Structural Adhesive Bonding of Vacuum-Infused Acrylic-Based Thermoplastic Fibre-Reinforced Laminates

Abstract

1. Introduction

1.1. Motivation

- Epoxy (EP) adhesives are characterised by high strength and temperature resistance, relatively low curing temperatures, easy processing, and low cost. Their application temperature range is between −40 °C and +100 °C (up to 180 °C for certain types). One-component epoxies cure under heat, while two-component epoxies cure at room temperature, with the possibility of accelerated polymerisation by elevated temperatures.

- Acrylic (AC) adhesives are versatile bonding agents with rapid curing, capable of adhering even to less clean or poorly prepared surfaces. They can be used within a temperature range of −40 °C to +120 °C and cure through a radical mechanism at room temperature.

- Polyurethane (PU) adhesives exhibit good flexibility at low temperatures, excellent fatigue resistance, high impact toughness, and long-term durability. Their application temperature range is from −200 °C to +80 °C, and they can also be cured at room temperature.

1.2. Research Gap and Aim

2. Materials and Methods

2.1. Materials

- ▪

- 0°: Saertex U-E-640 g/m2-1260 mm, Areal weight of 640 g/m2

- ▪

- 0°/90°: Saertex B-E-625 g/m2-1270 mm. Areal weight of 625 g/m2

- ▪

- ±45°: Saertex X-E-610 g/m2-1270 mm, Areal weight of 610 g/m2

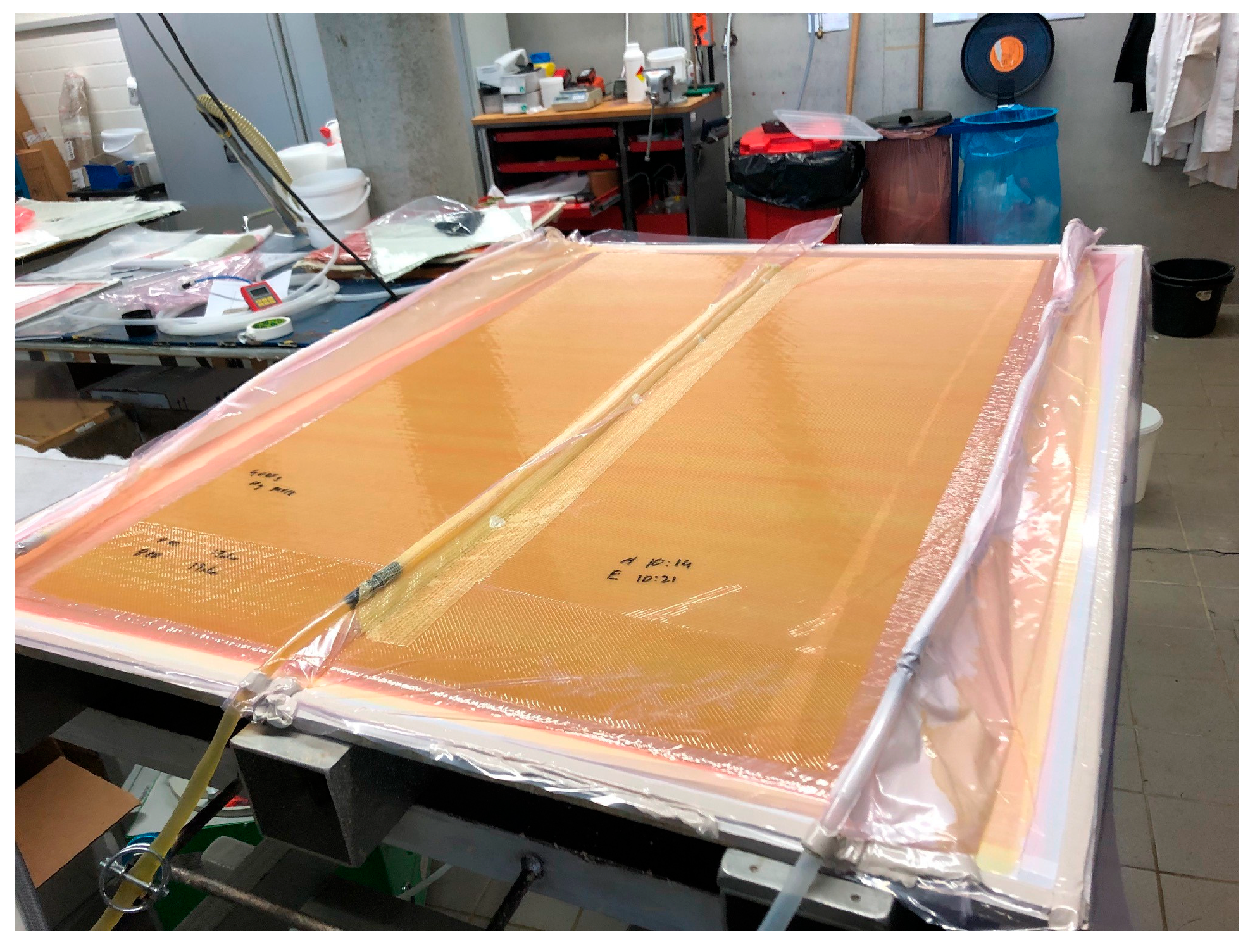

2.2. Manufacturing of Composite Laminate Using Vacuum Infusion

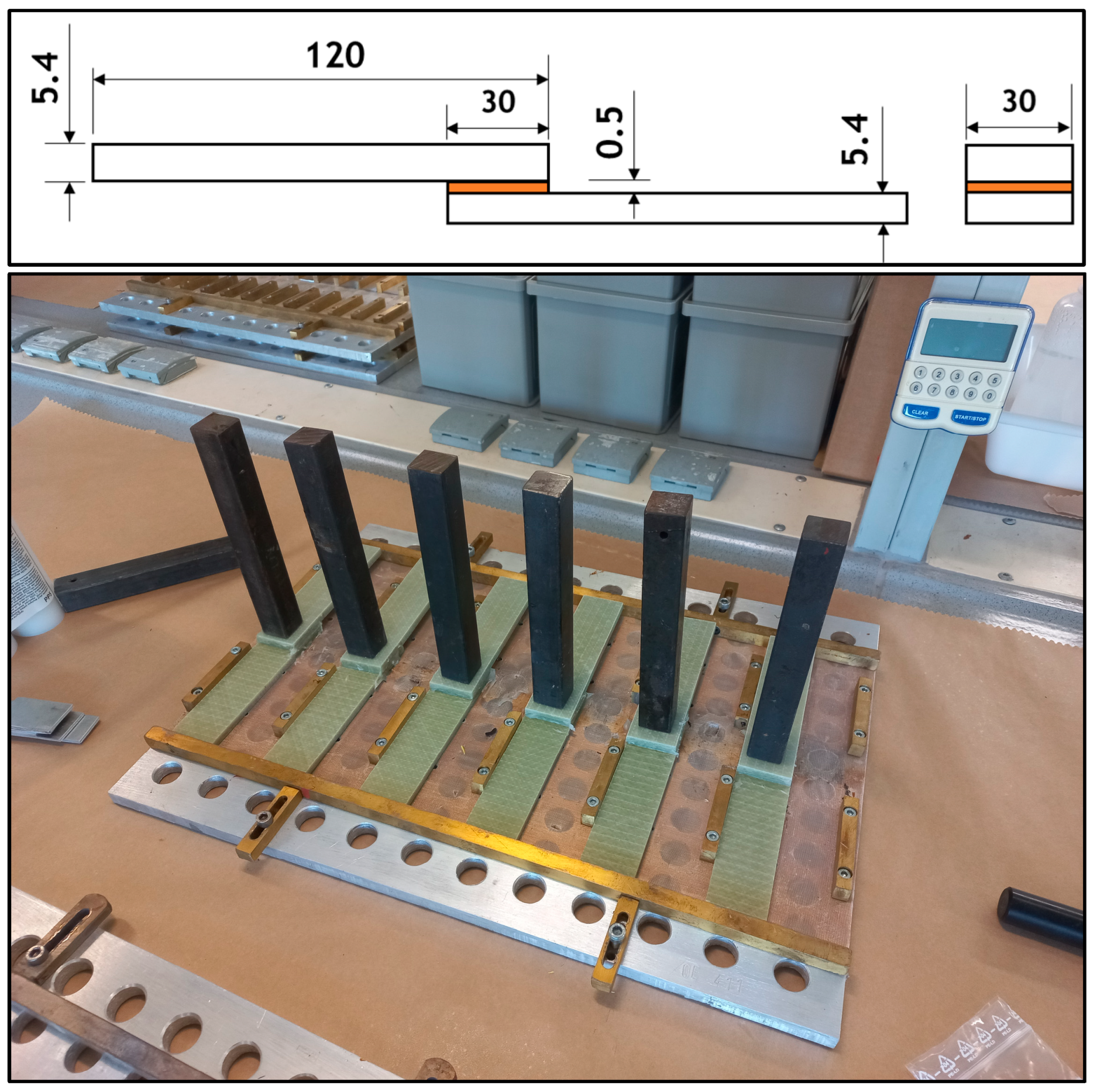

2.3. Manufacturing of Adhesively Bonded Lap-Shear Samples

2.4. Characterisation of Adhesives and Joints

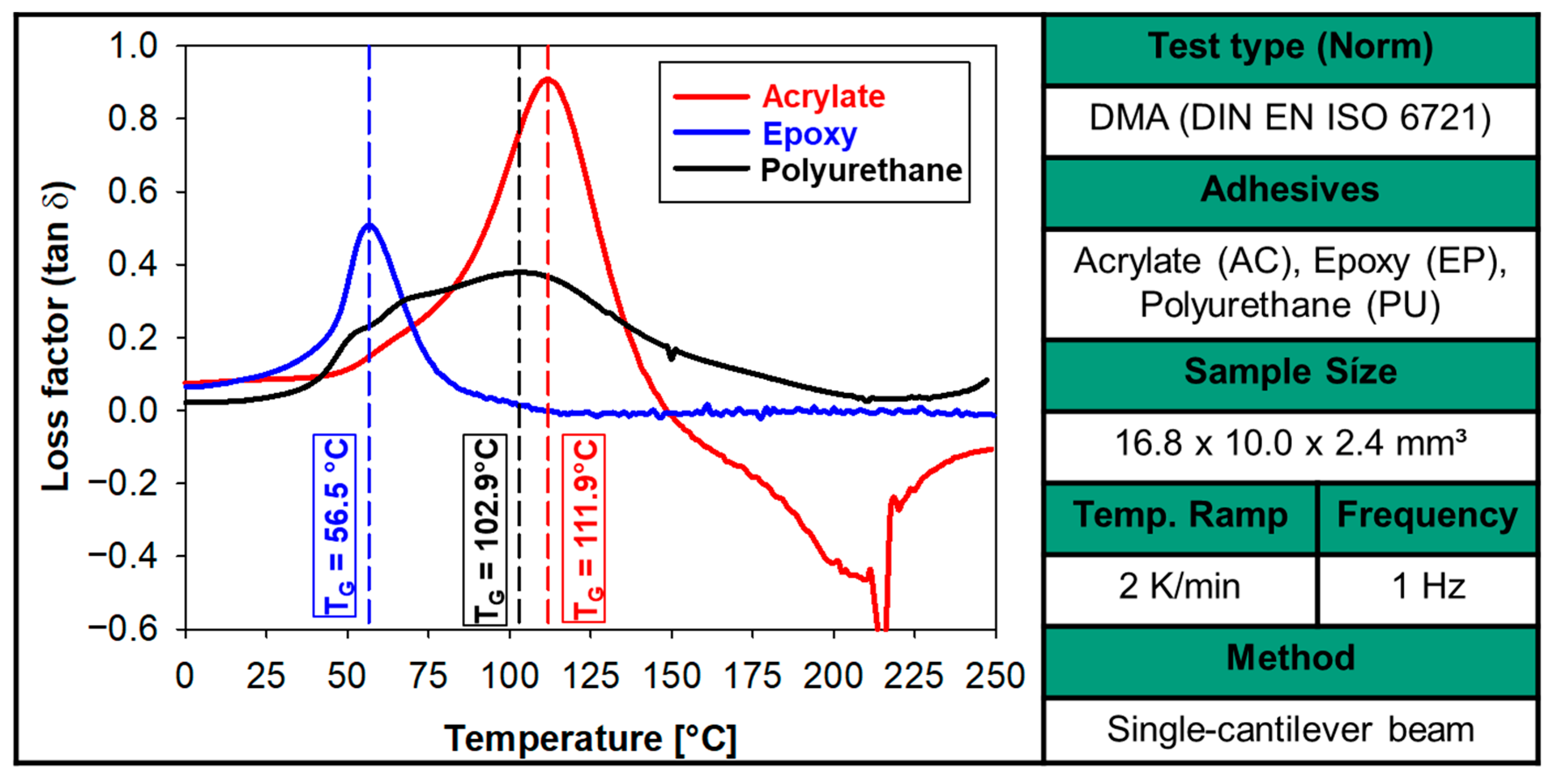

2.4.1. Glass Transition Temperature Determination Using Dynamic Mechanical Analysis

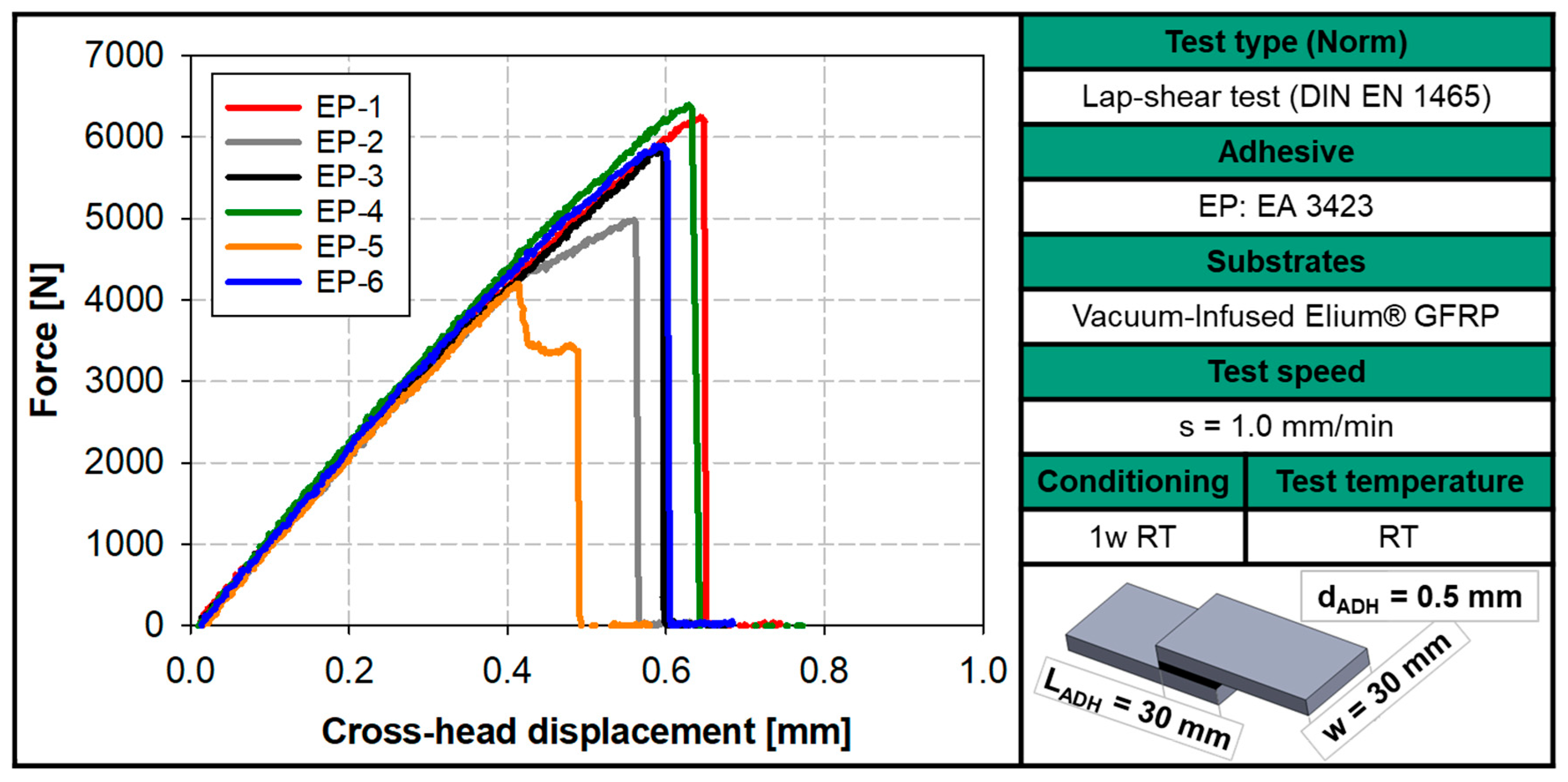

2.4.2. Lap-Shear Testing

2.4.3. Fracture Surface Analysis

3. Results and Discussion

3.1. Glass Transition Temperature of Adhesives

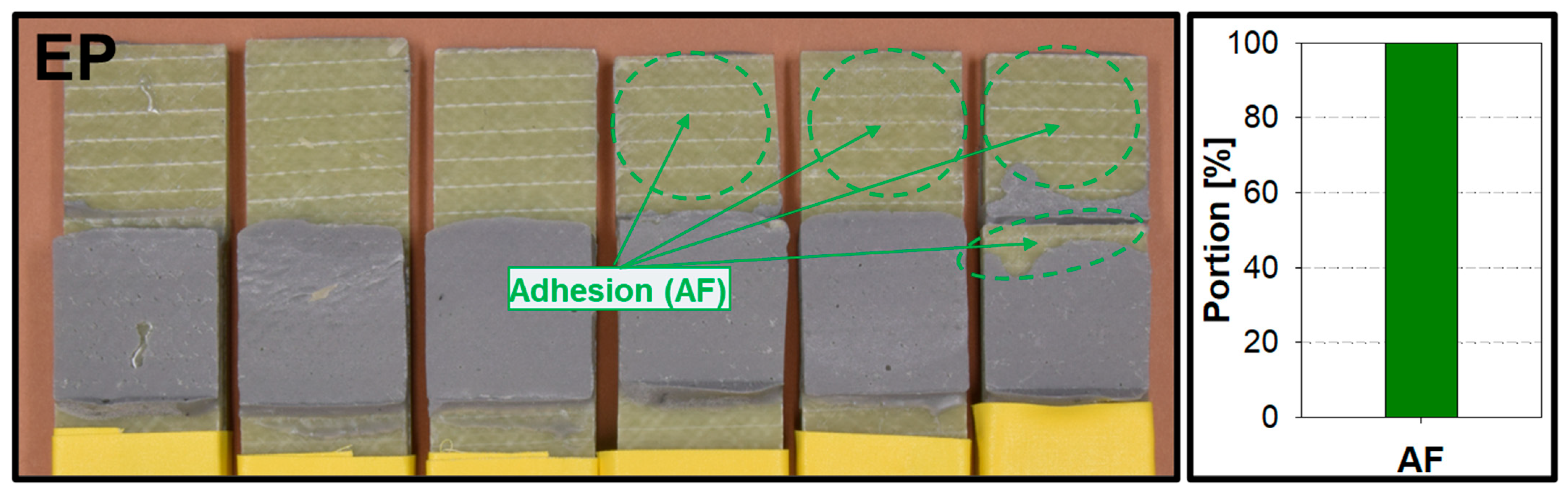

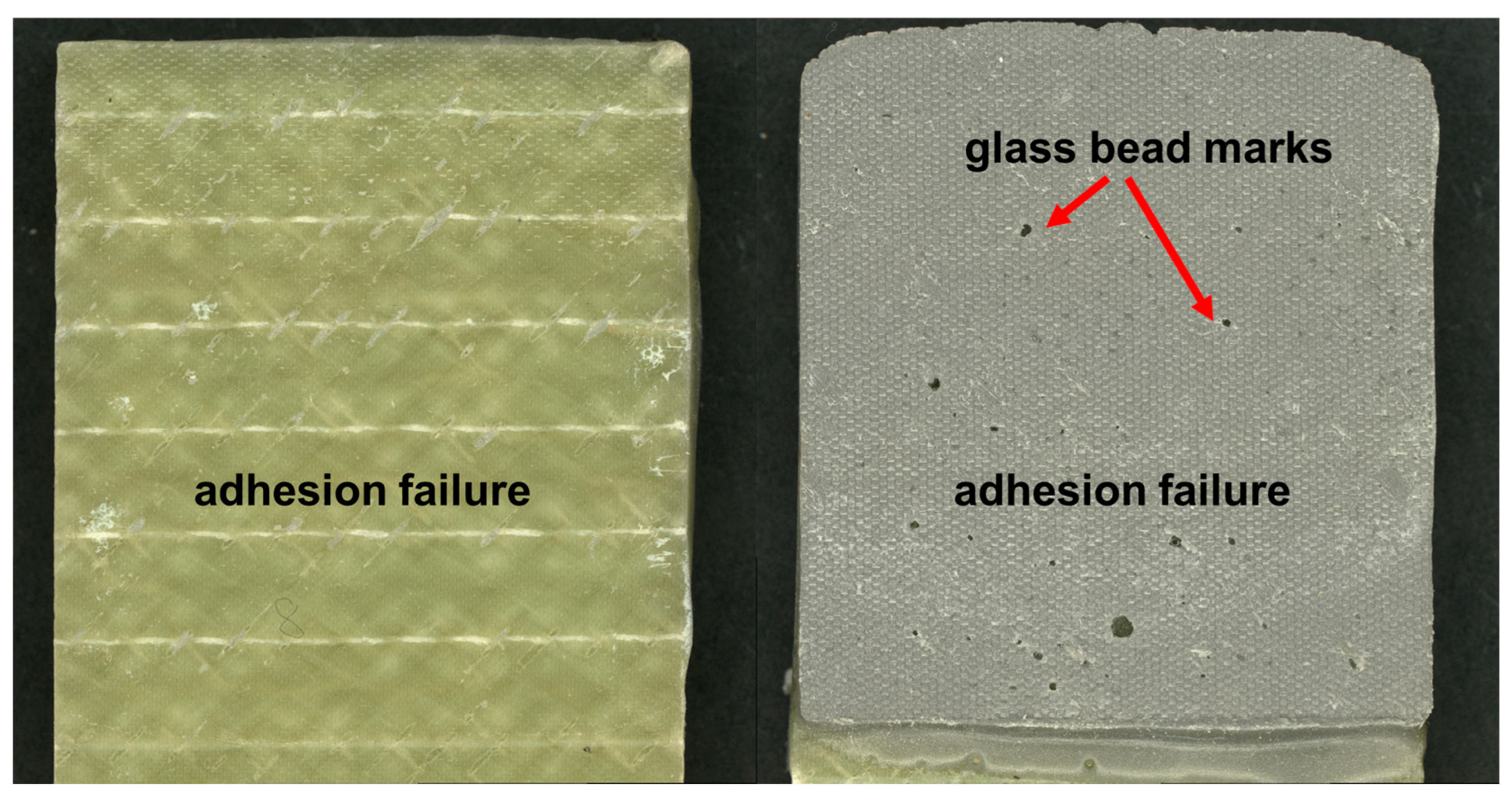

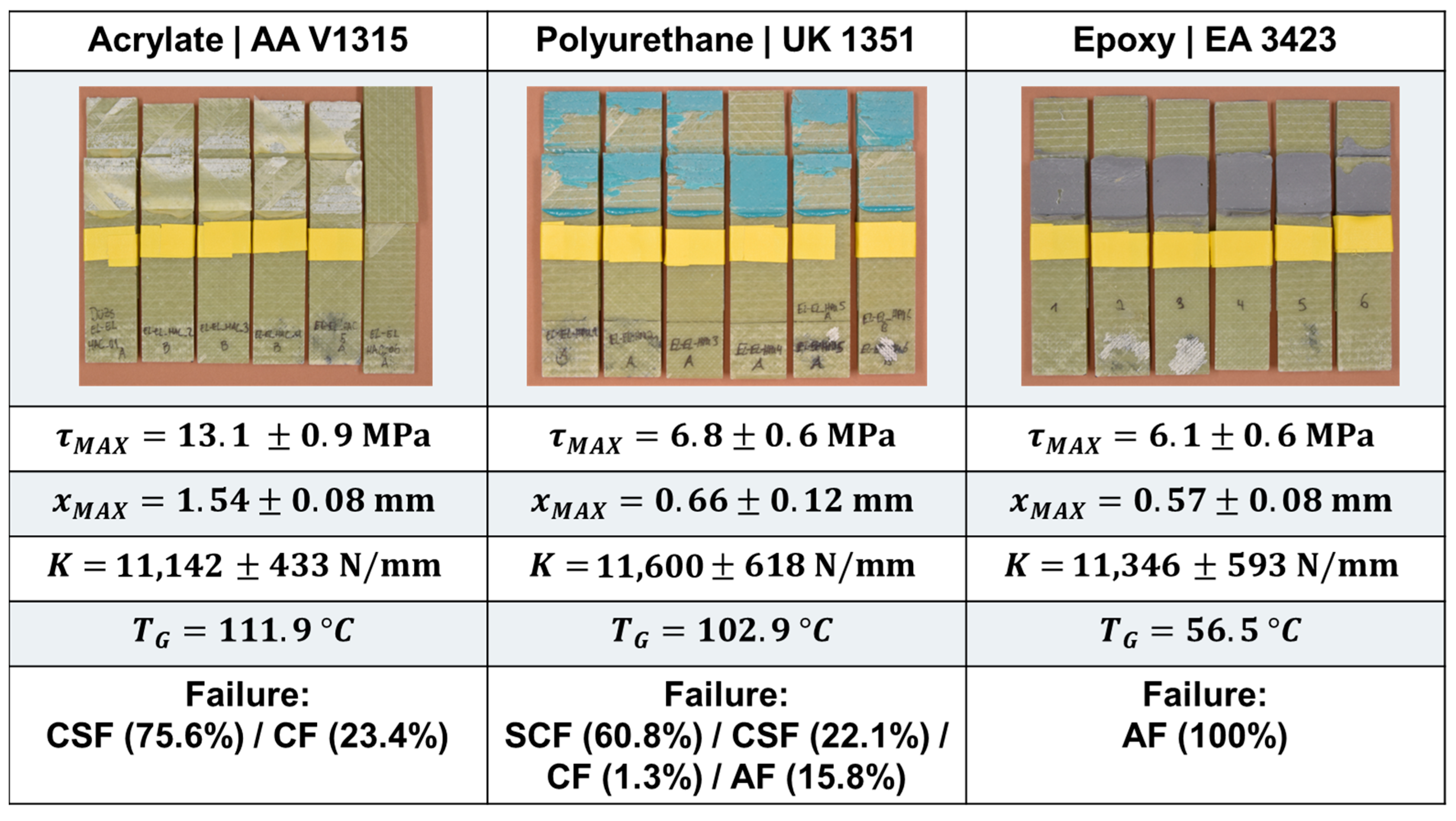

3.2. Epoxy (EP) Adhesive

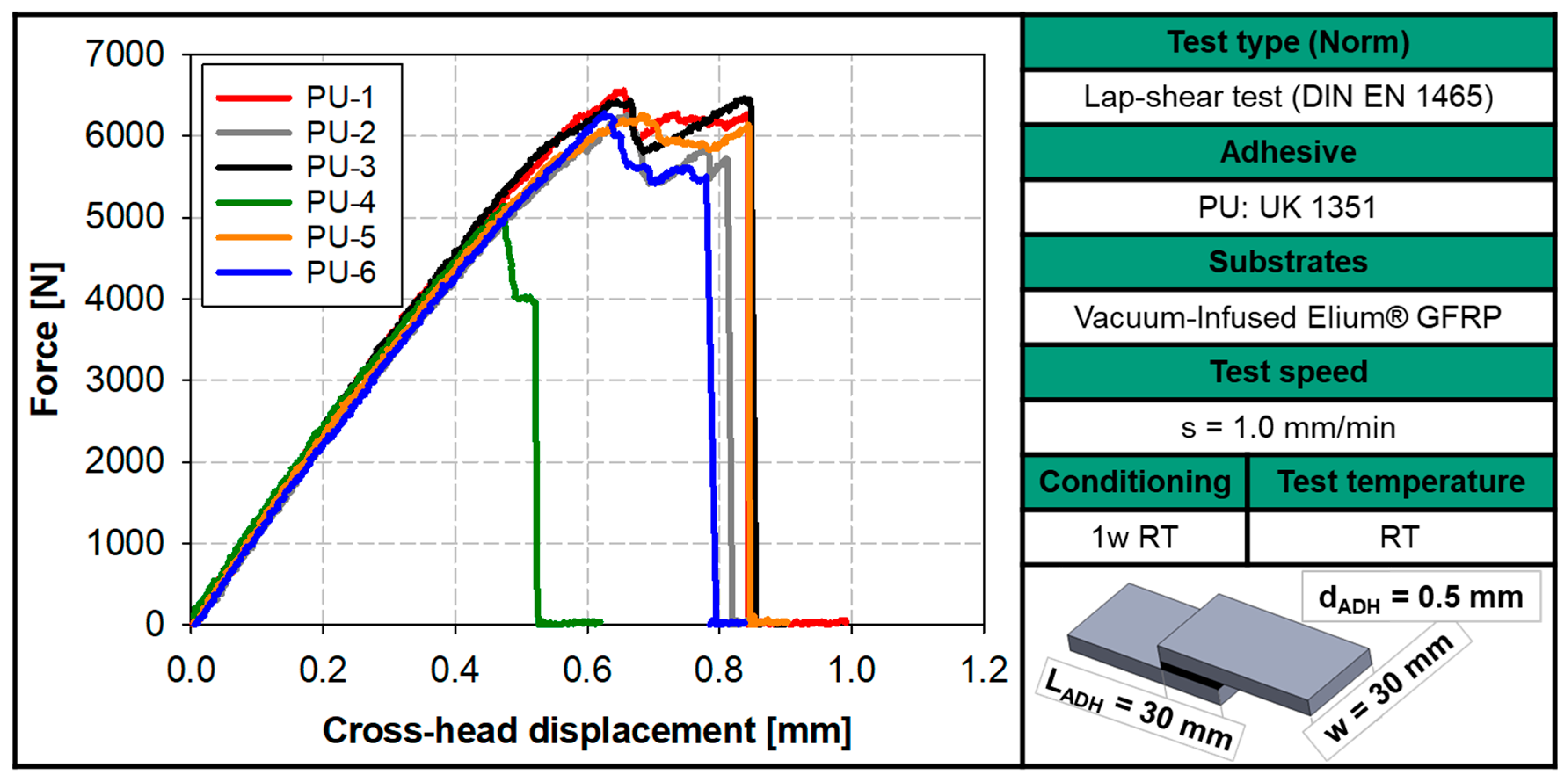

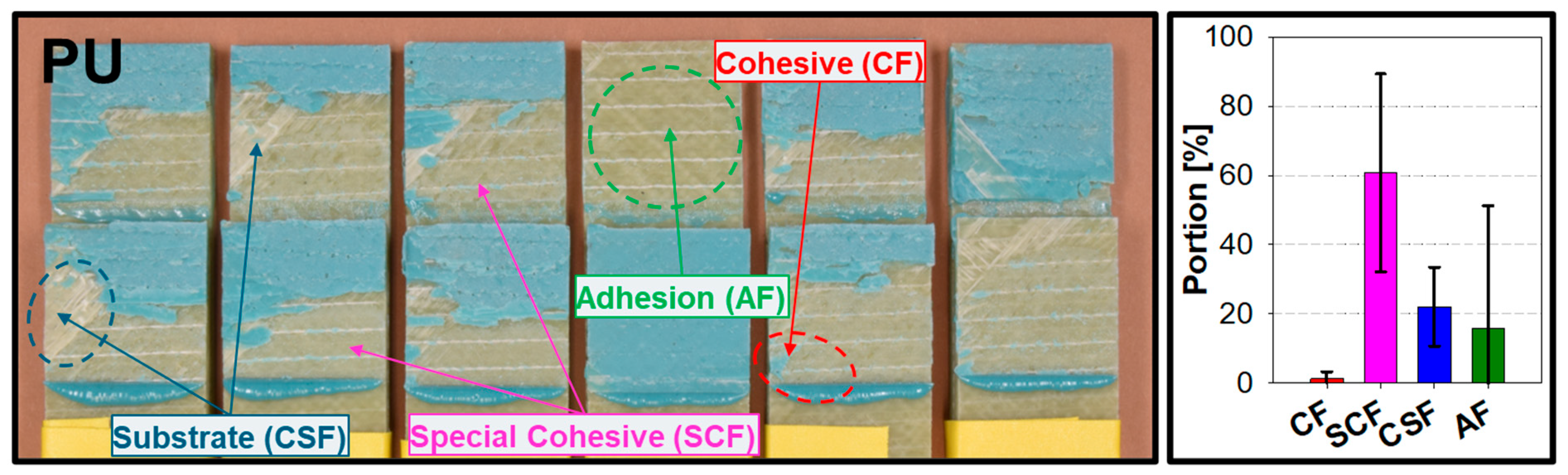

3.3. Polyurethane (PU) Adhesive

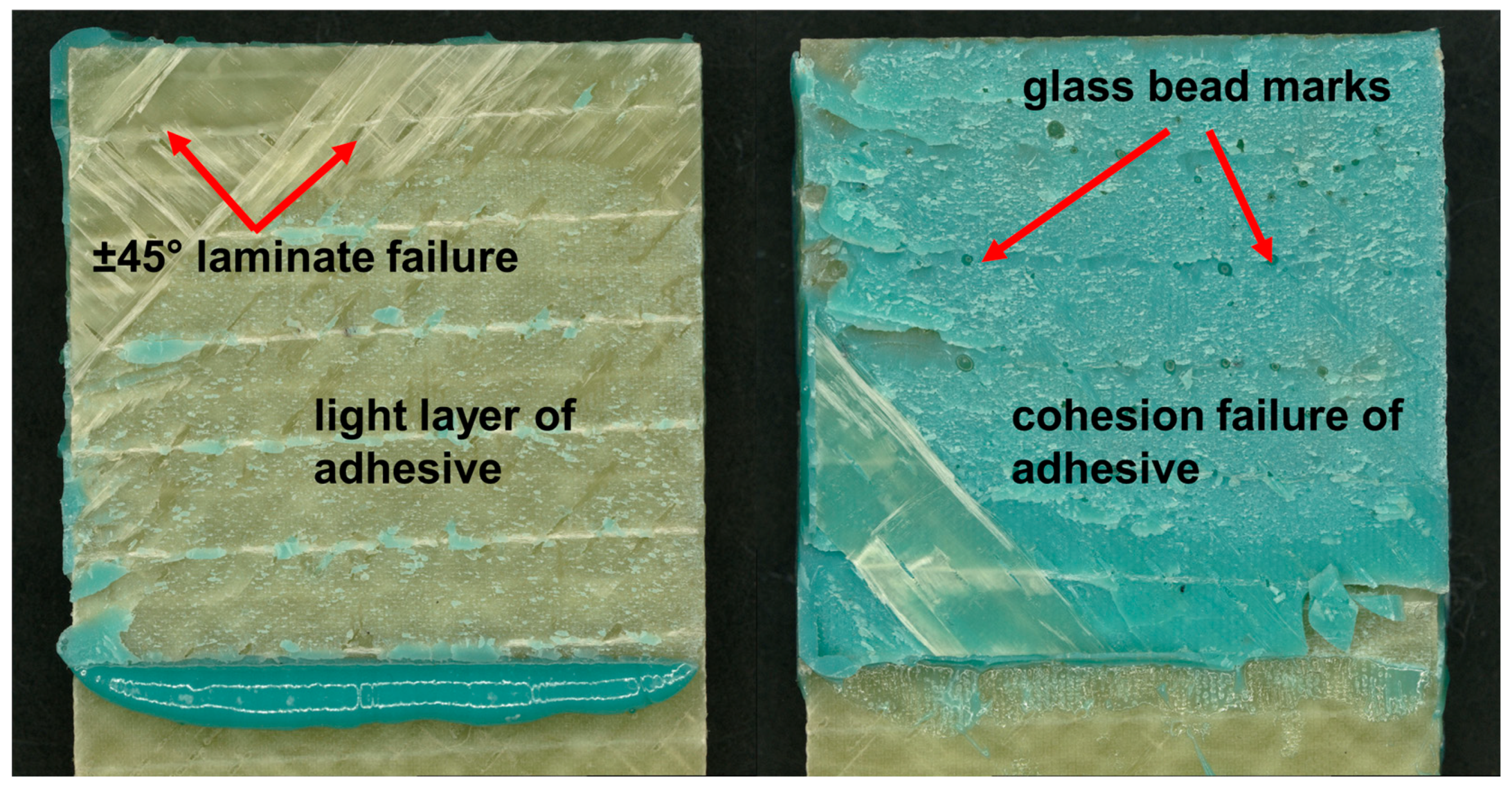

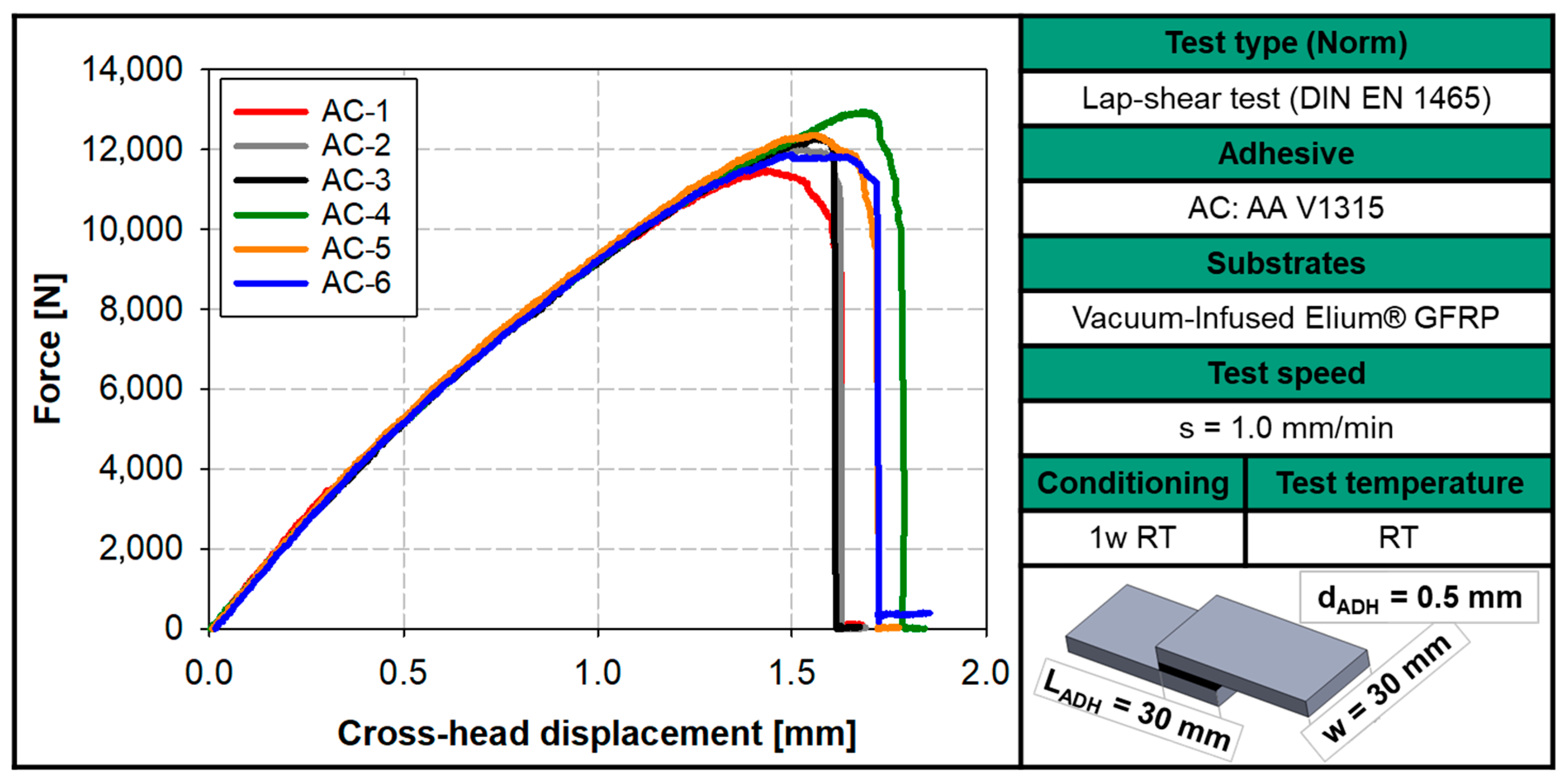

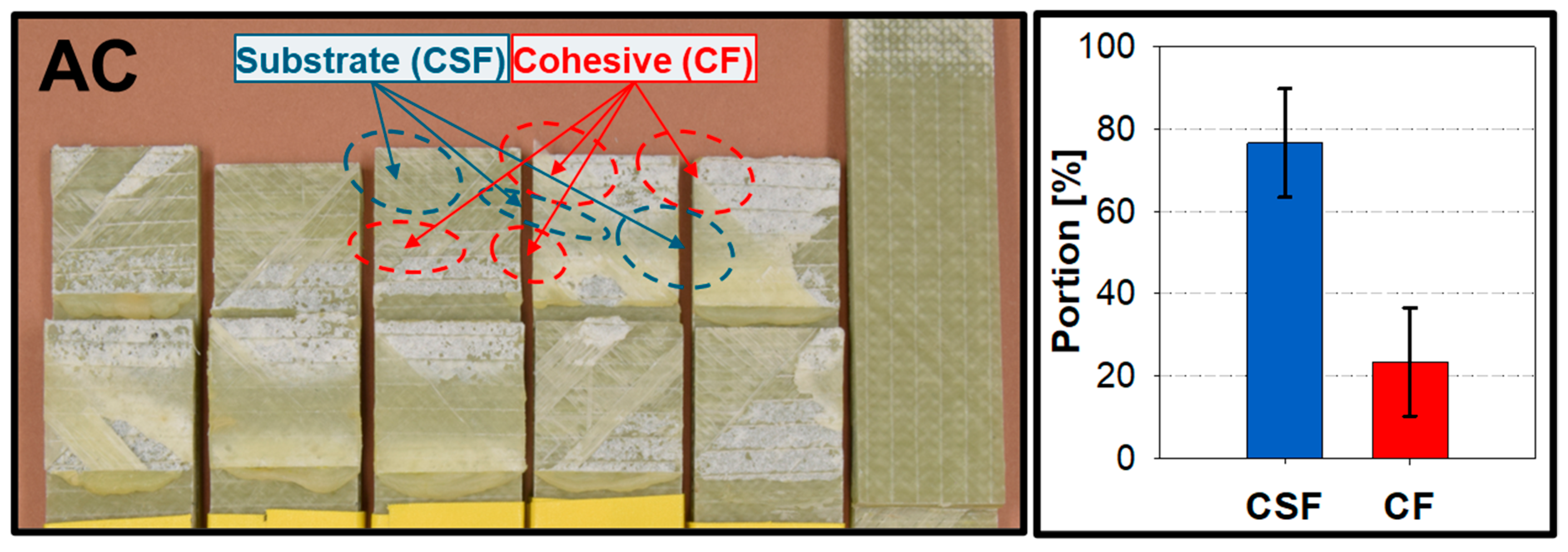

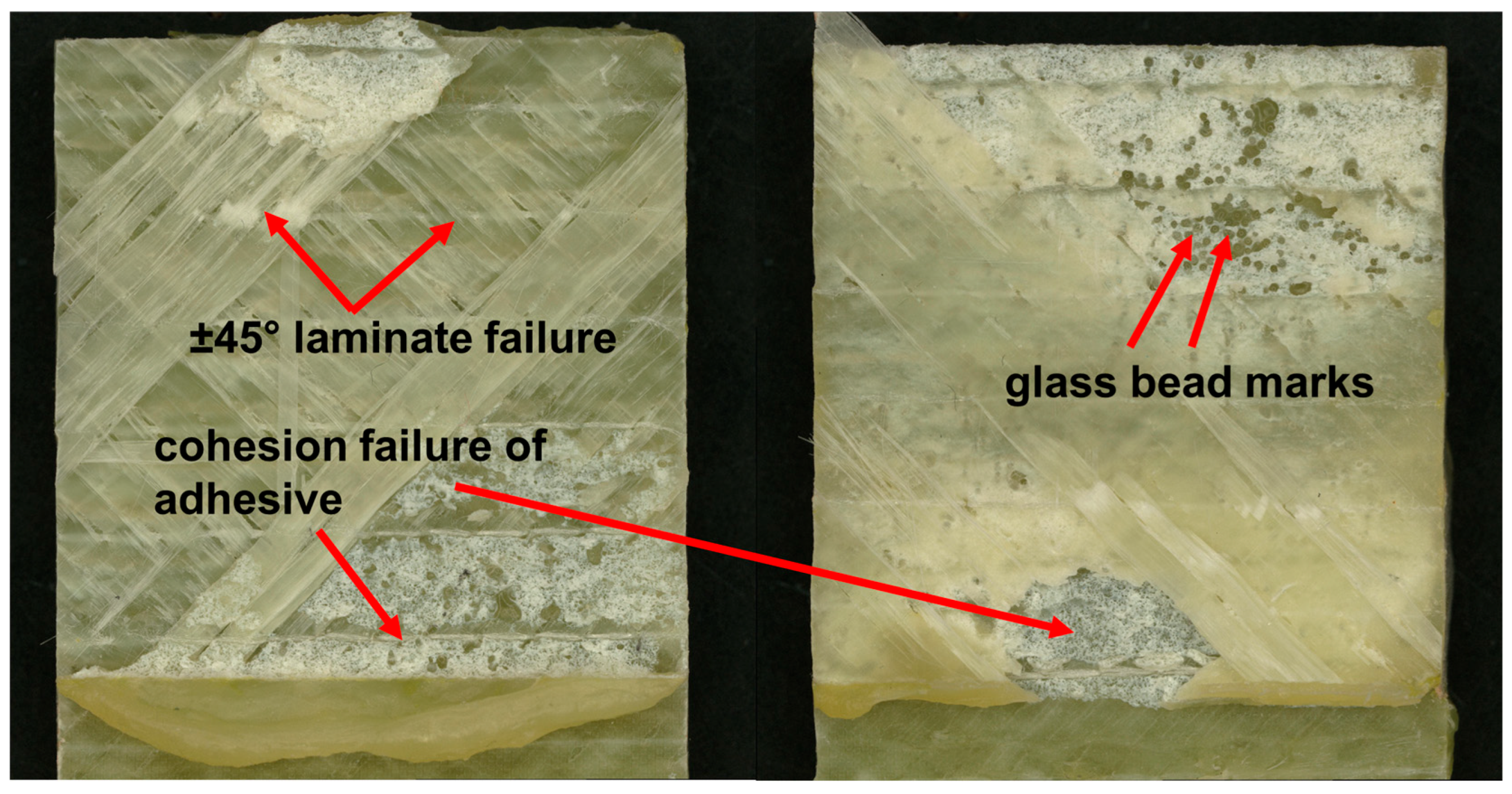

3.4. Acrylate (AC) Adhesive

3.5. Comparative Discussion

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Giorgini, L.; Benelli, T.; Brancolini, G.; Mazzocchetti, L. Recycling of carbon fiber reinforced composite waste to close their life cycle in a cradle-to-cradle approach. Curr. Opin. Green Sustain. Chem. 2020, 26, 100368. [Google Scholar] [CrossRef]

- Krauklis, A.E.; Karl, C.W.; Gagani, A.I.; Jørgensen, J.K. Composite Material Recycling Technology—State-of-the-Art and Sustainable Development for the 2020s. J. Compos. Sci. 2021, 5, 28. [Google Scholar] [CrossRef]

- Rani, M.; Choudhary, P.; Krishnan, V.; Zafar, S. A review on recycling and reuse methods for carbon fiber/glass fiber composites waste from wind turbine blades. Compos. Part B Eng. 2021, 215, 108768. [Google Scholar] [CrossRef]

- Veers, P.; Bottasso, C.L.; Manuel, L.; Naughton, J.; Pao, L.; Paquette, J.; Robertson, A.; Robinson, M.; Ananthan, S.; Barlas, T.; et al. Grand challenges in the design, manufacture, and operation of future wind turbine systems. Wind Energ. Sci. 2023, 8, 1071–1131. [Google Scholar] [CrossRef]

- Naqvi, S.R.; Prabhakara, H.M.; Bramer, E.A.; Dierkes, W.; Akkerman, R.; Brem, G. A critical review on recycling of end-of-life carbon fibre/glass fibre reinforced composites waste using pyrolysis towards a circular economy. Resour. Conserv. Recycl. 2018, 136, 118–129. [Google Scholar] [CrossRef]

- Bhudolia, S.K.; Joshi, S.C. Low-velocity impact response of carbon fibre composites with novel liquid Methylmethacrylate thermoplastic matrix. Compos. Struct. 2018, 203, 696–708. [Google Scholar] [CrossRef]

- Han, N.; Yuksel, O.; Zanjani, J.S.M.; An, L.; Akkerman, R.; Baran, I. Experimental Investigation of the Interlaminar Failure of Glass/Elium® Thermoplastic Composites Manufactured With Different Processing Temperatures. Appl. Compos. Mater. 2022, 29, 1061–1082. [Google Scholar] [CrossRef]

- Mishnaevsky, L., Jr. How to Repair the Next Generation of Wind Turbine Blades. Energies 2023, 16, 7694. [Google Scholar] [CrossRef]

- Builes Cárdenas, C.; Gayraud, V.; Rodriguez, M.E.; Costa, J.; Salaberria, A.M.; Ruiz de Luzuriaga, A.; Markaide, N.; Dasan Keeryadath, P.; Calderón Zapatería, D. Study into the Mechanical Properties of a New Aeronautic-Grade Epoxy-Based Carbon-Fiber-Reinforced Vitrimer. Polymers 2022, 14, 1223. [Google Scholar] [CrossRef]

- Wolf, A.; Pursche, L.; Boskamp, L.; Koschek, K. Amine Exchange of Aminoalkylated Phenols as Dynamic Reaction in Benzoxazine/Amine-Based Vitrimers. Macromol. Rapid Commun. 2024, 45, e2400557. [Google Scholar] [CrossRef]

- Tao, Y.; Liang, X.; Zhang, J.; Lei, I.M.; Liu, J. Polyurethane vitrimers: Chemistry, properties and applications. J. Polym. Sci. 2023, 61, 2233–2253. [Google Scholar] [CrossRef]

- Bhudolia, S.K.; Perrotey, P.; Joshi, S.C. Optimizing Polymer Infusion Process for Thin Ply Textile Composites with Novel Matrix System. Materials 2017, 10, 293. [Google Scholar] [CrossRef] [PubMed]

- Obande, W.; Mamalis, D.; Ray, D.; Yang, L.; Ó Brádaigh, C.M. Mechanical and thermomechanical characterisation of vacuum-infused thermoplastic- and thermoset-based composites. Mater. Des. 2019, 175, 107828. [Google Scholar] [CrossRef]

- Kaybal, H.B.; Ulus, H.; Cacik, F.; Eskizeybek, V.; Avci, A. Multi-Scale Mechanical Behavior of Liquid Elium® Based Thermoplastic Matrix Composites Reinforced with Different Fiber Types: Insights from Fiber–Matrix Adhesion Interactions. Fibers Polym. 2024, 25, 4935–4950. [Google Scholar] [CrossRef]

- Allagui, S.; El Mahi, A.; Rebiere, J.-L.; Beyaoui, M.; Bouguecha, A.; Haddar, M. Effect of Recycling Cycles on the Mechanical and Damping Properties of Flax Fibre Reinforced Elium Composite: Experimental and Numerical Studies. J. Renew. Mater. 2021, 9, 695–721. [Google Scholar] [CrossRef]

- Chilali, A.; Zouari, W.; Assarar, M.; Kebir, H.; Ayad, R. Analysis of the mechanical behaviour of flax and glass fabrics-reinforced thermoplastic and thermoset resins. J. Reinf. Plast. Compos. 2016, 35, 1217–1232. [Google Scholar] [CrossRef]

- Gohel, G.; Bhudolia, S.K.; Kantipudi, J.; Leong, K.F.; Barsotti, R.J. Ultrasonic welding of novel Carbon/Elium® with carbon/epoxy composites. Compos. Commun. 2020, 22, 100463. [Google Scholar] [CrossRef]

- Kaybal, H.B.; Ulus, H. Comparative analysis of thermoplastic and thermoset adhesives performance and the influence on failure analysis in jointed Elium-based composite structures. Polym. Compos. 2024, 45, 3474–3492. [Google Scholar] [CrossRef]

- Wolter, N.; Beber, V.C.; Brede, M.; Koschek, K. Adhesively- and hybrid-bonded joining of basalt and carbon fibre reinforced polybenzoxazine-based composites. Compos. Struct. 2020, 236, 111800. [Google Scholar] [CrossRef]

- Da Silva, L.F.M.; Öchsner, A.; Adams, R.D. Handbook of Adhesion Technology; Springer International Publishing: Cham, Switzerland, 2018; ISBN 978-3-319-55410-5. [Google Scholar]

- Budhe, S.; Banea, M.D.; de Barros, S.; Da Silva, L. An updated review of adhesively bonded joints in composite materials. Int. J. Adhes. Adhes. 2017, 72, 30–42. [Google Scholar] [CrossRef]

- Banea, M.D.; Da Silva, L.F.M. Adhesively bonded joints in composite materials: An overview. Proc. Inst. Mech. Eng. Part L J. Mater. Des. Appl. 2009, 223, 1–18. [Google Scholar] [CrossRef]

- de Azúa, O.R.; Agulló, N.; Arbusà, J.; Borrós, S. Improving Glass Transition Temperature and Toughness of Epoxy Adhesives by a Complex Room-Temperature Curing System by Changing the Stoichiometry. Polymers 2023, 15, 252. [Google Scholar] [CrossRef]

- Koumba, N.; Boumbimba, R.M.; Bonfoh, N.; Eba, F.; Wary, M. Effect of reparation on the mechanical behavior of glass fibers/ E lium acrylic laminate composites: Experimental and numerical approaches. Polym. Compos. 2024, 45, 6385–6403. [Google Scholar] [CrossRef]

- Henkel. Technical Datasheet: Loctite(R) AA V1315; Henkel: Dusseldorf, Germany, 2007. [Google Scholar]

- Henkel. Technical Datasheet: Loctite(R) EA 3423; Henkel: Dusseldorf, Germany, 2014. [Google Scholar]

- Henkel. Technical Datasheet: Loctite(R) UK1351/UK5452; Henkel: Dusseldorf, Germany, 2014. [Google Scholar]

- Beber, V.C.; Fernandes, P.H.E.; Nagel, C.; Arnaut, K. Integrated Analytical and Finite Element-Based Modelling, Manufacturing, and Characterisation of Vacuum-Infused Thermoplastic Composite Laminates Cured at Room Temperature. J. Compos. Sci. 2024, 8, 545. [Google Scholar] [CrossRef]

- Santos, J.P.J.R.; Marques, E.A.S.; Carbas, R.J.C.; Gilbert, F.; Da Silva, L.F.M. Experimental Study of the Impact of Glass Beads on Adhesive Joint Strength and Its Failure Mechanism. Materials 2021, 14, 7013. [Google Scholar] [CrossRef] [PubMed]

- Rządkowski, W.; Tracz, J.; Cisowski, A.; Gardyjas, K.; Groen, H.; Palka, M.; Kowalik, M. Evaluation of Bonding Gap Control Methods for an Epoxy Adhesive Joint of Carbon Fiber Tubes and Aluminum Alloy Inserts. Materials 2021, 14, 1977. [Google Scholar] [CrossRef]

- Ricca, F.; Galindo-Rosales, F.J.; Akhavan-Safar, A.; Da Silva, L.F.M.; Fkyerat, T.; Yokozeki, K.; Vallée, T.; Evers, T. Predicting the Adhesive Layer Thickness in Hybrid Joints Involving Pre-Tensioned Bolts. Polymers 2024, 16, 2284. [Google Scholar] [CrossRef] [PubMed]

- DIN EN ISO 6721; Plastics-Determination of Dynamic Mechanical Properties, German Version. DIN Media: Berlin, Germany, 2019.

- DIN EN 1465; Adhesives-Determination of Tensile Lap-Shear Strength of Bonded Assemblies, German Version. DIN Media: Berlin, Germany, 2009.

- DIN EN ISO 10365; Adhesives-Designation of Main Failure Patterns, German and English Versions. DIN Media: Berlin, Germany, 2020.

- Henriques, I.R.; Borges, L.A.; Costa, M.F.; Soares, B.G.; Castello, D.A. Comparisons of complex modulus provided by different DMA. Polym. Test. 2018, 72, 394–406. [Google Scholar] [CrossRef]

- Grant, L.; Adams, R.D.; Da Silva, L.F. Experimental and numerical analysis of single-lap joints for the automotive industry. Int. J. Adhes. Adhes. 2009, 29, 405–413. [Google Scholar] [CrossRef]

- Zhang, J.; de Souza, M.; Creighton, C.; Varley, R.J. New approaches to bonding thermoplastic and thermoset polymer composites. Compos. Part A Appl. Sci. Manuf. 2020, 133, 105870. [Google Scholar] [CrossRef]

- Hennemann, K.K.; Lenz, D.M. Structural methacrylate/epoxy based adhesives for aluminIum joints. Int. J. Adhes. Adhes. 2019, 89, 11–18. [Google Scholar] [CrossRef]

- Srinivasan, D.V.; Idapalapati, S. Review of debonding techniques in adhesively bonded composite structures for sustainability. Sustain. Mater. Technol. 2021, 30, e00345. [Google Scholar] [CrossRef]

- Veller, S.; Adam, M.; Hempel, M.; Rudlof, M. Improving the recyclability of rare earth magnets in electrical motors by using debonding-strategies. Sustain. Mater. Technol. 2025, 45, e01586. [Google Scholar] [CrossRef]

- Bekas, V.; Arnaut, K.; Beber, V.C. Debonding-on-demand of vacuum-infused thermoplastic fibre-reinforced laminates with improved recyclability. J. Adv. Join. Process. 2025, 12, 100364. [Google Scholar] [CrossRef]

| Adhesive Type | Commercial Name | Short Name | Cartridge Size | Pot Life | Handling Time | Shear Strength |

|---|---|---|---|---|---|---|

| Acrylate | Loctite® AA V1315 [25] | AC | 50 mL | 15 min | 30–35 min | 15 MPa (steel) 20 MPa (aluminium) |

| Epoxy | Loctite® EA 3423 [26] | EP | 50 mL | 30–60 min | 180 min | 15–19 MPa (steel) 7–12 MPa (aluminium) |

| Polyurethane | Loctite® UK 1351 [27] | PU | 400 mL | 20–30 min | 60–120 min | >20 MPa (substrate not specified) |

| Sample | [mm] | [mm] | [mm] | [N] | [mm] | [MPa] | [N/mm] |

|---|---|---|---|---|---|---|---|

| EP-1 | 0.58 | 30.27 | 30.33 | 6247 | 0.64 | 6.8 | 11,079 |

| EP-2 | 0.40 | 30.36 | 30.35 | 4981 | 0.56 | 5.4 | 11,019 |

| EP-3 | 0.25 | 30.24 | 30.23 | 5897 | 0.60 | 6.5 | 10,871 |

| EP-4 | 0.36 | 30.23 | 30.30 | 6392 | 0.63 | 7.0 | 12,506 |

| EP-5 | 0.48 | 30.89 | 30.30 | 4198 | 0.41 | 4.5 | 11,335 |

| EP-6 | 0.26 | 31.02 | 30.26 | 5895 | 0.59 | 6.3 | 11,264 |

| Average | 0.39 | 30.50 | 30.30 | 5602 | 0.57 | 6.1 | 11,346 |

| St. Dev | 0.12 | 0.32 | 0.06 | 771 | 0.08 | 0.9 | 541 |

| Sample | [mm] | [mm] | [mm] | [N] | [mm] | [MPa] | [N/mm] |

|---|---|---|---|---|---|---|---|

| PU-1 | 0.22 | 30.03 | 30.35 | 6563 | 0.66 | 7.2 | 12,590 |

| PU-2 | 0.40 | 30.04 | 30.35 | 6261 | 0.66 | 6.9 | 11,299 |

| PU-3 | 0.35 | 30.03 | 30.36 | 6461 | 0.84 | 7.1 | 12,027 |

| PU-4 | 0.36 | 30.30 | 30.20 | 5145 | 0.48 | 5.6 | 11,354 |

| PU-5 | 0.41 | 29.61 | 30.29 | 6258 | 0.68 | 7.0 | 11,498 |

| PU-6 | 0.73 | 29.93 | 30.28 | 6284 | 0.63 | 6.9 | 10,835 |

| Average | 0.41 | 29.99 | 30.30 | 6162 | 0.66 | 6.8 | 11,600 |

| St. Dev | 0.16 | 0.20 | 0.08 | 469 | 0.11 | 0.5 | 564 |

| Sample | [mm] | [mm] | [mm] | [N] | [mm] | [MPa] | [N/mm] |

|---|---|---|---|---|---|---|---|

| AC-1 | 0.46 | 30.94 | 30.26 | 11,474 | 1.44 | 12.3 | 10,747 |

| AC-2 | 0.56 | 30.56 | 30.28 | 12,029 | 1.53 | 13.0 | 10,687 |

| AC-3 | 0.49 | 30.62 | 30.26 | 12,267 | 1.55 | 13.2 | 10,823 |

| AC-4 | 0.42 | 30.73 | 30.28 | 12,951 | 1.68 | 13.9 | 11,628 |

| AC-5 | 0.44 | 30.38 | 30.31 | 12,370 | 1.56 | 13.4 | 11,513 |

| AC-6 | 0.32 | 30.99 | 30.34 | 11,886 | 1.50 | 12.6 | 11,454 |

| Average | 0.45 | 30.70 | 30.29 | 12,163 | 1.54 | 13.1 | 11,142 |

| St. Dev | 0.07 | 0.21 | 0.04 | 455 | 0.08 | 0.5 | 395 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2026 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license.

Share and Cite

Bohlmann, N.X.; Fernandes, P.H.E.; Voß, M.; Veller, S.; Nagel, C.; Arnaut, K.; Beber, V.C. Structural Adhesive Bonding of Vacuum-Infused Acrylic-Based Thermoplastic Fibre-Reinforced Laminates. J. Compos. Sci. 2026, 10, 6. https://doi.org/10.3390/jcs10010006

Bohlmann NX, Fernandes PHE, Voß M, Veller S, Nagel C, Arnaut K, Beber VC. Structural Adhesive Bonding of Vacuum-Infused Acrylic-Based Thermoplastic Fibre-Reinforced Laminates. Journal of Composites Science. 2026; 10(1):6. https://doi.org/10.3390/jcs10010006

Chicago/Turabian StyleBohlmann, Nils Xavier, Pedro Henrique Evangelista Fernandes, Morten Voß, Sebastian Veller, Christof Nagel, Katharina Arnaut, and Vinicius Carrillo Beber. 2026. "Structural Adhesive Bonding of Vacuum-Infused Acrylic-Based Thermoplastic Fibre-Reinforced Laminates" Journal of Composites Science 10, no. 1: 6. https://doi.org/10.3390/jcs10010006

APA StyleBohlmann, N. X., Fernandes, P. H. E., Voß, M., Veller, S., Nagel, C., Arnaut, K., & Beber, V. C. (2026). Structural Adhesive Bonding of Vacuum-Infused Acrylic-Based Thermoplastic Fibre-Reinforced Laminates. Journal of Composites Science, 10(1), 6. https://doi.org/10.3390/jcs10010006