Wire-Based Additive Manufacturing of Multi-Material Structures: A Review

Abstract

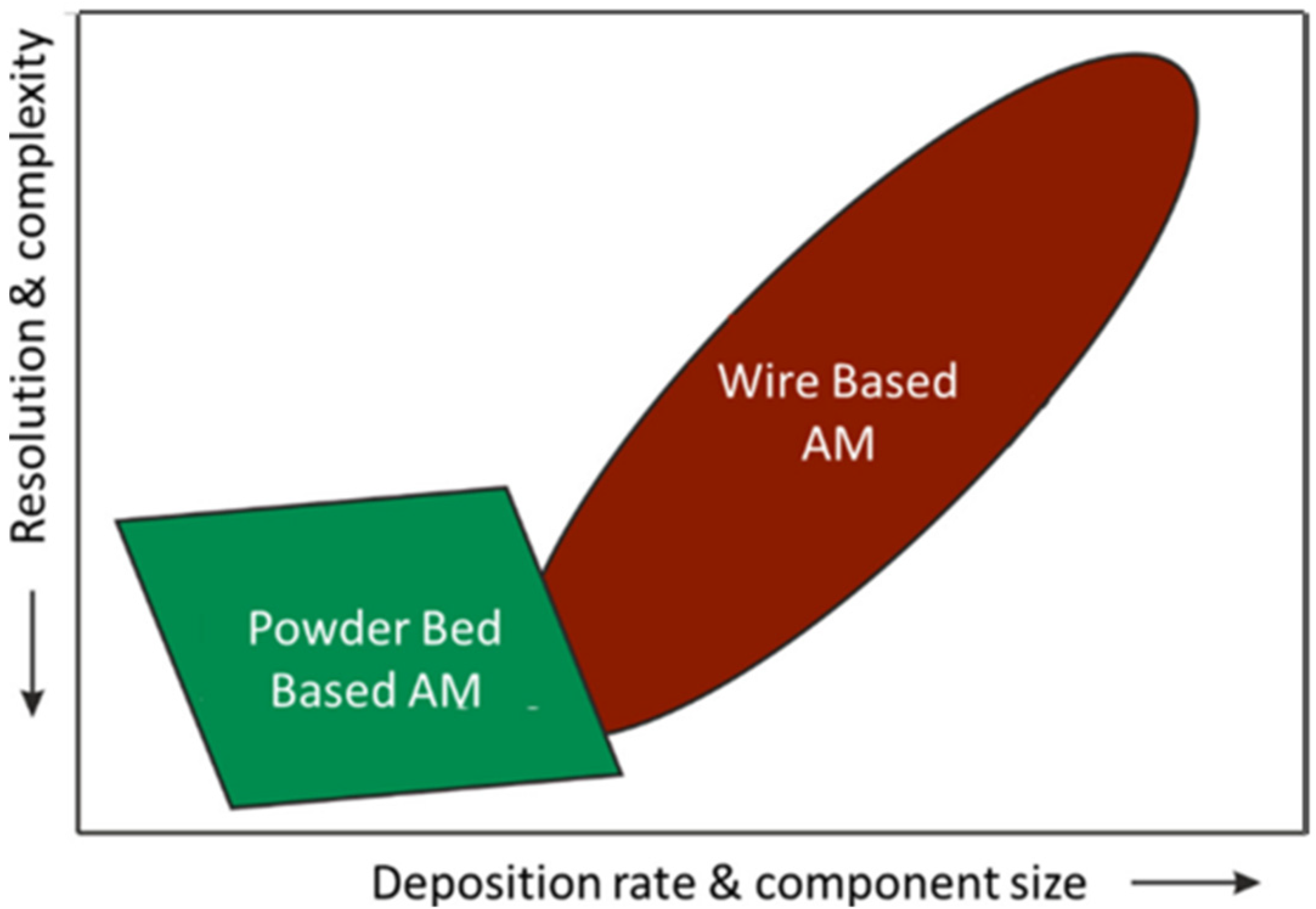

1. Introduction

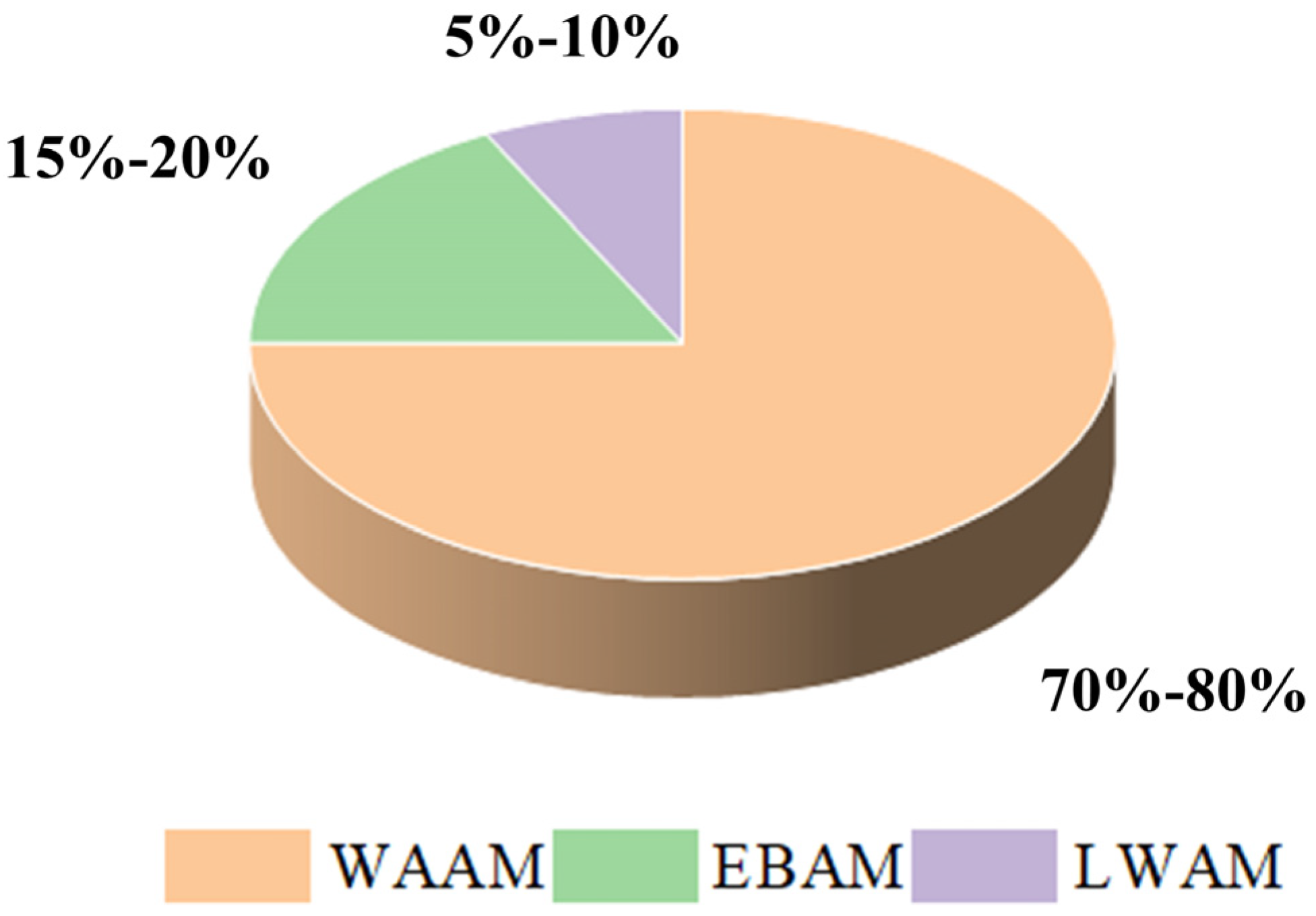

2. Heat Source of Metal Wire Additive Manufacturing

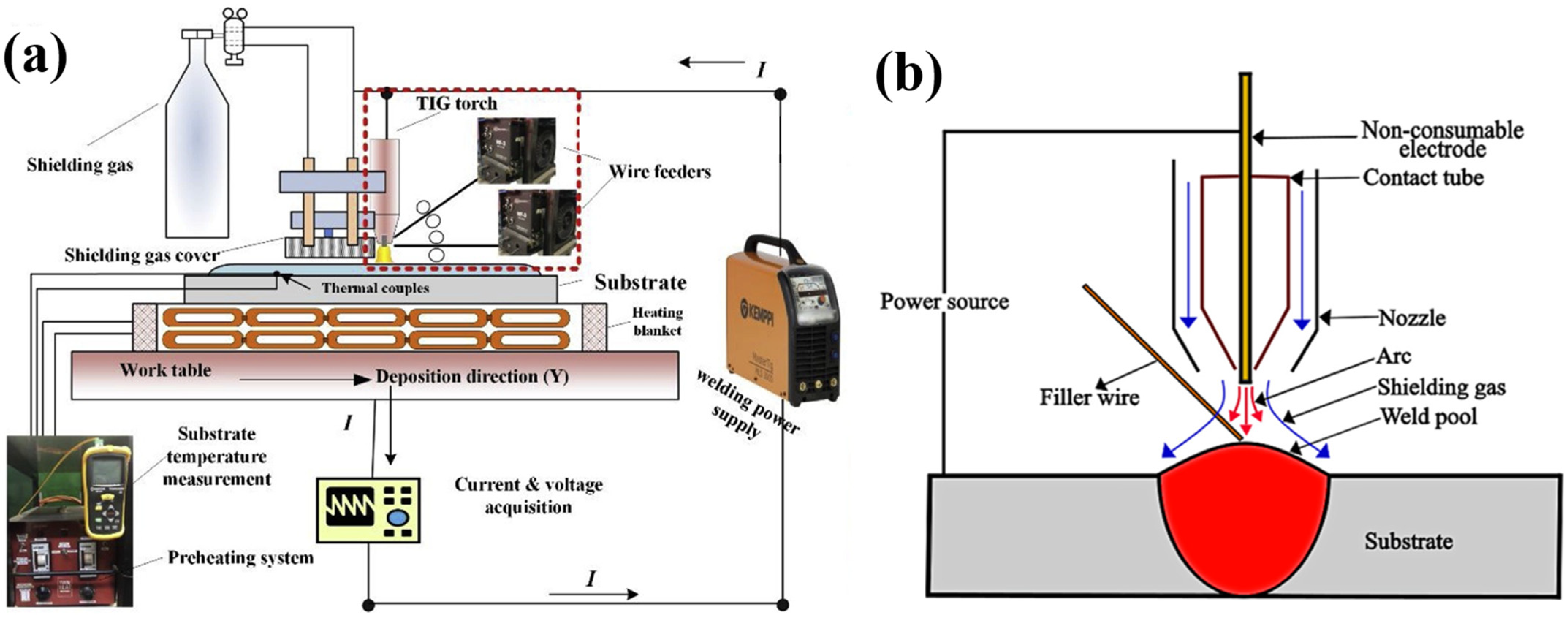

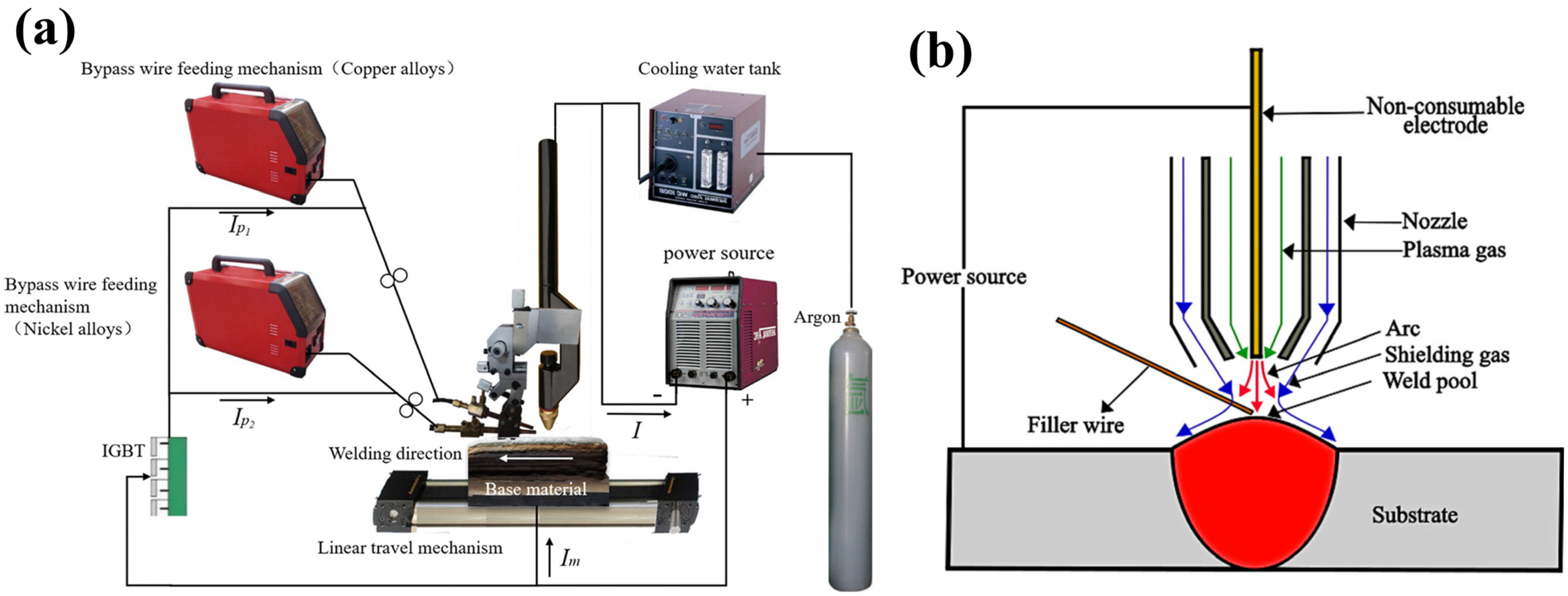

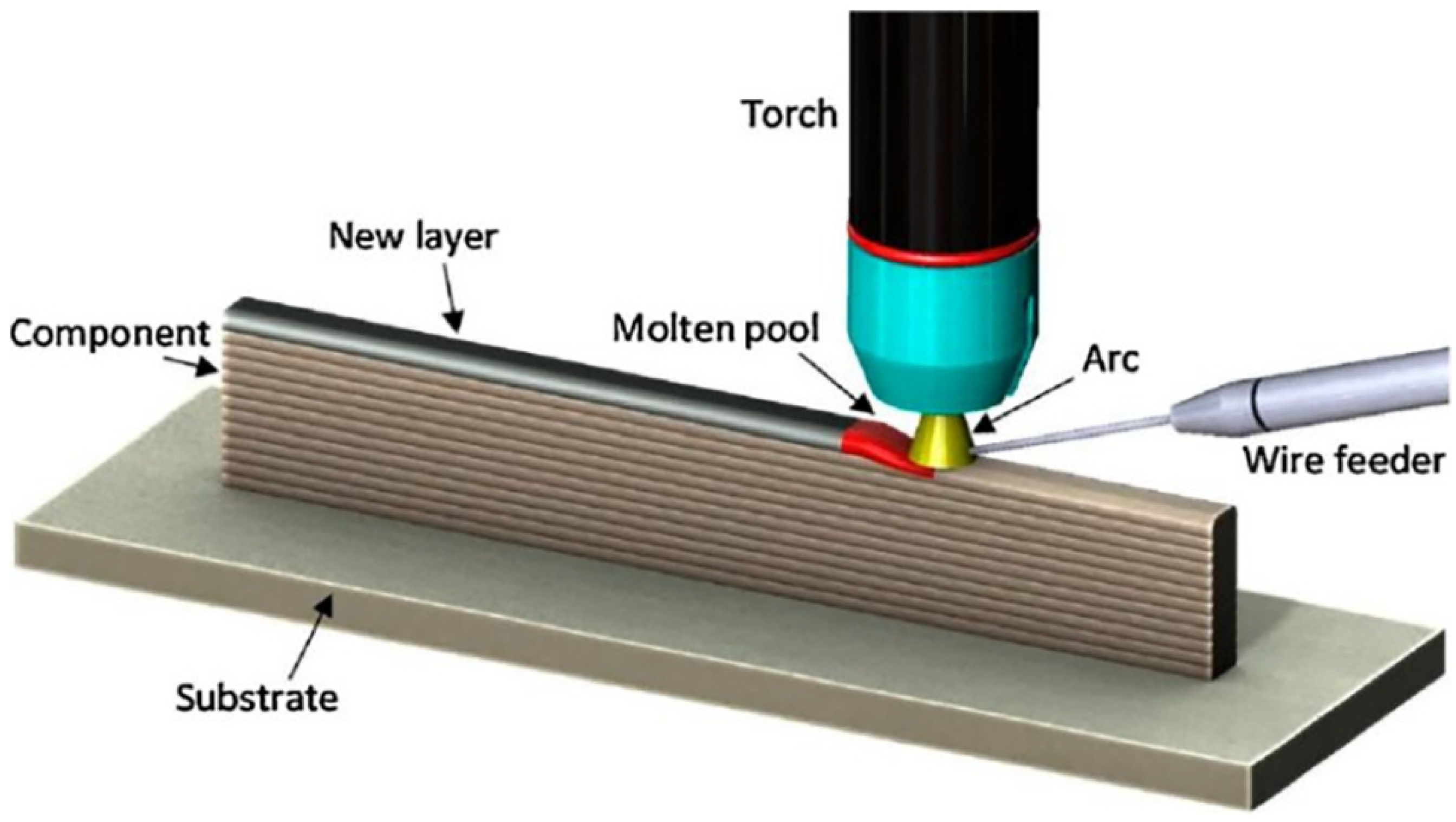

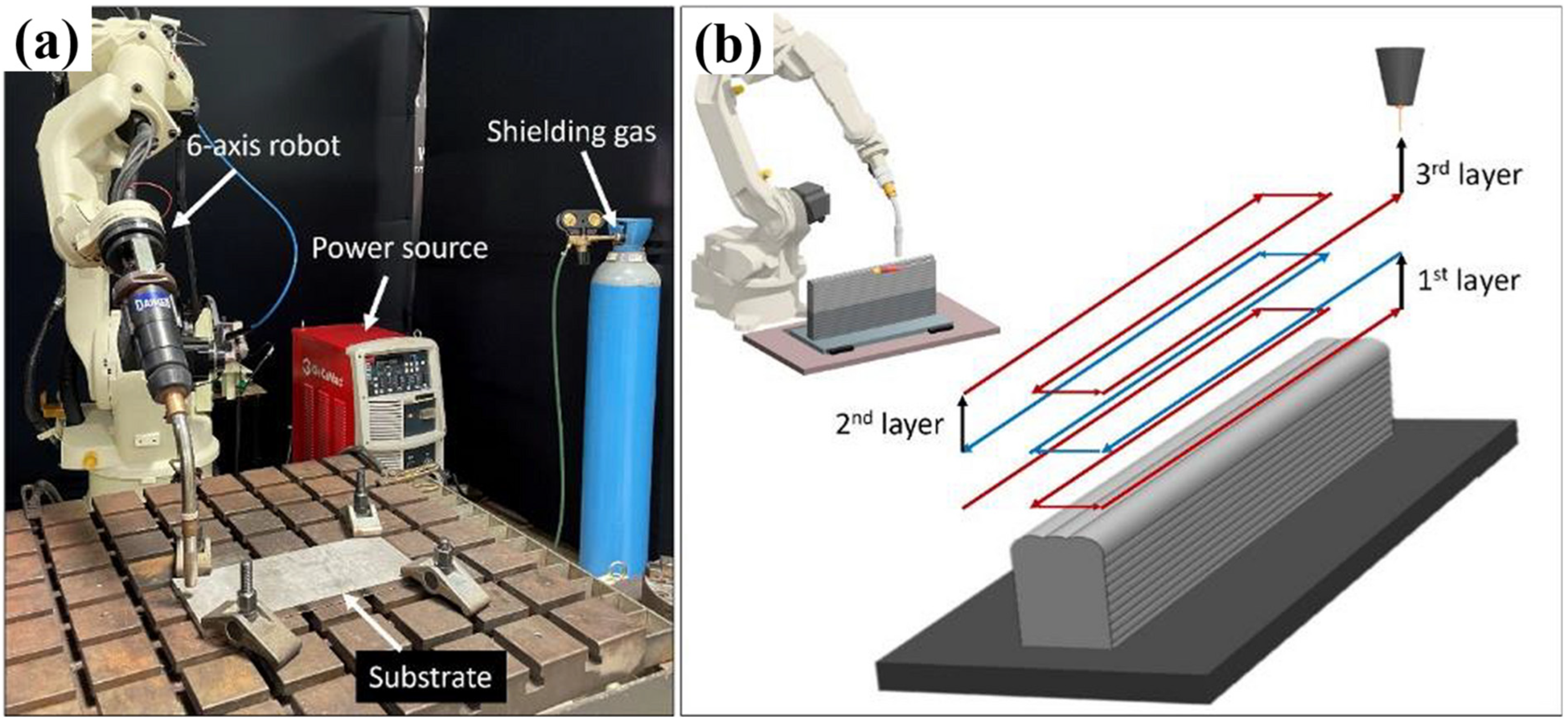

2.1. Wire Arc Additive Manufacturing

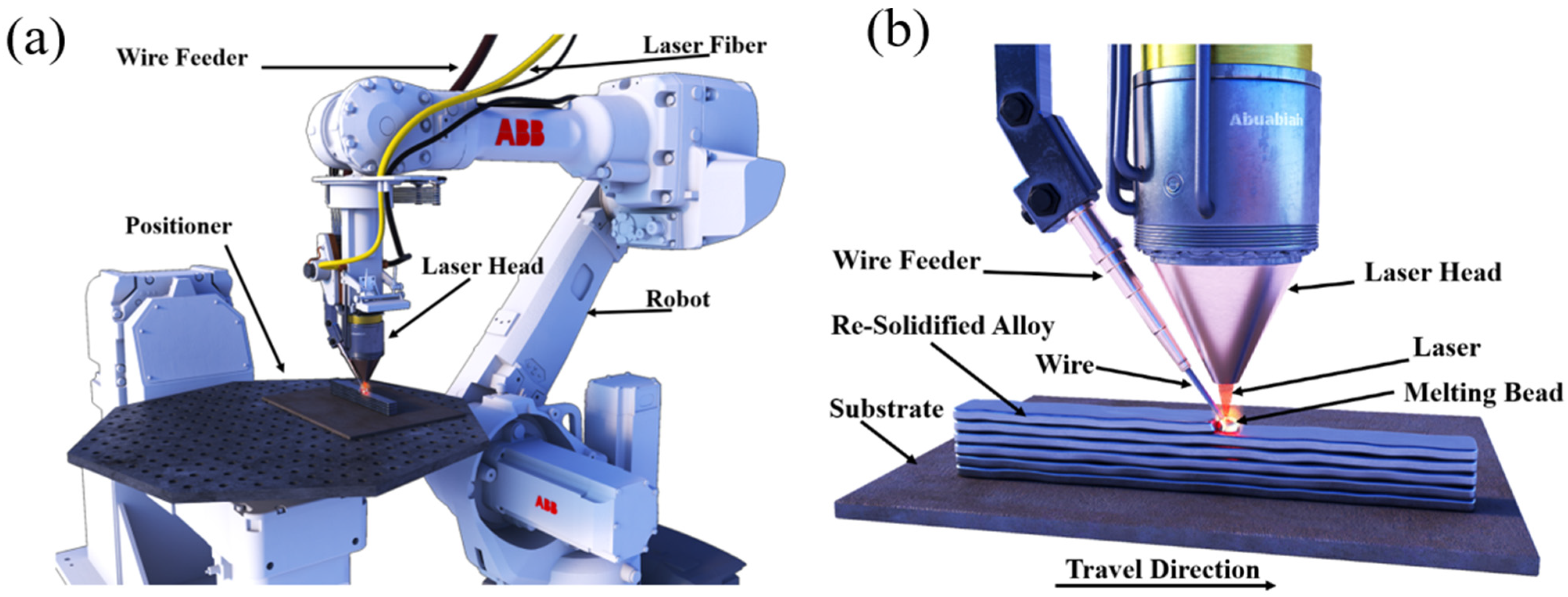

2.2. Laser Wire Additive Manufacturing

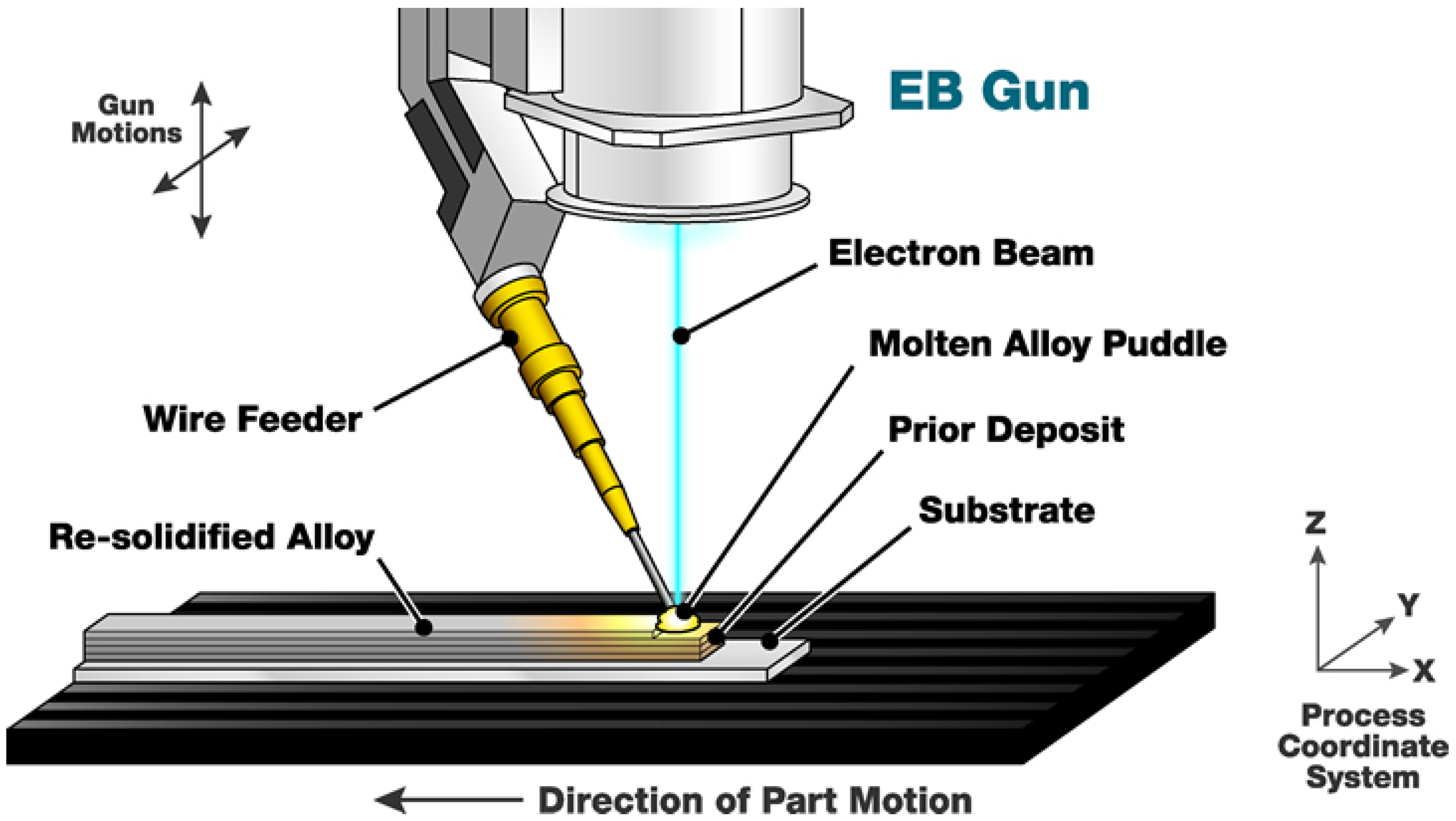

2.3. Electron Beam Additive Manufacturing

3. Wire Feeding System of Metal Wire Additive Manufacturing

3.1. Wire Feeding Method

3.1.1. Single-Wire Feeding

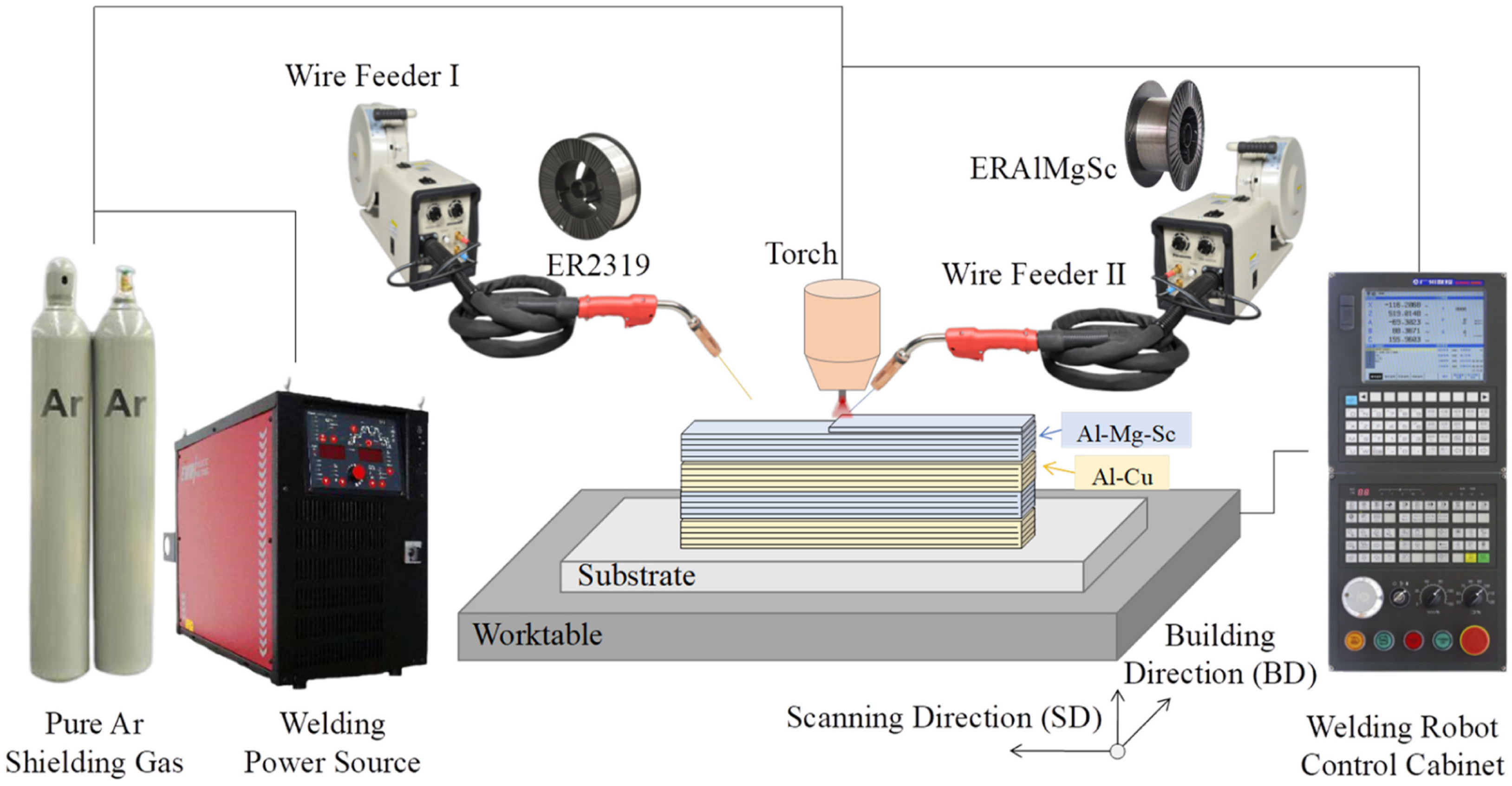

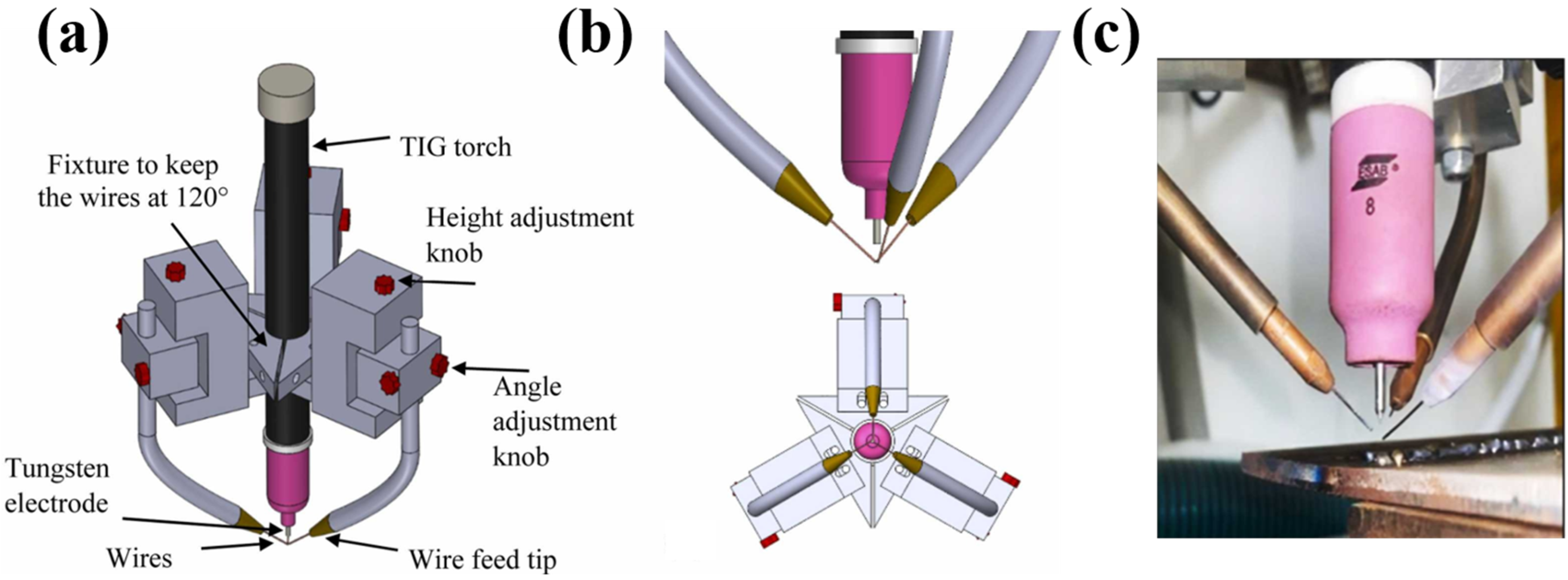

3.1.2. Multi-Wire Feeding

3.2. Wire-Feeding Direction

3.2.1. Coaxial Wire Feeding

3.2.2. Side-Axis Wire Feeding

4. Influencing Factors and Regulation Methods

4.1. Influencing Factors

4.1.1. Deposition Sequence

4.1.2. Deposition Current

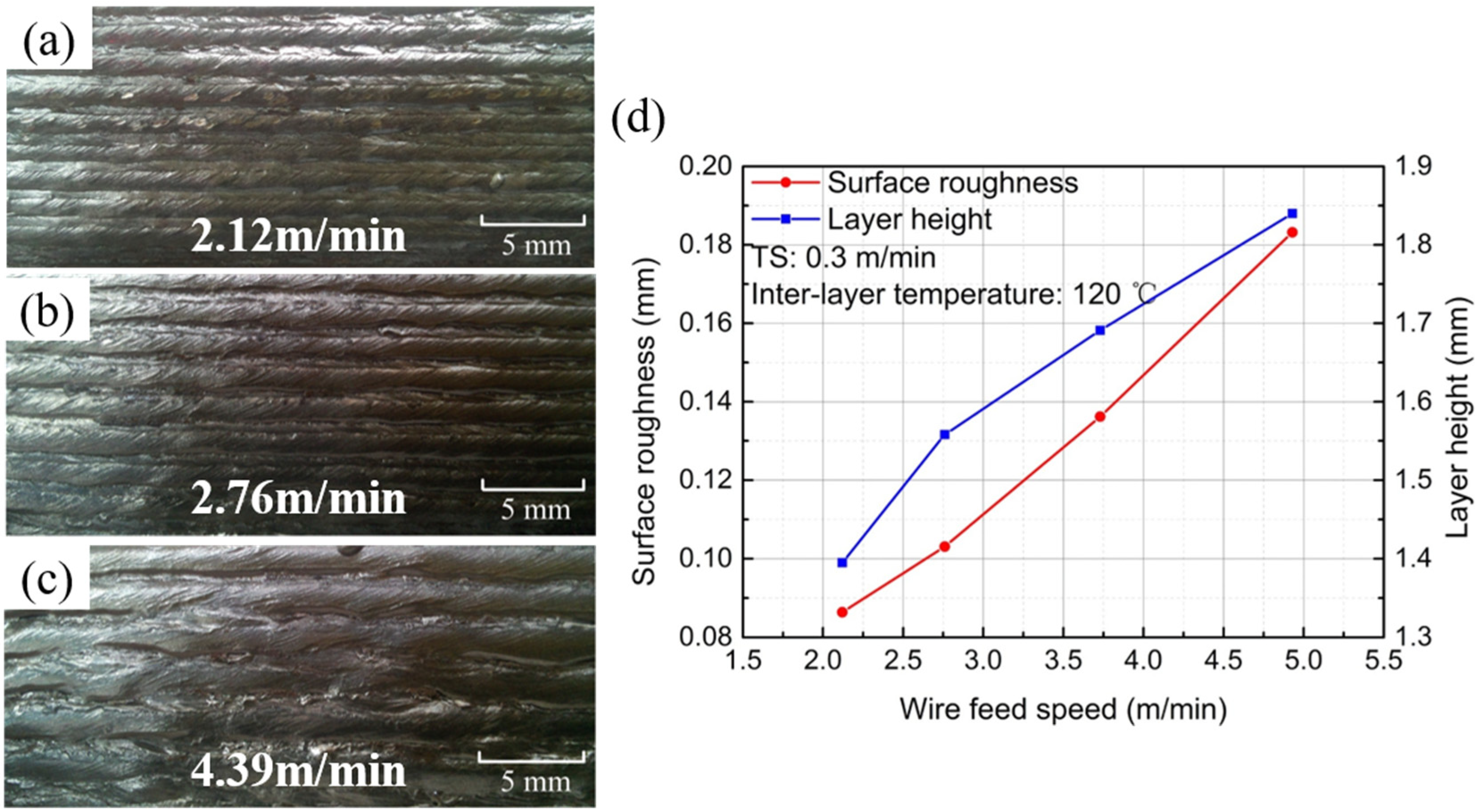

4.1.3. Wire Feeding Speed

4.2. Regulation Methods

4.2.1. Transition Layer

4.2.2. External Field

4.2.3. Post-Treatment

| Material | Heat Treatment Time and Temperature | Effect | Ref. |

|---|---|---|---|

| IN625–SS | 970 °C for 10 and 60 min | Increases hardness and strength | [141] |

| Al Bronze–Steel | 650 °C for 6 h | Redirects the grains and homogenizes the microstructure of Al bronze | [55] |

| Fe3Ni–FeNi | 900 °C held for 1800 s and cooled to 200 °C | Homogenizes the phase volume fraction of materials | [142] |

| SS–IN625 | 800 °C for 2 h | Leads to the formation of the IMCs phase and carbides | [143] |

| IN625–HSLA | 1080 °C for 1 h/1080 °C for 2 h | Dissolves the Laves phase | [144] |

| LCS–SS | 800 °C, 950 °C, and 1100 °C for 0.5, 1, and 2 h | Transferring the failure from the LCS side to the SS side increased the elongation. | [145] |

5. Conclusions and Prospects

5.1. Conclusions

5.2. Prospects

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| AM | Additive manufacturing |

| MMAM | Multi-material additive manufacturing |

| WAAM | Wire arc additive manufacturing |

| GMAW | Gas metal arc welding |

| GTAW | Gas tungsten arc welding |

| PAW | Plasma arc welding |

| CMT | Cold metal transfer |

| EBAM | Electron beam additive manufacturing |

| LWAM | Laser wire additive manufacturing |

| IMCs | Intermetallic compounds |

| DED | Directed energy deposition |

| FGM | Functionally graded material |

| UTS | Ultimate tensile strength |

| MWAAM | Multi-wire arc additive manufacturing |

| WLDED | Wire-feed laser directed energy deposition |

| WFS | Wire feeding speed |

| BS | Bimetallic structure |

| UPT | Ultrasonic peening treatment |

| PWHT | Post-weld heat treatment |

| YS | Yield strengths |

| TIG | Tungsten inert gas welding |

| MIG | Metal inert gas welding |

References

- Bandyopadhyay, A.; Heer, B. Additive manufacturing of multi-material structures. Mater. Sci. Eng. R Rep. 2018, 129, 1–16. [Google Scholar] [CrossRef]

- Bose, S.; Robertson, S.F.; Bandyopadhyay, A. Surface modification of biomaterials and biomedical devices using additive manufacturing. Acta Biomater. 2018, 66, 6–22. [Google Scholar] [CrossRef]

- DebRoy, T.; Mukherjee, T.; Milewski, J.; Elmer, J.; Ribic, B.; Blecher, J.; Zhang, W. Scientific, technological and economic issues in metal printing and their solutions. Nat. Mater. 2019, 18, 1026–1032. [Google Scholar] [CrossRef]

- Zhang, B.; Jaiswal, P.; Rai, R.; Nelaturi, S. Additive manufacturing of functionally graded material objects: A review. J. Comput. Inf. Sci. Eng. 2018, 18, 041002. [Google Scholar] [CrossRef]

- Udupa, G.; Rao, S.S.; Gangadharan, K. Functionally graded composite materials: An overview. Procedia Mater. Sci. 2014, 5, 1291–1299. [Google Scholar] [CrossRef]

- Yi, J.; Wan, L.; Shu, T.; Zhang, X.; Liu, F.; Cheng, G.J. Unleashing multi-scale mechanical enhancement in NiTi shape memory alloy via annular intra-laser deposition with homogenized Ti2Ni nanoprecipitates. Acta Mater. 2024, 262, 119418. [Google Scholar] [CrossRef]

- Xiang, R.; Huang, J.; Yu, X.; Zhao, H.; Song, X.; Fan, D. The effect of Ni/Ti atomic ratios on residual stress and deformation in WAAM of dissimilar filler wire NiTi alloys. J. Mater. Res. Technol. 2025, 35, 1813–1828. [Google Scholar] [CrossRef]

- He, Y.; Zhang, X.; Zhao, Z.; Xu, S.; Xia, M.; Zhang, C.; Hu, Y. Wire-feed laser additive manufacturing of dissimilar metals via dual molten pool interface interlocking mechanism. Sci. China Technol. Sci. 2023, 66, 976–986. [Google Scholar] [CrossRef]

- Domack, M.; Baughman, J. Development of nickel-titanium graded composition components. Rapid Prototyp. J. 2005, 11, 41–51. [Google Scholar] [CrossRef]

- Pompe, W.; Worch, H.; Epple, M.; Friess, W.; Gelinsky, M.; Greil, P.; Hempel, U.; Scharnweber, D.; Schulte, K. Functionally graded materials for biomedical applications. Mater. Sci. Eng. 2003, 362, 40–60. [Google Scholar] [CrossRef]

- Matsuo, S.; Watari, F.; Ohata, N. Fabrication of a functionally graded dental composite resin post and core by laser lithography and finite element analysis of its stress relaxation effect on tooth root. Dent. Mater. J. 2001, 20, 257–274. [Google Scholar] [CrossRef] [PubMed]

- Huang, S.H.; Liu, P.; Mokasdar, A.; Hou, L. Additive manufacturing and its societal impact: A literature review. Int. J. Adv. Manuf. Technol. 2013, 67, 1191–1203. [Google Scholar] [CrossRef]

- Mahamood, R.M.; Akinlabi, E.T.; Mahamood, R.M.; Akinlabi, E.T. Types of functionally graded materials and their areas of application. In Functionally Graded Materials; Springer International Publishing: Cham, Switzerland, 2017; pp. 9–21. [Google Scholar]

- Pajonk, A.; Prieto, A.; Blum, U.; Knaack, U. Multi-material additive manufacturing in architecture and construction: A review. J. Build. Eng. 2022, 45, 103603. [Google Scholar] [CrossRef]

- Li, K.; Yang, T.; Gong, N.; Wu, J.; Wu, X.; Zhang, D.Z.; Murr, L.E. Additive manufacturing of ultra-high strength steels: A review. J. Alloys Compd. 2023, 965, 171390. [Google Scholar] [CrossRef]

- Alammar, A.; Kois, J.C.; Revilla-León, M.; Att, W. Additive manufacturing technologies: Current status and future perspectives. J. Prosthodont. 2022, 31, 4–12. [Google Scholar] [CrossRef] [PubMed]

- Calignano, F.; Manfredi, D.; Ambrosio, E.P.; Biamino, S.; Lombardi, M.; Atzeni, E.; Salmi, A.; Minetola, P.; Iuliano, L.; Fino, P. Overview on additive manufacturing technologies. Proc. IEEE 2017, 105, 593–612. [Google Scholar] [CrossRef]

- Armstrong, M.; Mehrabi, H.; Naveed, N. An overview of modern metal additive manufacturing technology. J. Manuf. Process. 2022, 84, 1001–1029. [Google Scholar] [CrossRef]

- Han, D.; Lee, H. Recent advances in multi-material additive manufacturing: Methods and applications. Curr. Opin. Chem. Eng. 2020, 28, 158–166. [Google Scholar] [CrossRef]

- Guo, N.; Leu, M.C. Additive manufacturing: Technology, applications and research needs. Front. Mech. Eng. 2013, 8, 215–243. [Google Scholar] [CrossRef]

- Wei, C.; Zhang, Z.; Cheng, D.; Sun, Z.; Zhu, M.; Li, L. An overview of laser-based multiple metallic material additive manufacturing: From macro-to micro-scales. Int. J. Extrem. Manuf. 2020, 3, 012003. [Google Scholar] [CrossRef]

- Liu, Q.; Zhang, Z.; Yavas, D.; Shen, W.; Wu, D. Multi-material additive manufacturing: Effect of process parameters on flexural behavior of soft-hard sandwich beams. Rapid Prototyp. J. 2023, 29, 885–896. [Google Scholar] [CrossRef]

- Zheng, X.; Williams, C.; Spadaccini, C.M.; Shea, K. Perspectives on multi-material additive manufacturing. J. Mater. Res. 2021, 36, 3549–3557. [Google Scholar] [CrossRef]

- Gardan, J. Additive manufacturing technologies: State of the art and trends. In Additive Manufacturing Handbook; 2017; pp. 149–168. [Google Scholar]

- Ansari, M.; Jabari, E.; Toyserkani, E. Opportunities and challenges in additive manufacturing of functionally graded metallic materials via powder-fed laser directed energy deposition: A review. J. Mater. Process. Technol. 2021, 294, 117117. [Google Scholar] [CrossRef]

- Wang, D.; Liu, L.; Deng, G.; Deng, C.; Bai, Y.; Yang, Y.; Wu, W.; Chen, J.; Liu, Y.; Wang, Y. Recent progress on additive manufacturing of multi-material structures with laser powder bed fusion. Virtual Phys. Prototyp. 2022, 17, 329–365. [Google Scholar] [CrossRef]

- Wong, K.V.; Hernandez, A. A review of additive manufacturing. Int. Sch. Res. Not. 2012, 2012, 208760. [Google Scholar] [CrossRef]

- Ghanavati, R.; Naffakh-Moosavy, H. Additive manufacturing of functionally graded metallic materials: A review of experimental and numerical studies. J. Mater. Res. Technol. 2021, 13, 1628–1664. [Google Scholar] [CrossRef]

- Gradl, P.R.; Protz, C.S. Technology advancements for channel wall nozzle manufacturing in liquid rocket engines. Acta Astronaut. 2020, 174, 148–158. [Google Scholar] [CrossRef]

- Suzuki, S.; Akiba, M.; Araki, M.; Yokoyama, K. Thermal cycling experiments of monoblock divertor modules for fusion experimental reactors. Fusion Technol. 1992, 21, 1858–1862. [Google Scholar] [CrossRef]

- Venturini, G.; Montevecchi, F.; Scippa, A.; Campatelli, G. Optimization of WAAM deposition patterns for T-crossing features. Procedia Cirp 2016, 55, 95–100. [Google Scholar] [CrossRef]

- Zhou, Z.; Huang, L.; Shang, Y.; Li, Y.; Jiang, L.; Lei, Q. Causes analysis on cracks in nickel-based single crystal superalloy fabricated by laser powder deposition additive manufacturing. Mater. Des. 2018, 160, 1238–1249. [Google Scholar] [CrossRef]

- Treutler, K.; Wesling, V. New Developments in the Field of Production and Application of Multi-Material Wire Arc Additive Manufacturing Components: A Review. Adv. Eng. Mater. 2025, 2500578. [Google Scholar] [CrossRef]

- Zhang, X.; Wallinder, I.O.; Leygraf, C. Mechanistic studies of corrosion product flaking on copper and copper-based alloys in marine environments. Corros. Sci. 2014, 85, 15–25. [Google Scholar] [CrossRef]

- Pant, H.; Arora, A.; Gopakumar, G.S.; Chadha, U.; Saeidi, A.; Patterson, A.E. Applications of wire arc additive manufacturing (WAAM) for aerospace component manufacturing. Int. J. Adv. Manuf. Technol. 2023, 127, 4995–5011. [Google Scholar] [CrossRef]

- Rodrigues, T.A.; Duarte, V.; Miranda, R.M.; Santos, T.G.; Oliveira, J.P. Current status and perspectives on wire and arc additive manufacturing (WAAM). Materials 2019, 12, 1121. [Google Scholar] [CrossRef]

- Dhinakaran, V.; Ajith, J.; Fahmidha, A.F.Y.; Jagadeesha, T.; Sathish, T.; Stalin, B. Wire Arc Additive Manufacturing (WAAM) process of nickel based superalloys–A review. Mater. Today Proc. 2020, 21, 920–925. [Google Scholar] [CrossRef]

- Abuabiah, M.; Mbodj, N.G.; Shaqour, B.; Herzallah, L.; Juaidi, A.; Abdallah, R.; Plapper, P. Advancements in laser wire-feed metal additive manufacturing: A brief review. Materials 2023, 16, 2030. [Google Scholar] [CrossRef]

- Näsström, J.; Brueckner, F.; Kaplan, A.F. Laser enhancement of wire arc additive manufacturing. J. Laser Appl. 2019, 31, 022307. [Google Scholar] [CrossRef]

- Gong, X.; Anderson, T.; Chou, K. Review on Powder-Based Electron Beam Additive Manufacturing Technology. In Proceedings of the International Symposium on Flexible Automation, St. Louis, MO, USA, 18–20 June 2012; American Society of Mechanical Engineers: New York, NY, USA, 2012; pp. 507–515. [Google Scholar]

- Kovalchuk, D.; Melnyk, V.; Melnyk, I.; Tugai, B. Prospects of application of gas-discharge electron beam guns in additive manufacturing. Electrotech. Electron. (E + E) 2016, 51, 36–42. [Google Scholar]

- Osipovich, K.; Kalashnikov, K.; Chumaevskii, A.; Gurianov, D.; Kalashnikova, T.; Vorontsov, A.; Zykova, A.; Utyaganova, V.; Panfilov, A.; Nikolaeva, A. Wire-feed electron beam additive manufacturing: A review. Metals 2023, 13, 279. [Google Scholar] [CrossRef]

- Jin, W.; Zhang, C.; Jin, S.; Tian, Y.; Wellmann, D.; Liu, W. Wire arc additive manufacturing of stainless steels: A review. Appl. Sci. 2020, 10, 1563. [Google Scholar] [CrossRef]

- Herzog, D.; Seyda, V.; Wycisk, E.; Emmelmann, C. Additive manufacturing of metals. Acta Mater. 2016, 117, 371–392. [Google Scholar] [CrossRef]

- Kazanas, P.; Deherkar, P.; Almeida, P.; Lockett, H.; Williams, S. Fabrication of geometrical features using wire and arc additive manufacture. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2012, 226, 1042–1051. [Google Scholar] [CrossRef]

- Chakraborty, D.; Tirumala, T.; Chitral, S.; Sahoo, B.; Kiran, D.; Kumar, P.A. The state of the art for wire arc additive manufacturing process of titanium alloys for aerospace applications. J. Mater. Eng. Perform. 2022, 31, 6149–6182. [Google Scholar] [CrossRef]

- Indupuri, S.; Kiran, P.S.; Kumar, R.; Satish, C.; Keshri, A.K. High-temperature tribological behavior of plasma sprayed GNPs-reinforced YSZ coating over 316L stainless steel. Mater. Today Commun. 2024, 41, 110451. [Google Scholar] [CrossRef]

- Meng, W.; Zhang, W.; Zhang, W.; Yin, X.; Cui, B. Fabrication of steel-Inconel functionally graded materials by laser melting deposition integrating with laser synchronous preheating. Opt. Laser Technol. 2020, 131, 106451. [Google Scholar] [CrossRef]

- Jin, Q.-Y.; Kim, D.; Jo, H.; Lee, W. Micro-Anchor Design for Multi-Material Additive Manufacturing of Aluminum Alloy on Fe-based Alloy Using Laser Directed Energy Deposition. Met. Mater. Int. 2025, 1–19. [Google Scholar] [CrossRef]

- Eimer, E.; Suder, W.; Williams, S.; Ding, J. Wire laser arc additive manufacture of aluminium zinc alloys. Weld. World 2020, 64, 1313–1319. [Google Scholar] [CrossRef]

- Wu, B.; Qiu, Z.; Pan, Z.; Carpenter, K.; Wang, T.; Ding, D.; Van Duin, S.; Li, H. Enhanced interface strength in steel-nickel bimetallic component fabricated using wire arc additive manufacturing with interweaving deposition strategy. J. Mater. Sci. Technol. 2020, 52, 226–234. [Google Scholar] [CrossRef]

- Dharmendra, C.; Shakerin, S.; Ram, G.J.; Mohammadi, M. Wire-arc additive manufacturing of nickel aluminum bronze/stainless steel hybrid parts–Interfacial characterization, prospects, and problems. Materialia 2020, 13, 100834. [Google Scholar] [CrossRef]

- Gerashi, E.; Duan, X.; Alidokht, S.A. Functionally Graded Materials Fabrication Using Wire Arc Additive Manufacturing: A Review of Recent Research Progress. J. Mater. Eng. Perform. 2025, 1–32. [Google Scholar] [CrossRef]

- Shah, A.; Aliyev, R.; Zeidler, H.; Krinke, S. A review of the recent developments and challenges in wire arc additive manufacturing (WAAM) process. J. Manuf. Mater. Process. 2023, 7, 97. [Google Scholar] [CrossRef]

- Liu, J.; Miao, Y.; Wang, Z.; Zhao, Y.; Wu, Y.; Li, C. Effect of heat treatment on microstructure and properties of additively manufactured aluminum bronze-steel bimetallic structures. Mater. Charact. 2024, 207, 113462. [Google Scholar] [CrossRef]

- Miao, Y.; Li, C.; Zhao, Y.; Wu, Y.; Liu, J.; Wang, Z.; Zhang, B. Material properties of gradient copper-nickel alloy fabricated by wire arc additive manufacturing based on bypass-current PAW. J. Manuf. Process. 2022, 83, 637–649. [Google Scholar] [CrossRef]

- Reisgen, U.; Sharma, R.; Oster, L. Plasma multiwire technology with alternating wire feed for tailor-made material properties in wire and arc additive manufacturing. Metals 2019, 9, 745. [Google Scholar] [CrossRef]

- Abe, T.; Sasahara, H. Dissimilar metal deposition with a stainless steel and nickel-based alloy using wire and arc-based additive manufacturing. Precis. Eng. 2016, 45, 387–395. [Google Scholar] [CrossRef]

- Xiong, J.; Zhang, G. Adaptive control of deposited height in GMAW-based layer additive manufacturing. J. Mater. Process. Technol. 2014, 214, 962–968. [Google Scholar] [CrossRef]

- Kesarwani, S.; Yuvaraj, N.; Niranjan, M.S. CMT-based WAAM: A comprehensive review of process parameters, their effects, challenges, and future scope. J. Braz. Soc. Mech. Sci. Eng. 2024, 46, 699. [Google Scholar] [CrossRef]

- Kumar, N.; Bhavsar, H.; Mahesh, P.; Srivastava, A.K.; Bora, B.J.; Saxena, A.; Dixit, A.R. Wire arc additive manufacturing–a revolutionary method in additive manufacturing. Mater. Chem. Phys. 2022, 285, 126144. [Google Scholar] [CrossRef]

- Tomar, B.; Shiva, S.; Nath, T. A review on wire arc additive manufacturing: Processing parameters, defects, quality improvement and recent advances. Mater. Today Commun. 2022, 31, 103739. [Google Scholar] [CrossRef]

- Motwani, A.; Kumar, A.; Puri, Y.; Lautre, N.K. Mechanical characteristics and microstructural investigation of CMT deposited bimetallic SS316LSi-IN625 thin wall for WAAM. Weld. World 2023, 67, 967–980. [Google Scholar] [CrossRef]

- Karim, M.A.; Jadhav, S.; Kannan, R.; Pierce, D.; Lee, Y.; Nandwana, P.; Kim, D.B. Investigating stainless steel/aluminum bimetallic structures fabricated by cold metal transfer (CMT)-based wire-arc directed energy deposition. Addit. Manuf. 2024, 81, 104015. [Google Scholar] [CrossRef]

- Marefat, F.; Kapil, A.; Banaee, S.A.; Van Rymenant, P.; Sharma, A. Evaluating shielding gas-filler wire interaction in bi-metallic wire arc additive manufacturing (WAAM) of creep resistant steel-stainless steel for improved process stability and build quality. J. Manuf. Process. 2023, 88, 110–124. [Google Scholar] [CrossRef]

- Wang, J.; Pan, Z.; Wei, L.; He, S.; Cuiuri, D.; Li, H. Introduction of ternary alloying element in wire arc additive manufacturing of titanium aluminide intermetallic. Addit. Manuf. 2019, 27, 236–245. [Google Scholar] [CrossRef]

- Baufeld, B.; Van der Biest, O.; Gault, R. Additive manufacturing of Ti–6Al–4V components by shaped metal deposition: Microstructure and mechanical properties. Mater. Des. 2010, 31, S106–S111. [Google Scholar] [CrossRef]

- Shen, C.; Pan, Z.; Cuiuri, D.; Roberts, J.; Li, H. Fabrication of Fe-FeAl functionally graded material using the wire-arc additive manufacturing process. Metall. Mater. Trans. B 2016, 47, 763–772. [Google Scholar] [CrossRef]

- Wang, J.; Pan, Z.; Ma, Y.; Lu, Y.; Shen, C.; Cuiuri, D.; Li, H. Characterization of wire arc additively manufactured titanium aluminide functionally graded material: Microstructure, mechanical properties and oxidation behaviour. Mater. Sci. Eng. 2018, 734, 110–119. [Google Scholar] [CrossRef]

- Tanwar, R.S.; Jhavar, S. Multi-wire additive manufacturing: A comprehensive review on materials, microstructure, methodological advances, and applications. Results Eng. 2025, 26, 104814. [Google Scholar] [CrossRef]

- Ayan, Y.; Kahraman, N. Fabrication and characterization of functionally graded material (FGM) structure containing two dissimilar steels (ER70S-6 and 308LSi) by wire arc additive manufacturing (WAAM). Mater. Today Commun. 2022, 33, 104457. [Google Scholar] [CrossRef]

- Jia, Y.; Sun, S.; Li, B.; Yao, Z.; Li, C.; Huang, W.; Fang, M. Current research status and prospect of laser wire additive manufacturing technology. Int. J. Adv. Manuf. Technol. 2025, 137, 3229–3255. [Google Scholar] [CrossRef]

- Harwell, L.D.; Griffith, M.L.; Greene, D.L.; Pressly, G.A. Energetic additive manufacturing process with feed wire. U.S. Patent 6,143,378[P], 7 November 2000. [Google Scholar]

- Zapata, A.; Bernauer, C.; Stadter, C.; Kolb, C.G.; Zaeh, M.F. Investigation on the cause-effect relationships between the process parameters and the resulting geometric properties for wire-based coaxial laser metal deposition. Metals 2022, 12, 455. [Google Scholar] [CrossRef]

- Huang, W.; Chen, S.; Xiao, J.; Jiang, X.; Jia, Y. Laser wire-feed metal additive manufacturing of the Al alloy. Opt. Laser Technol. 2021, 134, 106627. [Google Scholar] [CrossRef]

- Syed, W.U.H.; Pinkerton, A.J.; Li, L. Combining wire and coaxial powder feeding in laser direct metal deposition for rapid prototyping. Appl. Surf. Sci. 2006, 252, 4803–4808. [Google Scholar] [CrossRef]

- Motta, M.; Demir, A.G.; Previtali, B. High-speed imaging and process characterization of coaxial laser metal wire deposition. Addit. Manuf. 2018, 22, 497–507. [Google Scholar] [CrossRef]

- Liu, D.; Wu, D.; Wang, R.; Shi, J.; Niu, F.; Ma, G. Formation mechanism of Al-Zn-Mg-Cu alloy fabricated by laser-arc hybrid additive manufacturing: Microstructure evaluation and mechanical properties. Addit. Manuf. 2022, 50, 102554. [Google Scholar] [CrossRef]

- Yue, W.; Zhang, Y.; Zheng, Z.; Lai, Y. Hybrid laser additive manufacturing of metals: A review. Coatings 2024, 14, 315. [Google Scholar] [CrossRef]

- Gong, M.; Meng, Y.; Zhang, S.; Zhang, Y.; Zeng, X.; Gao, M. Laser-arc hybrid additive manufacturing of stainless steel with beam oscillation. Addit. Manuf. 2020, 33, 101180. [Google Scholar] [CrossRef]

- Casalino, G.; Karamimoghadam, M.; Contuzzi, N. Metal wire additive manufacturing: A comparison between arc laser and laser/arc heat sources. Inventions 2023, 8, 52. [Google Scholar] [CrossRef]

- Çam, G. Prospects of producing aluminum parts by wire arc additive manufacturing (WAAM). Mater. Today Proc. 2022, 62, 77–85. [Google Scholar] [CrossRef]

- Negi, S.; Nambolan, A.A.; Kapil, S.; Joshi, P.S.; R, M.; Karunakaran, K.; Bhargava, P. Review on electron beam based additive manufacturing. Rapid Prototyp. J. 2020, 26, 485–498. [Google Scholar] [CrossRef]

- Węglowski, M.S.; Błacha, S.; Pilarczyk, J.; Dutkiewicz, J.; Rogal, Ł. Electron Beam Additive Manufacturing with Wire–Analysis of the Process. In AIP Conference Proceedings; AIP Publishing LLC: Melville, NY, USA, 2018; p. 140015. [Google Scholar]

- Kolubaev, E.; Rubtsov, V.; Chumaevsky, A.; Astafurova, E. Micro-, meso-and macrostructural design of bulk metallic and polymetallic materials by wire-feed electron-beam additive manufacturing. Phys. Mesomech. 2022, 25, 479–491. [Google Scholar] [CrossRef]

- Osipovich, K.S.; Astafurova, E.G.; Chumaevskii, A.V.; Kalashnikov, K.N.; Astafurov, S.V.; Maier, G.G.; Melnikov, E.V.; Moskvina, V.A.; Panchenko, M.Y.; Tarasov, S.Y. Gradient transition zone structure in “steel–copper” sample produced by double wire-feed electron beam additive manufacturing. J. Mater. Sci. 2020, 55, 9258–9272. [Google Scholar] [CrossRef]

- Utyaganova, V.; Filippov, A.; Tarasov, S.; Shamarin, N.; Gurianov, D.; Vorontsov, A.; Chumaevskii, A.; Fortuna, S.; Savchenko, N.; Rubtsov, V. Characterization of AA7075/AA5356 gradient transition zone in an electron beam wire-feed additive manufactured sample. Mater. Charact. 2021, 172, 110867. [Google Scholar] [CrossRef]

- Sadhya, S.; Khan, A.U.; Kumar, A.; Chatterjee, S.; Madhukar, Y.K. Development of concurrent multi wire feed mechanism for WAAM-TIG to enhance process efficiency. CIRP J. Manuf. Sci. Technol. 2024, 51, 313–323. [Google Scholar] [CrossRef]

- Ma, Z.; Liu, W.; Li, W.; Liu, H.; Song, J.; Liu, Y.; Huang, Y.; Xia, Y.; Wang, Z.; Liu, B. Additive manufacturing of functional gradient materials: A review of research progress and challenges. J. Alloys Compd. 2024, 971, 172642. [Google Scholar] [CrossRef]

- Gürol, U.; Turgut, B.; Kumek, H.; Dilibal, S.; Koçak, M. Fabrication and characterization of wire arc additively manufactured ferritic-austenitic bimetallic structure. Met. Mater. Int. 2024, 30, 1342–1355. [Google Scholar] [CrossRef]

- Turgut, B.; Gürol, U.; Onler, R. Effect of interlayer dwell time on output quality in wire arc additive manufacturing of low carbon low alloy steel components. Int. J. Adv. Manuf. Technol. 2023, 126, 5277–5288. [Google Scholar] [CrossRef]

- Zhai, W.; Guo, Y.; Canturri, C.; Shandro, R.; Zhou, W. Wire arc additive manufacturing of ER70S-6/S355 bimetal component. Mater. Sci. Eng. 2024, 900, 146498. [Google Scholar] [CrossRef]

- Pattanayak, S.; Sahoo, S.K.; Sahoo, A.K. An approach to tunable advanced high-strength steel fabrication through multi-wire arc additive manufacturing (M-WAAM). J. Manuf. Process. 2025, 133, 705–722. [Google Scholar] [CrossRef]

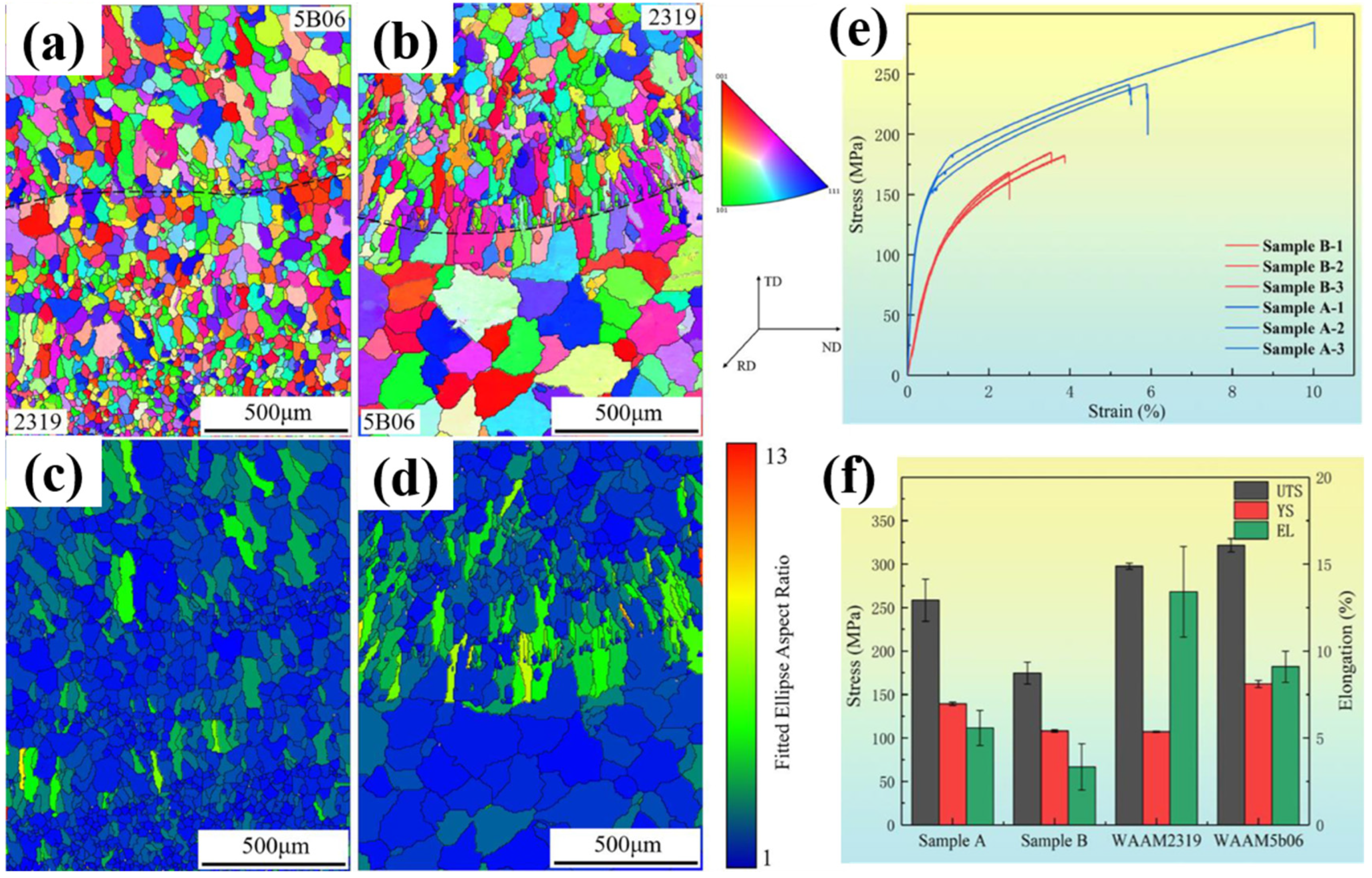

- Zhou, Y.; Fang, X.; Lin, X.; Jian, Z.; Huang, S.; Wu, Y.; Meng, J.; Yang, W. Tensile deformation behavior of triple heterogeneous microstructure comprising fine equiaxed/coarse equiaxed/columnar grains in AlCu/AlMgSc bimetal fabricated via dual-wire arc direct energy deposition. J. Mater. Sci. Technol. 2024, 193, 160–177. [Google Scholar] [CrossRef]

- Jiang, P.; Li, X.; Zong, X.; Wang, X.; Chen, Z.; Liu, C.; Gao, N.; Zhang, Z. Microstructure and mechanical properties of Ti basic bionic gradient heterogeneous alloy prepared by multi-wire arc additive manufacturing. J. Alloys Compd. 2022, 926, 166813. [Google Scholar] [CrossRef]

- Feng, Y.; Zhan, B.; He, J.; Wang, K. The double-wire feed and plasma arc additive manufacturing process for deposition in Cr-Ni stainless steel. J. Mater. Process. Technol. 2018, 259, 206–215. [Google Scholar] [CrossRef]

- Ding, D.; Pan, Z.; Cuiuri, D.; Li, H. Wire-feed additive manufacturing of metal components: Technologies, developments and future interests. Int. J. Adv. Manuf. Technol. 2015, 81, 465–481. [Google Scholar] [CrossRef]

- Yao, J.; Wang, Y.; Liu, X.; Chen, X.; Chen, S.; Hu, L.; Liu, H.; Qian, Y.; Cheng, Y.; Song, B. Multi laser beams directed energy deposition of a high-strength and high-toughness TC11 titanium alloy with coaxial wire feeding. Next Mater. 2025, 8, 100576. [Google Scholar] [CrossRef]

- Kelbassa, J.; Gasser, A.; Bremer, J.; Pütsch, O.; Poprawe, R.; Henrich Schleifenbaum, J. Equipment and process windows for laser metal deposition with coaxial wire feeding. J. Laser Appl. 2019, 31, 022320. [Google Scholar] [CrossRef]

- Zhang, X.; Lu, Q.; Zhang, P.; Yu, Z.; Shen, C.; Wang, L.; Hua, X. Microstructure and fatigue properties of Ti-48Al alloy fabricated by the twin-wire plasma arc additive manufacturing. J. Mater. Eng. Perform. 2022, 31, 8250–8260. [Google Scholar] [CrossRef]

- Liu, L.; Hu, C.; Yu, S.; Song, G. A triple-wire indirect arc welding method with high melting efficiency of base metal. J. Manuf. Process. 2019, 44, 252–260. [Google Scholar] [CrossRef]

- Treutler, K.; Wesling, V. The current state of research of wire arc additive manufacturing (WAAM): A review. Appl. Sci. 2021, 11, 8619. [Google Scholar] [CrossRef]

- Thapliyal, S. Challenges associated with the wire arc additive manufacturing (WAAM) of aluminum alloys. Mater. Res. Express 2019, 6, 112006. [Google Scholar] [CrossRef]

- Dass, A.; Moridi, A. State of the art in directed energy deposition: From additive manufacturing to materials design. Coatings 2019, 9, 418. [Google Scholar] [CrossRef]

- Yilmaz, O.; Ugla, A.A. Shaped metal deposition technique in additive manufacturing: A review. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2016, 230, 1781–1798. [Google Scholar] [CrossRef]

- Shamsaei, N.; Yadollahi, A.; Bian, L.; Thompson, S.M. An overview of Direct Laser Deposition for additive manufacturing; Part II: Mechanical behavior, process parameter optimization and control. Addit. Manuf. 2015, 8, 12–35. [Google Scholar] [CrossRef]

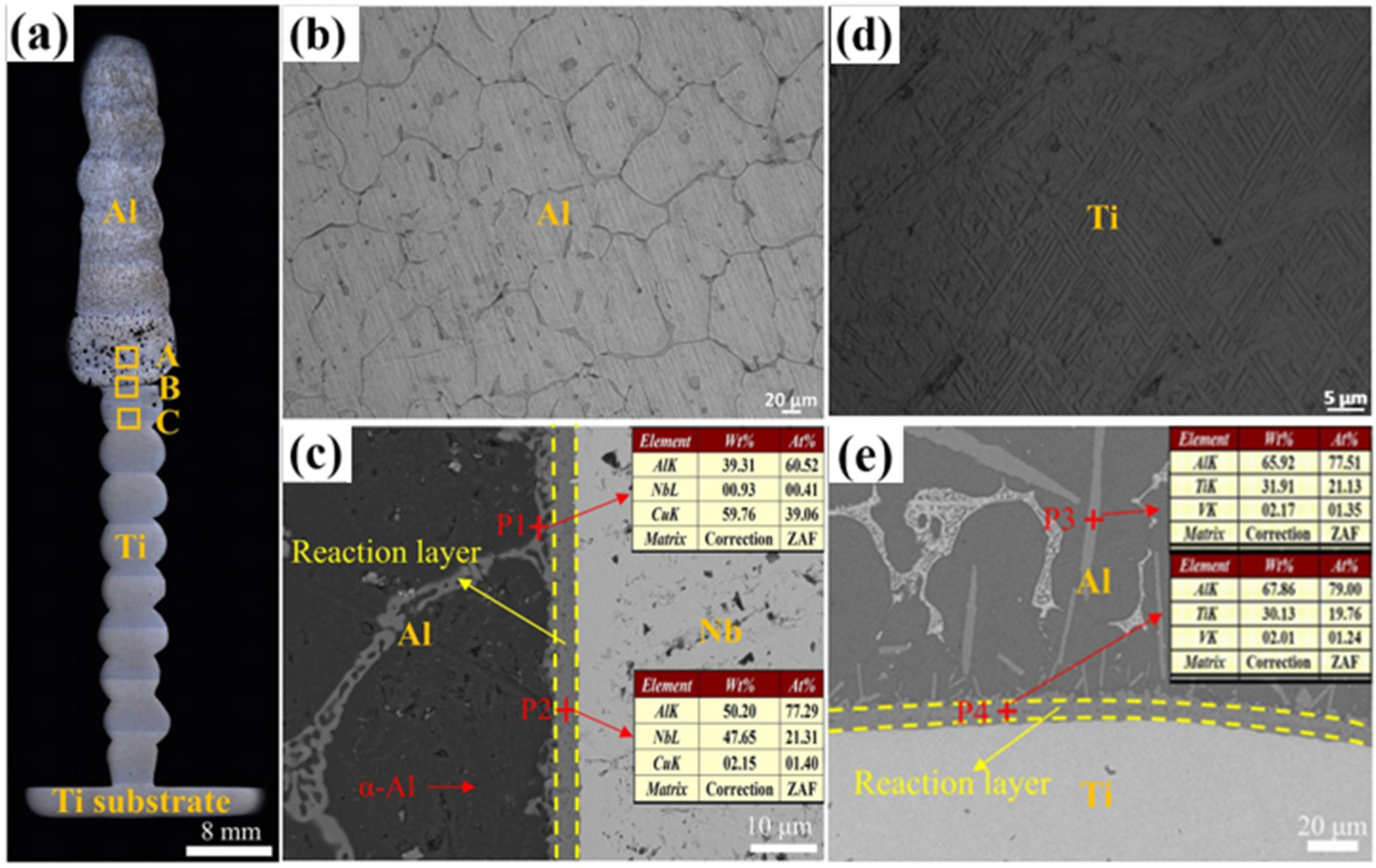

- Tian, Y.; Shen, J.; Hu, S.; Gou, J.; Kannatey-Asibu, E. Wire and arc additive manufactured Ti–6Al–4V/Al–6.25 Cu dissimilar alloys by CMT-welding: Effect of deposition order on reaction layer. Sci. Technol. Weld. Join. 2020, 25, 73–80. [Google Scholar] [CrossRef]

- Ozaner, O.C.; Karabulut, Ş.; Karakoç, H.; Sharma, A.; Talemi, R.; Tjahjowidodo, T. Influence of Deposition Sequence and Thermal Cycles on the Microstructure and Wear Behavior of WAAM-Fabricated SS309L and Inconel 625 Bimetallic Structures. Met. Mater. Int. 2025, 1–24. [Google Scholar] [CrossRef]

- Kennedy, J.R.; Davis, A.E.; Caballero, A.; White, M.; Fellowes, J.; Pickering, E.; Prangnell, P. Microstructure transition gradients in titanium dissimilar alloy (Ti-5Al-5V-5Mo-3Cr/Ti-6Al-4V) tailored wire-arc additively manufactured components. Mater. Charact. 2021, 182, 111577. [Google Scholar] [CrossRef]

- Chang, T.; Fang, X.; Liu, G.; Zhang, H.; Huang, K. Wire and arc additive manufacturing of dissimilar 2319 and 5B06 aluminum alloys. J. Mater. Sci. Technol. 2022, 124, 65–75. [Google Scholar] [CrossRef]

- Bandyopadhyay, A.; Zhang, Y.; Onuike, B. Additive manufacturing of bimetallic structures. Virtual Phys. Prototyp. 2022, 17, 256–294. [Google Scholar] [CrossRef]

- Bandyopadhyay, A.; Zhang, Y.; Bose, S. Recent developments in metal additive manufacturing. Curr. Opin. Chem. Eng. 2020, 28, 96–104. [Google Scholar] [CrossRef]

- Anirudhan, B.; Devasia, J.; Krishna, T.; Kuruvila, M.T. Manufacturing of a bimetallic structure of stainless steel and mild steel through wire arc additive manufacturing—A critical review. Int. J. Innov. Sci. Res. Technol 2020, 5, 679–685. [Google Scholar]

- Shekh, M.J.; Yeo, L.C.; Bair, J.L. A review of 3D-printed bimetallic alloys. Int. J. Adv. Manuf. Technol. 2024, 132, 4191–4204. [Google Scholar] [CrossRef]

- Tian, Y.; Shen, J.; Hu, S.; Gou, J.; Cui, Y. Effects of cold metal transfer mode on the reaction layer of wire and arc additive-manufactured Ti-6Al-4V/Al-6.25 Cu dissimilar alloys. J. Mater. Sci. Technol. 2021, 74, 35–45. [Google Scholar] [CrossRef]

- Kesarwani, S.; Yuvaraj, N.; Niranjan, M.S. Impact of depositional direction and current on microstructure and mechanical properties of the bimetallic wall of ER5356/ER4043 fabricated by cold metal transfer based wire arc additive manufacturing. CIRP J. Manuf. Sci. Technol. 2024, 53, 17–33. [Google Scholar] [CrossRef]

- Song, X.; Huang, J.; Yu, X.; Zhang, J.; Xu, J.; Fan, D. Microstructure transformation and mechanical behavior in NiTi alloys fabricated by dissimilar double wires arc additive manufacturing. J. Mater. Res. Technol. 2024, 33, 9603–9613. [Google Scholar] [CrossRef]

- Xiong, J.; Li, Y.; Li, R.; Yin, Z. Influences of process parameters on surface roughness of multi-layer single-pass thin-walled parts in GMAW-based additive manufacturing. J. Mater. Process. Technol. 2018, 252, 128–136. [Google Scholar] [CrossRef]

- Chen, Y.; Zhang, X.; Ding, D.; Wang, X.; Zhang, K.; Liu, Y.; Lu, T.; Tu, S. Integration of interlayer surface enhancement technologies into metal additive manufacturing: A review. J. Mater. Sci. Technol. 2023, 165, 94–122. [Google Scholar] [CrossRef]

- Farias, F.W.C.; dos Santos, T.J.G.; Oliveira, J.P. Directed energy deposition+ mechanical interlayer deformation additive manufacturing: A state-of-the-art literature review. Int. J. Adv. Manuf. Technol. 2024, 131, 999–1038. [Google Scholar] [CrossRef]

- Manohar, G.; Kumar, A.; Thapliyal, S.; Mamedipaka, R. Investigating the performance of aluminium-steel bimetallic structure fabricated through wire and arc additive manufacturing with interlayer approach. In Structures; Elsevier: Amsterdam, The Netherlands, 2025; p. 108304. [Google Scholar]

- Zhang, B.; Zhang, W.; Xiao, H.; Zhu, H.; Yang, H.; Wang, Y.; Chen, B. QCr0.8 Cu alloy/S06 stainless steel bimetal structure via In718 multi-interlayer fabricated by laser powder hybrid additive manufacturing. J. Mater. Res. Technol. 2023, 24, 1034–1042. [Google Scholar] [CrossRef]

- Paul, A.R.; Mukherjee, M.; Sahu, M.K. Influence of copper interlayer on the interface characteristics of stainless steel–aluminium transitional structure in wire arc directed energy deposition. Rapid Prototyp. J. 2024, 30, 1–14. [Google Scholar] [CrossRef]

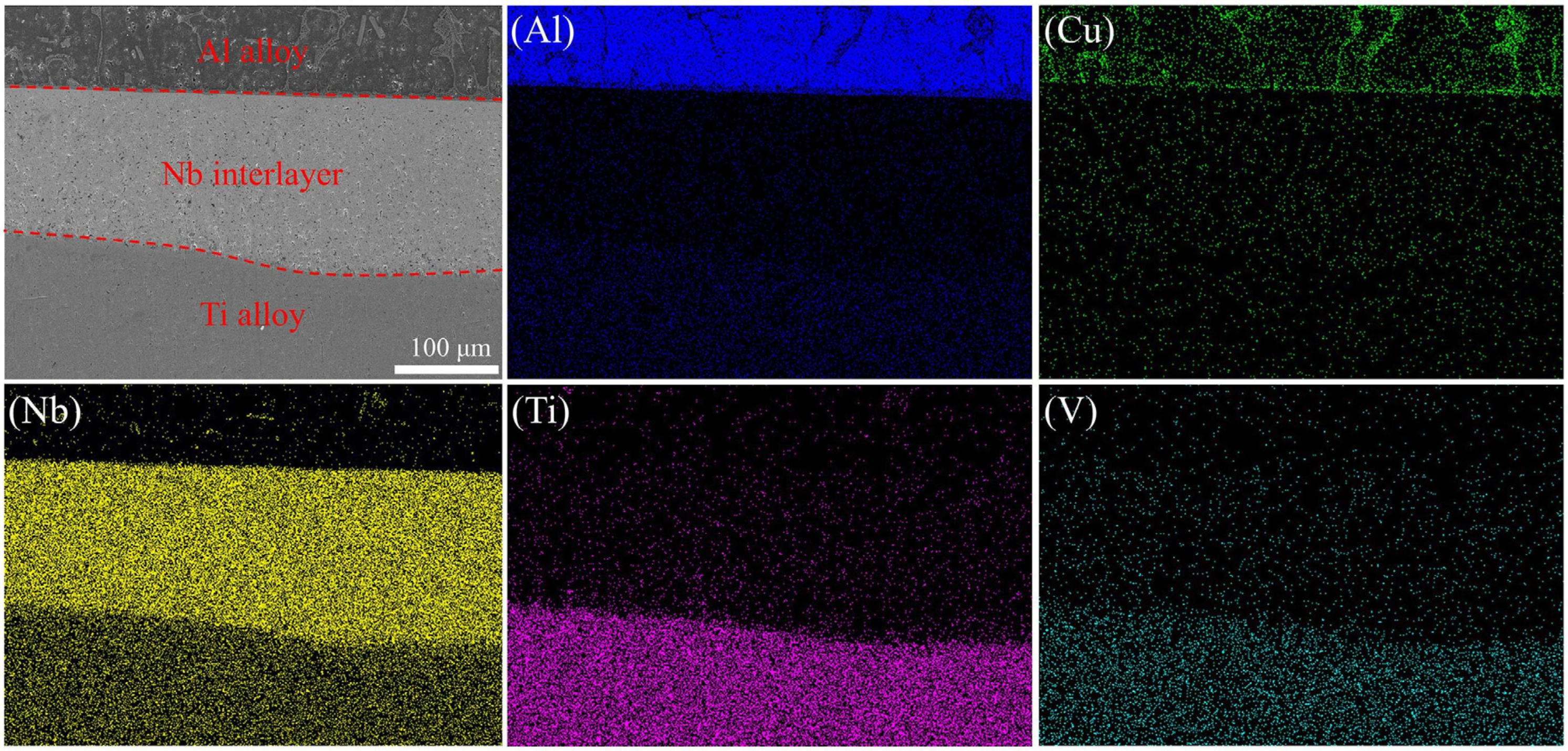

- Xu, N.; Shen, J.; Hu, S.; Tian, Y.; Bi, J. Bimetallic structure of Ti6Al4V and Al6.21Cu fabricated by cold metal transfer additive manufacturing via Nb interlayer added by TIG. Mater. Lett. 2021, 302, 130397. [Google Scholar] [CrossRef]

- Jiang, P.; Nie, M.; Teng, J.; Cui, X.; Liu, C.; Zhang, X.; Zhang, Z. Multi-material wire arc additive manufacturing of a bio-inspired heterogeneous layered NiTi/Nb/Ti6Al4V structure: Microstructural evolutions and mechanical properties. Mater. Sci. Eng. 2024, 890, 145896. [Google Scholar] [CrossRef]

- Shan, L.; Tan, C.; Shen, X.; Ramesh, S.; Zarei, M.; Kolahchi, R.; Hajmohammad, M. The effects of nano-additives on the mechanical, impact, vibration, and buckling/post-buckling properties of composites: A review. J. Mater. Res. Technol. 2023, 24, 7570–7598. [Google Scholar] [CrossRef]

- Zhou, C.; Wang, J.; Guo, C.; Zhao, C.; Jiang, G.; Dong, T.; Jiang, F. Numerical study of the ultrasonic impact on additive manufactured parts. Int. J. Mech. Sci. 2021, 197, 106334. [Google Scholar] [CrossRef]

- Li, X.; Wang, W.; Wu, Y.; Zhou, D.; Kang, H.; Guo, E.; Li, J.; Chen, Z.; Xu, Y.; Wang, T. Ultrasonic field-assisted metal additive manufacturing (U-FAAM): Mechanisms, research and future directions. Ultrason. Sonochem. 2024, 111, 107070. [Google Scholar] [CrossRef]

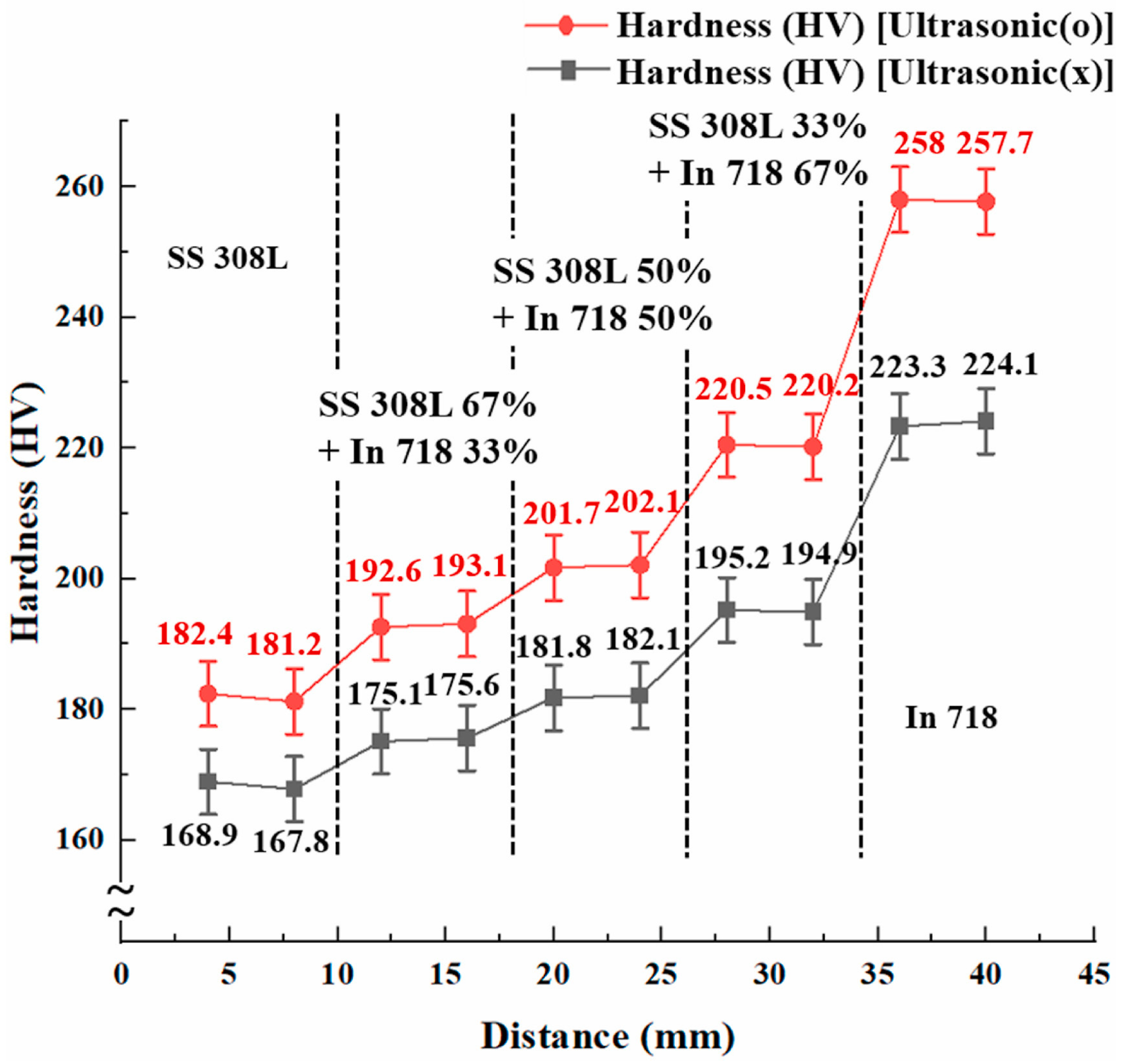

- Jeong, T.-W.; Cho, Y.T.; Lee, C.-M.; Kim, D.-H. Effects of ultrasonic treatment on mechanical properties and microstructure of stainless steel 308L and Inconel 718 functionally graded materials fabricated via double-wire arc additive manufacturing. Mater. Sci. Eng. 2024, 896, 146298. [Google Scholar] [CrossRef]

- Xu, N.; Shen, J.; Hu, S.; Li, T.; Tian, Y.; Sun, C. Effect of ultrasonic peening treatment on microstructure and properties of CMT additive-manufactured Ti6Al4V/Al6.21Cu dissimilar alloys with Nb interlayer. Mater. Lett. 2022, 308, 131179. [Google Scholar] [CrossRef]

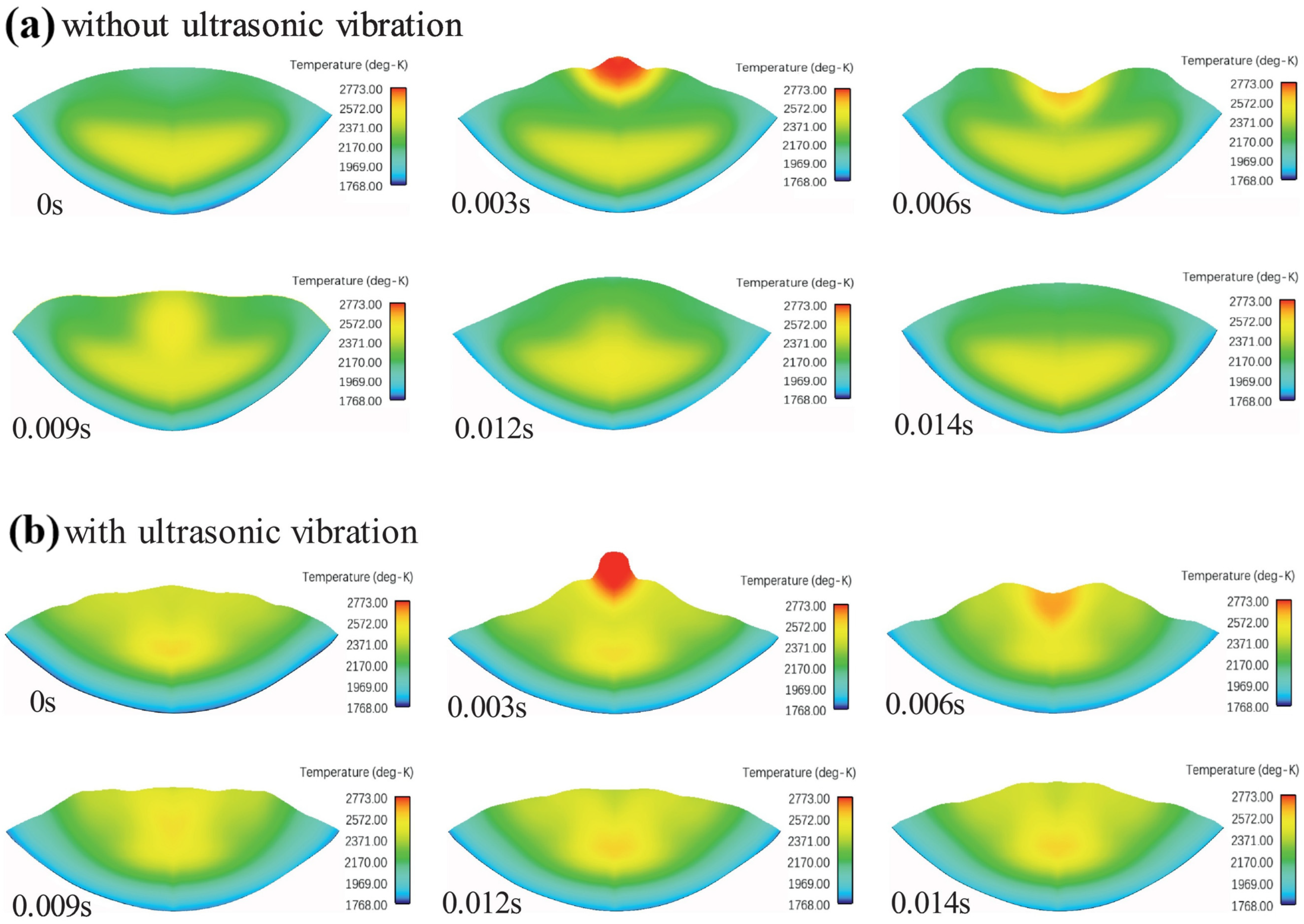

- Ji, F.; Qin, X.; Hu, Z.; Xiong, X.; Ni, M.; Wu, M. Influence of ultrasonic vibration on molten pool behavior and deposition layer forming morphology for wire and arc additive manufacturing. Int. Commun. Heat Mass Transf. 2022, 130, 105789. [Google Scholar] [CrossRef]

- Vazquez, L.; Rodriguez, M.N.; Rodriguez, I.; Alvarez, P. Influence of post-deposition heat treatments on the microstructure and tensile properties of Ti-6Al-4V parts manufactured by CMT-WAAM. Metals 2021, 11, 1161. [Google Scholar] [CrossRef]

- Li, K.; Klecka, M.A.; Chen, S.; Xiong, W. Wire-arc additive manufacturing and post-heat treatment optimization on microstructure and mechanical properties of Grade 91 steel. Addit. Manuf. 2021, 37, 101734. [Google Scholar] [CrossRef]

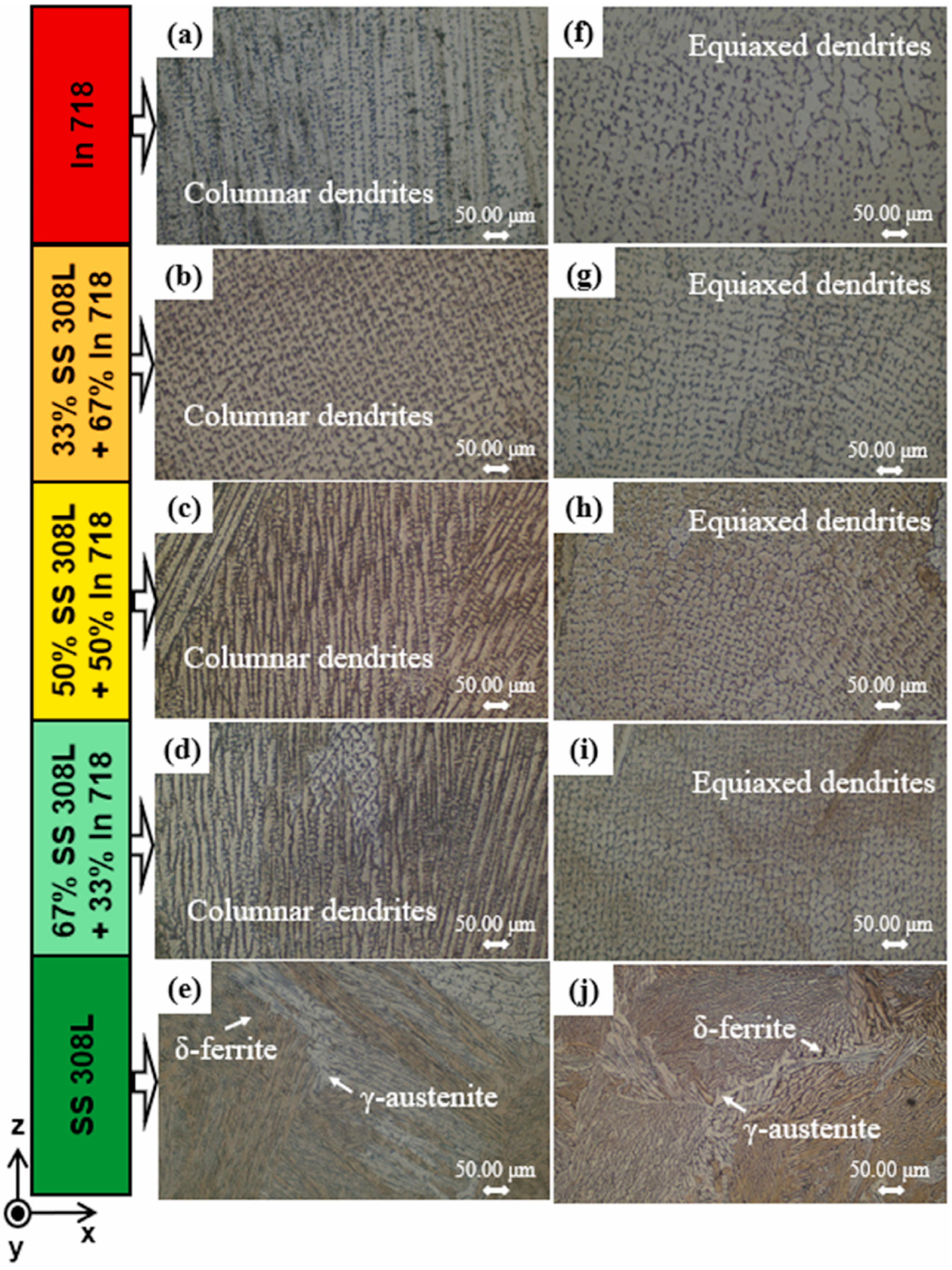

- Yadav, A.; Srivastava, M.; Jain, P.K. Development and post-process heat treatment of dissimilar steel structure via twin-wire arc additive manufacturing using heterogeneous functionally graded deposition strategy. In Structures; Elsevier: Amsterdam, The Netherlands, 2025; p. 108255. [Google Scholar]

- Singh, S.; Demidova, E.; Resnina, N.; Belyaev, S.; Iyamperumal, P.A.; Paul, C.P.; Prashanth, K.G. NiTi–Cu Bimetallic Structure Fabrication through Wire Arc Additive Manufacturing. Materials 2024, 17, 1006. [Google Scholar] [CrossRef]

- Chi, J.; Cai, Z.; Wan, Z.; Zhang, H.; Chen, Z.; Li, L.; Li, Y.; Peng, P.; Guo, W. Effects of heat treatment combined with laser shock peening on wire and arc additive manufactured Ti17 titanium alloy: Microstructures, residual stress and mechanical properties. Surf. Coat. Technol. 2020, 396, 125908. [Google Scholar] [CrossRef]

- Laleh, M.; Sadeghi, E.; Revilla, R.I.; Chao, Q.; Haghdadi, N.; Hughes, A.E.; Xu, W.; De Graeve, I.; Qian, M.; Gibson, I. Heat treatment for metal additive manufacturing. Prog. Mater. Sci. 2023, 133, 101051. [Google Scholar] [CrossRef]

- Munusamy, S.; Jerald, J. Effect of in-situ intrinsic heat treatment in metal additive manufacturing: A comprehensive review. Met. Mater. Int. 2023, 29, 3423–3441. [Google Scholar] [CrossRef]

- Masuo, H.; Tanaka, Y.; Morokoshi, S.; Yagura, H.; Uchida, T.; Yamamoto, Y.; Murakami, Y. Influence of defects, surface roughness and HIP on the fatigue strength of Ti-6Al-4V manufactured by additive manufacturing. Int. J. Fatigue 2018, 117, 163–179. [Google Scholar] [CrossRef]

- Ge, J.; Pillay, S.; Ning, H. Post-process treatments for additive-manufactured metallic structures: A comprehensive review. J. Mater. Eng. Perform. 2023, 32, 7073–7122. [Google Scholar] [CrossRef]

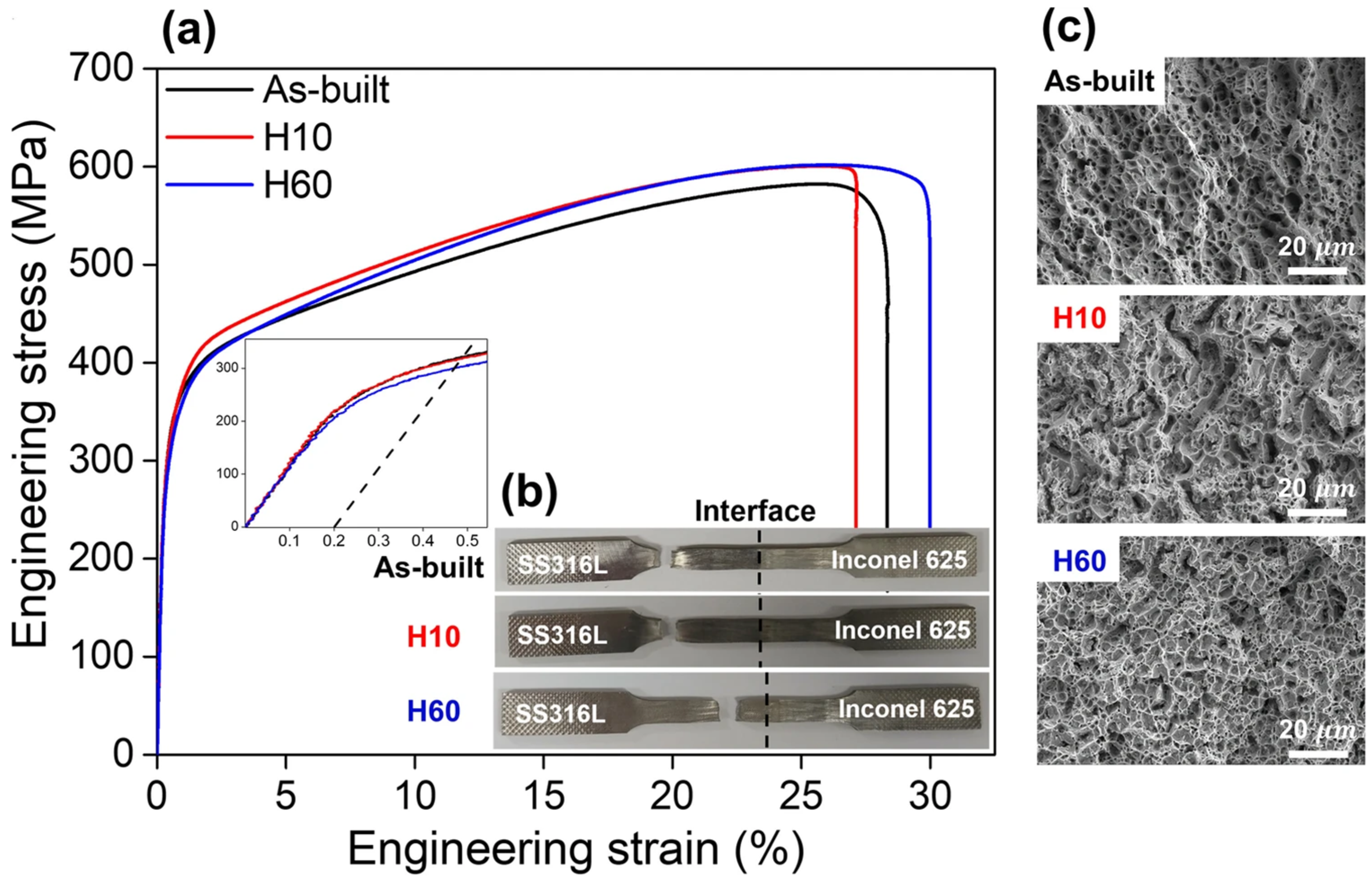

- Kim, Y.S.; Yun, D.; Han, J.H.; Ahsan, M.R.; Huang, E.-W.; Jain, J.; Ji, C.; Kim, D.B.; Lee, S.Y. Bimetallic additively manufactured structure (BAMS) of Inconel 625 and austenitic stainless steel: Effect of heat-treatment on microstructure and mechanical properties. Int. J. Adv. Manuf. Technol. 2022, 121, 7539–7549. [Google Scholar] [CrossRef]

- Shen, C.; Liss, K.-D.; Reid, M.; Pan, Z.; Hua, X.; Li, F.; Mou, G.; Huang, Y.; Dong, B.; Luo, D. Effect of the post-production heat treatment on phase evolution in the Fe3Ni–FeNi functionally graded material: An in-situ neutron diffraction study. Intermetallics 2021, 129, 107032. [Google Scholar] [CrossRef]

- Kaur, H.; Kumar, S.; Malhotra, D.; Nanda, T. Corrosion and metallurgical behavior of wire arc additively manufactured functionally graded superduplex stainless steel/Inconel 625. J. Mater. Eng. Perform. 2024, 33, 14011–14028. [Google Scholar] [CrossRef]

- Zhang, J.; Li, C.; Yang, X.; Wang, D.; Hu, W.; Di, X.; Zhang, J. In-situ heat treatment (IHT) wire arc additive manufacturing of Inconel625-HSLA steel functionally graded material. Mater. Lett. 2023, 330, 133326. [Google Scholar] [CrossRef]

- Ahsan, M.R.; Tanvir, A.; Seo, G.-J.; Bates, B.; Hawkins, W.; Lee, C.; Liaw, P.; Noakes, M.; Nycz, A.; Kim, D.B. Heat-treatment effects on a bimetallic additively-manufactured structure (BAMS) of the low-carbon steel and austenitic-stainless steel. Addit. Manuf. 2020, 32, 101036. [Google Scholar] [CrossRef]

- Banaee, S.A.; Kapil, A.; Marefat, F.; Sharma, A. Generalised overlapping model for multi-material wire arc additive manufacturing (WAAM). Virtual Phys. Prototyp. 2023, 18, e2210541. [Google Scholar] [CrossRef]

- Ding, D.; Pan, Z.; Cuiuri, D.; Li, H. A multi-bead overlapping model for robotic wire and arc additive manufacturing (WAAM). Robot. Comput.-Integr. Manuf. 2015, 31, 101–110. [Google Scholar] [CrossRef]

- Shunmugavel, M.; Polishetty, A.; Littlefair, G. Microstructure and mechanical properties of wrought and additive manufactured Ti-6Al-4 V cylindrical bars. Procedia Technol. 2015, 20, 231–236. [Google Scholar] [CrossRef]

- DebRoy, T.; Wei, H.L.; Zuback, J.S.; Mukherjee, T.; Elmer, J.W.; Milewski, J.O.; Beese, A.M.; Wilson-Heid, A.d.; De, A.; Zhang, W. Additive manufacturing of metallic components–process, structure and properties. Prog. Mater. Sci. 2018, 92, 112–224. [Google Scholar] [CrossRef]

- Amiri, V.; Naffakh-Moosavy, H. Wire arc additive manufacturing of functionally graded carbon steel-stainless steel 316L-Inconel 625: Microstructural characterization and mechanical behavior. J. Adv. Join. Process. 2024, 9, 100194. [Google Scholar] [CrossRef]

- Zhang, J.; Li, C.; Ba, L.; Di, X. Transition strategy optimization of Inconel625-HSLA steel functionally graded material fabricated by wire arc additive manufacturing. Met. Mater. Int. 2023, 29, 767–776. [Google Scholar] [CrossRef]

- Zhai, W.; Aishwarya; Shandro, R.; Zhou, W. Microstructure and mechanical properties of the wire arc additively manufactured 316L/ER70S-6 bimetal structure. Virtual Phys. Prototyp. 2024, 19, e2375105. [Google Scholar] [CrossRef]

- Liu, Y.; Li, B.; Zhang, W.; Liu, Z.; Jiang, M. Interfacial Behavior of Copper/Steel Bimetallic Composites Fabricated by CMT-WAMM. Coatings 2024, 14, 803. [Google Scholar] [CrossRef]

- Vinoth Kumar, D.; Karpagaraj, A.; Loganathan, T. Mechanical and Metallurgical Properties of SS304L–IN718 Bimetallic Wall Deposited using Cold Metal Transfer. J. Mater. Eng. Perform. 2025, 1–14. [Google Scholar] [CrossRef]

- Yelamasetti, B.; Vardhan, V. Weldability and mechanical properties of AA5052 and AA7075 dissimilar joints developed by GTAW process. Mater. Today Proc. 2021, 47, 4162–4166. [Google Scholar] [CrossRef]

- Jadhav, S.; Bajestani, M.S.; Islam, S.; Karim, M.A.; Kim, C.J.; Lee, H.-J.; Cho, Y.T.; Kim, D.B. Materials characterization of Ti6Al4V to NbZr1 bimetallic structure fabricated by wire arc additive manufacturing. Mater. Today Commun. 2023, 36, 106934. [Google Scholar] [CrossRef]

- Han, Q.; Di, X.; Guo, Y.; Ye, S.; Zheng, Y.; Liu, C. Microstructure and Mechanical Properties of Mg/Mg Bimetals Fabricated by Wire Arc Additive Manufacturing. Acta Met. Sin 2024, 61, 211–225. [Google Scholar]

- Sharma, P.; Dwivedi, D.K. Study on flux assisted-Tungsten inert gas welding of bimetallic P92 martensitic steel-304H austenitic stainless steel using SiO2–TiO2 binary flux. Int. J. Press. Vessel. Pip. 2021, 192, 104423. [Google Scholar] [CrossRef]

- Saranarayanan, R.; Lakshminarayanan, A.; Venkatraman, B. A combined full-field imaging and metallography approach to assess the local properties of gas tungsten arc welded copper—Stainless steel joints. Arch. Civ. Mech. Eng. 2019, 19, 251–267. [Google Scholar] [CrossRef]

- Tomar, B.; Shiva, S. Microstructural and mechanical properties examination of SS316L-Cu functionally graded material fabricated by wire arc additive manufacturing. CIRP J. Manuf. Sci. Technol. 2024, 50, 26–39. [Google Scholar] [CrossRef]

- Bang, H.; Bang, H.; Song, H.; Joo, S. Joint properties of dissimilar Al6061-T6 aluminum alloy/Ti–6% Al–4% V titanium alloy by gas tungsten arc welding assisted hybrid friction stir welding. Mater. Des. 2013, 51, 544–551. [Google Scholar] [CrossRef]

- Bezawada, S.; G, R. Mechanical and microstructural characteristics of gas tungsten arc welded similar and dissimilar joints of SS-316 L and Hastelloy C276. Trans. Indian Inst. Met. 2021, 74, 1623–1637. [Google Scholar] [CrossRef]

- Singh, I.J.; Murtaza, Q.; Kumar, P. Effect of CMT welding process parameters on the microstructural and mechanical properties of dissimilar aluminum Alloys of AA8011 and AA6061. Trans. Indian Inst. Met. 2025, 78, 3. [Google Scholar] [CrossRef]

- Ibekwe, I.G.; Awad, A.H.; Abdelwahed, M.; Aramide, F.O.; Taha, M.A. Processibility of Al5356 wire on Al6082 substrate by WAAM using MIG welding power. Ain Shams Eng. J. 2025, 16, 103505. [Google Scholar] [CrossRef]

- Jiang, P.; Nie, M.; Teng, J.; Li, X.; Zhang, Z. Wire arc additive manufacturing NiTi/Nb bionic laminated heterogeneous structure: Microsturcture evolution and mechanical properties. Mater. Charact. 2024, 217, 114326. [Google Scholar] [CrossRef]

- Kumar, R.; Sirohi, S. Microstructure and Mechanical Behavior Study of the GTAW Joint of AISI 310 and Modified 9Cr-1Mo (P91) Steel. J. Mater. Eng. Perform. 2025, 1–19. [Google Scholar] [CrossRef]

- Zhou, W.; Yue, J.; Zhou, H.; Li, H. Microstructure, tensile property and corrosion performance of GTAW 316 L/Q345 under compound-magnetic field. J. Constr. Steel Res. 2025, 228, 109468. [Google Scholar] [CrossRef]

- Yadav, A.; Srivastava, M.; Jain, P.K.; Rathee, S. Functionally graded deposition of dissimilar steel (316LSi and ER70S-6) fabricated through twin-wire arc additive manufacturing. Mater. Lett. 2024, 354, 135395. [Google Scholar] [CrossRef]

- Jawad, M.; Jahanzaib, M.; Ali, M.A.; Hussain, S.; Ahmad, W.; Ahmed, N. Improvement in mechanical and microstructural properties of novel TA7/Nb/Cu/SS304 composite joints by reducing intermetallic compounds. Int. J. Adv. Manuf. Technol. 2024, 130, 3257–3274. [Google Scholar] [CrossRef]

- Nakajima, K.; Sasahara, H.; Nagamatsu, H.; Abe, T. ERTi-2 cladding layer formation on a 5052 plate by a weaving strategy with wire and arc additive manufacturing. Int. J. Adv. Manuf. Technol. 2024, 134, 337–353. [Google Scholar] [CrossRef]

- Haque, M.S.; Moeed, K. Multi-objective optimization of input and output process parameters of dissimilar CMT welded joints of AA6082 and AA7075. J. Adhes. Sci. Technol. 2024, 1–23. [Google Scholar] [CrossRef]

- Muthu, S.; Prabu, S.S.; Sujai, S.; Sebastian, J.; Liyakat, N.A. Microstructure and mechanical properties of functionally graded materials alloy 82/AISI 304L by employing WAAM. Mater. Today Commun. 2025, 42, 111399. [Google Scholar] [CrossRef]

- Aghayar, Y.; Naghashzadeh, A.; Atapour, M. An assessment of microstructure and mechanical properties of inconel 601/304 stainless steel dissimilar weld. Vacuum 2021, 184, 109970. [Google Scholar] [CrossRef]

| Methods | Heat Sources | Advantages | Disadvantages | Applications | Ref. |

|---|---|---|---|---|---|

| WAAM | Arc | Low cost, high material utilization rate, fast deposition | Large thermal deformation, low precision, and numerous defects | Large and low-precision structural components | [35,36,37] |

| EBAM | Electron beam | High energy, vacuum anti-oxidation, small heat-affected zone | High cost, limited size, and high energy consumption | Precision components for aerospace and nuclear industries | [38,39] |

| LWAM | Laser | Low stress, high precision, stable quality | Slow deposition and poor compatibility with highly reflective materials | Complex components, medical implants, precision molds | [40,41,42] |

| Technology/Indicators | WAAM | LWAM | EBAM | Ref. |

|---|---|---|---|---|

| Deposition rate (kg/h) | 2–10 | 0.5–2 | 1–5 | [33,38,48,65] |

| Deposition size | Very large | Medium to large | Large (limited by the vacuum chamber) | [33,46] |

| Forming accuracy | Lower (several hundred micrometers) | Higher (tens of micrometers) | Medium to high | [48,65,76] |

| Heat input | High | Low-medium | High | [46,88] |

| Cost | Low (based on mature welding equipment) | High (laser, robot system) | Very high (vacuum system, electron gun, maintenance) | [33,46] |

| Vacuum requirement | No (protective gas is usually required) | No (protective gas is usually required) | Yes | [76,78] |

| Scope of applicable materials | Extensive (steel, nickel-based, aluminum, copper alloys, etc.) | Extensive | Very extensive, especially proficient in active metals (Ti, Ta, Zr, etc.) and high-melting-point materials | [76,80] |

| Multi-material forming capability | Excellent (the multi-wire synchronous feeding technology is mature | Good (coaxial high wire feeding accuracy) | Good (double wire feeding can be achieved) | [86,89] |

| Material-1 | Material-2 | Methods | UTS(MPa) | Ref. |

|---|---|---|---|---|

| SS316L | IN625 | GMAW | 487 | [150] |

| HSLA | IN625 | WAAW | 509 | [151] |

| ER70S-6 | ERNi-1 | GTAW | 634 | [51] |

| ER70S-6 | S355 | WAAM | 740 | [92] |

| SS316L | ER70S-6 | WAAM | 502 | [152] |

| ER120S-G | ERCuSi-A | CMT-WAAM | 404 | [153] |

| IN718 | SS304L | CMT-WAAM | 667 | [154] |

| AA5052 | AA7075 | GTAW | 182 | [155] |

| Ti6Al4V | Al-6.21Cu | CMT-WAAM | 164 | [130] |

| NbZr1 | Ti6Al4V | WAAM | 567 | [156] |

| Mg-Al-Si | Mg-Gd-Y-Zn | WAAM | 236 | [157] |

| P92 | Steel-304H | WAAM | 680 | [158] |

| AISI 304 | ErNiCu-7 | GTAW | 258 | [159] |

| Cu | SS316L | CMT-WAAM | 427 | [160] |

| Al-6.5Cu | Al-6.4Mg | WAAM | 258 | [110] |

| Ti6Al4V | Al6061-T6 | GTAW | 230 | [161] |

| Hastelloy C-276 | SS316L | GTAW | 780 | [162] |

| AA8011 | AA6061 | CMT-WAAM | 97 | [163] |

| Al5356 | Al6082 | GMAW | 263 | [164] |

| NiTi | Nb | WAAM | 789 | [165] |

| AISI 310 | 9Cr-1Mo | GTAW | 581 | [166] |

| SS316L | Q345 | GTAW | 1073 | [167] |

| SS316LSi | ER70S-6 | WAAM | 901 | [168] |

| TA7 | SS304 | GTAW | 293 | [169] |

| AA5052 | ERTi-2 | WAAM | 54 | [170] |

| AA7075 | AA6082 | CMT-WAAM | 212 | [171] |

| AA5356 | AA7075 | EBWAM | 289 | [87] |

| ERNiCr-3 | AISI 304L | WAAM | 565 | [172] |

| NiTi | Ti6Al4V | WAAM | 460 | [125] |

| IN601 | ER304 | GTAW | 485 | [173] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kang, X.; Li, G.; Jiang, W.; Li, F.; Wang, Y.; Wang, X.; Zeng, Q.; Fan, X. Wire-Based Additive Manufacturing of Multi-Material Structures: A Review. J. Compos. Sci. 2025, 9, 534. https://doi.org/10.3390/jcs9100534

Kang X, Li G, Jiang W, Li F, Wang Y, Wang X, Zeng Q, Fan X. Wire-Based Additive Manufacturing of Multi-Material Structures: A Review. Journal of Composites Science. 2025; 9(10):534. https://doi.org/10.3390/jcs9100534

Chicago/Turabian StyleKang, Xing, Guangyu Li, Wenming Jiang, Fafa Li, Yuejia Wang, Xiaoqiong Wang, Qiantong Zeng, and Xiuru Fan. 2025. "Wire-Based Additive Manufacturing of Multi-Material Structures: A Review" Journal of Composites Science 9, no. 10: 534. https://doi.org/10.3390/jcs9100534

APA StyleKang, X., Li, G., Jiang, W., Li, F., Wang, Y., Wang, X., Zeng, Q., & Fan, X. (2025). Wire-Based Additive Manufacturing of Multi-Material Structures: A Review. Journal of Composites Science, 9(10), 534. https://doi.org/10.3390/jcs9100534