Adaptive Torque Control for Process Optimization in Friction Stir Welding of Aluminum 6061-T6 Using a Horizontal 5-Axis CNC Machine

Abstract

1. Introduction

1.1. Applications and Use of AA6061-T6

1.2. Five-Axis Machining

1.3. Previous Work on FSW 6061

1.4. Benefits of FSW in 5-Axis CNC

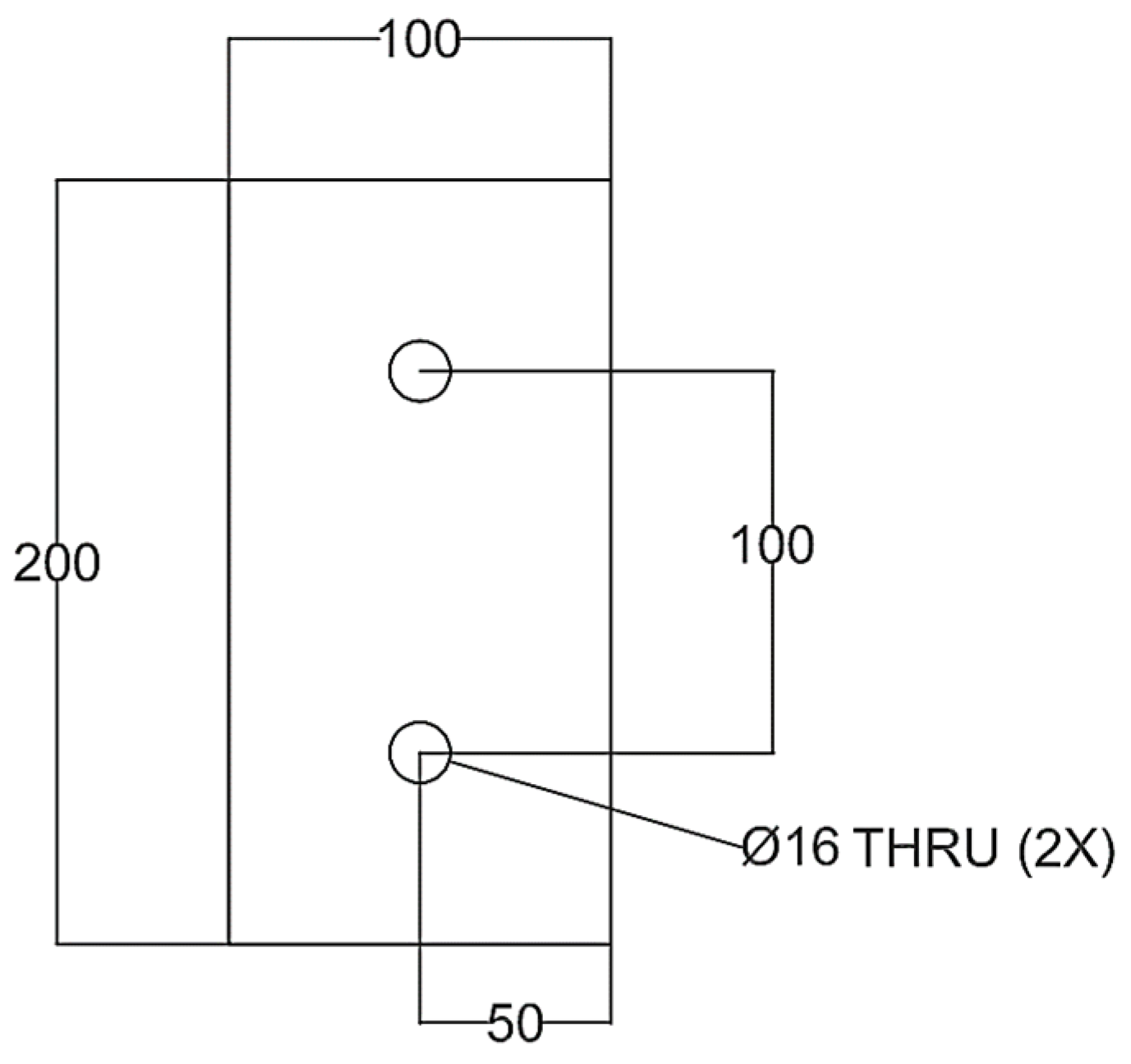

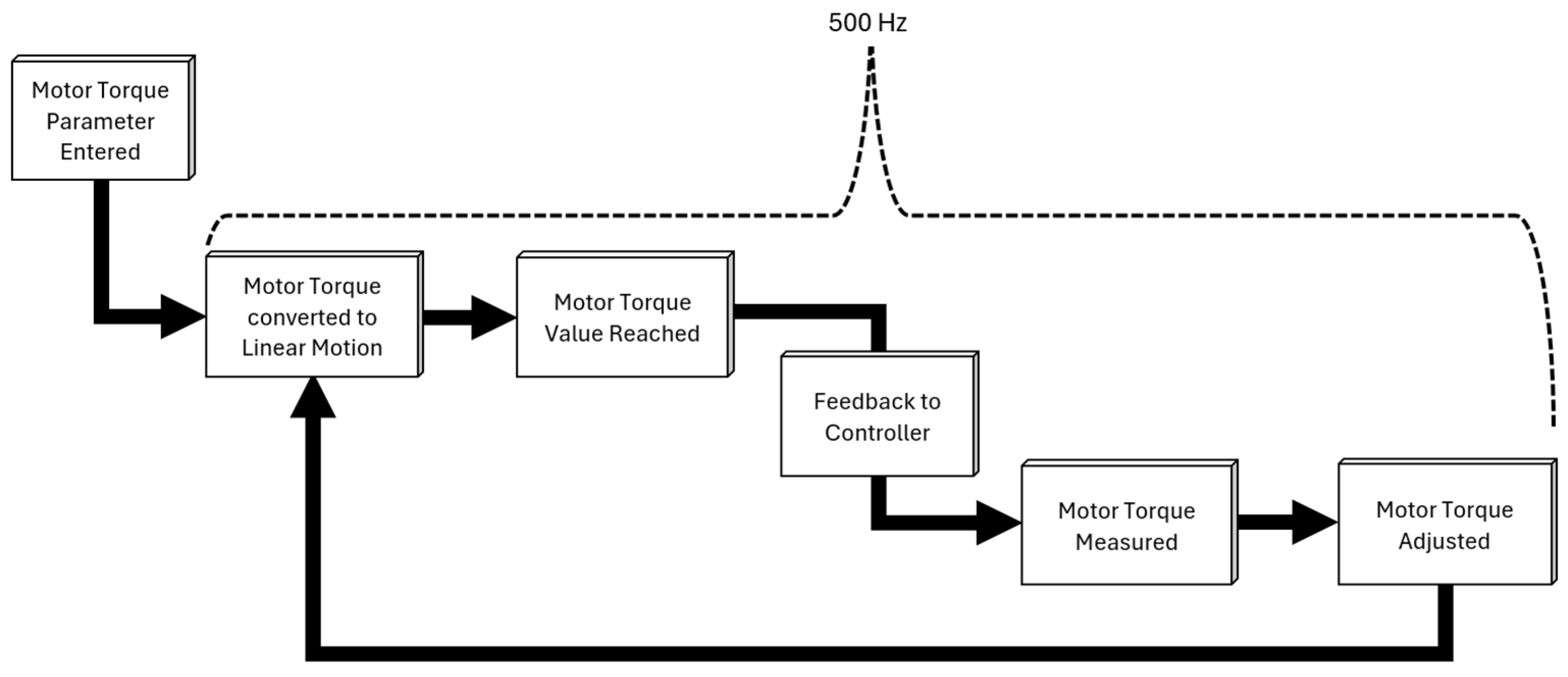

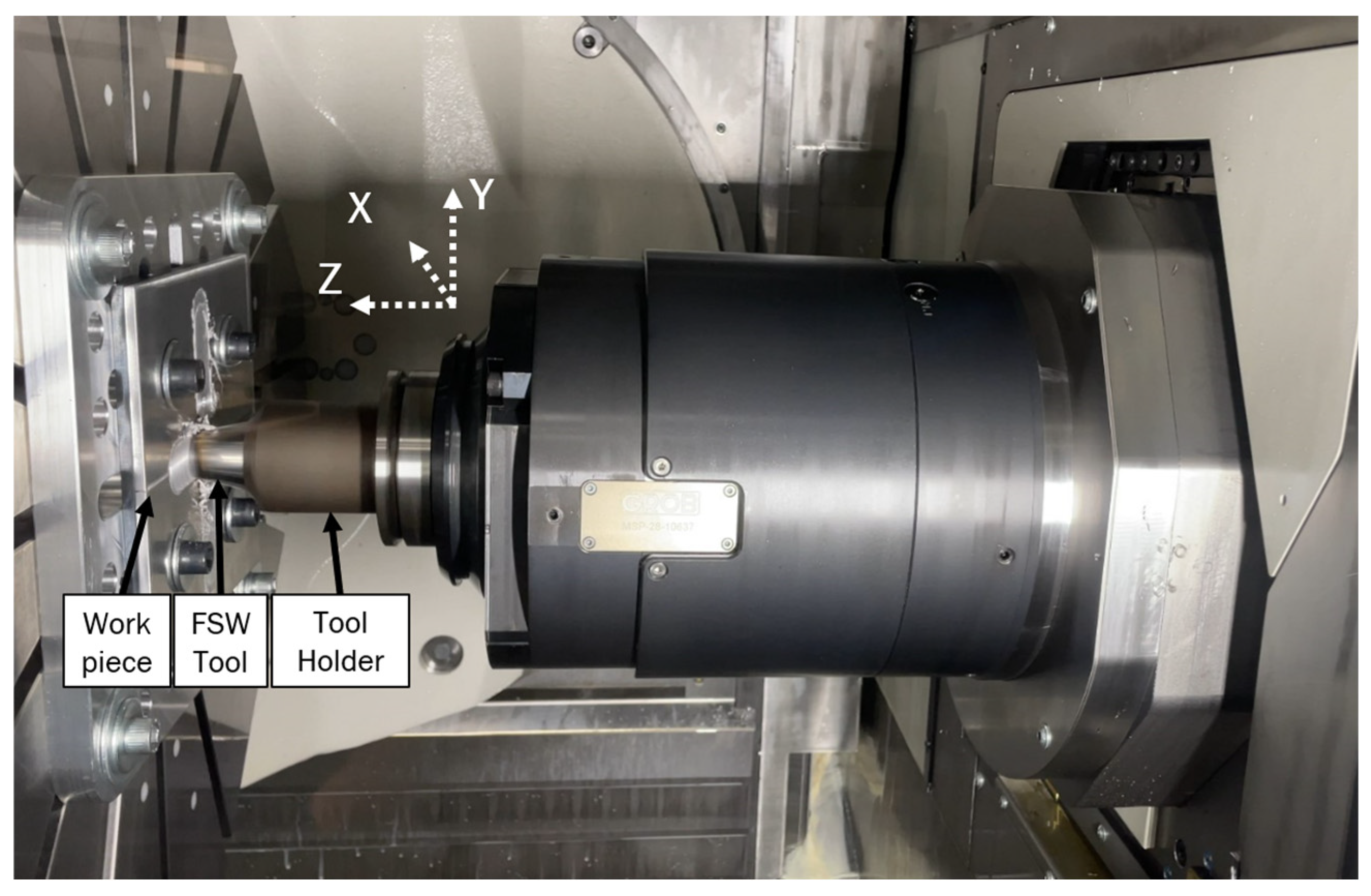

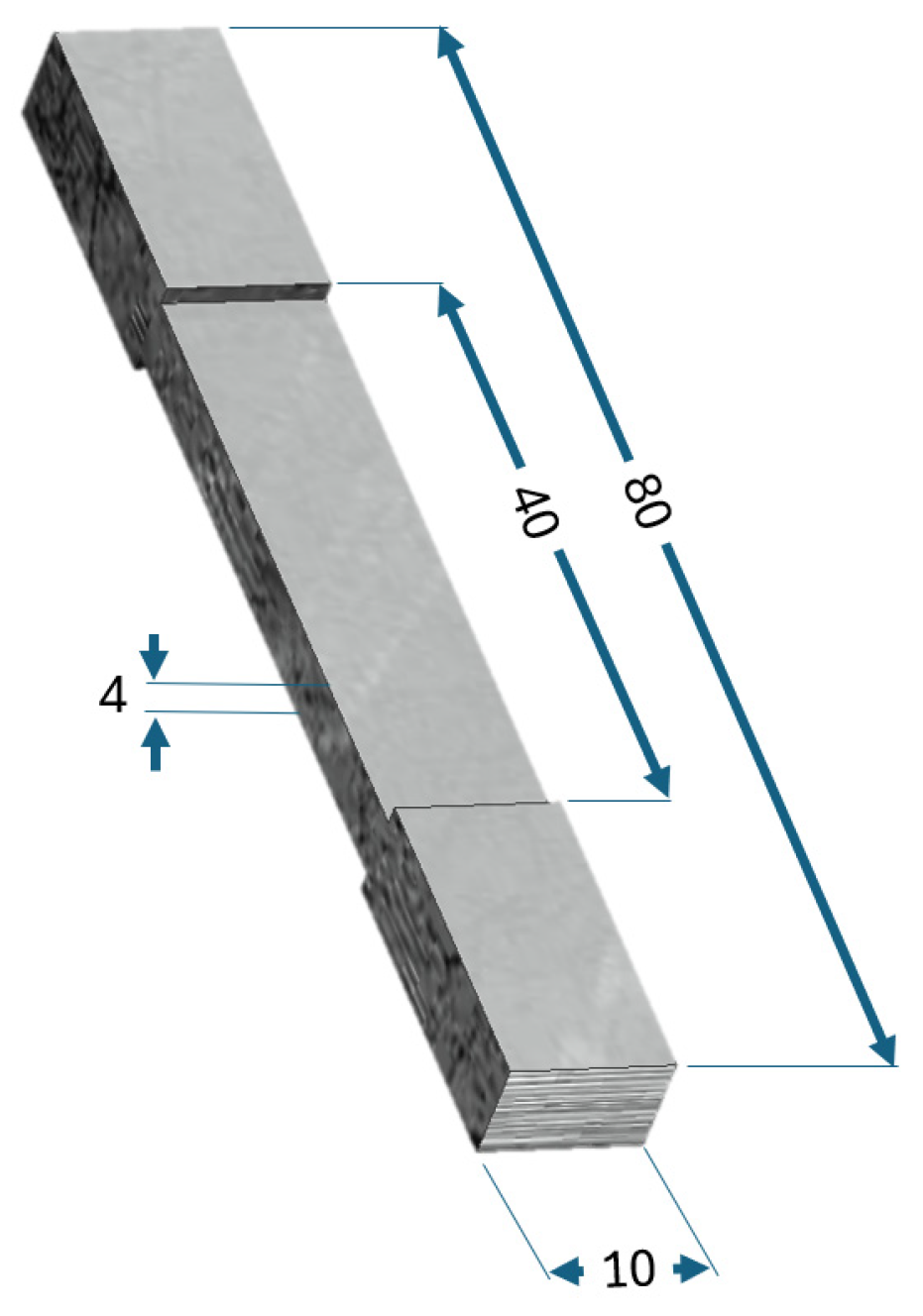

2. Testing Methodology

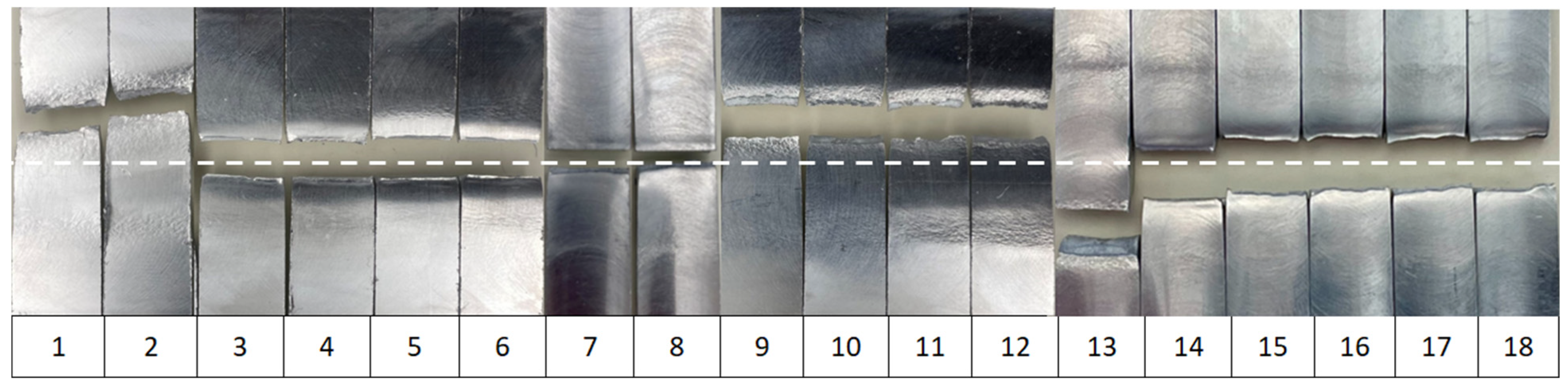

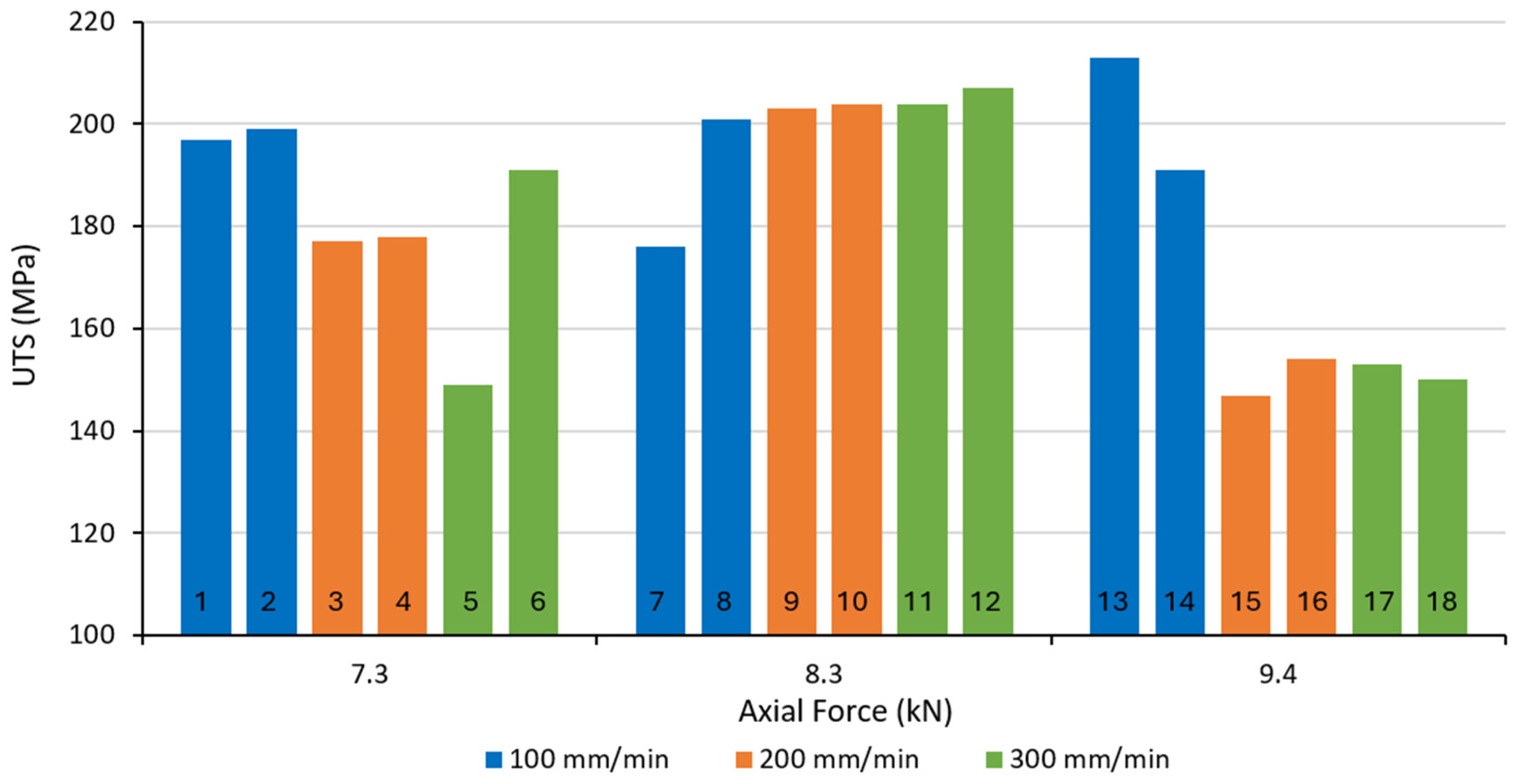

3. Results

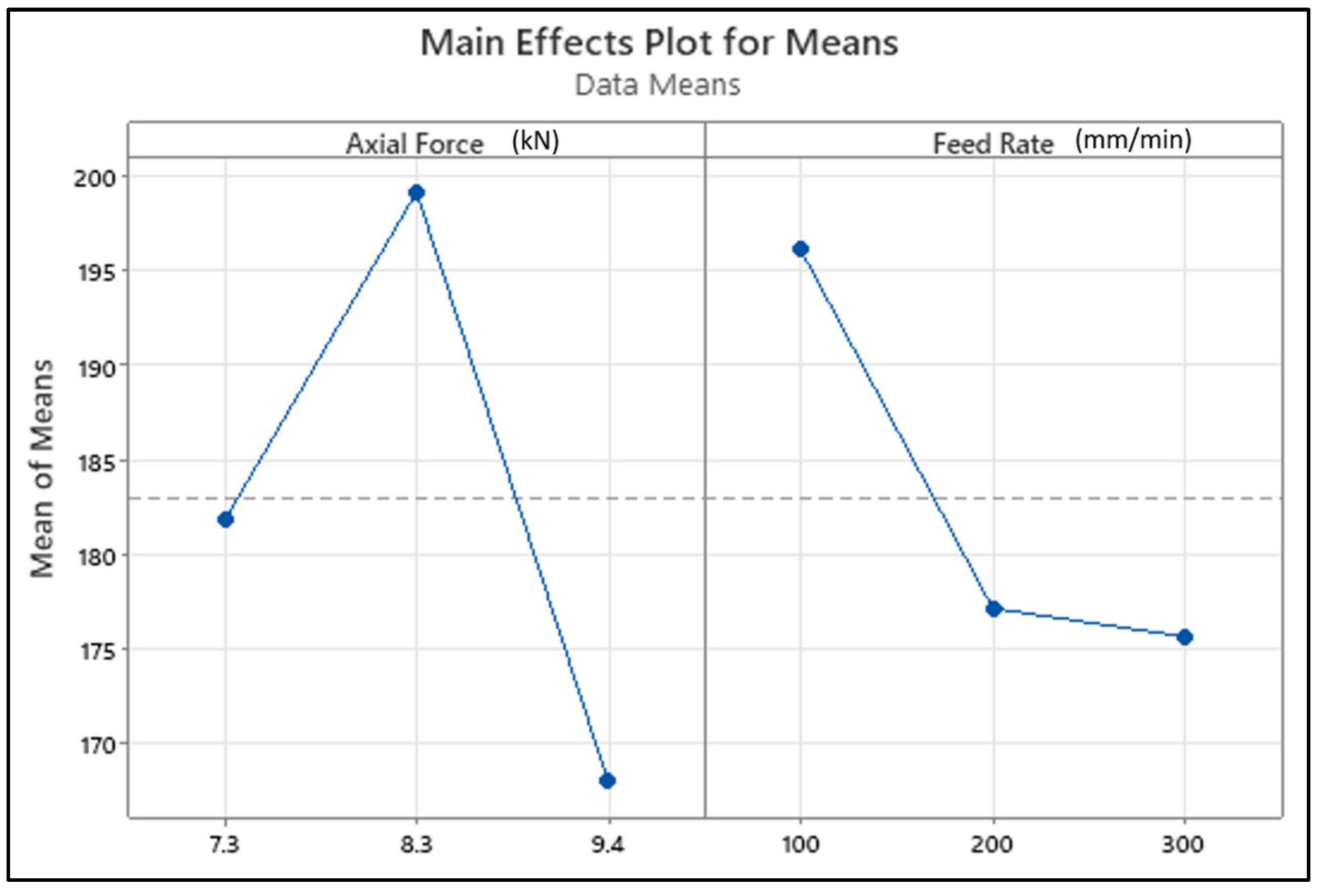

Taguchi Analysis/ANOVA

4. Conclusions

- The optimal parameters yielding the highest UTS with the fewest defects were welded with an 8.3 kN axial force at a 300 mm/min feed rate.

- A total of 67% of the base metal tensile strength was retained.

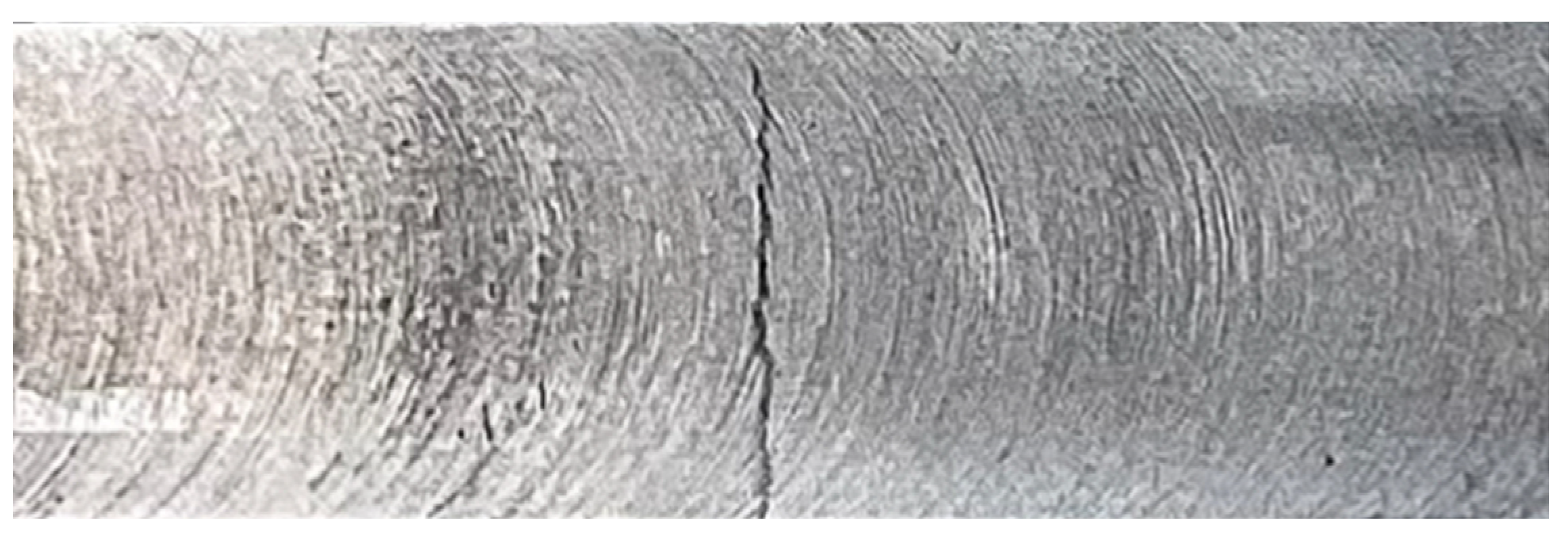

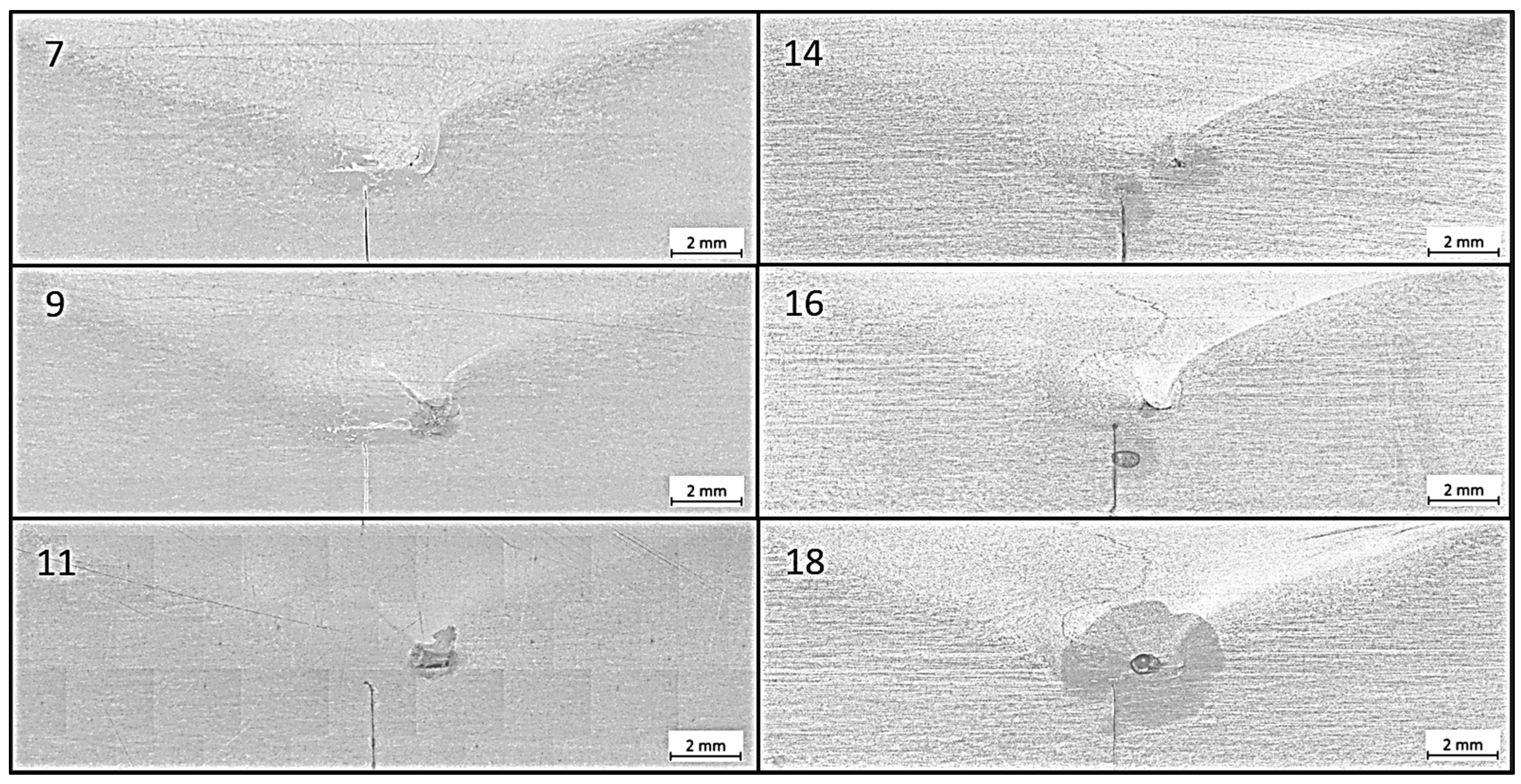

- Welds performed with higher axial force caused voids due to excessive heating and mixing under the FSW pin.

- Void creation and tunneling led to a decrease in UTS.

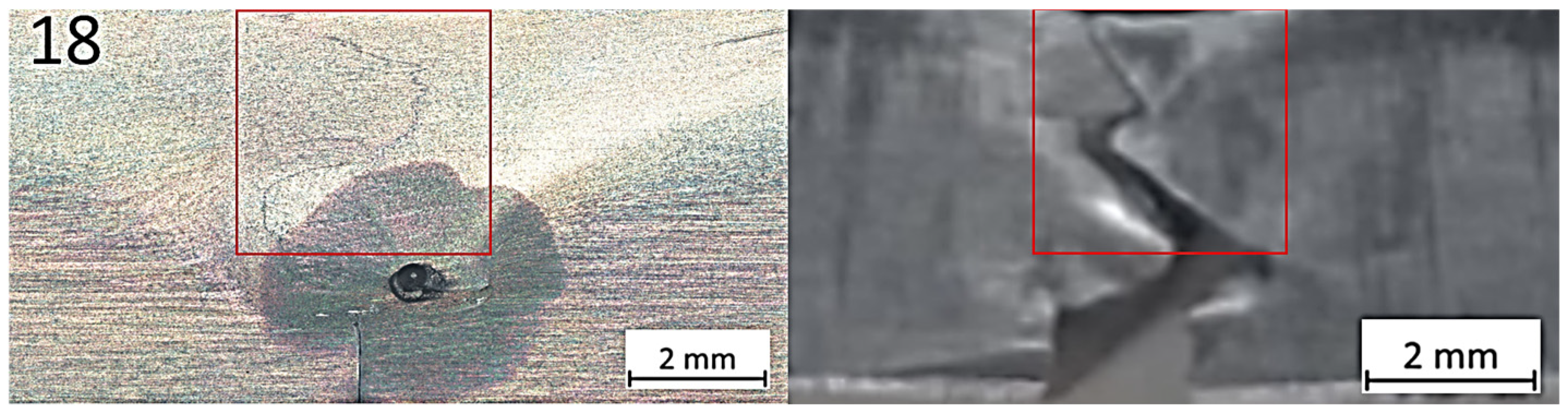

- Lazy “S” defects were found in micrographs across all welds performed with a 9.4 kN axial force.

- Higher feed rates increased the presence of the Lazy “S.”

- Taguchi analysis showed axial force had a greater effect on UTS than feed rate.

5. Future Work

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Thomas, W.M. Friction Stir Welding—Process Developments and Variant Techniques; The SME Summit: Oconomowoc, WI, USA, 2005; pp. 1–19. [Google Scholar]

- Kallee, S.W. Industrial Applications of Friction Stir Welding. In Friction Stir Welding; Elsevier: Amsterdam, The Netherlands, 2010; pp. 118–163. [Google Scholar] [CrossRef]

- Belalia, S.E.; Serier, M.; Al-Sabur, R. Parametric Analysis for Torque Prediction in Friction Stir Welding Using Machine Learning and Shapley Additive Explanations. J. Comput. Appl. Mech. 2024, 55, 113–124. [Google Scholar] [CrossRef]

- Alcoa Engineered Products. Alloy 6061 [Engineering]. Aluminum 6061-T6; 6061-T651. Available online: https://sites.astro.caltech.edu/sedm/_downloads/4c62586a69bdc57ca49a938a3e3fc082/Extruded_Alloy_6061.pdf (accessed on 18 December 2024).

- Nappi, D.C. The Global Aluminium Industry 40 Years from 1972 (No. R47294; p. 22). 2022. Available online: http://large.stanford.edu/courses/2016/ph240/mclaughlin1/docs/nappi.pdf (accessed on 18 December 2024).

- International Aluminum Institute. 50 Moments. The Key Milestones in the Development of Today’s Modern Aluminium Industry. 2022. Available online: https://international-aluminium.org/wp-content/uploads/2022/12/50-Moments.pdf (accessed on 5 January 2025).

- Aerospace Specification Metals Inc. Aluminum 6061-T6; 6061-T651. 2000. Available online: https://asm.matweb.com/search/SpecificMaterial.asp?bassnum=ma6061t6 (accessed on 31 January 2025).

- Industrial Metal Service. Aluminum 6061 Material Properties. 2024. Available online: https://industrialmetalservice.com/metal-university/aluminum-6061-material-properties (accessed on 29 April 2025).

- Yuan, C.; Mi, Z.; Jia, X.; Lin, F.; Shen, L. Tool Orientation Optimization and Path Planning for 5-Axis Machining. J. Syst. Sci. Complex. 2021, 34, 83–106. [Google Scholar] [CrossRef]

- Heidenheim GmbH. Accuracy in 5-Axis Machining [Technical Information]. Influence of Position Measurement on Accuracy in 5-Axis Machining. September 2011. Available online: https://www.heidenhain.de/fileadmin/pdf/en/01_Products/Technische_Dokumentation/TI_Influence_of_Position_Measurement_on_Accuracy_5-Axis_Machining_ID895283_en.pdf (accessed on 23 January 2025).

- Wang, Y. Design and Development of a Five-Axis Machine Tool with High Accuracy, Stiffness and Efficiency for Aero-engine Casing Manufacturing. Chin. J. Aeronaut. 2022, 35, 485–496. [Google Scholar] [CrossRef]

- ZTL. Choosing the Right Milling Machine [Technical]. A Comprehensive Guide to Horizontal Milling vs. Vertical Milling. 8 November 2023. Available online: https://www.zintilon.com/blog/horizontal-vs-vertical-milling/ (accessed on 28 March 2025).

- Rao, C.M.; Rao, K.M. Evolution of Microstructure and Hardness of Aluminium 6061 after Friction Stir Welding. Int. J. Theor. Appl. Mech. 2017, 12, 405–410. [Google Scholar]

- Patil, S.; Nagamadhu, M.; Malyadri, T. A Critical Review on Microstructure and Hardness of Aluminum Alloy 6061 Joints Obtained by Friction Stir Welding-Past, Present, and its Prospects. Mater. Today Proc. 2023, 82, 75–78. [Google Scholar] [CrossRef]

- Abdullah, A.M. Mechanical Properties of AA 6061-T6 Aluminum Alloy Friction Stir Welds. J. Eng. 2015, 21, 52–61. [Google Scholar] [CrossRef]

- Zaiedah Nasir, N.; Mohd Daud, M.A.; Selamat, M.Z.; Rivai, A.; Dhar Malingam, S. The Effect of Heat Treatment on Fatigue and Mechanical Properties of 6061 Aluminium Alloy. Appl. Mech. Mater. 2014, 699, 227–232. [Google Scholar] [CrossRef]

- Hussein, S.G.; Al-Shammari, M.A.; Takhakh, A.M.; Al-Waily, M. Effect of Heat Treatment on Mechanical and Vibration Properties for 6061 and 2024 Aluminum Alloys. J. Mech. Eng. Res. Dev. 2020, 43, 48–66. [Google Scholar]

- Abboud, M.; Dubourg, L.; Racineux, G.; Kerbrat, O. Experimental Methodology to Identify Optimal Friction Stir Welding Parameters Based on Temperature Measurement. J. Manuf. Mater. Process. 2024, 8, 137. [Google Scholar] [CrossRef]

- Ogunsemi, B.T.; Abioye, T.E.; Ogedengbe, T.I.; Zuhailawati, H. A Review of Various Improvement Strategies for Joint Quality of AA 6061-T6 Friction Stir Weldments. J. Mater. Res. Technol. 2021, 11, 1061–1089. [Google Scholar] [CrossRef]

- Sefene, E.M.; Tsai, Y.-H.; Jamil, M.; Jatti, V.S.; Mishra, A.; AsmareTsegaw, A.; Costa, E.C. A Multi-Criterion Optimization of Mechanical Properties and Sustainability Performance in Friction Stir Welding of 6061-T6 AA. Mater. Today Commun. 2023, 36, 106838. [Google Scholar] [CrossRef]

- Zhang, H.J.; Sun, S.L.; Liu, H.J.; Zhu, Z.; Wang, Y.L. Characteristic and Mechanism of Nugget Performance Evolution With Rotation Speed for High-Rotation-Speed Friction Stir Welded 6061 Aluminum Alloy. J. Manuf. Process. 2020, 60, 544–552. [Google Scholar] [CrossRef]

- Trueba, L.; Heredia, G.; Rybicki, D.; Johannes, L.B. Effect of Tool Shoulder Features on Defects and Tensile Properties of Friction Stir Welded Aluminum 6061-T6. J. Mater. Process. Technol. 2015, 219, 271–277. [Google Scholar] [CrossRef]

- Lader, S.K.; Baruah, M.; Ballav, R.; Bag, S. Recent Developments in Friction Stir Welding Tools for Weld Bead Defects Minimization—A Review. Soldag. Inspeção 2023, 28, e2806. [Google Scholar] [CrossRef]

- Nishant; Jha, S.K.; Prakash, P. Effect of Tool Rotation Speed on Microstructure and Mechanical Properties of Underwater Friction Stir Welding 6061 Aluminium Alloy. Mater. Today Proc. 2023, 91, 9–13. [Google Scholar] [CrossRef]

- Liu, X.C.; Li, W.T.; Zhou, Y.Q.; Li, Y.Z.; Pei, X.J.; Shen, Z.K.; Wang, Q.H. Multiple Effects of Forced Cooling on Joint Quality in Coolant-Assisted Friction Stir Welding. J. Mater. Res. Technol. 2023, 25, 4264–4276. [Google Scholar] [CrossRef]

- Barooni, O.; Abbasi, M.; Givi, M.; Bagheri, B. New Method to Improve the Microstructure and Mechanical Properties of Joint Obtained using FSW. Int. J. Adv. Manuf. Technol. 2017, 93, 4371–4378. [Google Scholar] [CrossRef]

- Khalaf, H.I.; Al-Sabur, R.; Abdullah, M.E.; Kubit, A.; Derazkola, H.A. Effects of Underwater Friction Stir Welding Heat Generation on Residual Stress of AA6068-T6 Aluminum Alloy. Materials 2022, 15, 2223. [Google Scholar] [CrossRef]

- Ahmed, M.M.Z.; El-Sayed Seleman, M.M.; Fydrych, D.; Çam, G. Friction Stir Welding of Aluminum in the Aerospace Industry: The Current Progress and State-of-the-Art Review. Materials 2023, 16, 2971. [Google Scholar] [CrossRef]

- Sun, Z.; Yang, X.; Li, D.; Cui, L. The Local Strength and Toughness for Stationary Shoulder Friction Stir Weld on AA6061-T6 Alloy. Mater. Charact. 2016, 111, 114–121. [Google Scholar] [CrossRef]

- Wen, Q.; Yue, Y.; Ji, S.; Li, Z.; Gao, S. Effect of Welding Speeds on Mechanical Properties of Level Compensation Friction Stir Welded 6061-T6 Aluminum Alloy. High Temp. Mater. Process. 2016, 35, 375–379. [Google Scholar] [CrossRef]

- Abu-Okail, M.; Mahmoud, T.S.; Abu-Oqail, A. Improving Microstructural and Mechanical Properties of AA2024 Base Metal by Adding Reinforced Strip Width of AA7075 via Vertical Compensation Friction Stir Welding Technique. J. Fail. Anal. Prev. 2020, 20, 184–196. [Google Scholar] [CrossRef]

- Fehrenbacher, A.; Smith, C.B.; Duffie, N.A.; Ferrier, N.J.; Pfefferkorn, F.E.; Zinn, M.R. Combined Temperature and Force Control for Robotic Friction Stir Welding. J. Manuf. Sci. Eng. 2014, 136, 021007. [Google Scholar] [CrossRef]

- Trimble, D.; Monaghan, J.; O’Donnell, G.E. Force Generation During Friction Stir Welding of AA2024-T3. CIRP Ann. 2012, 61, 9–12. [Google Scholar] [CrossRef]

- Zaeh, M.F.; Gebhard, P. Dynamical Behaviour of Machine Tools During Friction Stir Welding. Prod. Eng. 2010, 4, 615–624. [Google Scholar] [CrossRef]

- Baskoro, A.S.; Kurniawan, R.P.; Haikal, H. Evaluation of the 2-Axis Movement of a 5-Axis Gantry Robot for Welding Applications. Int. J. Technol. 2019, 10, 1024. [Google Scholar] [CrossRef]

- Breaz, R.-E.; Racz, S.-G.; Bologa, O.-C. 5-Axes Modular CNC Machining Center. MATEC Web Conf. 2017, 112, 06004. [Google Scholar] [CrossRef]

- Zeng, C.; Hu, Y.; Shi, J.; Bi, Q. On-machine Measurement and Compensation of Assembling Gap for 5-axis Friction Stir Welding based on 2D Laser Profilometer. In Proceedings of the 2019 IEEE 5th International Conference on Mechatronics System and Robots (ICMSR), Singapore, 3–5 May 2019; pp. 70–75. [Google Scholar] [CrossRef]

- Inada, K.; Fujii, H.; Ji, Y.S.; Sun, Y.F.; Morisada, Y. Effect of Gap on FSW Joint Formation and Development of Friction Powder Processing. Sci. Technol. Weld. Join. 2010, 15, 131–136. [Google Scholar] [CrossRef]

- Longhurst, W.R. Force Control of Friction Stir Welding. Ph.D. Thesis, Vanderbilt University, Nashville, TN, USA, 2009. [Google Scholar]

- Clark, A.; Ragai, I.; Buffa, G.; Fratini, L. Feasibility of 5-axis CNC Friction Stir Welding of Aluminum 3003-H14. Mater. Res. Proc. 2025, 54, 1344–1353. [Google Scholar] [CrossRef]

- Safeen, M.W.; Spena, P.R.; Buffa, G.; Campanella, D.; Masnata, A.; Fratini, L. Effect of Position and Force Tool Control in Friction Stir Welding of Dissimilar Aluminum-Steel Lap Joints for Automotive Applications. Adv. Manuf. 2020, 8, 59–71. [Google Scholar] [CrossRef]

- Dewangan, S.; Reddy, A.P.; Sunder, S.S.S.; Legutko, S.; Burja, J.; Kumar, U. Mechanical Property Analysis into the Welded Plates of Al-6061 Joined by TIG and FSW Techniques. J. Inst. Eng. Ser. D 2024, 105, 1703–1713. [Google Scholar] [CrossRef]

- Ji, S.; Meng, X.; Xing, J.; Ma, L.; Gao, S. Vertical Compensation Friction Stir Welding of 6061-T6 Aluminum Alloy. High Temp. Mater. Process. 2016, 35, 843–851. [Google Scholar] [CrossRef][Green Version]

- Kalinenko, A.; Vysotskiy, I.; Malopheyev, S.; Mironov, S.; Kaibyshev, R. Grain Structure Evolution During Friction-Stir Welding of 6061-T6 Aluminum Alloy. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1014, 012015. [Google Scholar] [CrossRef]

- Kalinenko, A.; Vysotskii, I.; Malopheyev, S.; Mironov, S.; Kaibyshev, R. Relationship between Welding Conditions, Abnormal Grain Growth and Mechanical Performance in Friction-Stir Welded 6061-T6 Aluminum Alloy. Mater. Sci. Eng. A 2021, 817, 141409. [Google Scholar] [CrossRef]

- Manickam, S.K.; Palanivel, I. Practical Implications of FSW Parameter Optimization for AA5754-AA6061 Alloys. Matéria 2024, 29, e20240482. [Google Scholar] [CrossRef]

- Trueba, L.; Torres, M.A.; Johannes, L.B.; Rybicki, D. Process Optimization in the Self-Reacting Friction Stir Welding of Aluminum 6061-T6. Int. J. Mater. Form. 2018, 11, 559–570. [Google Scholar] [CrossRef]

- Gupta, A. Guidelines to Avoid Formation of Defects in Friction Stir Welding of Aluminum Alloy. Available online: https://krishisanskriti.org/vol_image/25Oct2019041050zc06%20%20%20Arun%20Gupta%20%20%20%20%20275-276.pdf (accessed on 29 April 2025).

- Zhang, H.; Sun, Y.; Gong, W.; Cui, H. Growth Mechanism and Motion Trajectory of Lazy “S” in Friction Stir Welding Joint of 6082-T6 Aluminum Alloy. SN Appl. Sci. 2021, 3, 278. [Google Scholar] [CrossRef]

- Zhang, Z.; Xiao, B.L.; Ma, Z.Y. Effect of Segregation of Secondary Phase Particles and “S” Line on Tensile Fracture Behavior of Friction Stir-Welded 2024Al-T351 Joints. Metall. Mater. Trans. A 2013, 44, 4081–4097. [Google Scholar] [CrossRef]

- Zhang, Z.; Gong, P.; Ji, S.; Ma, L.; Jin, C.; Li, X.; Song, Q. Achievement of Superb-Strength Lap Joint via Opposite-Directions Flowing Friction Stir Lap Welding of 2024 Aluminum Alloys. Chin. J. Aeronaut. 2024, 38, 103278. [Google Scholar] [CrossRef]

- Ramamoorthi, R.; Yuvaraj, K.P.; Gokul, C.; Eashwar, S.J.; Arunkumar, N.; Dheen, S.A.T. An Investigation of the Impact of Axial Force on Friction Stir-Welded AA5086/AA6063 on Microstructure and Mechanical Properties Butt Joints. Mater. Today Proc. 2021, 37, 3159–3163. [Google Scholar] [CrossRef]

- Sreenivas, P.; Anil Kumar, R.; Sreejith, P.S. Effect of Applied Axial Force on FSW of AA6082-T6 Aluminum Alloys. Int. J. Mech. Eng. Technol. (IJMET) 2017, 8, 88–99. [Google Scholar]

| Chemical Composition | ||||||||

|---|---|---|---|---|---|---|---|---|

| Mg | Si | Cr | Cu | Mn | Ti | Fe | Zn | Other |

| 1.00 | 0.60 | 0.20 | 0.28 | 0.15 | 0.15 | 0.70 | 0.25 | 0.20 |

| Physical and Mechanical Properties | ||||||||

| Density | Elastic Modulus | Thermal Conductivity | Tensile Strength | Hardness | Yield | |||

| (kg/m3) | (GPa) | (W/m·K) | (MPa) | (Brinell) | (MPa) | |||

| 2700 | 69 | 167 | 310 | 95 | 275 | |||

| Level | Axial Force (kN) | Feed Rate (mm/min) |

|---|---|---|

| 1 | 7.3 | 100 |

| 2 | 8.3 | 200 |

| 3 | 9.4 | 300 |

| Sample # | Axial Force (kN) | Feed Rate (mm/min) |

|---|---|---|

| 1 | 7.3 | 100 |

| 2 | 7.3 | 100 |

| 3 | 7.3 | 200 |

| 4 | 7.3 | 200 |

| 5 | 7.3 | 300 |

| 6 | 7.3 | 300 |

| 7 | 8.3 | 100 |

| 8 | 8.3 | 100 |

| 9 | 8.3 | 200 |

| 10 | 8.3 | 200 |

| 11 | 8.3 | 300 |

| 12 | 8.3 | 300 |

| 13 | 9.4 | 100 |

| 14 | 9.4 | 100 |

| 15 | 9.4 | 200 |

| 16 | 9.4 | 200 |

| 17 | 9.4 | 300 |

| 18 | 9.4 | 300 |

| Response Table for S/N Ratios | Response Table for Means | |||

|---|---|---|---|---|

| Level | Axial Force | Feed Rate | Axial Force | Feed Rate |

| 1 | 45.11 | 45.82 | 181.8 | 196.2 |

| 2 | 45.96 | 44.9 | 199.2 | 177.2 |

| 3 | 44.41 | 44.76 | 168 | 175.7 |

| Delta | 1.55 | 1.06 | 31.2 | 20.5 |

| Rank | 1 | 2 | 1 | 2 |

| Source | DF | Adj SS | Adj MS | F-Value | p-Value |

|---|---|---|---|---|---|

| Axial Force | 2 | 2926 | 1463.2 | 4.17 | 0.040 |

| Feed Rate | 2 | 1567 | 783.5 | 2.23 | 0.147 |

| Error | 13 | 4561 | 350.8 | ||

| Lack-of-Fit | 4 | 3088 | 771.9 | 4.72 | 0.025 |

| Pure Error | 9 | 1473 | 163.7 | ||

| Total | 17 | 9054 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Clark, A.; Ragai, I. Adaptive Torque Control for Process Optimization in Friction Stir Welding of Aluminum 6061-T6 Using a Horizontal 5-Axis CNC Machine. J. Manuf. Mater. Process. 2025, 9, 232. https://doi.org/10.3390/jmmp9070232

Clark A, Ragai I. Adaptive Torque Control for Process Optimization in Friction Stir Welding of Aluminum 6061-T6 Using a Horizontal 5-Axis CNC Machine. Journal of Manufacturing and Materials Processing. 2025; 9(7):232. https://doi.org/10.3390/jmmp9070232

Chicago/Turabian StyleClark, Austin, and Ihab Ragai. 2025. "Adaptive Torque Control for Process Optimization in Friction Stir Welding of Aluminum 6061-T6 Using a Horizontal 5-Axis CNC Machine" Journal of Manufacturing and Materials Processing 9, no. 7: 232. https://doi.org/10.3390/jmmp9070232

APA StyleClark, A., & Ragai, I. (2025). Adaptive Torque Control for Process Optimization in Friction Stir Welding of Aluminum 6061-T6 Using a Horizontal 5-Axis CNC Machine. Journal of Manufacturing and Materials Processing, 9(7), 232. https://doi.org/10.3390/jmmp9070232