Effect of Surface Modification on the Properties of Buckwheat Husk—High-Density Polyethylene Biocomposites

Abstract

:1. Introduction

2. Experimental

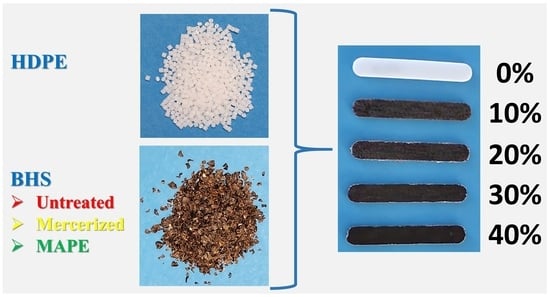

2.1. Materials

2.2. BHS Surface Treatment

2.3. Composites Preparation

2.3.1. Characterization

Morphology

Density/Hardness

2.3.2. Thermal Properties

Thermogravimetric Analysis (TGA)

Differential Scanning Calorimetry (DSC)

2.4. Mechanical Properties

3. Results and Discussion

3.1. Morphological Characterization

3.1.1. Density

3.1.2. Thermal Properties

Thermogravimetric Analysis (TGA)

3.2. Mechanical Properties

3.2.1. Hardness

3.2.2. Tensile Properties

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Schut, J.H. Wood is good for compounding, sheet & profile. Plast. Technol. 1999, 45, 46–52. [Google Scholar]

- Włoch, M.; Landowska, P. Preparation and Properties of Thermoplastic Polyurethane Composites Filled with Powdered Buckwheat Husks. Materials 2022, 15, 356. [Google Scholar] [CrossRef]

- Oksman, K.; Clemons, C. Mechanical properties and morphology of impact modified polypropylene–wood flour composites. J. Appl. Polym. Sci. 1998, 67, 1503–1513. [Google Scholar] [CrossRef]

- Simonsen, J.; Jacobsen, R.; Rowell, R. Wood-fiber reinforcement of styrene–maleic anhydride copolymers. J. Appl. Polym. Sci. 1998, 68, 1567–1573. [Google Scholar] [CrossRef]

- Taj, S.; Munawar, M.A.; Khan, S. Natural fiber-reinforced polymer composites. Pak. Acad. Sci. 2007, 44, 129–144. [Google Scholar] [CrossRef]

- Kamarudin, S.H.; Mohd Basri, M.S.; Rayung, M.; Abu, F.; Ahmad, S.; Norizan, M.N.; Osman, S.; Sarifuddin, N.; Desa, M.S.Z.M.; Abdullah, U.H.; et al. A Review on Natural Fiber Reinforced Polymer Composites (NFRPC) for Sustainable Industrial Applications. Polymers 2022, 14, 3698. [Google Scholar] [CrossRef]

- Kim, S.J.; Sohn, H.B.; Suh, J.T.; Kim, G.H.; Hong, S.Y.; Chang, D.C.; Kim, K.D.; Koo, B.C.; Kim, Y.H. Domestic and overseas status of buckwheat production and future trends. J. Korean Soc. Int. Agric. 2018, 29, 226–233. [Google Scholar] [CrossRef]

- Joka Yildiz, M.; Cwalina, P.; Obidziński, S. A comprehensive study of buckwheat husk co-pelletization for utilization via combustion. Biomass Convert. Biorefinery 2022, 1–16. [Google Scholar] [CrossRef]

- Shaikhiev, I.G.; Sverguzova, S.V.; Galimova, R.; Grechina, A.S. Using wastes of buckwheat processing as sorption materials for the removal of pollutants from aqueous media: A review. IOP Conf. Ser. Mater. Sci. Eng. 2020, 945, 012044. [Google Scholar] [CrossRef]

- Zhang, Q. Preparation of Porous Carbon from Buckwheat Husk and its Electrochemical Properties. Int. J. Electrochem. Sci. 2022, 17, 221145. [Google Scholar] [CrossRef]

- Yu, K.; Zhang, Z.; Liang, J. Natural biomass-derived porous carbons from buckwheat hulls used as anode for lithium-ion batteries. Diam. Relat. Mater. 2021, 119, 108553. [Google Scholar] [CrossRef]

- Andrzejewski, J.; Barczewski, M.; Szostak, M. Injection Molding of Highly Filled Polypropylene-based Biocomposites. Buckwheat Husk and Wood Flour Filler: A Comparison of Agricultural and Wood Industry Waste Utilization. Polymers 2019, 11, 1881. [Google Scholar] [CrossRef]

- Salikhov, R.B.; Bazunova, M.V.; Bazunova, A.; Salikhov, T.R.; Zakharov, V.E. Study of thermal properties of biodegradable composite materials based on recycled polypropylene. Lett. Mater. 2018, 8, 485–488. [Google Scholar] [CrossRef]

- Danchenko, Y.; Kariev, A.; Lebedev, V.S.; Barabash, E.; Obizhenko, T.N. Physic-echanical Properties of Composites Based on Secondary Polypropylene and Dispersed of Plant Waste. Mater. Sci. Forum 2020, 1006, 227–232. [Google Scholar] [CrossRef]

- Hejna, A.; Barczewski, M.; Kosmela, P.; Mysiukiewicz, O. Comparative Analysis of the Coffee and Cocoa Industry By-Products on the Performance of Polyethylene-Based Composites. Waste Biomass Valor 2023, 14, 2691–2706. [Google Scholar] [CrossRef]

- Mohanty, A.K.; Krawczak, A.M.; Wesoły, K.; Szostak, M. Rotational molding of biocomposites with addition of buckwheat husk filler. Structure-property correlation assessment for materials based on polyethylene (PE) and poly(lactic acid) PLA. Compos. Part B-Eng. 2020, 202, 108410. [Google Scholar] [CrossRef]

- Jałbrzykowski, M.; Oksiuta, Z.; Obidziński, S.; Czyzewska, U.; Osiecki, T.; Kroll, L.; Joka, M. Assessment of innovative PLA biopolymer compositions with plant waste fillers. Eng. Fail. Anal. 2022, 139, 106496. [Google Scholar] [CrossRef]

- Vašícek, A.; Lenfeld, P.; Behalek, L. Degradation of Polylactic Acid Polymer and Biocomposites Exposed to Controlled Climatic Ageing: Mechanical and Thermal Properties and Structures. Polymers 2023, 15, 2977. [Google Scholar] [CrossRef]

- Strąkowska, A.; Miedzińska, K.; Sylwia, C. Buckwheat Hulls/Perlite as an Environmentally Friendly Flame-Retardant System for Rigid Polyurethane Foams. Polymers 2023, 15, 1913. [Google Scholar] [CrossRef]

- Gotlib, E.M.; Valeeva, A.R.; Yamaleeva, E.S.; Tverdov, I.D.; Dolmatov, A.V. Comparison of the modifying effect of rice ash and buckwheat husk in epoxy antifriction coatings. Yugra State Univ. Bull. 2021, 17, 9–15. [Google Scholar] [CrossRef]

- Gotlib, E.M.; Schelton, R.; Valeeva, A.R.; Galimov, E.R.; Sokolova, A.L. Epoxy Materials Filled with Buckwheat Husk Ash. Proc. FORM 2022, 55–64. [Google Scholar] [CrossRef]

- Kozhusko, V.V.; Bukharov, S.N.; Alexiev, A.R.; Iankov, R. Buckwheat husk and epoxy resin based composites for noise abating. J. Akust. 2021, 40, 40. [Google Scholar] [CrossRef]

- Rodríguez, C.A.; Medina, J.A.; Reinecke, H. New Thermoplastic Materials Reinforced with Cellulose Based Fibers. J. Appl. Polym. Sci. 2003, 90, 3466–3472. [Google Scholar] [CrossRef]

- Anbupalani, M.S.; Venkatachalam, C.D.; Rajasekar, R. Influence of coupling agent on altering the reinforcing efficiency of natural fibre-incorporated polymers—A review. J. Reinfor. Plast. Compos. 2020, 39, 520–544. [Google Scholar] [CrossRef]

- Cisneros-López, E.O.; González-López, M.E.; Pérez-Fonseca, A.A.; González-Núñez, R.; Rodrigue, D.; Robledo-Ortíz, J.R. Effect of fiber content and surface treatment on the mechanical properties of natural fiber composites produced by rotomolding. Compos. Interface 2016, 24, 35–53. [Google Scholar] [CrossRef]

- Pérez-Fonseca, A.A.; Arellano, M.; Rodrigue, D.; González-Núñez, R.; Robledo-Ortíz, J.R. Effect of coupling agent content and water absorption on the mechanical properties of coir-agave fibers reinforced polyethylene hybrid composites. Polym. Compos. 2015, 37, 3015–3024. [Google Scholar] [CrossRef]

- Yang, H.; Yan, R.; Chen, H.; Zheng, C.; Lee, D.H.; Liang, D.T. In-Depth Investigation of Biomass Pyrolysis Based on Three Major Components: Hemicellulose, Cellulose and Lignin. Energy Fuels 2006, 20, 388–393. [Google Scholar] [CrossRef]

- Lütke, S.F.; Igansi, A.V.; Pegoraro, L.; Pinto, L.; Cadaval, T.R. Preparation of activated carbon from black wattle bark waste and its application for phenol adsorption. J. Environ. Chem. Eng. 2019, 7, 103396. [Google Scholar] [CrossRef]

- Kuram, E. Advances in development of green composites based on natural fibers: A review. Emergent Mater. 2021, 5, 811–831. [Google Scholar] [CrossRef]

- Ābele, A.; Merijs-Meri, R.; Žiganova, M.; Iesalniece, Z.; Bochkov, I. Effect of agricultural biomass residues on the properties of recycled polypropylene/polyethylene composites. Polymers 2023, 15, 2672. [Google Scholar] [CrossRef]

| BHS Content (wt.) | Untreated BHS (UC) | Mercerized BHS (MEC) | MAPE-Treated BHS (MAC) |

|---|---|---|---|

| 10 | 997 | 955 | 979 |

| 20 | 998 | 970 | 1013 |

| 30 | 1019 | 1052 | 1018 |

| 40 | 1082 | 1070 | 1103 |

| 50 | 1145 | 1090 | 1188 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vázquez-Fletes, R.C.; Sadeghi, V.; González-Núñez, R.; Rodrigue, D. Effect of Surface Modification on the Properties of Buckwheat Husk—High-Density Polyethylene Biocomposites. J. Compos. Sci. 2023, 7, 429. https://doi.org/10.3390/jcs7100429

Vázquez-Fletes RC, Sadeghi V, González-Núñez R, Rodrigue D. Effect of Surface Modification on the Properties of Buckwheat Husk—High-Density Polyethylene Biocomposites. Journal of Composites Science. 2023; 7(10):429. https://doi.org/10.3390/jcs7100429

Chicago/Turabian StyleVázquez-Fletes, Roberto C., Vahid Sadeghi, Rubén González-Núñez, and Denis Rodrigue. 2023. "Effect of Surface Modification on the Properties of Buckwheat Husk—High-Density Polyethylene Biocomposites" Journal of Composites Science 7, no. 10: 429. https://doi.org/10.3390/jcs7100429

APA StyleVázquez-Fletes, R. C., Sadeghi, V., González-Núñez, R., & Rodrigue, D. (2023). Effect of Surface Modification on the Properties of Buckwheat Husk—High-Density Polyethylene Biocomposites. Journal of Composites Science, 7(10), 429. https://doi.org/10.3390/jcs7100429