Axial Compressive Behavior of CFRP and MWCNT Incorporated GFRP Confined Concrete Cylinders after Exposure to Various Aggressive Environments

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Methods

2.2.1. FRP Composite Preparation

2.2.2. Confinement of FRP on the Cylindrical Concrete Specimen

2.2.3. Test Specimens

2.2.4. Durability Studies

3. Results

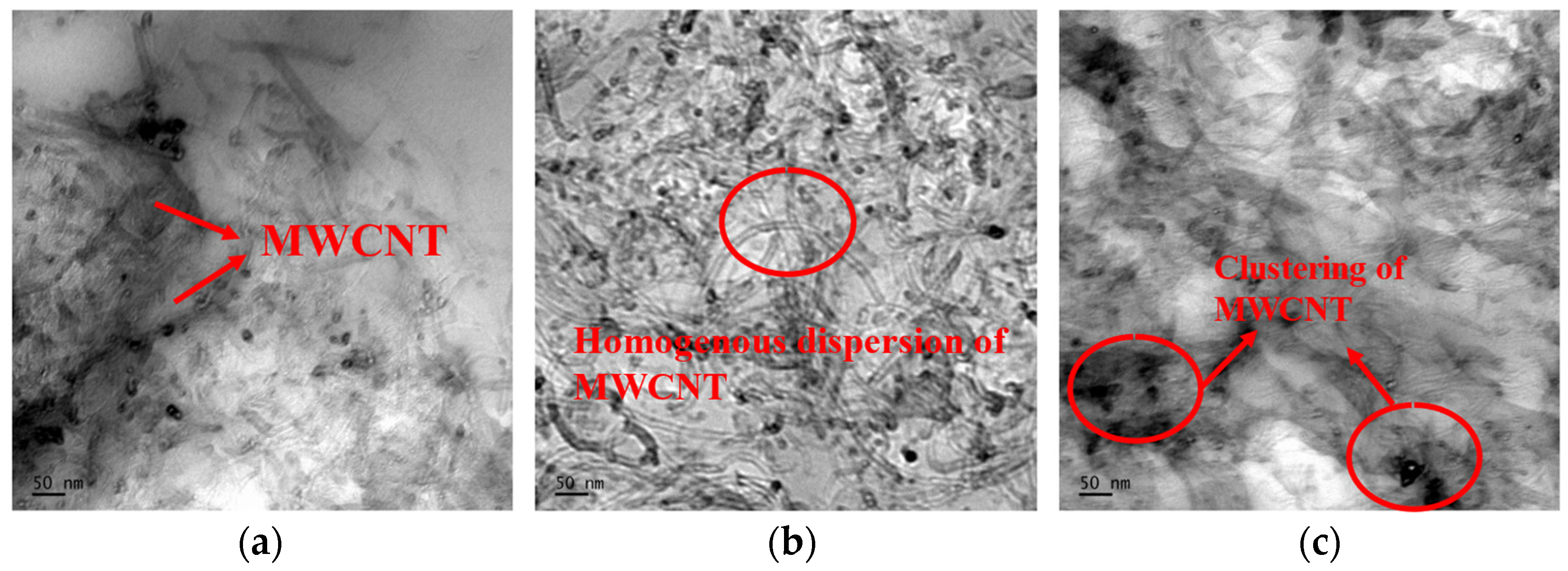

3.1. Morphology and Mechanical Properties of Composite Laminates

3.2. Axial Compressive Behavior

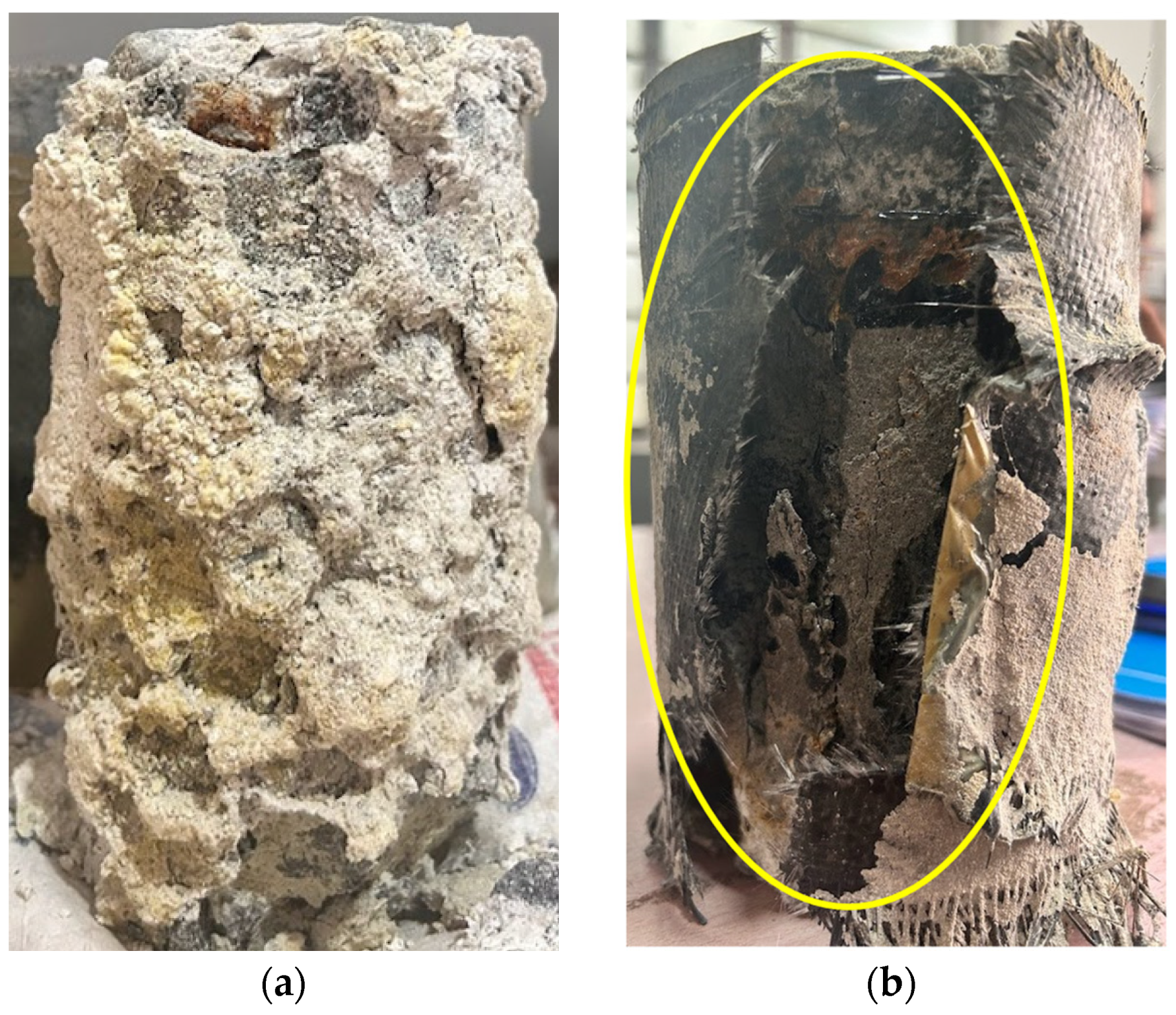

3.3. Effect of Acid Exposure

3.4. Effect of Alkaline Exposure

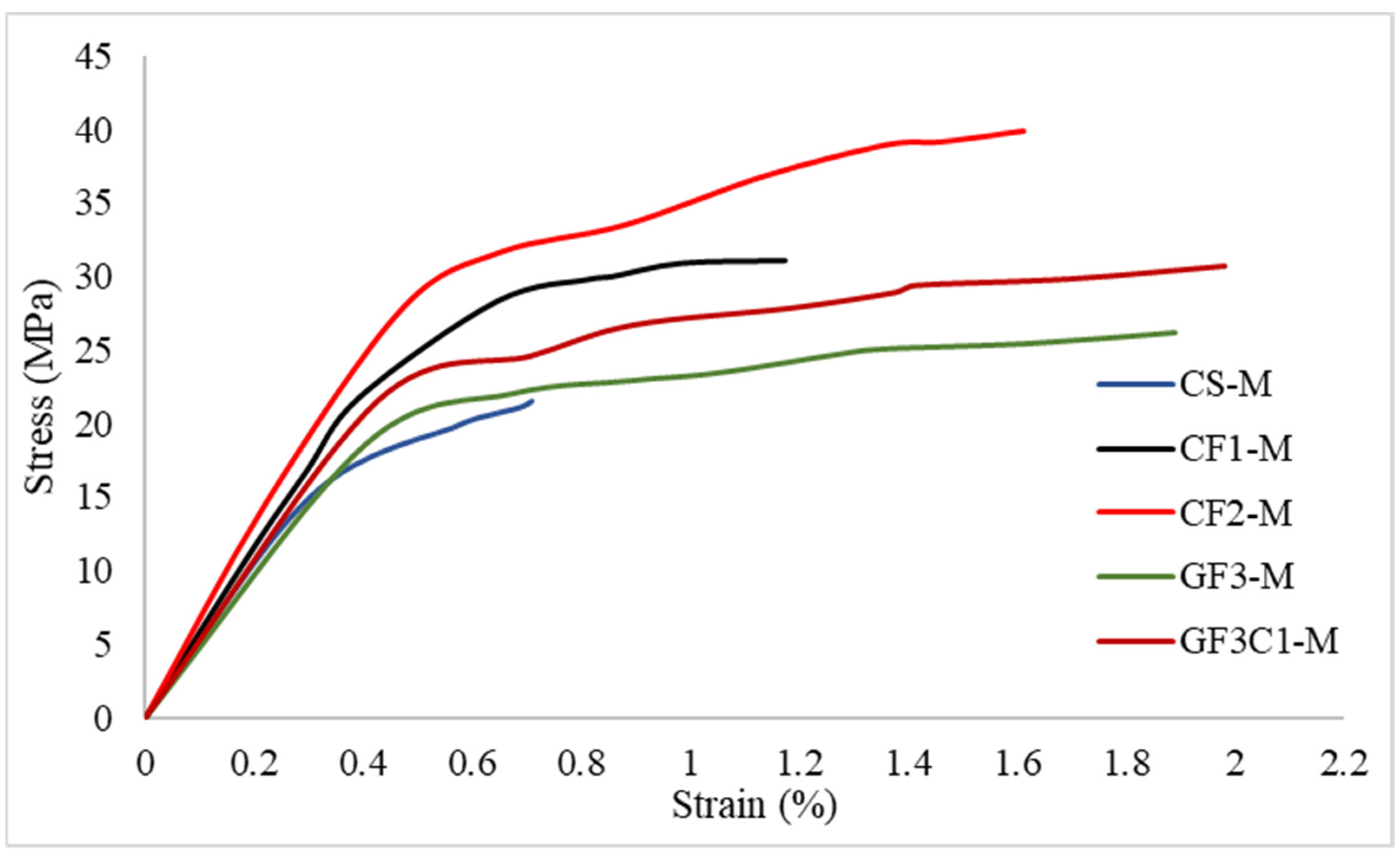

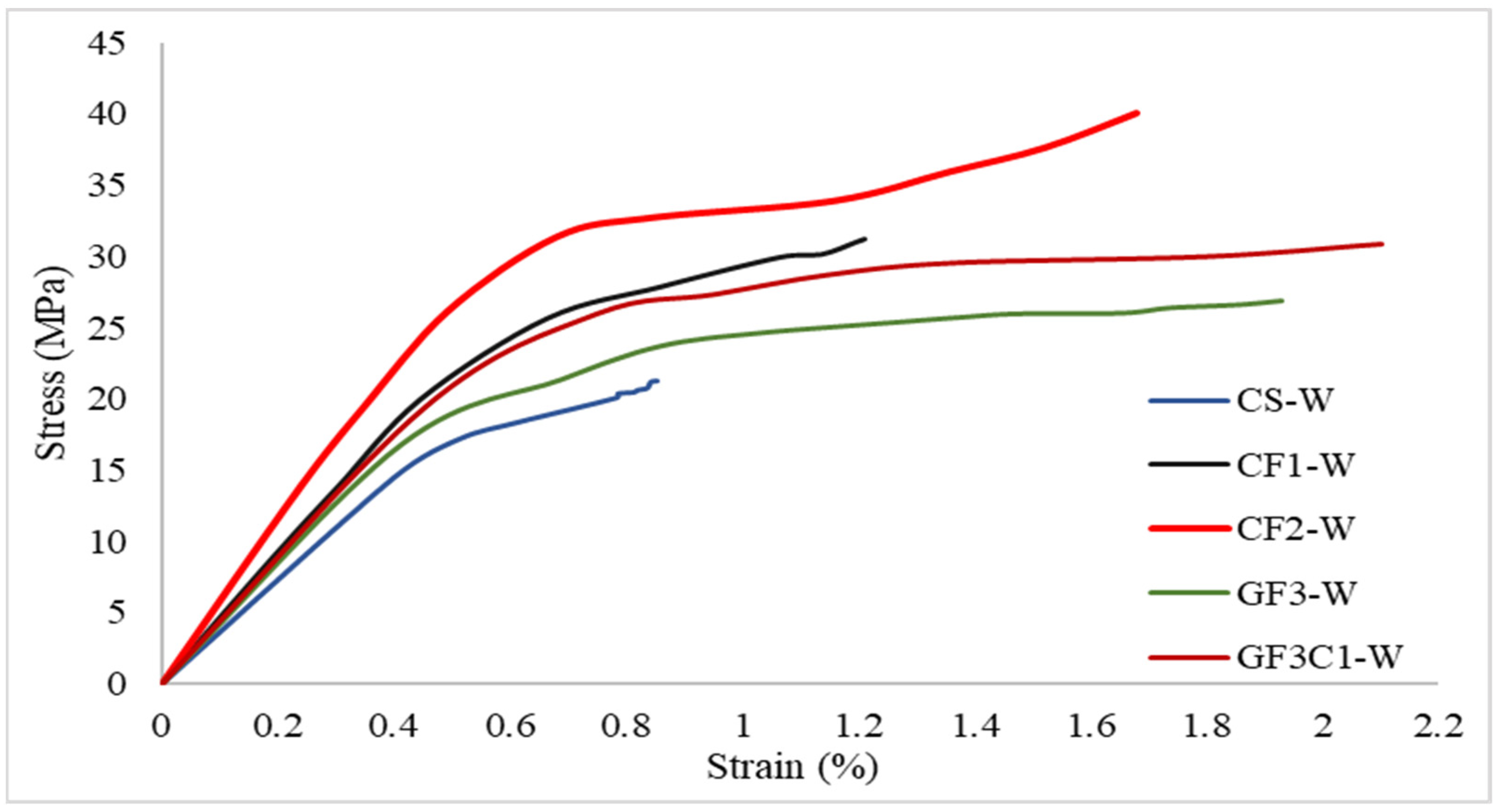

3.5. Effect of Marine and Normal Water

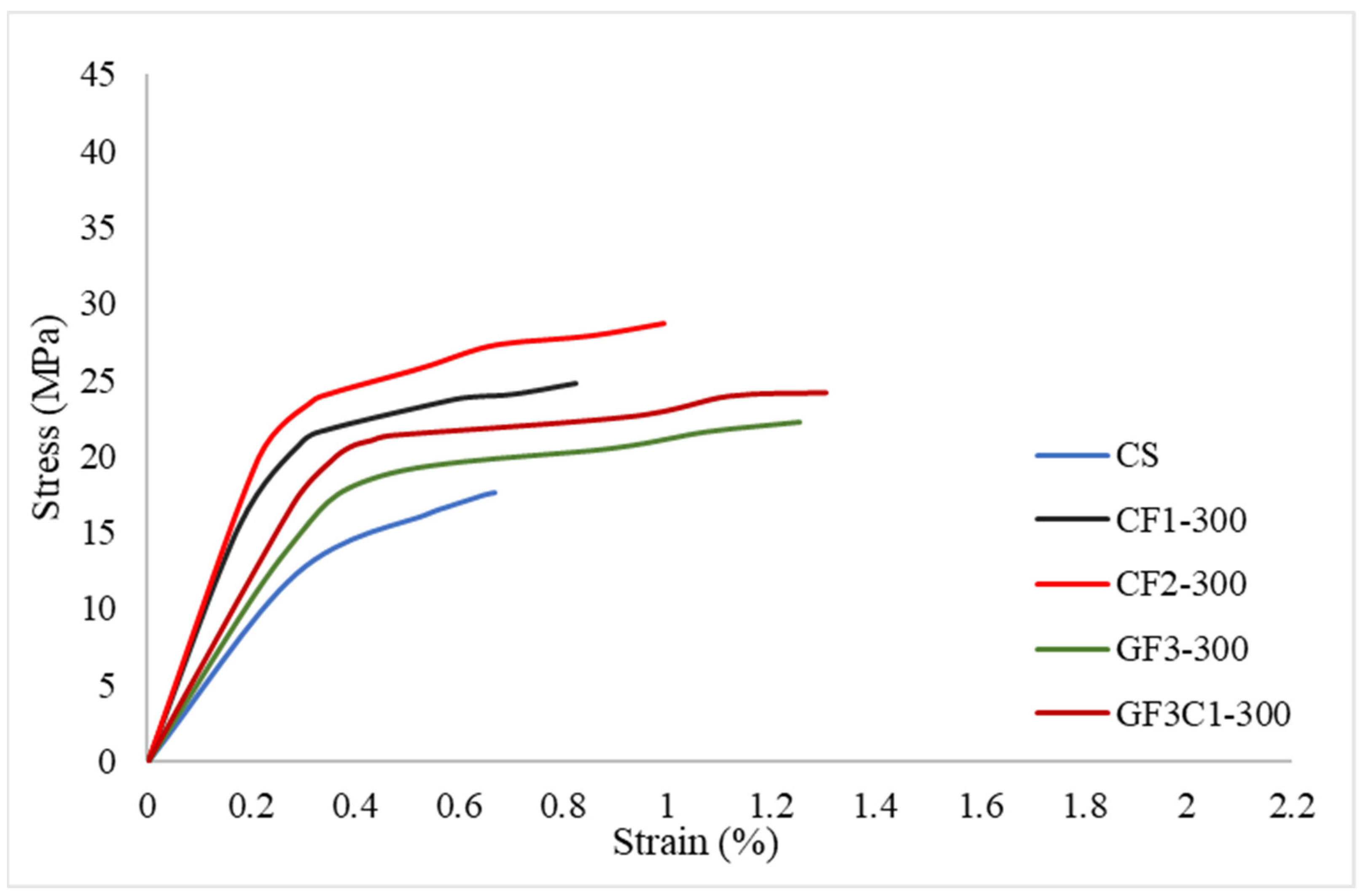

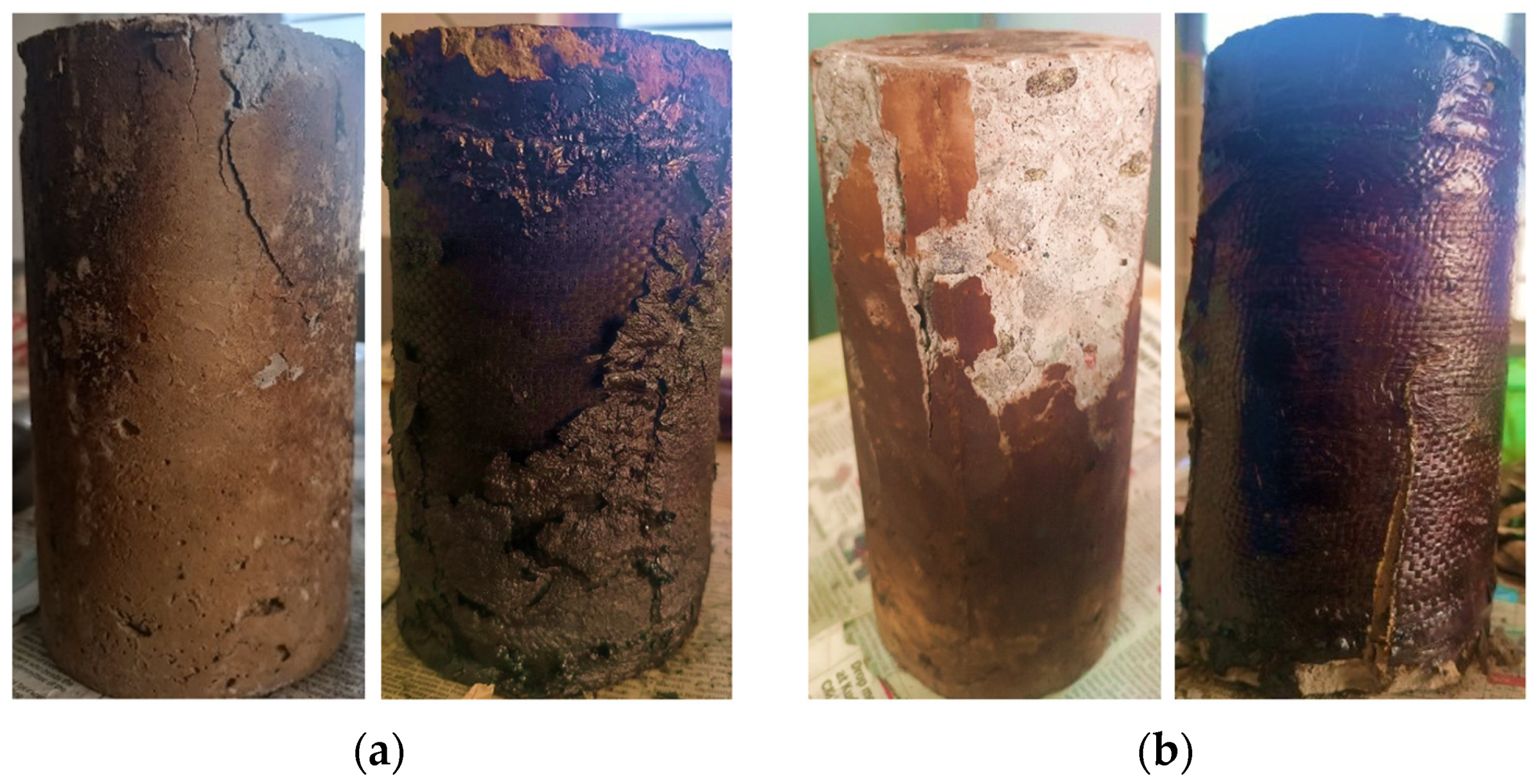

3.6. Elevated Temperature

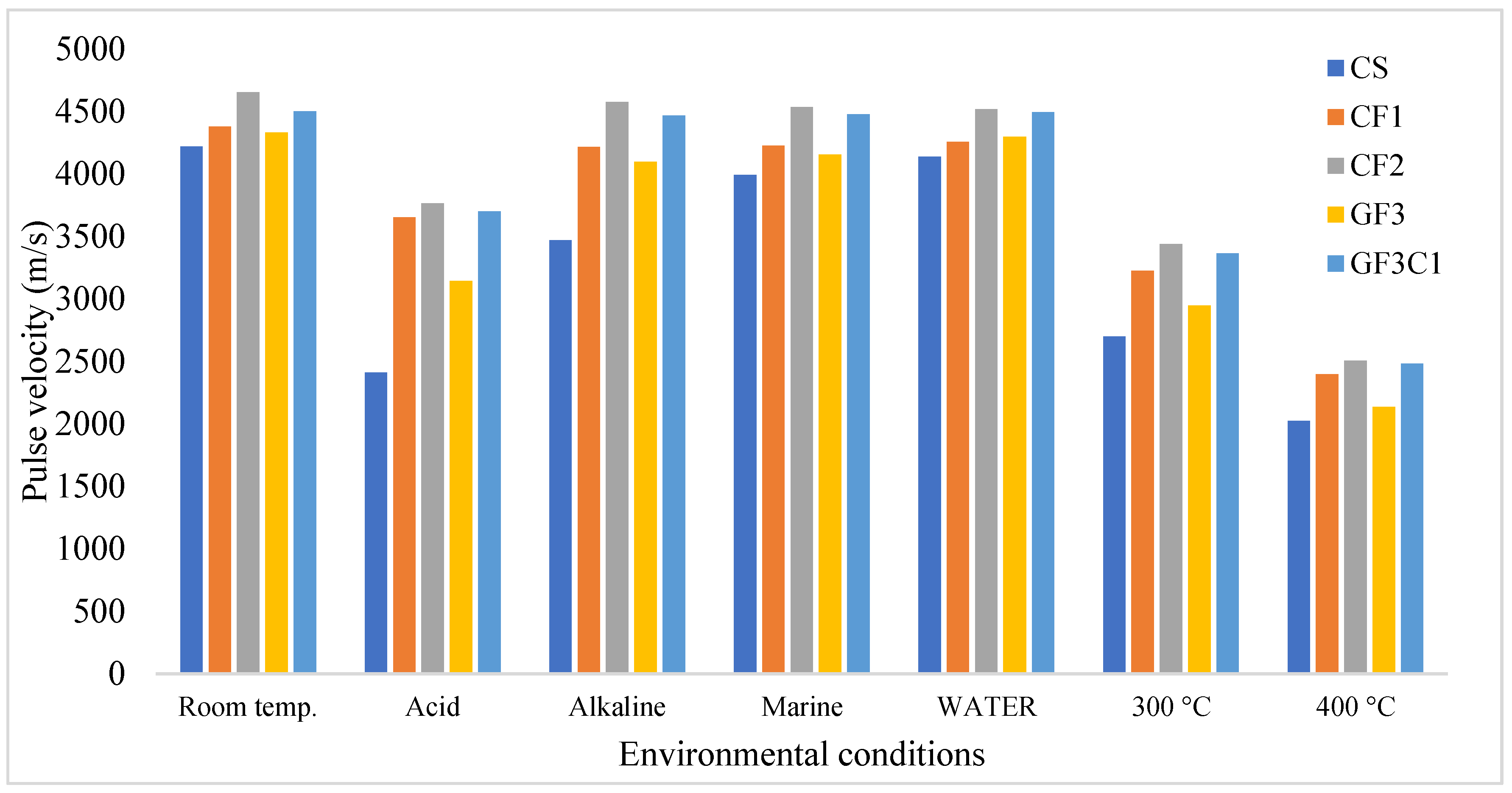

3.7. Ultrasonic Pulse Velocity Test

4. Conclusions

- Optimized percentage of MWCNT incorporated GFRP confinement increased the load-carrying capability and thereby the compressive strength of confined cylinders. The axial strain of GF3C1-AC was 75% higher than that of CF1-N and 12% higher than that of CF2-N;

- When comparing GF3C1-AC and GF3C1-N, the percentage drop in compressive strength of GF3C1-AC was approximately 5%, indicating the resistance offered by MWCNTs. The axial strain of GF3C1-AC was 23% and 12% higher than that of CF1-AC and CF2-AC, respectively. The compressive stress of CF1-AL is almost similar to that of GF3C1-AL and the axial strain of GF3C1-AL was 70% and 30% higher than CF1-AL and CF2-AL, respectively;

- The compressive stress of one-layer CFRP specimens was equivalent to three-layer MWCNT incorporated GFRP specimens, whereas the axial strain of GF3C1-M was 69% and 22% higher than CF1-M and CF2-M, respectively;

- The compressive strength of MWCNT integrated GFRP confined cylinders was 27% and 24% greater than exposed unconfined samples, respectively, even after exposure to temperatures of 300 °C to 400 °C. At 300 °C, the axial strain of GF3C1-300 is 30% and 38% higher than CF1-300 and CF2-300, respectively. This can be considered as an improvement in the structure’s ductility parameters. In the case of 400 °C, when compared with CF1-400 and CF2-400, the axial strain of GF3C1-400 increased by 50% and 20%, respectively.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Akogbe, R.-K.; Liang, M.; Wu, Z.-M. Size Effect of Axial Compressive Strength of CFRP Confined Concrete Cylinders. Int. J. Concr. Struct. Mater. 2011, 5, 49–55. [Google Scholar] [CrossRef]

- Issa, M.A.; Alrousan, R.Z.; Issa, M.A. Experimental and Parametric Study of Circular Short Columns Confined with CFRP Composites. J. Compos. Constr. 2009, 13, 135–147. [Google Scholar] [CrossRef]

- Padanattil, A.; Karingamanna, J.; Mini, K.M. Novel Hybrid Composites Based on Glass and Sisal Fiber for Retrofitting of Reinforced Concrete Structures. Constr. Build. Mater. 2017, 133, 146–153. [Google Scholar] [CrossRef]

- Joseph, L.; Kumar, P.S.; Deeraj, B.D.S.; Joseph, K.; Jayanarayanan, K.; Mini, K.M. Modification of Epoxy Binder with Multi Walled Carbon Nanotubes in Hybrid Fiber Systems Used for Retrofitting of Concrete Structures: Evaluation of Strength Characteristics. Heliyon 2022, 8, e09609. [Google Scholar] [CrossRef] [PubMed]

- Sreekumar Kavitha, S.; Joseph, L.; Madhavan, M.K.; Jayanarayanan, K. Comparative Study of Carbon and Glass Fiber Reinforced Polymer Composites for the Confinement of Concrete Columns. Mater. Today Proc. 2023; in press. [Google Scholar] [CrossRef]

- Li, D.; Cui, S.; Zhang, J. Experimental Investigation on Reinforcing Effects of Engineered Cementitious Composites (ECC) on Improving Progressive Collapse Performance of Planar Frame Structure. Constr. Build. Mater. 2022, 347, 128510. [Google Scholar] [CrossRef]

- Hariharan, H.; Rajeshkumar, G. Investigation of Mechanical Properties of Sisal Fiber and Sugar Palm Fiber Reinforced Hybrid Composites. Qeios 2024, 1–15. [Google Scholar] [CrossRef]

- Ramesh, M.; Palanikumar, K.; Reddy, K.H. Mechanical Property Evaluation of Sisal–Jute–Glass Fiber Reinforced Polyester Composites. Compos. Part B Eng. 2013, 48, 1–9. [Google Scholar] [CrossRef]

- Sen, T.; Paul, A. Confining Concrete with Sisal and Jute FRP as Alternatives for CFRP and GFRP. Int. J. Sustain. Built Environ. 2015, 4, 248–264. [Google Scholar] [CrossRef]

- Chaiyasarn, K.; Hussain, Q.; Joyklad, P.; Rodsin, K. New Hybrid Basalt/E-Glass FRP Jacketing for Enhanced Confinement of Recycled Aggregate Concrete with Clay Brick Aggregate. Case Stud. Constr. Mater. 2021, 14, e00507. [Google Scholar] [CrossRef]

- Pan, Y.; Yan, D. Study on the Durability of GFRP Bars and Carbon/Glass Hybrid Fiber Reinforced Polymer (HFRP) Bars Aged in Alkaline Solution. Compos. Struct. 2021, 261, 113285. [Google Scholar] [CrossRef]

- Li, W.; Li, W.; Lu, Y.; Hu, B.; Zhou, Y.; Wu, H.; Wang, P.; Ke, L.; Yu, J. Axial Compressive Behavior and Failure Mechanism of CFRP Partially Confined Ultra-High Performance Concrete (UHPC). Constr. Build. Mater. 2024, 426, 136104. [Google Scholar] [CrossRef]

- Haj Seiyed Taghia, S.A.; Darvishvand, H.R.; Pourhasan, M. An Economic Approach to the Confinement of Different Concrete Classes with Carbon and Glass Fibers Reinforced Polymers. Int. J. Eng. 2023, 36, 776–787. [Google Scholar] [CrossRef]

- Benzaid, R.; Mesbah, H.; Chikh, N.E. FRP-Confined Concrete Cylinders: Axial Compression Experiments and Strength Model. J. Reinf. Plast. Compos. 2010, 29, 2469–2488. [Google Scholar] [CrossRef]

- Anand, P.B.; Nagaraja, S.; Jayaram, N.; Sreenivasa, S.P.; Almakayeel, N.; Khan, T.M.Y.; Kumar, R.; Kumar, R.; Ammarullah, M.I. Kenaf Fiber and Hemp Fiber Multi-Walled Carbon Nanotube Filler-Reinforced Epoxy-Based Hybrid Composites for Biomedical Applications: Morphological and Mechanical Characterization. J. Compos. Sci. 2023, 7, 324. [Google Scholar] [CrossRef]

- Ghaleb, Z.; Mariatti, M.; Ariff, Z. Synergy Effects of Graphene and Multiwalled Carbon Nanotubes Hybrid System on Properties of Epoxy Nanocomposites. J. Reinf. Plast. Compos. 2017, 36, 685–695. [Google Scholar] [CrossRef]

- Zhang, J.; Zhuang, R.; Liu, J.; Mäder, E.; Heinrich, G.; Gao, S. Functional Interphases with Multi-Walled Carbon Nanotubes in Glass Fibre/Epoxy Composites. Carbon 2010, 48, 2273–2281. [Google Scholar] [CrossRef]

- Abadel, A.; Abbas, H.; Almusallam, T.; Alshaikh, I.M.H.; Khawaji, M.; Alghamdi, H.; Salah, A.A. Experimental Study of Shear Behavior of CFRP Strengthened Ultra-High-Performance Fiber-Reinforced Concrete Deep Beams. Case Stud. Constr. Mater. 2022, 16, e01103. [Google Scholar] [CrossRef]

- Smith, S.T.; Kim, S.J.; Zhang, H. Behavior and Effectiveness of FRP Wrap in the Confinement of Large Concrete Cylinders. J. Compos. Constr. 2010, 14, 573–582. [Google Scholar] [CrossRef]

- Wahab, N.; Srinophakun, P.; Hussain, Q.; Chaimahawan, P. Performance of Concrete Confined with a Jute–Polyester Hybrid Fiber Reinforced Polymer Composite: A Novel Strengthening Technique. Fibers 2019, 7, 72. [Google Scholar] [CrossRef]

- Zhang, Q.; Wu, J.; Gao, L.; Liu, T.; Zhong, W.; Sui, G.; Zheng, G.; Fang, W.; Yang, X. Dispersion Stability of Functionalized MWCNT in the Epoxy–Amine System and Its Effects on Mechanical and Interfacial Properties of Carbon Fiber Composites. Mater. Des. 2016, 94, 392–402. [Google Scholar] [CrossRef]

- Feng, C.; Yu, F.; Fang, Y. Mechanical Behavior of PVC Tube Confined Concrete and PVC-FRP Confined Concrete: A Review. Structures 2021, 31, 613–635. [Google Scholar] [CrossRef]

- Li, Y.-L.; Zhao, X.-L.; Raman, R.S. Durability of Seawater and Sea Sand Concrete and Seawater and Sea Sand Concrete–Filled Fibre-Reinforced Polymer/Stainless Steel Tubular Stub Columns. Adv. Struct. Eng. 2021, 24, 1074–1089. [Google Scholar] [CrossRef]

- Cleary, D.B.; Cassino, C.D.; Tortorice, R.; Newell, J.A.; Tyers, B.W. Effect of Elevated Temperatures on a Fiber Composite Used to Strengthen Concrete Columns. J. Reinf. Plast. Compos. 2003, 22, 881–895. [Google Scholar] [CrossRef]

- Cerniauskas, G.; Tetta, Z.; Bournas, D.A.; Bisby, L.A. Concrete Confinement with TRM versus FRP Jackets at Elevated Temperatures. Mater. Struct. 2020, 53, 58. [Google Scholar] [CrossRef]

- Al-Salloum, Y.A.; Elsanadedy, H.M.; Abadel, A.A. Behavior of FRP-Confined Concrete after High Temperature Exposure. Constr. Build. Mater. 2011, 25, 838–850. [Google Scholar] [CrossRef]

- Li, Y.; Liu, X.; Wu, M. Mechanical Properties of FRP-Strengthened Concrete at Elevated Temperature. Constr. Build. Mater. 2017, 134, 424–432. [Google Scholar] [CrossRef]

- Xiang, Z.; Tong, Y.; Niu, J.; Yin, L.; Zhou, J. Experimental Study on the Axial Compressive Mechanical Performance of Concrete Short Columns Jointly Confined with CC and CFRP after Sulfate Attack. J. Build. Eng. 2024, 95, 110342. [Google Scholar] [CrossRef]

- Alzeebaree, R.; Çevik, A.; Mohammedameen, A.; Niş, A.; Gülşan, M.E. Mechanical Performance of FRP-Confined Geopolymer Concrete under Seawater Attack. Adv. Struct. Eng. 2020, 23, 1055–1073. [Google Scholar] [CrossRef]

- Zhou, Y.; Li, M.; Sui, L.; Xing, F. Effect of Sulfate Attack on the Stress–Strain Relationship of FRP-Confined Concrete. Constr. Build. Mater. 2016, 110, 235–250. [Google Scholar] [CrossRef]

- Alzeebaree, R.; Çevik, A.; Nematollahi, B.; Sanjayan, J.; Mohammedameen, A.; Gülşan, M.E. Mechanical Properties and Durability of Unconfined and Confined Geopolymer Concrete with Fiber Reinforced Polymers Exposed to Sulfuric Acid. Constr. Build. Mater. 2019, 215, 1015–1032. [Google Scholar] [CrossRef]

- IS 10262; Guidelines for Concrete Mix Design Proportioning. Indian Standard: New Delhi, India, 2009.

- Sarath Kumar, P.; Jayanarayanan, K.; Deeraj, B.D.S.; Joseph, K.; Balachandran, M. Synergistic Effect of Carbon Fabric and Multiwalled Carbon Nanotubes on the Fracture, Wear and Dynamic Load Response of Epoxy-Based Multiscale Composites. Polym. Bull. 2022, 79, 5063–5084. [Google Scholar] [CrossRef]

- Ispir, M.; Dalgic, K.D.; Ilki, A. Hybrid Confinement of Concrete through Use of Low and High Rupture Strain FRP. Compos. Part B Eng. 2018, 153, 243–255. [Google Scholar] [CrossRef]

- Micelli, F.; Mazzotta, R.; Leone, M.; Aiello, M.A. Review Study on the Durability of FRP-Confined Concrete. J. Compos. Constr. 2015, 19, 04014056. [Google Scholar] [CrossRef]

- Kodur, V. Properties of Concrete at Elevated Temperatures. ISRN Civ. Eng. 2014, 2014, 468510. [Google Scholar] [CrossRef]

- El-Hacha, R.; Green, M.F.; Wight, G.R. Effect of Severe Environmental Exposures on CFRP Wrapped Concrete Columns. J. Compos. Constr. 2010, 14, 83–93. [Google Scholar] [CrossRef]

- Rasana, N.; Jayanarayanan, K. Experimental and Micromechanical Modeling of Fracture Toughness: MWCNT-Reinforced Polypropylene/Glass Fiber Hybrid Composites. J. Thermoplast. Compos. Mater. 2019, 32, 1031–1055. [Google Scholar] [CrossRef]

- Tehrani, M.; Boroujeni, A.Y.; Hartman, T.B.; Haugh, T.P.; Case, S.W.; Al-Haik, M.S. Mechanical Characterization and Impact Damage Assessment of a Woven Carbon Fiber Reinforced Carbon Nanotube–Epoxy Composite. Compos. Sci. Technol. 2013, 75, 42–48. [Google Scholar] [CrossRef]

- Xue, Y.; Wu, W.; Jacobs, O.; Schädel, B. Tribological Behaviour of UHMWPE/HDPE Blends Reinforced with Multi-Wall Carbon Nanotubes. Polym. Test. 2006, 25, 221–229. [Google Scholar] [CrossRef]

- Tiwari, M.; Billing, B.K.; Bedi, H.S.; Agnihotri, P.K. Quantification of Carbon Nanotube Dispersion and Its Correlation with Mechanical and Thermal Properties of Epoxy Nanocomposites. J. Appl. Polym. Sci. 2020, 137, 48879. [Google Scholar] [CrossRef]

- D638 Standard Test Method for Tensile Properties of Plastics. Available online: https://www.astm.org/d0638-14.html (accessed on 14 June 2024).

- Parameswaranpillai, J.; Gopi, J.A.; Pathak, C.; Rashmi; Dominic, C.D.M.; Ganguly, S.; Radoor, S.; Krishnasamy, S. Mechanical Properties of Epoxy/Carbon Nanotube Composites. In Synthetic and Natural Nanofillers in Polymer Composites; Elsevier: Amsterdam, The Netherlands, 2023; pp. 75–87. ISBN 978-0-443-19053-7. [Google Scholar]

- Chandran, A.R.; Radhika, N. Investigation on Mechanical Properties and Wear Behaviour of Chopped Carbon-Basalt Epoxy Hybrid Composite. Mater. Res. Express 2019, 6, 105303. [Google Scholar] [CrossRef]

- Sarath Kumar, P.; Jayanarayanan, K.; Balachandran, M. Thermal and Mechanical Behavior of Functionalized MWCNT Reinforced Epoxy Carbon Fabric Composites. Mater. Today Proc. 2020, 24, 1157–1166. [Google Scholar] [CrossRef]

- Compressive Strength Test (IS: 4031 (Part 6)—1988). Available online: https://www.scribd.com/document/481271038/Testing-of-CEMENT-2 (accessed on 14 June 2024).

- Joseph, L.; Sarath Kumar, P.; Chakravarthi, E.K.; Mogal, A.; Jayanarayanan, K.; Madhavan, M.K. Experimental and Statistical Investigation on Synergistic Effect of Nano Based Epoxy Hybrid FRP on Strength and Durability of Circular Concrete Columns. Dev. Built Environ. 2023, 14, 100163. [Google Scholar] [CrossRef]

- Ali Dadvar, S.; Mostofinejad, D.; Bahmani, H. Strengthening of RC Columns by Ultra-High Performance Fiber Reinforced Concrete (UHPFRC) Jacketing. Constr. Build. Mater. 2020, 235, 117485. [Google Scholar] [CrossRef]

- Rousakis, T.C. Inherent Seismic Resilience of RC Columns Externally Confined with Nonbonded Composite Ropes. Compos. Part B Eng. 2018, 135, 142–148. [Google Scholar] [CrossRef]

- Rousakis, T.C.; Kouravelou, K.B.; Karachalios, T.K. Effects of Carbon Nanotube Enrichment of Epoxy Resins on Hybrid FRP–FR Confinement of Concrete. Compos. Part B Eng. 2014, 57, 210–218. [Google Scholar] [CrossRef]

- Pimanmas, A.; Hussain, Q.; Panyasirikhunawut, A.; Rattanapitikon, W. Axial Strength and Deformability of Concrete Confined with Natural Fibre-Reinforced Polymers. Mag. Concr. Res. 2019, 71, 55–70. [Google Scholar] [CrossRef]

- Gu, L.; Bennett, T.; Visintin, P. Sulphuric Acid Exposure of Conventional Concrete and Alkali-Activated Concrete: Assessment of Test Methodologies. Constr. Build. Mater. 2019, 197, 681–692. [Google Scholar] [CrossRef]

- Arjomandi, A.; Mousavi, R.; Tayebi, M.; Nematzadeh, M.; Gholampour, A.; Aminian, A.; Gencel, O. The Effect of Sulfuric Acid Attack on Mechanical Properties of Steel Fiber-Reinforced Concrete Containing Waste Nylon Aggregates: Experiments and RSM-Based Optimization. J. Build. Eng. 2023, 64, 105500. [Google Scholar] [CrossRef]

- Yan, L. Plain Concrete Cylinders and Beams Externally Strengthened with Natural Flax Fabric Reinforced Epoxy Composites. Mater. Struct. 2016, 49, 2083–2095. [Google Scholar] [CrossRef]

- Toutanji, H.; Deng, Y. Strength and Durability Performance of Concrete Axially Loaded Members Confined with AFRP Composite Sheets. Compos. Part B Eng. 2002, 33, 255–261. [Google Scholar] [CrossRef]

- El-Gamal, S.; Al-Jabri, K.; Al-Mahri, A.; Al-Mahrouqi, S. Effects of Elevated Temperatures on the Compressive Strength Capacity of Concrete Cylinders Confined with FRP Sheets: An Experimental Investigation. Int. J. Polym. Sci. 2015, 2015, 549187. [Google Scholar] [CrossRef]

- Pitchan, M.K.; Bhowmik, S.; Balachandran, M.; Abraham, M. Effect of Surface Functionalization on Mechanical Properties and Decomposition Kinetics of High Performance Polyetherimide/MWCNT Nano Composites. Compos. Part A Appl. Sci. Manuf. 2016, 90, 147–160. [Google Scholar] [CrossRef]

- Liu, J.; Huo, J.; Wang, H.; Tang, Z.; Zhang, Q.; Yi, S. Experimental Study on Dynamic Mechanical Performance of Post-Fire Concrete Confined by CFRP Sheets. Materials 2024, 17, 2076. [Google Scholar] [CrossRef] [PubMed]

- IS 13311-1; Method of Non-Destructive Testing of Concret, Part 1: Ultrasonic Pulse Velocity. Indian Standard: New Delhi, India, 1992.

- Mirmiran, A.; Wei, Y. Damage Assessment of FRP-Encased Concrete Using Ultrasonic Pulse Velocity. J. Eng. Mech. 2001, 127, 126–135. [Google Scholar] [CrossRef]

- Sasmal, S.; Basu, S.; Himakar, C.V.V.; Kundu, T. Detection of Interface Flaws in Concrete-FRP Composite Structures Using Linear and Nonlinear Ultrasonics Based Techniques. Ultrasonics 2023, 132, 107007. [Google Scholar] [CrossRef]

- Rabehi, B.; Ghernouti, Y.; Li, A.; Boumchedda, K. Comparative Behavior under Compression of Concrete Columns Repaired by Fiber Reinforced Polymer (FRP) Jacketing and Ultra High-Performance Fiber Reinforced Concrete (UHPFRC). J. Adhes. Sci. Technol. 2014, 28, 2327–2346. [Google Scholar] [CrossRef]

| Materials | Properties |

|---|---|

| Cement | Specific gravity—2.9 |

| Initial setting time—45 min | |

| Final setting time—540 min | |

| Fine aggregate—river sand (Zone II) | Specific gravity—2.64 |

| Fineness modulus—2.82 | |

| Bulk density—1691 kg/m3 | |

| Water absorption—0.8% | |

| Coarse aggregate (20 mm size) | Specific gravity—2.65 |

| Water absorption—1.8% | |

| Bulk density—1697 kg/m3 |

| Exposure Environment/Elevated Temp. | Composition | ||||

|---|---|---|---|---|---|

| Control Specimen | CFRP—1 Layer | CFRP—2 Layer | GFRP—3 Layer | MWCNT Incorporated 3 Layer GFRP | |

| Normal Condition | CS-N | CF1-N | CF2-N | GF3-N | GF3C1-N |

| Acid | CS-AC | CF1-AC | CF2-AC | GF3-AC | GF3C1-AC |

| Alkaline | CS-AL | CF1-AL | CF2-AL | GF3-AL | GF3C1-AL |

| Marine | CS-M | CF1-M | CF2-M | GF3-M | GF3C1-M |

| Water | CS-W | CF1-W | CF2-W | GF3-W | GF3C1-W |

| 100 °C | CS-100 | CF1-100 | CF2-100 | GF3-100 | GF3C1-100 |

| 200 °C | CS-200 | CF1-200 | CF2-200 | GF3-200 | GF3C1-200 |

| 300 °C | CS-300 | CF1-300 | CF2-300 | GF3-300 | GF3C1-300 |

| 400 °C | CS-400 | CF1-400 | CF2-400 | GF3-400 | GF3C1-400 |

| Sample | Tensile Strength (MPa) | Strain at Break (%) | Young’s Modulus (GPa) |

|---|---|---|---|

| E | 0.1 | 0.3 | 0.1 |

| EC0.5 | 0.4 | 0.3 | 0.2 |

| EC1 | 0.3 | 0.1 | 0.4 |

| EC1.5 | 0.1 | 0.2 | 0.1 |

| EC2 | 0.2 | 0.5 | 0.2 |

| ECF1 | 0.3 | 0.2 | 0.1 |

| ECF2 | 0.2 | 0.3 | 0.3 |

| EGF3 | 0.5 | 0.2 | 0.1 |

| EC0.5GF3 | 0.1 | 0.1 | 0.2 |

| EC1GF3 | 0.3 | 0.2 | 0.1 |

| EC1.5GF3 | 0.3 | 0.3 | 0.1 |

| EC2GF3 | 0.1 | 0.1 | 0.3 |

| Concrete Specimen | Compressive Strength (f′co or f′cc) (MPa) | Strength Enhancement (%) | Confinement Effectiveness (f′cc/f′co) | Axial Strain (%) |

|---|---|---|---|---|

| CS-N | 0.4 | - | - | 0.1 |

| CF1-N | 0.2 | 43 | 1.43 | 0.1 |

| CF2-N | 0.1 | 81.3 | 1.8 | 0.2 |

| GF3-N | 0.3 | 23 | 1.22 | 0.1 |

| GF3C1-N | 0.4 | 42 | 1.41 | 0.4 |

| Concrete Specimen | Compressive Strength (f′co or f′cc) (MPa) | Strength Enhancement (%) | Confinement Effectiveness (f′cc/f′co) | Axial Strain (%) |

|---|---|---|---|---|

| CS-N | 0.2 | - | 0.1 | |

| CS-AC | 0.3 | - | 0.4 | |

| CF1-AC | 0.4 | 317 | 1.3 | 0.1 |

| CF2-AC | 0.3 | 432 | 1.7 | 0.2 |

| GF3-AC | 0.2 | 260 | 1.1 | 0.3 |

| GF3C1-AC | 0.1 | 321 | 1.3 | 0.2 |

| Concrete Specimen | Compressive Strength (f′co or f′cc) (MPa) | Strength Enhancement (%) | Confinement Effectiveness (f′cc/f′co) | Axial Strain (%) |

|---|---|---|---|---|

| CS-N | 0.2 | - | - | 0.1 |

| CS-AL | 0.1 | - | - | 0.2 |

| CF1-AL | 0.2 | 47 | 1.4 | 0.1 |

| CF2-AL | 0.3 | 87 | 1.7 | 0.2 |

| GF3-AL | 0.4 | 18 | 1.1 | 0.1 |

| GF3C1-AL | 0.1 | 44 | 1.3 | 0.3 |

| Concrete Specimen | Compressive Strength (f′co or f′cc) (MPa) | Strength Enhancement (%) | Confinement Effectiveness (f′cc/f′co) | Axial Strain (%) |

|---|---|---|---|---|

| CS | 0.2 | - | - | 0.1 |

| CS-M | 0.3 | - | - | 0.2 |

| CF1-M | 0.4 | 44 | 1.4 | 0.3 |

| CF2-M | 0.2 | 85 | 1.8 | 0.1 |

| GF3-M | 0.1 | 22 | 1.2 | 0.4 |

| GF3C1-M | 0.2 | 43 | 1.4 | 0.2 |

| Concrete Specimen | Compressive Strength (f′co or f′cc) (MPa) | Strength Enhancement (%) | Confinement Effectiveness (f′cc/f′co) | Axial Strain (%) |

|---|---|---|---|---|

| CS | 0.2 | - | 0.2 | |

| CS-W | 0.1 | - | 0.4 | |

| CF1-W | 0.4 | 46 | 1.4 | 0.1 |

| CF2-W | 0.5 | 88 | 1.8 | 0.3 |

| GF3-W | 0.2 | 26 | 1.2 | 0.2 |

| GF3C1-W | 0.3 | 45 | 1.4 | 0.1 |

| Concrete Specimen | Compressive Strength (f′co or f′cc) (MPa) | Strength Enhancement Compared to CS-300 (%) | Confinement Effectiveness (f′cc/f′co) | Axial Strain (%) |

|---|---|---|---|---|

| CS | 0.2 | - | 0.1 | |

| CS-300 | 0.1 | - | - | 0.2 |

| CF1-300 | 0.3 | 41 | 1.4 | 0.1 |

| CF2-300 | 0.4 | 63 | 1.6 | 0.3 |

| GF3-300 | 0.2 | 27 | 1.2 | 0.1 |

| GF3C1-300 | 0.1 | 38 | 1.3 | 0.4 |

| Concrete Specimen | Compressive Strength (f′co or f′cc) (MPa) | Strength Enhancement Compared to CS-400 (%) | Confinement Effectiveness (f′cc/f′co) | Axial Strain (%) |

|---|---|---|---|---|

| CS | 0.2 | - | - | 0.1 |

| CS-400 | 0.1 | - | - | 0.2 |

| CF1-400 | 0.3 | 33 | 1.4 | 0.1 |

| CF2-400 | 0.4 | 58 | 1.6 | 0.3 |

| GF3-400 | 0.1 | 24 | 1.2 | 0.2 |

| GF3C1-400 | 0.2 | 31 | 1.3 | 0.1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kavitha, S.S.; Madhavan, M.K.; Jayanarayanan, K.; Sarker, P.K. Axial Compressive Behavior of CFRP and MWCNT Incorporated GFRP Confined Concrete Cylinders after Exposure to Various Aggressive Environments. J. Compos. Sci. 2024, 8, 313. https://doi.org/10.3390/jcs8080313

Kavitha SS, Madhavan MK, Jayanarayanan K, Sarker PK. Axial Compressive Behavior of CFRP and MWCNT Incorporated GFRP Confined Concrete Cylinders after Exposure to Various Aggressive Environments. Journal of Composites Science. 2024; 8(8):313. https://doi.org/10.3390/jcs8080313

Chicago/Turabian StyleKavitha, Sruthi Sreekumar, Mini K. Madhavan, Karingamanna Jayanarayanan, and Prabir Kumar Sarker. 2024. "Axial Compressive Behavior of CFRP and MWCNT Incorporated GFRP Confined Concrete Cylinders after Exposure to Various Aggressive Environments" Journal of Composites Science 8, no. 8: 313. https://doi.org/10.3390/jcs8080313

APA StyleKavitha, S. S., Madhavan, M. K., Jayanarayanan, K., & Sarker, P. K. (2024). Axial Compressive Behavior of CFRP and MWCNT Incorporated GFRP Confined Concrete Cylinders after Exposure to Various Aggressive Environments. Journal of Composites Science, 8(8), 313. https://doi.org/10.3390/jcs8080313