Enhancing Strength and Toughness of Hierarchical Composites through Optimization of Position and Orientation of Nanotubes: A Computational Study

Abstract

1. Introduction

2. Methodology

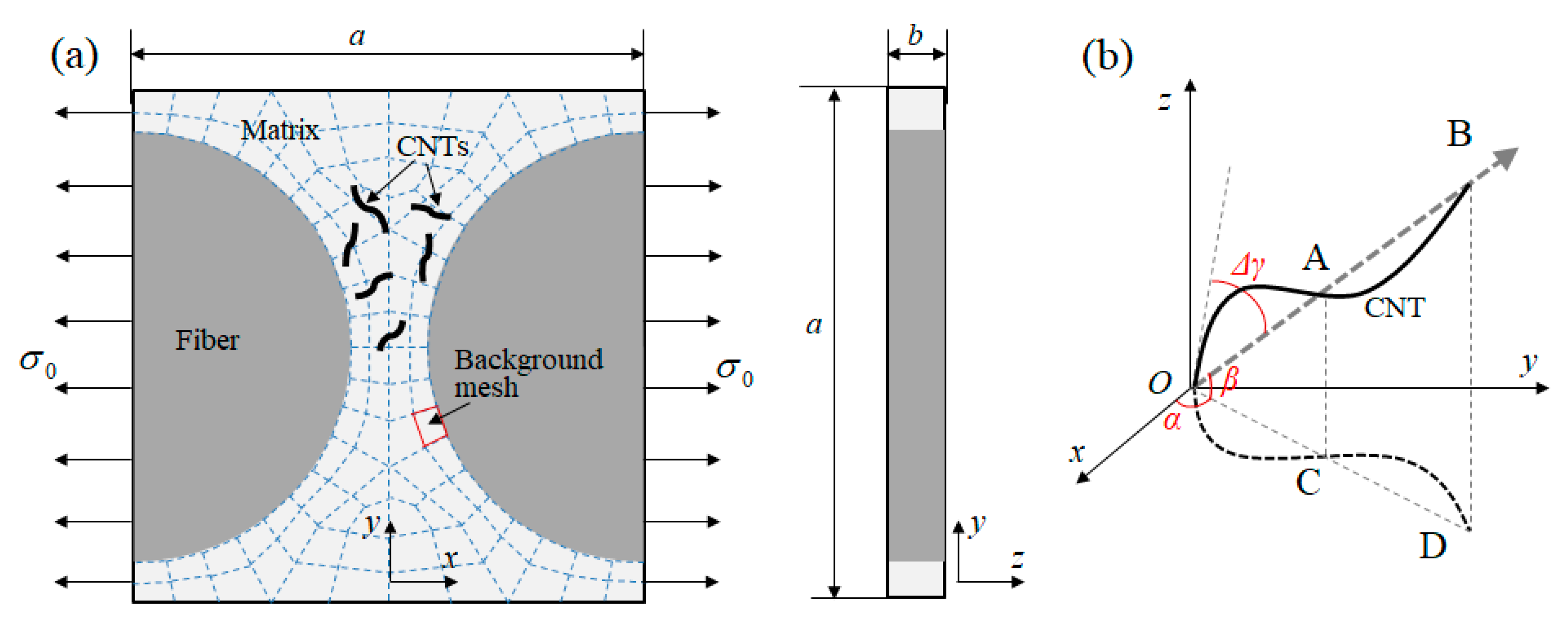

2.1. Description of the Optimization Problem

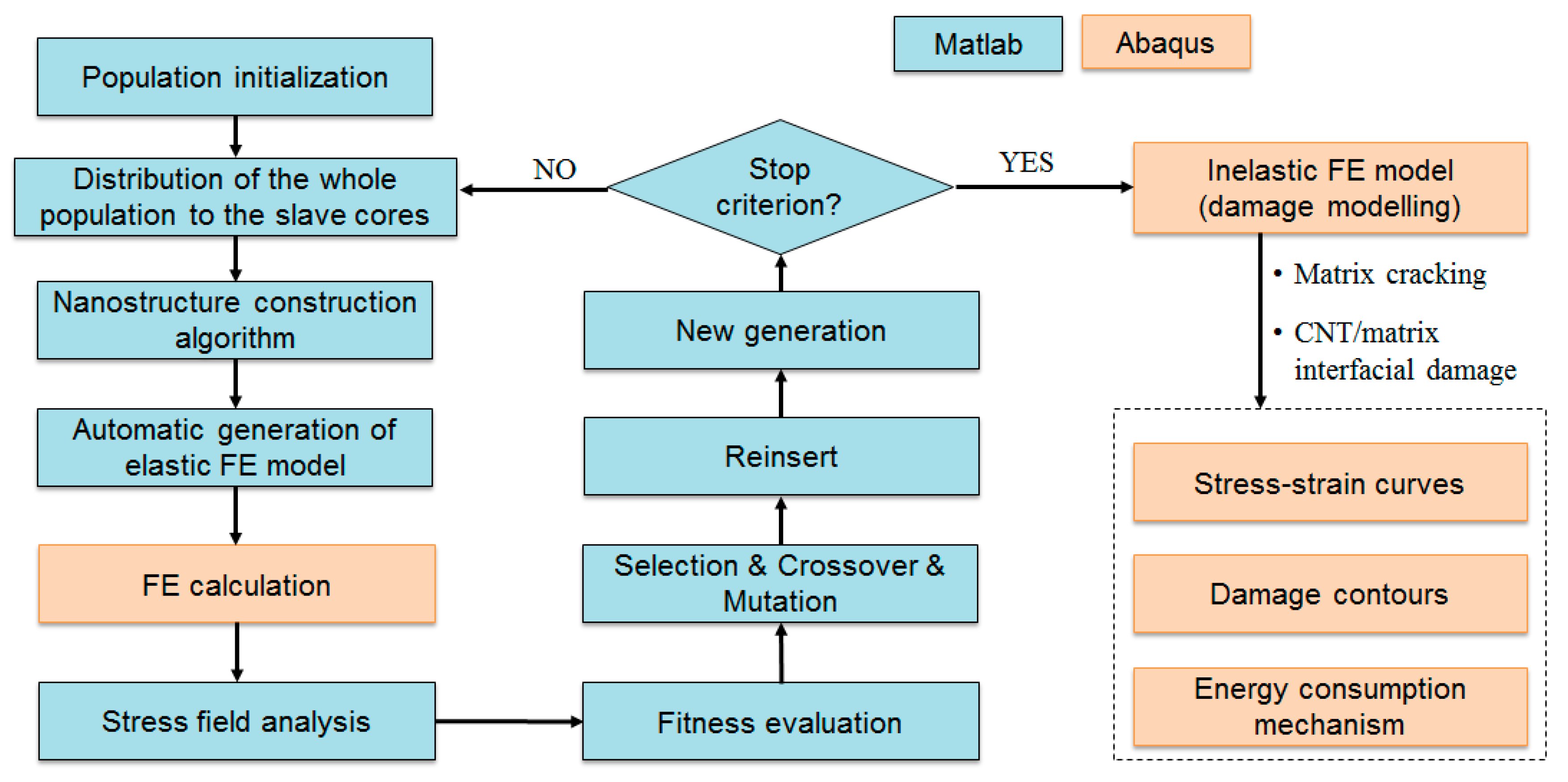

2.2. GA-FEM Optimization Tool

2.3. Constitutive Model and Material Parameters

3. Results and Discussions

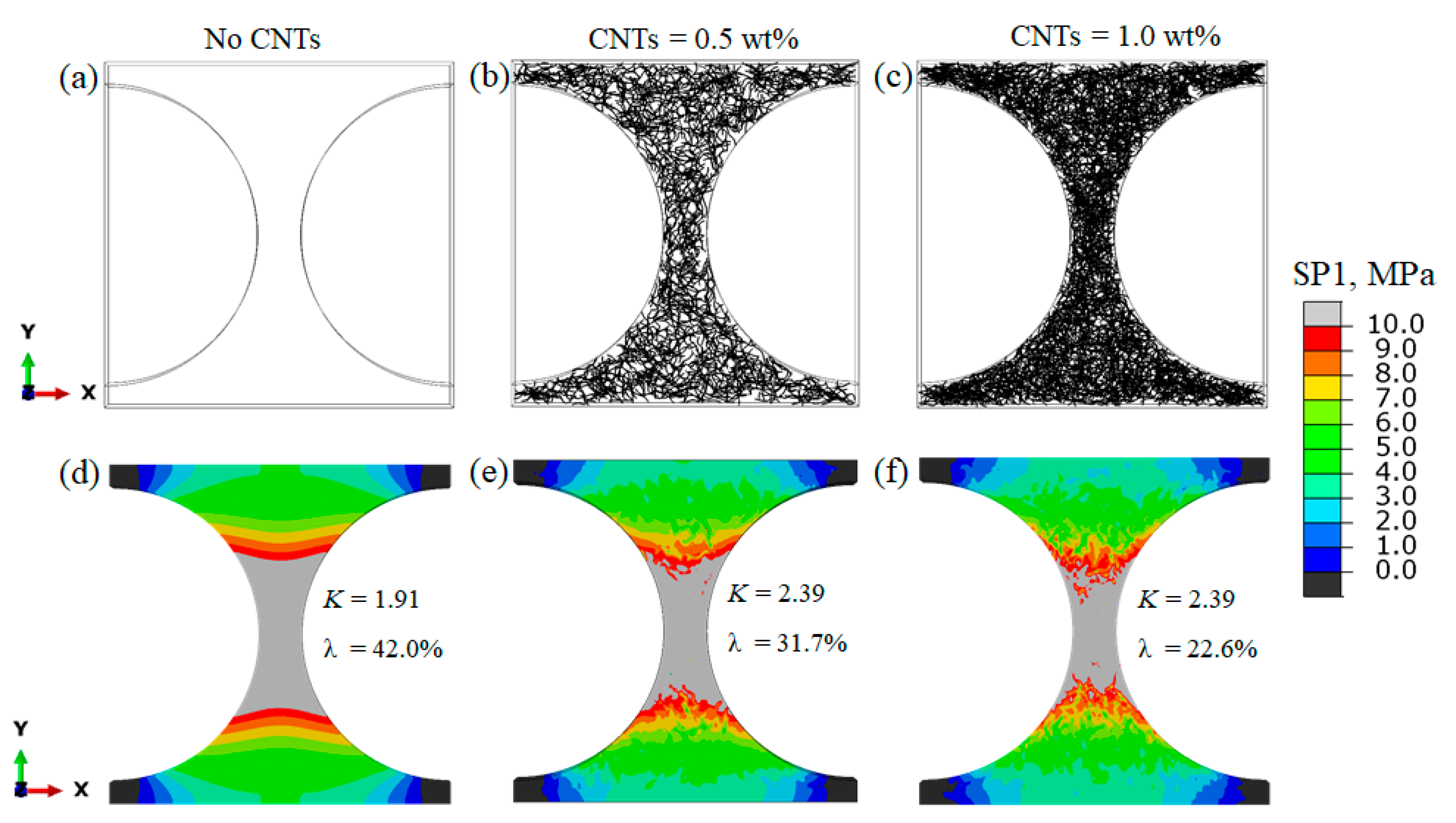

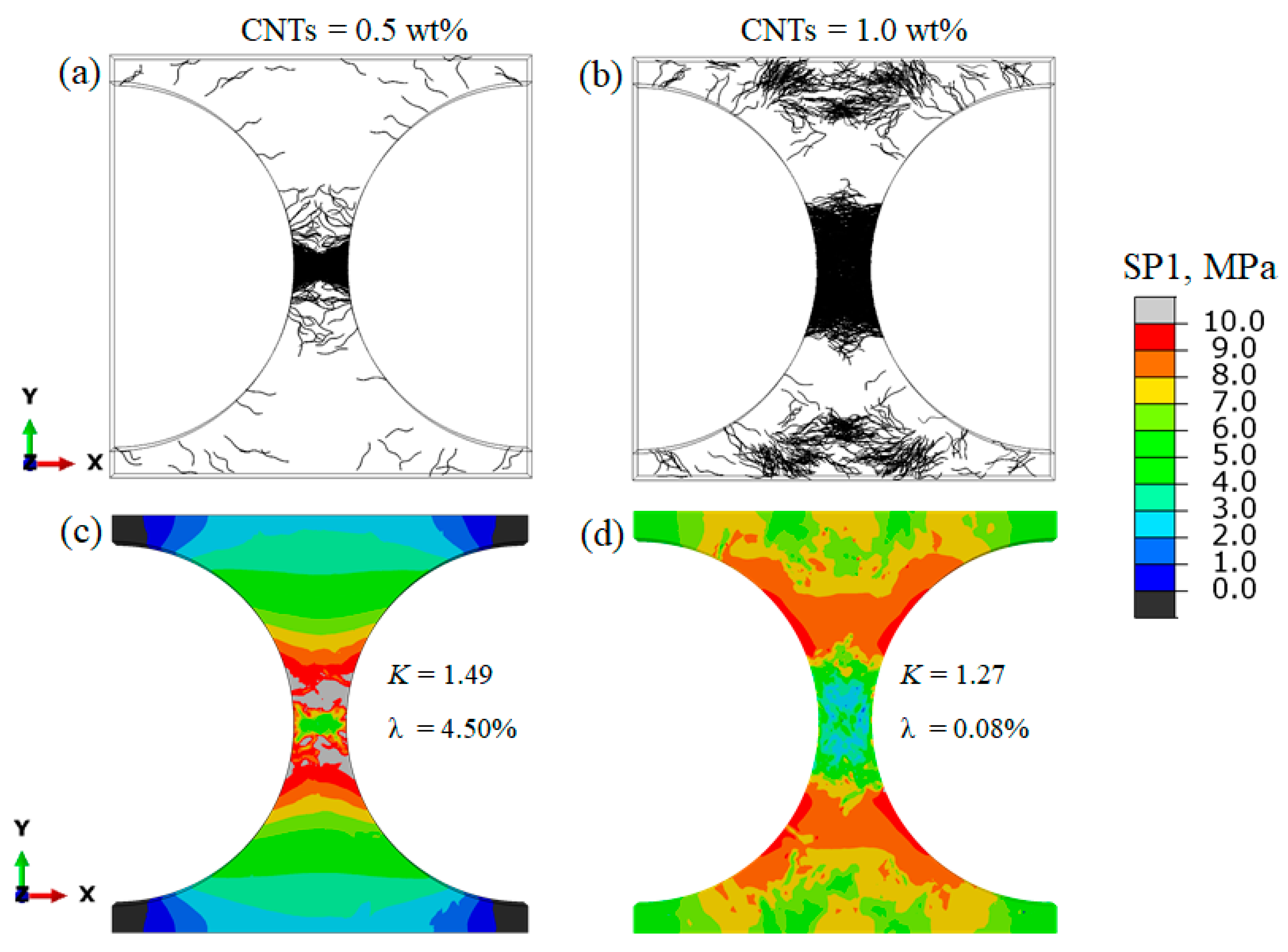

3.1. Effects of CNT-Network Morphology on Elastic Stress Field

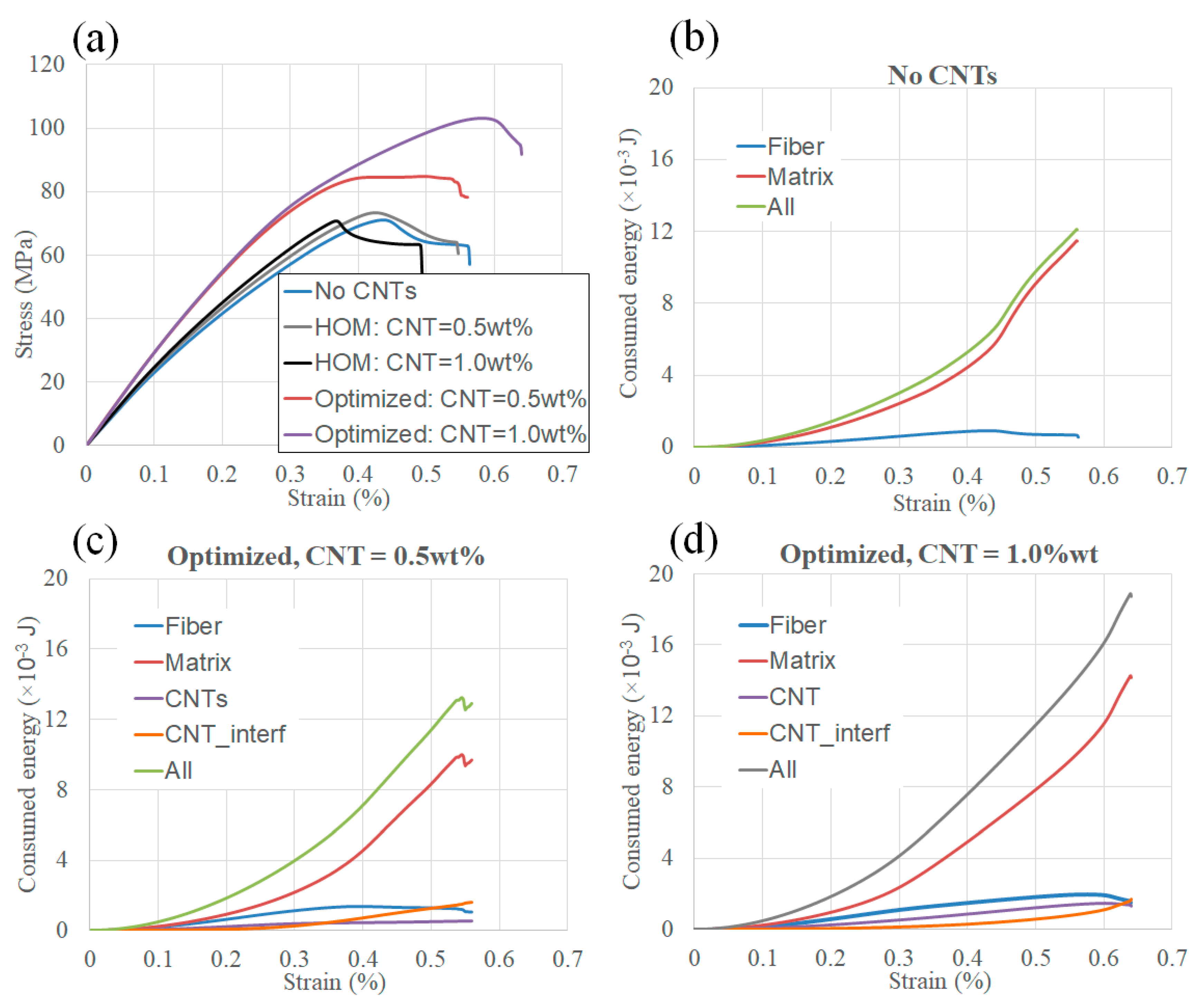

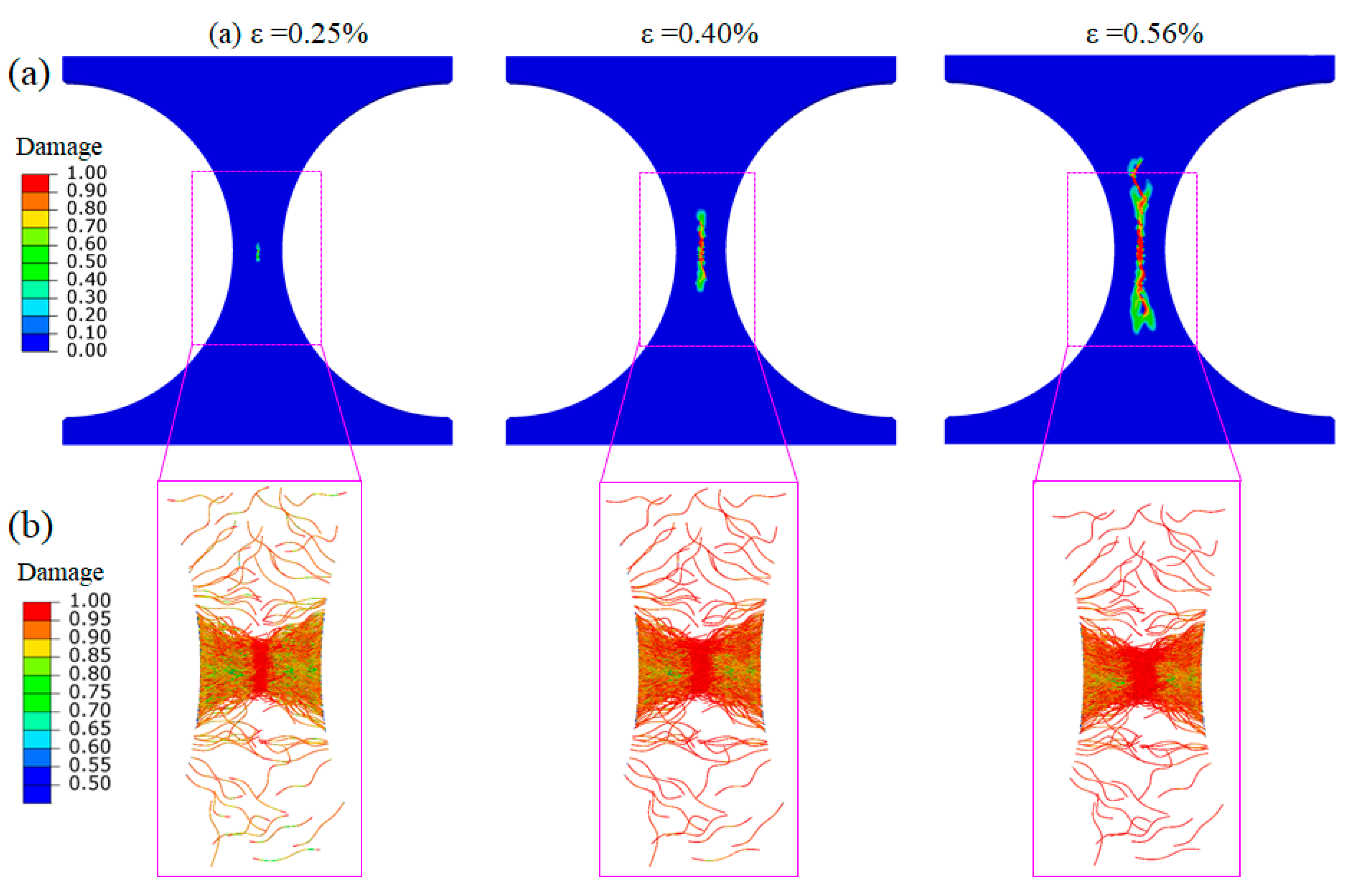

3.2. Effects of CNT-Network Morphology on Stiffness, Strength and Toughness and Underlying Mechanisms

4. Conclusions

- The optimal CNT networks have a suppressing effect on the stress concentrations in the matrix, while the homogenously distributed CNTs produce negligible effects on the overstressed region, even when CNT content is high.

- Two types of damage mechanisms, i.e., crack bridging (nano-scale) and damage diffusion (micro-scale), are observed in the models. Activation of the damage diffusion is shown to lead to large improvements in the strength and toughness of FRCs. This mechanism further compliments the well-known crack bridging mechanism.

- Activation of the two damage mechanisms depends on the network morphology of CNTs. In composites with homogenously distributed CNTs, crack bridging is limited and damage diffusion is absent. Therefore, the increase in the composite strength is small in this case, while the toughness even decreases. In composites with optimized CNT distribution and orientation but low CNT content, the mechanism of crack bridging is enhanced, leading to moderate increases of strength and toughness. In composites with an optimized network morphology and higher CNT content, damage diffusion is activated, as yet another mechanism for energy consumption. The diffuse matrix cracking results in significant improvement on the strength and toughness of FRCs.

- The present modelling results indicate that suppression of stress concentrations in the matrix using CNTs is a viable design principal for strengthening and toughening FRCs. Our work supports recent experimental evidence [10,11] on the critical role of the CNT-network morphology, which extends the design space for CNT-reinforced hierarchical FRCs.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Meyers, M.A.; McKittrick, J.; Chen, P.-Y. Structural biological materials: Critical mechanics-materials connections. Science 2013, 339, 773–779. [Google Scholar] [CrossRef] [PubMed]

- Wegst, U.G.; Bai, H.; Saiz, E.; Tomsia, A.P.; Ritchie, R.O. Bioinspired structural materials. Nat. Mater. 2015, 14, 23–36. [Google Scholar] [CrossRef] [PubMed]

- Zakaria, M.R.; Akil, H.M.; Kudus, M.H.A.; Ullah, F.; Javed, F.; Nosbi, N. Hybrid carbon fiber-carbon nanotubes reinforced polymer composites: A review. Compos. Part B 2019, 176, 107313. [Google Scholar] [CrossRef]

- Zhang, Y.; Heo, Y.-J.; Son, Y.-R.; In, I.; An, K.-H.; Kim, B.-J.; Park, S.-J. Recent advanced thermal interfacial materials: A review of conducting mechanisms and parameters of carbon materials. Carbon 2018, 142, 445–460. [Google Scholar] [CrossRef]

- Wagner, H.D.; Ajayan, P.; Schulte, K. Nanocomposite toughness from a pull-out mechanism. Compos. Sci. Technol. 2013, 83, 27–31. [Google Scholar] [CrossRef]

- Shtein, M.; Nadiv, R.; Lachman, N.; Wagner, H.D.; Regev, O. Fracture behavior of nanotube–polymer composites: Insights on surface roughness and failure mechanism. Compos. Sci. Technol. 2013, 87, 157–163. [Google Scholar] [CrossRef]

- Wicks, S.S.; de Villoria, R.G.; Wardle, B.L. Interlaminar and intralaminar reinforcement of composite laminates with aligned carbon nanotubes. Compos. Sci. Technol. 2010, 70, 20–28. [Google Scholar] [CrossRef]

- Sahoo, N.G.; Rana, S.; Cho, J.W.; Li, L.; Chan, S.H. Polymer nanocomposites based on functionalized carbon nanotubes. Prog. Polym. Sci. 2010, 35, 837–867. [Google Scholar] [CrossRef]

- Haesch, A.; Clarkson, T.; Ivens, J.; Lomov, S.V.; Verpoest, I.; Gorbatikh, L. Localization of carbon nanotubes in resin rich zones of a woven composite linked to the dispersion state. Nanocomposites 2015, 1, 204–213. [Google Scholar] [CrossRef]

- Liu, Y.; Wilkinson, A. Rheological percolation behaviour and fracture properties of nanocomposites of MWCNTs and a highly crosslinked aerospace-grade epoxy resin system. Compos. Part A 2018, 105, 97–107. [Google Scholar] [CrossRef]

- Abidin, M.S.Z.; Herceg, T.; Greenhalgh, E.S.; Shaffer, M.; Bismarck, A. Enhanced fracture toughness of hierarchical carbon nanotube reinforced carbon fibre epoxy composites with engineered matrix microstructure. Compos. Sci. Technol. 2019, 170, 85–92. [Google Scholar] [CrossRef]

- Quaresimin, M.; Schulte, K.; Zappalorto, M.; Chandrasekaran, S. Toughening mechanisms in polymer nanocomposites: From experiments to modelling. Compos. Sci. Technol. 2016, 123, 187–204. [Google Scholar] [CrossRef]

- Nadiv, R.; Shachar, G.; Peretz-Damari, S.; Varenik, M.; Levy, I.; Buzaglo, M.; Ruse, E.; Regev, O. Performance of nano-carbon loaded polymer composites: Dimensionality matters. Carbon 2018, 126, 410–418. [Google Scholar] [CrossRef]

- Eskizeybek, V.; Yar, A.; Avcı, A. CNT-PAN hybrid nanofibrous mat interleaved carbon/epoxy laminates with improved Mode I interlaminar fracture toughness. Compos. Sci. Technol. 2018, 157, 30–39. [Google Scholar] [CrossRef]

- De Greef, N.; Gorbatikh, L.; Lomov, S.V.; Verpoest, I. Damage development in woven carbon fiber/epoxy composites modified with carbon nanotubes under tension in the bias direction. Compos. Part A 2011, 42, 1635–1644. [Google Scholar] [CrossRef]

- Herceg, T.M.; Abidin, M.S.Z.; Greenhalgh, E.S.; Shaffer, M.S.; Bismarck, A. Thermosetting hierarchical composites with high carbon nanotube loadings: En route to high performance. Compos. Sci. Technol. 2016, 127, 134–141. [Google Scholar] [CrossRef]

- Du, C.; Li, M.; Cao, M.; Feng, S.; Guo, H.; Li, B. Enhanced thermal and mechanical properties of polyvinlydene fluoride composites with magnetic oriented carbon nanotube. Carbon 2018, 126, 197–207. [Google Scholar] [CrossRef]

- Ariu, G.; Hamerton, I.; Ivanov, D. Positioning and aligning CNTs by external magnetic field to assist localised epoxy cure. Open Phys. 2016, 14, 508–516. [Google Scholar] [CrossRef][Green Version]

- Derenskyi, V.; Gomulya, W.; Talsma, W.; Salazar-Rios, J.M.; Fritsch, M.; Nirmalraj, P.; Riel, H.; Allard, S.; Scherf, U.; Loi, M.A. On-chip chemical self-assembly of semiconducting single-walled carbon nanotubes (SWNTs): Toward robust and scale invariant SWNTs transistors. Adv. Mater. 2017, 29, 1606757. [Google Scholar] [CrossRef]

- Martin, J.J.; Fiore, B.E.; Erb, R.M. Designing bioinspired composite reinforcement architectures via 3D magnetic printing. Nat. Commun. 2015, 6, 8641. [Google Scholar] [CrossRef]

- Subramanian, N.; Koo, B.; Venkatesan, K.R.; Chattopadhyay, A. Interface mechanics of carbon fibers with radially-grown carbon nanotubes. Carbon 2018, 134, 123–133. [Google Scholar] [CrossRef]

- Subramanian, N.; Rai, A.; Chattopadhyay, A. Atomistically derived cohesive behavior of interphases in carbon fiber reinforced CNT nanocomposites. Carbon 2017, 117, 55–64. [Google Scholar] [CrossRef]

- Kundalwal, S.; Ray, M. Effective properties of a novel composite reinforced with short carbon fibers and radially aligned carbon nanotubes. Mech. Mater. 2012, 53, 47–60. [Google Scholar] [CrossRef]

- Hassanzadeh-Aghdam, M.K.; Ansari, R.; Darvizeh, A. Micromechanical analysis of carbon nanotube-coated fiber-reinforced hybrid composites. Int. J. Eng. Sci. 2018, 130, 215–229. [Google Scholar] [CrossRef]

- Venkatesan, K.R.; Subramanian, N.; Rai, A.; Chattopadhyay, A. Atomistically informed multiscale modeling of radially grown nanocomposite using a continuum damage mechanics approach. Carbon 2019, 142, 420–429. [Google Scholar] [CrossRef]

- Gorbatikh, L.; Wardle, B.L.; Lomov, S.V. Hierarchical lightweight composite materials for structural applications. MRS Bull. 2016, 41, 672–677. [Google Scholar] [CrossRef]

- Romanov, V.S.; Lomov, S.V.; Verpoest, I.; Gorbatikh, L. Modelling evidence of stress concentration mitigation at the micro-scale in polymer composites by the addition of carbon nanotubes. Carbon 2015, 82, 184–194. [Google Scholar] [CrossRef]

- Romanov, V.S.; Lomov, S.V.; Verpoest, I.; Gorbatikh, L. Can carbon nanotubes grown on fibers fundamentally change stress distribution in a composite? Compos. Part A 2014, 63, 32–34. [Google Scholar] [CrossRef]

- Romanov, V.; Lomov, S.V.; Verpoest, I.; Gorbatikh, L. Inter-fiber stresses in composites with carbon nanotube grafted and coated fibers. Compos. Sci. Technol. 2015, 114, 79–86. [Google Scholar] [CrossRef]

- Romanov, V.S.; Lomov, S.V.; Verpoest, I.; Gorbatikh, L. Stress magnification due to carbon nanotube agglomeration in composites. Compos. Struct. 2015, 133, 246–256. [Google Scholar] [CrossRef]

- Rai, A.; Chattopadhyay, A. Multifidelity multiscale modeling of nanocomposites for microstructure and macroscale analysis. Compos. Struct. 2018, 200, 204–216. [Google Scholar] [CrossRef]

- Liu, Q.; Gorbatikh, L.; Lomov, S.V. A combined use of embedded and cohesive elements to model damage development in fibrous composites. Compos. Struct. 2019, 223, 110921. [Google Scholar] [CrossRef]

- Lu, F.; Liu, Q.; Druzhinin, P.; Vandepitte, D.; Zhou, G.; Lomov, S.V. Reduction of the volume redundancy in combined embedded elements/cohesive zone modelling–Comments on the paper: Liu, Q.; Gorbatikh, L.; Lomov, S.V. A combined use of embedded and cohesive elements to model damage development in fibrous composites. Compos. Struct. 2019, 223, 110921. Compos. Struct. 2019, 226, 111273. [Google Scholar] [CrossRef]

- Liu, Q.; Lomov, S.V.; Gorbatikh, L. The interplay between multiple toughening mechanisms in nanocomposites with spatially distributed and oriented carbon nanotubes as revealed by dual-scale simulations. Carbon 2019, 142, 141–149. [Google Scholar] [CrossRef]

- Brighenti, R. Fibre distribution optimisation in fibre-reinforced composites by a genetic algorithm. Compos. Struct. 2005, 71, 1–15. [Google Scholar] [CrossRef]

- Ghasemi, H.; Brighenti, R.; Zhuang, X.; Muthu, J.; Rabczuk, T. Optimization of fiber distribution in fiber reinforced composite by using NURBS functions. Comp. Mater. Sci. 2014, 83, 463–473. [Google Scholar] [CrossRef]

- Wu, C.; Gao, Y.; Fang, J.; Lund, E.; Li, Q. Discrete topology optimization of ply orientation for a carbon fiber reinforced plastic (CFRP) laminate vehicle door. Mater. Des. 2017, 128, 9–19. [Google Scholar] [CrossRef]

- Konak, A.; Coit, D.W.; Smith, A.E. Multi-objective optimization using genetic algorithms: A tutorial. Reliab. Eng. Syst. Safe 2006, 91, 992–1007. [Google Scholar] [CrossRef]

- Liu, Q.; Lomov, S.V.; Gorbatikh, L. Spatial distribution and orientation of nanotubes for suppression of stress concentrations optimized using genetic algorithm and finite element analysis. Mater. Des. 2018, 158, 136–146. [Google Scholar] [CrossRef]

- Melro, A.; Camanho, P.; Pires, F.A.; Pinho, S. Micromechanical analysis of polymer composites reinforced by unidirectional fibres: Part I–Constitutive modelling. Int. J. Solids Struct. 2013, 50, 1897–1905. [Google Scholar] [CrossRef]

- Herráez, M.; González, C.; Lopes, C.; de Villoria, R.G.; LLorca, J.; Varela, T.; Sánchez, J. Computational micromechanics evaluation of the effect of fibre shape on the transverse strength of unidirectional composites: An approach to virtual materials design. Compos. Part A 2016, 91, 484–492. [Google Scholar] [CrossRef]

- Cooper, C.A.; Cohen, S.R.; Barber, A.H.; Wagner, H.D. Detachment of nanotubes from a polymer matrix. Appl. Phys. Lett. 2002, 81, 3873–3875. [Google Scholar] [CrossRef]

| Composites | CNT Content, wt% | Stiffness (GPa) | Strength (MPa) | Toughness (×109 J/m3) |

|---|---|---|---|---|

| Pristine FRC | 0 | 23.8 | 69.3 | 26.7 |

| Homogeneous distribution of CNTs | 0.5 | 25.3 | 73.3 | 26.6 |

| Homogeneous distribution of CNTs | 1.0 | 25.5 | 70.9 | 23.2 |

| Optimized distribution of CNTs | 0.5 | 30.5 | 84.7 | 33.6 |

| Optimized distribution of CNTs | 1.0 | 30.0 | 103.1 | 44.0 |

| Hierarchical FRCs | Fiber | Matrix | CNT | CNT/Matrix Interface | All |

|---|---|---|---|---|---|

| Homogeneous, 0.5 wt% | 0.1 | −2.7 | 1.3 | 1.0 | −0.3 |

| Homogeneous, 1.0 wt% | 0 | −16 | 2 | 1 | −13 |

| Optimized, 0.5 wt% | 6 | −10 | 6 | 24 | 26 |

| Optimized, 1.0 wt% | 9 | 28 | 13 | 15 | 65 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, Q.; Lomov, S.V.; Gorbatikh, L. Enhancing Strength and Toughness of Hierarchical Composites through Optimization of Position and Orientation of Nanotubes: A Computational Study. J. Compos. Sci. 2020, 4, 34. https://doi.org/10.3390/jcs4020034

Liu Q, Lomov SV, Gorbatikh L. Enhancing Strength and Toughness of Hierarchical Composites through Optimization of Position and Orientation of Nanotubes: A Computational Study. Journal of Composites Science. 2020; 4(2):34. https://doi.org/10.3390/jcs4020034

Chicago/Turabian StyleLiu, Qiang, Stepan V. Lomov, and Larissa Gorbatikh. 2020. "Enhancing Strength and Toughness of Hierarchical Composites through Optimization of Position and Orientation of Nanotubes: A Computational Study" Journal of Composites Science 4, no. 2: 34. https://doi.org/10.3390/jcs4020034

APA StyleLiu, Q., Lomov, S. V., & Gorbatikh, L. (2020). Enhancing Strength and Toughness of Hierarchical Composites through Optimization of Position and Orientation of Nanotubes: A Computational Study. Journal of Composites Science, 4(2), 34. https://doi.org/10.3390/jcs4020034