Mechanical Properties of a Unidirectional Basalt-Fiber/Epoxy Composite

Abstract

1. Introduction

2. Materials and Methods

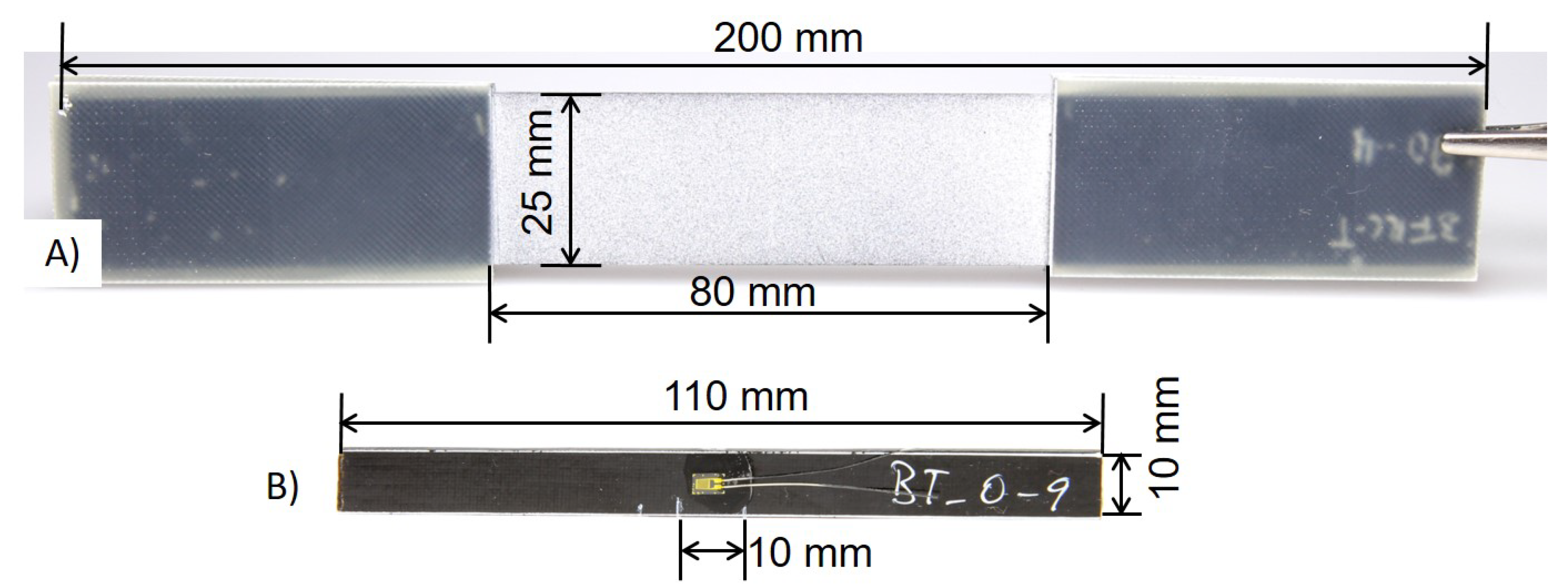

2.1. Material and Specimen Geometry

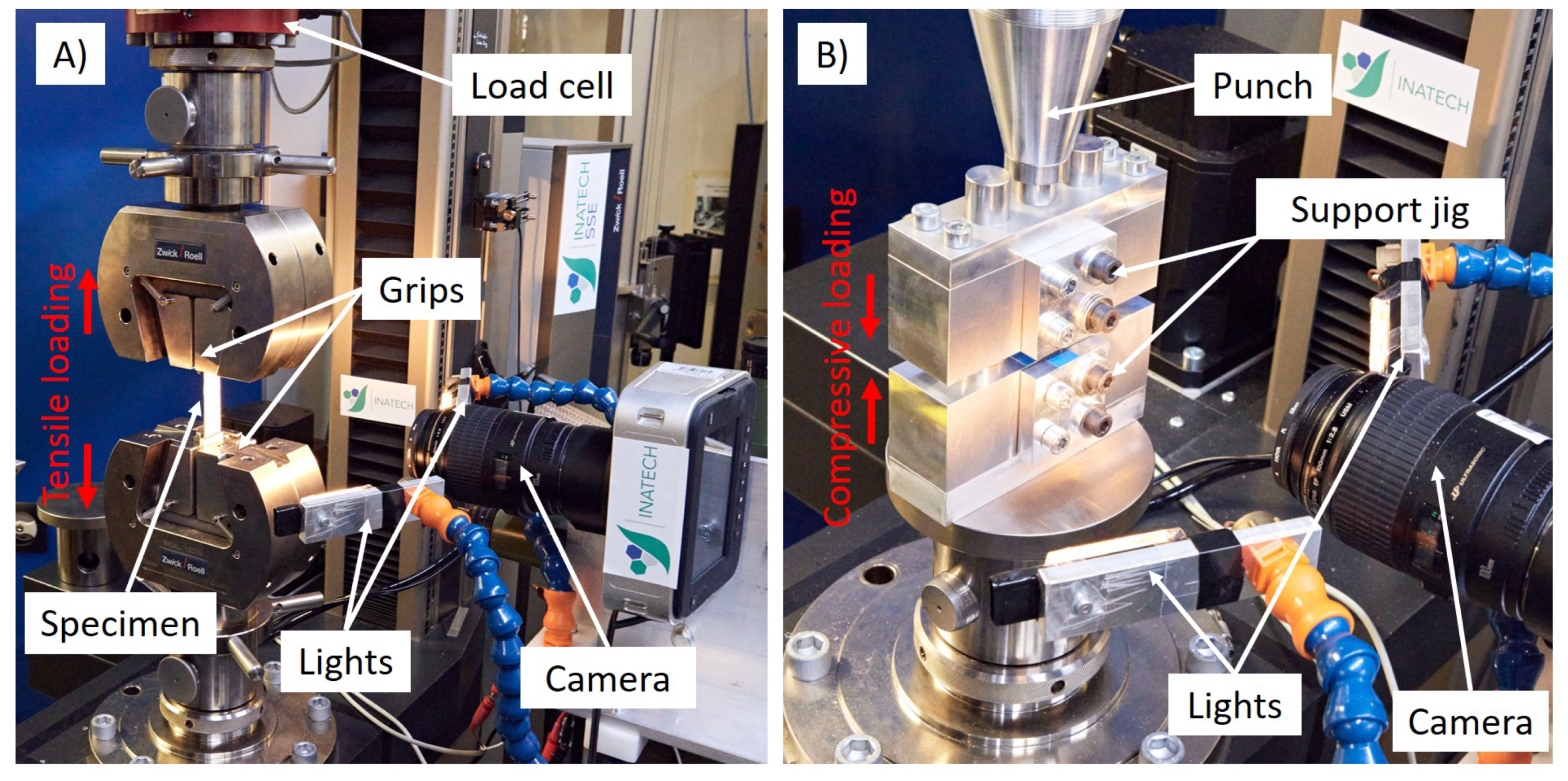

2.2. Mechanical Characterization Setup

3. Results

3.1. Mechanical Characterization of BFRP

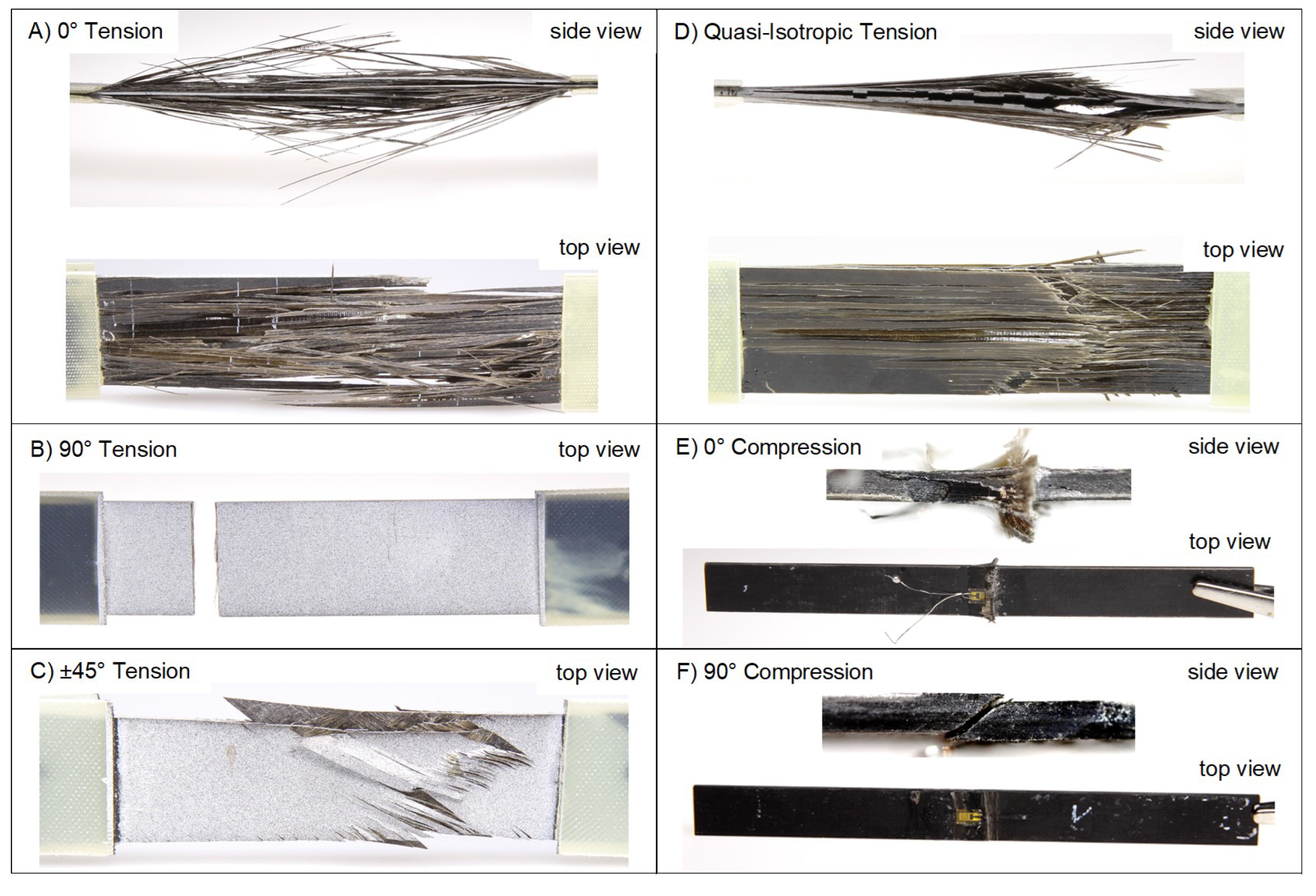

3.1.1. Tensile Tests Parallel to the Fiber Direction—0

3.1.2. Tensile Tests Perpendicular to the Fiber Direction—90

3.1.3. ±45 Tension Test—In-Plane Shear Modulus and Shear Strength

3.1.4. Quasi-Isotropic Laminate Configuration—Tensile Properties

3.1.5. Compressive Properties Parallel to the Fiber Direction—0

3.1.6. Compressive 90 Properties Perpendicular to the Fiber Direction

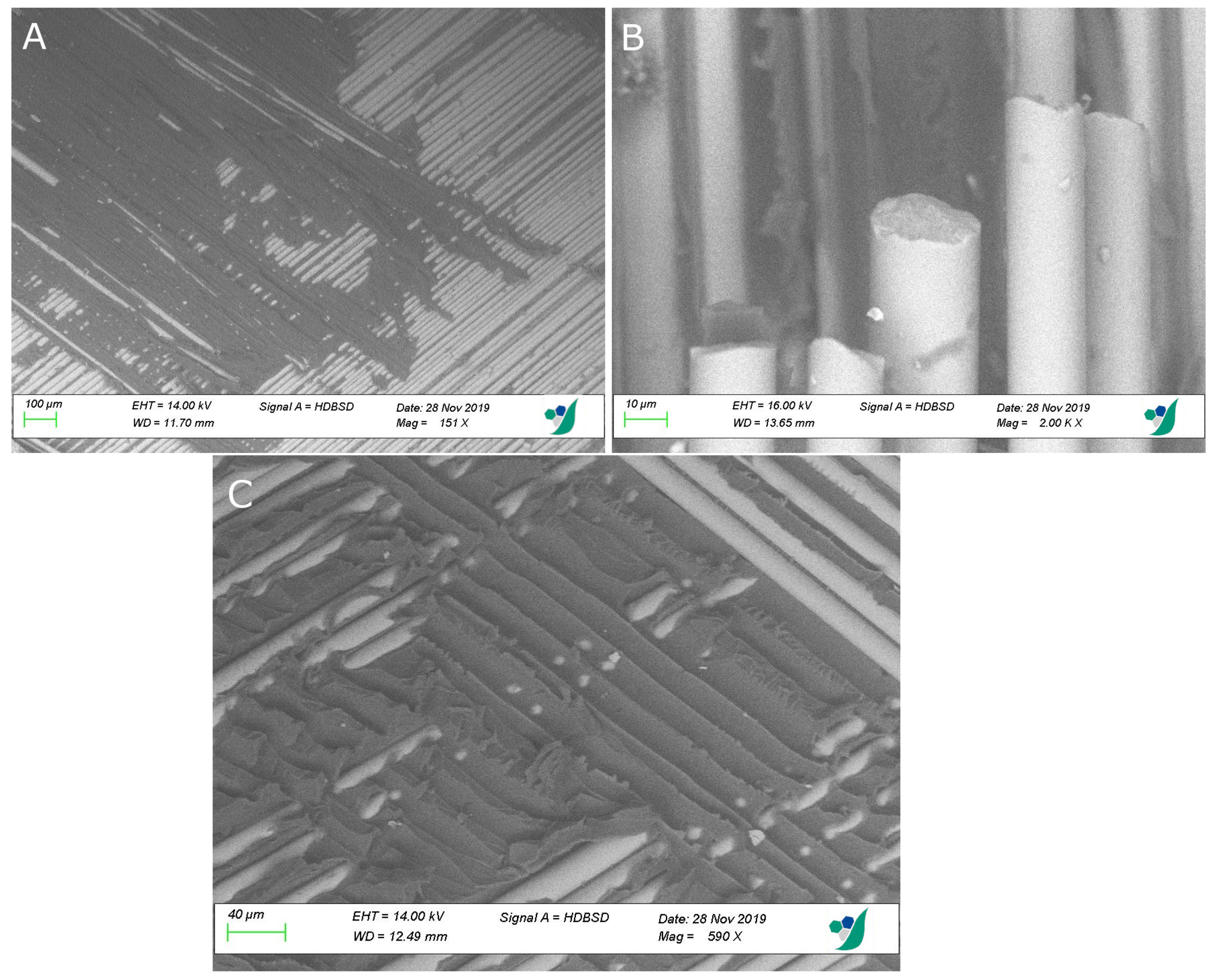

3.2. SEM Observations

4. Discussion

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Dorigato, A.; Pegoretti, A. Fatigue Resistance of Basalt Fibers-Reinforced Laminates. J. Compos. Mater. 2012, 46, 1773–1785. [Google Scholar] [CrossRef]

- Lopresto, V.; Leone, C.; De Iorio, I. Mechanical Characterisation of Basalt Fibre Reinforced Plastic. Compos. Part B Eng. 2011, 42, 717–723. [Google Scholar] [CrossRef]

- Yao, Y.; Zhu, D.; Zhang, H.; Li, G.; Mobasher, B. Tensile Behaviors of Basalt, Carbon, Glass, and Aramid Fabrics under Various Strain Rates. J. Mater. Civ. Eng. 2016, 28, 04016081. [Google Scholar] [CrossRef]

- Dhand, V.; Mittal, G.; Rhee, K.Y.; Park, S.J.; Hui, D. A Short Review on Basalt Fiber Reinforced Polymer Composites. Compos. Part B Eng. 2015, 73, 166–180. [Google Scholar] [CrossRef]

- Colombo, C.; Vergani, L.; Burman, M. Static and Fatigue Characterisation of New Basalt Fibre Reinforced Composites. Compos. Struct. 2012, 94, 1165–1174. [Google Scholar] [CrossRef]

- Lapena, M.H.; Marinucci, G.; Lapena, M.H.; Marinucci, G. Mechanical Characterization of Basalt and Glass Fiber Epoxy Composite Tube. Mater. Res. 2017, 21. [Google Scholar] [CrossRef]

- Wu, G.; Wang, X.; Wu, Z.; Dong, Z.; Zhang, G. Durability of basalt fibers and composites in corrosive environments. J. Compos. Mater. 2015, 49, 873–887. [Google Scholar] [CrossRef]

- Militký, J.; Kovačič, V.; Rubnerová, J. Influence of Thermal Treatment on Tensile Failure of Basalt Fibers. Eng. Fract. Mech. 2002, 69, 1025–1033. [Google Scholar] [CrossRef]

- Liu, Q.; Shaw, M.T.; Parnas, R.S.; McDonnell, A.M. Investigation of Basalt Fiber Composite Aging Behavior for Applications in Transportation. Polym. Compos. 2006, 27, 475–483. [Google Scholar] [CrossRef]

- Overkamp, T.; Mahltig, B.; Kyosev, Y. Strength of Basalt Fibers Influenced by Thermal and Chemical Treatments. J. Ind. Text. 2018, 47, 815–833. [Google Scholar] [CrossRef]

- Hao, L.; Yu, W. Evaluation of Thermal Protective Performance of Basalt Fiber Nonwoven Fabrics. J. Therm. Anal. Calorim. 2010, 100, 551–555. [Google Scholar] [CrossRef]

- Meyer, L.; Schulte, K.; Grove-Nielsen, E. CFRP-Recycling Following a Pyrolysis Route: Process Optimization and Potentials. J. Compos. Mater. 2009, 43, 1121–1132. [Google Scholar] [CrossRef]

- Deák, T.; Czigány, T. Chemical Composition and Mechanical Properties of Basalt and Glass Fibers: A Comparison. Text. Res. J. 2009, 79, 645–651. [Google Scholar] [CrossRef]

- Fiore, V.; Scalici, T.; Di Bella, G.; Valenza, A. A Review on Basalt Fibre and Its Composites. Compos. Part B Eng. 2015, 74, 74–94. [Google Scholar] [CrossRef]

- Lebedev, M.P.; Startsev, O.V.; Kychkin, A.K. The effects of aggressive environments on the mechanical properties of basalt plastics. Heliyon 2020, 6, e03481. [Google Scholar] [CrossRef] [PubMed]

- Davies, P.; Verbouwe, W. Evaluation of Basalt Fibre Composites for Marine Applications. Appl. Compos. Mater. 2018, 25, 299–308. [Google Scholar] [CrossRef]

- ASTM. D2101: Standard Test Methods for Tensile Properties of Single Man-Made Textile Fibers Taken from Yarns And Tows; American Society of Testing and Materials: West Conshohocken, PA, USA, 1994. [Google Scholar]

- Varley, R.J.; Tian, W.; Leong, K.H.; Leong, A.Y.; Fredo, F.; Quaresimin, M. The effect of surface treatments on the mechanical properties of basalt-reinforced epoxy composites. Polym. Compos. 2013, 34, 320–329. [Google Scholar] [CrossRef]

- ASTM. D3039: Standard Test Method for Tensile Properties of Polymer Matrix Composite Materials; American Society of Testing and Materials: West Conshohocken, PA, USA, 2000. [Google Scholar]

- ISO. 14126: 1999-Fibre-Reinforced Plastic Composites. Determination of Compressive Properties in the In-Plane Direction; International Organization for Standardization: Geneva, Switzerland, 1999. [Google Scholar]

- ISO. 14129: Fibre Reinforced Plastics Composite-Determination of the In-Plane Shear Stress/Shear Strain Response, Including the In-Plane Shear Modulus and Strength by the +-45 Tension Test Method; British Standard Institute: London, UK, 1998. [Google Scholar]

- Ganzenmüller, G.C.; Plappert, D.; Trippel, A.; Hiermaier, S. A Split-Hopkinson Tension Bar study on the dynamic strength of basalt-fibre composites. Compos. Part B Eng. 2019, 171, 310–319. [Google Scholar] [CrossRef]

- Sathishkumar, T.; Satheeshkumar, S.; Naveen, J. Glass Fiber-Reinforced Polymer Composites—A Review. J. Reinf. Plast. Compos. 2014, 33, 1258–1275. [Google Scholar] [CrossRef]

- ASTM. D3518: Standard Test Method for In-Plane Shear Response of Polymer Matrix Composite Materials by Tensile Test of a 45 Laminate; American Society of Testing and Materials: West Conshohocken, PA, USA, 2001. [Google Scholar]

- Carlsson, L.A.; Adams, D.F.; Pipes, R.B. Experimental Characterization of Advanced Composite Materials; CRC Press: Boca Raton, FL, USA, 2014. [Google Scholar] [CrossRef]

- Zhou, H.W.; Yi, H.Y.; Gui, L.L.; Dai, G.M.; Peng, R.D.; Wang, H.W.; Mishnaevsky, L. Compressive Damage Mechanism of GFRP Composites under Off-Axis Loading: Experimental and Numerical Investigations. Compos. Part B Eng. 2013, 55, 119–127. [Google Scholar] [CrossRef]

- Schoßig, M. Schädigungsmechanismen in faserverstärkten Kunststoffen: Quasistatische und Dynamische Untersuchungen; Vieweg+Teubner Verlag: Berlin, Geramny, 2011. [Google Scholar] [CrossRef]

- Schürmann, H. Konstruieren mit Faser-Kunststoff-Verbunden, 2nd ed.; VDI-Buch; Springer: Berlin/Heidelberg, Germany, 2007. [Google Scholar]

- Hausrath, R.L.; Longobardo, A.V. High-Strength Glass Fibers and Markets. In Fiberglass and Glass Technology: Energy-Friendly Compositions and Applications; Wallenberger, F.T., Bingham, P.A., Eds.; Springer US: Boston, MA, USA, 2010; pp. 197–225. [Google Scholar] [CrossRef]

- Daniel, I.M.; Ishai, O. Engineering Mechanics of Composite Materials, 2nd ed.; Oxford University Press: New York, NY, USA, 2006. [Google Scholar]

- Burgoyne, C.J.; Byars, E.; Guadagnini, M.; Manfredi, G.; Neocleous, K.; Pilakoutas, K.; Taerwe, L.; Taranu, N.; Tepfers, R.; Weber, A.; et al. FRP Reinforcement in RC Structures; fib Bulletin No. 40; The International Federation for Structural Concrete: Lausanne, Switzerland, 2007. [Google Scholar] [CrossRef]

- Robert, C.; Pecur, T.; McCarthy, E.D.; Brádaigh, C. Tidal Turbine Blade Composites Using Basalt Fibre Reinforced Powder Epoxy; Engineers Australia: Barton, Australia, 2019; p. 3687. [Google Scholar]

| Tension Specimen | Length | Width | Thickness | L0 | Layers |

|---|---|---|---|---|---|

| mm | mm | mm | – | ||

| 0° | 200.0 | 25.0 | 2.0 | 80.0 | 10 |

| 90° | 200.0 | 25.0 | 2.0 | 80.0 | 10 |

| shear | 200.0 | 25.0 | 2.0 | 80.0 | 10 |

| QI | 200.0 | 25.0 | 1.6 | 80.0 | 8 |

| Compression Specimen | |||||

| 0° | 110.0 | 10.0 | 2.0 | 10.0 | 10 |

| 90° | 110.0 | 10.0 | 2.0 | 10.0 | 10 |

| Tensile Properties Standard Size | ||||

|---|---|---|---|---|

| Ultimate Tensile Strength 0° | 1310 | ± | 34 | MPa |

| Ultimate Tensile Strain 0° | 3.1 | ± | 0.1 | % |

| Ultimate Tensile Strength 90° | 49.8 | ± | 5.5 | MPa |

| Ultimate Tensile Strain 90° | 0.47 | ± | 0.09 | % |

| Ultimate Tensile Strength QI | 441 | ± | 33 | MPa |

| Ultimate Tensile Strain QI | 2.8 | ± | 0.2 | % |

| Young’s Modulus 0° | 44.3 | ± | 2.3 | GPa |

| Young’s Modulus 90° | 11.9 | ± | 1.2 | GPa |

| Effective Y. Modulus QI | 20.3 | ± | 1.6 | GPa |

| Ultimate Shear Strength | 50.5 | ± | 2.5 | MPa |

| Ultimate Shear Strain | 0.05 | ± | - | % |

| Shear Modulus | 3.73 | ± | 0.29 | GPa |

| Major Poisson’s Ratio | 0.27 | ± | 0.03 | - |

| Compressive Properties Standard Size | ||||

| Ultimate Compressive Strength 0° | 776 | ± | 25 | MPa |

| Ultimate Compressive Strain 0° | −1.7 | ± | 0.07 | % |

| Ultimate Compressive Strength 90° | 135 | ± | 6 | MPa |

| Ultimate Compressive Strain 90° | −1.6 | ± | 0.6 | % |

| Compressive Y. Modulus 0° | 46.2 | ± | 2.4 | GPa |

| Compressive Y. Modulus 90° | 15.2 | ± | 1.8 | GPa |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Plappert, D.; Ganzenmüller, G.C.; May, M.; Beisel, S. Mechanical Properties of a Unidirectional Basalt-Fiber/Epoxy Composite. J. Compos. Sci. 2020, 4, 101. https://doi.org/10.3390/jcs4030101

Plappert D, Ganzenmüller GC, May M, Beisel S. Mechanical Properties of a Unidirectional Basalt-Fiber/Epoxy Composite. Journal of Composites Science. 2020; 4(3):101. https://doi.org/10.3390/jcs4030101

Chicago/Turabian StylePlappert, David, Georg C. Ganzenmüller, Michael May, and Samuel Beisel. 2020. "Mechanical Properties of a Unidirectional Basalt-Fiber/Epoxy Composite" Journal of Composites Science 4, no. 3: 101. https://doi.org/10.3390/jcs4030101

APA StylePlappert, D., Ganzenmüller, G. C., May, M., & Beisel, S. (2020). Mechanical Properties of a Unidirectional Basalt-Fiber/Epoxy Composite. Journal of Composites Science, 4(3), 101. https://doi.org/10.3390/jcs4030101