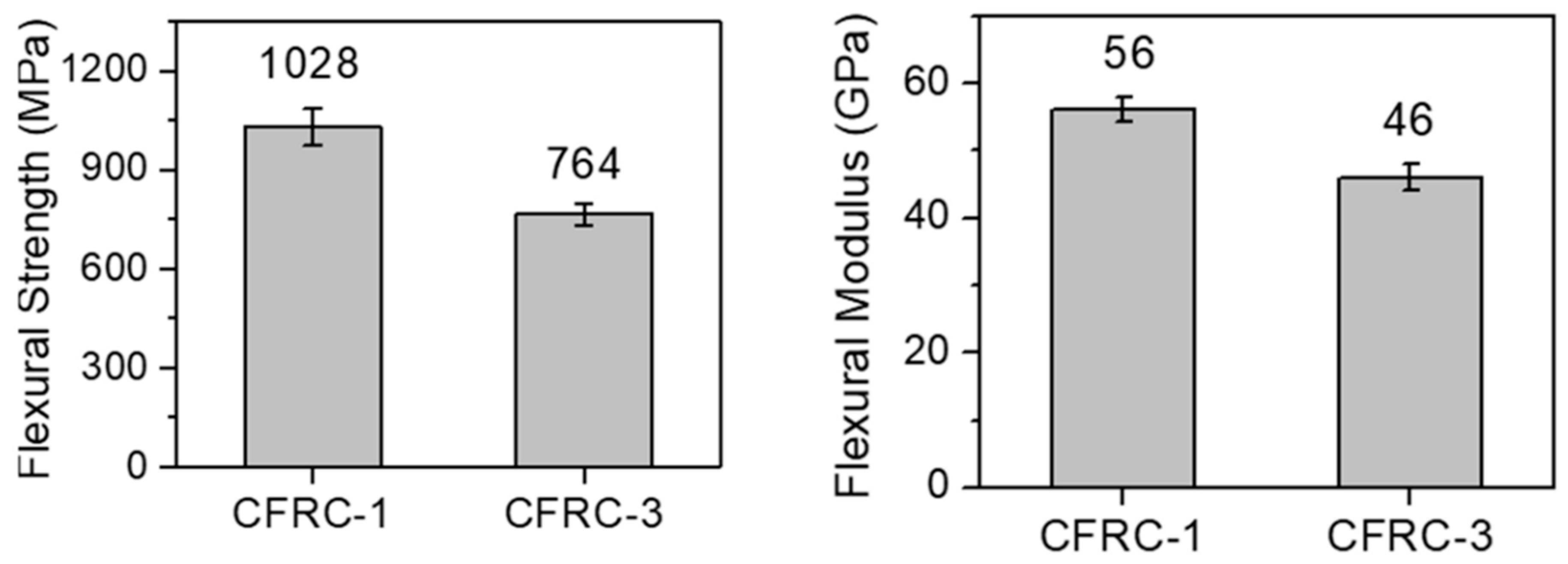

| Epoxy vitrimer (imine-cured DGEBA) | Carbon fiber | – | 1028 | 56 | 70–80% after 3 chemical recycling cycles | ASTM D790 | [153] | |

| Epoxy vitrimer (disulfide cured DGEBA) | Carbon fiber | 1460 | – | 144 | Retained ~33 MPa tensile after grinding & hot-pressing | ASTM D3039 | [75] | |

| Bio-based epoxy vitrimer (vanillin-based) | Neat polymer | 90 | – | 1.18 | ~85 MPa tensile after reprocessing | ASTM D3039 | [132] | |

| Conventional GFRP (pultruded) | Glass fiber | 253 | – | 24.5 | Not recyclable | ASTM D3039/ASTM D790 | [114] | |

| Conventional hybrid (kenaf/glass) | Hybrid fibers | – | – | – | 21.5 | Not recyclable | ASTM D2344 (ILSS) | [115] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kumar, V.; Shahwan, K.W.; Kuang, W.; Simmons, K.L.; Taynton, P.; Cieslinski, E.R. Pultrusion and Vitrimer Composites: Emerging Pathways for Sustainable Structural Materials. J. Compos. Sci. 2025, 9, 559. https://doi.org/10.3390/jcs9100559

Kumar V, Shahwan KW, Kuang W, Simmons KL, Taynton P, Cieslinski ER. Pultrusion and Vitrimer Composites: Emerging Pathways for Sustainable Structural Materials. Journal of Composites Science. 2025; 9(10):559. https://doi.org/10.3390/jcs9100559

Chicago/Turabian StyleKumar, Vishal, Khaled W. Shahwan, Wenbin Kuang, Kevin L. Simmons, Philip Taynton, and Emily R. Cieslinski. 2025. "Pultrusion and Vitrimer Composites: Emerging Pathways for Sustainable Structural Materials" Journal of Composites Science 9, no. 10: 559. https://doi.org/10.3390/jcs9100559

APA StyleKumar, V., Shahwan, K. W., Kuang, W., Simmons, K. L., Taynton, P., & Cieslinski, E. R. (2025). Pultrusion and Vitrimer Composites: Emerging Pathways for Sustainable Structural Materials. Journal of Composites Science, 9(10), 559. https://doi.org/10.3390/jcs9100559