A Survey of Scrutinizing Delaminated Composites via Various Categories of Sensing Apparatus

Abstract

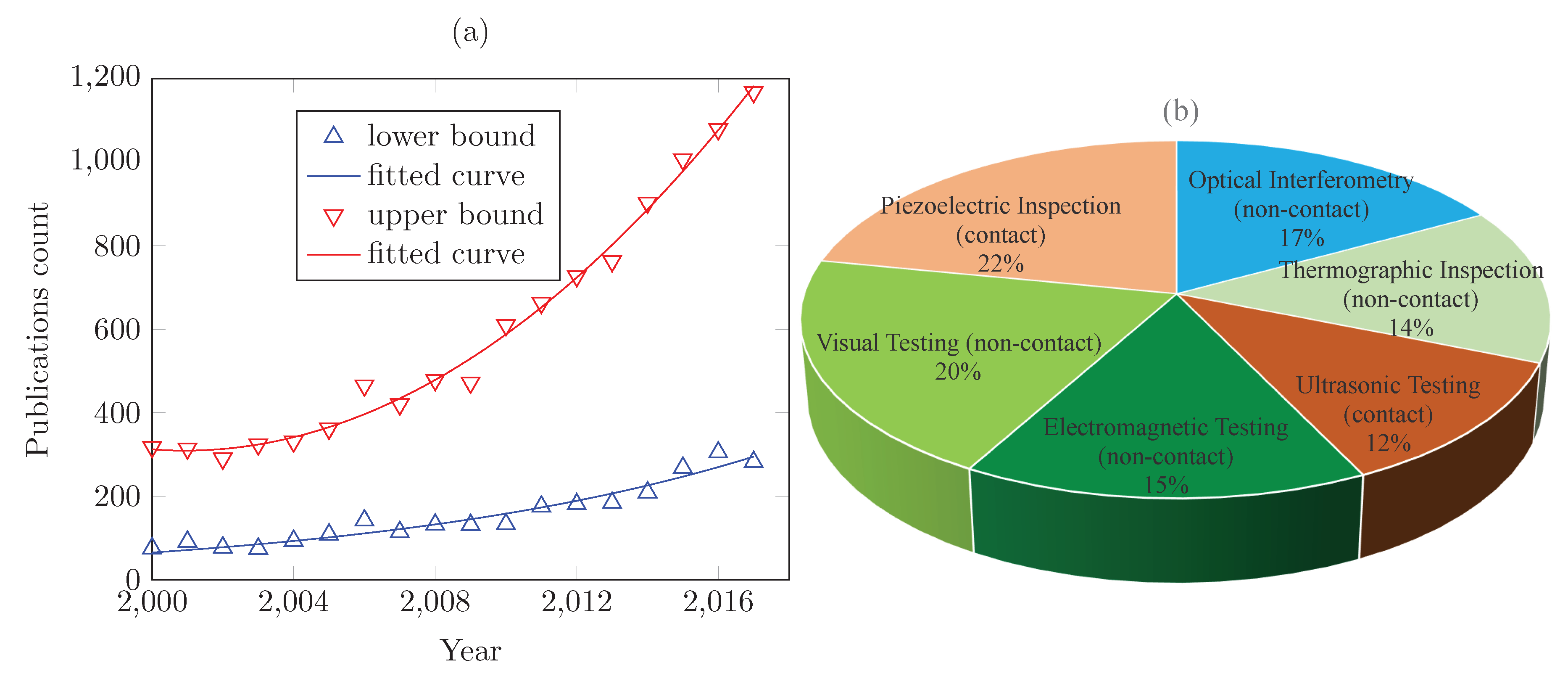

1. Introduction

2. Delamination Damage in Composites

3. NDE Techniques

- (a)

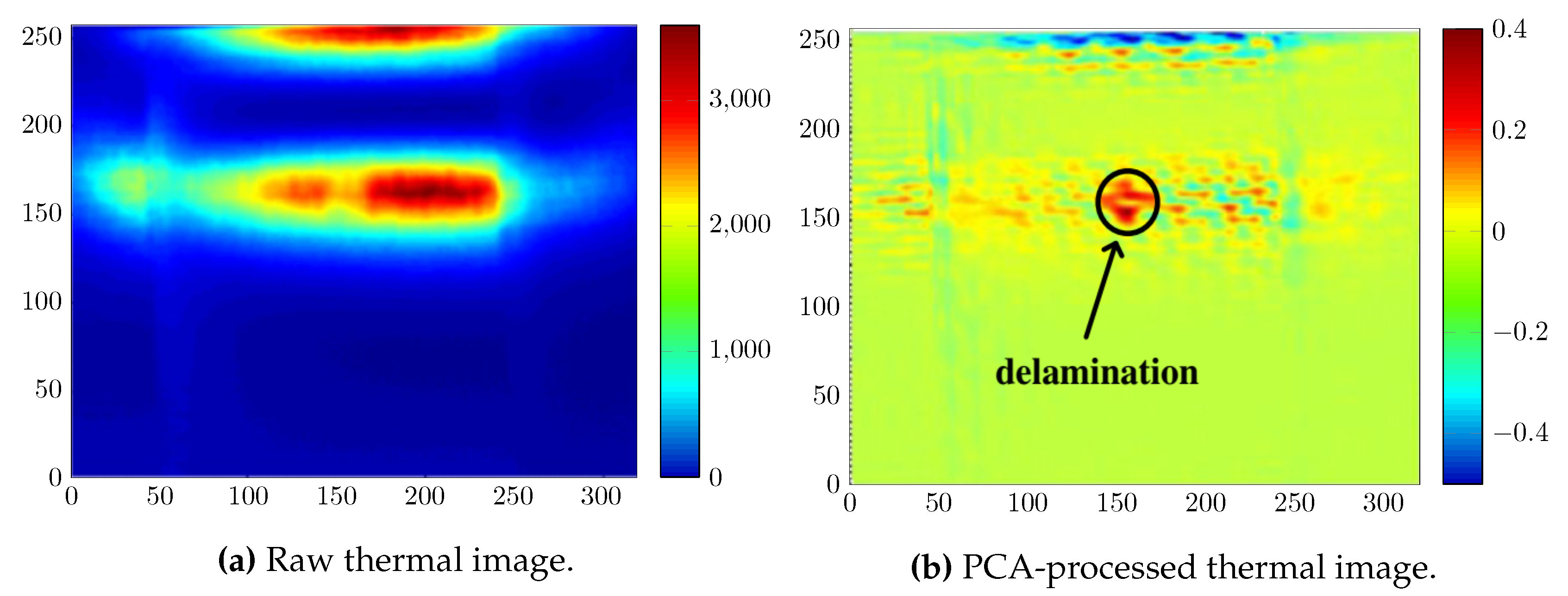

- Thermographic inspection: Thermography can be considered as a branch of electromagnetic inspection since heat is a result of the material’s resistance to the input current flowing through it. However, it is separated due to rich information in the field.Thermography employs the principle that thermal properties of different materials including a host structure and embedded discontinuities cause thermal radiation to differ. The range of thermal radiation in most applications is placed at the infrared area of the wavelength spectrum [13,14]. Therefore, high-precision infrared cameras have extensively been applied to acquire thermal information and convert them into a map of surface temperature, developing infrared ray (IR) thermography. However, visible thermography incorporating color cameras has been used toward an inexpensive technique compared to IR thermography, as well. Thermographic inspection is hierarchically illustrated in Figure 3. Visible liquid–crystal (LC) thermography acts based on the fact that LCs having a dynamic phase between solid and liquid exhibit phase transitions against temperature changes, reflecting visible colors [15]. In [15], LC is sprayed on one side of the sample coated with paint and the other side is heated. Temperature maps appeared in the form of visible lights are captured by a color camera. According to Figure 3, IR thermography is classified into (a) passive infrared (PIR) thermography and (b) active infrared (AIR) thermography [13,16]. PIR thermography without employing any external heat acquires thermal radiation of the specimen’s surface resulted from the in-service operation or natural ambient lights. In this regard, a rotor blade operating under production or repair processes, under frequently changed loads such as heavy wind, or under sun illumination can be pointed out [17]. On the other hand, the specimen’s surface is externally exposed to energy sources, including electromagnetic, optical, and mechanical excitations, to disturb thermal equilibrium in AIR thermography by which the accuracy of the inspection will be increased against environmental noises [18]. Generally speaking, temperature maps of thermography are characterized as full-field, non-contact, fairly fast, and effective for detecting multiple damages in complex composite structures.AIR thermography has extensively been applied for delamination detection in composite structures, owing to its reliable temperature measurement resulted from the application of controllable heating [19,20,21,22,23,24,25,26,27,28,29,30,31,32,33,34]. Depending on the excitation source used, there are two types of heating techniques: (1) electromagnetic induction heating [20,21,22,23,24,25] and (2) thermal direct heating [26,27,28,29,30,31,32,33,34]. The former technique, known as eddy current (EC) thermography (induction thermography), induces EC in the specimen by an electrical excitation generated through the induction coil placed adjacent to the specimen. The EC induced generates resistive heating by which discontinuities are detected [19]. The latter technique can be organized into pulsed thermography [26,27,28,29,30,31], step thermography [28,32], lock-in (LI) thermography [29,33,34], and vibrothermography [26,30] depending on the type of the excitation source and exposure time. In another classification, non-contact pulsed thermography, step thermography, and LI thermography are included in optical excitation thermography, whereas vibrothermography, as a contact-based technique, is placed in ultrasonic mechanical excitation thermography [30], requiring the excitation source to be coupled to the specimen’s surface. Relating to optical excitation thermography, pulsed thermography technique applies high energy within a short time by means of the heat generated from flash lights; whereas, in step thermography, the specimen’s surface is incrementally heated, for instance, by a halogen lamp within a relatively long time. It has been alluded that step heating is appropriate to inspect composites under impact damage [32]. Furthermore, LI thermography is stimulated by either a halogen lamp, termed optical LI thermography, or a high-frequency guided wave, termed ultrasound LI thermography. In the process, a periodic input stimulation applied to the specimen’s surface penetrates into the specimen while shifting phase. Then, the interference of the reflected part of the wave in the input wave at the specimen’s surface will effect an interference pattern, utilized for detecting internal anomalies and discontinuities. Regardless of the class of IR thermography technique utilized, infrared camera map surface infrared radiation is induced by numerous external stimuli into thermal images within a specified time.

- (b)

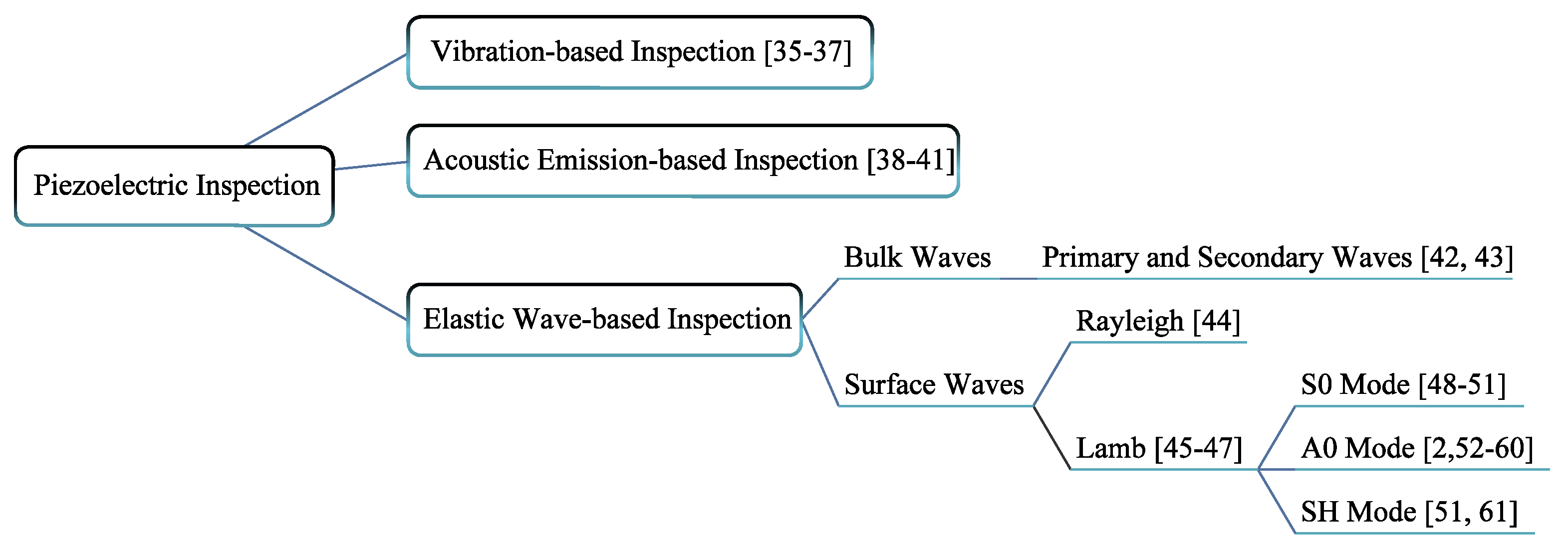

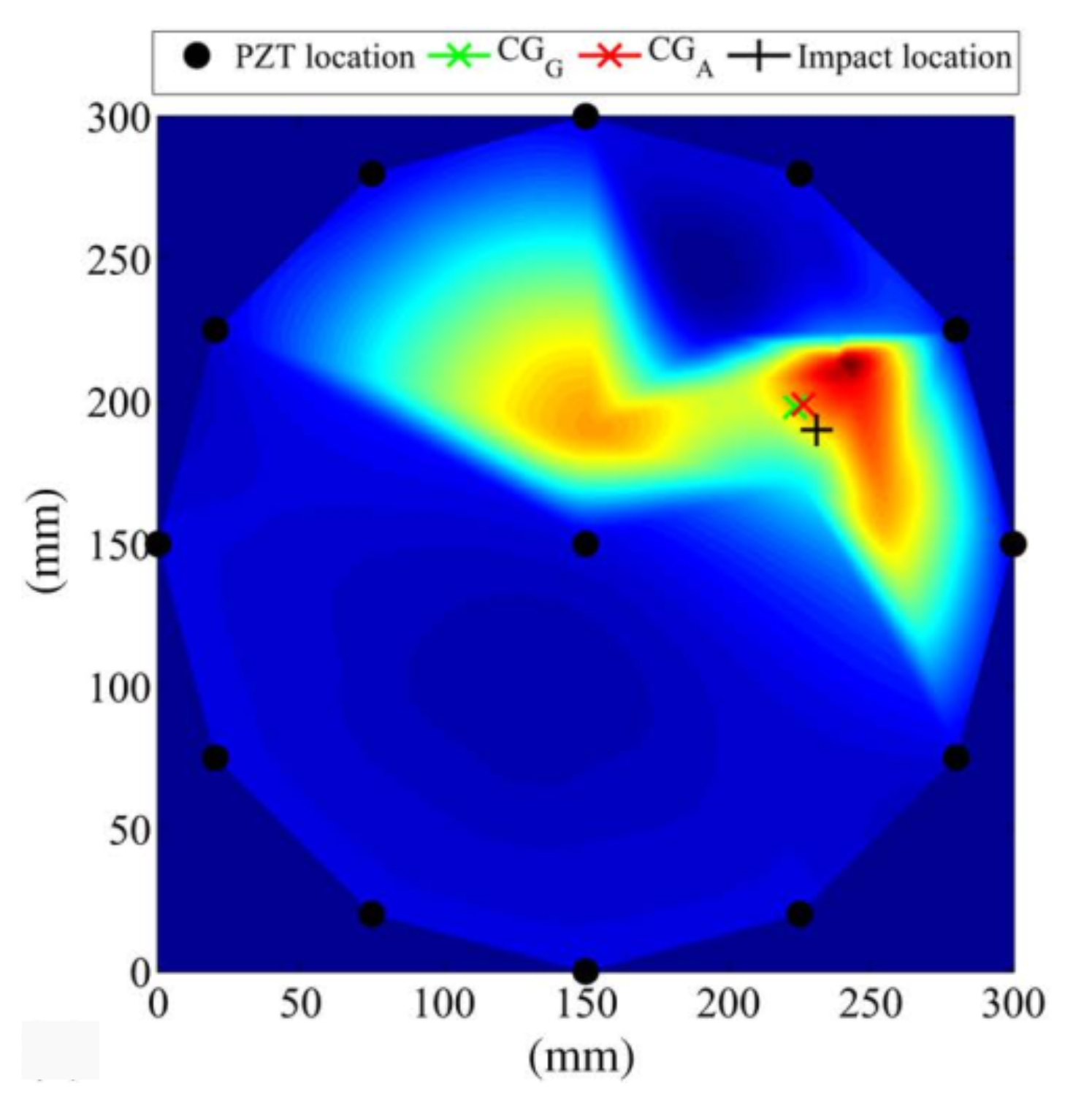

- Piezoelectric inspection: Notably, when employing a short ultrasound pulse for detection of materials with high sound conductivity, piezoelectric inspection can be placed into ultrasonic inspection. However, the authors’ preference is to assign a separate section to it due to extensive research works.Utilizing piezoelectric sensors to inspect composite laminates integrity, termed as piezoelectric inspection, can be considered as one of the active research areas of NDE techniques. The functionality of piezoelectric transducers in this technique is associated with the piezoelectric effect, as a reversible effect between the mechanical deformation and electrical field. Piezoelectric (PZT; lead zirconate titanate) transducers can be bonded with the host composite’s surface (surface-bonded PZT) or be embedded into composite laminates during manufacturing (embedded PZT), out of which the latter allows for developing smart composite structures. The PZT-composite’s surface bond necessitates meticulous surface preparation, and the configuration should also be treated with caution against external loading. Surface-bonded PZT transducers configured in various patterns have extensively been employed to both excite and detect different laminated composite structures subjected to delamination in various actuator–sensor locations associated with pitch-catch or pulse-echo modes, as explained in ultrasonic inspection section. As they represent potentially exciting composites, piezoelectric inspection based on vibration-based methods, acoustic emission, and ultrasonic elastic waves are illustrated in Figure 4, referring to the respective technical literature [2,35,36,37,38,39,40,41,42,43,44,45,46,47,48,49,50,51,52,53,54,55,56,57,58,59,60,61,62].According to Figure 4, in acoustic emission (AE)-based inspection, AE is referred to those waves resulted from energy release in a structure containing damage, thereby categorized as a passive technique. AE without any external excitation is therefore propagated only in loaded structures while it is usually recorded by means of a PZT sensor, also known as AE sensor. The AE technique has proved the potential to be applied as an NDE technique for damage detection in composites. Not only is this technique prone to localize the AE source, but also to identify damage mode type considering energy emitted in different directions. For example, signals emitted from delamination form low-frequency flexural waveforms, whereas fiber breakage and matrix cracking emit high-frequency extensional waveforms [63].Elastic waves, known as mechanical waves, requiring an elastic medium to be propagated, can be classified into bulk waves and surface waves, as a consequence of partially constraining the medium [64]. With respect to the motion of medium elements as well as wave propagation direction, bulk waves are divided into longitudinal (primary) and shear (secondary) waves, whereas Rayleigh and Lamb waves are placed in the surface wave class. Elastic wave technique has abundantly been utilized as an NDE technique to inspect composite laminates containing delamination via piezoelectric sensors. PZT transducers can be applied as a wave source to initiate delamination detection.

- (c)

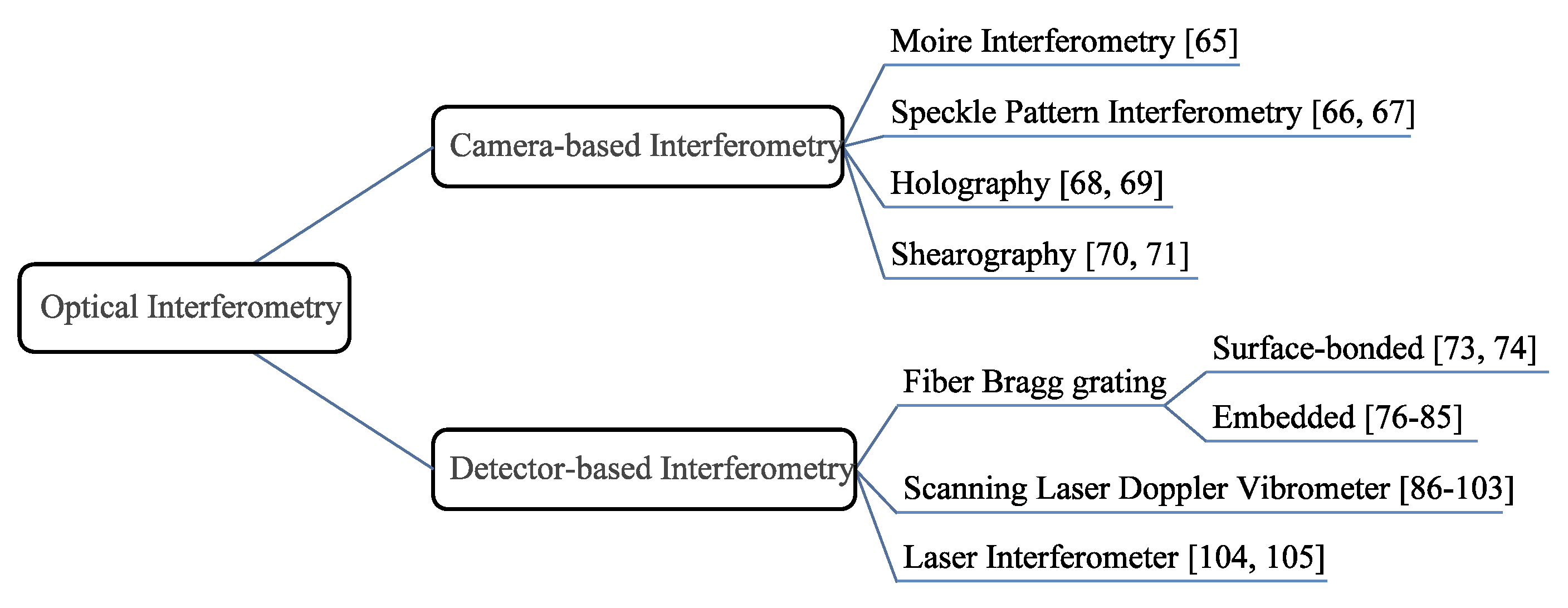

- Optical interferometric inspection: NDE techniques based on optical interferometry, emitting a laser light toward the specimen’s surface, make use of the waves principle of superposition effecting the interference phenomenon so as to extract information. To accurately extract output information, various fringe processing strategies such as phase shifting or transform methods need to be incorporated into the system. The basic concept of phase shifting interferometry is inserting a device (e.g., a PZT transducer) into the optical path to incorporate known phase shifts. As depicted in Figure 5, the techniques may classified into camera-based interferometry [65,66,67,68,69,70,71] and detector-based interferometry [72,73,74,75,76,77,78,79,80,81,82,83,84,85,86,87,88,89,90,91,92,93,94,95,96,97,98,99,100,101,102,103,104,105], out of which the former is limited in temporal domain resolution, whereas the latter limited in spatial domain resolution [11].In second classification, when coupling a broadband light into the fiber, local FBG sensors using Bragg gratings as sensing elements placed within an optical fiber reflect back a narrowband signal whose peak wavelength (Bragg wavelength) depends on the grating’s period and effective refractive index. Bragg wavelength can be affected when exposing FBG sensor to either mechanical strains or temperature changes, requiring thus discrimination of temperature-strain effects by designing an individual temperature compensation FBG [106]. Owing to the benefits of decisive factors such as electromagnetic immunity, small dimensions, lightweight, long lifetime, corrosion, and high-temperature resistance, and multiplex and embedding capabilities compared to strain gauges, the FBG sensor attached in surface-bonded or embedded configuration has found practical applications in composite health monitoring particularly for local average strain measurements [72,73,74,75,76,77,78,79,80,81,82,83,84,85]. However, the FBG’s lower sensitivity to AE signals as well as the higher cost to cover a large area than PZT sensors led to the cooperative application of FBGs and PZTs. Upon drawbacks, FBG’s responses are complicated to be associated with strain field distribution, thus used in short gauge lengths or surface-bonded configuration with limitations imposed on their position and orientation [82]. Embedded FBGs are considered the best option for internal strain monitoring, owing to their high compatibility with composites under harsh situations, the capability of controlling fabrication process-induced thermal residual strain, and not affecting structural properties when embedded parallel to reinforcing fibers. Nevertheless, as this is a challenge relating the output of embedded FBGs to the structure’s strain, the following steps need to be taken; transfer the deformation and wavelength shifts of the reflected signal into the FBG’s strain and transfer FBG’s strain into composite’s strain [75]. The other technique, laser Doppler vibrometry (LDV), as a non-contact NDE technique, yields the target point’s velocity by directing a laser beam toward the specimen’s surface and extracting its vibration components from the Doppler shift of the frequency of the reflected laser.

- (d)

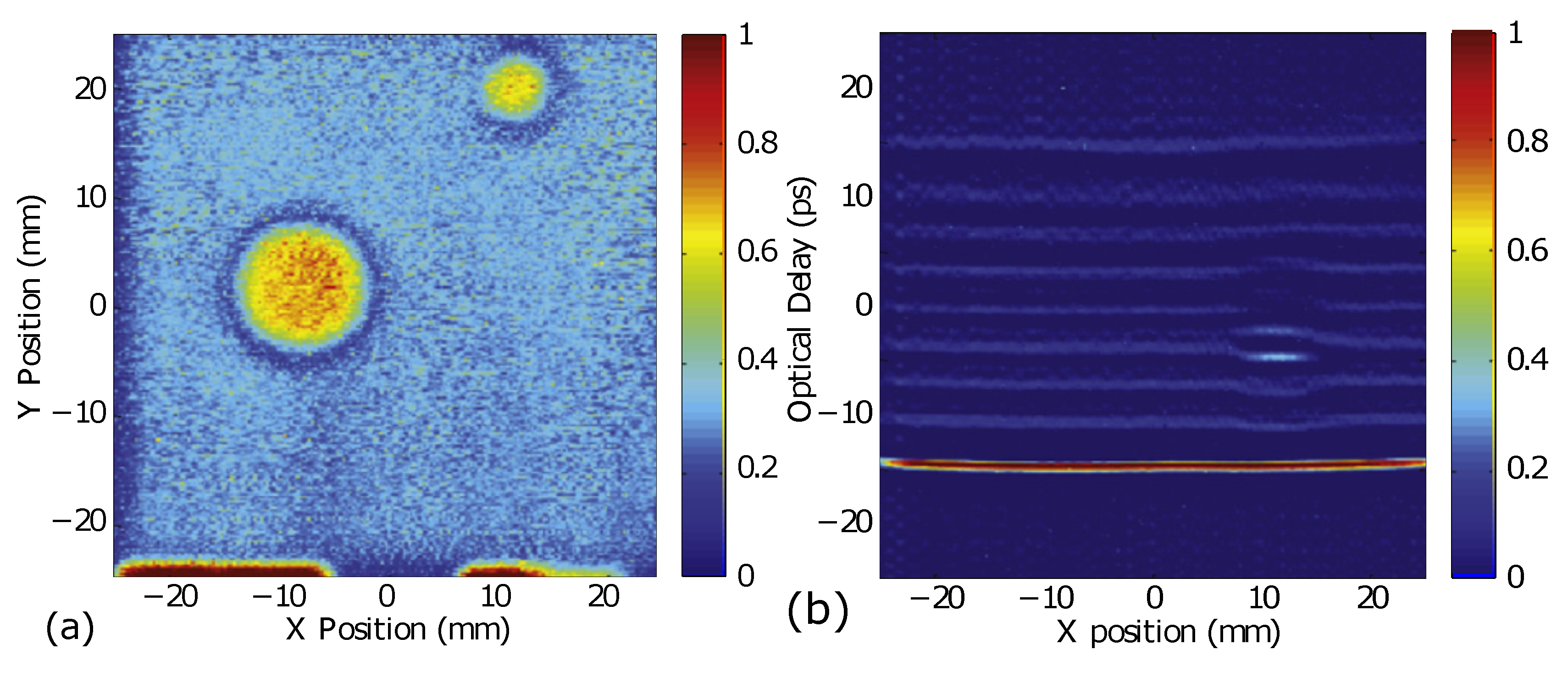

- Electromagnetic testing: In NDE electromagnetic testing, composite laminates undergo a process in which the internal anomalies are inspected in terms of electromagnetic responses utilizing electric currents or magnetic fields induced. As shown in Figure 6, radiography, computed tomography, terahertz (THz) spectroscopy, and the electrical resistance change-based method may be included in electromagnetic testing [107,108,109,110,111,112,113,114,115,116,117,118,119,120]. In addition, thermography, as explained above, is a part of electromagnetic testing.Radiography imaging technique has been applied to inspect the internal structure of composite laminates using an x-ray generator and detector mapped in a 2D representation. For computerized processing X-ray images captured from different angles in either transmission mode or reflection mode, computed tomography (CT) technique produces a 3D representation of the specimen. In another technique, utilizing terahertz (THz) radiation of electromagnetic spectrum, ranging from 100 GHz to 10 THz, THz spectroscopy has recently been introduced for NDE field within fiber-reinforced composites, out of which CFRP inspection owing to the carbon’s conductivity has, to date, demonstrated THz waves to be effective only for near-surface damages, whereas THz waves can penetrate deeper into GFRP composites to detect the composite’s structure and buried damages such as delamination. THz waves are excited using an ultrafast laser within a THz time-domain spectroscopy system, involving a THz transmitter and receiver configured in either transmission mode or reflection mode.Potential of delamination-induced changes of electric resistance (ER) to inspect composite laminates have been studied by means of piezoelectric sensors as well as electrodes in numerous research works. In this NDE system, composite laminates possess small and very high ER along directions of the fiber such as carbon fiber and matrix, respectively, thus with fiber operating as an internal sensor.

- (e)

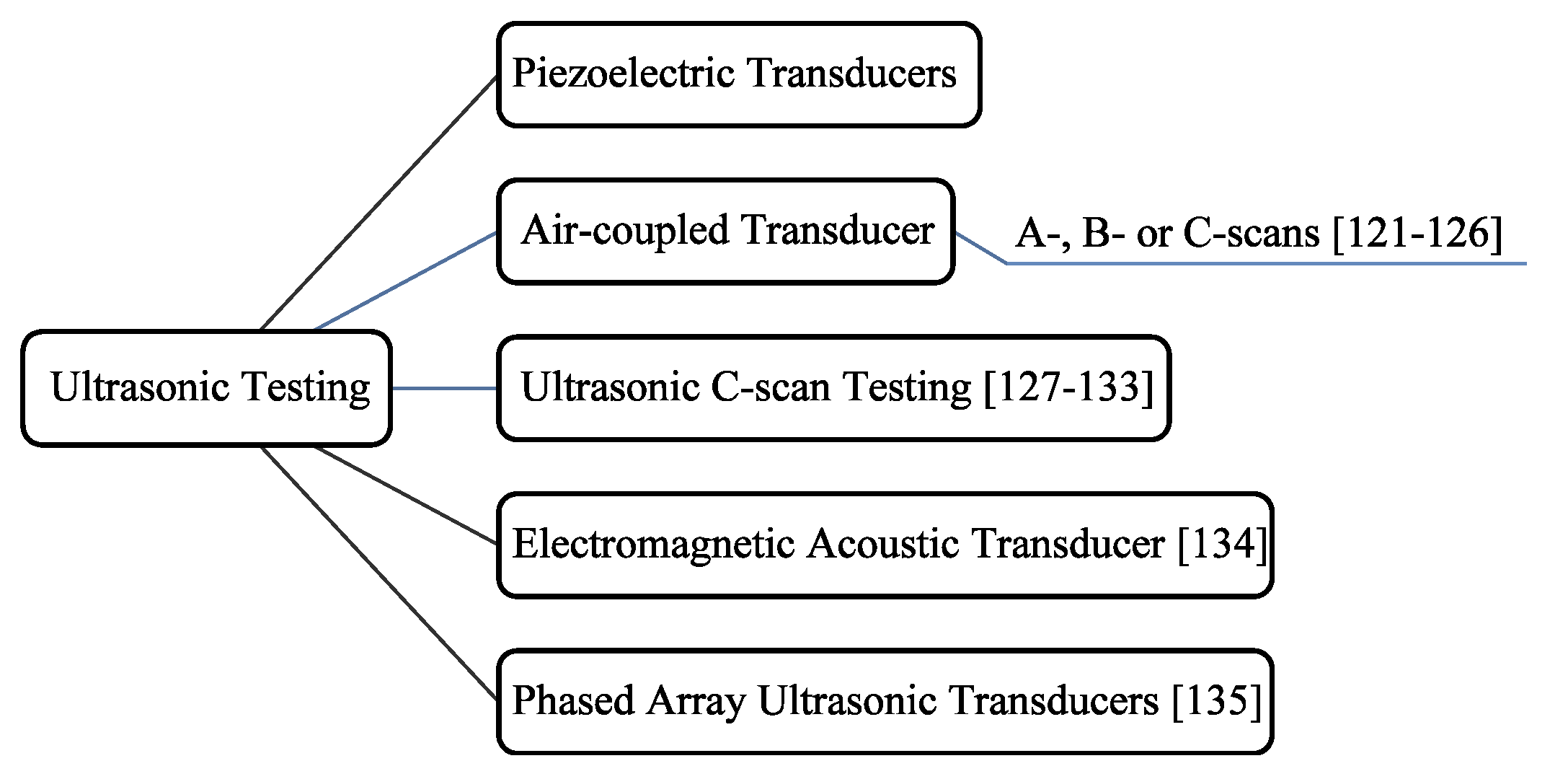

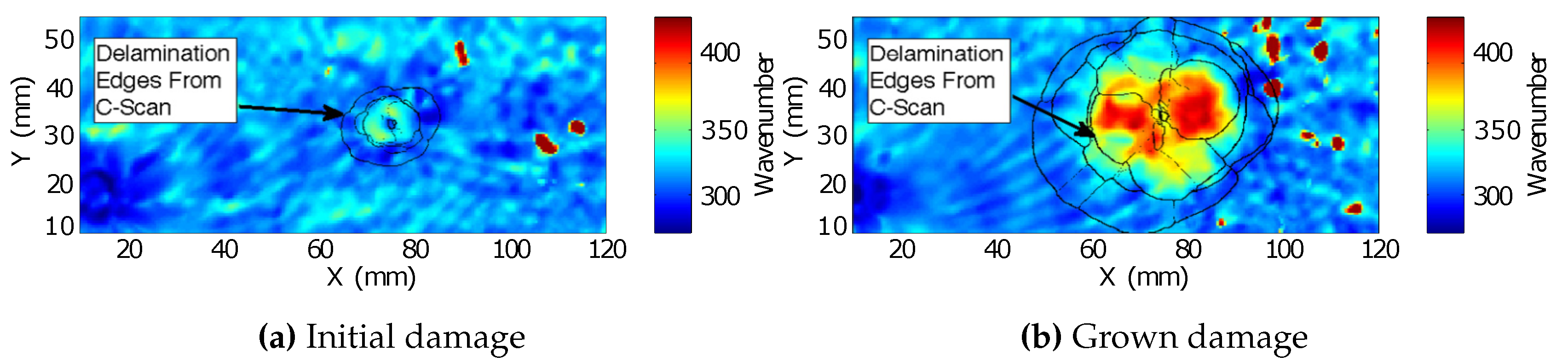

- Ultrasonic testing: In NDE ultrasonic testing, a couplant is, in practice, utilized to enable efficient sound penetration into the composite laminates generated from an ultrasonic transducer. When necessitating separate actuator and sensor, three different transducer configurations, i.e., the pulse-echo, through-transmission, and pitch-catch methods, have experimentally been employed to inspect delamination via ultrasonic testing. In the pulse-echo method, one PZT transmitter can be used for both actuating the ultrasonic waves and sensing the waves reflected by either discontinuities or boundaries. Regarding the through-transmission method, actuating the waves is conducted on one side while sensing the waves transmitted through the specimen on the other side. Actuating the waves and sensing the reflected waves from discontinuities in the pitch-catch method is conducted through individual transducers placed on the same side. It should also be noted that A-, B-, and C-scans refer to energy amount vs. time signal, transducer position vs. time image, and a spatial plan view of the specimen features, respectively.According to Figure 7, air-coupled transducers and ultrasonic C-scan testing may be included in ultrasonic testing [121,122,123,124,125,126,127,128,129,130,131,132,133].Air-coupled transducers (ACTs), when coupling media, cannot be applied is an attractive alternative to excite ultrasonic waves and receive those leaked into the air. Incident and reception angles of ultrasonic waves as well as transducer–composite distances are the sensitive parameters to be set up on output signals. Contact-based ultrasonic C-scan testing (UCT) as one of the most widely used ultrasonic testing techniques is simple to analysis as well as effective to geometrically localize delamination. In the immersion testing process, a liquid couplant is employed to establish direct contact between a transducer and the composite specimen. Most of the research effort in the technical literature searched regarding the ultrasonic C-scan testing has been focused on either verification of other NDE techniques with ultrasonic C-scan as a reference standard [35,47,89,91,109,112,126] or yielding supplementary information [26,38,105,117,127].Furthermore, piezoelectric transducers, electromagnetic acoustic transducer [134], and phased array ultrasonic transducers are placed into the category of ultrasonic testing. Employing the transduction mechanisms of either Lorentz force or magnetostriction, non-contact, and couplant-free electromagnetic acoustic transducers (EMATs) can be utilized for both sound excitation and sensation. Employing multiple probe elements, phased array transducers [135] can efficiently illustrate a slice of the target.

- (f)

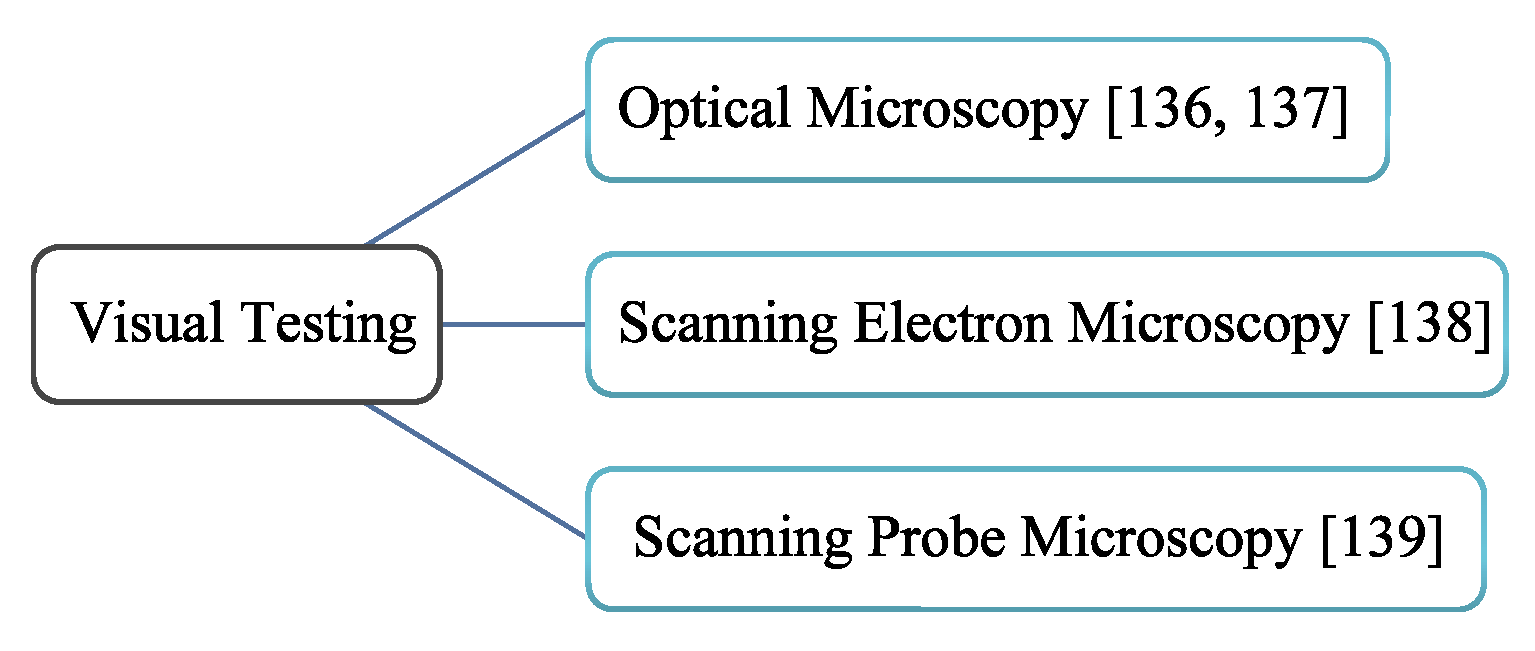

- Visual testing: Visual testing focusing on microscopy techniques is referred to non-contact NDE techniques of optical, scanning electron, and scanning probe microscopy, according to Figure 8 [136,137,138,139]. Supplementary information obtained through optical microscopy [24,39,72,119] and scanning electron microscopy [40,41,117] have been utilized along with measurements of other NDE techniques for delamination detection.

4. Industrial Applications of NDE Techniques

5. Division of NDE Techniques

6. Review Description

6.1. Thermographic Inspection

6.1.1. Postprocessing of Thermograms

6.1.2. Corresponding Results

6.2. Piezoelectric Inspection

6.2.1. Vibration Based Inspection

6.2.2. Acoustic Emission-Based Inspection

6.2.3. Elastic Wave-Based Inspection

6.3. Optical Interferometric Inspection

6.3.1. Camera-Based Interferometry

6.3.2. Detector-Based Interferometry

6.4. Electromagnetic Testing

6.4.1. Radiography

6.4.2. Computed Tomography

6.4.3. Terahertz Spectroscopy

6.4.4. Electric Resistance-Based Inspection

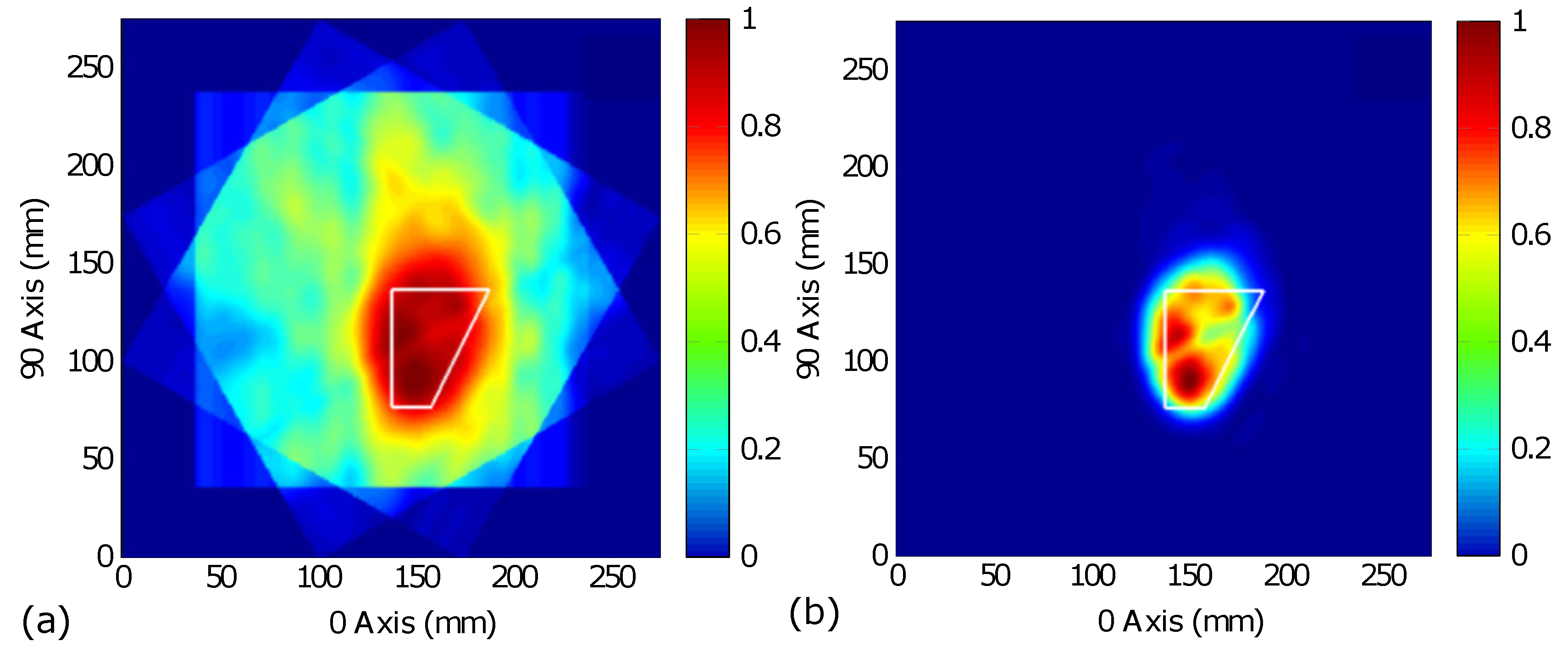

6.5. Ultrasonic Testing

6.5.1. Air-Coupled Transducers

6.5.2. Ultrasonic C-scan Testing

6.5.3. Electromagnetic Acoustic Transducer

6.5.4. Phased Array Ultrasonic Transducer

6.6. Visual Testing

7. Exemplary Results

8. Conclusions

Funding

Conflicts of Interest

References

- Herrmann, A.W. ASCE 2013 Report Card for America’s Infrastructure; IABSE Symposium Report; International Association for Bridge and Structural Engineering: Zürich, Switzerland, 2013; Volume 99, pp. 9–10. [Google Scholar]

- Ricci, F.; Monaco, E.; Maio, L.; Boffa, N.D.; Mal, A.K. Guided waves in a stiffened composite laminate with a delamination. Struct. Health Monit. 2016, 15, 351–358. [Google Scholar] [CrossRef]

- Balageas, D.; Fritzen, C.P.; Güemes, A. Structural Health Monitoring; John Wiley & Sons: Hoboken, NJ, USA, 2010; Volume 90. [Google Scholar]

- Steinmann, W.; Saelhoff, A.K. Essential properties of fibres for composite applications. In Fibrous and Textile Materials for Composite Applications; Springer: Berlin/Heidelberg, Germany, 2016; pp. 39–73. [Google Scholar]

- Yang, Q.; Cox, B. Cohesive models for damage evolution in laminated composites. Int. J. Fract. 2005, 133, 107–137. [Google Scholar] [CrossRef]

- Liu, D.; Raju, B.B.; Dang, X. Size effects on impact response of composite laminates. Int. J. Impact Eng. 1998, 21, 837–854. [Google Scholar] [CrossRef]

- Mouritz, A. Review of z-pinned composite laminates. Compos. Part A Appl. Sci. Manuf. 2007, 38, 2383–2397. [Google Scholar] [CrossRef]

- Choi, I.; Ahn, S.; Yeom, C.; Hwang, I.; Lee, D. Manufacturing of z-pinned composite laminates. In Proceedings of the 17 th International Conference on Composite Materials, Edinburgh, UK, 27–31 July 2009; Volume 27. [Google Scholar]

- Ladani, R.B.; Pingkarawat, K.; Nguyen, A.T.; Wang, C.H.; Mouritz, A.P. Delamination toughening and healing performance of woven composites with hybrid z-fibre reinforcement. Compos. Part A Appl. Sci. Manuf. 2018, 110, 258–267. [Google Scholar] [CrossRef]

- Ravindran, A.R.; Ladani, R.B.; Wang, C.H.; Mouritz, A.P. Hierarchical mode I and mode II interlaminar toughening of Z-pinned composites using 1D and 2D carbon nanofillers. Compos. Part A Appl. Sci. Manuf. 2019, 124, 105470. [Google Scholar] [CrossRef]

- Fu, Y.; Pedrini, G.; Li, X. Interferometric dynamic measurement: Techniques based on high-speed imaging or a single photodetector. Sci. World J. 2014, 2014, 232906. [Google Scholar] [CrossRef]

- Lee, H.S.; Lee, H.D.; Kim, H.J.; Cho, J.D.; Jeong, M.Y.; Kim, C.S. A fiber Bragg grating sensor interrogation system based on a linearly wavelength-swept thermo-optic laser chip. Sensors 2014, 14, 16109–16116. [Google Scholar] [CrossRef]

- Usamentiaga, R.; Venegas, P.; Guerediaga, J.; Vega, L.; Molleda, J.; Bulnes, F.G. Infrared thermography for temperature measurement and nondestructive testing. Sensors 2014, 14, 12305–12348. [Google Scholar] [CrossRef]

- Chrysafi, A.; Athanasopoulos, N.; Siakavellas, N. Damage detection on composite materials with active thermography and digital image processing. Int. J. Therm. Sci. 2017, 116, 242–253. [Google Scholar] [CrossRef]

- Khatibi, A.A.; Maleki, H.R. On the application of liquid–crystal thermography for the nondestructive detection of delamination in composite structures. Polym. Compos. 2008, 29, 798–803. [Google Scholar] [CrossRef]

- Hellstein, P.; Szwedo, M. 3D thermography in nondestructive testing of composite structures. Meas. Sci. Technol. 2016, 27, 124006. [Google Scholar] [CrossRef]

- Meinlschmidt, P.; Aderhold, J. Thermographic inspection of rotor blades. In Proceedings of the 9th European Conference on NDT, Berlin, Germany, 25–29 September 2006. [Google Scholar]

- Hung, Y.; Chen, Y.S.; Ng, S.; Liu, L.; Huang, Y.; Luk, B.; Ip, R.; Wu, C.; Chung, P. Review and comparison of shearography and active thermography for nondestructive evaluation. Mater. Sci. Eng. R Rep. 2009, 64, 73–112. [Google Scholar] [CrossRef]

- Netzelmann, U.; Walle, G.; Lugin, S.; Ehlen, A.; Bessert, S.; Valeske, B. Induction thermography: Principle, applications and first steps towards standardisation. Quant. InfraRed Thermogr. J. 2016, 13, 170–181. [Google Scholar] [CrossRef]

- Pan, M.; He, Y.; Tian, G.; Chen, D.; Luo, F. Defect characterisation using pulsed eddy current thermography under transmission mode and NDT applications. NdT E Int. 2012, 52, 28–36. [Google Scholar] [CrossRef]

- He, Y.; Pan, M.; Luo, F. Defect characterisation based on heat diffusion using induction thermography testing. Rev. Sci. Instrum. 2012, 83, 104702. [Google Scholar] [CrossRef]

- He, Y.; Yang, R. Eddy current volume heating thermography and phase analysis for imaging characterization of interface delamination in CFRP. IEEE Trans. Ind. Informat. 2015, 11, 1287–1297. [Google Scholar] [CrossRef]

- Wilson, J.; Tian, G.; Abidin, I.; Yang, S.; Almond, D. Pulsed eddy current thermography: System development and evaluation. Insight-Non Test. Cond. Monit. 2010, 52, 87–90. [Google Scholar] [CrossRef]

- Yang, R.; He, Y. Polymer-matrix composites carbon fibre characterisation and damage inspection using selectively heating thermography (SeHT) through electromagnetic induction. Compos. Struct. 2016, 140, 590–601. [Google Scholar] [CrossRef]

- Tian, G.; Gao, Y.; Li, K.; Wang, Y.; Gao, B.; He, Y. Eddy current pulsed thermography with different excitation configurations for metallic material and defect characterization. Sensors 2016, 16, 843. [Google Scholar] [CrossRef]

- Ibarra-Castanedo, C.; Avdelidis, N.P.; Grinzato, E.G.; Bison, P.G.; Marinetti, S.; Plescanu, C.C.; Bendada, A.; Maldague, X.P. Delamination detection and impact damage assessment of GLARE by active thermography. Int. J. Mater. Prod. Technol. 2011, 41, 5–16. [Google Scholar] [CrossRef]

- Duan, Y.; Servais, P.; Genest, M.; Ibarra-Castanedo, C.; Maldague, X.P. ThermoPoD: A reliability study on active infrared thermography for the inspection of composite materials. J. Mech. Sci. Technol. 2012, 26, 1985–1991. [Google Scholar] [CrossRef]

- Roche, J.M.; Balageas, D.L. Common tools for quantitative pulse and step-heating thermography–part II: Experimental investigation. Quant. Infrared Thermogr. J. 2015, 12, 1–23. [Google Scholar] [CrossRef]

- Sakagami, T.; Kubo, S. Applications of pulse heating thermography and lock-in thermography to quantitative nondestructive evaluations. Infrared Phys. Technol. 2002, 43, 211–218. [Google Scholar] [CrossRef]

- Liu, B.; Zhang, H.; Fernandes, H.; Maldague, X. Quantitative evaluation of pulsed thermography, lock-in thermography and vibrothermography on foreign object defect (FOD) in CFRP. Sensors 2016, 16, 743. [Google Scholar] [CrossRef]

- Maldague, X.; Galmiche, F.; Ziadi, A. Advances in pulsed phase thermography. Infrared Phys. Technol. 2002, 43, 175–181. [Google Scholar] [CrossRef]

- Ghadermazi, K.; Khozeimeh, M.; Taheri-Behrooz, F.; Safizadeh, M. Delamination detection in glass–epoxy composites using step-phase thermography (SPT). Infrared Phys. Technol. 2015, 72, 204–209. [Google Scholar] [CrossRef]

- Meola, C.; Carlomagno, G.; Annicchiarico, D.; Giordano, M.; Zarrelli, M. Detection of delamination in carbon-fibre-reinforced polymers with lock-in thermography. Proc. Inst. Mech. Eng. Part G J. Aerosp. Eng. 2010, 224, 1219–1227. [Google Scholar] [CrossRef]

- Ranjit, S.; Choi, M.; Kim, W. Quantification of defects depth in glass fiber-reinforced plastic plate by infrared lock-in thermography. J. Mech. Sci. Technol. 2016, 30, 1111–1118. [Google Scholar] [CrossRef]

- Park, G.; Rutherford, A.C.; Wait, J.R.; Nadler, B.; Farrar, C.; Claytor, T.N. High-frequency response functions for composite plate monitoring with ultrasonic validation. AIAA J. 2005, 43, 2431–2437. [Google Scholar] [CrossRef][Green Version]

- Yan, Y.; Yam, L. Detection of delamination damage in composite plates using energy spectrum of structural dynamic responses decomposed by wavelet analysis. Comput. Struct. 2004, 82, 347–358. [Google Scholar] [CrossRef]

- Yam, L.; Wei, Z.; Cheng, L. Nondestructive detection of internal delamination by vibration-based method for composite plates. J. Compos. Mater. 2004, 38, 2183–2198. [Google Scholar] [CrossRef]

- Crivelli, D.; Guagliano, M.; Eaton, M.; Pearson, M.; Al-Jumaili, S.; Holford, K.; Pullin, R. Localisation and identification of fatigue matrix cracking and delamination in a carbon fibre panel by acoustic emission. Compos. Part B Eng. 2015, 74, 1–12. [Google Scholar] [CrossRef]

- Nikbakht, M.; Yousefi, J.; Hosseini-Toudeshky, H.; Minak, G. Delamination evaluation of composite laminates with different interface fiber orientations using acoustic emission features and micro visualization. Compos. Part B Eng. 2017, 113, 185–196. [Google Scholar] [CrossRef]

- Fotouhi, M.; Najafabadi, M.A. Acoustic emission-based study to characterize the initiation of delamination in composite materials. J. Thermoplast. Compos. Mater. 2016, 29, 519–537. [Google Scholar] [CrossRef]

- Fotouhi, M.; Ahmadi Najafabadi, M. Investigation of the mixed-mode delamination in polymer-matrix composites using acoustic emission technique. J. Reinf. Plast. Compos. 2014, 33, 1767–1782. [Google Scholar] [CrossRef]

- Pasquali, M.; Lacarbonara, W. Delamination detection in composite laminates using high-frequency P-and S-waves–Part I: Theory and analysis. Compos. Struct. 2015, 134, 1095–1108. [Google Scholar] [CrossRef]

- Pasquali, M.; Lacarbonara, W.; Farrar, C.R. Delamination detection in composite laminates using high-frequency P-and S-waves–Part II: Experimental validation. Compos. Struct. 2015, 134, 1109–1117. [Google Scholar] [CrossRef]

- Schaal, C.; Samajder, H.; Baid, H.; Mal, A. Rayleigh to Lamb wave conversion at a delamination-like crack. J. Sound Vib. 2015, 353, 150–163. [Google Scholar] [CrossRef]

- Chrysochoidis, N.A.; Barouni, A.K.; Saravanos, D.A. Delamination detection in composites using wave modulation spectroscopy with a novel active nonlinear acousto-ultrasonic piezoelectric sensor. J. Intell. Mater. Syst. Struct. 2011, 22, 2193–2206. [Google Scholar] [CrossRef]

- Muc, A.; Stawiarski, A. Location of delaminations in curved laminated panels. Compos. Struct. 2015, 133, 652–658. [Google Scholar] [CrossRef]

- Memmolo, V.; Maio, L.; Boffa, N.D.; Monaco, E.; Ricci, F. Damage detection tomography based on guided waves in composite structures using a distributed sensor network. Opt. Eng. 2015, 55, 011007. [Google Scholar] [CrossRef]

- Rosalie, S.; Vaughan, M.; Bremner, A.; Chiu, W. Variation in the group velocity of Lamb waves as a tool for the detection of delamination in GLARE aluminium plate-like structures. Compos. Struct. 2004, 66, 77–86. [Google Scholar] [CrossRef]

- Hu, N.; Shimomukai, T.; Yan, C.; Fukunaga, H. Identification of delamination position in cross-ply laminated composite beams using S0 Lamb mode. Compos. Sci. Technol. 2008, 68, 1548–1554. [Google Scholar] [CrossRef]

- Greve, D.; Neumann, J.; Nieuwenhuis, J.; Oppenheim, I.; Tyson, N. Use of Lamb waves to monitor plates: Experiments and simulations. In Smart Structures and Materials 2005: Sensors and Smart Structures Technologies for Civil, Mechanical, and Aerospace Systems; International Society for Optics and Photonics: Bellingham, WA, USA, 2005; Volume 5765, pp. 281–293. [Google Scholar]

- Su, Z.; Ye, L. Fundamental Lamb mode-based delamination detection for CF/EP composite laminates using distributed piezoelectrics. Struct. Health Monit. 2004, 3, 43–68. [Google Scholar] [CrossRef]

- Hu, N.; Liu, Y.; Li, Y.; Peng, X.; Yan, B. Optimal excitation frequency of Lamb waves for delamination detection in CFRP laminates. J. Compos. Mater. 2010, 44, 1643–1663. [Google Scholar] [CrossRef]

- Purekar, A.; Pines, D. Damage detection in thin composite laminates using piezoelectric phased sensor arrays and guided Lamb wave interrogation. J. Intell. Mater. Syst. Struct. 2010, 21, 995–1010. [Google Scholar] [CrossRef]

- Yeum, C.M.; Sohn, H.; Lim, H.J.; Ihn, J.B. Reference-free delamination detection using Lamb waves. Struct. Control Health Monit. 2014, 21, 675–684. [Google Scholar] [CrossRef]

- Yeum, C.M.; Sohn, H.; Ihn, J.B.; Lim, H.J. Instantaneous delamination detection in a composite plate using a dual piezoelectric transducer network. Compos. Struct. 2012, 94, 3490–3499. [Google Scholar] [CrossRef]

- Yelve, N.P.; Mitra, M.; Mujumdar, P.; Ramadas, C. A hybrid method based upon nonlinear Lamb wave response for locating a delamination in composite laminates. Ultrasonics 2016, 70, 12–17. [Google Scholar] [CrossRef]

- Yelve, N.P.; Mitra, M.; Mujumdar, P. Detection of delamination in composite laminates using Lamb wave based nonlinear method. Compos. Struct. 2017, 159, 257–266. [Google Scholar] [CrossRef]

- Soleimanpour, R.; Ng, C.T. Locating delaminations in laminated composite beams using nonlinear guided waves. Eng. Struct. 2017, 131, 207–219. [Google Scholar] [CrossRef]

- Ip, K.H.; Mai, Y.W. Delamination detection in smart composite beams using Lamb waves. Smart Mater. Struct. 2004, 13, 544. [Google Scholar] [CrossRef]

- Sohn, H.; Park, G.; Wait, J.R.; Limback, N.P.; Farrar, C.R. Wavelet-based active sensing for delamination detection in composite structures. Smart Mater. Struct. 2003, 13, 153. [Google Scholar] [CrossRef]

- Su, Z.; Yang, C.; Pan, N.; Ye, L.; Zhou, L.M. Assessment of delamination in composite beams using shear horizontal (SH) wave mode. Compos. Sci. Technol. 2007, 67, 244–251. [Google Scholar] [CrossRef]

- Barnard, D.J. A variable pitch comb fixture for Rayleigh wave generation and reception. In Proceedings of the AIP Conference Proceedings, Omsk, Russia, 26 February–2 March 2018; Volume 894, pp. 1684–1690. [Google Scholar]

- Mal, A. Elastic waves from localized sources in composite laminates. Int. J. Solids Struct. 2002, 39, 5481–5494. [Google Scholar] [CrossRef]

- Ostachowicz, W.; Kudela, P.; Krawczuk, M.; Zak, A. Guided waves in Structures for SHM: The Time-Domain Spectral Element Method; John Wiley & Sons: Hoboken, NJ, USA, 2011. [Google Scholar]

- Seif, M.A.; Khashaba, U.A.; Rojas-Oviedo, R. Measuring delamination in carbon/epoxy composites using a shadow moiré laser based imaging technique. Compos. Struct. 2007, 79, 113–118. [Google Scholar] [CrossRef]

- Maranon, A.; Ruiz, P.; Nurse, A.; Huntley, J.; Rivera, L.; Zhou, G. Identification of subsurface delaminations in composite laminates. Compos. Sci. Technol. 2007, 67, 2817–2826. [Google Scholar] [CrossRef]

- Hatta, H.; Aly-Hassan, M.S.; Hatsukade, Y.; Wakayama, S.; Suemasu, H.; Kasai, N. Damage detection of C/C composites using ESPI and SQUID techniques. Compos. Sci. Technol. 2005, 65, 1098–1106. [Google Scholar] [CrossRef]

- Akhter, N.; Jung, H.C.; Chang, H.S.; Kim, K.S. Location of delamination in laminated composite plates by pulsed laser holography. Opt. Lasers Eng. 2009, 47, 584–588. [Google Scholar] [CrossRef]

- Bruno, F.; Laurent, J.; Prada, C.; Lamboul, B.; Passilly, B.; Atlan, M. Non-destructive testing of composite plates by holographic vibrometry. J. Appl. Phys. 2014, 115, 154503. [Google Scholar] [CrossRef]

- De Angelis, G.; Meo, M.; Almond, D.P.; Pickering, S.G.; Angioni, S.L. A new technique to detect defect size and depth in composite structures using digital shearography and unconstrained optimization. NdT E Int. 2012, 45, 91–96. [Google Scholar] [CrossRef]

- Gryzagoridis, J.; Findeis, D. Simultaneous shearographic and thermographic NDT of aerospace materials. Insight-Non Test. Cond. Monit. 2006, 48, 294–297. [Google Scholar] [CrossRef]

- Ling, H.Y.; Lau, K.T.; Lam, C.K. Effects of embedded optical fibre on mode II fracture behaviours of woven composite laminates. Compos. Part B Eng. 2005, 36, 534–543. [Google Scholar] [CrossRef]

- Takeda, N.; Okabe, Y.; Kuwahara, J.; Kojima, S.; Ogisu, T. Development of smart composite structures with small-diameter fiber Bragg grating sensors for damage detection: Quantitative evaluation of delamination length in CFRP laminates using Lamb wave sensing. Compos. Sci. Technol. 2005, 65, 2575–2587. [Google Scholar] [CrossRef]

- Jang, B.W.; Kim, C.G. Real-time detection of low-velocity impact-induced delamination onset in composite laminates for efficient management of structural health. Compos. Part B Eng. 2017, 123, 124–135. [Google Scholar] [CrossRef]

- Luyckx, G.; Voet, E.; Lammens, N.; Degrieck, J. Strain measurements of composite laminates with embedded fibre Bragg gratings: Criticism and opportunities for research. Sensors 2010, 11, 384–408. [Google Scholar] [CrossRef]

- Takeda, S.; Okabe, Y.; Takeda, N. Delamination detection in CFRP laminates with embedded small-diameter fiber Bragg grating sensors. Compos. Part A Appl. Sci. Manuf. 2002, 33, 971–980. [Google Scholar] [CrossRef]

- Takeda, S.; Okabe, Y.; Yamamoto, T.; Takeda, N. Detection of edge delamination in CFRP laminates under cyclic loading using small-diameter FBG sensors. Compos. Sci. Technol. 2003, 63, 1885–1894. [Google Scholar] [CrossRef]

- Ling, H.Y.; Lau, K.T.; Cheng, L. Determination of dynamic strain profile and delamination detection of composite structures using embedded multiplexed fibre-optic sensors. Compos. Struct. 2004, 66, 317–326. [Google Scholar] [CrossRef]

- Leung, C.K.; Yang, Z.; Xu, Y.; Tong, P.; Lee, S.K. Delamination detection in laminate composites with an embedded fiber optical interferometric sensor. Sens. Actuators A Phys. 2005, 119, 336–344. [Google Scholar] [CrossRef]

- Frieden, J.; Cugnoni, J.; Botsis, J.; Gmür, T. Vibration-based characterization of impact-induced delamination in composite plates using embedded FBG sensors and numerical modelling. Compos. Part B Eng. 2011, 42, 607–613. [Google Scholar] [CrossRef]

- Nalawade, S.M.; Mahra, N.; Grattan, K.; Thakur, H.V. Delamination detection in glass composites using embedded Hi-Bi photonic crystal fiber. Smart Mater. Struct. 2011, 20, 055023. [Google Scholar] [CrossRef]

- Lam, P.M.; Lau, K.T.; Ling, H.Y.; Su, Z.; Tam, H.Y. Acousto-ultrasonic sensing for delaminated GFRP composites using an embedded FBG sensor. Opt. Lasers Eng. 2009, 47, 1049–1055. [Google Scholar] [CrossRef]

- Sorensen, L.; Botsis, J.; Gmür, T.; Cugnoni, J. Delamination detection and characterisation of bridging tractions using long FBG optical sensors. Compos. Part A Appl. Sci. Manuf. 2007, 38, 2087–2096. [Google Scholar] [CrossRef]

- Bao, Y.; Valipour, M.; Meng, W.; Khayat, K.H.; Chen, G. Distributed fiber optic sensor-enhanced detection and prediction of shrinkage-induced delamination of ultra-high-performance concrete overlay. Smart Mater. Struct. 2017, 26, 085009. [Google Scholar] [CrossRef]

- Mieloszyk, M.; Skarbek, L.; Krawczuk, M.; Ostachowicz, W.; Zak, A. Application of fibre Bragg grating sensors for structural health monitoring of an adaptive wing. Smart Mater. Struct. 2011, 20, 125014. [Google Scholar] [CrossRef]

- Sohn, H.; Dutta, D.; Yang, J.; Park, H.; DeSimio, M.; Olson, S.; Swenson, E. Delamination detection in composites through guided wave field image processing. Compos. Sci. Technol. 2011, 71, 1250–1256. [Google Scholar] [CrossRef]

- Sohn, H.; Dutta, D.; Yang, J.; DeSimio, M.; Olson, S.; Swenson, E. Automated detection of delamination and disbond from wavefield images obtained using a scanning laser vibrometer. Smart Mater. Struct. 2011, 20, 045017. [Google Scholar] [CrossRef]

- Park, B.; An, Y.K.; Sohn, H. Visualization of hidden delamination and debonding in composites through noncontact laser ultrasonic scanning. Compos. Sci. Technol. 2014, 100, 10–18. [Google Scholar] [CrossRef]

- Rogge, M.D.; Leckey, C.A. Characterization of impact damage in composite laminates using guided wavefield imaging and local wavenumber domain analysis. Ultrasonics 2013, 53, 1217–1226. [Google Scholar] [CrossRef] [PubMed]

- Tian, Z.; Yu, L.; Leckey, C. Delamination detection and quantification on laminated composite structures with Lamb waves and wavenumber analysis. J. Intell. Mater. Syst. Struct. 2015, 26, 1723–1738. [Google Scholar] [CrossRef]

- Tian, Z.; Yu, L.; Leckey, C.; Seebo, J. Guided wave imaging for detection and evaluation of impact-induced delamination in composites. Smart Mater. Struct. 2015, 24, 105019. [Google Scholar] [CrossRef]

- Tian, Z.; Yu, L.; Leckey, C. Rapid guided wave delamination detection and quantification in composites using global-local sensing. Smart Mater. Struct. 2016, 25, 085042. [Google Scholar] [CrossRef]

- Staszewski, W.; Mahzan, S.; Traynor, R. Health monitoring of aerospace composite structures–Active and passive approach. Compos. Sci. Technol. 2009, 69, 1678–1685. [Google Scholar] [CrossRef]

- Żak, A.; Ostachowicz, W.; Krawczuk, M. Damage detection strategies for aircraft shell–like structures based on propagation guided elastic waves. J. Phys. Conf. Ser. 2011. [Google Scholar] [CrossRef]

- Kudela, P.; Wandowski, T.; Malinowski, P.; Ostachowicz, W. Application of scanning laser Doppler vibrometry for delamination detection in composite structures. Opt. Lasers Eng. 2017, 99, 46–57. [Google Scholar] [CrossRef]

- Mesnil, O.; Ruzzene, M. Sparse wavefield reconstruction and source detection using compressed sensing. Ultrasonics 2016, 67, 94–104. [Google Scholar] [CrossRef]

- Park, B.; Sohn, H.; Malinowski, P.; Ostachowicz, W. Delamination localization in wind turbine blades based on adaptive time-of-flight analysis of noncontact laser ultrasonic signals. Nondestruct. Test. Eval. 2017, 32, 1–20. [Google Scholar] [CrossRef]

- Amraoui, M.; Lieven, N. Laser vibrometry based detection of delaminations in glass/epoxy composites. J. Vib. Acoust. 2004, 126, 430–437. [Google Scholar] [CrossRef]

- Qiao, P.; Lu, K.; Lestari, W.; Wang, J. Curvature mode shape-based damage detection in composite laminated plates. Compos. Struct. 2007, 80, 409–428. [Google Scholar] [CrossRef]

- Cao, M.; Ostachowicz, W.; Radzieński, M.; Xu, W. Multiscale shear-strain gradient for detecting delamination in composite laminates. Appl. Phys. Lett. 2013, 103, 101910. [Google Scholar] [CrossRef]

- Le Bas, P.Y.; Remillieux, M.; Pieczonka, L.; Ten Cate, J.; Anderson, B.; Ulrich, T. Damage imaging in a laminated composite plate using an air-coupled time reversal mirror. Appl. Phys. Lett. 2015, 107, 184102. [Google Scholar] [CrossRef]

- Soleimanpour, R.; Ng, C.T.; Wang, C.H. Higher harmonic generation of guided waves at delaminations in laminated composite beams. Struct. Health Monit. 2017, 16, 400–417. [Google Scholar] [CrossRef]

- Wandowski, T.; Malinowski, P.; Ostachowicz, W. Delamination detection in CFRP panels using EMI method with temperature compensation. Compos. Struct. 2016, 151, 99–107. [Google Scholar] [CrossRef]

- Sun, G.; Zhou, Z.; Chen, X.; Wang, J. Ultrasonic characterization of delamination in aeronautical composites using noncontact laser generation and detection. Appl. Opt. 2013, 52, 6481–6486. [Google Scholar] [CrossRef]

- Sun, G.; Zhou, Z. Application of laser ultrasonic technique for non-contact detection of drilling-induced delamination in aeronautical composite components. Opt.-Int. J. Light Electron Opt. 2014, 125, 3608–3611. [Google Scholar] [CrossRef]

- Kinet, D.; Mégret, P.; Goossen, K.W.; Qiu, L.; Heider, D.; Caucheteur, C. Fiber Bragg grating sensors toward structural health monitoring in composite materials: Challenges and solutions. Sensors 2014, 14, 7394–7419. [Google Scholar] [CrossRef]

- Larrosa, C.; Lonkar, K.; Chang, F.K. In situ damage classification for composite laminates using Gaussian discriminant analysis. Struct. Health Monit. 2014, 13, 190–204. [Google Scholar] [CrossRef]

- Aymerich, F.; Dore, F.; Priolo, P. Prediction of impact-induced delamination in cross-ply composite laminates using cohesive interface elements. Compos. Sci. Technol. 2008, 68, 2383–2390. [Google Scholar] [CrossRef]

- Tsao, C.; Hocheng, H. Computerized tomography and C-Scan for measuring delamination in the drilling of composite materials using various drills. Int. J. Mach. Tools Manuf. 2005, 45, 1282–1287. [Google Scholar] [CrossRef]

- Schilling, P.J.; Karedla, B.R.; Tatiparthi, A.K.; Verges, M.A.; Herrington, P.D. X-ray computed microtomography of internal damage in fiber-reinforced polymer matrix composites. Compos. Sci. Technol. 2005, 65, 2071–2078. [Google Scholar] [CrossRef]

- Vavrik, D.; Jakubek, J.; Jandejsek, I.; Krejci, F.; Kumpova, I.; Zemlicka, J. Visualization of delamination in composite materials utilizing advanced X-ray imaging techniques. J. Instrum. 2015, 10, C04012. [Google Scholar] [CrossRef]

- Dong, J.; Kim, B.; Locquet, A.; McKeon, P.; Declercq, N.; Citrin, D. Nondestructive evaluation of forced delamination in glass fiber-reinforced composites by terahertz and ultrasonic waves. Compos. Part B Eng. 2015, 79, 667–675. [Google Scholar] [CrossRef]

- Ryu, C.H.; Park, S.H.; Kim, D.H.; Jhang, K.Y.; Kim, H.S. Nondestructive evaluation of hidden multi-delamination in a glass-fiber-reinforced plastic composite using terahertz spectroscopy. Compos. Struct. 2016, 156, 338–347. [Google Scholar] [CrossRef]

- Todoroki, A.; Tanaka, M.; Shimamura, Y. High performance estimations of delamination of graphite/epoxy laminates with electric resistance change method. Compos. Sci. Technol. 2003, 63, 1911–1920. [Google Scholar] [CrossRef]

- Escalona Galvis, L.; Diaz-Montiel, P.; Venkataraman, S. Optimal electrode selection for electrical resistance tomography in carbon fiber-reinforced polymer composites. Materials 2017, 10, 125. [Google Scholar] [CrossRef]

- Zhao, Q.; Zhang, K.; Zhu, S.; Xu, H.; Cao, D.; Zhao, L.; Zhang, R.; Yin, W. Review on the Electrical Resistance/Conductivity of Carbon Fiber Reinforced Polymer. Appl. Sci. 2019, 9, 2390. [Google Scholar] [CrossRef]

- Matsuzaki, R.; Todoroki, A. Wireless detection of internal delamination cracks in CFRP laminates using oscillating frequency changes. Compos. Sci. Technol. 2006, 66, 407–416. [Google Scholar] [CrossRef]

- Todoroki, A. Delamination monitoring analysis of CFRP structures using multi-probe electrical method. J. Intell. Mater. Syst. Struct. 2008, 19, 291–298. [Google Scholar] [CrossRef]

- Matsuzaki, R.; Yamamoto, K.; Todoroki, A. Delamination detection in carbon fiber-reinforced plastic cross-ply laminates using crack swarm inspection: Experimental verification. Compos. Struct. 2017, 173, 127–135. [Google Scholar] [CrossRef]

- Tan, P.; Tong, L. Delamination detection of composite beams using piezoelectric sensors with evenly distributed electrode strips. J. Compos. Mater. 2004, 38, 321–352. [Google Scholar] [CrossRef]

- Kažys, R.; Demčenko, A.; Žukauskas, E.; Mažeika, L. Air-coupled ultrasonic investigation of multi-layered composite materials. Ultrasonics 2006, 44, e819–e822. [Google Scholar] [CrossRef] [PubMed]

- Ramadas, C.; Balasubramaniam, K.; Joshi, M.; Krishnamurthy, C. Interaction of the primary anti-symmetric Lamb mode (Ao) with symmetric delaminations: Numerical and experimental studies. Smart Mater. Struct. 2009, 18, 085011. [Google Scholar] [CrossRef]

- Liu, Z.; Yu, H.; He, C.; Wu, B. Delamination detection in composite beams using pure Lamb mode generated by air-coupled ultrasonic transducer. J. Intell. Mater. Syst. Struct. 2014, 25, 541–550. [Google Scholar] [CrossRef]

- Ramadas, C.; Janardhan Padiyar, M.; Balasubramaniam, K.; Joshi, M.; Krishnamurthy, C. Delamination size detection using time of flight of anti-symmetric (Ao) and mode converted Ao mode of guided Lamb waves. J. Intell. Mater. Syst. Struct. 2010, 21, 817–825. [Google Scholar] [CrossRef]

- Michaels, T.E.; Michaels, J.E.; Ruzzene, M. Frequency–wavenumber domain analysis of guided wavefields. Ultrasonics 2011, 51, 452–466. [Google Scholar] [CrossRef]

- Liu, Z.; Yu, H.; Fan, J.; Hu, Y.; He, C.; Wu, B. Baseline-free delamination inspection in composite plates by synthesizing non-contact air-coupled Lamb wave scan method and virtual time reversal algorithm. Smart Mater. Struct. 2015, 24, 045014. [Google Scholar] [CrossRef]

- Grimberg, R.; Steigmann, R.; Leitoiu, S.; Andreescu, A.; Savin, A. Ultrasound and eddy current data fusion evaluation of carbon–epoxy composites delaminations. Emerg. Technol. Nondestruct. Test. 2008, 349–355. [Google Scholar] [CrossRef]

- Freeman, B.; Schwingler, E.; Mahinfalah, M.; Kellogg, K. The effect of low-velocity impact on the fatigue life of Sandwich composites. Compos. Struct. 2005, 70, 374–381. [Google Scholar] [CrossRef]

- Benammar, A.; Drai, R.; Guessoum, A. Detection of delamination defects in CFRP materials using ultrasonic signal processing. Ultrasonics 2008, 48, 731–738. [Google Scholar] [CrossRef] [PubMed]

- Long, S.; Yao, X.; Zhang, X. Delamination prediction in composite laminates under low-velocity impact. Compos. Struct. 2015, 132, 290–298. [Google Scholar] [CrossRef]

- Wang, H.R.; Long, S.C.; Zhang, X.Q.; Yao, X.H. Study on the delamination behavior of thick composite laminates under low-energy impact. Compos. Struct. 2018, 184, 461–473. [Google Scholar] [CrossRef]

- Hocheng, H.; Tsao, C. Effects of special drill bits on drilling-induced delamination of composite materials. Int. J. Mach. Tools Manuf. 2006, 46, 1403–1416. [Google Scholar] [CrossRef]

- Post, W.; Kersemans, M.; Solodov, I.; Van Den Abeele, K.; García, S.; van der Zwaag, S. Non-destructive monitoring of delamination healing of a CFRP composite with a thermoplastic ionomer interlayer. Compos. Part A Appl. Sci. Manuf. 2017, 101, 243–253. [Google Scholar] [CrossRef]

- Gao, H.; Ali, S.; Lopez, B. Efficient detection of delamination in multilayered structures using ultrasonic guided wave EMATs. NDT E Int. 2010, 43, 316–322. [Google Scholar] [CrossRef]

- Taheri, H.; Hassen, A.A. Nondestructive Ultrasonic Inspection of Composite Materials: A Comparative Advantage of Phased Array Ultrasonic. Appl. Sci. 2019, 9, 1628. [Google Scholar] [CrossRef]

- Davim, J.P.; Rubio, J.C.; Abrao, A. A novel approach based on digital image analysis to evaluate the delamination factor after drilling composite laminates. Compos. Sci. Technol. 2007, 67, 1939–1945. [Google Scholar] [CrossRef]

- Cortes, P.; Cantwell, W. The impact properties of high-temperature fiber-metal laminates. J. Compos. Mater. 2007, 41, 613–632. [Google Scholar] [CrossRef]

- Jalalvand, M.; Czél, G.; Fuller, J.D.; Wisnom, M.R.; Canal, L.P.; González, C.D.; LLorca, J. Energy dissipation during delamination in composite materials–An experimental assessment of the cohesive law and the stress-strain field ahead of a crack tip. Compos. Sci. Technol. 2016, 134, 115–124. [Google Scholar] [CrossRef]

- Yamanaka, K.; Kobari, K.; Tsuji, T. Evaluation of functional materials and devices using atomic force microscopy with ultrasonic measurements. Jpn. J. Appl. Phys. 2008, 47, 6070. [Google Scholar] [CrossRef]

| Technique | Keyword (s) |

|---|---|

| Thermographic inspection | Thermography; Thermosonic |

| Piezoelectric inspection | Piezoelectric (PZT) |

| Optical interferometry | Moiré interferometry; Shearography; Digital holography; Electronic speckle pattern interferometry; Laser vibrometry; Fiber Bragg grating |

| Electromagnetic testing | Radiography; Computed tomography; Terahertz spectroscopy |

| Ultrasonic testing | Air-coupled transducer; Ultrasonic C-scan |

| Visual testing | Microscope |

| Category | Industrial Applications |

|---|---|

| Thermographic inspection | Electrical high-voltage and low-voltage installations such as electrical power grid and electrical cabinets and motor control centers; Mechanical installations such as gearboxes and bearings; Pipework; Construction; Medical imaging; Petrochemical sector; Refractory and petrochemical installations; Flare detection. |

| Piezoelectric inspection | Automobile manufacturing; Medical technology; Aerospace and nuclear instrumentation. |

| Optical interferometry | The optical industry to test the surfaces quality; Power industry. |

| Electromagnetic testing | Medical imaging; Manufacturing; Aerospace and automotive. |

| Ultrasonic testing | Aerospace and automotive sectors; Manufacturing; Medical imaging; Pipelines and Construction. |

| Visual testing | Medical; Machinery; Aircraft. |

| Technique | Merits and Demerits |

|---|---|

| LC thermography | Inexpensive; Easy setup; Surface preparation by painting and detector (LC) application; Requiring two-sided accessibility of specimen’s surface; Qualitative measurement |

| PIR thermography | Requiring no excitation; Low resolution; Qualitative measurement |

| EC thermography | Selectively heating (e.g., pulsed); High resolution; Cooling phase for delamination detection; Lower frequency excitation for deeper delamination; Induction coil directed perpendicular to the defect |

| Pulsed thermography | Quantitative measurement; Requireing application of processing techniques |

| Step thermography | Appropriate for impact damages |

| LI thermography | Ability of decreasing frequencies to inspect deep and small delaminations; quantitative measurement |

| Vibrothermography | Contact based nature, thereby varying vibration spectrum by contact |

| Input | Output (Data Acquisition) |

|---|---|

| Different loading patterns: temperature gradient, acoustics, negative pressure, Lamb waves | Difference of the distribution of speckle patterns analyzed for output measurements |

| Surface illumination by laser light source | Full-field measurements |

| Phase shifting technique applied to enhance fringe pattern distribution, thereby extracting desired quantitative measurements | Rendering mechanical deformation and its derivatives |

| Delamination detection by finding highly deformed areas | |

| Non-contact operation but FBG; Lower cost and faster measurement; Susceptible to environmental noises; Difficulty in interpreting the resultant images; The possibility of surface ablation by laser light | |

| Imaging Technique | Merits/Demerits |

|---|---|

| 2D and 3D X-ray imaging | High-resolution images of micro-CT, but low spatial resolution threshold |

| Lifetime reduction of materials under long term exposure of electromagnetic radiation | |

| High initial cost | |

| Applying dye penetrant to enhance the image contrast | |

| Low-contrast images of radiography | |

| Limited application for large specimens | |

| THz imaging | Through-the-thickness quantitative information |

| High spatial resolution images |

| Technique | Merits/Demerits |

|---|---|

| Ultrasonic C-scan testing | Full-field measurement |

| Clear delamination localization due to difference between sound impedance scattered from delamination area and intact area | |

| Limited resolution owing to insufficient operating frequency | |

| Lack of through-the-thickness quantitative information occurred in small ratios of thickness and wavelength | |

| The possibility of liquid coupling requirement (contact-based nature and probable detrimental effect) | |

| Bonding degradation due to penetrating couplant into the composite | |

| Point-wise inspection, and consequently a tedious technique | |

| Air-coupled transducer | Non-contact; No couplant requirement |

| Extracting good A-scans; Air–solid material acoustic impedance misfit | |

| Necessity of setting up the appropriate actuator–sensor distance, transducer–composite distance, and incident and reception angles to actuate and receive a particular wave mode |

| (A) | (B) | (C) | (D) | (E) | (F) | |

|---|---|---|---|---|---|---|

| destructive/nondestructive | ✗/ ✓ | ✗/ ✓ | ✗/ ✓ | ✗/ ✓ | ✓/ ✓ | ✗/ ✓ |

| contact/non-contact | vibrothermography / ✓ | ✓/ ✗ | FBG / ✓ | ✗/ ✓ | ✓/ ACT | ✗/ ✓ |

| local/gobal | ✗/ ✓ | ✓/ ✗ | FBG / ✓ | ✗/ ✓ | ✗/ ✓ | ✗/ ✓ |

| low/high frequency | ✓/ ✓ | ✗/ ✓ | ✓/ ✓ | ✗/ ✓ | ✗/ ✓ | ✓/ ✓ |

| vibration/image based | ✗/ ✓ | ✓/ ✗ | FBG / ✓ | ✗/ ✓ | ✗/ ✓ | ✗/ ✓ |

| active/passive | ✓/ ✗ | ✓/ AE based | ✓/ ✗ | ✓/ ✗ | ✓/ ✗ | ✓/ ✗ |

| Mode | Characteristics |

|---|---|

| Transmission mode | More accurate for relatively thin-thickness specimens; High contrast results due to blocking heat conduction (smaller 3D heating conduction) |

| Reflection mode | More practical; Excitation source blocks camera’s view; Appropriate for deeper defects; Larger 3D heating conduction |

| Technique | Reference (s) |

|---|---|

| Fourier transform | [14,22,23,27,31,32] |

| Wavelet transform | [14,27] |

| Principal component analysis (thermography); Independent component analysis | [20,27] |

| Cross correlation matched filtering | [23] |

| Thermal signal reconstruction; Differential absolute contrast | [27] |

| Wedge method [48,49,61] | Single mode excitation | Fixed angle | Heavy and expensive for widespread use |

| Variable angle | |||

| Comb method [62] | Multimode wave problem and requiring data postprocessing | ||

| Wafer method [50,51,57] | Low cost; Practicality; Minimum invasion; Wider frequency bandwidth | ||

| Indicator | Reference (s) |

|---|---|

| Time of flight or the group velocity | [42,43,48,49,51,53,56,57,59] |

| Wave conversion | [44,51,61] |

| Amplitude signal degradation | [46,54,60] |

| Delamination induced contact nonlinearity | [56,57,58] |

| Statistical-geometrical damage index | [46,47] |

| Wavenumber analysis | [53] |

| Nonlinear wave modulation technique | [45] |

| Higher amplitude and smaller wavelength, thereby higher sensitivity to small delamination | Faster mode at the low range of frequency-thickness product; Lower attenuation |

| Generating a shear stress distribution at low frequency range | The strong reflection amplitude dependency on the delamination depth such that the amplitude reflected at mid-plane delamination is zero |

| More delamination-induced delay and amplitude attenuation as a result of shear strength decrease | |

| No reflection from symmetrically located delamination (zero shear stress) or no mode–delamination interaction | Overlapping reflections from boundaries with modes |

| Merits | Appropriate for large area inspection due to low energy and amplitude attenuation; Delamination detection at early stages |

| Demerits | Anisotropy nature of composites with different multiple laminas requires signal processing techniques. Strong boundary reflected multiple waves; Sensitive to structural geometrical features in addition to discontinuities; Dispersive nature of Lamb waves; Presence of edge reflections; Low through-the-air transmittance |

| Challenges | Requiring temperature-strain discrimination through employing an individual temperature compensation FBG immune to strain changes |

| Amplitude spectrum demodulation | |

| FBG-surrounding material connection; Calibration requirement | |

| Features | FBGs are contact-based and local measuring tools; Compatibility with composite materials |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Askaripour, K.; Zak, A. A Survey of Scrutinizing Delaminated Composites via Various Categories of Sensing Apparatus. J. Compos. Sci. 2019, 3, 95. https://doi.org/10.3390/jcs3040095

Askaripour K, Zak A. A Survey of Scrutinizing Delaminated Composites via Various Categories of Sensing Apparatus. Journal of Composites Science. 2019; 3(4):95. https://doi.org/10.3390/jcs3040095

Chicago/Turabian StyleAskaripour, Khadijeh, and Arkadiusz Zak. 2019. "A Survey of Scrutinizing Delaminated Composites via Various Categories of Sensing Apparatus" Journal of Composites Science 3, no. 4: 95. https://doi.org/10.3390/jcs3040095

APA StyleAskaripour, K., & Zak, A. (2019). A Survey of Scrutinizing Delaminated Composites via Various Categories of Sensing Apparatus. Journal of Composites Science, 3(4), 95. https://doi.org/10.3390/jcs3040095