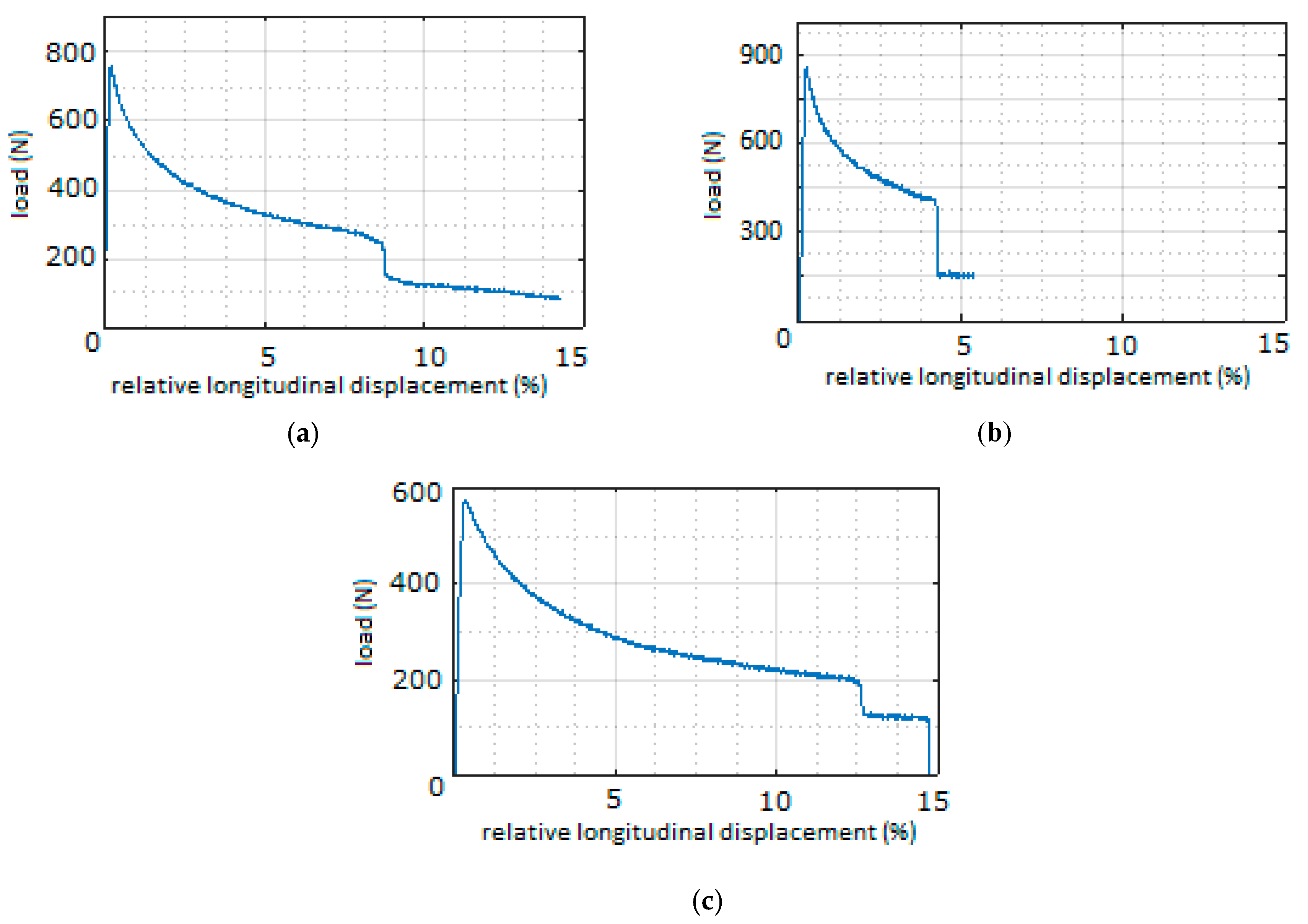

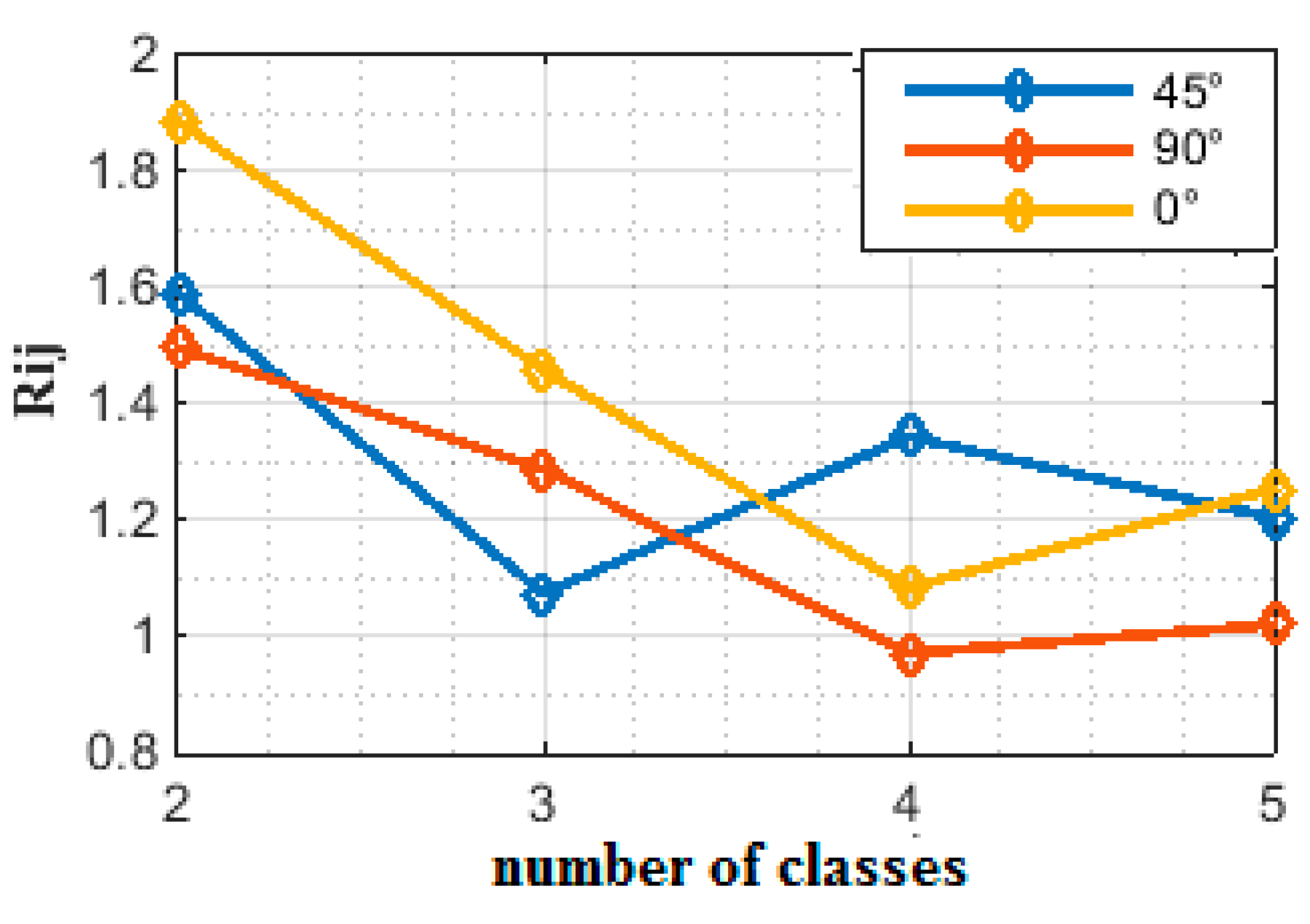

3.5.3. Analysis of 90° Specimen Behavior

According to

Figure 11, it is concluded that the optimal number of classes is equal to 4.

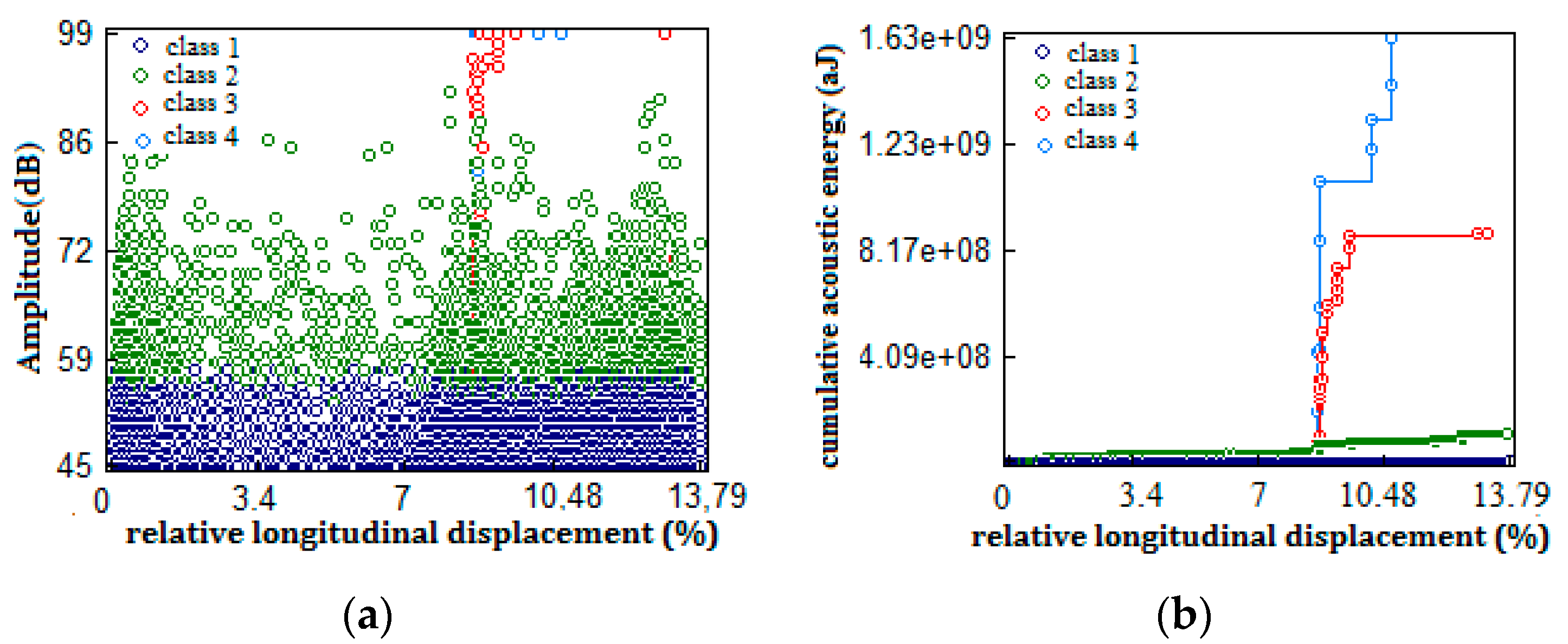

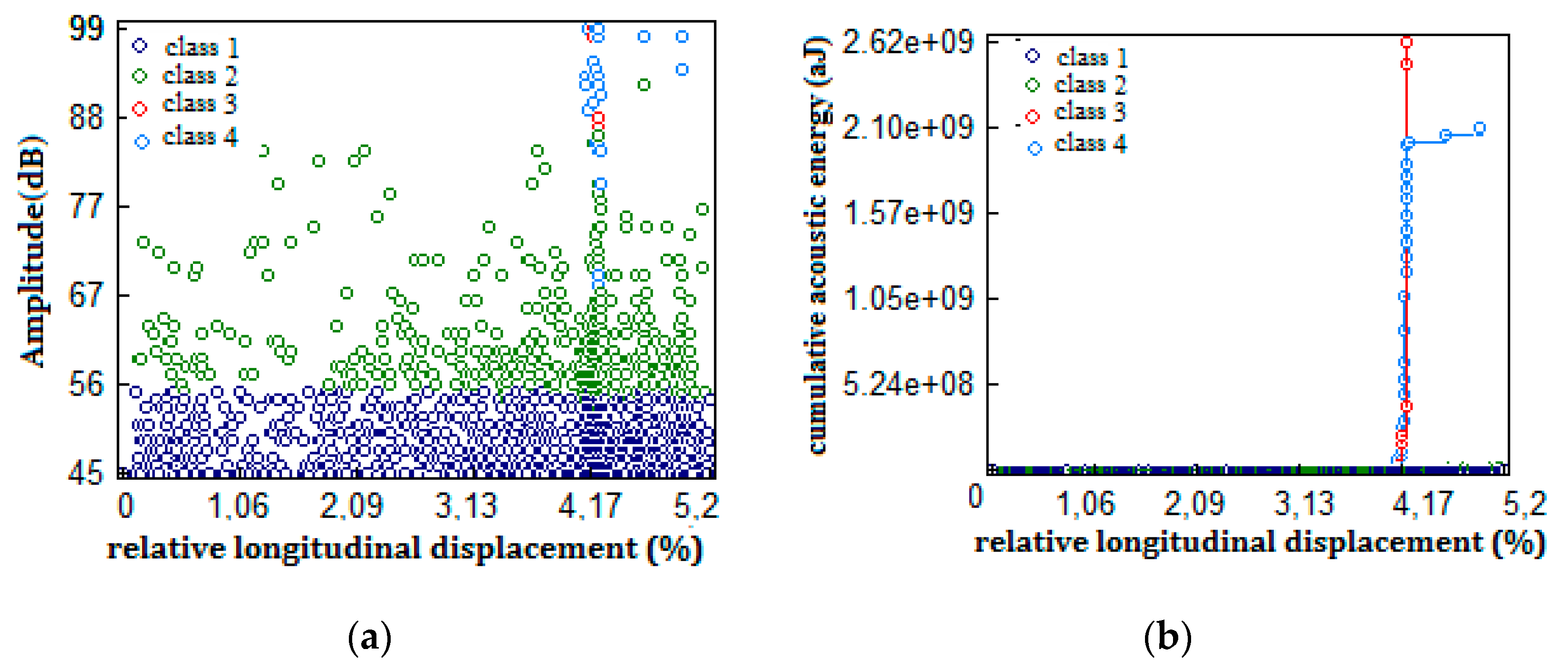

Figure 13a shows that classes 1 and 2 are distinct with amplitude ranges specific to each class while a large overlap is observed between classes 2, 3 and 4 (

Table 5) making assignment of damage mechanisms by referring only to the uncertain amplitude. It is by analyzing the other most discriminating parameters of the EA signals that the class labelling will have to be done.

On the other side,

Figure 13b shows the evolution of the acoustic activity of the different classes. Thus, we note that the classes 3 and 4 that occur late, near the end of the test, are very energetic, developing almost all the energy released (

Table 5). It can be concluded that these last two are high intensity damage modes that caused a major degradation of the sample while the first two classes are very low energy.

3.5.6. Synthesis and Proposal of Attribution to the Mechanisms of Damage

A “spiderweb” representation was chosen to compare the average characteristics of the different signal classes obtained for the three categories of tested specimens and for the five chosen descriptors. Acoustic signatures of the various classes are quite similar from one specimen type to another. Then, we suppose that a class obtained in such configuration corresponds to the same class obtained in another configuration (

Figure 16).

Thus, it is deduced from

Figure 16 that the signatures of classes 1 and 2 are quite similar for the three types of specimens and it can be assumed that they represent the same mechanism of damage. Likewise, for class 3 we note that the average characteristics are similar for the 3 configurations which leads us to attribute them to the same phenomenon. The last class identified only for the 0° et 90° configuration, are considered to be representative of the same mechanism of damage despite some dispersion in the orders of magnitude of the energy of the signals.

The approach for identifying the signature of the damage mechanisms was established based on the representative and conventional waveforms of the various damage modes of the composites (

Table 7) and also on the average characteristics of the different descriptors (

Figure 16). For the three types of specimens, the class 1 signals have the lowest amplitude range. These signals are characterized by a slow average rise time and a slow damping compared to the other types as well as a resonant signal shape, a short duration and a low absolute energy. Referring to the literature [

15,

16,

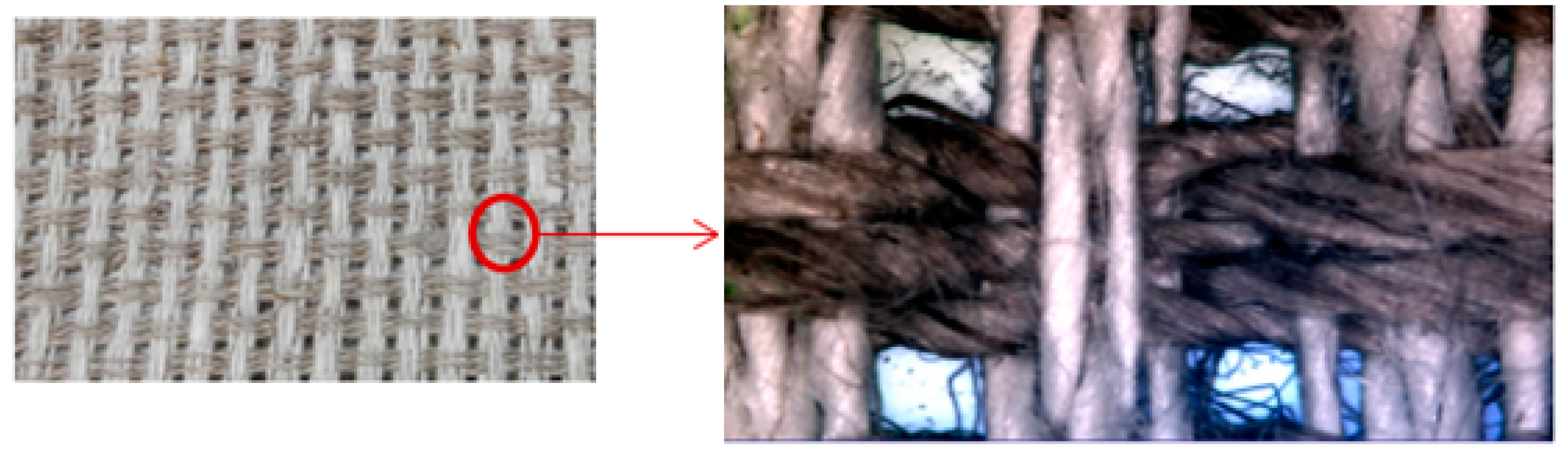

17], we can conclude that these signals correspond to the mechanism of matrix cracking. Since the mechanical properties of the matrix are inferior to that of the reinforcement, the initiation and the development of the damages begin mainly by the matrix cracking. Microcracks are created and propagate from the matrix towards the whole structure causing in its path the creation of other damages. Note that the specific architecture of the fabric presented by an initially high void rate (35% of void rate) and a low compaction capacity favours the creation of porosities. This last is a source of stress concentration and propagation of matrix cracks.

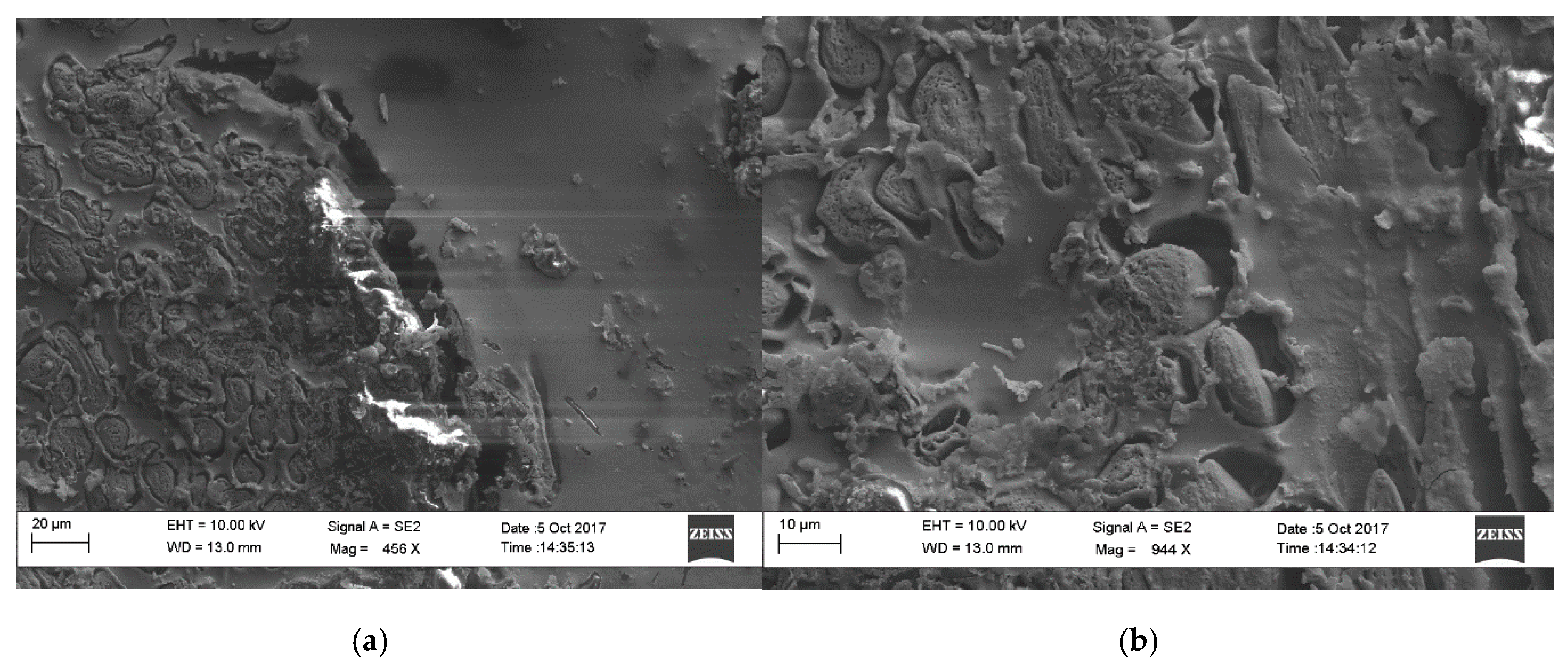

Concerning class 2 signals, the signal shape is of the pulse type, with short rise times, which, in agreement with the literature [

22], can be associated with the reinforcement/matrix interface decohesion mechanism. Thus, the microscopic observations established in 4.3 (

Figure 7 and

Figure 8) shows fibre/matrix decohesions. The following scenario can be assumed for class 2, decohesions begin to form at the fibre/matrix interface progressively, whether fibres on the periphery of the wire or on the inside (we remember that each wire is composed of several fibres). These decohesions start very early and spread on the edge of the wire ending up creating decohesion between wires and matrix.

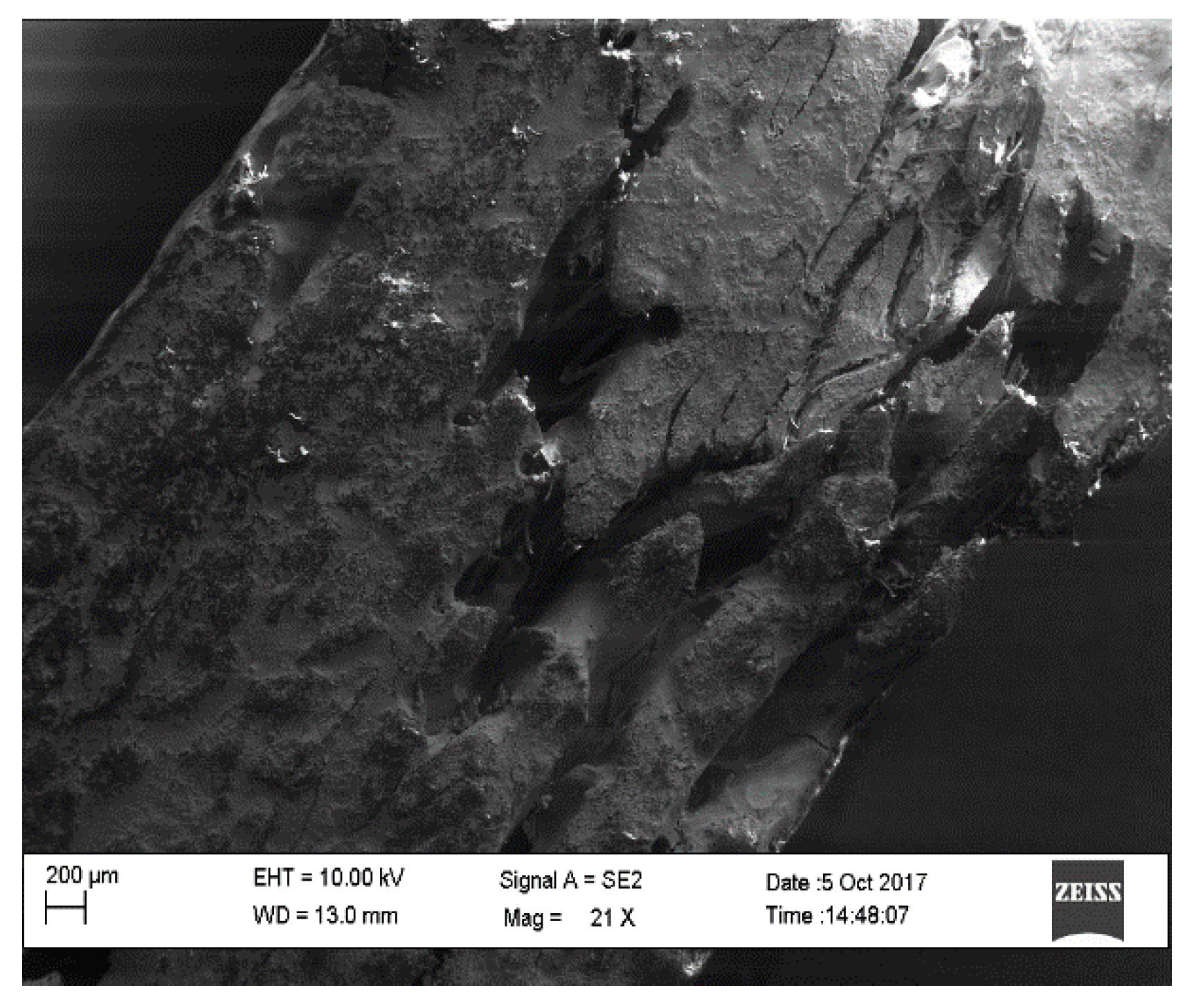

Class 3 for the 3 tested direction, generate signals of high amplitude and relatively high liberated energy. These signals are detected later and are associated with the breaking of the fibres and precisely those of the outer layers as shown by the microscopic observations (

Figure 10). The weak adhesion between reinforcement and matrix (hydrophilic nature of the reinforcement against hydrophobic of the matrix) led to a weak interface. The latter coupled with a high porosity rate in the composite leads to a charge transfer that is not properly ensured and to an anticipated rupture of certain fibers.

Regarding the class 4 signals for 0° and 90° specimens, they appear later, anticipated by the initiation of matrix cracking and interfacial decohesion, it is mainly the accentuation of these two mechanisms which gave birth to this new damage. The signals that correspond to those mechanisms are characterized by very long durations, slow rise times and an impulse waveform, they are quite energetic with a fairly wide range of amplitude. From these properties, and in agreement with

Table 7, this class can be attributed to the delamination mechanism. In fact, the low chemical compatibility between the flax fabric and the matrix leads to a poor adhesion between them. Subsequently this weak interface will promote the development of delamination [

23] in addition to the fact that the fibre/matrix decohesion leads to a concentration of stress at the interface which becomes the privileged site of the initiation of the damage [

24]. These damages then propagate along the fibres in the form of intra-laminar cracks and develop in the adjacent folds or at the interface of these folds causing the appearance of delamination [

25]. This type of damage largely contributes to the degradation of the mechanical properties of the structure, which results in a relatively large released acoustic energy.

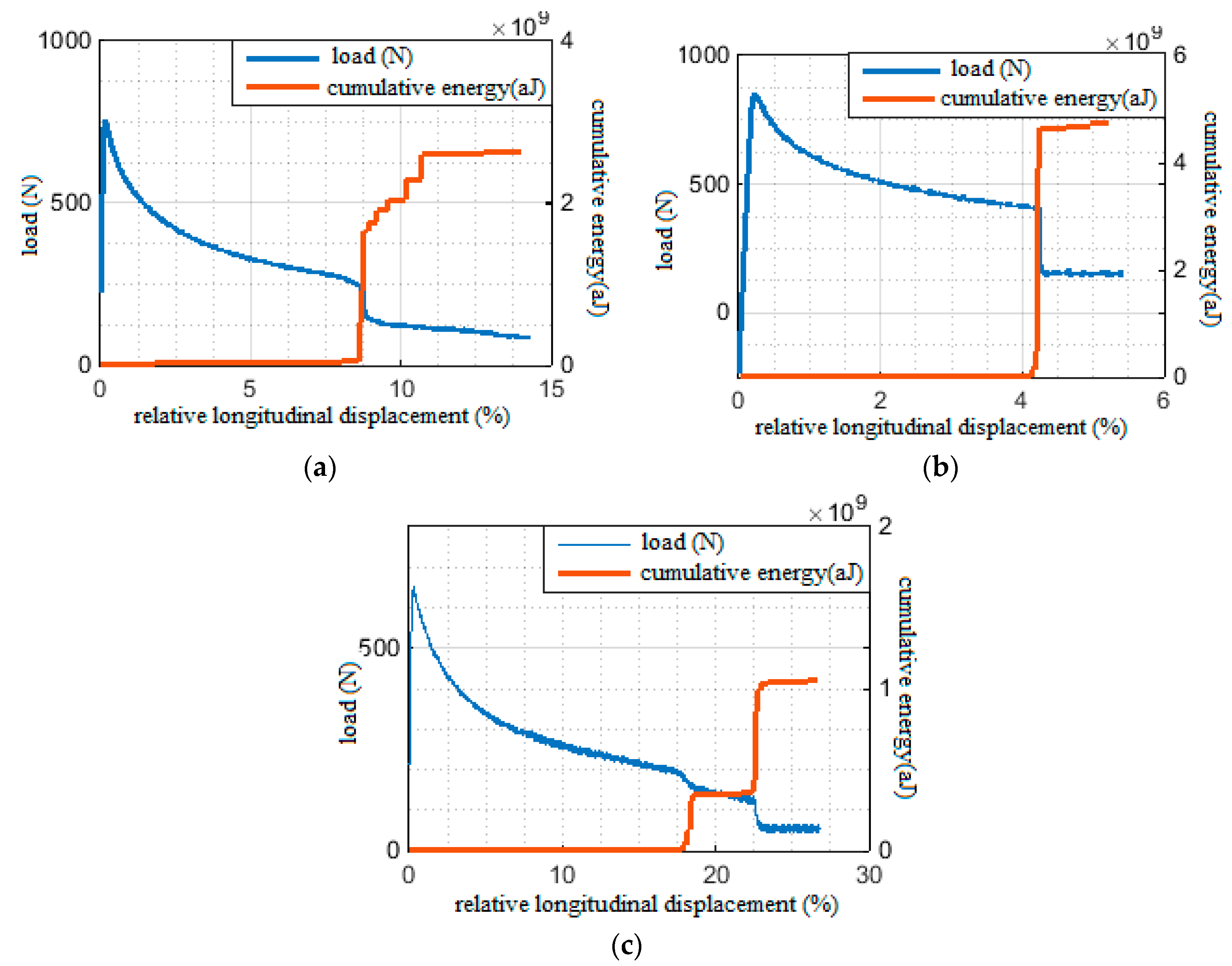

Figure 12b,

Figure 13b present energy jumps, showing that the appearance of delamination did not occur in a uniform and progressive manner, but in a series of jerks. The delamination appears at the same time as the rupture of the external folds for these 2 configurations (

Figure 12b and

Figure 13b). For the 45° configuration, this phenomenon was not noticed which can be explained by stopping the test at the appearance of first cracks on the external faces and due to the fact that the kinetics of development of damage is very slow for this direction, so, it is quite possible that the delamination was posterior to cracks.