Numerical Investigation of Flexural Behavior of Reinforced Concrete (RC) T-Beams Strengthened with Pre-Stressed Iron-Based (FeMnSiCrNi) Shape Memory Alloy Bars

Abstract

1. Introduction

2. Description of the FE Numerical Models

2.1. Material Properties

2.1.1. Concrete Definition in ABAQUS

2.1.2. Reinforcement Definition in ABAQUS

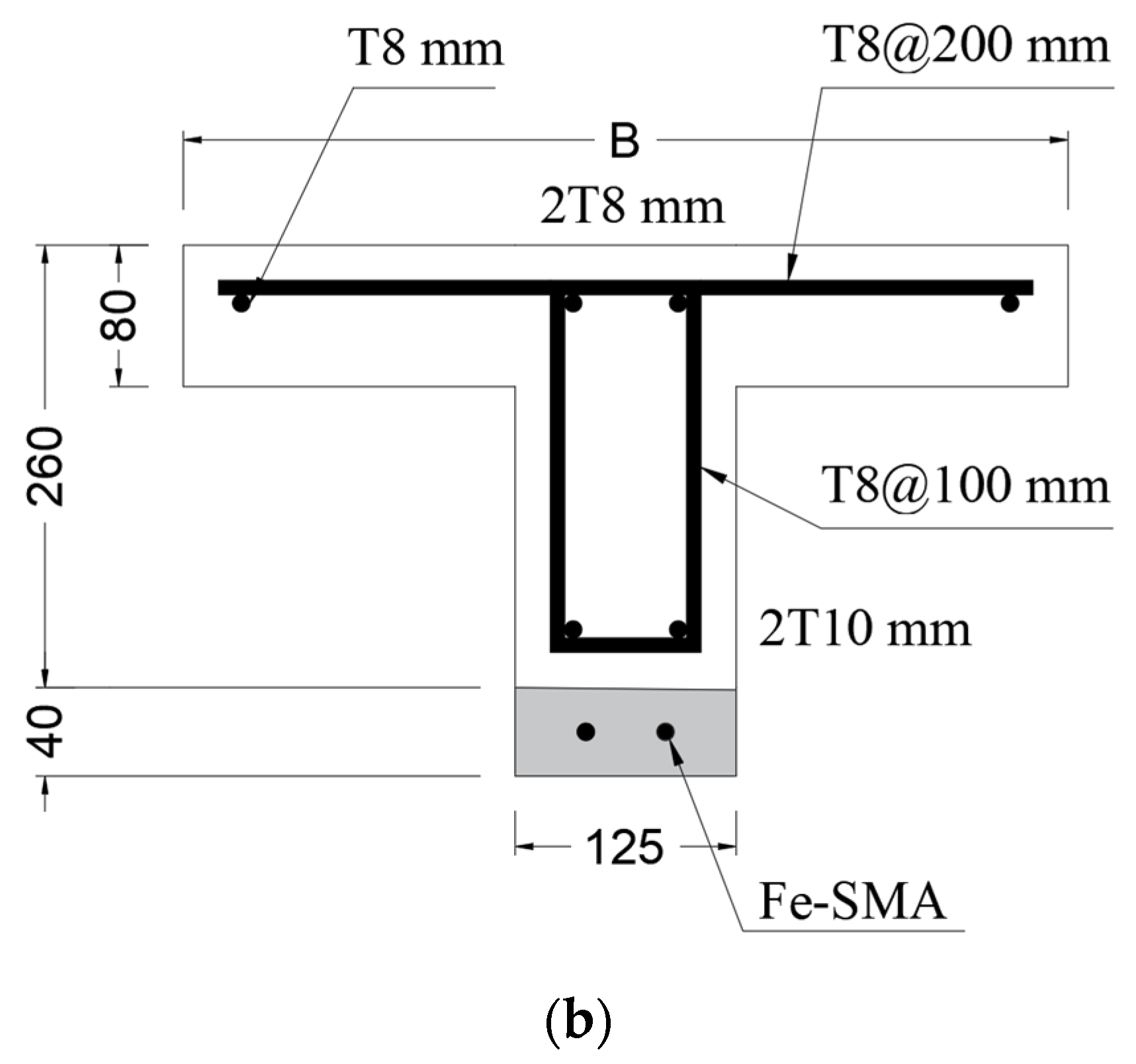

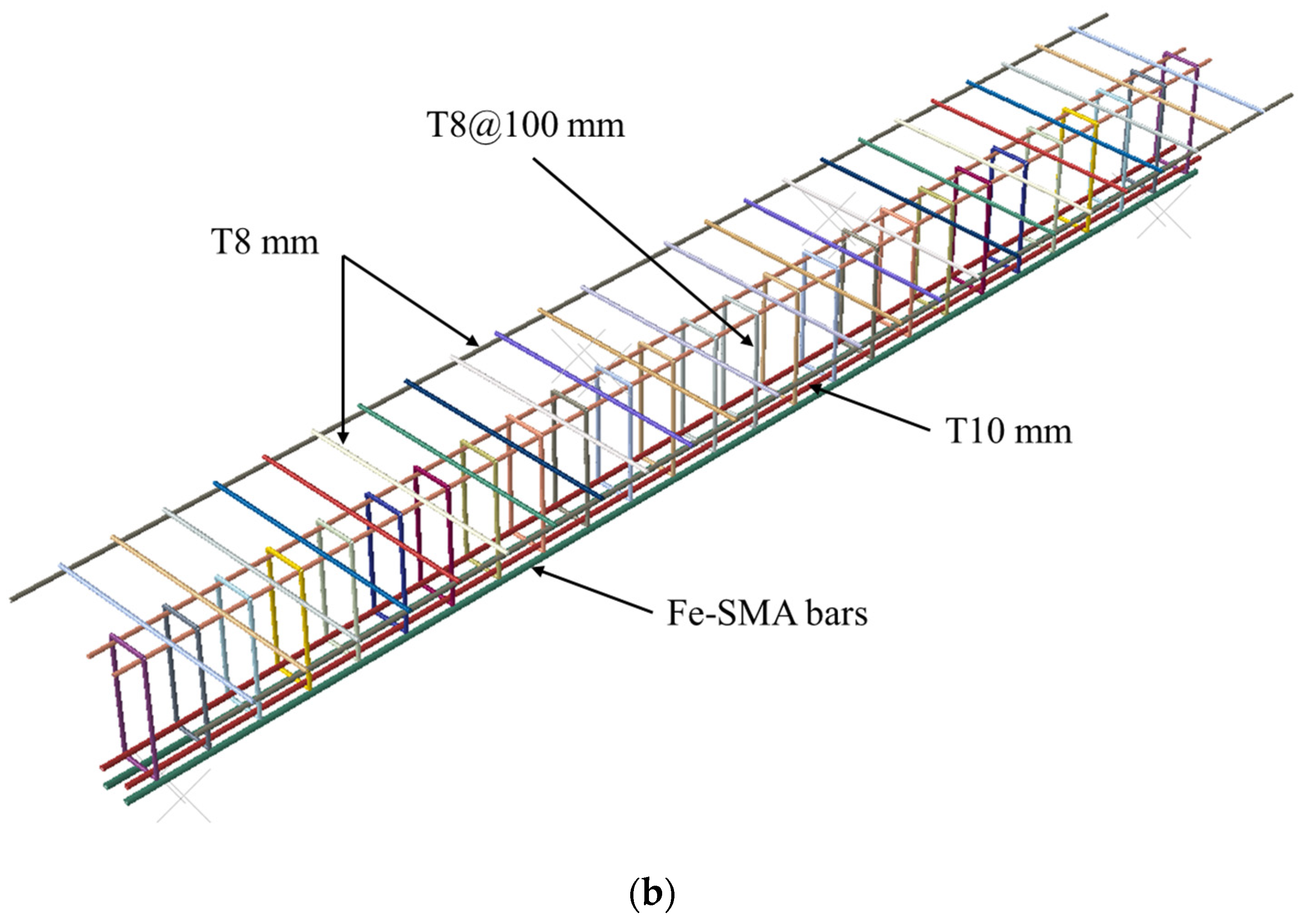

2.2. Geometrical Configuration

2.3. Elements Description

2.4. Pre-Stressing Modeling

3. Results and Discussion

3.1. Evaluating the Accuracy of FE Models

3.2. Influence of Compressive Strength of Concrete ()

3.3. Effect of Changing the Diameter of Fe-SMA Rebars

3.4. Effect of Flange Width

4. Summary and Conclusions

- Pre-stressed T-beams with greater concrete compressive strength showed a slight improvement in cracking, yielding, and ultimate loads. However, it significantly enhances the ductility of the beam. For instance, changing the compressive strength from 30 to 60 MPa could attain higher cracking, yielding, and ultimate loads of approximately 11%, 2%, and 2%, respectively. While the 60 MPa beam achieved 45% higher ductility than the 30 MPa beam.

- By substituting 12 mm Fe-SMA bars for 6 mm Fe-SMA bars, the prestressed T-beams showed 65% and 47% stronger strength and improved ductility, respectively.

- Increasing the flange width of the pre-stressed T-beam enabled the beam to attain higher strength and ductility. Specifically, a 500 mm flange width achieved higher strength and ductility of 7% and 25%, respectively, compared to the pre-stressed rectangular-section beam.

- This study highly recommends considering the flange of the pre-stressed beam in the flexural design as it significantly affects the beam’s ductility.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Khalil, A.E.-H.; Etman, E.; Atta, A.; Essam, M. Nonlinear behavior of RC beams strengthened with strain hardening cementitious composites subjected to monotonic and cyclic loads. Alex. Eng. J. 2016, 55, 1483–1496. [Google Scholar] [CrossRef]

- Kunieda, M.; Banno, K. Overlay of RC Bridge Deck Deteriorated by ASR Using an Ultra High Performance-Strain Hardening Cementitious Composite (UHP-SHCC). In Strain Hardening Cementitious Composites: SHCC5; Springer: Berlin/Heidelberg, Germany, 2023; pp. 302–309. [Google Scholar]

- Zhu, J.-X.; Xu, L.-Y.; Huang, B.-T.; Weng, K.-F.; Dai, J.-G. Recent developments in Engineered/Strain-Hardening Cementitious Composites (ECC/SHCC) with high and ultra-high strength. Constr. Build. Mater. 2022, 342, 127956. [Google Scholar] [CrossRef]

- Khalil, A.E.-H.; Etman, E.; Atta, A.; Essam, M. Behavior of RC beams strengthened with strain hardening cementitious composites (SHCC) subjected to monotonic and repeated loads. Eng. Struct. 2017, 140, 151–163. [Google Scholar] [CrossRef]

- Khalil, A.E.-H.; Etman, E.; Atta, A.; Essam, M. Ductility Enhancement of Rc Beams Strengthened With Strain Hardening Cementitious Composites. Proc. Int. Struct. Eng. Constr. 2017, 4, 1–6. [Google Scholar] [CrossRef]

- Kim, G.W.; Oh, T.; Lee, S.K.; Banthia, N.; Yoo, D.-Y. Development of Ca-rich slag-based ultra-high-performance fiber-reinforced geopolymer concrete (UHP-FRGC): Effect of sand-to-binder ratio. Constr. Build. Mater. 2023, 370, 130630. [Google Scholar] [CrossRef]

- Abadel, A.A.; Abbas, H.; Alshaikh, I.M.; Sennah, K.; Tuladhar, R.; Altheeb, A.; Alamri, M. Experimental study on the effects of external strengthening and elevated temperature on the shear behavior of ultra-high-performance fiber-reinforced concrete deep beams. In Structures; Elsevier: Amsterdam, The Netherlands, 2023; pp. 943–957. [Google Scholar]

- Al-Zu’bi, H.; Abdel-Jaber, M.; Katkhuda, H. Flexural Strengthening of Reinforced Concrete Beams with Variable Compressive Strength Using Near-Surface Mounted Carbon-Fiber-Reinforced Polymer Strips [NSM-CFRP]. Fibers 2022, 10, 86. [Google Scholar] [CrossRef]

- Aljidda, O.; El Refai, A.; Alnahhal, W. Comparative study on the bond performance of near-surface mounted fiber-reinforced polymer bars. Constr. Build. Mater. 2023, 364, 129923. [Google Scholar] [CrossRef]

- Effiong, J.U.; Ede, A.N. Experimental Investigation on the Strengthening of Reinforced Concrete Beams Using Externally Bonded and Near-Surface Mounted Natural Fibre Reinforced Polymer Composites—A Review. Materials 2022, 15, 5848. [Google Scholar] [CrossRef]

- Su, M.; Gong, S.; Liu, Y.; Peng, H. Flexural behavior of RC beams strengthened with fully or partially prestressed near-surface mounted FRP strips: An experimental investigation. Eng. Struct. 2022, 262, 114345. [Google Scholar] [CrossRef]

- RHawileh, R.A.; El-Maaddawy, T.A.; Naser, M.Z. Nonlinear finite element modeling of concrete deep beams with openings strengthened with externally-bonded composites. Mater. Des. 2012, 42, 378–387. [Google Scholar] [CrossRef]

- El-Maaddawy, T.; Ismail, E.S. Three-Dimensional Finite Element Modeling of Nsm-Cfrp Strengthened Continuous Concrete Slab Strips Containing Cut-Outs. In Infrastructure Management, Assessment and Rehabilitation; Cambridge Scholars Publishing: Newcastle upon Tyne, UK, 2021; p. 135. [Google Scholar]

- Mansour, M.; El-Maaddawy, T. Testing and modeling of deep beams strengthened with NSM-CFRP reinforcement around cutouts. Case Stud. Constr. Mater. 2021, 15, e00670. [Google Scholar] [CrossRef]

- Abdalla, J.A.; Abokwiek, R.; Hawileh, R.A. Models for Predicting Strength of RC Columns Strengthened with NSM-CFRP Strips and CFRP-Fabric Wraps. Procedia Struct. Integr. 2022, 37, 660–667. [Google Scholar] [CrossRef]

- Hawileh, R.A.; Saleh, R.B.; Saqan, E.I.; Abdalla, J.A. Contribution of Longitudinal NSM-CFRP Bars on the Shear Strength of RC Beams with Varying Depths and Concrete Strengths. J. Compos. Constr. 2022, 26, 04022025. [Google Scholar] [CrossRef]

- Youssf, O.; Hassanli, R.; Mills, J.E. Retrofitting square columns using FRP-confined crumb rubber concrete to improve confinement efficiency. Constr. Build. Mater. 2017, 153, 146–156. [Google Scholar] [CrossRef]

- Sabzi, J.; Esfahani, M.R.; Ozbakkaloglu, T.; Farahi, B. Effect of concrete strength and longitudinal reinforcement arrangement on the performance of reinforced concrete beams strengthened using EBR and EBROG methods. Eng. Struct. 2020, 205, 110072. [Google Scholar] [CrossRef]

- Gholampour, A.; Hassanli, R.; Mills, J.E.; Vincent, T.; Kunieda, M. Experimental investigation of the performance of concrete columns strengthened with fiber reinforced concrete jacket. Constr. Build. Mater. 2018, 194, 51–61. [Google Scholar] [CrossRef]

- Hassanli, R.; Youssf, O.; Mills, J.E. Seismic Performance of Precast Posttensioned Segmental FRP-Confined and Unconfined Crumb Rubber Concrete Columns. J. Compos. Constr. 2017, 21, 04017006. [Google Scholar] [CrossRef]

- Mhanna, H.H.; Hawileh, R.A.; Abdalla, J.A. Comparative analysis of design guidelines for FRP contribution to shear capacity of strengthened RC beams. Procedia Struct. Integr. 2022, 37, 359–366. [Google Scholar] [CrossRef]

- Hawileh, R.A.; Al Nuaimi, N.; Nawaz, W.; Abdalla, J.A.; Sohail, M.G. Flexural and Bond Behavior of Concrete Beams Strengthened with CFRP and Galvanized Steel Mesh Laminates. Pract. Period. Struct. Des. Constr. 2022, 27, 04021068. [Google Scholar] [CrossRef]

- Mhanna, H.H.; Hawileh, R.A.; Al Rashed, A.; Abdalla, J.A. Performance of RC beams externally strengthened with hybrid CFRP and PET-FRP laminates. Procedia Struct. Integr. 2022, 42, 1190–1197. [Google Scholar] [CrossRef]

- Mhanna, H.H.; Hawileh, R.A.; Abdalla, J.A. Shear behavior of RC T-beams externally strengthened with anchored high modulus carbon fiber-reinforced polymer (CFRP) laminates. Compos. Struct. 2021, 272, 114198. [Google Scholar] [CrossRef]

- Abuodeh, O.R.; Abdalla, J.A.; Hawileh, R.A. Prediction of shear strength and behavior of RC beams strengthened with externally bonded FRP sheets using machine learning techniques. Compos. Struct. 2019, 234, 111698. [Google Scholar] [CrossRef]

- Bazli, M.; Abolfazli, M. Mechanical Properties of Fibre Reinforced Polymers under Elevated Temperatures: An Overview. Polymers 2020, 12, 2600. [Google Scholar] [CrossRef] [PubMed]

- Feng, P.; Wang, J.; Tian, Y.; Loughery, D.; Wang, Y. Mechanical Behavior and Design of FRP Structural Members at High and Low Service Temperatures. J. Compos. Constr. 2016, 20, 04016021. [Google Scholar] [CrossRef]

- Meng, J.; Wang, Y.; Yang, H.; Wang, P.; Lei, Q.; Shi, H.; Lei, H.; Fang, D. Mechanical properties and internal microdefects evolution of carbon fiber reinforced polymer composites: Cryogenic temperature and thermocycling effects. Compos. Sci. Technol. 2020, 191, 108083. [Google Scholar] [CrossRef]

- Hosseini, A.; Michels, J.; Izadi, M.; Ghafoori, E. A comparative study between Fe-SMA and CFRP reinforcements for prestressed strengthening of metallic structures. Constr. Build. Mater. 2019, 226, 976–992. [Google Scholar] [CrossRef]

- Youssef, M.A.; Alam, M.S.; Nehdi, M. Experimental Investigation on the Seismic Behavior of Beam-Column Joints Reinforced with Superelastic Shape Memory Alloys. J. Earthq. Eng. 2008, 12, 1205–1222. [Google Scholar] [CrossRef]

- Sidharth, R.; Abuzaid, W.; Vollmer, M.; Niendorf, T.; Sehitoglu, H. Fatigue Crack Initiation in the Iron-Based Shape Memory Alloy FeMnAlNiTi. Shape Mem. Superelasticity 2020, 6, 323–331. [Google Scholar] [CrossRef]

- Raza, S.; Shafei, B.; Saiidi, M.S.; Motavalli, M.; Shahverdi, M. Shape memory alloy reinforcement for strengthening and self-centering of concrete structures—State of the art. Constr. Build. Mater. 2022, 324, 126628. [Google Scholar] [CrossRef]

- Salunkhe, P.; Agawane, P.; Chaudhari, D.; Patil, S. Experimental and Analytical Study of Shape Memory Alloy in Civil Structures—A Review. In Smart Technologies for Energy, Environment and Sustainable Development, Vol 1: Select Proceedings of ICSTEESD 2020; Springer: Singapore, 2022; pp. 81–89. [Google Scholar]

- Zhang, Z.-X.; Zhang, J.; Wu, H.; Ji, Y.; Kumar, D.D. Iron-based shape memory alloys in construction: Research, applications and opportunities. Materials 2022, 15, 1723. [Google Scholar] [CrossRef]

- Qiang, X.; Chen, L.; Jiang, X. Achievements and Perspectives on Fe-Based Shape Memory Alloys for Rehabilitation of Reinforced Concrete Bridges: An Overview. Materials 2022, 15, 8089. [Google Scholar] [CrossRef] [PubMed]

- Sohn, J.W.; Ruth, J.S.; Yuk, D.-G.; Choi, S.-B. Application of Shape Memory Alloy Actuators to Vibration and Motion Control of Structural Systems: A Review. Appl. Sci. 2023, 13, 995. [Google Scholar] [CrossRef]

- Khalil, A.E.-H.; Etman, E.; Atta, A.; Essam, M. Strengthening of RC beams subjected to cyclic load using ultra high-performance strain hardening cementitious composites. In Proceedings of the International Structural Engineering and Construction, ISEC, Valencia, Spain, 24–29 July 2017. [Google Scholar] [CrossRef]

- Hong, K.; Lee, S.; Yeon, Y.; Jung, K. Flexural Response of Reinforced Concrete Beams Strengthened with Near-Surface-Mounted Fe-Based Shape-Memory Alloy Strips. Int. J. Concr. Struct. Mater. 2018, 12, 45. [Google Scholar] [CrossRef]

- Ruiz-Pinilla, J.G.; Montoya-Coronado, L.A.; Ribas, C.; Cladera, A. Finite element modeling of RC beams externally strengthened with iron-based shape memory alloy (Fe-SMA) strips, including analytical stress-strain curves for Fe-SMA. Eng Struct. 2020, 223, 111152. [Google Scholar] [CrossRef]

- Shahverdi, M.; Czaderski, C.; Motavalli, M. Iron-based shape memory alloys for prestressed near-surface mounted strengthening of reinforced concrete beams. Constr. Build. Mater. 2016, 112, 28–38. [Google Scholar] [CrossRef]

- Cladera, A.; Montoya-Coronado, L.A.; Ruiz-Pinilla, J.G.; Ribas, C. Shear strengthening of slender reinforced concrete T-shaped beams using iron-based shape memory alloy strips. Eng. Struct. 2020, 221, 111018. [Google Scholar] [CrossRef]

- Czaderski, C.; Shahverdi, M.; Michels, J. Iron based shape memory alloys as shear reinforcement for bridge girders. Constr. Build. Mater. 2020, 274, 121793. [Google Scholar] [CrossRef]

- Elkafrawy, M.; Alashkar, A.; Hawileh, R.; AlHamaydeh, M. FEA Investigation of Elastic Buckling for Functionally Graded Material (FGM) Thin Plates with Different Hole Shapes under Uniaxial Loading. Buildings 2022, 12, 802. [Google Scholar] [CrossRef]

- Karzad, A.S.; Al-Sadoon, Z.A.; Sagheer, A.; AlHamaydeh, M. Experimental and Nonlinear Finite Element Analysis Data for an Innovative Buckling Restrained Bracing System to Rehabilitate Seismically Deficient Structures. Data 2022, 7, 171. [Google Scholar] [CrossRef]

- AlHamaydeh, M.; Elkafrawy, M.E.; Amin, F.M.; Maky, A.M.; Mahmoudi, F. Analysis and Design of UHPC Tall Buildings in UAE with Ductile Coupled Shear Walls Lateral Load Resisting System. In Proceedings of the 2022 Advances in Science and Engineering Technology International Conferences (ASET), Dubai, United Arab Emirates, 21–24 February 2022; pp. 1–6. [Google Scholar] [CrossRef]

- Alashkar, A.; Elkafrawy, M.; Hawileh, R.; AlHamaydeh, M. Buckling Analysis of Functionally Graded Materials (FGM) Thin Plates with Various Circular Cutout Arrangements. J. Compos. Sci. 2022, 6, 27. [Google Scholar] [CrossRef]

- Markou, G.; AlHamaydeh, M. 3D Finite Element Modeling of GFRP-Reinforced Concrete Deep Beams without Shear Reinforcement. Int. J. Comput. Methods 2017, 15, 1850001. [Google Scholar] [CrossRef]

- Alhamaydeh, M.; Elayyan, L. Impact of diverse seismic hazard estimates on design and performance of Steel Plate Shear Walls buildings in Dubai, UAE. In Proceedings of the 2017 7th International Conference on Modeling, Simulation, and Applied Optimization, ICMSAO 2017, Sharjah, United Arab Emirates, 4–6 April 2017; pp. 1–3. [Google Scholar] [CrossRef]

- AlHamaydeh, M.; Sagher, A. Key parameters influencing the behavior of Steel Plate Shear Walls (SPSW). In Proceedings of the 2017 7th International Conference on Modeling, Simulation, and Applied Optimization (ICMSAO), Sharjah, United Arab Emirates, 4–6 April 2017; pp. 1–6. [Google Scholar] [CrossRef]

- AlHamaydeh, M.; Elkafrawy, M.; Banu, S. Seismic Performance and Cost Analysis of UHPC Tall Buildings in UAE with Ductile Coupled Shear Walls. Materials 2022, 15, 2888. [Google Scholar] [CrossRef] [PubMed]

- AlHamaydeh, M.; Elkafrawy, M.E.; Aswad, N.G.; Talo, R.; Banu, S. Evaluation of UHPC Tall Buildings in UAE with Ductile Coupled Shear Walls under Seismic Loading. In Proceedings of the 2022 Advances in Science and Engineering Technology International Conferences (ASET), Dubai, United Arab Emirates, 21–24 February 2022; pp. 1–6. [Google Scholar] [CrossRef]

- Debski, H.; Rozylo, P.; Wysmulski, P. Stability and load-carrying capacity of short open-section composite columns under eccentric compression loading. Compos. Struct. 2020, 252, 112716. [Google Scholar] [CrossRef]

- Kopuri, N.A.G.K.M.; Priyadharshani, S.A. Numerical analysis of concrete filled steel tube columns using ABAQUS. Mater. Today Proc. 2022, 65, 3476–3482. [Google Scholar] [CrossRef]

- AlHamaydeh, M.; Elkafrawy, M.E.; Kyaure, M.; Elyas, M.; Uwais, F. Cost Effectiveness of UHPC Ductile Coupled Shear Walls for High-Rise Buildings in UAE Subjected to Seismic Loading. In Proceedings of the 2022 Advances in Science and Engineering Technology International Conferences (ASET), Dubai, United Arab Emirates, 21–24 February 2022; pp. 1–6. [Google Scholar] [CrossRef]

- Yeon, Y.-M.; Lee, W.; Hong, K.-N. Finite Element Analysis of Reinforced Concrete Beams Prestressed by Fe-Based Shape Memory Alloy Bars. Appl. Sci. 2022, 12, 3255. [Google Scholar] [CrossRef]

- Elkafrawy, M.E.; Khalil, A.M.; Abuzaid, W.; Hawileh, R.A.; AlHamaydeh, M. Nonlinear Finite Element Analysis (NLFEA) of Pre-stressed RC Beams Reinforced with Iron-Based Shape Memory Alloy (Fe-SMA). In Proceedings of the 2022 Advances in Science and Engineering Technology International Conferences (ASET), Dubai, United Arab Emirates, 21–24 February 2022; pp. 1–7. [Google Scholar]

- Yeon, Y.-M.; Hong, K.-N.; Lee, S.; Ji, S.-W. Numerical Study of RC Beams Strengthened with Fe-Based Shape Memory Alloy Strips Using the NSM Method. Appl. Sci. 2021, 11, 6809. [Google Scholar] [CrossRef]

- Smith, M. ABAQUS/Standard User’s Manual, Version 6.9; Dassault Systèmes Simulia Corp.: Providence, RI, USA, 2009. [Google Scholar]

- ASTM. Standard test methods for flexural properties of unreinforced and reinforced plastics and electrical insulating materials. In Annual Book of ASTM Standards; ASTM D790; ASTM: West Conshohocken, PA, USA, 1997. [Google Scholar]

- Hafezolghorani, M.; Hejazi, F.; Vaghei, R.; Jaafar, M.S.B.; Karimzade, K. Simplified Damage Plasticity Model for Concrete. Struct. Eng. Int. 2017, 27, 68–78. [Google Scholar] [CrossRef]

- Shahverdi, M.; Czaderski, C.; Annen, P.; Motavalli, M. Strengthening of RC beams by iron-based shape memory alloy bars embedded in a shotcrete layer. Eng. Struct. 2016, 117, 263–273. [Google Scholar] [CrossRef]

- Khalil, A.; Elkafrawy, M.; Abuzaid, W.; Hawileh, R.; AlHamaydeh, M. Flexural Performance of RC Beams Strengthened with Pre-Stressed Iron-Based Shape Memory Alloy (Fe-SMA) Bars: Numerical Study. Buildings 2022, 12, 2228. [Google Scholar] [CrossRef]

- Olivia, M.; Mandal, P. Curvature Ductility of Reinforced Concrete Beam. J. Civ. Eng. 2005, 6, 1–13. [Google Scholar]

- Khatami, S.; Kheyroddin, A. The Effect of Flange Thickness on the Behavior of Flanged-Section Shear Walls. Procedia Eng. 2011, 14, 2994–3000. [Google Scholar] [CrossRef]

- Elkafrawy, M.; Khalil, A.; AlHamaydeh, M.; Hawileh, R.; Abuzaid, W. Enhancing the Shear Capacity of RC Beams with Web Openings in Shear Zones Using Pre-Stressed Fe-SMA Bars: Numerical Study. Buildings 2023, 13, 1505. [Google Scholar] [CrossRef]

| Compression | Tension | ||

|---|---|---|---|

| (1) | (5) | ||

| (2) | (6) | ||

| (3) | (7) | ||

| (4) | (8) | ||

| Dilation Angle | Eccentricity | fb0/fc0 | K | Viscosity Parameter |

|---|---|---|---|---|

| 55° | 0.1 | 1.16 | 0.67 | 0.0001 |

| No. | Specimen ID | f’c (MPa) | Fe-SMA Bar Diameter(mm) | Flange Width “B” (mm) | Test Parameters |

|---|---|---|---|---|---|

| 1 | C30-2T12-500 | 30 | 12 | 500 | Concrete grade |

| 2 | C40-2T12-500 | 40 | 12 | 500 | |

| 3 | C50-2T12-500 | 50 | 12 | 500 | |

| 4 | C60-2T12-500 | 60 | 12 | 500 | |

| 5 | C40-500 | 40 | - | 500 | Fe-SMA diameter |

| 6 | C40-2T6-500 | 40 | 6 | 500 | |

| 7 | C40-2T8-500 | 40 | 8 | 500 | |

| 8 | C40-2T10-500 | 40 | 10 | 500 | |

| 9 | C40-2T12-500 | 40 | 12 | 500 | |

| 10 | C50-2T12-125 | 50 | 12 | 125 | Width of flange |

| 11 | C50-2T12-250 | 50 | 12 | 250 | |

| 12 | C50-2T12-375 | 50 | 12 | 375 | |

| 13 | C50-2T12-500 | 50 | 12 | 500 |

| Beam ID | Pu | Py | Pcr | δ0.9u | δy | δcr | µ |

|---|---|---|---|---|---|---|---|

| kN | kN | kN | mm | mm | mm | ||

| C30-2T12-500 | 159.1 | 127.3 | 56.1 | 82.90 | 10.10 | 0.71 | 8.21 |

| C40-2T12-500 | 160.4 | 127.8 | 58.2 | 98.50 | 9.40 | 0.62 | 10.48 |

| C50-2T12-500 | 162.1 | 128.5 | 60.5 | 96.10 | 9.30 | 0.57 | 10.33 |

| C60-2T12-500 | 162.6 | 129.3 | 62.3 | 108.30 | 9.10 | 0.49 | 11.90 |

| Beam ID | Pu | Py | Pcr | δ0.9u | δy | δcr | µ |

|---|---|---|---|---|---|---|---|

| kN | kN | kN | mm | mm | mm | ||

| C40-500 | 79.6 | 51.2 | 15.5 | 39.40 | 6.80 | 0.28 | 5.79 |

| C40-2T6-500 | 97.2 | 67.9 | 26.9 | 50.60 | 7.10 | 0.39 | 7.13 |

| C40-2T8-500 | 115.9 | 84.3 | 34.5 | 71.40 | 7.80 | 0.41 | 9.15 |

| C40-2T10-500 | 135.1 | 104.8 | 45.5 | 67.80 | 8.60 | 0.53 | 7.88 |

| C40-2T12-500 | 160.4 | 127.8 | 58.2 | 98.50 | 9.40 | 0.62 | 10.48 |

| Beam ID | Pu | Py | Pcr | δ0.9u | δy | δcr | µ |

|---|---|---|---|---|---|---|---|

| kN | kN | kN | mm | mm | mm | ||

| C50-2T12-500 | 162.1 | 128.5 | 60.5 | 96.10 | 9.30 | 0.57 | 10.33 |

| C50-2T12-375 | 160.9 | 124.7 | 57.6 | 94.40 | 9.20 | 0.61 | 10.26 |

| C50-2T12-250 | 157.2 | 120.9 | 56.1 | 97.10 | 9.10 | 0.62 | 10.67 |

| C50-2T12-125 | 150.8 | 119.5 | 53.9 | 83.50 | 10.10 | 0.76 | 8.27 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Khalil, A.; Elkafrawy, M.; Hawileh, R.; AlHamaydeh, M.; Abuzaid, W. Numerical Investigation of Flexural Behavior of Reinforced Concrete (RC) T-Beams Strengthened with Pre-Stressed Iron-Based (FeMnSiCrNi) Shape Memory Alloy Bars. J. Compos. Sci. 2023, 7, 258. https://doi.org/10.3390/jcs7060258

Khalil A, Elkafrawy M, Hawileh R, AlHamaydeh M, Abuzaid W. Numerical Investigation of Flexural Behavior of Reinforced Concrete (RC) T-Beams Strengthened with Pre-Stressed Iron-Based (FeMnSiCrNi) Shape Memory Alloy Bars. Journal of Composites Science. 2023; 7(6):258. https://doi.org/10.3390/jcs7060258

Chicago/Turabian StyleKhalil, Ahmed, Mohamed Elkafrawy, Rami Hawileh, Mohammad AlHamaydeh, and Wael Abuzaid. 2023. "Numerical Investigation of Flexural Behavior of Reinforced Concrete (RC) T-Beams Strengthened with Pre-Stressed Iron-Based (FeMnSiCrNi) Shape Memory Alloy Bars" Journal of Composites Science 7, no. 6: 258. https://doi.org/10.3390/jcs7060258

APA StyleKhalil, A., Elkafrawy, M., Hawileh, R., AlHamaydeh, M., & Abuzaid, W. (2023). Numerical Investigation of Flexural Behavior of Reinforced Concrete (RC) T-Beams Strengthened with Pre-Stressed Iron-Based (FeMnSiCrNi) Shape Memory Alloy Bars. Journal of Composites Science, 7(6), 258. https://doi.org/10.3390/jcs7060258