Design of Experiments (DoE) Approach for Optimizing the Processing and Manufacturing Parameters of SnO2 Thin Films via Ultrasonic Pyrolytic Deposition

Abstract

1. Introduction

2. Materials and Methods

2.1. Deposition Process

2.2. Experimental Design

3. Results

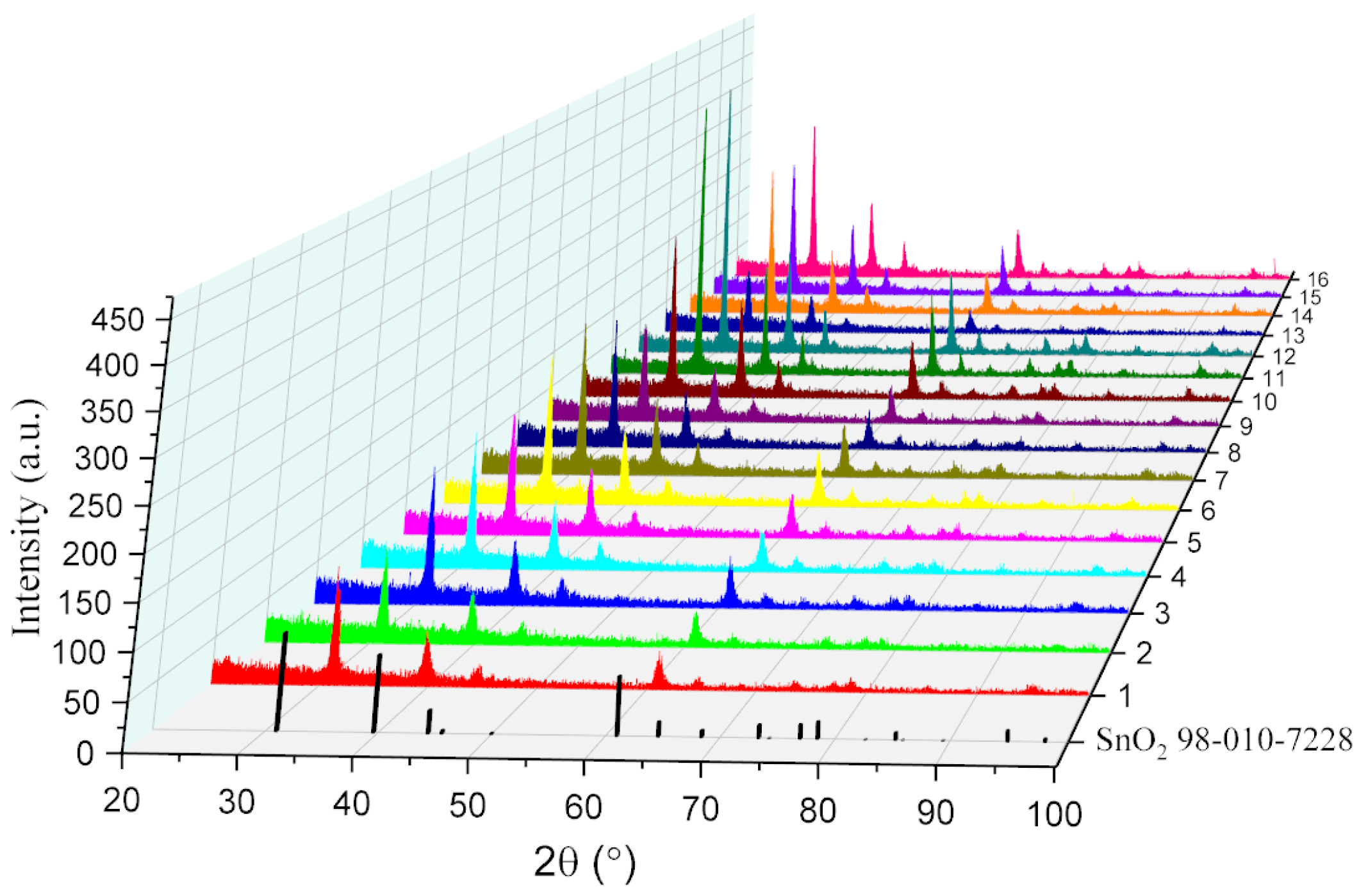

3.1. Response Variable (X-Ray Diffraction)

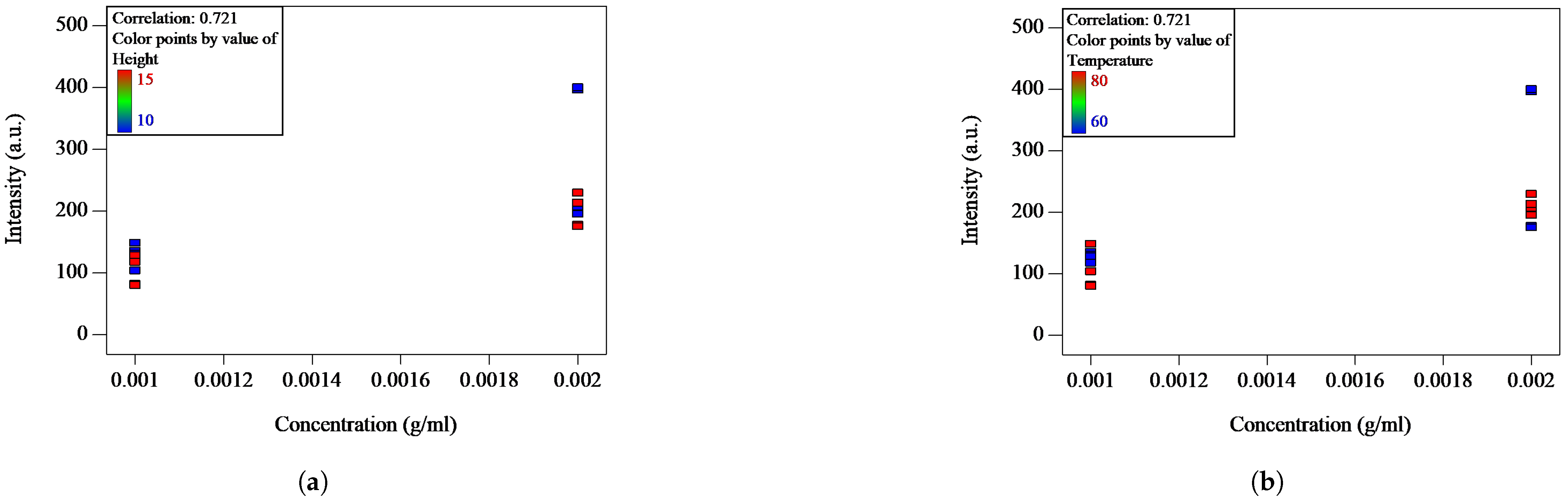

3.2. Design Disposition

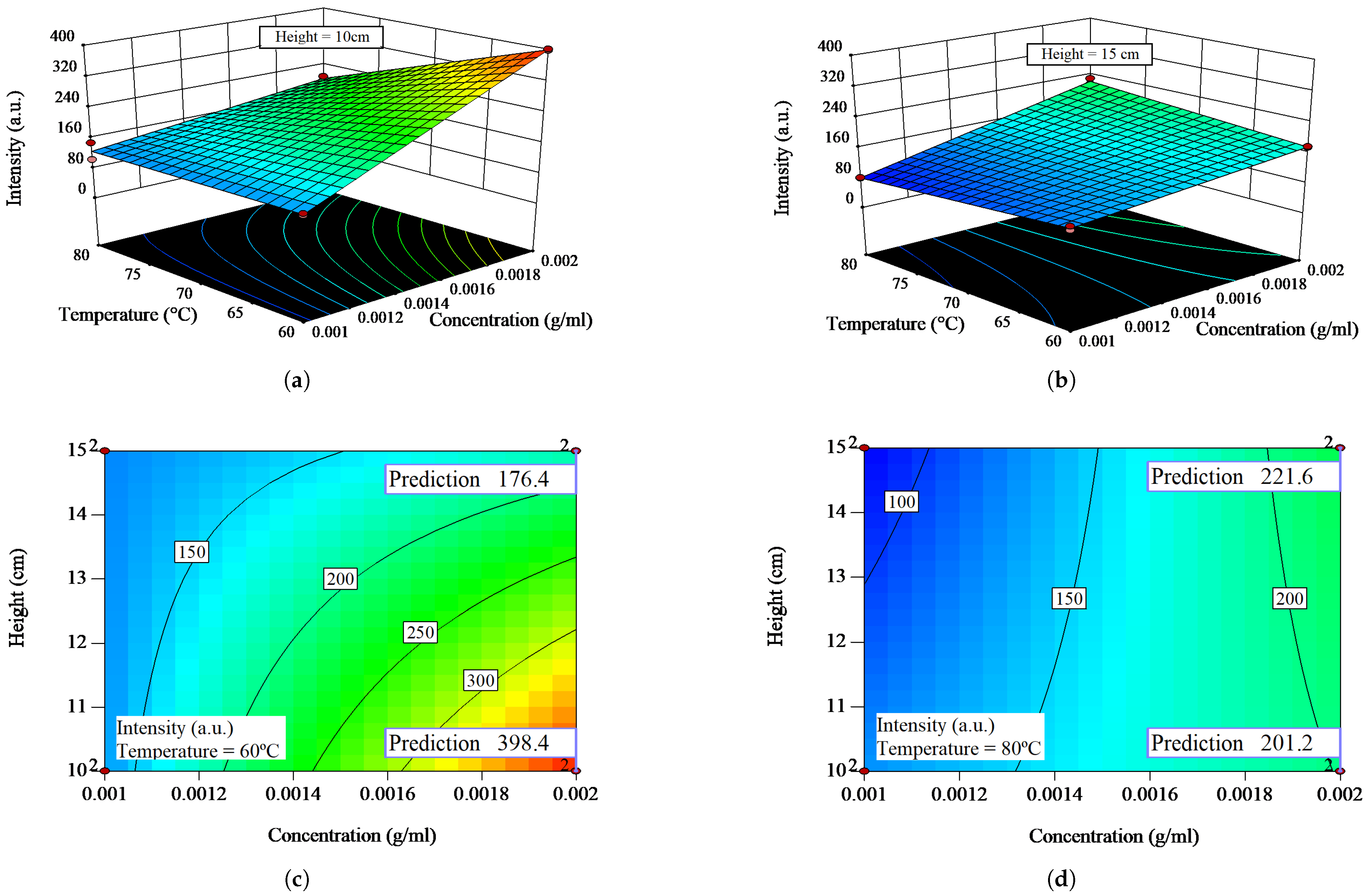

3.3. DoE Analysis

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| SnO2 | Tin(IV) oxide |

| DoE | Design of Experiments |

| OVAT | One Variable At a Time |

| RSM | Response Surface Methodology |

| CCD | Central Composite Design |

| USP | Ultrasonic Spray Pyrolysis |

| APS | Atmospheric Pressure Solvothermal |

| EBPVD | Electron Beam Physical Vapor Deposition |

| CBD | Chemical Bath Deposition |

| XRD | X-ray Diffraction |

| ANOVA | Analysis of Variance |

| SS | Sum of Squares |

| df | Degrees of Freedom |

| Std. Dev. | Standard Deviation |

| C.V.% | Coefficient of Variation (Percentage) |

| PRESS | Predicted Residual Sum of Squares |

| R-Squared () | Coefficient of Determination |

| Adj R-Squared | Adjusted R-Squared |

| Pred R-Squared | Predicted R-Squared |

| Adeq Precision | Adequate Precision |

| Suspension Concentration (g/mL) | |

| Substrate Temperature (°C) | |

| Deposition Height (cm) | |

| Y | Response variable (Net peak intensity in XRD, a.u.) |

| Mean value of responses across all experiments |

References

- Wang, F.; Lv, Z.; Zhong, X.; Wang, J.; Li, F.; Chen, H.; Li, M. Soft-template-assisted bottom-up fabrication of tunable porosity monolithic copper film for interconnection in microelectronics. J. Taiwan Inst. Chem. Eng. 2023, 152, 105192. [Google Scholar] [CrossRef]

- Ahn, K.; Islam, M.M.; Chang, Y.; Jang, J. Highly Robust Spray-Pyrolyzed Al2O3 Gate Insulator for Flexible a-IGZO Thin-Film Transistors for Low-Power Displays. Phys. Status Solidi 2025, 222, 2400894. [Google Scholar] [CrossRef]

- Oh, I.; Park, J.; Choe, D.; Jo, J.; Jeong, H.; Jin, M.J.; Jo, Y.; Suh, J.; Min, B.C.; Yoo, J.W. A scalable molecule-based magnetic thin film for spin-thermoelectric energy conversion. Nat. Commun. 2021, 12, 1057. [Google Scholar] [CrossRef] [PubMed]

- Alsulami, Q.A.; Rajeh, A. Modification and development in the microstructure of PVA/CMC-GO/Fe3O4 nanocomposites films as an application in energy storage devices and magnetic electronics industry. Ceram. Int. 2023, 49, 14399–14407. [Google Scholar] [CrossRef]

- Geistert, K.; Pappenberger, R.; Scharfer, P.; Cavadini, P.; Schabel, W.; Sadegh, F.; Ritzer, D.B.; Abdollahi Nejand, B.; Paetzold, U.W. Spatially Regulated Gas Flow Control for Batch-Drying of Large Area Slot-Die-Coated Perovskite Thin Films. Adv. Energy Mater. 2025, 15, 2500923. [Google Scholar] [CrossRef]

- Cho, Y.; Lee, S.; Heo, S.; Choi, S.; Bae, J.H.; Kang, I.M.; Kim, K.; Lee, W.Y.; Jang, J. Electrically and environmentally stable nitric acid-assisted SnO2 films for the active channel layer of thin-film transistors. Mater. Today Adv. 2025, 26, 100575. [Google Scholar] [CrossRef]

- Jaffri, S.B.; Ahmad, K.S.; Abrahams, I.; Almanqur, L.; Alharbi, Y.T.; Alderhami, S.A. N-type semiconductor [Gd3+-Ho3+-Dy3+]:SnO2 driven functionality enhancement in energy systems associated with photovoltaic and electrochemical contraptions. Mater. Today Sustain. 2024, 25, 100673. [Google Scholar] [CrossRef]

- Kania, A.; Szindler, M.M.; Szindler, M.; Brytan, Z.; Łoński, W. Structure and Selected Properties of SnO2 Thin Films. Materials 2024, 17, 3348. [Google Scholar] [CrossRef] [PubMed]

- Siva Jahnavi, V.; Rajesh Babu, B.; Lakshmi, C.S. Synthesis, characterization of Al-doped SnO2 nanoparticles for enhanced dielectric properties and antibacterial activity. Phys. B Condens. Matter 2024, 692, 416359. [Google Scholar] [CrossRef]

- Reshma, T.; Sahu, B.K.; Panda, M.; Annalekshmi, O.; Das, A. Band edge tuned SnO2 quantum dots allowing superoxide generation for efficient organic pollutant degradation. J. Alloys Compd. 2025, 1030, 180846. [Google Scholar] [CrossRef]

- Chai, N.; Chen, X.; Zeng, Z.; Yu, R.; Yue, Y.; Mai, B.; Wu, J.; Mai, L.; Cheng, Y.B.; Wang, X. Photoexcitation-induced passivation of SnO2 thin film for efficient perovskite solar cells. Natl. Sci. Rev. 2023, 10, nwad245. [Google Scholar] [CrossRef]

- Naffouti, W.; Kamoun-Turki, N. Photocatalytic performance and solar cell simulations of TiO2–SnO2:F mixed oxide thin films grown by spray pyrolysis method. Opt. Mater. 2025, 158, 116491. [Google Scholar] [CrossRef]

- Atman, B.; Karakaş, G.; Uludağ, Y. Mathematical modeling of response dynamics of n-type SnO2-based thick film gas sensor. Mater. Sci. Semicond. Process. 2025, 190, 109360. [Google Scholar] [CrossRef]

- Senthilkumar, P.; Raja, S.; Ramesh Babu, R.; Sriramkumar, M.; Jothivenkatachalam, K.; Vasuki, G. Enhanced optoelectronic and catalytic properties of Sm doped SnO2 thin films. Phys. B Condens. Matter 2024, 690, 416208. [Google Scholar] [CrossRef]

- Emam-Ismail, M.; Gharieb, A.A.; Moustafa, S.; Mahasen, M.; Shaaban, E.; El-Hagary, M. Enhancement of multifunctional optoelectronic and spintronic applications of nanostructured Cr-doped SnO2 thin films by conducting microstructural, optical, and magnetic measurements. J. Phys. Chem. Solids 2021, 157, 110195. [Google Scholar] [CrossRef]

- Mohajir, A.E.; Yazdi, M.A.P.; Krystianiak, A.; Heintz, O.; Martin, N.; Berger, F.; Sanchez, J.B. Nanostructuring of SnO2 Thin Films by Associating Glancing Angle Deposition and Sputtering Pressure for Gas Sensing Applications. Chemosensors 2022, 10, 426. [Google Scholar] [CrossRef]

- Gangwar, A.K.; Godiwal, R.; Jaiswal, J.; Baloria, V.; Pal, P.; Gupta, G.; Singh, P. Magnetron configurations dependent surface properties of SnO2 thin films deposited by sputtering process. Vacuum 2020, 177, 109353. [Google Scholar] [CrossRef]

- Sarica, E.; Ozcan, H.B.; Gunes, I.; Terlemezoglu, M.; Akyuz, I. Fine-tuning SnO2 films: Unleashing their potential through deposition temperature optimization by ultrasonic spray pyrolysis. Ceram. Int. 2024, 50, 9270–9279. [Google Scholar] [CrossRef]

- Liu, J.; Wang, Y.; Sun, Y.; Zhang, K.; Ding, Y.; Fu, C.; Wang, J. Preparation and Optimization of Mesoporous SnO2 Quantum Dot Thin Film Gas Sensors for H2S Detection Using XGBoost Parameter Importance Analysis. Chemosensors 2023, 11, 525. [Google Scholar] [CrossRef]

- Kasar, R.; Deshpande, N.; Gudage, Y.; Vyas, J.; Sharma, R. Studies and correlation among the structural, optical and electrical parameters of spray-deposited tin oxide (SnO2) thin films with different substrate temperatures. Phys. B Condens. Matter 2008, 403, 3724–3729. [Google Scholar] [CrossRef]

- Newman, S.G. Optimizing Chemical Reactions. Chem. Rev. 2024, 124, 3645–3647. [Google Scholar] [CrossRef] [PubMed]

- Panico, A.; Corvi, A.; Collini, L.; Sciancalepore, C. Multi objective optimization of FDM 3D printing parameters set via design of experiments and machine learning algorithms. Sci. Rep. 2025, 15, 16753. [Google Scholar] [CrossRef]

- Antony, J. 1 - Introduction to Industrial Experimentation. In Design of Experiments for Engineers and Scientists, 2nd ed.; Antony, J., Ed.; Elsevier: Oxford, UK, 2014; pp. 1–6. [Google Scholar] [CrossRef]

- Salma, S.; Hartiti, B.; Ziti, A.; Tchognia Nkuissi, H.J.; Benali, H.; Aykut, Y.; Fadili, S.; Thevenin, P.; Ertuğrul, M. Elaboration and characterization of quaternary material Cu2ZnSnS4 by spray pyrolysis technique using Taguchi method. Appl. Phys. A 2023, 129, 633. [Google Scholar] [CrossRef]

- Pinheiro, X.; Vilanova, A.; Mesquita, D.; Monteiro, M.; Eriksson, J.; Barbosa, J.; Matos, C.; Oliveira, A.; Oliveira, K.; Capitão, J.; et al. Design of experiments optimization of fluorine-doped tin oxide films prepared by spray pyrolysis for photovoltaic applications. Ceram. Int. 2023, 49, 13019–13030. [Google Scholar] [CrossRef]

- Patel, S.B.; Vaghela, G.D.; Gohel, J.V. Chapter Seven - Superior power conversion efficiency of novel solar cell and multi-response optimization of spray coated SnO2 thin films. In Custom Power Devices for Efficient Distributed Energy Systems; Al-Durra, A., Raj Arya, S., K. Giri, A., Eds.; Elsevier: Amsterdam, The Netherlands, 2024; pp. 169–188. [Google Scholar] [CrossRef]

- Zapata-Cruz, J.R.; Armendáriz-Mireles, E.N.; Rocha-Rangel, E.; Suarez-Velazquez, G.; González-Quijano, D.; Pech-Rodríguez, W.J. Implementation of Taguchi method to investigate the effect of electrophoretic deposition parameters of SnO2 on dye sensitised solar cell performance. Mater. Technol. 2019, 34, 549–557. [Google Scholar] [CrossRef]

- Nabizadeh Chianeh, F.; Basiri Parsa, J. Degradation of azo dye from aqueous solutions using nano-SnO2/Ti electrode prepared by electrophoretic deposition method: Experimental Design. Chem. Eng. Res. Des. 2014, 92, 2740–2748. [Google Scholar] [CrossRef]

- Tilebon, S.M.S.; Norouzbeigi, R. Anti-icing nano SnO2 coated metallic surface wettability: Optimization via statistical design. Surfaces Interfaces 2020, 21, 100720. [Google Scholar] [CrossRef]

- Fisenko, N.A.; Solomatov, I.A.; Simonenko, N.P.; Mokrushin, A.S.; Gorobtsov, P.Y.; Simonenko, T.L.; Volkov, I.A.; Simonenko, E.P.; Kuznetsov, N.T. Atmospheric Pressure Solvothermal Synthesis of Nanoscale SnO2 and Its Application in Microextrusion Printing of a Thick-Film Chemosensor Material for Effective Ethanol Detection. Sensors 2022, 22, 9800. [Google Scholar] [CrossRef]

- Ghamari, F.; Raoufi, D.; Arjomandi, J. Influence of thickness on crystallographic, stereometric, optoelectronic, and electrochemical characteristics of electron-beam deposited indium tin oxide thin films. Mater. Chem. Phys. 2021, 260, 124051. [Google Scholar] [CrossRef]

- Jaishree, N.; Hashmi, A.; Katre, Y.; Singh, R.S.; Singh, J.; Srivastava, A.; Singh, A.K. The influence of different complexing agents on the properties of tin dioxide (SnO2) deposited thin films through chemical bath approach. Phys. B Condens. Matter 2023, 650, 414520. [Google Scholar] [CrossRef]

| Variable | USP Process Factors | Units | Low Level (−1) | High Level (+1) |

|---|---|---|---|---|

| Concentration | g/mL | 0.001 | 0.002 | |

| Temperature | °C | 60 | 80 | |

| Height | cm | 10 | 15 |

| Run | X1 | X2 | X3 | Y |

|---|---|---|---|---|

| Intensity (a.u.) | ||||

| 1 | −1 | 1 | −1 | 103.9 |

| 2 | −1 | 1 | 1 | 80.2 |

| 3 | −1 | −1 | −1 | 135.4 |

| 4 | −1 | −1 | 1 | 127.8 |

| 5 | −1 | −1 | −1 | 130.8 |

| 6 | 1 | −1 | 1 | 175.4 |

| 7 | 1 | −1 | 1 | 177.4 |

| 8 | −1 | 1 | −1 | 148.5 |

| 9 | −1 | −1 | 1 | 117.9 |

| 10 | 1 | 1 | 1 | 213.6 |

| 11 | 1 | −1 | −1 | 396.6 |

| 12 | 1 | −1 | −1 | 400.2 |

| 13 | −1 | 1 | 1 | 81.6 |

| 14 | 1 | 1 | −1 | 206.9 |

| 15 | 1 | 1 | −1 | 195.5 |

| 16 | 1 | 1 | 1 | 229.6 |

| Term | Coefficient | SS | df | Mean Square | F-Value | p-Value * |

|---|---|---|---|---|---|---|

| Model | 1.360 × 105 | 7 | 19434.06 | 123.72 | <0.0001 | |

| 182.58 | ||||||

| 66.82 | 71,435.93 | 1 | 71,435.93 | 454.79 | <0.0001 | |

| −25.11 | 10,085.18 | 1 | 10,085.18 | 64.21 | <0.0001 | |

| −32.14 | 16,531.53 | 1 | 16,531.53 | 105.25 | <0.0001 | |

| −12.89 | 2659.98 | 1 | 2659.98 | 16.93 | 0.0034 | |

| −18.26 | 5332.65 | 1 | 5332.65 | 33.95 | 0.0004 | |

| 25.92 | 10,748.51 | 1 | 10,748.51 | 68.43 | <0.0001 | |

| 34.68 | 19,244.63 | 1 | 19,244.63 | 122.52 | <0.0001 | |

| Pure Error | 1256.60 | 8 | 157.08 | |||

| Corrected Total | 1.373 × 105 | 15 | ||||

| Std. Dev. | 12.53 | R-Squared | 0.9908 | |||

| Mean | 182.58 | Adj R-Squared | 0.9828 | |||

| C.V.% | 6.86 | Pred R-Squared | 0.9634 | |||

| PRESS | 5026.42 | Adeq Precision | 35.826 | |||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mariño-Gámez, A.E.; Juarez-Huitron, M.E.; Aguilar-Martínez, J.A.; Felipe-Verdeja, L.; García-Quiñonez, L.V.; Gómez-Rodríguez, C. Design of Experiments (DoE) Approach for Optimizing the Processing and Manufacturing Parameters of SnO2 Thin Films via Ultrasonic Pyrolytic Deposition. J. Compos. Sci. 2025, 9, 555. https://doi.org/10.3390/jcs9100555

Mariño-Gámez AE, Juarez-Huitron ME, Aguilar-Martínez JA, Felipe-Verdeja L, García-Quiñonez LV, Gómez-Rodríguez C. Design of Experiments (DoE) Approach for Optimizing the Processing and Manufacturing Parameters of SnO2 Thin Films via Ultrasonic Pyrolytic Deposition. Journal of Composites Science. 2025; 9(10):555. https://doi.org/10.3390/jcs9100555

Chicago/Turabian StyleMariño-Gámez, Aldo Enrique, Maria Eugenia Juarez-Huitron, Josúe Amilcar Aguilar-Martínez, Luis Felipe-Verdeja, Linda Viviana García-Quiñonez, and Cristian Gómez-Rodríguez. 2025. "Design of Experiments (DoE) Approach for Optimizing the Processing and Manufacturing Parameters of SnO2 Thin Films via Ultrasonic Pyrolytic Deposition" Journal of Composites Science 9, no. 10: 555. https://doi.org/10.3390/jcs9100555

APA StyleMariño-Gámez, A. E., Juarez-Huitron, M. E., Aguilar-Martínez, J. A., Felipe-Verdeja, L., García-Quiñonez, L. V., & Gómez-Rodríguez, C. (2025). Design of Experiments (DoE) Approach for Optimizing the Processing and Manufacturing Parameters of SnO2 Thin Films via Ultrasonic Pyrolytic Deposition. Journal of Composites Science, 9(10), 555. https://doi.org/10.3390/jcs9100555