Bio-Based Sustainable Polymers and Materials: From Processing to Biodegradation

Abstract

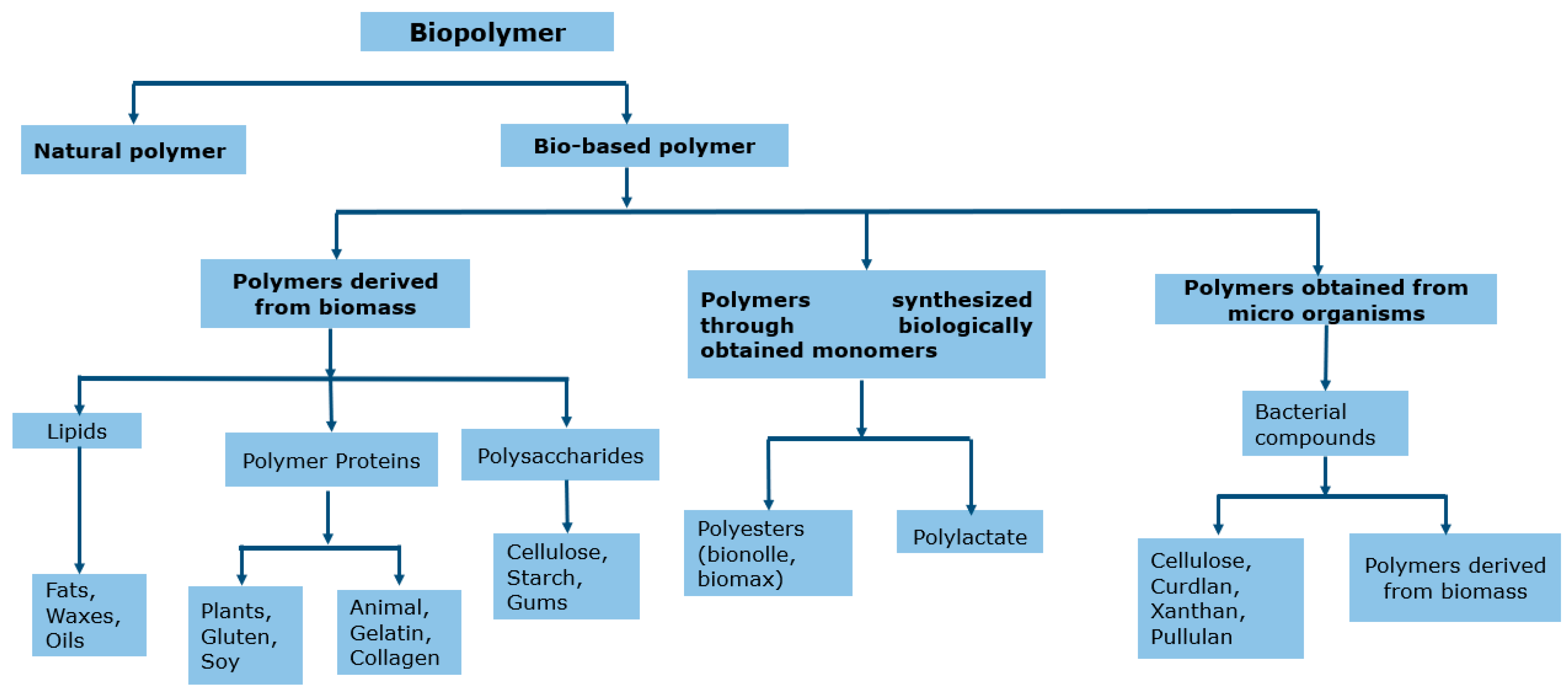

1. Introduction

2. Processing and Synthesis of Bio-Based Polymers

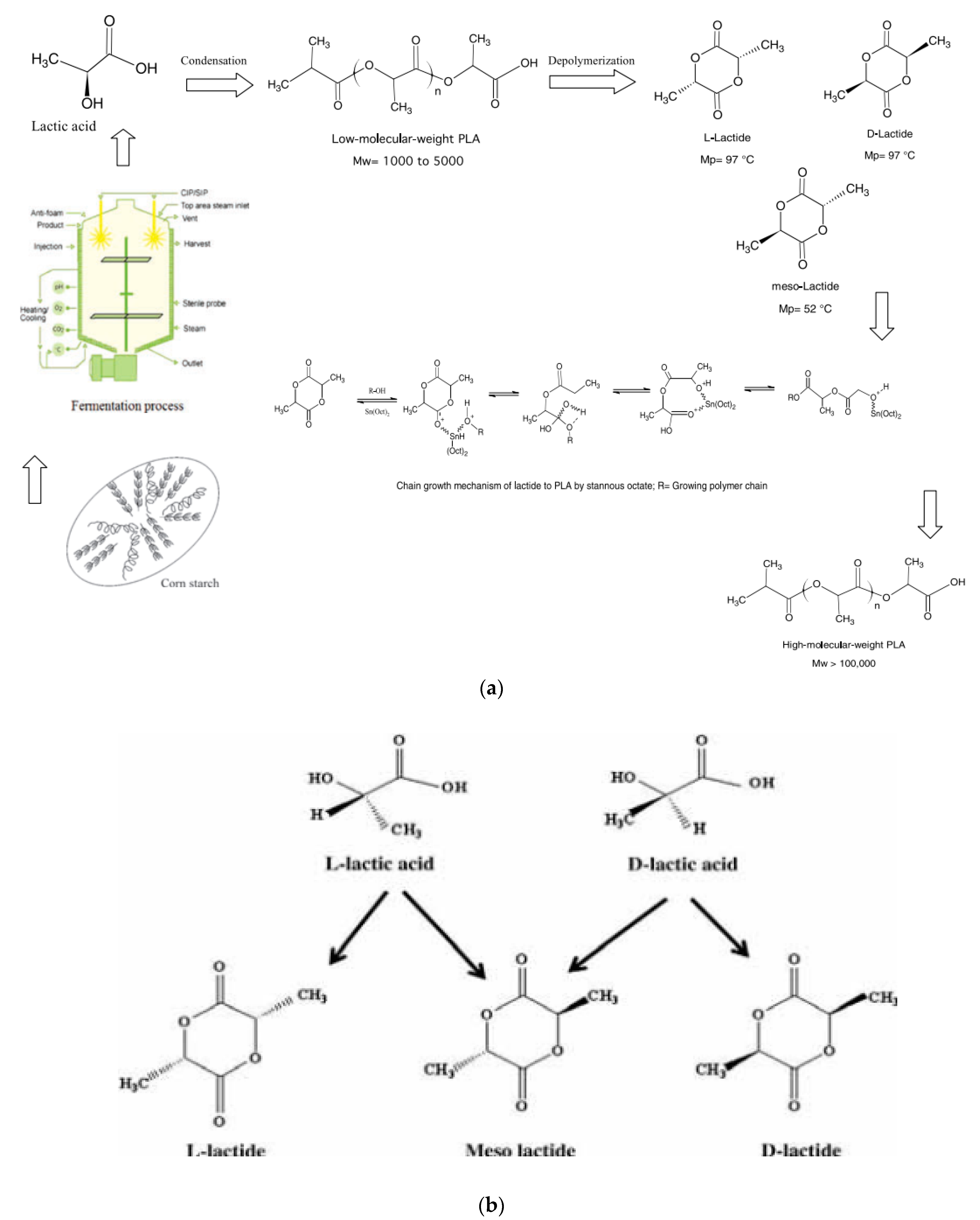

2.1. Processing of PLA-Based Materials

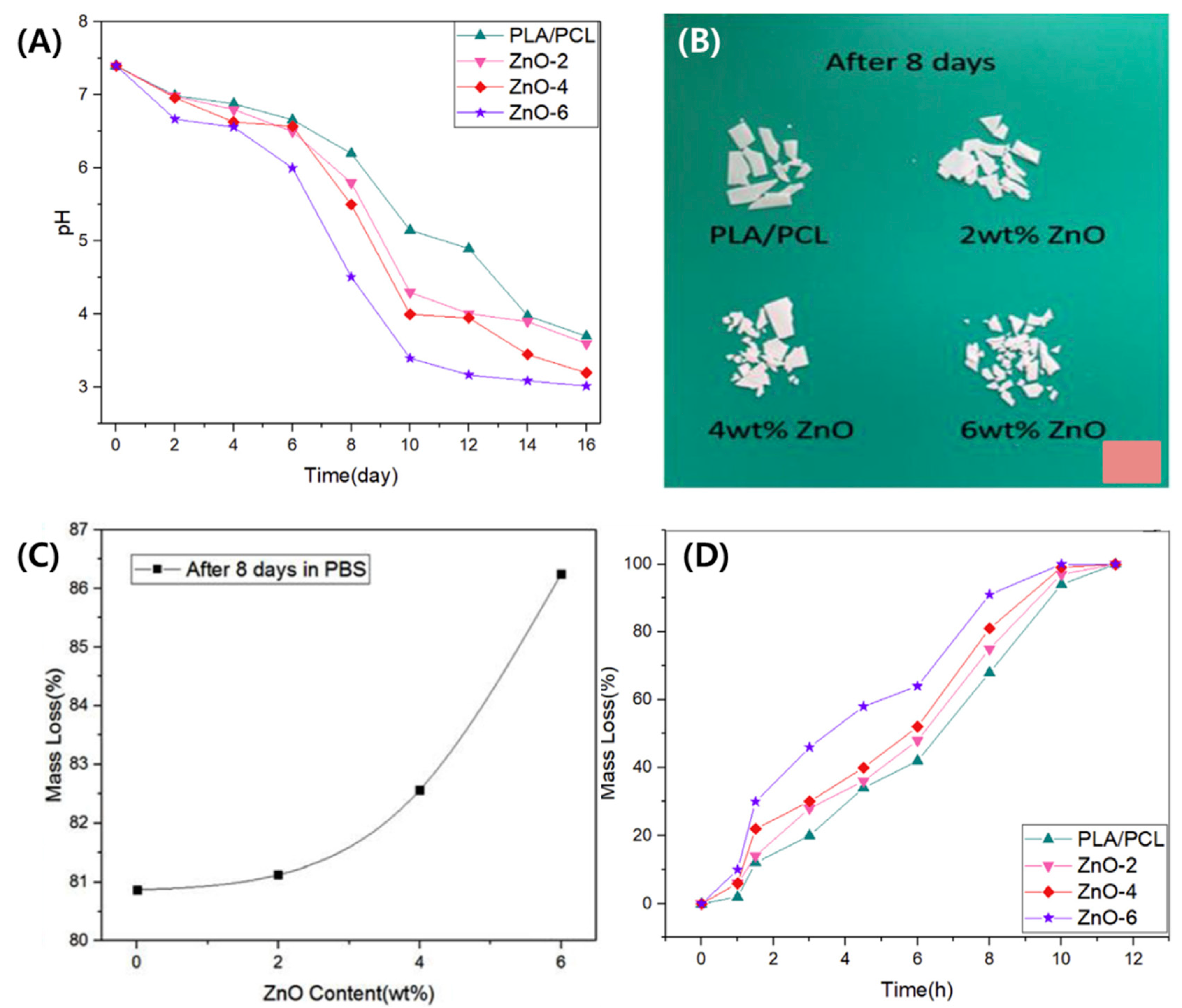

2.2. Processing of PCL-Based Materials

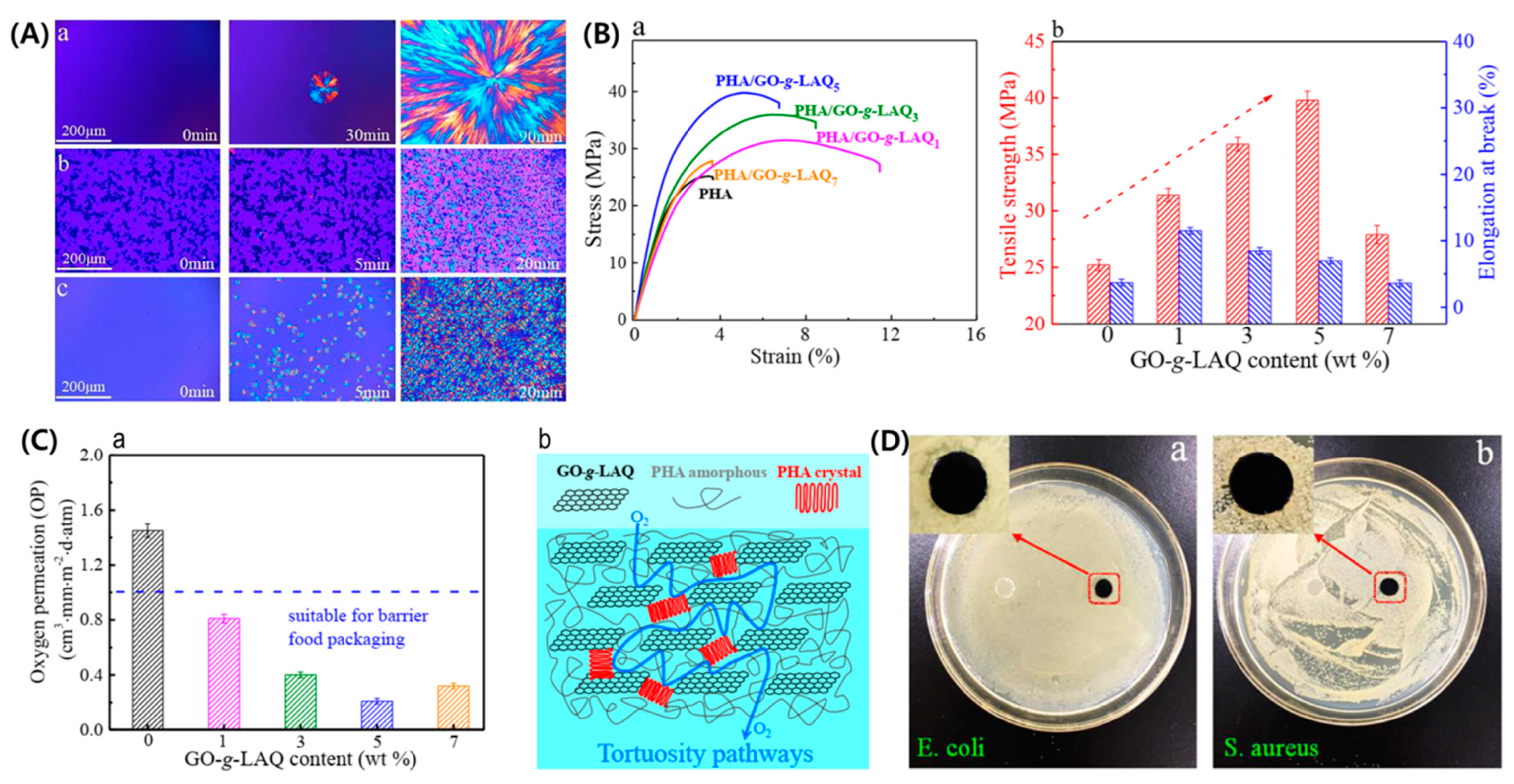

2.3. Processing of PHA-Based Materials

- (PHA): Polyhydroxyalkanoates

- (PHB): Polyhydroxy butyrate

- Poly(3HB): Poly(3-hydroxybutyrate)

- Poly(3-HB-co-4HB): Poly(3-hydroxybutyrate-co-4-hydroxybutyrate)

- Poly(3HB-co-3HH): Poly(3-hydroxyoctanoate-co-hydroxyhexanoate)

- Poly(3HO-co-3HH): Poly(3-hydroxyoctanoate-co-hydroxyhexanoate)

- Poly (4-HB): Poly(4-hydroxybutyrate)

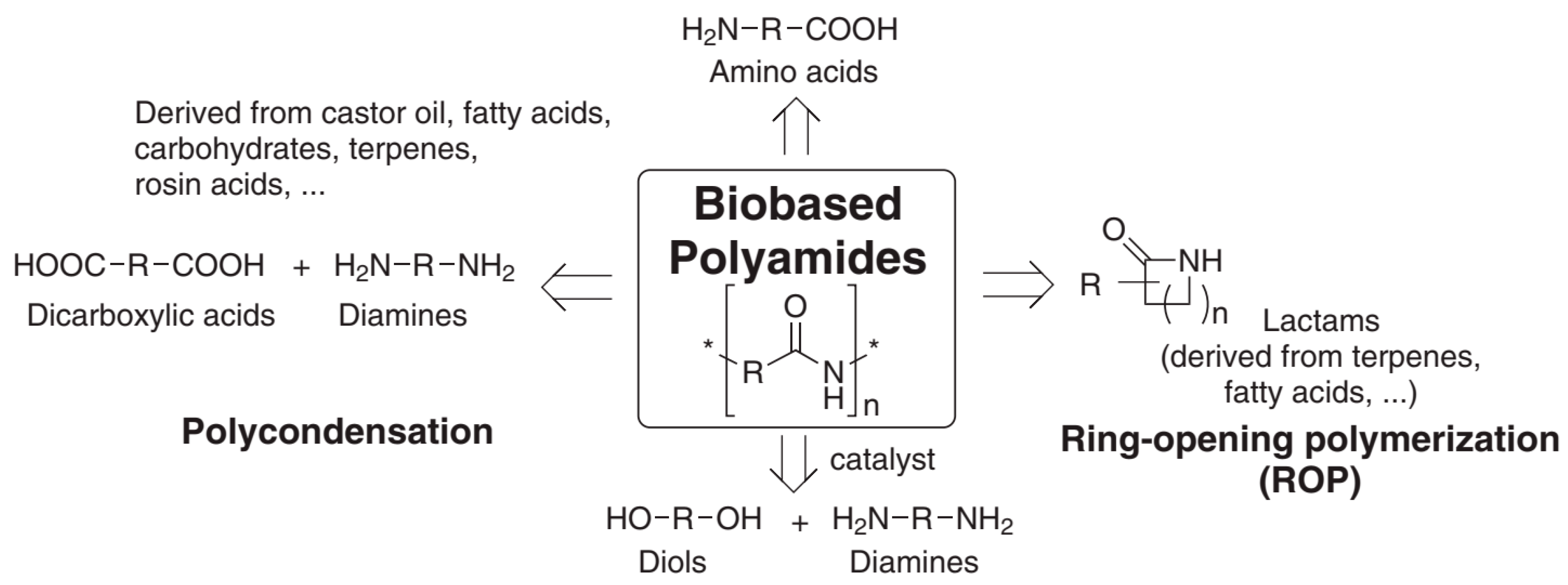

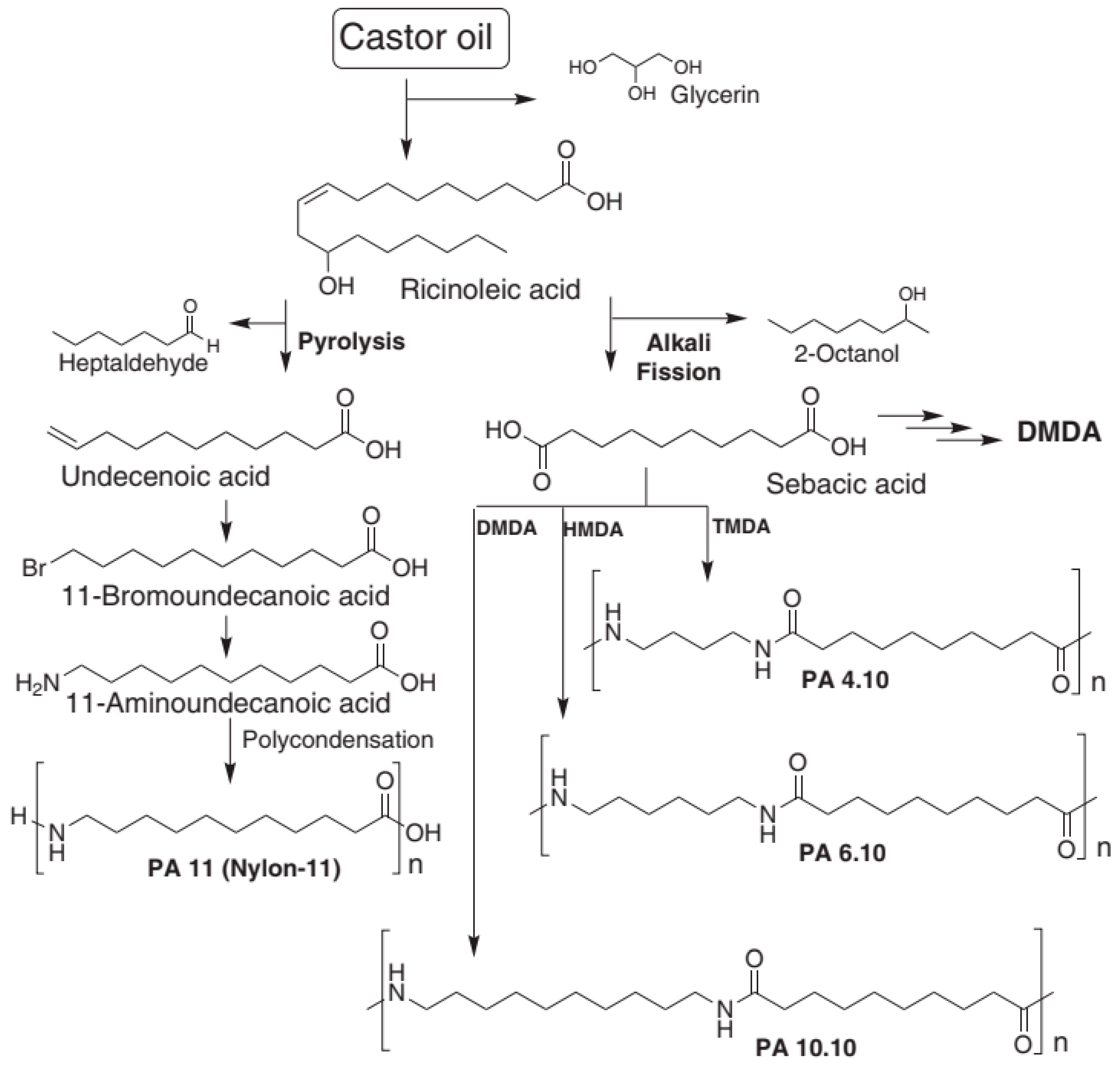

2.4. Processing of PA-Based Materials

3. Bio-Based Polymer Degradation

3.1. PLA Biodegradation

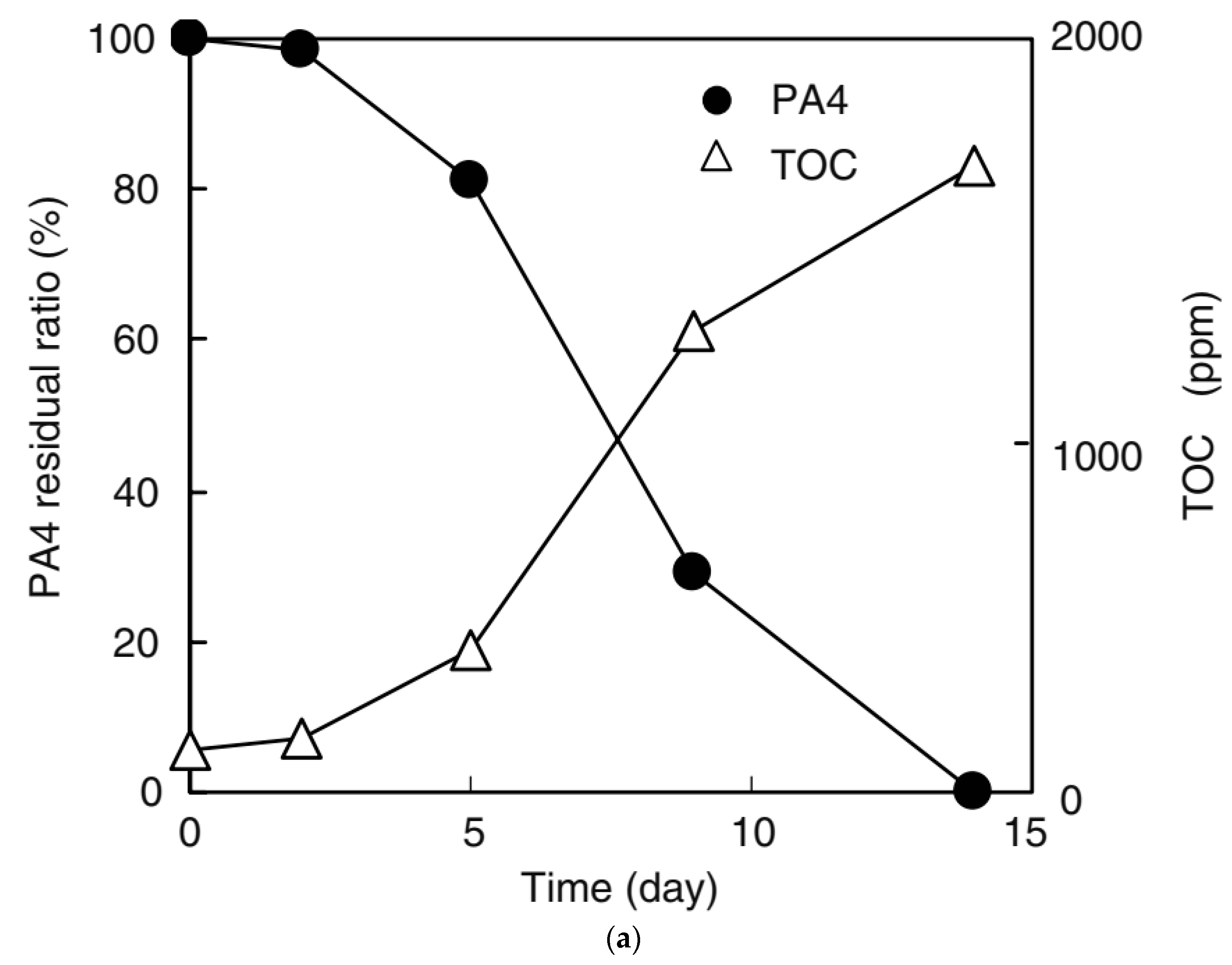

3.2. PA Biodegradation

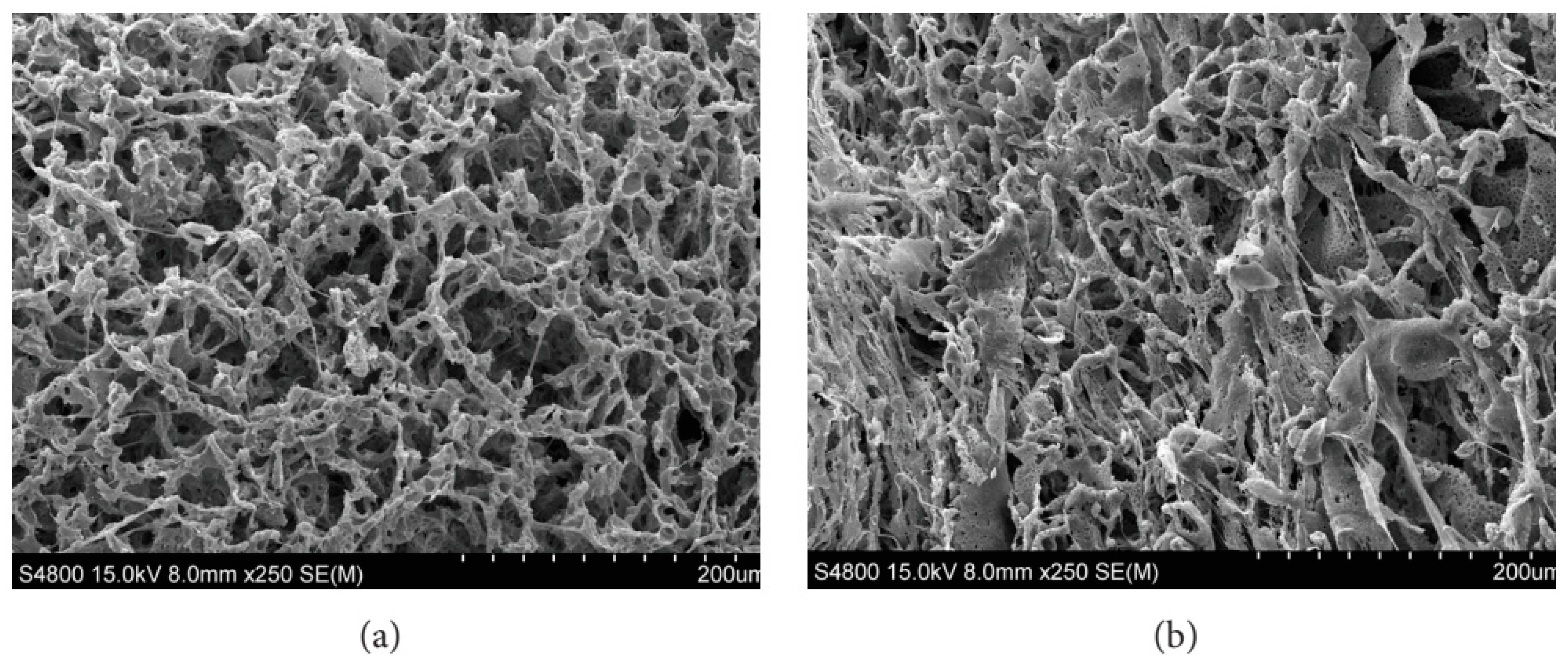

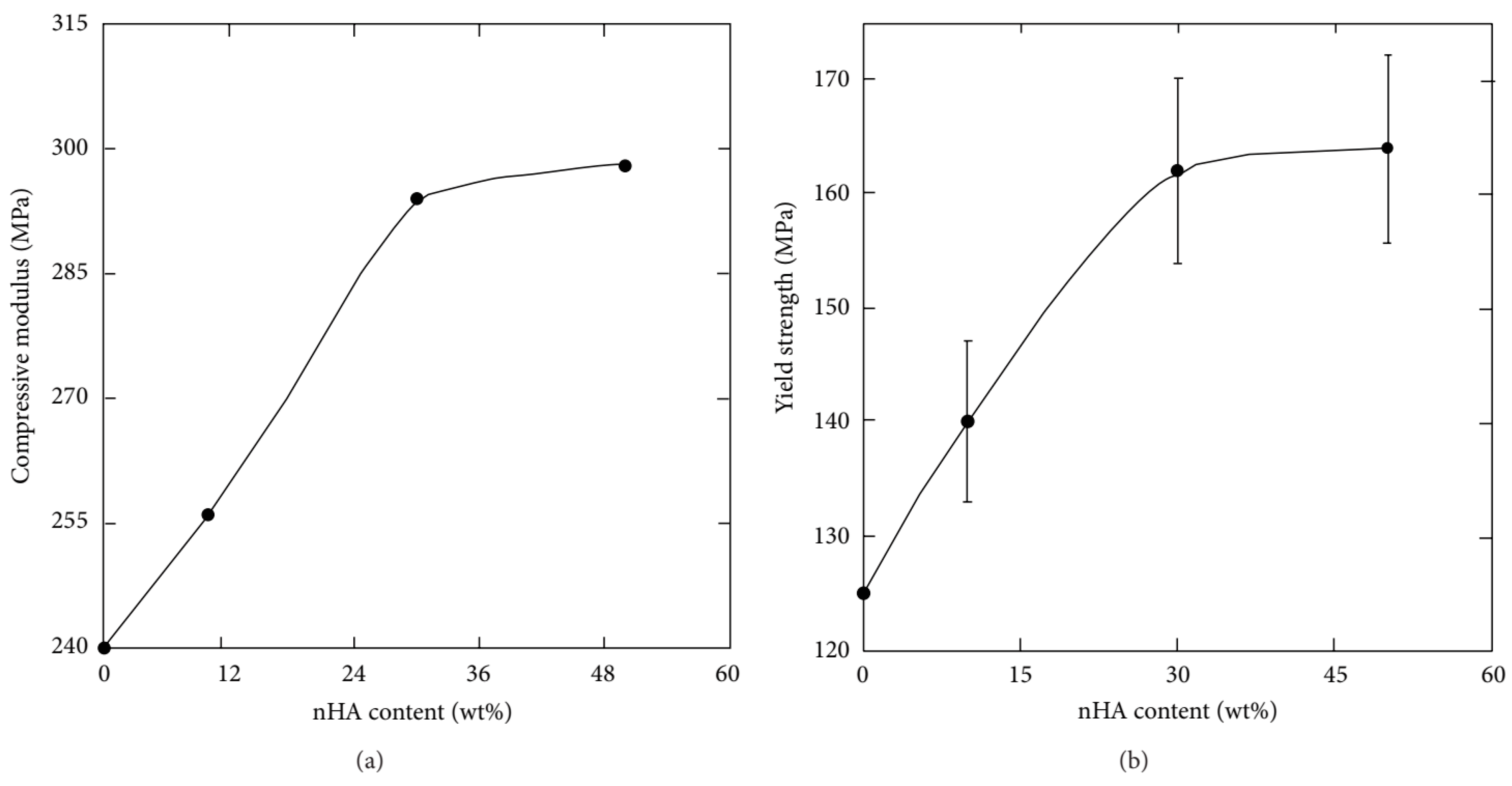

3.3. PCL Biodegradation

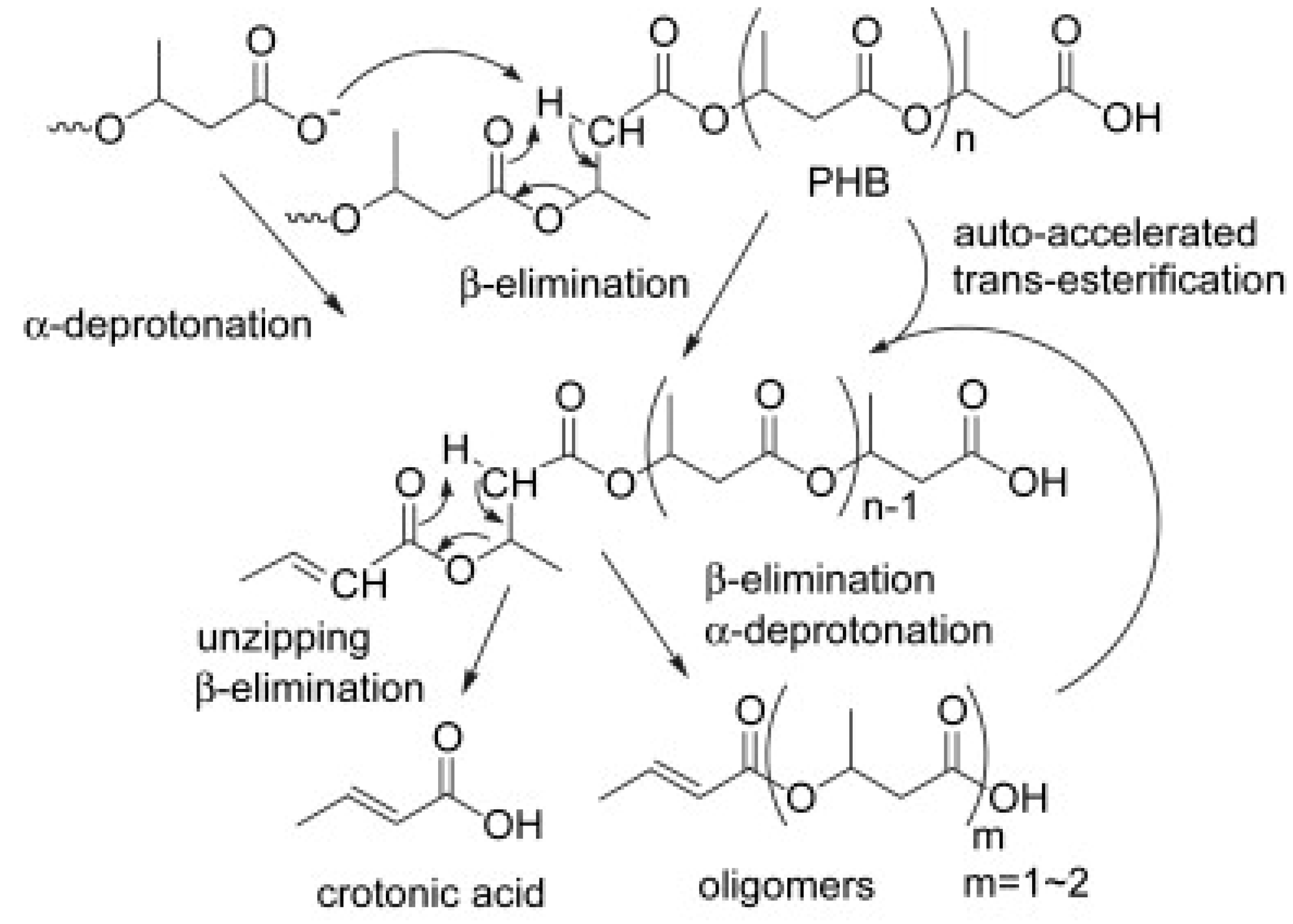

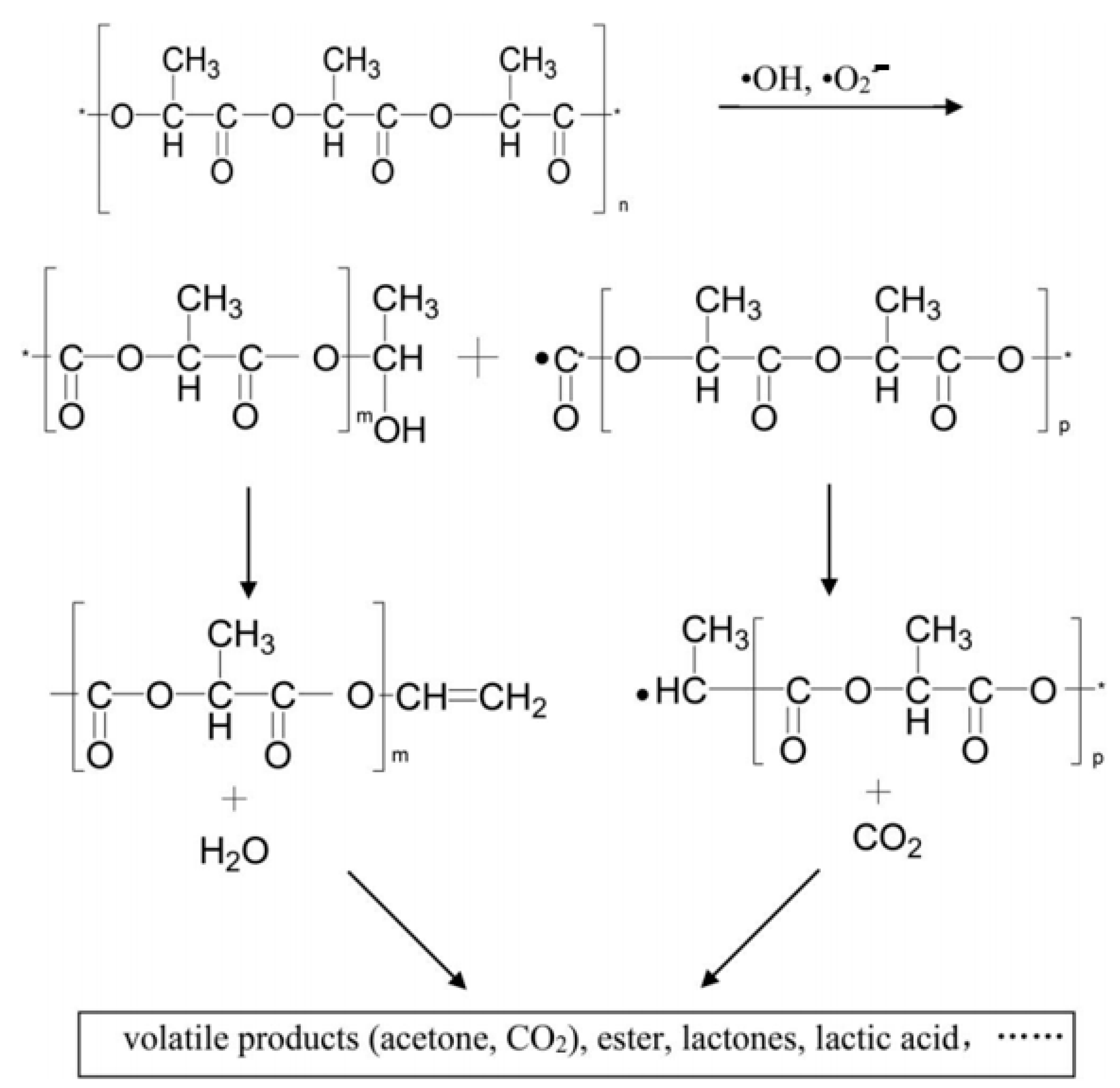

3.4. PHA Biodegradation

4. Other Influential Forms of Degradation

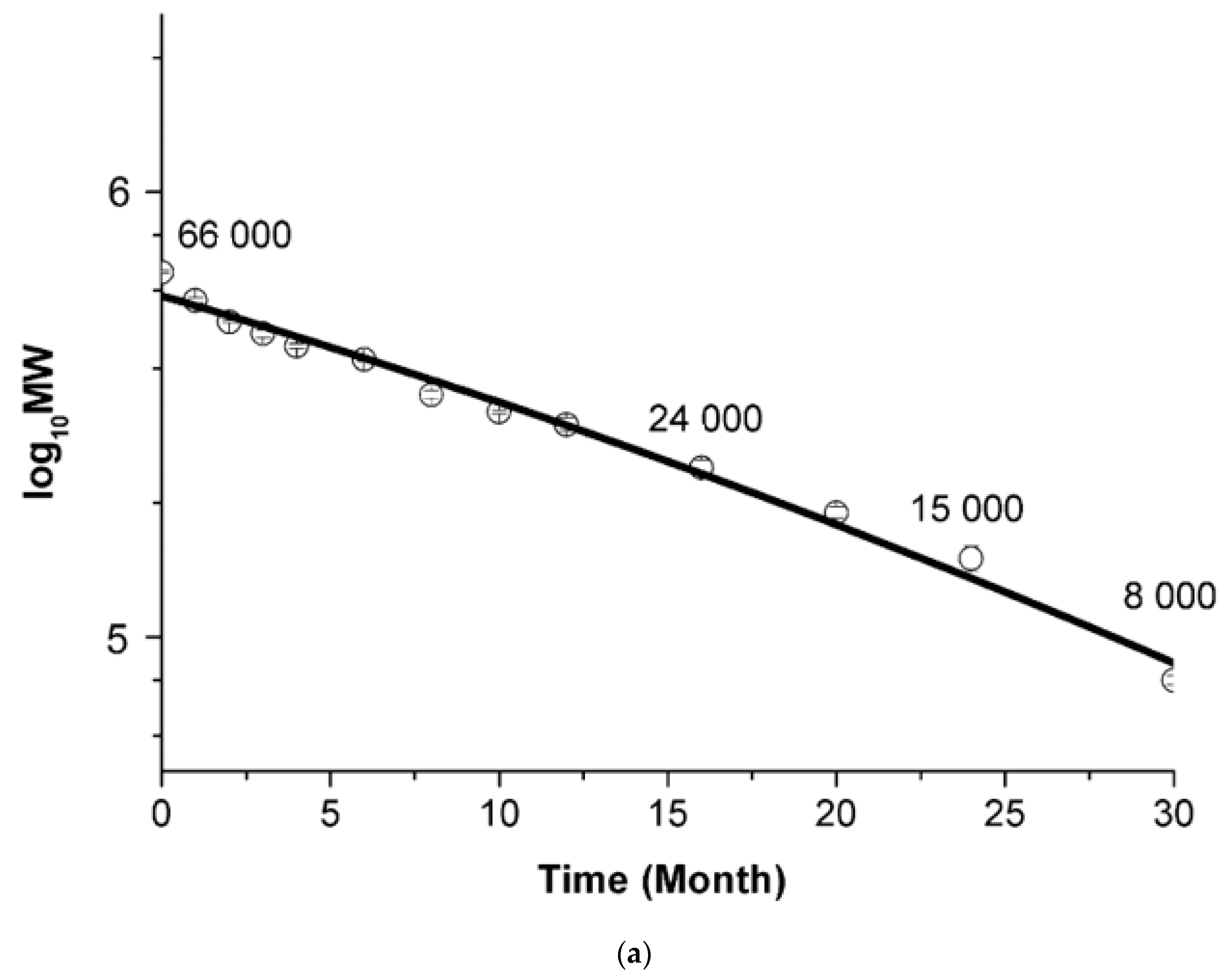

4.1. Thermal Degradation

- (i)

- Initiation;

- (ii)

- Propagation;

- (iii)

- Termination.

4.2. Photodegradation

- (1)

- Internal impurities—may possess chromophoric groups (acids, carbonyls, esters, etc.) that are being added to macromolecules in a polymerization process and storages, and they are:

- (a)

- Catalyst residue.

- (b)

- Carbonyl.

- (c)

- Charge-transfer complexes with oxygen.

- (d)

- Hydroperoxide.

- (e)

- Unsaturated bonds(-C=C-).

- (2)

- External impurities—which possesses chromophoric groups are:

- (a)

- The compounds from polluted environments and smog (naphthalene and anthracene).

- (b)

- Traces of metals and metal oxides from machines and equipment (Cr, Fe, and Ni).

- (c)

- Traces of catalysts and solvents.

- (d)

- Additives (dyes, pigments, photo stabilizers, and thermal stabilizers).

- Photooxidation—for the process there is a combination of UV lights and oxidants such as H2O2, Fenton or O3 to enhance the degradation rather than solely UV [202].

- Photolysis‚—this process utilizes radiation and ultraviolet (UV) light to produce some reactive species, e.g., excited molecules, ions, and radicals [202,203]. The impact of radiation in the compound relies on the energy amount transferred through radiation and the compound’s nature. The intensity can be increased in aqueous solutions via the formation of primary products from photolysis of water; this acts as an intermediate species and generates hydroxyl (OH−), electrons (e−aq), and hydrogen radicals (H−), which decompose the solutes.

- Photocatalysis—this comprises a photoinduced reaction, which is enhanced through catalytic reactions. The process is initiated when the photon has the required energy (equal or greater than catalysts bandgap energy) to be absorbed. Consequently, there will be a separation of charges due to the movement of the excited electron (e−) from the valence band to the conduction band of the catalysts; this produces a hole (h+). The electron-charged holes can meander to the surface of the catalyst, which can move into other species that are spotted on the surface.

5. Potential Applications and Trends

6. Concluding Remarks

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Oke, A.; Osobajo, O.; Obi, L.; Omotayo, T. Rethinking and optimising post-consumer packaging waste: A sentiment analysis of consumers’ perceptions towards the introduction of a deposit refund scheme in Scotland. Waste Manag. 2020, 118, 463–470. [Google Scholar] [CrossRef] [PubMed]

- Keshavarz, T.; Roy, I. Polyhydroxyalkanoates: Bioplastics with a green agenda. Curr. Opin. Microbiol. 2010, 13, 321–326. [Google Scholar] [CrossRef] [PubMed]

- Lambert, S.; Wagner, M. Environmental performance of bio-based and biodegradable plastics: The road ahead. Chem. Soc. Rev. 2017, 46, 6855–6871. [Google Scholar] [CrossRef]

- Karamanlioglu, M.; Preziosi, R.; Robson, G.D. Abiotic and biotic environmental degradation of the bioplastic polymer poly(lactic acid): A review. Polym. Degrad. Stab. 2017, 137, 122–130. [Google Scholar] [CrossRef]

- Geissdoerfer, M.; Savaget, P.; Bocken, N.M.; Hultink, E.J. The Circular Economy–A new sustainability paradigm? J. Clean. Prod. 2017, 143, 757–768. [Google Scholar] [CrossRef]

- Mohan, S.; Oluwafemi, O.S.; George, S.C.; Jayachandran, V.; Lewu, F.B.; Songca, S.P.; Kalarikkal, N.; Thomas, S. Completely green synthesis of dextrose reduced silver nanoparticles, its antimicrobial and sensing properties. Carbohydr. Polym. 2014, 106, 469–474. [Google Scholar] [CrossRef]

- Benavides, P.T.; Dunn, J.B.; Han, J.; Biddy, M.; Markham, J. Exploring Comparative Energy and Environmental Benefits of Virgin, Recycled, and Bio-Derived PET Bottles. ACS Sustain. Chem. Eng. 2018, 6, 9725–9733. [Google Scholar] [CrossRef]

- Pawar, R.P.; Tekale, S.U.; Shisodia, S.U.; Totre, J.T.; Domb, A.J. Biomedical applications of poly (lactic acid). Recent Pat. Regen. Med. 2014, 4, 40–51. [Google Scholar] [CrossRef]

- Ren, J. Modification of PLA. In Biodegradable Poly (Lactic Acid): Synthesis, Modification, Processing and Applications; Springer: Berlin/Heidelberg, Germany, 2010; pp. 38–141. [Google Scholar]

- Lim, L.T.; Cink, K.; Vanyo, T. Processing of poly (lactic acid). In Poly (lactic acid): Synthesis, Structures, Properties, Processing and Applications; Auras, R., Lim, L.T., Selke, S.E.M., Tsuji, H., Eds.; Wiley: Hoboken, NJ, USA; pp. 189–215.

- Lasprilla, A.J.; Martinez, G.A.; Lunelli, B.H.; Jardini, A.L.; Maciel Filho, R. Poly (lactic acid) synthesis for application in biomedical devices—A review. Biotechnol. Adv. 2012, 30, 321–328. [Google Scholar] [CrossRef]

- Kalia, S.; Avérous, L. Biodegradable and Biobased Polymers for Environmental and Biomedical Applications; John Wiley & Sons: Hoboken, NJ, USA, 2016; Volume 6, p. 171. [Google Scholar]

- Genovese, L.; Soccio, M.; Lotti, N.; Gazzano, M.; Siracusa, V.; Salatelli, E.; Balestra, F.; Munari, A. Design of bio-based PLLA triblock copolymers for sustainable food packaging: Thermo-mechanical properties, gas barrier ability and compostability. Eur. Polym. J. 2017, 95, 289–303. [Google Scholar] [CrossRef]

- Wang, L.; Qiu, J.; Sakai, E.; Wei, X. The relationship between microstructure and mechanical properties of carbon nanotubes/poly (lactic acid) nanocomposites prepared by twin-screw extrusion. Compos. Part A Appl. Sci. Manuf. 2016, 89, 18–25. [Google Scholar] [CrossRef]

- Mohammad NN, B.; Arsad, A.; Choi, H.J.; Ngadi, N.; Desa MS, Z.M. Influences of pristine carbon nanotube on the rheological properties of compatibilized poly (lactic acid)/natural rubber nanocomposite. Mater. Today Proc. 2012, 39, 951–955. [Google Scholar] [CrossRef]

- Zhou, Y.; Lei, L.; Yang, B.; Li, J.; Ren, J. Preparation and characterization of poly (lactic acid) (PLA) carbon nano-tube nanocomposites. Polym. Test. 2018, 68, 34–38. [Google Scholar] [CrossRef]

- Liu, Y.; Wang, S.; Lan, W.; Qin, W. Fabrication of poly (lactic acid)/carbon nanotubes/chitosan composite fibers by electrospinning for strawberry preservation. Int. J. Biol. Macromol. 2019, 121, 1329–1336. [Google Scholar] [CrossRef]

- Kian, L.K.; Saba, N.; Jawaid, M.; Sultan, M.T.H. A review on processing techniques of bast fibers nanocellulose and its poly (lactic acid) (PLA) nanocomposites. Int. J. Biol. Macromol. 2019, 121, 1314–1328. [Google Scholar] [CrossRef]

- Li, L.; Chen, Y.; Yu, T.; Wang, N.; Wang, C.; Wang, H. Preparation of poly (lactic acid)/TEMPO-oxidized bacterial cellulose nanocomposites for 3D printing via Pickering emulsion approach. Compos. Commun. 2019, 16, 162–167. [Google Scholar] [CrossRef]

- Geng, S.; Wloch, D.; Herrera, N.; Oksman, K. Large-scale manufacturing of ultra-strong, strain-responsive poly (lactic acid)-based nanocomposites reinforced with cellulose nanocrystals. Compos. Sci. Technol. 2020, 194, 108144. [Google Scholar] [CrossRef]

- Wang, X.; Tang, Y.; Zhu, X.; Zhou, Y.; Hong, X. Preparation and characterization of poly (lactic acid)/polyaniline/nanocrystalline cellulose nanocomposite films. Int. J. Biol. Macromol. 2020, 146, 1069–1075. [Google Scholar] [CrossRef]

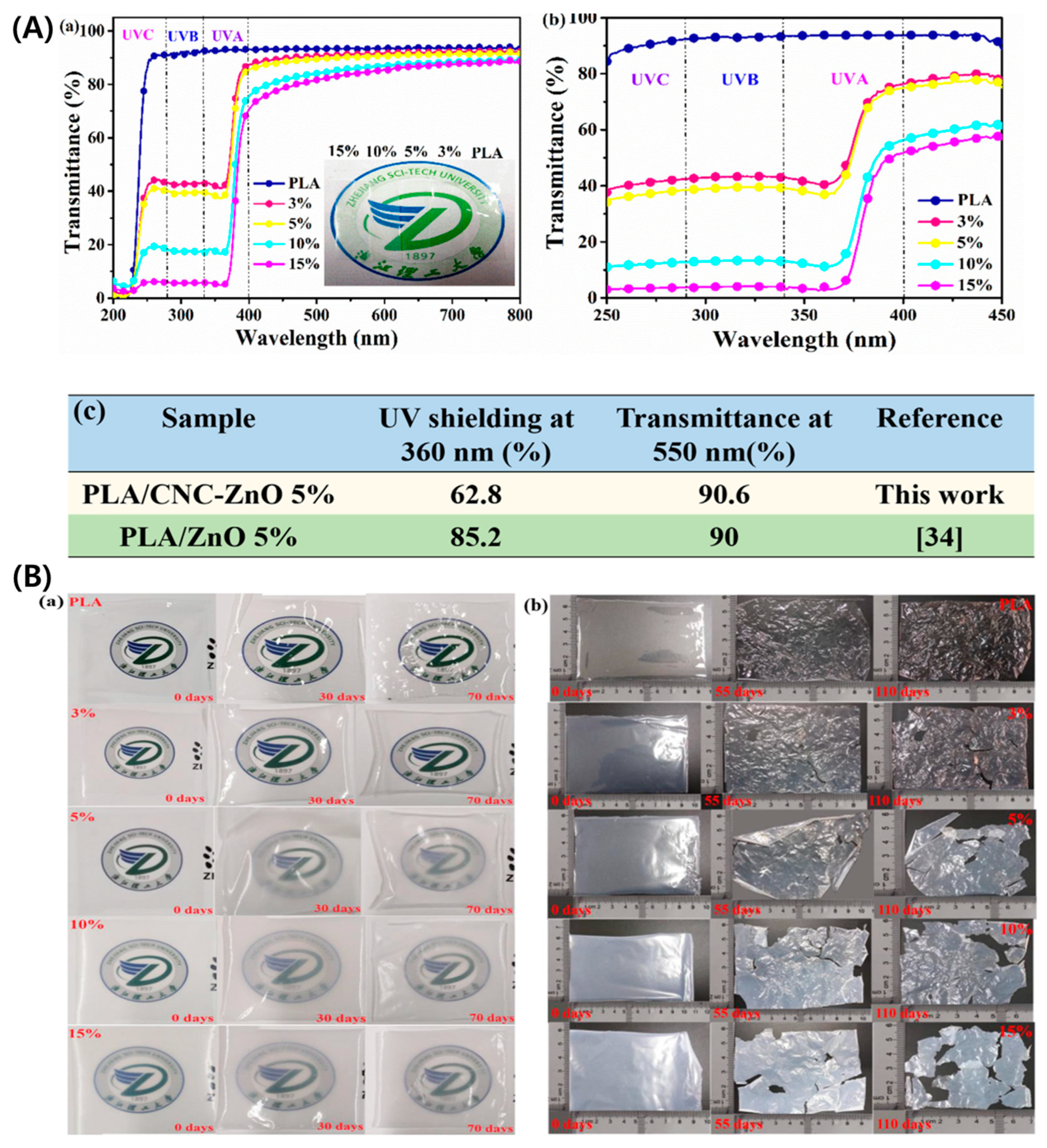

- Wang, Y.Y.; Yu, H.Y.; Yang, L.; Abdalkarim, S.Y.H.; Chen, W.L. Enhancing long-term biodegradability and UV-shielding performances of transparent poly (lactic acid) nanocomposite films by adding cellulose nanocrystal-zinc oxide hybrids. Int. J. Biol. Macromol. 2019, 141, 893–905. [Google Scholar] [CrossRef]

- Arjmandi, R.; Hassan, A.; Haafiz, M.K.M.; Zakaria, Z.; Islam, M.S. Effect of hydrolysed cellulose nanowhiskers on properties of montmorillonite/poly (lactic acid) nanocomposites. Int. J. Biol. Macromol. 2016, 82, 998–1010. [Google Scholar] [CrossRef]

- Barmouz, M.; Behravesh, A.H. The role of foaming process on shape memory behavior of poly (lactic acid)-thermoplastic polyurethane-nano cellulose bio-nanocomposites. J. Mech. Behav. Biomed. Mater. 2019, 91, 266–277. [Google Scholar] [CrossRef] [PubMed]

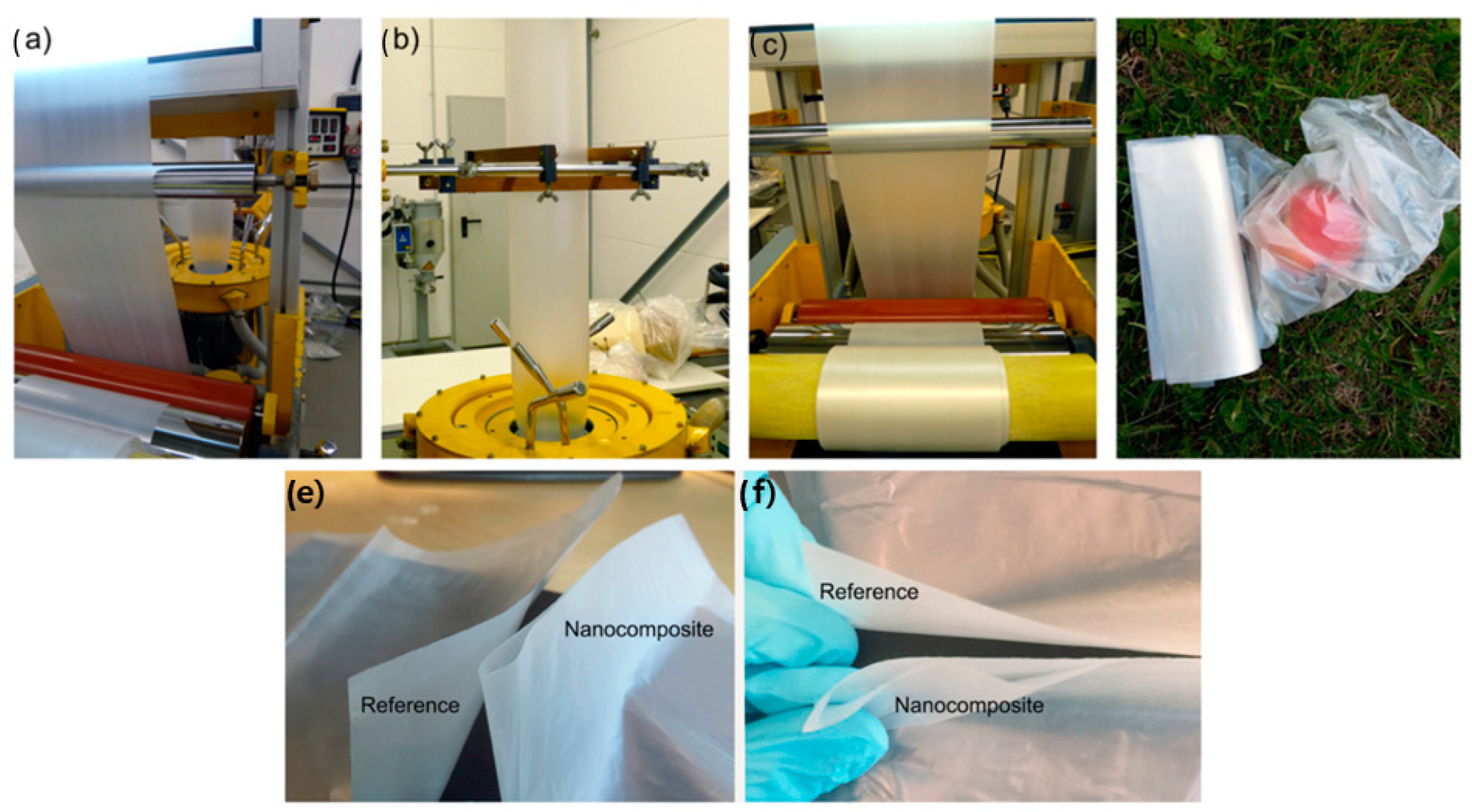

- Herrera, N.; Roch, H.; Salaberria, A.M.; Pino-Orellana, M.A.; Labidi, J.; Fernandes, S.C.M.; Radic, D.; Leiva, A.; Oksman, K. Functionalized blown films of plasticized poly (lactic acid)/chitin nanocomposite: Preparation and characterization. Mater. Des. 2016, 92, 846–852. [Google Scholar] [CrossRef]

- Swaroop, C.; Shukla, M. Development of blown poly (lactic acid)-MgO nanocomposite films for food packaging. Compos. Part A Appl. Sci. Manuf. 2019, 124, 105482. [Google Scholar] [CrossRef]

- Balakrishnan, H.; Hassan, A.; Wahit, M.U.; Yussuf, A.A.; Razak, S.B.A. Novel toughened poly (lactic acid) nanocomposite: Mechanical, thermal and morphological properties. Mater. Des. 2010, 31, 3289–3298. [Google Scholar] [CrossRef]

- Connolly, M.; Zhang, Y.; Brown, D.M.; Ortuño, N.; Jordá-Beneyto, M.; Stone, V.; Fernandez, T.F.; Johnston, H.J. Novel poly (lactic acid) (PLA)-organoclay nanocomposite bio-packaging for the cosmetic industry; migration studies and in vitro assessment of the dermal toxicity of migration extracts. Polym. Degrad. Stab. 2019, 168, 108938. [Google Scholar] [CrossRef]

- Nam, B.U.; Min, K.D.; Son, Y. Investigation of the nanostructure, thermal stability, and mechanical properties of poly (lactic acid)/cellulose acetate butyrate/clay nanocomposites. Mater. Lett. 2015, 150, 118–121. [Google Scholar] [CrossRef]

- Sharma, S.; Singh, A.A.; Majumdar, A.; Butola, B.S. Harnessing the ductility of poly (lactic acid)/halloysite nano-composites by synergistic effects of impact modifier and plasticiser. Compos. Part B Eng. 2020, 188, 107845. [Google Scholar] [CrossRef]

- Fu, Y.; Liu, L.; Zhang, J.; Hiscox, W.C. Functionalized graphenes with polymer toughener as novel interface modifier for property-tailored poly (lactic acid)/graphene nanocomposites. Polymer 2014, 55, 6381–6389. [Google Scholar] [CrossRef]

- Najafi, N.; Heuzey, M.; Carreau, P. Polylactide (PLA)-clay nanocomposites prepared by melt compounding in the presence of a chain extender. Compos. Sci. Technol. 2012, 72, 608–615. [Google Scholar] [CrossRef]

- Cai, X.; Tong, H.; Shen, X.; Chen, W.; Yan, J.; Hu, J. Preparation and characterization of homogeneous chitosan–poly (lactic acid)/hydroxyapatite nanocomposite for bone tissue engineering and evaluation of its mechanical properties. Acta Biomater. 2009, 5, 2693–2703. [Google Scholar] [CrossRef]

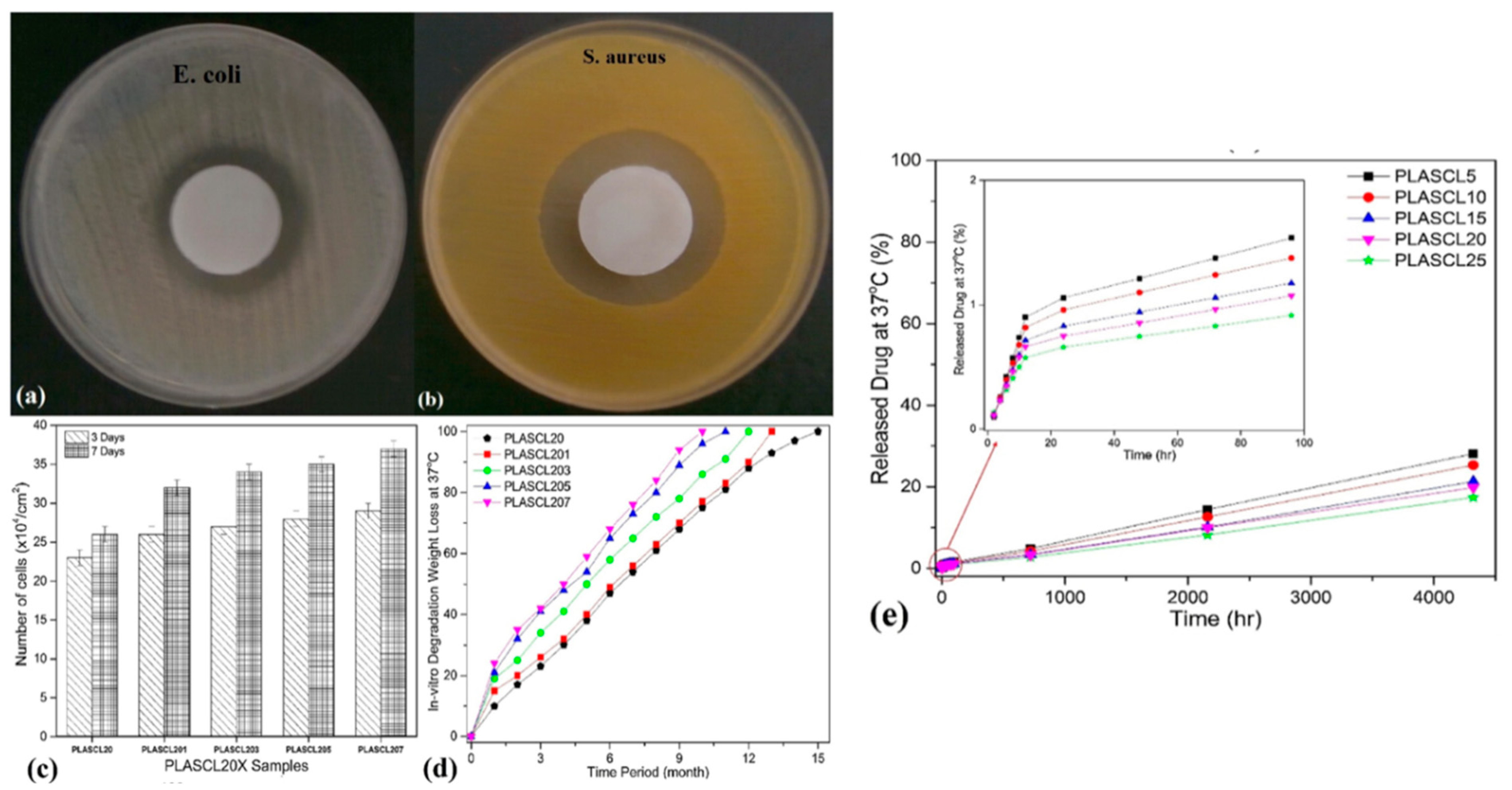

- Davachi, S.M.; Heidari, B.S.; Hejazi, I.; Seyfi, J.; Oliaei, E.; Farzaneh, A.; Rashedi, H. Interface modified poly (lactic acid)/starch/poly ε-caprolactone antibacterial nanocomposite blends for medical applications. Carbohydr. Polym. 2017, 155, 336–344. [Google Scholar] [CrossRef] [PubMed]

- Alam, F.; Shukla, V.R.; Varadarajan, K.M.; Kumar, S. Microarchitected 3D printed poly (lactic acid) (PLA) nano-composite scaffolds for biomedical applications. J. Mech. Behav. Biomed. Mater. 2020, 103, 103576. [Google Scholar] [CrossRef] [PubMed]

- Alam, F.; Varadarajan, K.M.; Kumar, S. 3D printed poly (lactic acid) nanocomposite scaffolds for tissue engineering applications. Polym. Test. 2020, 81, 106203. [Google Scholar] [CrossRef]

- Ansari, Z.; Kalantar, M.; Kharaziha, M.; Ambrosio, L.; Raucci, M.G. Poly (ε-caprolactone) /fluoride substituted-hydroxyapatite (PCL/FHA) nanocomposite coatings prepared by in-situ sol-gel process for dental implant applications. Prog. Org. Coat. 2020, 147, 105873. [Google Scholar] [CrossRef]

- Tay, B.Y.; Zhang, S.X.; Myint, M.H.; Ng, F.L.; Chandrasekaran, M.; Tan, L.K.A. Processing of Poly (ε-caprolactone) porous structure for scaffold development. J. Mater. Process. Technol. 2007, 182, 117–121. [Google Scholar] [CrossRef]

- Lee, S.H.; Teramoto, Y.; Endo, T. Cellulose nanofiber-reinforced Poly (ε-caprolactone)/polypropylene hybrid nanocomposite. Compos. Part A Appl. Sci. Manuf. 2011, 42, 151–156. [Google Scholar] [CrossRef]

- Ahmadzadeh, Y.; Babaei, A.; Goudarzi, A. Assessment of localization and degradation of ZnO nano-particles in the PLA/PCL biocompatible blend through a comprehensive rheological characterization. Polym. Degrad. Stab. 2018, 158, 136–147. [Google Scholar] [CrossRef]

- Guadagno, L.; Raimondo, M.; Longo, R.; Sarno, M.; Iuliano, M.; Mariconda, A.; Saturnino, C.; Ceramella, J.; Lacopetta, D.; Sinicropi, M.S. Development and characterization of antitumoral electrospun Poly (ε-caprolactone)/functionalized Fe3O4 hybrid membranes. Mater. Today Chem. 2020, 17, 100309. [Google Scholar] [CrossRef]

- Mallakpour, S.; Nouruzi, N. Effects of citric acid-functionalized ZnO nanoparticles on the structural, mechanical, thermal and optical properties of Poly (ε-caprolactone) nanocomposite films. Mater. Chem. Phys. 2017, 197, 129–137. [Google Scholar] [CrossRef]

- Ahmadi, T.; Monshi, A.; Mortazavi, V.; Fathi, M.H.; Sharifi, S.; Kharaziha, M.; Khazdooz, M.; Zarei, A.; Dehaghani, M.T. Fabrication and characterization of Poly (ε-caprolactone) fumarate/gelatin-based nanocomposite incorporated with silicon and magnesium co-doped fluorapatite nanoparticles using electrospinning method. Mater. Sci. Eng. C 2020, 106, 110172. [Google Scholar] [CrossRef]

- Abdal-hay, A.; Raveendran, N.T.; Fournier, B.; Ivanovski, S. Fabrication of biocompatible and bioabsorbable Poly (ε-caprolactone) /magnesium hydroxide 3D printed scaffolds: Degradation and in vitro osteoblasts interactions. Compos. Part B Eng. 2020, 197, 108158. [Google Scholar] [CrossRef]

- Torres, E.; Fombuena, V.; Vallés-Lluch, A.; Ellingham, T. Improvement of mechanical and biological properties of Poly (ε-caprolactone) loaded with hydroxyapatite and halloysite nanotubes. Mater. Sci. Eng. C 2017, 75, 418–424. [Google Scholar] [CrossRef] [PubMed]

- Abdal-hay, A.; Abbasi, N.; Gwiazda, M.; Hamlet, S.; Ivanovski, S. Novel Poly (ε-caprolactone) /hydroxyapatite nanocomposite fibrous scaffolds by direct melt-electrospinning writing. Eur. Polym. J. 2018, 105, 257–264. [Google Scholar] [CrossRef]

- Esmaeilzadeh, J.; Hesaraki, S.; Hadavi, S.M.M.; Ebrahimzadeh, M.H.; Esfandeh, M. Poly (D/L) lactide/Poly (ε-caprolactone) /bioactive glasss nanocomposites materials for anterior cruciate ligament reconstruction screws: The effect of glass surface functionalization on mechanical properties and cell behaviors. Mater. Sci. Eng. C 2017, 77, 978–989. [Google Scholar] [CrossRef]

- Yildirim, S.; Demirtas, T.T.; Dincer, C.A.; Yildiz, N.; Karakecili, A. Preparation of Poly (ε-caprolactone)/graphene oxide scaffolds: A green route combining supercritial CO2 technology and porogen leaching. J. Supercrit. Fluids 2018, 133, 156–162. [Google Scholar] [CrossRef]

- Sadeghi, M.; Talakesh, M.M.; Ghalei, B.; Shafiei, M. Preparation, characterization and gas permeation properties of a Poly (ε-caprolactone) based polyurethane-silica nanocomposite membrane. J. Membr. Sci. 2013, 427, 21–29. [Google Scholar] [CrossRef]

- Seema, K.M.; Mamba, B.B.; Njuguna, J.; Bakhtizin, R.Z.; Mishra, A.K. Removal of lead (II) from aqeouos waste using (CD-PCL-TiO2) bio-nanocomposites. Int. J. Biol. Macromol. 2018, 109, 136–142. [Google Scholar] [CrossRef]

- Karagoz, S.; Kiremitler, N.B.; Sakir, M.; Salem, S.; Onses, M.S.; Sahmetlioglu, E.; Ceylan, A.; Yilmaz, E. Synthesis of Ag and TiO2 modified Poly (ε-caprolactone) electrospun nanofibers (PCL/TiO2-Ag NFs) as a multifunctional material for SERS, photocatalysis and antibacterial applications. Ecotoxicol. Environ. Saf. 2020, 188, 109856. [Google Scholar] [CrossRef]

- Larsson, M.; Markbo, O.; Jannasch, P. Melt processability and thermomechanical properties of blends based on polyhydroxyalkanoates and poly(butylene adipate-co-terephthalate). RSC Adv. 2016, 6, 44354–44363. [Google Scholar] [CrossRef]

- Lemoigne, M. Products of dehydration and of polymerization of β-hydroxybutyric acid. Bull Soc. Chem. Biol 1926, 8, 770–782. [Google Scholar]

- Catara, V. Pseudomonas corrugata: Plant pathogen and/or biological resource? Mol. Plant Pathol. 2007, 8, 233–244. [Google Scholar] [CrossRef] [PubMed]

- Thakur, P. Screening of Plastic Degrading Bacteria from Dumped Soil Area. Doctoral Dissertation, National Institute of Technology, Rourkela, India, 10 May 2012. [Google Scholar]

- Lim, J.; You, M.; Li, J.; Li, Z. Emerging bone tissue engineering via Polyhydroxyalkanoate (PHA)-based scaf-folds. Mater. Sci. Eng. C 2017, 79, 917–929. [Google Scholar] [CrossRef] [PubMed]

- Tarrahi, R.; Fathi, Z.; Seydibeyoğlu, M.Ö.; Doustkhah, E.; Khataee, A. Polyhydroxyalkanoates (PHA): From production to nanoarchitecture. Int. J. Biol. Macromol. 2020, 146, 596–619. [Google Scholar] [CrossRef] [PubMed]

- Phukon, P.; Radhapyari, K.; Konwar, B.K.; Khan, R. Natural polyhydroxyalkanoate–gold nanocomposite based biosensor for detection of antimalarial drug artemisinin. Mater. Sci. Eng. C 2014, 37, 314–320. [Google Scholar] [CrossRef]

- Bugnicourt, E.; Cinelli, P.; Lazzeri, A.; Alvarez, V. Polyhydroxyalkanoate (PHA): Review of synthesis, characteristics, processing and potential applications in packaging. Express Polym. Lett. 2014, 8, 791–808. [Google Scholar] [CrossRef]

- Grassie, N.; Murray, E.J.; Holmes, P.A. The thermal degradation of poly(-(d)-β-hydroxybutyric acid): Part 2—Changes in molecular weight. Polym. Degrad. Stabil. 1984, 6, 95–103. [Google Scholar] [CrossRef]

- Ishida, K.; Wang, Y.; Inoue, Y. Comonomer Unit Composition and Thermal Properties of Poly (3-hydroxybutyrate-co-4-hydroxybutyrate) s Biosynthesized by Ralstonia eutropha. Biomacromolecules 2001, 2, 1285–1293. [Google Scholar] [CrossRef]

- Pal, A.K.; Wu, F.; Misra, M.; Mohanty, A.K. Reactive extrusion of sustainable PHBV/PBAT-based nanocompo-site films with organically modified nanoclay for packaging applications: Compression moulding vs. cast film extrusion. Compos. Part B Eng. 2020, 198, 108141. [Google Scholar] [CrossRef]

- Perret, E.; Reifler, F.A.; Gooneie, A.; Hufenus, R. Tensile study of melt-spun poly(3-hydroxybutyrate) P3HB fibers: Reversible transformation of a highly oriented phase. Polymer 2019, 180, 121668. [Google Scholar] [CrossRef]

- Tebaldi, M.L.; Maia, A.L.C.; Poletto, F.; de Andrade, F.V.; Soares, D.C.F. Poly (-3-hydroxybutyrate-co-3-hydroxyvalerate)(PHBV): Current advances in synthesis methodologies, antitumor applications and biocompatibility. J. Drug Deliv. Sci. Technol. 2019, 51, 115–126. [Google Scholar] [CrossRef]

- Naderi, P.; Zarei, M.; Karbasi, S.; Salehi, H. Evaluation of the effects of keratin on physical, mechanical and bio-logical properties of poly (3-hydroxybutyrate) electrospun scaffold: Potential application in bone tissue engineering. Eur. Polym. J. 2020, 124, 109502. [Google Scholar] [CrossRef]

- Figueroa-Lopez, K.J.; Enescu, D.; Torres-Giner, S.; Cabedo, L.; Cerqueira, M.A.; Pastrana, L.; Fuciños, P.; Lagaron, J.M. Development of electrospun active films of poly(3-hydroxybutyrate-co-3-hydroxyvalerate) by the incorporation of cyclodextrin inclusion complexes containing oregano essential oil. Food Hydrocoll. 2020, 108, 106013. [Google Scholar] [CrossRef]

- Lee, R.E.; Azdast, T.; Wang, G.; Wang, X.; Lee, P.C.; Park, C.B. Highly expanded fine-cell foam of polylactide/polyhydroxyalkanoate/nano-fibrillated polytetrafluoroethylene composites blown with mold-opening injection molding. Int. J. Biol. Macromol. 2020, 155, 289–292. [Google Scholar] [CrossRef] [PubMed]

- Xu, P.; Yang, W.; Niu, D.; Yu, M.; Du, M.; Dong, W.; Chen, M.; Jan Lemstra, P.; Ma, P. Multifunctional and robust polyhydroxyalkanoate nanocomposites with superior gas barrier, heat resistant and inherent antibacterial performances. Chem. Eng. J. 2020, 382, 122864. [Google Scholar] [CrossRef]

- Jayakumar, A.; Prabhu, K.; Shah, L.; Radha, P. Biologically and environmentally benign approach for PHB-silver nanocomposite synthesis and its characterization. Polym. Test. 2020, 81, 106197. [Google Scholar] [CrossRef]

- Castro-Mayorga, J.; Freitas, F.; Reis, M.; Prieto, M.; Lagaron, J. Biosynthesis of silver nanoparticles and polyhydroxybutyrate nanocomposites of interest in antimicrobial applications. Int. J. Biol. Macromol. 2018, 108, 426–435. [Google Scholar] [CrossRef]

- Rivera-Briso, A.L.; Aachmann, F.L.; Moreno-Manzano, V.; Serrano-Aroca, Á. Graphene oxide nanosheets versus carbon nanofibers: Enhancement of physical and biological properties of poly (3-hydroxybutyrate-co-3-hydroxyvalerate) films for biomedical applications. Int. J. Biol. Macromol. 2020, 143, 1000–1008. [Google Scholar] [CrossRef]

- Parvizifard, M.; Karbasi, S. Physical, mechanical and biological performance of PHB-Chitosan/MWCNTs nano-composite coating deposited on bioglass based scaffold: Potential application in bone tissue engineering. Int. J. Biol. Macromol. 2020, 152, 645–662. [Google Scholar] [CrossRef]

- Torres, M.G. 3D-composite scaffolds from radiation-induced chitosan grafted poly (3-hydroxybutyrate) polyure-thane. Mater. Today Commun. 2020, 23, 100902. [Google Scholar] [CrossRef]

- Ochoa-Segundo, E.I.; González-Torres, M.; Cabrera-Wrooman, A.; Sánchez-Sánchez, R.; Huerta-Martínez, B.M.; Melgarejo-Ramírez, Y.; Leyva-Gómez, G.; Rivera-Muñoz, E.M.; Cortés, H.; Velasquillo, C.; et al. Gamma radiation-induced grafting of n-hydroxyethyl acrylamide onto poly(3-hydroxybutyrate): A companion study on its polyurethane scaffolds meant for potential skin tissue engineering applications. Mater. Sci. Eng. C 2020, 116, 111176. [Google Scholar] [CrossRef]

- Wu, C.S. Comparative assessment of the interface between poly (3-hydroxybutyrate-co-3-hydroxyvalerate) and fish scales in composites: Preparation, characterization, and applications. Mater. Sci. Eng. C 2019, 104, 109878. [Google Scholar] [CrossRef] [PubMed]

- de Almeida Neto, G.R.; Barcelos, M.V.; Ribeiro, M.E.A.; Folly, M.M.; Rodríguez, R.J.S. Formulation and characterization of a novel PHBV nanocomposite for bone defect filling and infection treatment. Mater. Sci. Eng. C 2019, 104, 110004. [Google Scholar] [CrossRef]

- Oprea, M.; Panaitescu, D.M.; Nicolae, C.A.; Gabor, A.R.; Frone, A.N.; Raditoiu, V.; Trusca, R.; Casarica, A. Nanocomposites from functionalized bacterial cellulose and poly(3-hydroxybutyrate-co-3-hydroxyvalerate). Polym. Degrad. Stab. 2020, 179, 109203. [Google Scholar] [CrossRef]

- Nishida, M.; Ogura, T.; Shinzawa, H.; Nishida, M.; Kanematsu, W. Tensile properties of polyhydroxyalka-noate/Poly (ε-caprolactone) blends studied by rheo-optical near-infrared (NIR) spectroscopy. J. Mol. Struct. 2016, 1124, 92–97. [Google Scholar] [CrossRef]

- Panaitescu, D.M.; Nicolae, C.A.; Gabor, A.R.; Trusca, R. Thermal and mechanical properties of poly(3-hydroxybutyrate) reinforced with cellulose fibers from wood waste. Ind. Crop. Prod. 2020, 145, 112071. [Google Scholar] [CrossRef]

- Garcia-Garcia, D.; Lopez-Martinez, J.; Balart, R.; Strömberg, E.; Moriana, R. Reinforcing capability of cellulose nanocrystals obtained from pine cones in a biodegradable poly (3-hydroxybutyrate)/poly (ε-caprolactone)(PHB/PCL) thermoplastic blend. Eur. Polym. J. 2018, 104, 10–18. [Google Scholar] [CrossRef]

- Garcia-Garcia, D.; Garcia-Sanoguera, D.; Fombuena, V.; Lopez-Martinez, J.; Balart, R. Improvement of mechanical and thermal properties of poly(3-hydroxybutyrate) (PHB) blends with surface-modified halloysite nanotubes (HNT). Appl. Clay Sci. 2018, 162, 487–498. [Google Scholar] [CrossRef]

- Garcia-Garcia, D.; Rayón, E.; Carbonell-Verdu, A.; López-Martínez, J.; Balart, R. Improvement of the compatibility between poly (3-hydroxybutyrate) and poly (ε-caprolactone) by reactive extrusion with dicumyl peroxide. Eur. Polym. J. 2017, 86, 41–57. [Google Scholar] [CrossRef]

- Clavería, I.; Elduque, D.; Santolaria, J.; Pina, C.; Javierre, C.; Fernandez, A. The influence of environmental conditions on the dimensional stability of components injected with PA6 and PA66. Polym. Test. 2016, 50, 15–25. [Google Scholar] [CrossRef]

- Chavarria, F.; Paul, D. Comparison of nanocomposites based on nylon 6 and nylon 66. Polymer 2004, 45, 8501–8515. [Google Scholar] [CrossRef]

- Ogunsona, E.O.; Codou, A.; Misra, M.; Mohanty, A.K. A critical review on the fabrication processes and performance of polyamide biocomposites from a biofiller perspective. Mater. Today Sustain. 2019, 5, 100014. [Google Scholar] [CrossRef]

- Winnacker, M.; Rieger, B. Biobased Polyamides: Recent Advances in Basic and Applied Research. Macromol. Rapid Commun. 2016, 37, 1391–1413. [Google Scholar] [CrossRef] [PubMed]

- Munoz-Guerra, S. Carbohydrate-based polyamides and polyesters: An overview illustrated with two selected examples. High Perform. Polym. 2012, 24, 9–23. [Google Scholar] [CrossRef]

- Thiyagarajan, S.; Gootjes, L.; Vogelzang, W.; Wu, J.; van Haveren, J.; van Es, D.S. Chiral building blocks from biomass: 2,5-diamino-2,5-dideoxy-1,4-3,6-dianhydroiditol. Tetrahedron 2010, 67, 383–389. [Google Scholar] [CrossRef]

- Bou, J.J.; Rodriguez-Galan, A.; Munoz-Guerra, S. Optically active polyamides derived from L-tartaric acid. Macromolecules 1993, 26, 5664–5670. [Google Scholar] [CrossRef]

- Kiely, D.E.; Chen, L.; Lin, T.H. Synthetic polyhydroxypolyamides from galactaric, xylaric, D-glucaric, and D-mannaric acids and alkylenediamine monomers—Some comparisons. J. Polym. Sci. Part A Polym. Chem. 2000, 38, 594–603. [Google Scholar] [CrossRef]

- Arabpour, A.; Shockravi, A.; Rezania, H.; Farahati, R. Investigation of anticorrosive properties of novel silane-functionalized polyamide/GO nanocomposite as steel coatings. Surf. Interfaces 2020, 18, 100453. [Google Scholar] [CrossRef]

- Pant, H.R.; Risal, P.; Park, C.H.; Tijing, L.D.; Jeong, Y.J.; Kim, C.S. Synthesis, characterization, and mineralization of polyamide-6/calcium lactate composite nanofibers for bone tissue engineering. Colloids Surf. B Biointerfaces 2013, 102, 152–157. [Google Scholar] [CrossRef]

- Vasiljević, J.; Čolović, M.; Jerman, I.; Simončič, B.; Demšar, A.; Samaki, Y.; Sobak, M.; Sest, E.; Golja, B.; Leskovsek, M.; et al. In situ prepared polyamide 6/DOPO-derivative nano-composite for melt-spinning of flame retardant textile filaments. Polym. Degrad. Stab. 2019, 166, 50–59. [Google Scholar] [CrossRef]

- Ali, F.A.A.; Alam, J.; Shukla, A.K.; Alhoshan, M.; Khaled, J.M.; Al-Masry, W.A.; Alharby, N.S.; Alam, M. Graphene oxide-silver nanosheet-incorporated polyamide thin-film composite membranes for antifouling and antibacterial action against Escherichia coli and bovine serum albumin. J. Ind. Eng. Chem. 2019, 80, 227–238. [Google Scholar]

- Touchaleaume, F.; Soulestin, J.; Sclavons, M.; Devaux, J.; Lacrampe, M.F.; Krawczak, P. One-step water-assisted melt-compounding of polyamide 6/pristine clay nanocomposites: An efficient way to prevent matrix degradation. Polym. Degrad. Stab. 2011, 96, 1890–1900. [Google Scholar] [CrossRef]

- Abdelwahab, M.; Codou, A.; Anstey, A.; Mohanty, A.K.; Misra, M. Studies on the dimensional stability and mechanical properties of nanobiocomposites from polyamide 6-filled with biocarbon and nanoclay hybrid systems. Compos. Part A Appl. Sci. Manuf. 2020, 129, 105695. [Google Scholar] [CrossRef]

- Battegazzore, D.; Salvetti, O.; Frache, A.; Peduto, N.; De Sio, A.; Marino, F. Thermo-mechanical properties enhancement of bio-polyamides (PA10. 10 and PA6. 10) by using rice husk ash and nanoclay. Compos. Part A Appl. Sci. Manuf. 2016, 81, 193–201. [Google Scholar] [CrossRef]

- Shabanian, M.; Mirzakhanian, Z.; Basaki, N.; Khonakdar, H.A.; Faghihi, K.; Hoshyargar, F.; Wagenknecht, U. Flammability and thermal properties of novel semi aromatic polyamide/organoclay nanocomposite. Thermochim. Acta 2014, 585, 63–70. [Google Scholar] [CrossRef]

- Shabanian, M.; Hajibeygi, M.; Roohani, M. Synthesis of a novel CNT/polyamide composite containing phosphine oxide groups and its flame retardancy and thermal properties. New Carbon Mater. 2015, 30, 397–403. [Google Scholar] [CrossRef]

- Venkatraman, P.; Gohn, A.M.; Rhoades, A.M.; Foster, E.J. Developing high performance PA 11/cellulose nano-composites for industrial-scale melt processing. Compos. Part B Eng. 2019, 174, 106988. [Google Scholar] [CrossRef]

- Rahimi, S.K.; Otaigbe, J.U. The role of particle surface functionality and microstructure development in isothermal and non-isothermal crystallization behavior of polyamide 6/cellulose nanocrystals nanocomposites. Polymer 2016, 107, 316–331. [Google Scholar] [CrossRef]

- Rahimi, S.K.; Otaigbe, J.U. The effects of the interface on microstructure and rheo-mechanical properties of pol-yamide 6/cellulose nanocrystal nanocomposites prepared by in-situ ring-opening polymerization and subsequent melt extrusion. Polymer 2017, 127, 269–285. [Google Scholar] [CrossRef]

- Panaitescu, D.M.; Frone, A.N.; Nicolae, C. Micro- and nano-mechanical characterization of polyamide 11 and its composites containing cellulose nanofibers. Eur. Polym. J. 2013, 49, 3857–3866. [Google Scholar] [CrossRef]

- Shrestha, B.K.; Mousa, H.M.; Tiwari, A.P.; Ko, S.W.; Park, C.H.; Kim, C.S. Development of polyamide-6, 6/chitosan electrospun hybrid nanofibrous scaffolds for tissue engineering application. Carbohydr. Polym. 2016, 148, 107–114. [Google Scholar] [CrossRef]

- Masui, A.; Ikawa, S.; Kawasaki, N.; Yamano, N.; Nakayama, A. Biodegradation control of a polyamide 4–visible-light-sensitive TiO2 composite by a fluorescent light irradiation. Polym. Degrad. Stab. 2019, 167, 44–49. [Google Scholar] [CrossRef]

- Zammarano, M.; Bellayer, S.; Gilman, J.W.; Franceschi, M.; Beyer, F.L.; Harris, R.H.; Meriani, S. Delamination of organo-modified layered double hydroxides in polyamide 6 by melt processing. Polymer 2006, 47, 652–662. [Google Scholar] [CrossRef]

- Pospíšil, J.; Nešpůrek, S. Highlights in chemistry and physics of polymer stabilization. In Macromolecular Symposia; Hüthig & Wepf Verlag: Basel, Switzerland, 1997; Volume 115, pp. 143–163. [Google Scholar]

- Doi, Y.; Kanesawa, Y.; Tanahashi, N.; Kumagai, Y. Biodegradation of microbial polyesters in the marine environment. Polym. Degrad. Stab. 1992, 36, 173–177. [Google Scholar] [CrossRef]

- Guo, D.; Chen, F.; Wheeler, J.; Winder, J.; Selman, S.; Peterson, M.; Dixon, R.A. Improvement of in-rumen digestibility of alfalfa forage by genetic manipulation of lignin O-methyltransferases. Transgenic Res. 2001, 10, 457–464. [Google Scholar] [CrossRef] [PubMed]

- Olayan, H.B.; Hami, H.S.; Owen, E.D. Photochemical and Thermal Crosslinking of Polymers. J. Macromol. Sci. Part C Polym. Rev. 1996, 36, 671–719. [Google Scholar] [CrossRef]

- Elbanna, K.; Lütke-Eversloh, T.; Jendrossek, D.; Luftmann, H.; Steinbüchel, A. Studies on the biodegradability of polythioester copolymers and homopolymers by polyhydroxyalkanoate (PHA)-degrading bacteria and PHA depolymerases. Arch. Microbiol. 2004, 182, 212–225. [Google Scholar] [CrossRef]

- Jendrossek, D.; Schirmer, A.; Schlegel, H.G. Biodegradation of polyhydroxyalkanoic acids. Appl. Microbiol. Biotechnol. 1996, 46, 451–463. [Google Scholar] [CrossRef]

- Mabrouk, M.; Sabry, S.A. Degradation of poly (3-hydroxybutyrate) and its copolymer poly (3-hydroxybutyrate-co-3-hydroxyvalerate) by a marine Streptomyces sp. SNG9. Microbiol. Res. 2001, 156, 323–335. [Google Scholar] [CrossRef]

- Feng, L.; Wang, Y.; Inagawa, Y.; Kasuya, K.; Saito, T.; Doi, Y.; Inoue, Y. Enzymatic degradation behavior of comonomer compositionally fractionated bacterial poly(3-hydroxybutyrate-co-3-hydroxyvalerate)s by poly(3-hydroxyalkanoate) depolymerases isolated from Ralstonia pickettii T1 and Acidovorax sp. TP4. Polym. Degrad. Stab. 2004, 84, 95–104. [Google Scholar] [CrossRef]

- Kasuya, K.-I.; Doi, Y.; Yao, T. Enzymatic degradation of poly[(R)-3-hydroxybutyrate] by Comamonas testosteroni ATSU of soil bacterium. Polym. Degrad. Stab. 1994, 45, 379–386. [Google Scholar] [CrossRef]

- Kita, K.; Mashiba, S.I.; Nagita, M.; Ishimaru, K.; Okamoto, K.; Yanase, H.; Kato, N. Cloning of poly (3-hydroxybutyrate) depolymerase from a marine bacterium, Alcaligenes faecalis AE122, and characterization of its gene product. Biochim. Et Biophys. Acta (BBA)-Gene Struct. Expr. 1997, 1352, 113–122. [Google Scholar] [CrossRef]

- Romen, F.; Reinhardt, S.; Jendrossek, D. Thermotolerant poly(3-hydroxybutyrate)-degrading bacteria from hot compost and characterization of the PHB depolymerase of Schlegelella sp. KB1a. Arch. Microbiol. 2004, 182, 157–164. [Google Scholar] [CrossRef] [PubMed]

- Abou-Zeid, D.M.; Müller, R.J.; Deckwer, W.D. Biodegradation of aliphatic homopolyesters and aliphatic−aro-matic copolyesters by anaerobic microorganisms. Biomacromolecules 2004, 5, 1687–1697. [Google Scholar] [CrossRef] [PubMed]

- Benedict, C.V.; Cameron, J.A.; Huang, S.J. Poly (ε-caprolactone) degradation by mixed and pure cultures of bacteria and a yeast. J. Appl. Polym. Sci. 1983, 28, 335–342. [Google Scholar] [CrossRef]

- Torres, A.; Li, S.M.; Roussos, S.; Vert, M. Poly (lactic acid) degradation in soil or under controlled conditions. J. Appl. Polym. Sci. 1996, 62, 2295–2302. [Google Scholar] [CrossRef]

- Pranamuda, H.; Tokiwa, Y.; Tanaka, H. Polylactide Degradation by an Amycolatopsis sp. Appl. Environ. Microbiol. 1997, 63, 1637–1640. [Google Scholar] [CrossRef] [PubMed]

- Pranamuda, H.; Tokiwa, Y. Degradation of poly (L-lactide) by strains belonging to genus Amycolatopsis. Biotechnol. Lett. 1999, 21, 901–905. [Google Scholar] [CrossRef]

- Shah, A.A.; Hasan, F.; Hameed, A.; Ahmed, S. Biological degradation of plastics: A comprehensive review. Biotechnol. Adv. 2008, 26, 246–265. [Google Scholar] [CrossRef]

- Fukuzaki, H.; Yoshida, M.; Asano, M.; Kumakura, M. Synthesis of copoly(d,l-lactic acid) with relatively low molecular weight and in vitro degradation. Eur. Polym. J. 1989, 25, 1019–1026. [Google Scholar] [CrossRef]

- Lee, B.; Pometto, A.L.; Fratzke, A.; Bailey, T.B. Biodegradation of degradable plastic polyethylene by Phanero-chaete and Streptomyces species. Appl. Environ. Microbiol. 1991, 57, 678–685. [Google Scholar] [CrossRef]

- Guo, B.; Glavas, L.; Albertsson, A.C. Biodegradable and electrically conducting polymers for biomedical applications. Prog. Polym. Sci. 2013, 38, 1263–1286. [Google Scholar] [CrossRef]

- Jamshidian, M.; Tehrany, E.A.; Imran, M.; Jacquot, M.; Desobry, S. Poly-Lactic Acid: Production, applications, nanocomposites, and release studies. Compr. Rev. Food Sci. Food Saf. 2010, 9, 552–571. [Google Scholar] [CrossRef] [PubMed]

- Lim, L.-T.; Auras, R.; Rubino, M. Processing technologies for poly(lactic acid). Prog. Polym. Sci. 2008, 33, 820–852. [Google Scholar] [CrossRef]

- Nampoothiri, K.M.; Nair, N.R.; John, R.P. An overview of the recent developments in polylactide (PLA) research. Bioresour. Technol. 2010, 101, 8493–8501. [Google Scholar] [CrossRef]

- Haw, T.C.; Ahmad, A.; Anuar, F.H. Synthesis and characterization of poly (D,L-lactide)-poly (ethylene glycol) multiblock poly (ether-ester-urethane)s. In AIP Conference Proceedings; AIP Publishing LLC: Melville, NY, USA, 2015; Volume 1678, p. 050025. [Google Scholar]

- Drumright, R.E.; Gruber, P.R.; Henton, D.E. Poly (lactic acid) technology. Adv. Mater. 2000, 12, 1841–1846. [Google Scholar] [CrossRef]

- Vert, M.; Li, S.M.; Garreau, H. Attempts to map the structure and degradation characteristics of aliphatic polyesters derived from lactic and glycolic acids. J. Biomater. Sci. 1995, 6, 639–649. [Google Scholar] [CrossRef]

- Li, S.M.; Garreau, H.; Vert, M. Structure-property relationships in the case of the degradation of massive aliphatic poly-(α-hydroxy acids) in aqueous media. J. Mater. Sci. Mater. Med. 1990, 1, 123–130. [Google Scholar] [CrossRef]

- Therin, M.; Christel, P.; Li, S.; Garreau, H.; Vert, M. In vivo degradation of massive poly (α-hydroxy acids): Validation of in vitro findings. Biomaterials 1992, 13, 594–600. [Google Scholar] [CrossRef]

- Shimpi, N.; Borane, M.; Mishra, S.; Kadam, M.; Sonawane, S.S. Biodegradation of Isotactic Polypropylene (iPP)/Poly (lactic acid)(PLA) and iPP/PLA/Nano Calcium Carbonates Using Phanerochaete chrysosporium. Adv. Polym. Technol. 2018, 37, 522–530. [Google Scholar] [CrossRef]

- Okada, M. Molecular design and syntheses of glycopolymers. Prog. Polym. Sci. 2001, 26, 67–104. [Google Scholar] [CrossRef]

- Hudson, J.A.; Crugnola, A. The in vivo Biodegradation of Nylon 6 Utilized in a Particular IUD. J. Biomater. Appl. 1986, 1, 487–501. [Google Scholar] [CrossRef] [PubMed]

- Smith, R.; Oliver, C.; Williams, D.F. The enzymatic degradation of polymers in vitro. J. Biomed. Mater. Res. 1987, 21, 991–1003. [Google Scholar] [CrossRef]

- Deguchi, T.; Kitaoka, Y.; Kakezawa, M.; Nishida, T. Purification and characterization of a nylon-degrading enzyme. Appl. Environ. Microbiol. 1998, 64, 1366–1371. [Google Scholar] [CrossRef] [PubMed]

- Nomura, I.; Narita, K.; Kurokawa, M. Mitsubishi Gas Chemical Co Inc. Molding Polyamide Resin Composition. U.S. Patent 4,822,846, 2001. [Google Scholar]

- Yamano, N.; Nakayama, A.; Kawasaki, N.; Yamamoto, N.; Aiba, S. Mechanism and Characterization of Polyamide 4 Degradation by Pseudomonas sp. J. Polym. Environ. 2008, 16, 141–146. [Google Scholar] [CrossRef]

- Wu, J.; Eduard, P.; Thiyagarajan, S.; van Haveren, J.; van Es, D.S.; Koning, C.E.; Lutz, M.; Guerra, C.F. Isohexide Derivatives from Renewable Resources as Chiral Building Blocks. Chemsuschem 2011, 4, 599–603. [Google Scholar] [CrossRef] [PubMed]

- Díaz, E.; Sandonis, I.; Valle, M.B. In vitro degradation of poly (caprolactone)/nHA composites. J. Nanomater. 2014, 2014, 185. [Google Scholar] [CrossRef]

- Heimowska, A.; Morawska, M.; Bocho-Janiszewska, A. Biodegradation of poly(ε-caprolactone) in natural water environments. Pjct 2017, 19, 120–126. [Google Scholar] [CrossRef]

- Fukumura, D.; Jain, R.K. Tumor microvasculature and microenvironment: Targets for anti-angiogenesis and normalization. Microvasc. Res. 2007, 74, 72–84. [Google Scholar] [CrossRef]

- Klun, U.; Friedrich, J.; Kržan, A. Polyamide-6 fibre degradation by a lignolytic fungus. Polym. Degrad. Stab. 2003, 79, 99–104. [Google Scholar] [CrossRef]

- Lam Christopher, X.F.; Dietmar, W. Hutmacher, Jan-Thorsten Schantz, Maria Ann Woodruff, and Swee Hin Teoh. Evaluation of Poly (ε-caprolactone) scaffold degradation for 6 months in vitro and in vivo. J. Biomed. Mater. Res. Part A Off. J. Soc. Biomater. Jpn. Soc. Biomater. Aust. Soc. Biomater. Korean Soc. Biomater. 2009, 90, 906–919. [Google Scholar]

- Woodward, S.C.; Brewer, P.S.; Moatamed, F.; Schindler, A.; Pitt, C.G. The intracellular degradation of poly (ε-caprolactone). J. Biomed. Mater. Res. 1985, 19, 437–444. [Google Scholar] [CrossRef]

- Sun, H.; Mei, L.; Song, C.; Cui, X.; Wang, P. The in vivo degradation, absorption and excretion of PCL-based implant. Biomaterials 2006, 27, 1735–1740. [Google Scholar] [CrossRef] [PubMed]

- Mohan, S.; Oluwafemi, O.S.; Kalarikkal, N.; Thomas, S.; Songca, S.P. Biopolymers–Application in Nanoscience and Nanotechnology. Recent Adv. Biopolym. 2016, 1, 47–66. [Google Scholar] [CrossRef]

- Babu, R.P.; Oconnor, K.; Seeram, R. Current progress on bio-based polymers and their future trends. Prog. Biomater. 2013, 2, 8. [Google Scholar] [CrossRef] [PubMed]

- Williams, S.F.; Martin, D.P.; Horowitz, D.M.; Peoples, O.P. PHA applications: Addressing the price performance issue: I. Tissue engineering. Int. J. Biol. Macromol. 1999, 25, 111–121. [Google Scholar] [CrossRef]

- Gilmore, I.S.; Seah, M.P. Static SIMS: A study of damage using polymers. Surf. Interface Anal. Int. J. Devoted Dev. Appl. Tech. Anal. Surf. 1996 Interfaces Thin Film. 1996, 24, 746–762. [Google Scholar] [CrossRef]

- Gilliam, K.D.; Paschke, E.E. BP Corporation North America Inc. Diisocyanate-Modified Polyesters as Hot Melt Adhesives and Coatings. U.S. Patent 4,166,873, 04 September 1979. [Google Scholar]

- Doi, Y.; Tamaki, A.; Kunioka, M.; Soga, K. Production of copolyesters of 3-hydroxybutyrate and 3-hydroxyvalerate by Alcaligenes eutrophus from butyric and pentanoic acids. Appl. Microbiol. Biotechnol. 1988, 28, 330–334. [Google Scholar] [CrossRef]

- Luzier, W.D. Materials derived from biomass/biodegradable materials. Proc. Natl. Acad. Sci. USA 1992, 89, 839–842. [Google Scholar] [CrossRef]

- Scott, G. Why Degradable Polymers? In Degradable Polymers; Springer: Dordrecht, The Netherlands, 2002; pp. 1–15. [Google Scholar]

- Lee, S.; Parthasarathy, R.; Botwin, K.; Kunneman, D.; Rowold, E.; Lange, G.; Klover, J.; Abegg, A.; Zobel, J.; Beck, T.; et al. Biochemical and Immunological Properties of Cytokines Conjugated to Dendritic Polymers. Biomed. Microdevices 2004, 6, 191–202. [Google Scholar] [CrossRef]

- Shah, A.; Hasan, F.; Hameed, A.; Ahmed, S. A novel poly(3-hydroxybutyrate)-degrading Streptoverticillium kashmirense AF1 isolated from soil and purification of PHB-depolymerase. Acta Biol. Hung. 2008, 59, 489–499. [Google Scholar] [CrossRef]

- Seng, W.P.; Tam, K.C.; Jenkins, R.D.; Bassett, D.R. Calorimetric studies of model hydrophobically modified alka-li-soluble emulsion polymers with varying spacer chain length in ionic surfactant solutions. Macromolecules 2000, 33, 1727–1733. [Google Scholar] [CrossRef]

- Shah, A.A.; Hasan, F.; Hameed, A.; Ahmed, S. Isolation and characterization of poly(3-hydroxybutyrate-co-3-hydroxyvalerate) degrading bacteria and purification of PHBV depolymerase from newly isolated Bacillus sp. AF3. Int. Biodeterior. Biodegradation 2007, 60, 109–115. [Google Scholar] [CrossRef]

- Molitoris, H.P.; Moss, S.T.; De Koning, G.J.M.; Jendrossek, D. Scanning electron microscopy of polyhydroxyalka-noate degradation by bacteria. Appl. Microbiol. Biotechnol. 1996, 46, 570–579. [Google Scholar] [CrossRef]

- Whitchurch, P.C.; Bogdan, P.L.; Deak, T.E.; Trufanov, D.A. UOP LLC. Aromatic Isomerization Catalyst and a Process of Use Thereof. U.S. Patent 7939701, 10 May 2011. [Google Scholar]

- Bachmann, B.M.; Seebach, D. Investigation of the enzymatic cleavage of diastereomeric oligo (3-hydroxybutanoates) containing two to eight HB units. A model for the stereoselectivity of PHB depolymerase from Alcali-genes faecalis T1. Macromolecules 1999, 32, 1777–1784. [Google Scholar] [CrossRef]

- Shimamura, E.; Kasuya, K.; Kobayashi, G.; Shiotani, T.; Shima, Y.; Doi, Y. Physical properties and biodegradability of microbial poly (3-hydroxybutyrate-co-3-hydroxyhexanoate). Macromolecules 1994, 27, 878–880. [Google Scholar] [CrossRef]

- Nakayama, K. Biological image motion processing: A review. Vis. Res. 1985, 25, 625–660. [Google Scholar] [CrossRef]

- Mukai, K.; Yamada, K.; Doi, Y. Efficient hydrolysis of polyhydroxyalkanoates by Pseudomonas stutzeri YM1414 isolated from lake water. Polym. Degrad. Stab. 1994, 43, 319–327. [Google Scholar] [CrossRef]

- Schober, B.J.; Pialet, J.W.; Pollack, R.A.; Clark, D.R. Lubrizol Corp. Polymeric Materials to Self-Regulate the Level of Polar Activators in Electrorheological Fluids. U.S. Patent 6,065,572, 23 May 2000. [Google Scholar]

- Kalia, S.; Averous, L. Biopolymers: Biomedical and Environmental Applications; John Wiley & Sons: Hoboken, NJ, USA, 2011; Volume 70. [Google Scholar]

- Abdel-Monem, M.O. Thermal Degradation of Polymers, SlideShare, Alexandria University Egypt. Available online: https://pt.slideshare.net/MohamedMahmoud443/thermal-degradation-of-polymers (accessed on 12 November 2017).

- Kopinke, F.D.; Remmler, M.; Mackenzie, K.; Möder, M.; Wachsen, O. Thermal decomposition of biodegradable polyesters—II. Poly (lactic acid). Polym. Degrad. Stab. 1996, 53, 329–342. [Google Scholar] [CrossRef]

- Gupta, M.; Deshmukh, V.G. Radiation effects on poly(lactic acid). Polymer 1983, 24, 827–830. [Google Scholar] [CrossRef]

- Carrasco, F.; Pagès, P.; Gámez-Pérez, J.; Santana, O.O.; Maspoch, M.L. Processing of poly (lactic acid): Characterization of chemical structure, thermal stability and mechanical properties. Polym. Degrad. Stab. 2010, 95, 116–125. [Google Scholar] [CrossRef]

- Hyon, S.H.; Jamshidi, K.; Ikada, Y. Effects of residual monomer on the degradation of DL-lactide poly-mer. Polym. Int. 1998, 46, 196–202. [Google Scholar] [CrossRef]

- Wang, Y.; Steinhoff, B.; Brinkmann, C.; Alig, I. In-line monitoring of the thermal degradation of poly (l-lactic acid) during melt extrusion by UV–vis spectroscopy. Polymer 2008, 49, 1257–1265. [Google Scholar] [CrossRef]

- McNeill, I.C.; Leiper, H.A. Degradation studies of some polyesters and polycarbonates—2. Polylactide: Degradation under isothermal conditions 1985, thermal degradation mechanism and photolysis of the polymer. Polym. Degrad. Stab. 1985, 11, 309–326. [Google Scholar] [CrossRef]

- Jamshidi, K.; Hyon, S.-H.; Ikada, Y. Thermal characterization of polylactides. Polymers 1988, 29, 2229–2234. [Google Scholar] [CrossRef]

- Södergård, A.; Stolt, M. Properties of lactic acid based polymers and their correlation with composition. Prog. Polym. Sci. 2002, 27, 1123–1163. [Google Scholar] [CrossRef]

- Tsuji, H.; Fukui, I. Enhanced thermal stability of poly (lactide) s in the melt by enantiomeric polymer blending. Polymer 2003, 44, 2891–2896. [Google Scholar] [CrossRef]

- Ohkita, T.; Lee, S.H. Thermal degradation and biodegradability of poly (lactic acid)/corn starch biocomposites. J. Appl. Polym. Sci. 2006, 100, 3009–3017. [Google Scholar] [CrossRef]

- Persenaire, O.; Alexandre, M.; Degée, P.; Dubois, P. Mechanisms and Kinetics of Thermal Degradation of Poly(ε-caprolactone). Biomacromolecules 2001, 2, 288–294. [Google Scholar] [CrossRef]

- Rattanapan, S.; Pasetto, P.; Pilard, J.F.; Tanrattanakul, V. Preparation and properties of bio-based polyurethane foams from natural rubber and Poly (ε-caprolactone) diol. J. Polym. Res. 2016, 23, 182. [Google Scholar] [CrossRef]

- Saetung, A.; Kaenhin, L.; Klinpituksa, P.; Rungvichaniwat, A.; Tulyapitak, T.; Munleh, S.; Campistron, I.; Pilard, J.-F. Synthesis, characteristic, and properties of waterborne polyurethane based on natural rubber. J. Appl. Polym. Sci. 2012, 124, 2742–2752. [Google Scholar] [CrossRef]

- Saetung, A.; Rungvichaniwat, A.; Campistron, I.; Klinpituksa, P.; Laguerre, A.; Phinyocheep, P.; Doutres, O.; Pilard, J.-F. Preparation and physico-mechanical, thermal and acoustic properties of flexible polyurethane foams based on hydroxytelechelic natural rubber. J. Appl. Polym. Sci. 2010, 117, 828–837. [Google Scholar] [CrossRef]

- Chattopadhyay, D.K.; Webster, D.C. Thermal stability and flame retardancy of polyurethanes. Prog. Polym. Sci. 2009, 34, 1068–1133. [Google Scholar] [CrossRef]

- Li, S.D.; He, J.D.; Yu, P.H.; Cheung, M.K. Thermal degradation of poly (3-hydroxybutyrate) and poly (3-hydroxybutyrate-co-3-hydroxyvalerate) as studied by TG, TG–FTIR, and Py–GC/MS. J. Appl. Polym. Sci. 2003, 89, 1530–1536. [Google Scholar] [CrossRef]

- Aoyagi, Y.; Yamashita, K.; Doi, Y. Thermal degradation of poly [(R)-3-hydroxybutyrate], poly [ε-caprolactone], and poly [(S)-lactide]. Polym. Degrad. Stab. 2002, 76, 53–59. [Google Scholar] [CrossRef]

- Melchiors, M.; Keul, H.; Höcker, H. Depolymerization of Poly[(R)-3-hydroxybutyrate] to Cyclic Oligomers and Polymerization of the Cyclic Trimer: An Example of Thermodynamic Recycling. Macromolecules 1996, 29, 6442–6451. [Google Scholar] [CrossRef]

- Myung, J.; Strong, N.I.; Galega, W.M.; Sundstrom, E.R.; Flanagan, J.C.; Woo, S.G.; Waymouth, R.M.; Criddle, C.S. Disassembly and reassembly of polyhydroxyalkanoates: Recycling through abiotic depolymerization and biotic repolymerization. Bioresour. Technol. 2014, 170, 167–174. [Google Scholar] [CrossRef] [PubMed]

- Flanagan, J.C.; Myung, J.; Criddle, C.S.; Waymouth, R.M. Poly (hydroxyalkanoate) s from waste biomass: A combined chemical–biological approach. ChemistrySelect 2016, 1, 2327–2331. [Google Scholar] [CrossRef]

- Ariffin, H.; Nishida, H.; Hassan, M.A.; Shirai, Y. Chemical recycling of polyhydroxyalkanoates as a method towards sustainable development. Biotechnol. J. 2010, 5, 484–492. [Google Scholar] [CrossRef]

- Hatti-Kaul, R.; Nilsson, L.J.; Zhang, B.; Rehnberg, N.; Lundmark, S. Designing Biobased Recyclable Polymers for Plastics. Trends Biotechnol. 2020, 38, 50–67. [Google Scholar] [CrossRef]

- Otsuka, H.; Endo, T. Poly(hemiacetal ester)s: New Class of Polymers with Thermally Dissociative Units in the Main Chain. Macromolecules 1999, 32, 9059–9061. [Google Scholar] [CrossRef]

- Morikawa, H.; Marchessault, R.H. Pyrolysis of bacterial polyalkanoates. Can. J. Chem. 1981, 59, 2306–2313. [Google Scholar] [CrossRef]

- Kasirajan, S.; Ngouajio, M. Polyethylene and biodegradable mulches for agricultural applications: A review. Agron. Sustain. Dev. 2012, 32, 501–529. [Google Scholar] [CrossRef]

- Jayanth, D.; Kumar, P.S.; Nayak, G.C.; Kumar, J.S.; Pal, S.K.; Rajasekar, R. A Review on Biodegradable Polymeric Materials Striving Towards the Attainment of Green Environment. J. Polym. Environ. 2018, 26, 838–865. [Google Scholar] [CrossRef]

- Morro, A.; Catalina, F.; Sanchez-León, E.; Abrusci, C. Photodegradation and Biodegradation Under Thermophile Conditions of Mulching Films Based on Poly (Butylene Adipate-co-Terephthalate) and Its Blend with Poly (Lactic Acid). J. Polym. Environ. 2019, 27, 352–363. [Google Scholar] [CrossRef]

- Gu, J.D.; Ford, T.E.; Mitchell, R. Microbial degradation of materials: General processes. In Uhlig′s Corrosion Handbook; John Wiley and Sons: Hoboken, NJ, USA, 2011. [Google Scholar]

- Schnabel, W. Polymers and light: Fundamentals and Technical Applications; John Wiley & Sons: Hoboken, NJ, USA, 2007. [Google Scholar]

- Yousif, E.; Haddad, R. Photodegradation and photostabilization of polymers, especially polystyrene: Review. Springerplus 2013, 2, 1–32. [Google Scholar] [CrossRef]

- Callao, M.P.; Larrechi, M.S. Simultaneous determination of organic dyes using second-order data. In Data Handling in Science and Technology; Elsevier: Amsterdam, The Netherlands, 2015; Volume 29, pp. 399–426. [Google Scholar]

- Rauf, M.; Ashraf, S. Radiation induced degradation of dyes—An overview. J. Hazard. Mater. 2009, 166, 6–16. [Google Scholar] [CrossRef]

- Wojnárovits, L.; Takács, E. Irradiation treatment of azo dye containing wastewater: An overview. Radiat. Phys. Chem. 2007, 77, 225–244. [Google Scholar] [CrossRef]

- Akpan, U.G.; Hameed, B.H. Parameters affecting the photocatalytic degradation of dyes using TiO2-based photocatalysts: A review. J. Hazard. Mater. 2009, 170, 520–529. [Google Scholar] [CrossRef]

- Luo, Y.; Cao, Y.; Guo, G. Effects of TiO2 nanoparticles on the photodegradation of poly(lactic acid). J. Appl. Polym. Sci. 2018, 135, 46509. [Google Scholar] [CrossRef]

- França, D.C.; Morais, D.D.; Bezerra, E.B.; Araújo, E.M.; Wellen, R.M.R. Photodegradation Mechanisms on Poly (ε-caprolactone)(PCL). Materials Research 2018, 21. [Google Scholar] [CrossRef]

- Wellen, R.M.R.; Canedo, E.L.; Rabello, M.S.; Fechine, G.J.M. Photodegradation and Photostabilization of Poly(3-Hydroxybutyrate). Mater. Res. 2016, 19, 759–764. [Google Scholar] [CrossRef]

- Han, W.; Luo, C.; Yang, Y.; Ren, J.; Xuan, H.; Ge, L. Free-standing poly (lactic acid)/chitosan/molybdenum disulfide films with controllable visible-light photodegradation. Colloids Surf. A Physicochem. Eng. Asp. 2018, 558, 488–494. [Google Scholar] [CrossRef]

- Arrigo, R.; Dintcheva, N.T. Natural anti-oxidants for bio-polymeric materials. Arch. Chem. Res. 2017, 1, 1–4. [Google Scholar]

- Pan, F.; Chen, L.; Jiang, Y.; Xiong, L.; Min, L.; Xie, J.; Qi, J.; Xiao, H.; Chen, Y.; Cornelis, F. Bio-based UV protective films prepared with poly (lactic acid) (PLA) and Phoebe zhennan extractives. Int. J. Biol. Macromol. 2018, 119, 582–587. [Google Scholar] [CrossRef] [PubMed]

- Salač, J.; Šerá, J.; Jurča, M.; Verney, V.; Marek, A.A.; Koutný, M. Photodegradation and Biodegradation of Poly(Lactic) Acid Containing Orotic Acid as a Nucleation Agent. Materials 2019, 12, 481. [Google Scholar] [CrossRef]

- Garrison, T.F.; Murawski, A.; Quirino, R.L. Bio-based polymers with potential for biodegradability. Polymers 2016, 8, 262. [Google Scholar] [CrossRef]

- Artham, T.; Doble, M. Biodegradation of Aliphatic and Aromatic Polycarbonates. Macromol. Biosci. 2008, 8, 14–24. [Google Scholar] [CrossRef]

- Business Wire. Global Biodegradable Polymers Market to 2030–End-Use, Type and Region–ResearchAndMarkets.com. [online]. 2022. Available online: https://www.businesswire.com/news/home/20220202005451/en/Global-Biodegradable-Polymers-Market-to-2030---by-End-use-Type-and-Region---ResearchAndMarkets.com (accessed on 2 November 2022).

- Iwata, T. Biodegradable and bio-based polymers: Future prospects of eco-friendly plastics. Angew. Chem. Int. Ed. 2015, 54, 3210–3215. [Google Scholar] [CrossRef]

| Poly Amide | Monomer Feed, mol Ratio (a) (DAB/DAII) | Built-in Composition (DAB/DAII) (b) | Mn (c) [g mol−1] Pre-Polymer | Mn (d) after SSP | T5% [°C] | Tm [°C] | Tc [°C] |

|---|---|---|---|---|---|---|---|

| PA1 | 1.0/0 | 1.0/0 | 9600 | 21,900 | 424 | 246 | 221 |

| coPA2 | 0.91/0.09 | 0.89/0.11 | 6500 | 21,300 | 388 | 242 | 209 |

| coPA3 | 0.83/0.17 | 0.86/0.14 | 5000 | 18,700 | 379 | 236 | 201 |

| coPA4 | 0.78/0.22 | 0.80/0.20 | 5500 | 20,400 | 377 | 232 | 198 |

| coPA5 | 0.55/0.45 | 0.57/0.43 | 2500 | 3900 | 321 | 198 | 156 |

| PA6 | 0/1.0 | 0/1.0 | 4200 | - | 300 | 152 | 96 |

| Factors (Requirement/Activity) | Photo-Degradation | Thermo-Oxidative Degradation | Biodegradation |

|---|---|---|---|

| Active agent | UV-light or high-energy radiation | Heat and oxygen | Microbial agents |

| Requirement of heat | Not required | Higher than ambient temperature required | Not required |

| Rate of degradation | Initiation is slow; ut propagation is fast | Fast | Moderate |

| Other consideration | Environment friendly if high-energy radiation is not used | Environmentally not acceptable | Environment friendly |

| Overall acceptance | Acceptable but costly | Not acceptable | Cheap and very much acceptable |

| Polymer | Micro-Organism | Incubation Time | Reference |

|---|---|---|---|

| Poly(3-hydroxybutyrate-co-3-mercaptopropionate) | Schlegelella thermodepolymerans | 18 h | [111] |

| Poly(3-hydroxybutyrate) | Pseudomonas lemoignei | 60 h | [112] |

| Poly(3-hydroxybutyrate-co-3-mercaptopropionate) | Pseudomonas indicaK2 | 18 h | [111] |

| Poly(3-hydroxybutyrate) Poly(3-hydroxybutyrate-co-3-hydroxyvalerate) | Streptomyces sp. SNG9 | 30 days | [113] |

| Poly(3-hydroxybutyrate-co-3-hydroxypropionate) | Ralstonia pikettiiT1 | 18 h | [111] |

| Poly(3-hydroxybutyrate-co-3-hydroxypropionate) | Acidovorax sp. TP4 | 100 h | [114] |

| Poly(3-hydroxybutyrate) Poly(3-hydroxypropionate) Poly(4-hydroxybutyrate) Poly(ethylene succinate) Poly(ethylene adipate) | Alcaligenes faecalis | 120 days | [115] |

| Pseudomonas stutzeri | |||

| Comamonas acidovorans | |||

| Poly(3-hydroxybutyrate) | Alcaligenes faecalis | 20 h | [116] |

| Poly(3-hydroxybutyrate) | Schlegelella thermodepolymerans | 2–3 days | [117] |

| Caenibacterium thermophilum | |||

| Poly(3-hydroxybutyrate-co-3-hydroxyvalerate) | Clostridium botulinum | 14 weeks | [118] |

| Clostridium acetobutylicum | |||

| Poly (ε-caprolactone) | Clostridium botulinum | 14 weeks | [118] |

| Clostridium acetobutylicum | |||

| Fusarium solani | 60 days | [119] | |

| Poly (lactic acid) | Fusarium moniliforme | 40 weeks | [120] |

| Penicillium roquefort Amycolatopsis sp. | 14 days, 7 days | [121,122] | |

| Bacillus brevis | - | [123] | |

| Rhizopus delemer | - | [124] | |

| Polymer Blends | |||

| Starch/polyethylene | Aspergillus niger | 8 weeks | [125] |

| Penicillium funiculosm | |||

| Phanerochaete chrysosporium | |||

| Starch/polyester | Streptomyces Phanerochaete chyrsosporium | 8 weeks | [125] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Okolie, O.; Kumar, A.; Edwards, C.; Lawton, L.A.; Oke, A.; McDonald, S.; Thakur, V.K.; Njuguna, J. Bio-Based Sustainable Polymers and Materials: From Processing to Biodegradation. J. Compos. Sci. 2023, 7, 213. https://doi.org/10.3390/jcs7060213

Okolie O, Kumar A, Edwards C, Lawton LA, Oke A, McDonald S, Thakur VK, Njuguna J. Bio-Based Sustainable Polymers and Materials: From Processing to Biodegradation. Journal of Composites Science. 2023; 7(6):213. https://doi.org/10.3390/jcs7060213

Chicago/Turabian StyleOkolie, Obinna, Anuj Kumar, Christine Edwards, Linda A. Lawton, Adekunle Oke, Seonaidh McDonald, Vijay Kumar Thakur, and James Njuguna. 2023. "Bio-Based Sustainable Polymers and Materials: From Processing to Biodegradation" Journal of Composites Science 7, no. 6: 213. https://doi.org/10.3390/jcs7060213

APA StyleOkolie, O., Kumar, A., Edwards, C., Lawton, L. A., Oke, A., McDonald, S., Thakur, V. K., & Njuguna, J. (2023). Bio-Based Sustainable Polymers and Materials: From Processing to Biodegradation. Journal of Composites Science, 7(6), 213. https://doi.org/10.3390/jcs7060213