Research and Development in Carbon Fibers and Advanced High-Performance Composites Supply Chain in Europe: A Roadmap for Challenges and the Industrial Uptake

Abstract

:1. Introduction

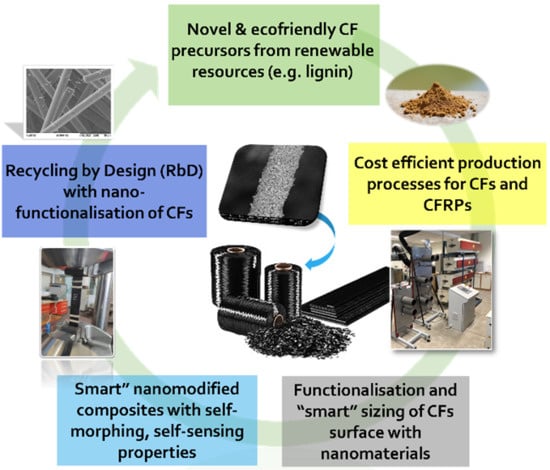

2. Novel Materials and Optimized Processing

2.1. Carbon Fiber Conversion Technologies

- The improvement of carbon fiber properties by optimizing the carbon fiber conversion technologies;

- The generation of additional functionalities for carbon fibers;

- The reduction of energy consumption during the carbon fiber conversion while maintaining the CF properties.

- Understanding the process parameter–structure–property relationships during thermomechanical conversion;

- Process influence on tailored CF properties for multifunctional applications;

- Mechanisms of crosslinking of precursor fibers within laser-, plasma-, and e-beam stabilization and their influence on the structural change during conversion to carbon fibers;

- Energy conditions for resource-efficient CF structure formation.

2.2. Semi-Product Development and Supply Chain

2.3. Enhanced Process Throughput for High Volume Applications

2.4. Development of Structural Materials Driven by Enhanced Energy Management

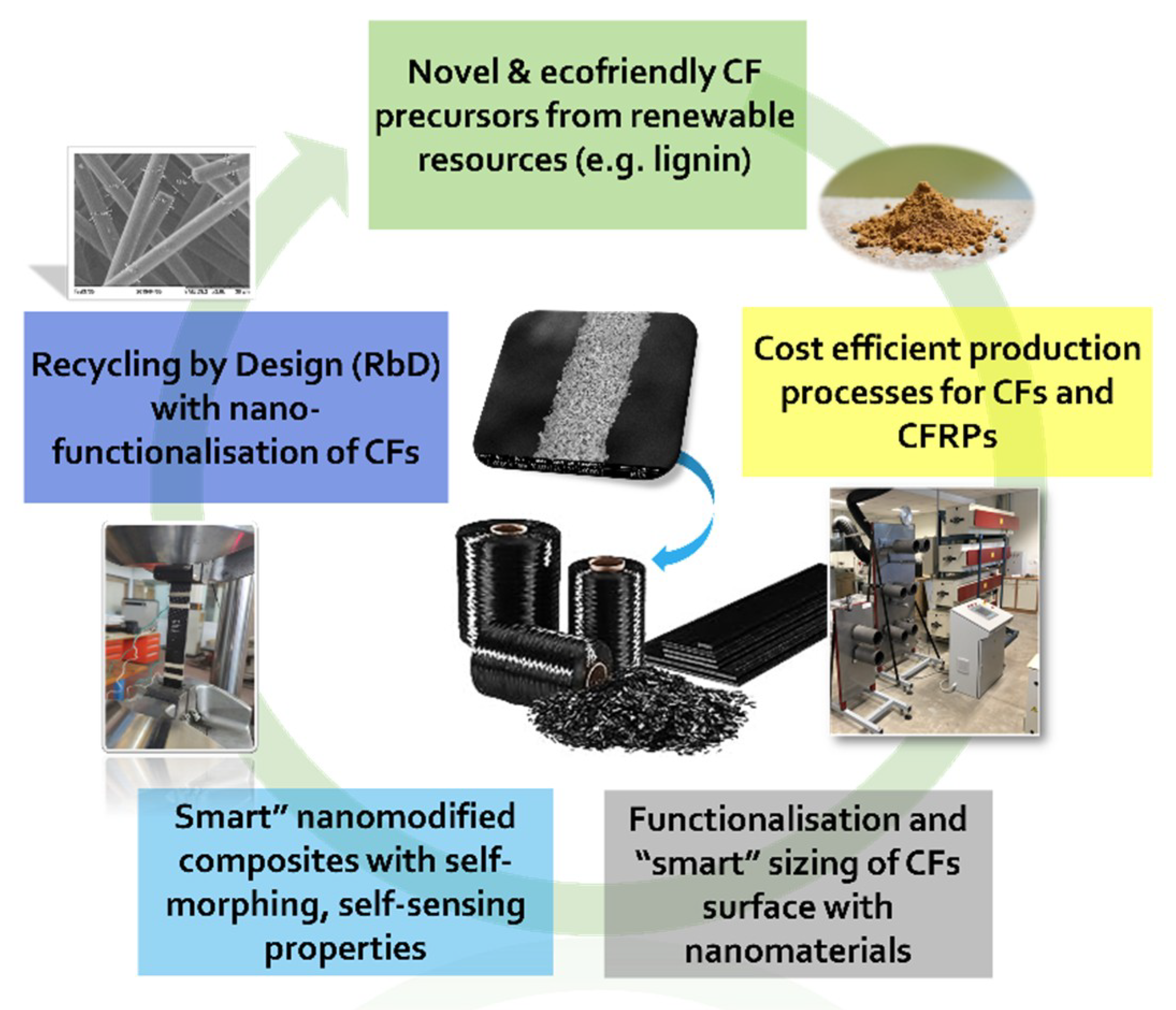

2.5. Nanomodification to Enable More Applications for Enhanced Mechanical Properties and Multifunctionalities

- Issues related to the poor dispersion and re-agglomeration phenomena of carbon-based nanostructures;

- Processability difficulties associated with a dramatic increase of the shear viscosity due to the incorporation of the nanostructures within polymeric matrices;

- Formation of weak interfaces between the nano-reinforcements and the matrix;

- Difficulties in transferring the remarkable properties of nanomaterials from the nanocomposite (nano-modified matrix) to composite level.

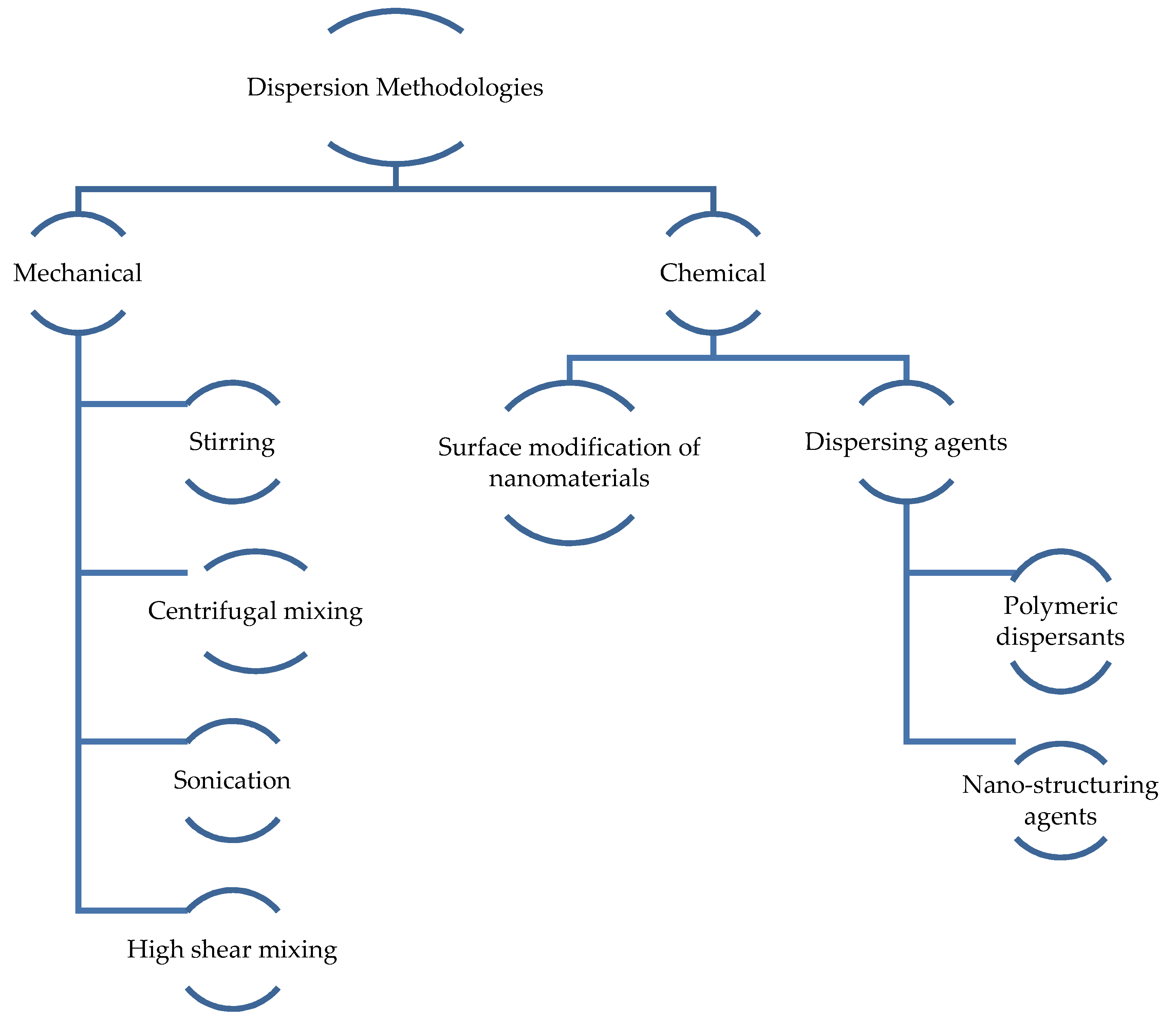

2.6. Additive Manufacturing of CFRPs

2.7. High Performance REACH Compliant Matrices for Nanocomposites

2.8. Occupational Health and Safety Practices in Composites Manufacturing Industry

- Handling dry colloidal deposits and unprocessed nanoparticle powders;

- Spraying from engineering nanoparticle suspensions, solutions, and slurries (i.e., thermal spraying);

- Dry blending of manufactured nanomaterials (MNMs) into a matrix (e.g., polymer);

- Processing solid matrixes containing MNMs e.g., weave, knit, twist, cut, grind, and scrape;

- Cutting/grinding a matrix containing MNMs.

- Validation of the in vitro methods and methods to determine physico-chemical properties as tools to determine health effects;

- Identification of the nanomaterials in the working place and description of exposure;

- Measurement (proper instrumentation) of exposures of nanomaterials and efficacy of protective measures.

3. Characterization and Modeling: From Experiment to Simulation and Vice Versa

3.1. Advanced Characterization Techniques, Including Standardization and Data

- Optimum composite data generation, storage, and dissemination processes (design data, manufacturing data, operation condition data, and diagnostic data);

- European standardization of composite testing methods;

- Development of novel characterization methods (e.g., in situ test methods) for complex materials and complex load scenarios.

3.2. Multiscale, Multiphysics, High-Performance Computational Tools for Advanced Composites

3.3. Hybrid Reinforced Composites and Multiscale Simulation

4. Environmental and Economical Circularity

4.1. The European CFs and Advanced Composites Industry Today and Tomorrow

4.2. Alternative Precursors—Critical Non-Dependence

- Spinnable defect free or low defect precursors in reproducible quality;

- Process-independent precursor copolymers for melt and solvent spinning;

- Healing of defects through targeted doping of precursor systems;

- Mechanisms of structure formation of alternative precursor fibers in different spinning processes;

- Influencing the process for local defect healing or targeted porosity control;

- Modular and energy-efficient process chains.

4.3. Recyclability of CFRPs and Reintegration of Recovered Materials into Manufacturing Processes

4.4. Cost Effective Repairing

- Uncertainties surrounding the parts that are most-safety-critical parts of an object, such as an aircraft, which simply cannot be allowed to fail or be compromised, therefore, will have extremely high accuracy demand;

- Another challenge can be the lack of standards or limited standardization of composite materials and repair techniques, such as in wind energy and automotive repairs, especially the automotive situation is more nascent and critical;

- Without the appropriate standards and the low level of training and awareness of workers handling composites, difficulties arise regarding the detection and repair of composites damage.

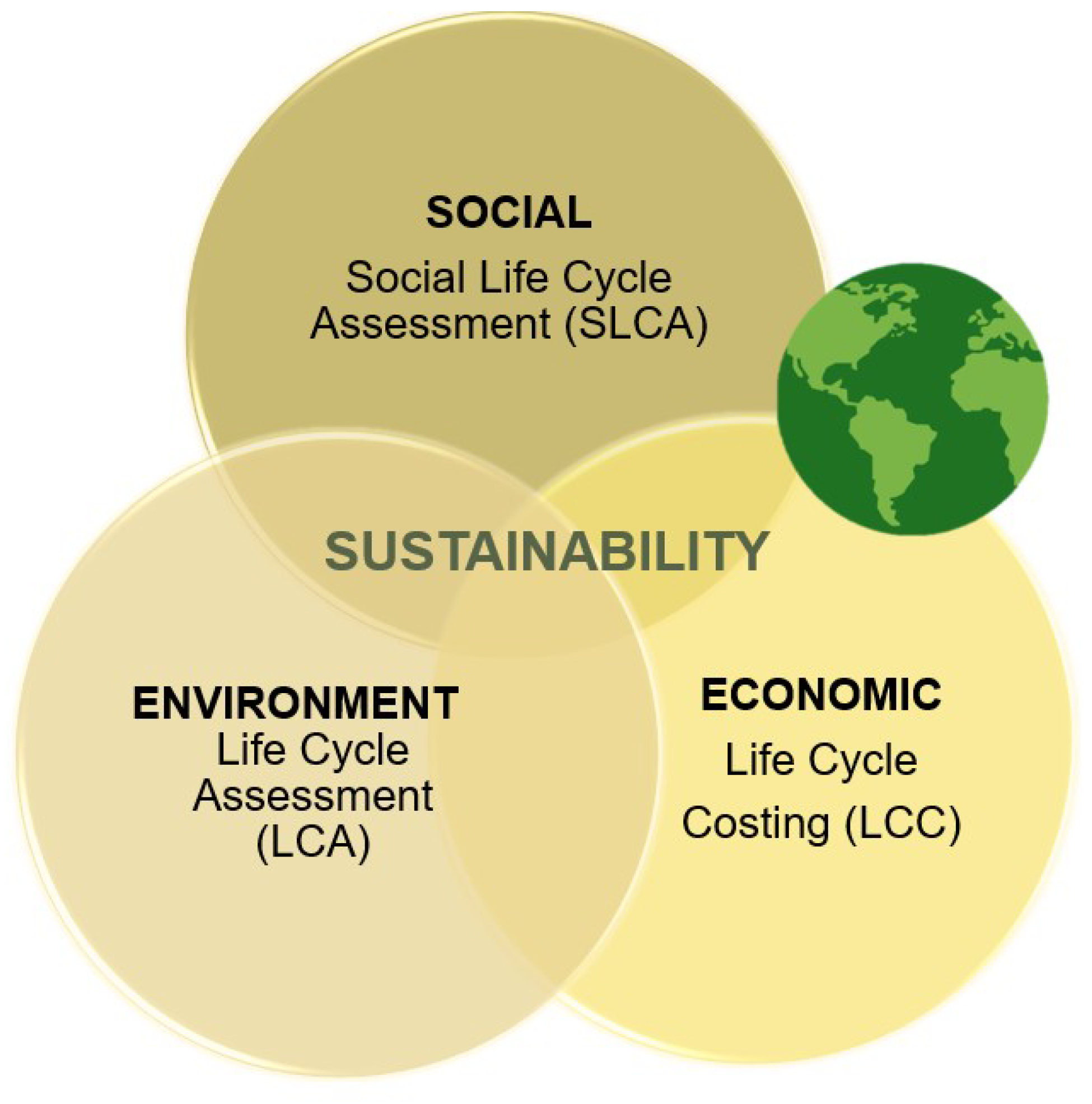

4.5. Life Cycle Assessment of Carbon Fiber Composite Products

5. Conclusions

- A significant number of industries for CFRP composites sector will be attracted and new job profiles will be created;

- The implementation of open innovation networks across Europe will boost long-term innovation, identifying a common background in CFRP sector design, prototyping, production, and validation;

- CFRP processing technologies can be adopted in the wider industry and increase the product variety and customization;

- Industries will be benefitted from R&D partner assets and improve technological reputation and investor relationships;

- An improved European industrial manufacturing capacity for composites will be achieved and extended supply networks in the CFRP industry will be supported;

- Improvement of the processability and use of CFRP with a cost-reduction perspective, as well as synergies between industries will pave the way to high volume production;

- Tailored business models need to be created for the engineering of CFRP customized solutions, in order to increase the quality of products and revenues.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Huang, Χ. Fabrication and Properties of Carbon Fibers. Materials 2009, 2, 2369–2403. [Google Scholar] [CrossRef]

- Lukaszewicz, D. Automotive composite structures for crashworthiness. In Advanced Composite Materials for Automotive Applications: Structural Integrity and Crashworthiness; Elmarakbi, A., Ed.; John Wiley & Sons, Ltd.: Hoboken, NJ, USA, 2013. [Google Scholar] [CrossRef]

- Taherian, R.; Ghorbani, M.M.; Nasr, M.; Kiahosseini, S.R. Fabrication and investigation of polymer-based carbon composite as gas diffusion layer of proton exchange membrane of fuel cells. Mater. Sci. Adv. Comp. Mater. 2018. [Google Scholar] [CrossRef]

- Käseberg, S.; Holschemacher, K.; Mende, K. Innovations in Construction of Carbon Concrete Composite Members. In Proceedings of the Fifteenth East Asia-Pacific Conference on Structural Engineering and Construction, Xi’an, China, 11–13 October 2017. [Google Scholar]

- Szabó, R.; Szabó, L. Composite materials for wind power turbine blades. Expres 2017, 35, 505–538. [Google Scholar] [CrossRef]

- Pandey, J.K.; Ahn, S.H.; Lee, C.S.; Mohanty, A.K.; Misra, M. Recent Advances in the Application of Natural Fiber Based Composites. Macromol. Mater. Eng. 2010, 295, 975–989. [Google Scholar] [CrossRef]

- Horizon 2020: Smart by Design and Intelligent by Architecture for Turbine Blade Fan and structural Components Systems; Smartfan, Grant Agreement ID: 760779; European Commission: Brussels, Belgium, 2018; Available online: http://www.smartfan-project.eu/ (accessed on 5 August 2019).

- Kumar, V.; Balaganesan, G.; Lee, J.K.Y.; Neisiany, R.E.; Surendran, S.; Ramakrishna, S. A Review of Recent Advances in Nanoengineered Polymer Composites. Polymers 2019, 11, 644. [Google Scholar] [CrossRef]

- The Paris Agreement. Available online: https://unfccc.int/process-and-meetings/the-paris-agreement/the-paris-agreement (accessed on 22 October 2018).

- EU Climate Action. Available online: https://ec.europa.eu/clima/citizens/eu_en (accessed on 5 August 2019).

- Pleşa, I.; Noţingher, P.V.; Schlögl, S.; Sumereder, C.; Muhr, M. Properties of Polymer Composites Used in High-Voltage Applications. Polymers 2016, 8, 173. [Google Scholar] [CrossRef] [PubMed]

- Behera, B.K.; Mishra, R. 3-Dimensional weaving. Indian J. Fibre Text. Res. 2008, 33, 274–287. [Google Scholar]

- LMI Receives Multiyear Thermoplastics Contract from Boeing. Available online: https://www.compositesworld.com/news/lmi-receives-multiyear-thermoplastics-contract-from-boeing (accessed on 21 March 2018).

- Borowski, E.; Soliman, E.; Kandil, U.F.; Taha, M.R. Interlaminar Fracture Toughness of CFRP Laminates Incorporating Multi-Walled Carbon Nanotubes. Polymers 2015, 7, 1020–1045. [Google Scholar] [CrossRef] [Green Version]

- Zhang, H.; Liu, Y.; Kuwata, M.; Bilotti, E.; Peijs, T. Improved fracture toughness and integrated damage sensing capability by spray coated CNTs on carbon fibre prepreg. Compos. Part A Appl. Sci. Manuf. 2015, 70, 102–110. [Google Scholar] [CrossRef]

- Herceg, T.M.; Abidin, M.S.Z.; Greenhalgh, E.S.; Shaffer, M.S.; Bismarck, A. Thermosetting hierarchical composites with high carbon nanotube loadings: En route to high performance. Compos. Sci. Technol. 2016, 127, 134–141. [Google Scholar] [CrossRef]

- Sanchez, M.; Campo, M.; Jiménez-Suárez, A.; Ureña, A. Effect of the carbon nanotube functionalization on flexural properties of multiscale carbon fiber/epoxy composites manufactured by VARIM. Compos. Part B Eng. 2013, 45, 1613–1619. [Google Scholar] [CrossRef]

- Cataldi, P.; Athanassiou, A.; Bayer, I.S. Graphene Nanoplatelets-Based Advanced Materials and Recent Progress in Sustainable Applications. Appl. Sci. 2018, 8, 1438. [Google Scholar] [CrossRef]

- Sahoo, N.G.; Rana, S.; Cho, J.W.; Li, L.; Chan, S.H. Polymer nanocomposites based on functionalized carbon nanotubes. Prog. Polym. Sci. 2010, 35, 837–867. [Google Scholar] [CrossRef]

- Spitalsky, Z.; Tasis, D.; Papagelis, K.; Galiotis, C. Carbon nanotube–polymer composites: Chemistry, processing, mechanical and electrical properties. Prog. Polym. Sci. 2010, 35, 357–401. [Google Scholar] [CrossRef]

- Liu, W.-W.; Chai, S.-P.; Mohamed, A.R.; Hashim, U. Synthesis and characterization of graphene and carbon nanotubes: A review on the past and recent developments. J. Ind. Eng. Chem. 2014, 20, 1171–1185. [Google Scholar] [CrossRef]

- Xie, X.; Mai, Y.; Zhou, X. Dispersion and alignment of carbon nanotubes in polymer matrix: A review. Mater. Sci. Eng. R Rep. 2005, 49, 89–112. [Google Scholar] [CrossRef]

- Yue, L.; Pircheraghi, G.; Monemian, S.A.; Manas-Zloczower, I. Epoxy composites with carbon nanotubes and graphene nanoplatelets—Dispersion and synergy effects. Carbon 2014, 78, 268–278. [Google Scholar] [CrossRef]

- Hung, P.-Y.; Lau, K.-T.; Fox, B.; Hameed, N.; Lee, J.H.; Hui, D. Surface modification of carbon fibre using graphene–related materials for multifunctional composites. Compos. Part B Eng. 2018, 133, 240–257. [Google Scholar] [CrossRef]

- Guo, Q. Thermosets: Structure, Properties, and Applications; Woodhead Publishing: Sawston, UK, 2017. [Google Scholar]

- Hallad, S.A.; Banapurmath, N.R.; Hunashyal, A.M.; Shettar, A.S.; Ayachit, N.H.; Mruthunjaya, A.K.; Lohit, R.B.; Uttur, M. Experimental investigation for graphene and carbon fibre in polymer-based matrix for structural applications. J. Appl. Res. Technol. 2017, 15, 297–302. [Google Scholar] [CrossRef]

- Punetha, V.D.; Rana, S.; Yoo, H.J.; Chaurasia, A.; McLeskey, J.T.; Ramasamy, M.S.; Sahoo, N.G.; Cho, J.W. Functionalization of carbon nanomaterials for advanced polymer nanocomposites: A comparison study between CNT and graphene. Prog. Polym. Sci. 2017, 67, 1–47. [Google Scholar] [CrossRef]

- Zhang, X.; Fan, X.; Yan, C.; Li, H.; Zhu, Y.; Li, X.; Yu, L. Interfacial Microstructure and Properties of Carbon Fiber Composites Modified with Graphene Oxide. ACS Appl. Mater. Interfaces 2012, 4, 1543–1552. [Google Scholar] [CrossRef] [PubMed]

- Schaefer, J.D.; Guzman, M.E.; Lim, C.-S.; Rodriguez, A.J.; Minaie, B. Influence of functionalized carbon nanofibers on the single carbon fiber–epoxy matrix interface. Compos. Part B Eng. 2013, 55, 41–47. [Google Scholar] [CrossRef]

- Martin, J.J.; Fiore, B.E.; Erb, R.M. Designing bioinspired composite reinforcement architectures via 3D magnetic printing. Nat. Commun. 2015, 6, 8641. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Continuous Composites. Available online: https://www.continuouscomposites.com/ (accessed on 8 August 2019).

- Chacón, J.M.; Caminero, M.A.; Núñez, P.J.; García-Plaza, E.; García-Moreno, I.; Reverte, J.M. Additive manufacturing of continuous fibre reinforced thermoplastic composites using fused deposition modelling: Effect of process parameters on mechanical properties. Compos. Sci. Technol. 2018. [Google Scholar] [CrossRef]

- Goh, G.D.; Yap, Y.L.; Tan, H.K.J.; Sing, S.L.; Goh, G.L.; Yeong, W.Y. Process-Structure-Properties in Polymer Additive Manufacturing via Material Extrusion: A Review. Crit. Rev. Solid State Mater. Sci. 2019. [Google Scholar] [CrossRef]

- Hofstätter, T.; Pedersen, D.B.; Tosello, G.; Hansen, H.N. Challenges and opportunities of fibre reinforced, polymers in additive manufacturing with focus on industrial applications. In Proceedings of the Joint Special Interest Group Meeting between EUSPEN and ASPE: Dimensional Accuracy and Surface Finish in Additive Manufacturing, Leuven, Belgium, 10–11 October 2017. [Google Scholar]

- Caminero, M.Á.; Chacón, J.M.; García-Plaza, E.; Núñez, P.J.; Reverte, J.M.; Becar, J.P. Additive Manufacturing of PLA-Based Composites Using Fused Filament Fabrication: Effect of Graphene Nanoplatelet Reinforcement on Mechanical Properties, Dimensional Accuracy and Texture. Polymers 2019, 11, 799. [Google Scholar] [CrossRef]

- Ming, Y.; Duan, Y.; Wang, B.; Xiao, H.; Zhang, X. A Novel Route to Fabricate High-Performance 3D Printed Continuous Fiber-Reinforced Thermosetting Polymer Composites. Materials 2019, 12, 1369. [Google Scholar] [CrossRef]

- Marchi, B.; Zanoni, S. Supply Chain Management for Improved Energy Efficiency: Review and Opportunities. Energies 2017, 10, 1618. [Google Scholar] [CrossRef]

- Taiebat, M.; Brown, A.L.; Safford, H.R.; Qu, S.; Xu, M. A Review on Energy, Environmental, and Sustainability Implications of Connected and Automated Vehicles. Environ. Sci. Technol. 2018, 52, 11449–11465. [Google Scholar] [CrossRef]

- The Society of the Plastics Industry. Epoxy Resin Systems Safe Handling Guide; The Society of the Plastics Industry, Inc.: Washington, DC, USA, 1997. [Google Scholar]

- EU-OSHA (European Agency for Safety and Health at Work). Expert Forecast on Emerging Chemical Risks Related to Occupational Safety and Health; European Agency for Safety and Health at Work: Bilbao, Spain, 2009; Available online: http://osha.europa.eu/en/publications/reports/TE3008390ENC_chemical_risks (accessed on 15 September 2018).

- Zhang, Q.; Huang, J.-Q.; Qian, W.-Z.; Zhang, Y.-Y.; Wei, F. The Road for Nanomaterials Industry: A Review of Carbon Nanotube Production, Post-Treatment, and Bulk Applications for Composites and Energy Storage. Small 2013, 9, 1237–1265. [Google Scholar] [CrossRef]

- Methner, M.M.; Birch, M.E.; Evans, D.E.; Ku, B.K.; Crouch, K.; Hoover, M.D. Identification and Characterization of Potential Sources of Worker Exposure to Carbon Nanofibers During Polymer Composite Laboratory Operations. J. Occup. Environ. Hyg. 2007, 4, D125–D130. [Google Scholar] [PubMed]

- Available online: https://osha.europa.eu/en/emerging-risks/nanomaterials (accessed on 5 September 2018).

- Kuhlbusch, T.A.; Wijnhoven, S.W.; Haase, A. Nanomaterial exposures for worker, consumer and the general public. NanoImpact 2018, 10, 11–25. [Google Scholar] [CrossRef]

- Boonruksa, P.; Bello, D.; Zhang, J.; Isaacs, J.A.; Mead, J.L.; Woskie, S.R. Exposures to nanoparticles and fibers during injection molding and recycling of carbon nanotube reinforced polycarbonate composites. J. Expo. Sci. Environ. Epidemiol. 2016, 27, 379–390. [Google Scholar] [CrossRef] [PubMed]

- ISO. ISO/TR 27628 Workplace Atmospheres—Ultrafine, Nanoparticle and Nano-Structured Aerosols-Inhalation Exposure Characterization and Assessment; ISO: Geneva, Switzerland, 2007. [Google Scholar]

- Workplace Exposure to Nanoparticles - Safety and Health at Work. Available online: http://osha.europa.eu/en/publications/literature_reviews/workplace_exposure_to_nanoparticles/view (accessed on 15 September 2018).

- WHO. Guidelines on Protecting Workers from Potential Risks of Manufactured Nanomaterials; WHO: Geneva, Switzerland, 2017. [Google Scholar]

- European Agency for Safety and Health at Work. Guidance on the Protection of the Health and Safety of Workers from the Potential Risks Related to Nanomaterials at Work; Employment, Social Affairs & Inclusion, European Commission: Brussels, Belgium, 2013. [Google Scholar]

- WHO. Health Indicators of Sustainable Jobs, Presented at Initial Findings from a WHO Expert Consultation; WHO: Geneva, Switzerland, 2012; pp. 17–18. [Google Scholar]

- Jilcha, K.; Kitaw, D. Industrial occupational safety and health innovation for sustainable development. Eng. Sci. Technol. Int. J. 2017, 20, 372–380. [Google Scholar] [CrossRef] [Green Version]

- Ogin, S.L.; Brøndsted, P.; Zangenberg, J. Composite materials: Constituents, architecture, and generic damage. In Woodhead Publishing Series in Composites Science and Engineering, Modeling Damage, Fatigue and Failure of Composite Materials; Talreja, R., Varna, J., Eds.; Woodhead Publishing: Sawston, UK, 2016; pp. 3–23. [Google Scholar]

- Beaumont, P.W.; Soutis, C. Structural integrity of engineering composite materials: A cracking good yarn. Philos. Trans. Ser. A Math. Phys. Eng. Sci. 2016, 374, 20160057. [Google Scholar] [CrossRef] [PubMed]

- Koumoulos, E.; Tofail, S.; Silien, C.; De Felicis, D.; Moscatelli, R.; Dragatogiannis, D.; Bemporad, E.; Sebastiani, M.; Charitidis, C. Metrology and nano-mechanical tests for nano-manufacturing and nano-bio interface: Challenges & future perspectives. Mater. Des. 2018, 137, 446–462. [Google Scholar] [Green Version]

- Swolfs, Y.; Verpoest, I.; Gorbatikh, L. Recent advances in fibre-hybrid composites: Materials selection, opportunities and applications. Int. Mater. Rev. 2019, 64, 181–215. [Google Scholar] [CrossRef]

- Semitekolos, D.; Kainourgios, P.; Jones, C.; Rana, A.; Koumoulos, E.P.; Charitidis, C.A. Advanced carbon fibre composites via poly methacrylic acid surface treatment; surface analysis and mechanical properties investigation. Compos. Part B Eng. 2018, 155, 237–243. [Google Scholar] [CrossRef]

- Koumoulos, E.P.; Charitidis, C.A. Integrity of Carbon-Fibre Epoxy Composites through a Nanomechanical Mapping Protocol towards Quality Assurance. Fibers 2018, 6, 78. [Google Scholar] [CrossRef]

- Böhm, R.; Thieme, M.; Wohlfahrt, D.; Wolz, D.S.; Richter, B.; Jäger, H. Reinforcement Systems for Carbon Concrete Composites Based on Low-Cost Carbon Fibres. Fibres 2018, 6, 56. [Google Scholar] [CrossRef]

- Kainourgios, P.; Kartsonakis, I.; Dragatogiannis, A.; Koumoulos, E.P.; Goulis, P.; Charitidis, C. Electrochemical surface functionalization of carbon fibres for chemical affinity improvement with epoxy resins. Appl. Surf. Sci. 2017, 416, 593–604. [Google Scholar] [CrossRef]

- Romanos, N.; Kalogerini, M.; Koumoulos, E.; Morozinis, A.; Sebastiani, M.; Charitidis, C. Innovative Data Management in advanced characterization: Implications for materials design. Mater. Today Commun. 2019, 100541. [Google Scholar] [CrossRef]

- Koumoulos, E.P.; Paraskevoudis, K.; Charitidis, C.A. Constituents Phase Reconstruction through Applied Machine Learning in Nanoindentation Mapping Data of Mortar Surface. J. Compos. Sci. 2019, 3, 63. [Google Scholar] [CrossRef]

- Van De Velde, K.; Kiekens, P. Development of a flax/polypropylene composite with optimal mechanical characteristics by fibre and matrix modification. J. Thermoplast. Compos. Mater. 2002, 15, 281–300. [Google Scholar] [CrossRef]

- Kiekens, P.; Van Der Burght, E.; Kny, E.; Uyar, T.; Milašius, R. Functional Textiles—From Research and Development to Innovations and Industrial Uptake. Autex Res. J. 2014, 14, 219–225. [Google Scholar] [CrossRef]

- Caggiano, A. Machining of Fibre Reinforced Plastic Composite Materials. Materials 2018, 11, 442. [Google Scholar] [CrossRef] [PubMed]

- Kratz, J.; Shane Low, Y.; Fox, B. Resource-friendly carbon fibre composites: Combining production waste with virgin feedstock. Adv. Manuf. Polym. Compos. Sci. 2017, 3, 121–129. [Google Scholar]

- Peças, P.; Carvalho, H.; Salman, H.; Leite, M. Natural Fibre Composites and Their Applications: A Review. J. Compos. Sci. 2018, 2, 66. [Google Scholar] [CrossRef]

- Miravete, A.; Bielsa, J.; Chiminelli, A.; Cuartero, J.; Serrano, S.; Tolosana, N.; De Villoria, R.G. 3D mesomechanical analysis of three-axial braided composite materials. Compos. Sci. Technol. 2006, 66, 2954–2964. [Google Scholar] [CrossRef]

- Tamás, P. Decision Support Simulation Method for Process Improvement of Intermittent Production Systems. Appl. Sci. 2017, 7, 950. [Google Scholar] [CrossRef]

- Baran, I.; Cinar, K.; Ersoy, N. A Review on the Mechanical Modeling of Composite Manufacturing Processes. Arch. Computat. Methods Eng. 2017, 24, 365. [Google Scholar] [CrossRef] [PubMed]

- Horizon 2020: H2020-EU.2.1.5.1. Zero-Defect Manufacturing of Composite Parts in the Aerospace Industry; ZAero Funded Project, Grant Agreement ID: 721362; European Commission: Brussels, Belgium, 2016; Available online: http://www.zaero-project.eu/ (accessed on 5 August 2019).

- Koumoulos, E.P.; Sebastiani, M.; Romanos, N.; Kalogerini, M.; Charitidis, C. Data Management Plan Template for H2020 Projects (Version v01.100419). Zenodo, 10 April 2019. [Google Scholar] [CrossRef]

- Koumoulos, E.P.; Sebastiani, M.; Romanos, N.; Kalogerini, M.; Charitidis, C. Data Management Plan with CHADA Workflow Sheet Embedded (Version v01.110419). Zenodo, 11 April 2019. [Google Scholar] [CrossRef]

- Brüning, J.; Denkena, B.; Dittrich, M.-A.; Hocke, T. Machine Learning Approach for Optimization of Automated Fibre Placement Processes. Procedia CIRP 2017, 66, 74–78. [Google Scholar]

- Lorca, J.; Gonzalez, C.; Molina-Aldareguia, J.N.; Segurado, J.; Seltzer, R.; Sket, F.; Rodriquez, M.; Sadaba, S.; Munoz, R.; Canal, L.P. Multiscale Modeling of Composite Materials: A Roadmap Towards Virtual Testing. Adv. Mater. 2011, 23, 5130–5147. [Google Scholar] [CrossRef]

- Camanho, P.P.; Maimó, P.; Dávila, C.G. Prediction of size effects in notched laminates using continuum damage mechanics. Compos. Sci. Technol. 2007, 67, 2715. [Google Scholar] [CrossRef]

- Maimí, P.; Camanho, P.P.; Mayugo, J.A. A three-dimensional damage model for transversely isotropic composite laminates. J. Compos. Mater. 2008, 42, 2717. [Google Scholar]

- Violeau, D.; Ladevèze, P.; Lubineau, G. Micromodel-based simulations for laminated composites. Compos. Sci. Technol. 2009, 69, 1364. [Google Scholar] [CrossRef]

- Pinho, S.T.; Dávila, C.G.; Camanho, P.P.; Iannucci, L.; Robinson, P. Failure Models and Criteria for FRP under In-Plane or Three-Dimensional Stress States Including Shear Non-Linearity; NASA/TM-2005-213530; NASA Langley Research Center: Hampton, VA, USA, 2005. [Google Scholar]

- Verpoest, I.; Lomov, S.V. Virtual textile composites software WiseTex: Integration with micro-mechanical, permeability and structural analysis. Compos. Sci. Technol. 2005, 65, 2563–2574. [Google Scholar] [CrossRef]

- Pinho, S.T.; Robinson, P.; Iannucci, L. Fracture toughness of the tensile and compressive fibre failure modes in laminated composites. Compos. Sci. Technol. 2006, 66, 2069. [Google Scholar] [CrossRef]

- Bazant, Z.P.; Oh, B.H. Crack band theory for fracture of concrete. Mater. Struct. 1983, 16, 155. [Google Scholar]

- Lopes, C.S.; Camanho, P.P.; Gürdal, Z.; Tatting, B.F. Progressive failure analysis of tow-placed, variable-stiffness composite panels. Int. J. Solids Struc. 2007, 44, 8493. [Google Scholar] [CrossRef]

- Liu, J.; Zhang, L.; Cao, D.; Wang, W. Static, rheological and mechanical properties of polymer nanocomposites studied by computer modeling and simulation. Phys. Chem. Chem. Phys. 2009, 11, 11365. [Google Scholar] [CrossRef]

- Baschnagel, J.; Wittmer, J.P.; Meyer, H. Computational Soft Matter: From Synthetic Polymers to Proteins; Attig, N., Binder, K., Grubmüller, H., Kremer, K., Eds.; John von Neumann Institute for Computing: Jülich, Germany, 2004; pp. 83–140. [Google Scholar]

- Huh, J.; Balazs, A.C. Behavior of Confined Telechelic Chains under Shear. J. Chem. Phys. 2000, 113, 2025. [Google Scholar] [CrossRef]

- McCrary-Dennis, M.C.L.; Okoli, O.I. A review of multiscale composite manufacturing and challenges. J. Reinf. Plast.Comp. 2012, 31, 1687–1711. [Google Scholar] [CrossRef]

- Wu, C.; Xu, W. Atomistic molecular modelling of cross-linked epoxy resin. Polymer 2006, 47, 6004–6009. [Google Scholar] [CrossRef]

- Das, S.; Warren, J.; West, D.; Schexnayde, S.M. Global Carbon Fibre Composites Supply Chain Competitiveness Analysis; ORNL/SR-2016/100 | NREL/TP-6A50-66071; CEMAC: N’Djamena, Chad, 2016. [Google Scholar]

- Warren, C.D. Low Cost Carbon Fibre Overview; U.S. Department of Energy: Washington, DC, USA, 2011. [Google Scholar]

- Church, D. A revolution in low-cost carbon fibre production. Reinf. Plast. 2018, 62, 35–37. [Google Scholar] [CrossRef]

- Carbon Fibre Market—Growth, Trends and Forecast (2019–2024); Mordor Intelligence Report; Mordor Intelligence: Hyderabad, India, 2018.

- Witten, E.; Kraus, T.; Kuhnel, M. Composites Market Report 2016, Market Developments, Trends, Outlook and Challenges; AVK: Frankfurt, Germany, 2016. [Google Scholar]

- FIBRES Composites Consortium. U.S. Composites Manufacturing Industry, Technical Roadmap; FIBRES Composites Consortium: Lowell, MA, USA, 2017. [Google Scholar]

- Soulis, S.; Anagnou, S.; Milioni, E.; Mpalias, C.; Kartsonakis, I.; Kanellopoulou, I.; Markakis, V.; Koumoulos, E.P.; Kontou, E.; Charitidis, C. Strategies towards Novel Carbon Fibre Precursors: The Research Results on the Synthesis of PAN Copolymers via AGET ATRP and on Lignin as a Precursor. NanoWorld J. 2015, 1, 88–94. [Google Scholar] [CrossRef]

- FP7, Functionalised Innovative Carbon Fibres Developed from Novel Precursors with Cost Efficiency and Tailored Properties; Fibralspec, Grant Agreement ID: 604248; European Commission: Brussels, Belgium, 2014; Available online: http://www.fibralspec.net/ (accessed on 11 November 2018).

- FP7, New Cost-Effective and Sustainable Polyethylene Based Carbon Fibres for Volume Market Applications; Newspec, Grant Agreement ID: 604168; European Commission: Brussels, Belgium, 2013; Available online: http://www.newspec.eu/ (accessed on 30 October 2018).

- FP7, Renewable Source Nanostructured Precursors for Carbon Fibres; Carboprec, Grant Agreement ID: 604215; European Commission: Brussels, Belgium, 2014; Available online: https://cordis.europa.eu/project/rcn/111186/factsheet/en (accessed on 30 October 2018).

- Tomani, P. The lignoboost process. Cellul. Chem. Technol. 2010, 44, 53–58. [Google Scholar]

- Horizon 2020: Cost Effective Lignin-Based Carbon Fibres for Innovative Light-Weight Applications; Greenlight, Grant Agreement ID: 667501; European Commission: Brussels, Belgium, 2015; Available online: https://greenlight-project.eu/ (accessed on 15 November 2018).

- BBI. Lignin Based Carbon Fibres for Composites; LIBRE, Grant Agreement ID: 720707; BBI: Brussels, Belgium, 2019; Available online: http://libre2020.eu/ (accessed on 15 November 2018).

- Culebras, M.; Beaucamp, A.; Wang, Y.; Clauss, M.M.; Frank, E.; Collins, M.N. Biobased Structurally Compatible Polymer Blends Based on Lignin and Thermoplastic Elastomer Polyurethane as Carbon Fiber Precursors. ACS Sustain. Chem. Eng. 2018, 6, 8816–8825. [Google Scholar] [CrossRef]

- Jagdale, P.; Koumoulos, E.P.; Cannavaro, I.; Khan, A.; Castellino, M.; Dragatogiannis, D.A.; Tagliaferro, A.; Charitidis, C.A. Towards green carbon fibre manufacturing from waste cotton: A microstructural and physical property investigation. Manuf. Rev. 2017, 4, 10. [Google Scholar] [CrossRef]

- Horizon 2020: Recycling and Repurposing of Plastic Waste for Advanced 3D Printing Applications; Repair3D, Grant Agreement ID: 814588; European Commission: Brussels, Belgium, 2019; Available online: http://www.repair3d.net/project-overview/ (accessed on 5 August 2019).

- Russell, A.J.; Bowers, C.P. Repairing Delamination with Low Viscosity Epoxy Resins; AGARD (Advisory Group for Aerospace Research & Developments): Neuilly sur Seine, France, 1992; pp. 1–10. [Google Scholar]

- Russell, A.J.; Bowers, C.P. Resin requirements for successful repair of delaminations. In Proceedings of the 36th International SAMPE Symposium, San Diego, CA, USA, 15–18 April 1991; pp. 2279–2290. [Google Scholar]

- Kyono, T. Life Cycle Assessment of Carbon Fibre-Reinforced Plastic. Int. J. Life Cycle Assess. 2011, 16, 268–282. [Google Scholar]

| The Needs | The Research Required | The Impacts |

|---|---|---|

| -Demonstration of a few production technologies for CFRP composite products corresponding to a production rate, such as 100,000–500,000 units/year or manufactured structure equivalent to 100–500 tonnes/year -Demonstration of an automated manufacturing process for a selected automotive and/or aircraft structural component with a production aforementioned -Identification and characterization of new composite materials with lower manufacture costs -Identification of appropriate manufacturing technologies for large load-bearing structural elements | -Great effort should be devoted to low-cost and bio-resourced carbon fiber and resin production -Development and optimization of design, forming simulation, and assembly: (1) Simplified tools are needed to reduce the lead time for design iteration; (2) Kinematic drape models are only suited to a first-order approximation and do not capture critical forming constraints. Finite element models incorporating contact demonstrate better correlation, but extensive validation is required; (3) Transition from welding processes to a combination of bonding and/or mechanical fasteners may be required. -Development and optimization of composite properties, producibility, CAE, material specs, and standards -Enhancement of recyclability and repairability of composite materials -Significantly reduce the composite manufacturing cost possibly by reducing raw materials especially carbon fiber cost and by reducing part production cost -Enhancing design and analysis of composite structures by developing the institutional culture and knowledge base and enhancing tool sets -Addressing life cycle factors by ensuing the life cycle value | Societal Impact -Increased number of business and industries that use lightweight solutions -Increased level of competence for the use of composites in different industrial sectors -Enhanced fuel use efficiency hence energy saving -Lowered greenhouse gas emissions Technological Impact -Increased skills of suppliers and networks in the field -Increased knowledge of rational composite manufacturing methods of lightweight parts -Increased speed of technology conversion regarding bio-resourced resin and carbon fibers -Improving automation of composite manufacturing -Improving processing and structural simulation Economic Impact -Lowered cost of resin and carbon fibers, especially those currently with high prices -Reduced energy consumption |

| Challenges -Still high production costs including raw material cost especially carbon fibers, the current inadequacy for long automotive run lengths and limits in recycling techniques -Composites in cars have a low penetration rate because they are not significantly used in structural parts and their usage is limited to static load-resistant parts -Composites lack robust design and performance data and guidance, and thus more difficult to move through the design cycle compared to metal -Innovation-driven, highly dynamic, rapidly evolving manufacturing landscape in this area is difficult to codify, model, and simulate since the key players such as material and machinery developers and suppliers focus on their own business |

| Strengths | Weaknesses |

| Good level of fundamental understanding and academic research Innovative manufacturing processes Wide-ranging of materials that can be used in many applications Good capability in specific areas (e.g., sports and leisure crafts) SMEs with flexible approaches | Shortage of trained staff and skilled engineers Limited knowledge of composites Shortage of design guides and design data Industry fragmented and lagging behind USA Low margins for composite industries Little applied R&D for composite industries Unstable primary material supply and costs Few suppliers and much raw material needed Small companies cannot influence specifiers Not defined/clear recycling routes for composites EU higher labor costs than foreign competitors |

| Opportunities | Threats |

| New markets in infrastructure, air and rail transport, offshore, lightweight products, and renewable energy Use of composites in new applications due to environmental regulations Stronger company/university links and the transfer of knowledge from academia to overcome some of the industry’s problems Use of natural fibers Use of low-cost carbon materials Use of new processes and new materials | Low cost imports from cheaper countries Lack of design guidance and standard Environmental legislation and other regulations The lack of a clear recycling route, especially for thermosets Reduced research and development funding for new ideas and consequent technical stagnation Overselling of composites and the risk of high-profile failures The development of competitive technologies, such as titanium and high-strength steel |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Koumoulos, E.P.; Trompeta, A.-F.; Santos, R.-M.; Martins, M.; Santos, C.M.d.; Iglesias, V.; Böhm, R.; Gong, G.; Chiminelli, A.; Verpoest, I.; et al. Research and Development in Carbon Fibers and Advanced High-Performance Composites Supply Chain in Europe: A Roadmap for Challenges and the Industrial Uptake. J. Compos. Sci. 2019, 3, 86. https://doi.org/10.3390/jcs3030086

Koumoulos EP, Trompeta A-F, Santos R-M, Martins M, Santos CMd, Iglesias V, Böhm R, Gong G, Chiminelli A, Verpoest I, et al. Research and Development in Carbon Fibers and Advanced High-Performance Composites Supply Chain in Europe: A Roadmap for Challenges and the Industrial Uptake. Journal of Composites Science. 2019; 3(3):86. https://doi.org/10.3390/jcs3030086

Chicago/Turabian StyleKoumoulos, Elias P., Aikaterini-Flora Trompeta, Raquel-Miriam Santos, Marta Martins, Cláudio Monterio dos Santos, Vanessa Iglesias, Robert Böhm, Guan Gong, Agustin Chiminelli, Ignaas Verpoest, and et al. 2019. "Research and Development in Carbon Fibers and Advanced High-Performance Composites Supply Chain in Europe: A Roadmap for Challenges and the Industrial Uptake" Journal of Composites Science 3, no. 3: 86. https://doi.org/10.3390/jcs3030086

APA StyleKoumoulos, E. P., Trompeta, A.-F., Santos, R.-M., Martins, M., Santos, C. M. d., Iglesias, V., Böhm, R., Gong, G., Chiminelli, A., Verpoest, I., Kiekens, P., & Charitidis, C. A. (2019). Research and Development in Carbon Fibers and Advanced High-Performance Composites Supply Chain in Europe: A Roadmap for Challenges and the Industrial Uptake. Journal of Composites Science, 3(3), 86. https://doi.org/10.3390/jcs3030086