Heat Treatment and Fracture Behavior of Aluminum/Steel FSW Joints: A Comprehensive Analysis of a Curved Interface

Abstract

1. Introduction

2. Experimental Procedure

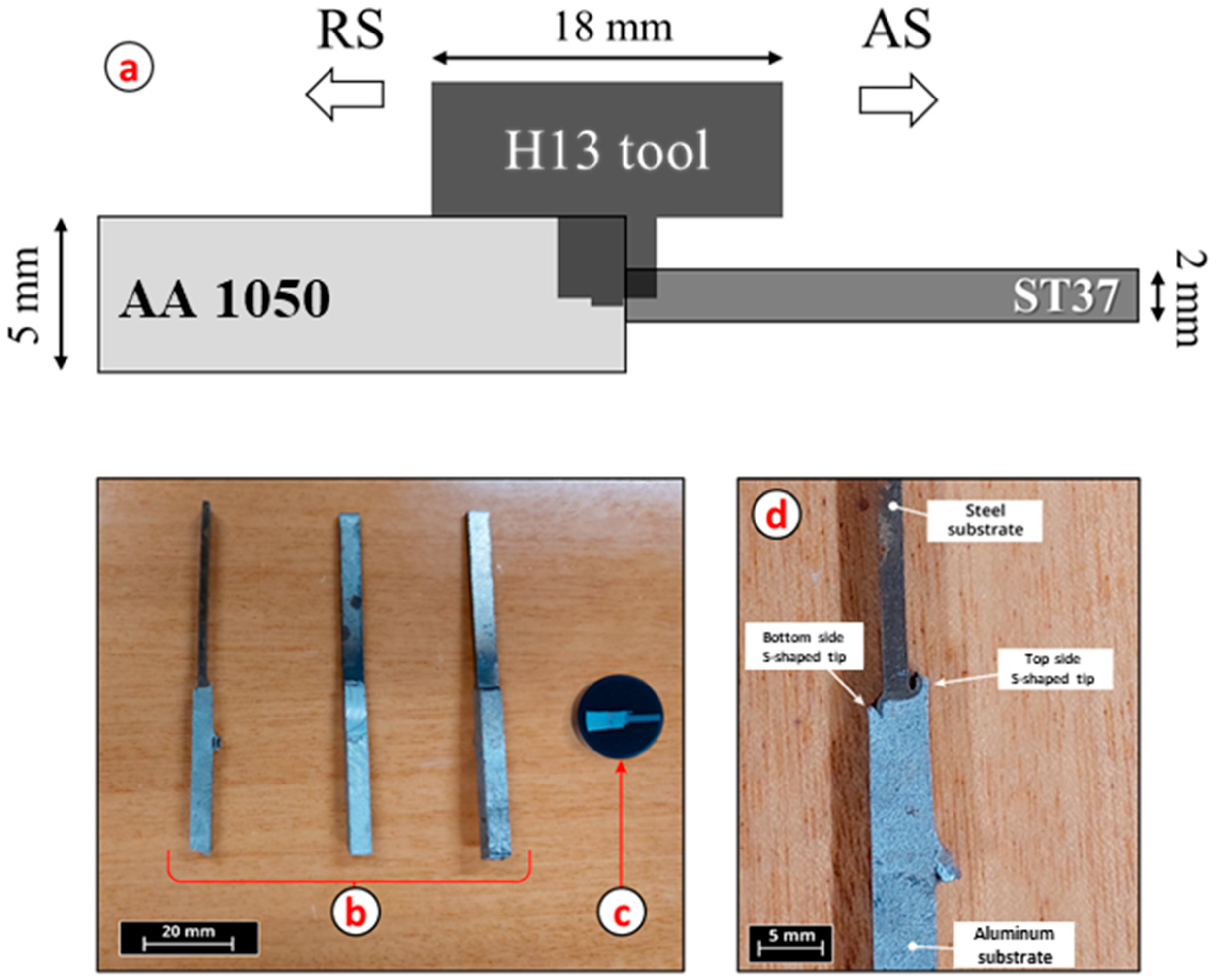

2.1. Materials and FSW Process

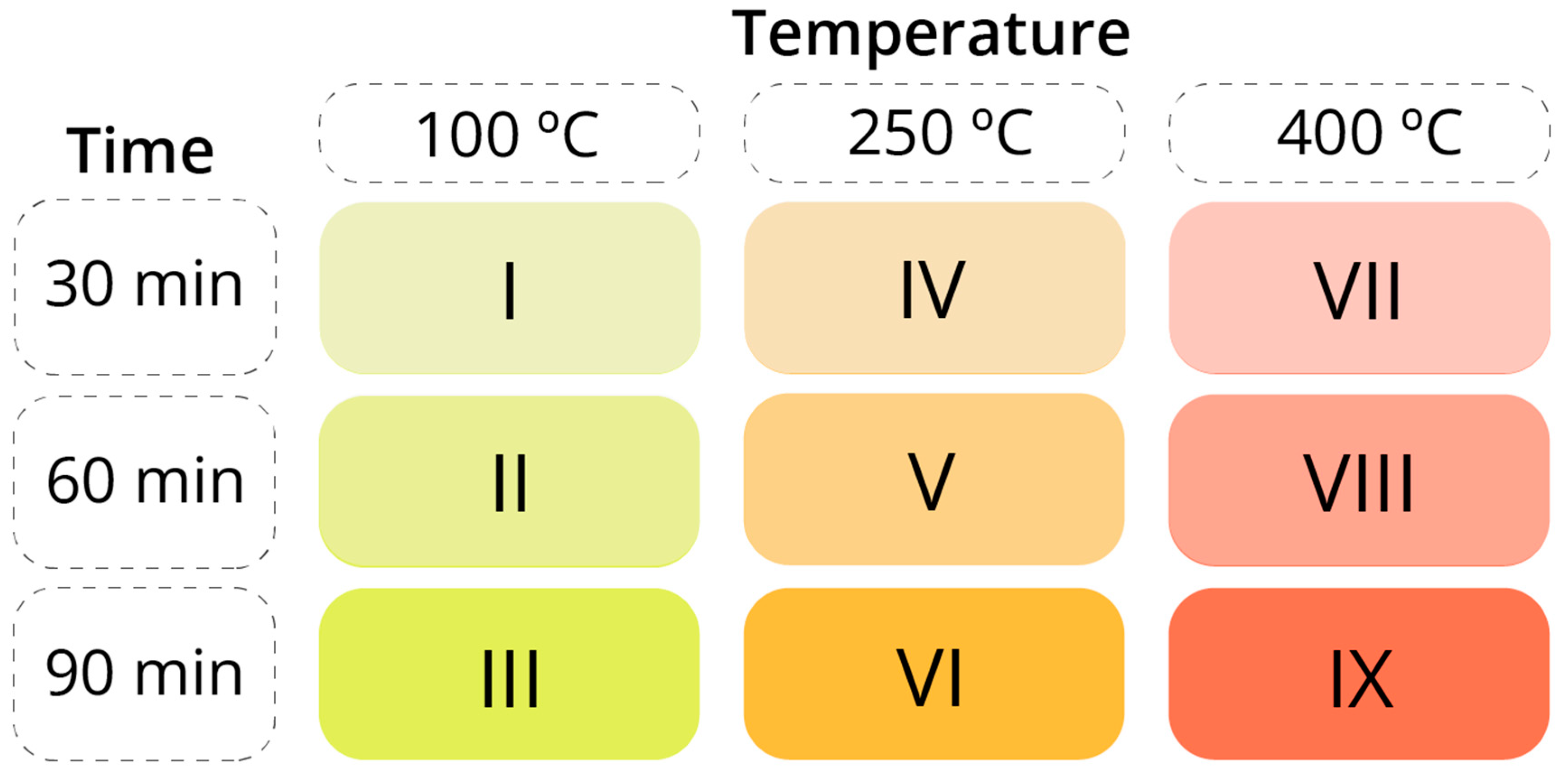

2.2. Post-Weld Heat Treatment

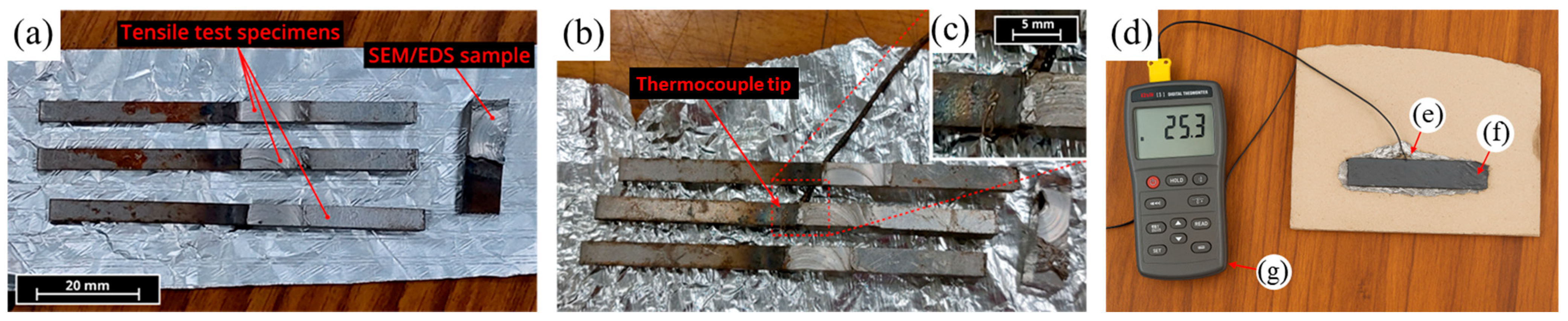

2.3. SEM/EDS Analysis

2.4. Mechanical Tests

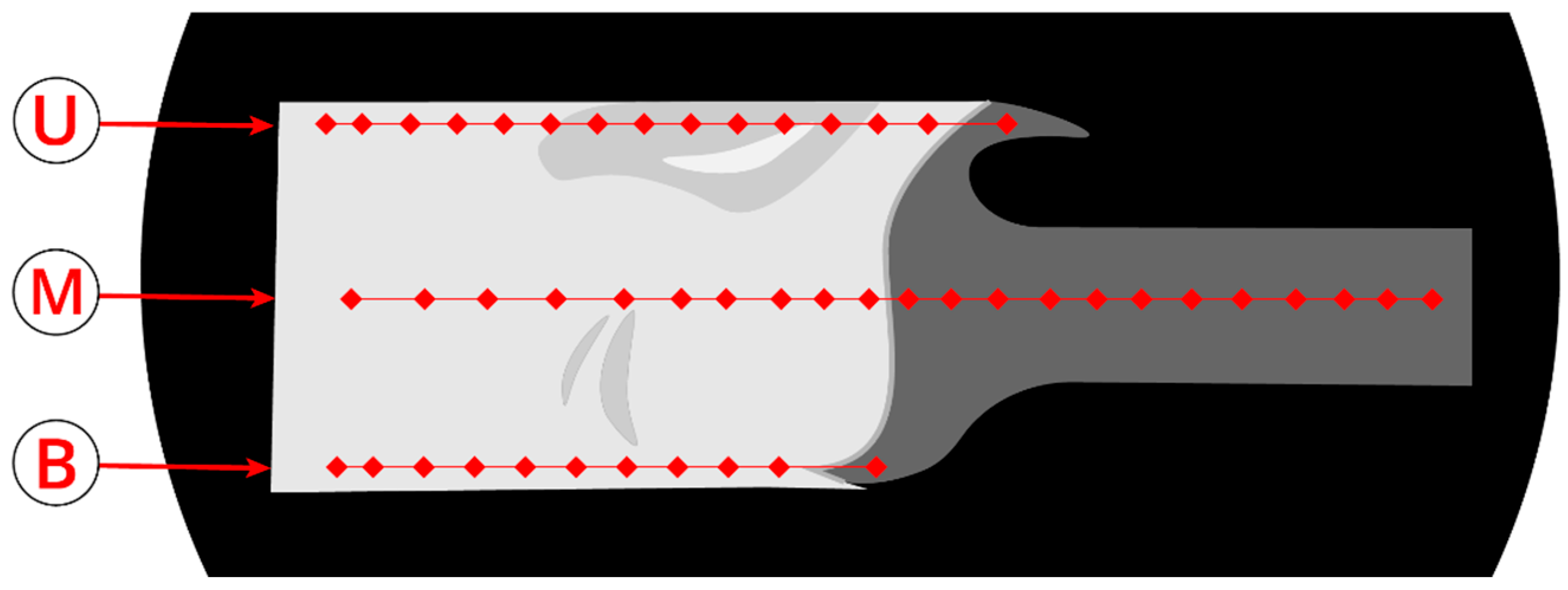

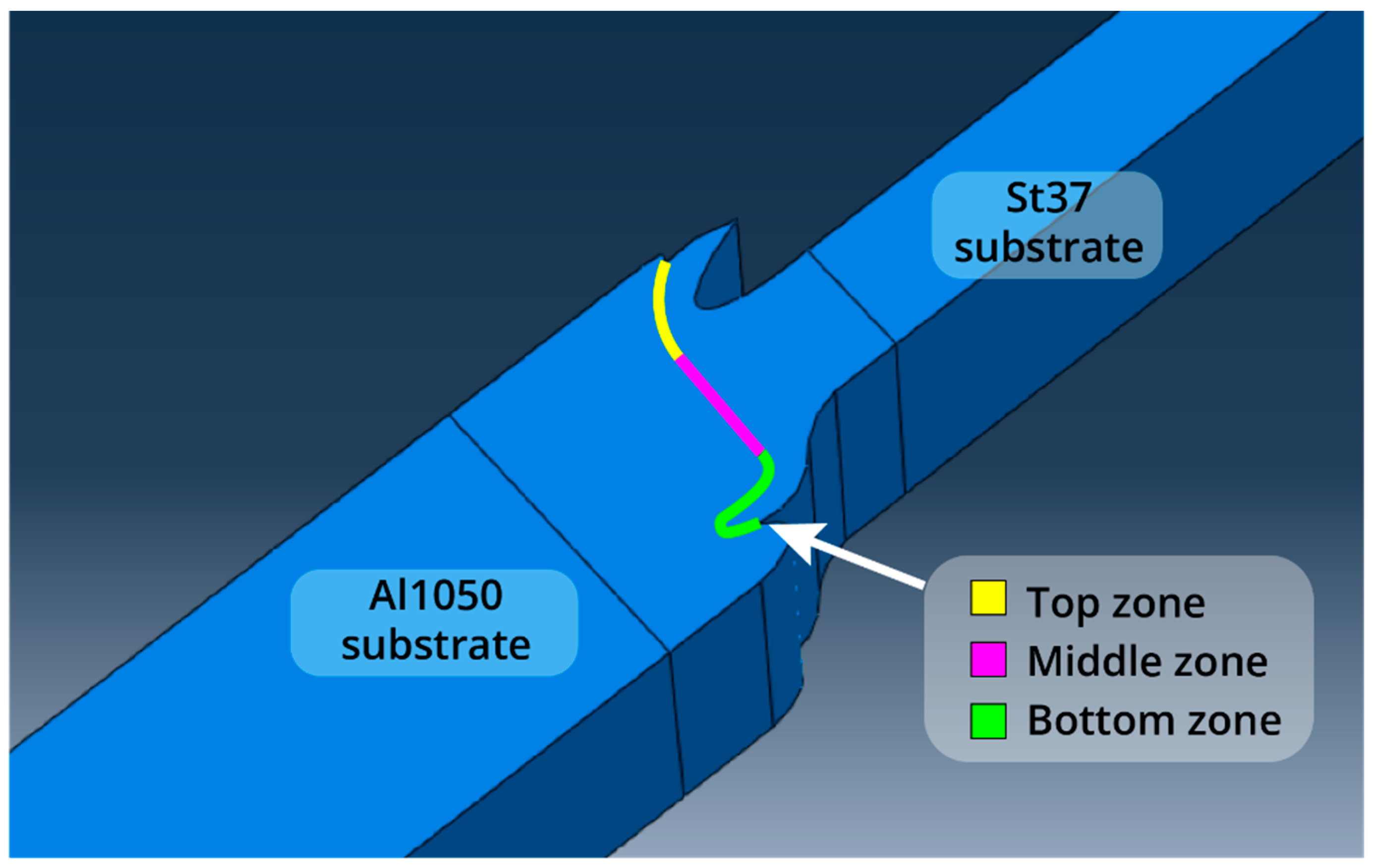

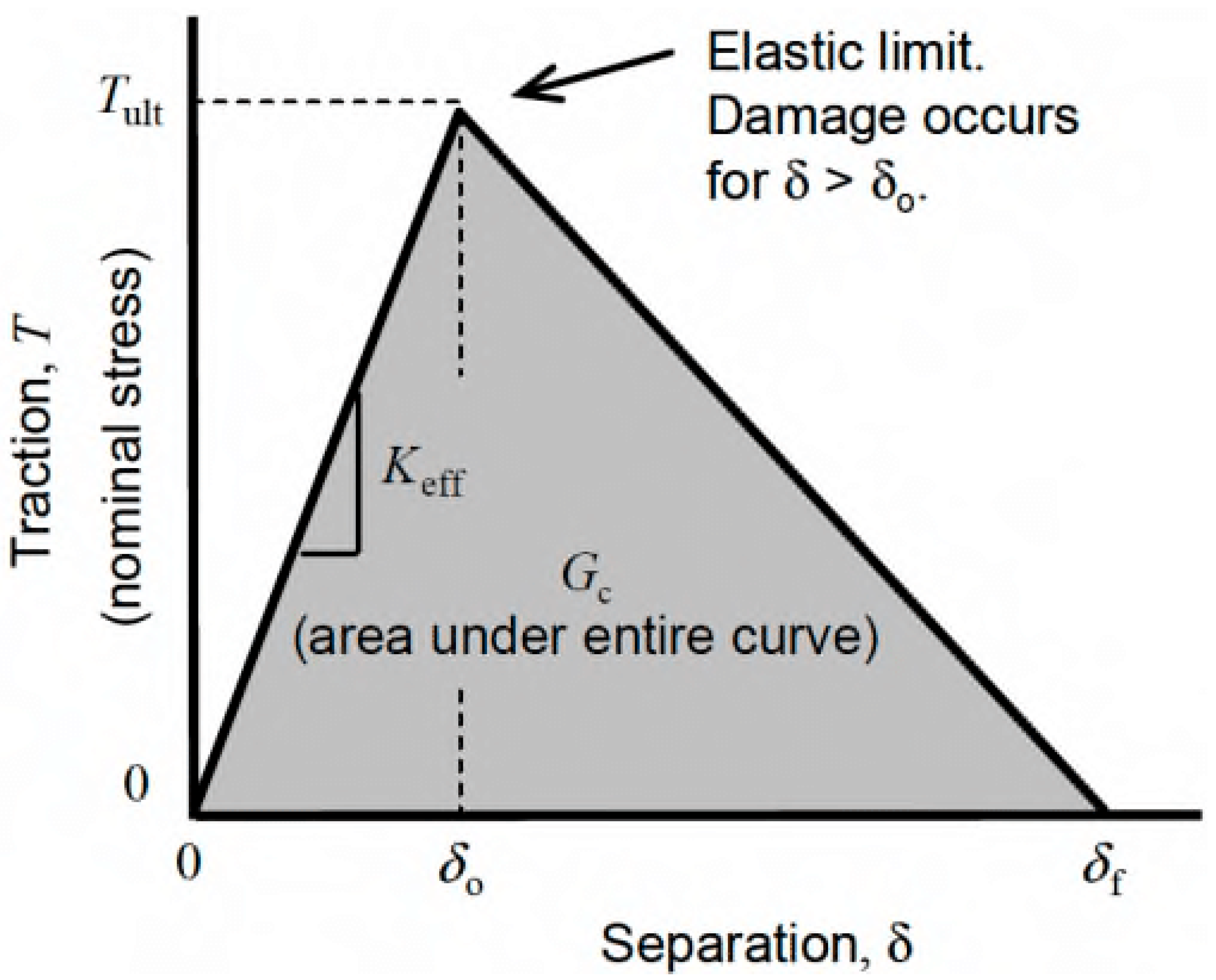

2.5. Simulation of the Fracture

3. Results and Discussion

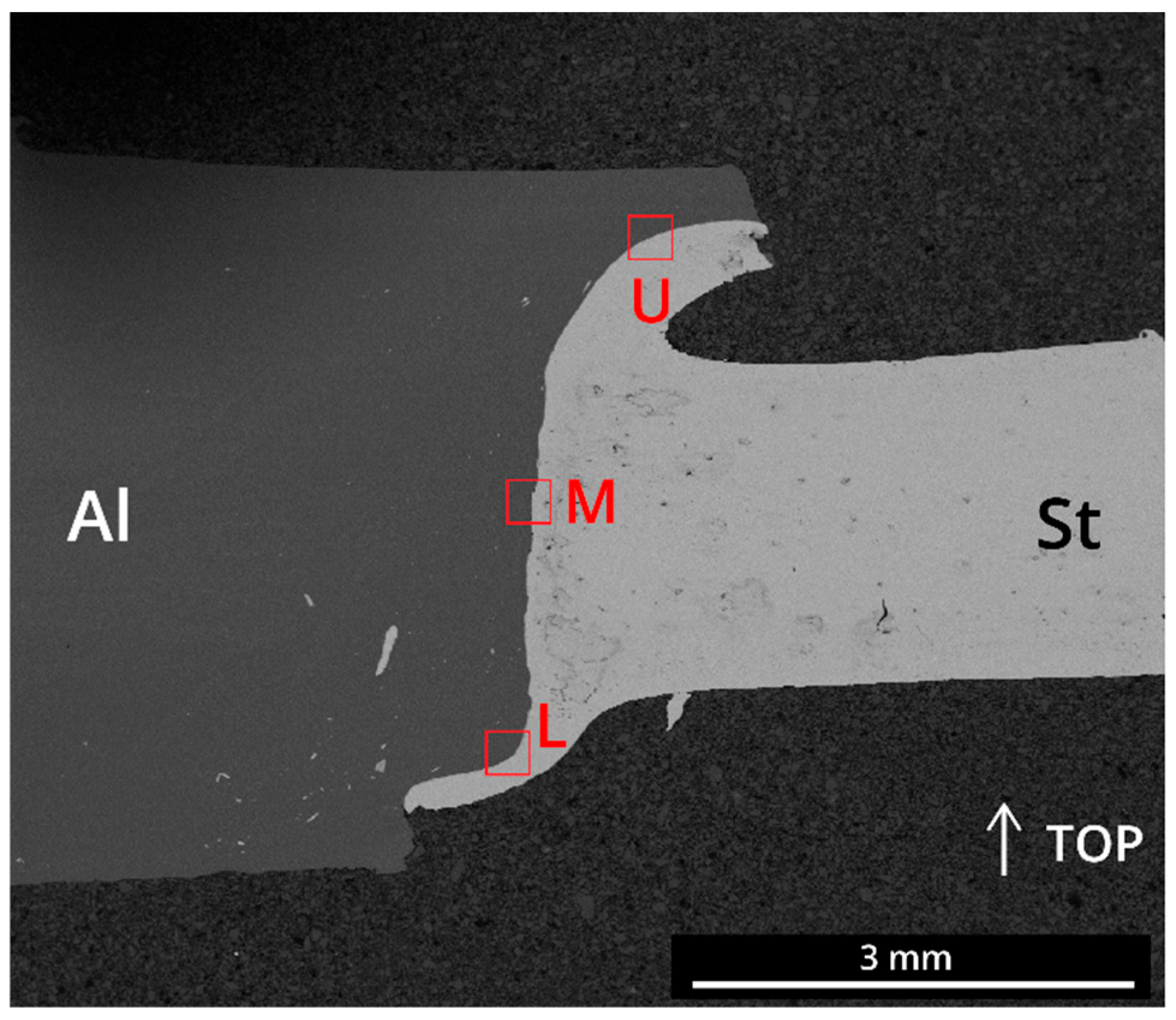

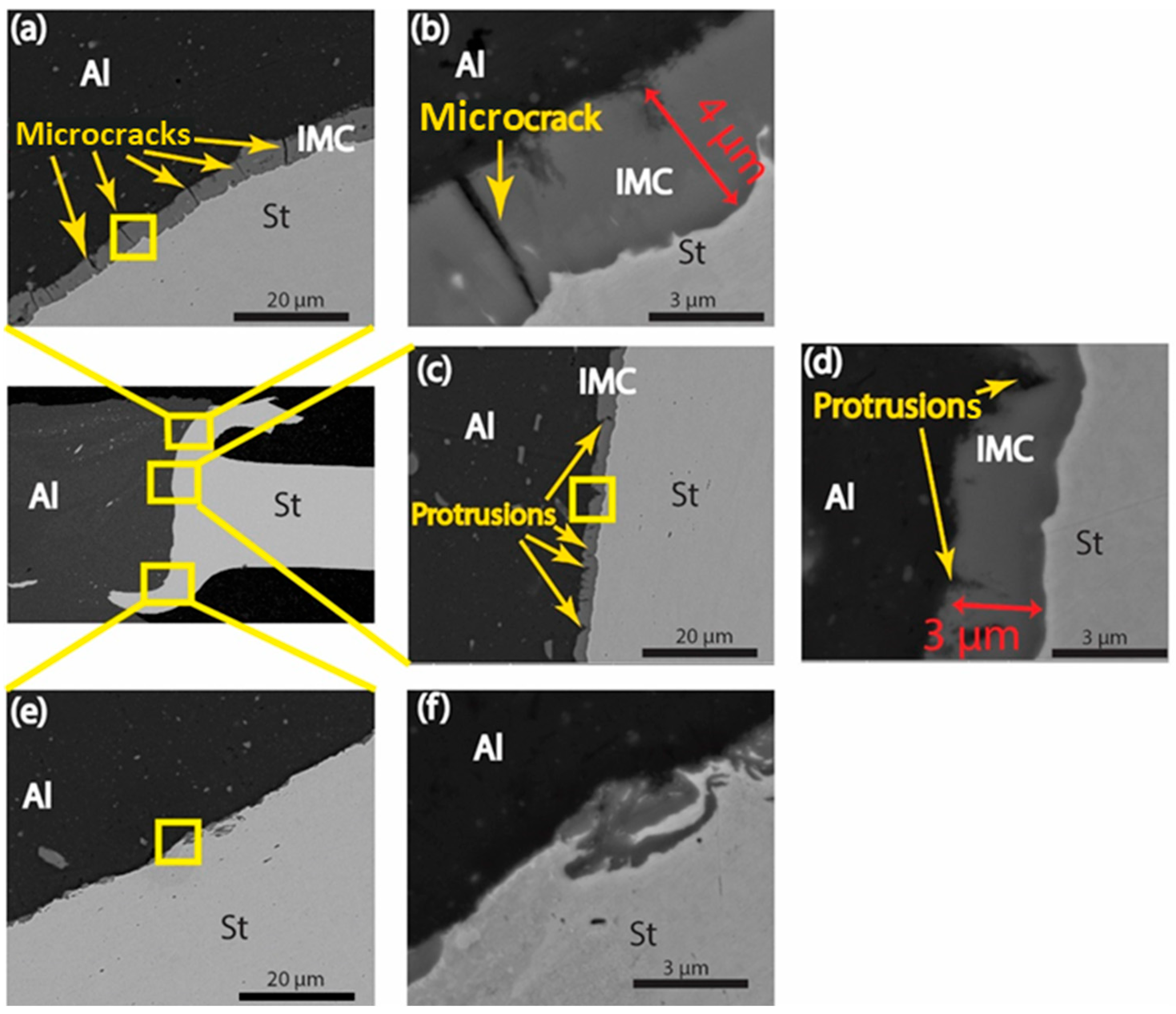

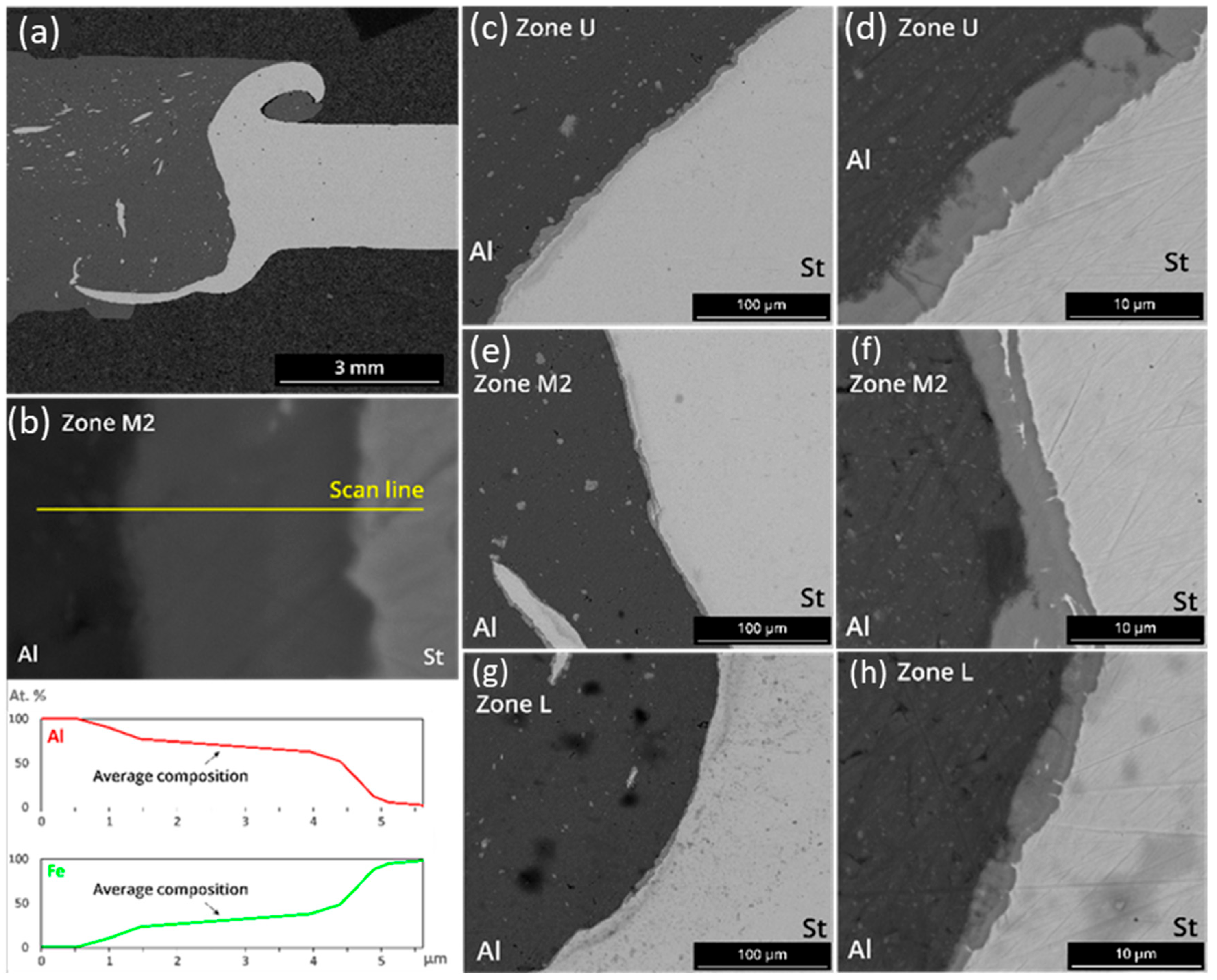

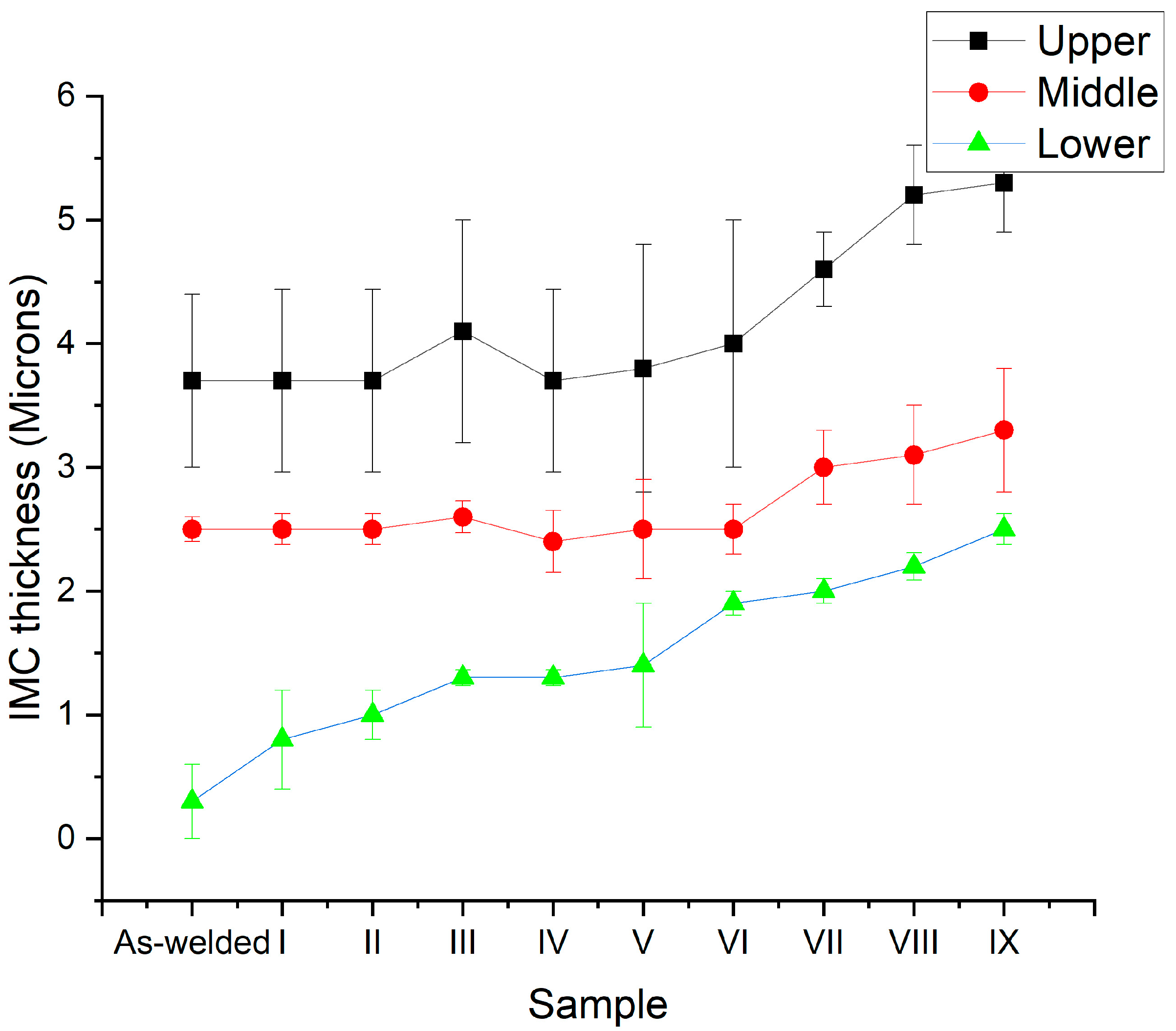

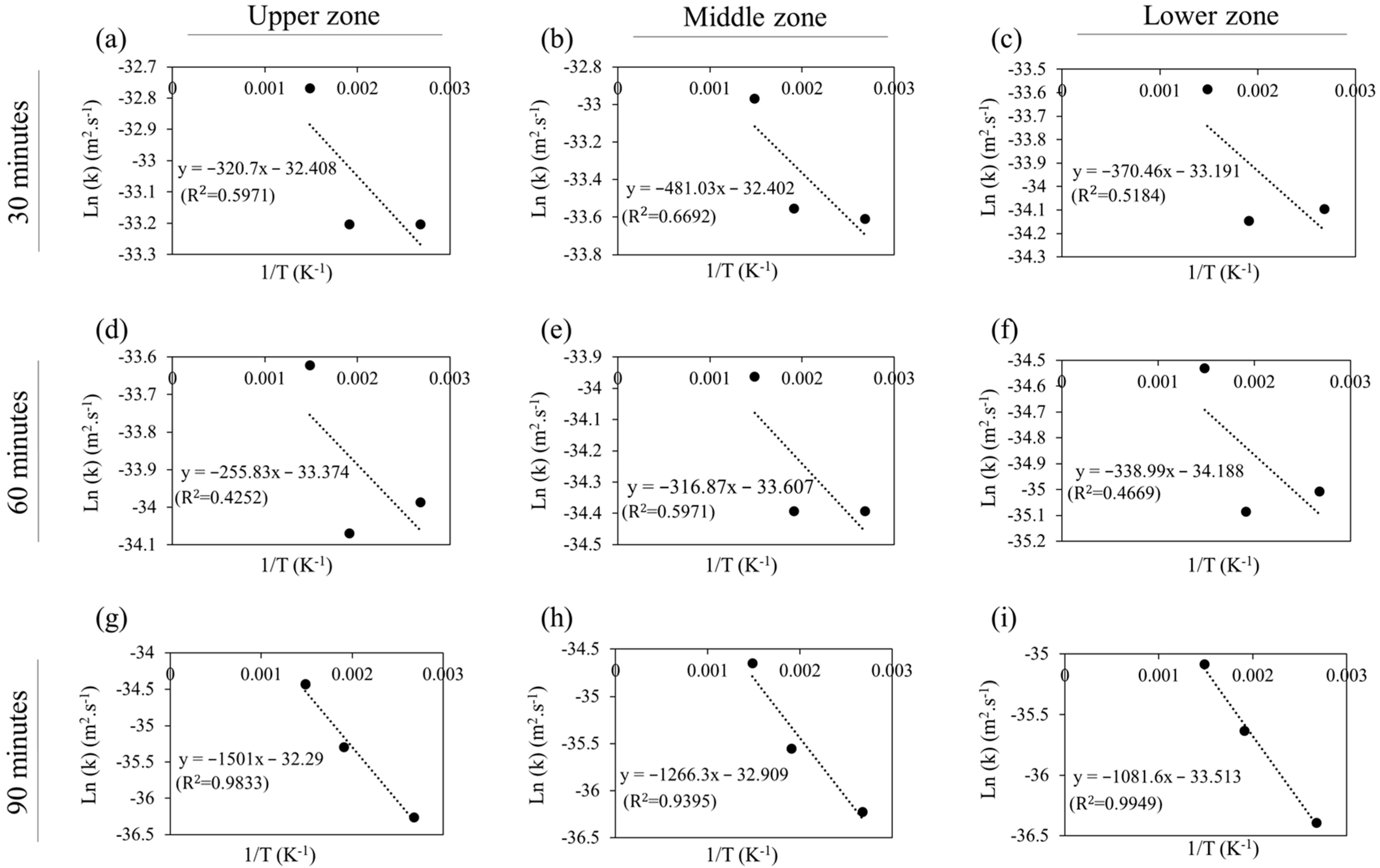

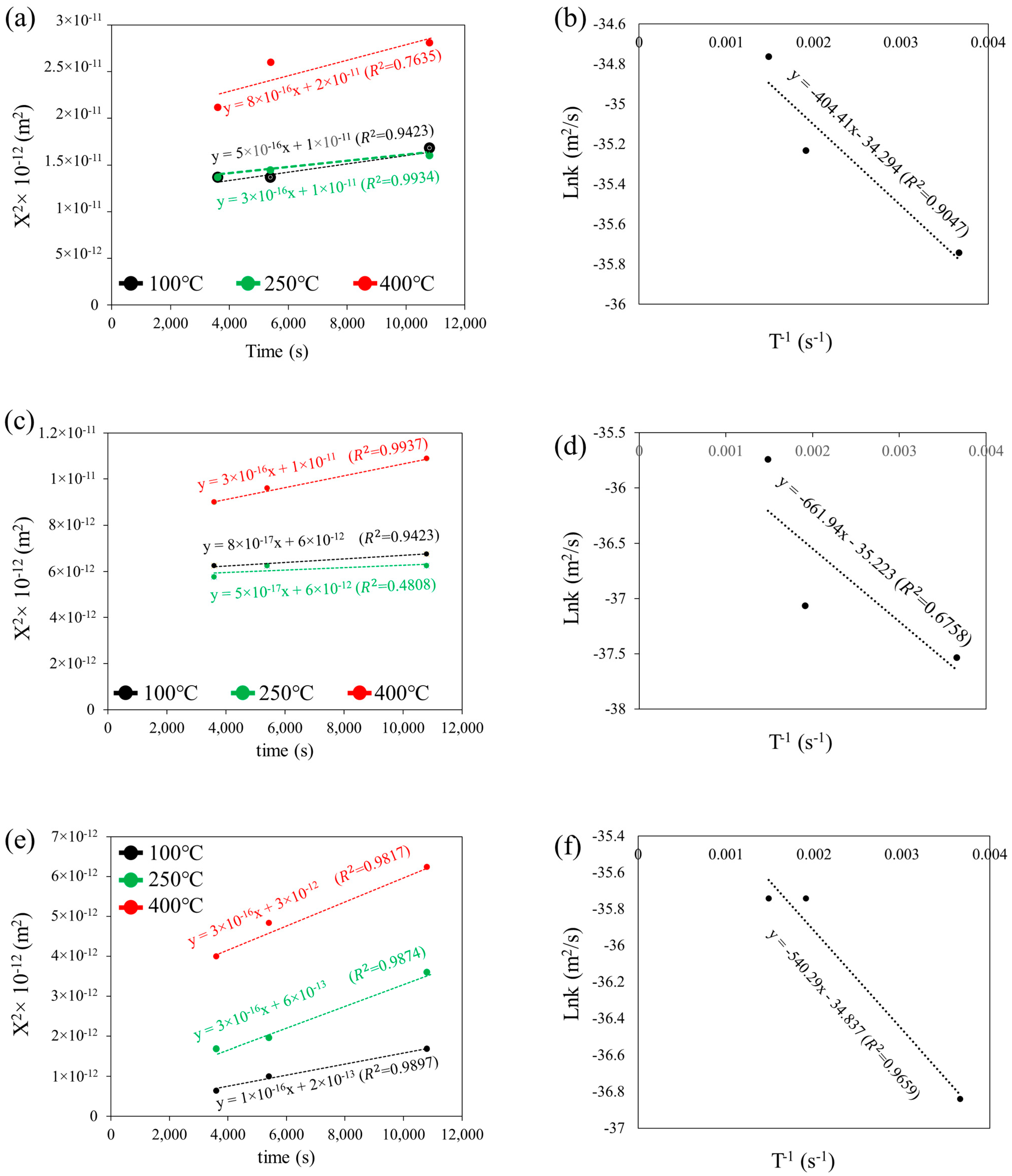

3.1. Interface Microstructure and IMC Layer Thickness

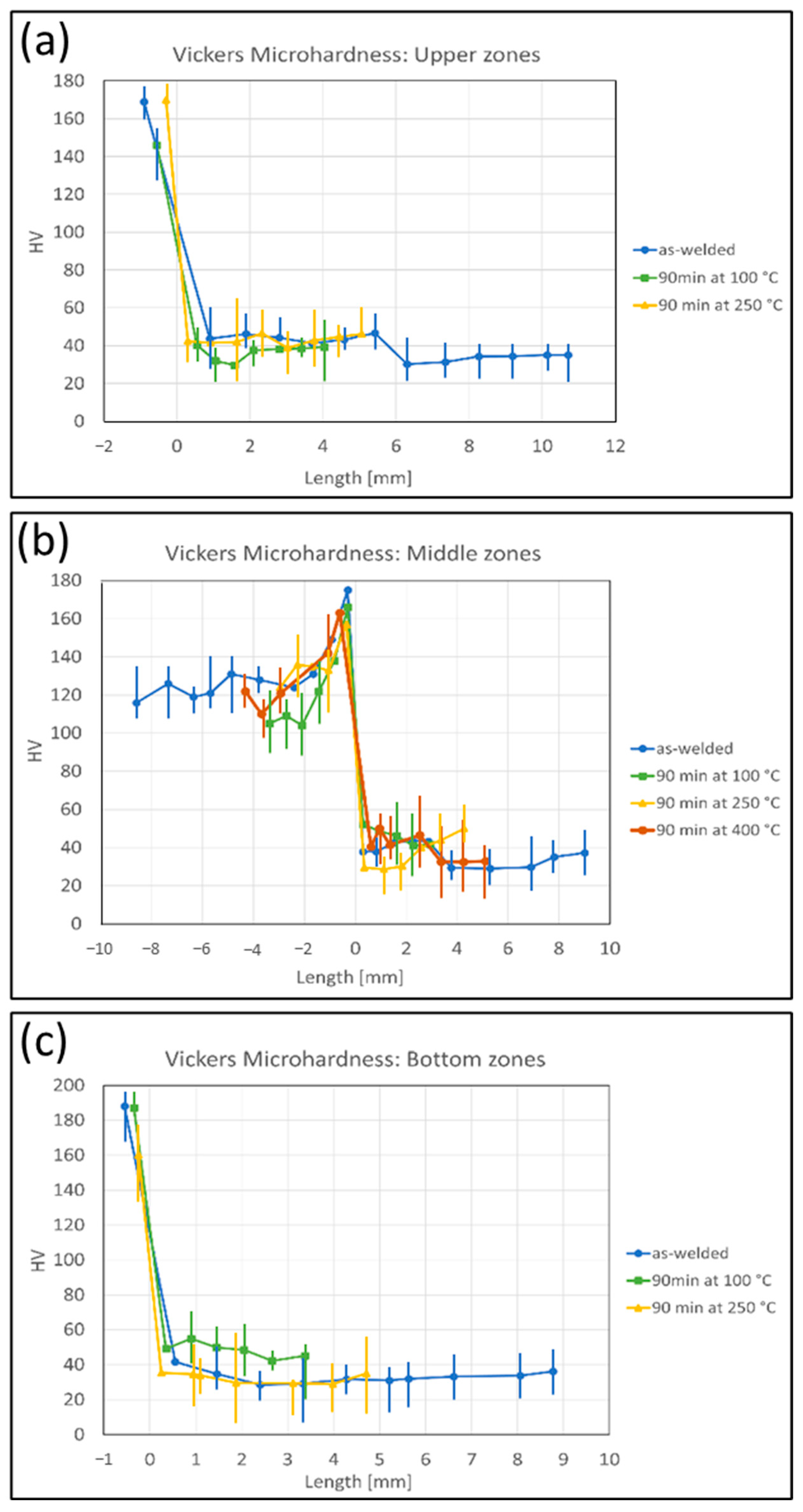

3.2. Microhardness Results

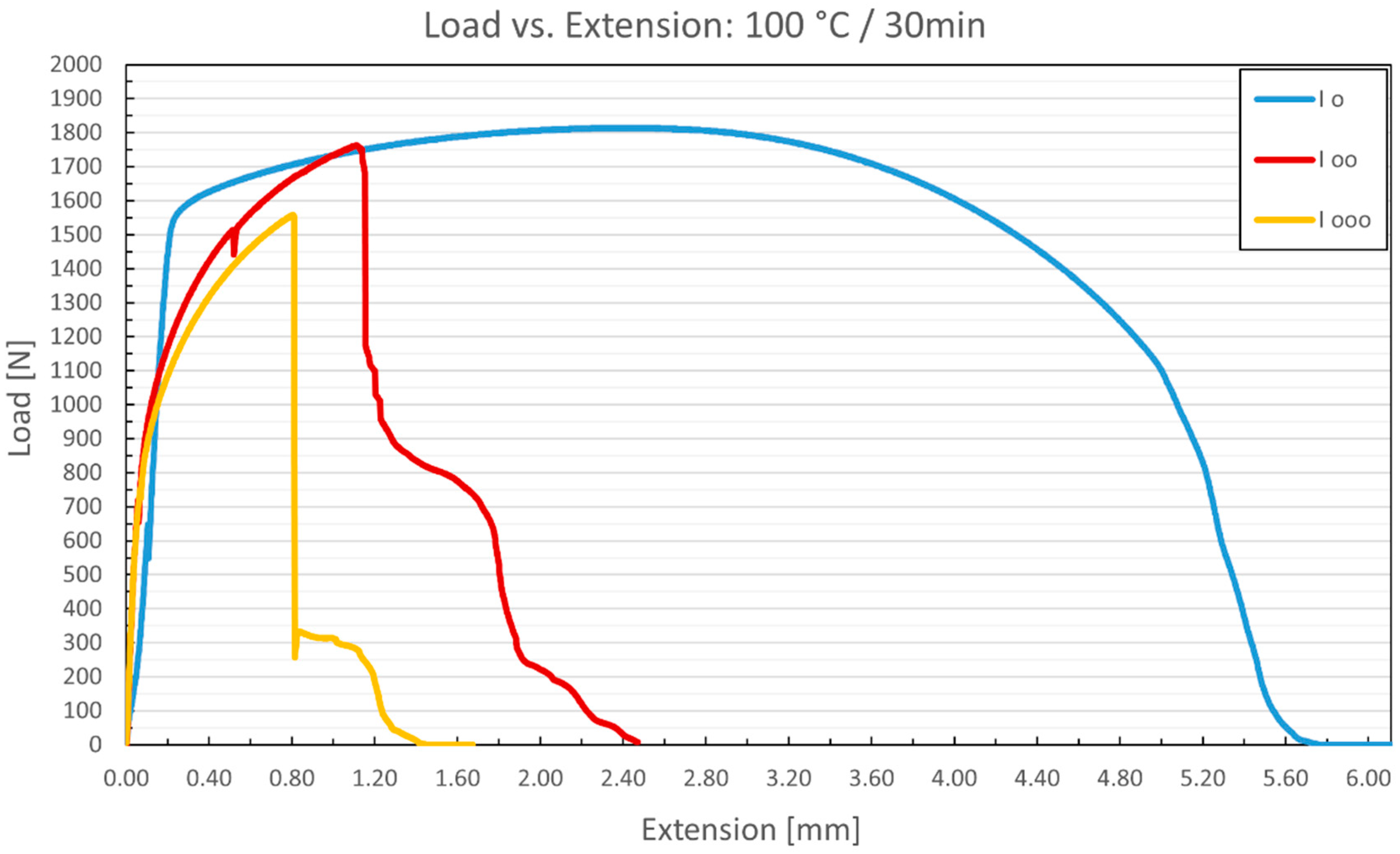

3.3. Tensile Tests

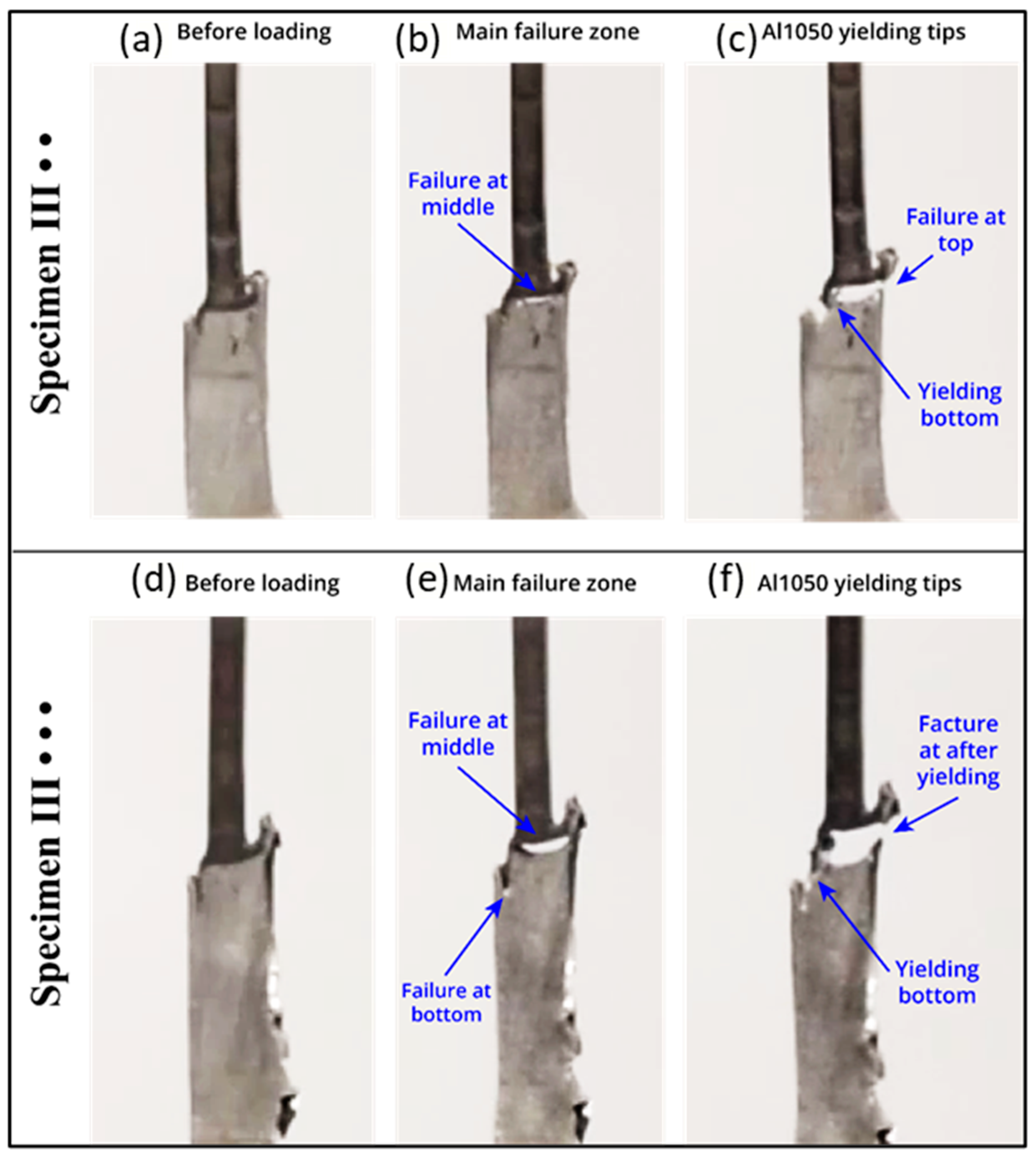

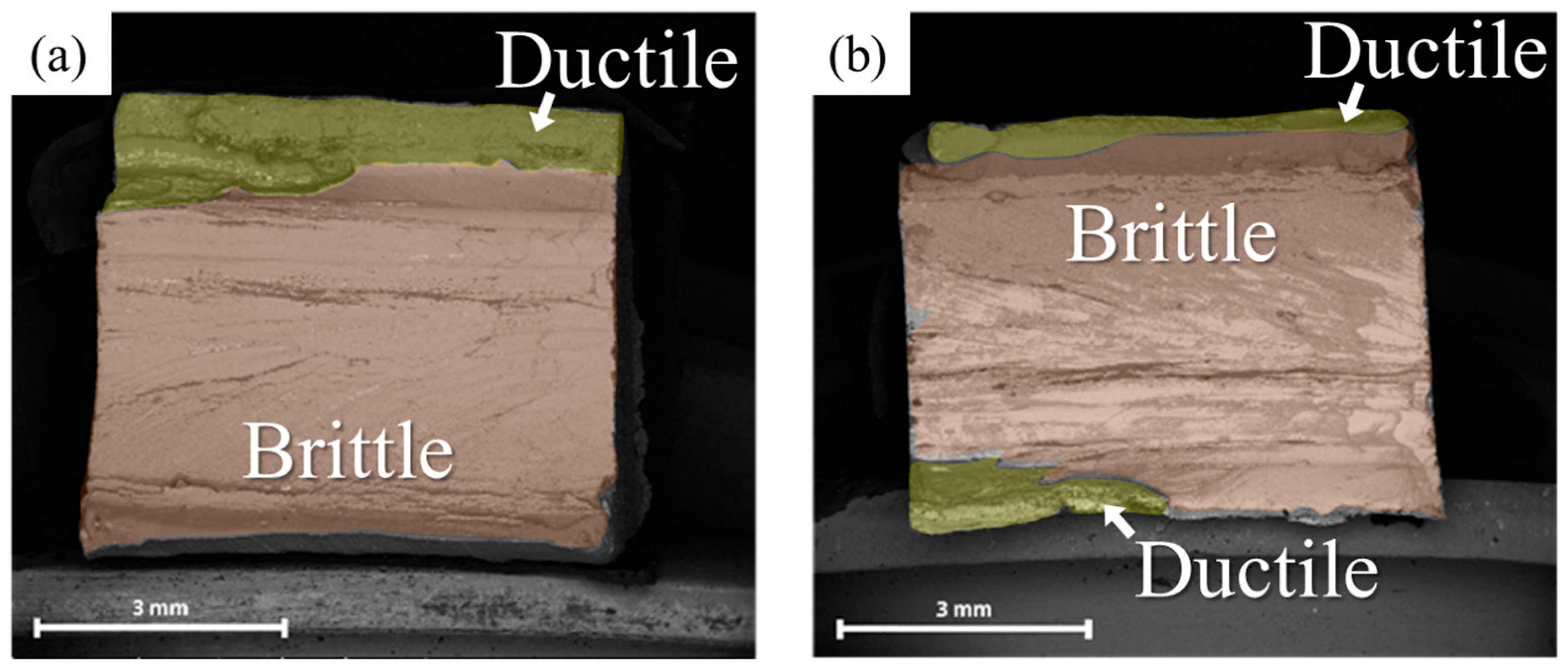

3.4. Fracture Behavior

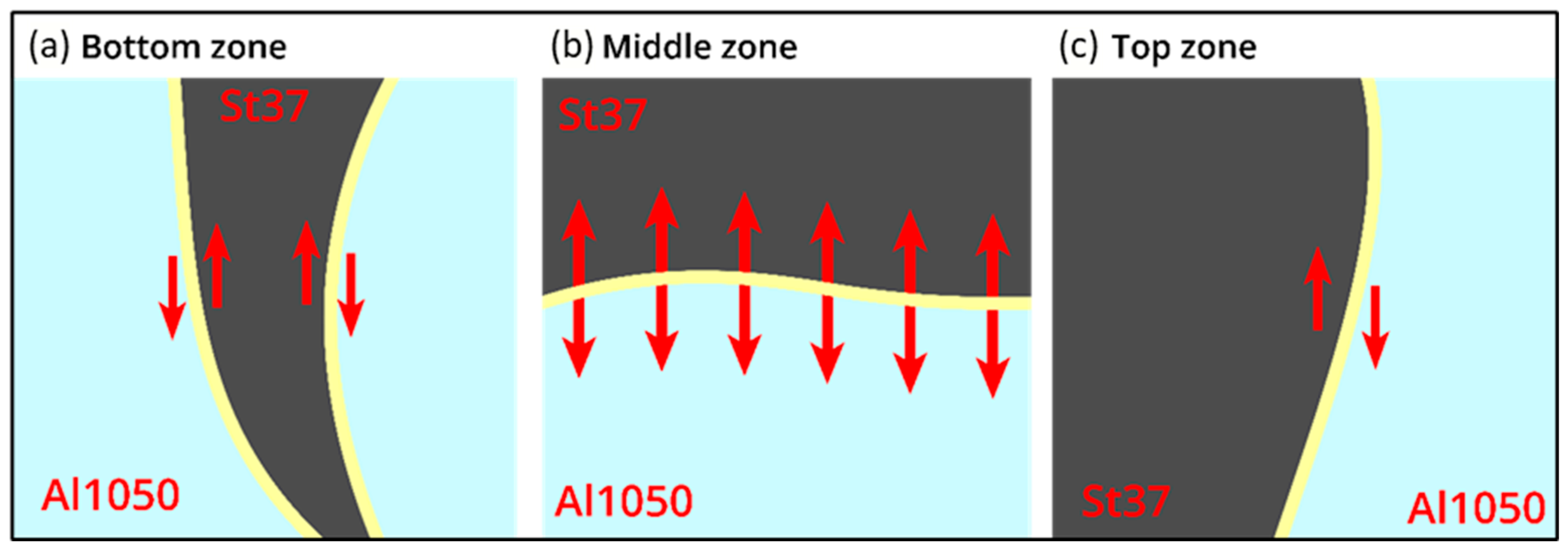

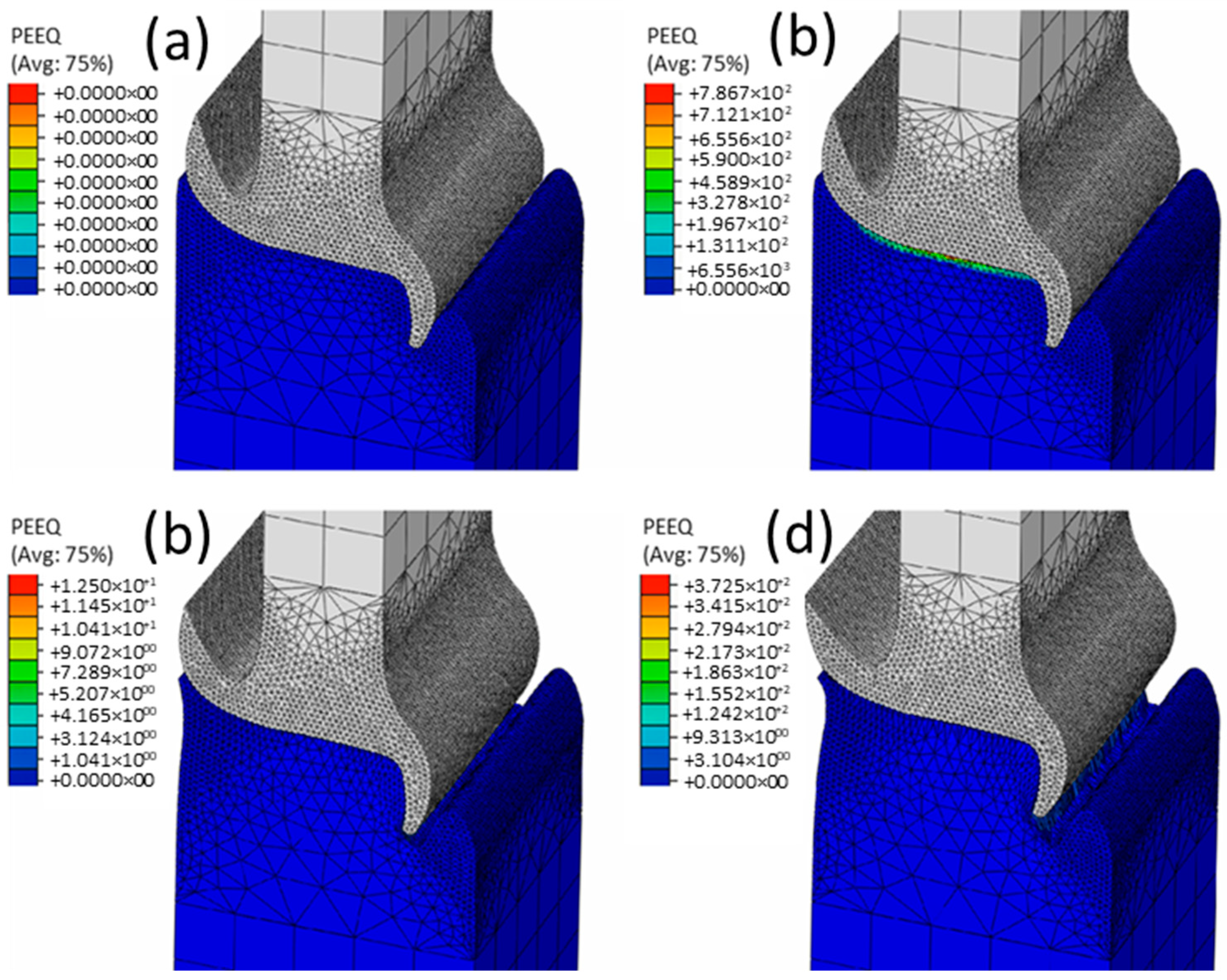

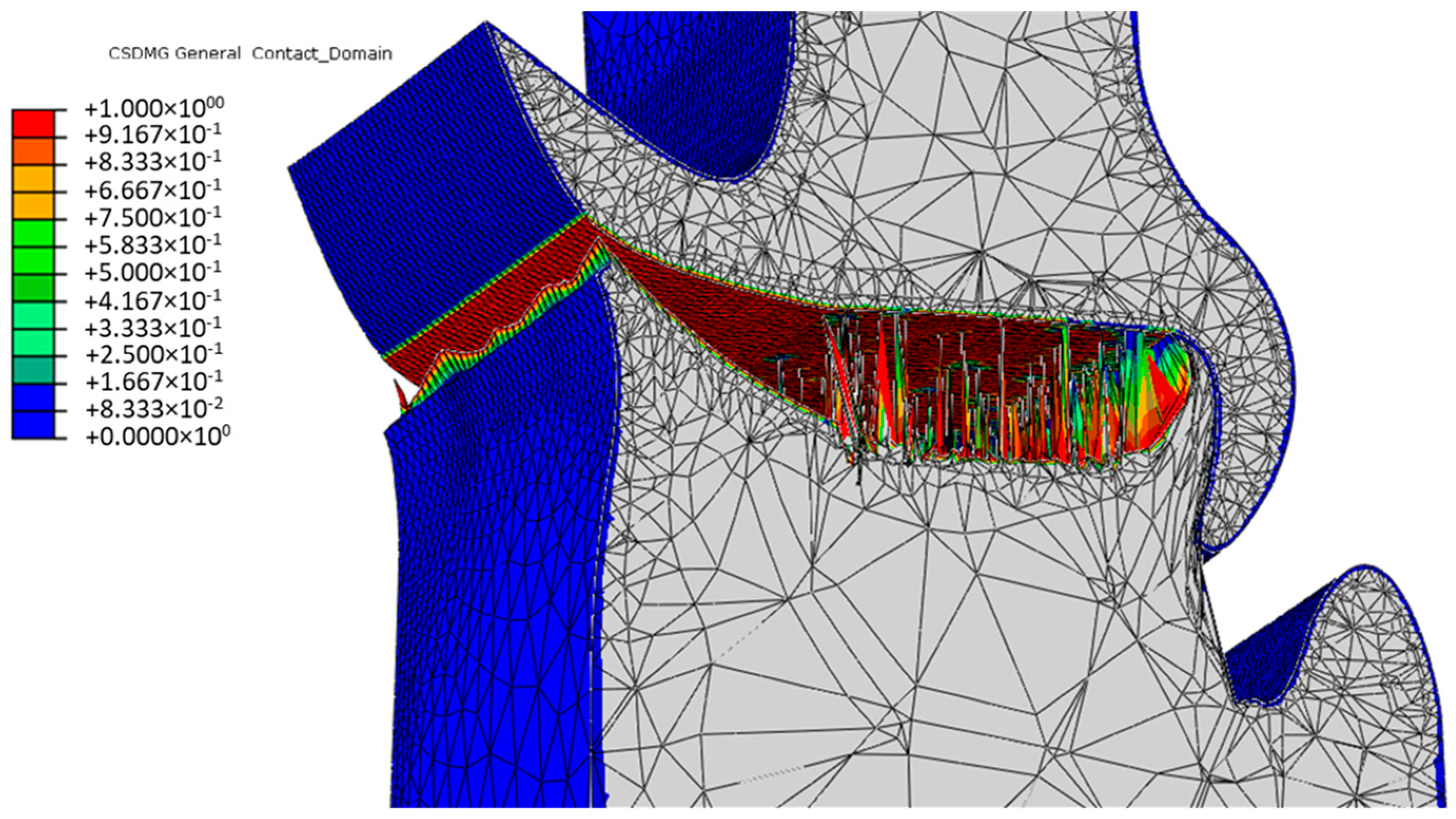

3.5. Numerical Model of Fracture

4. Conclusions

- Successful fabrication of high-quality FSW joints between St37 steel (2 mm thickness) and Al1050 aluminum (5 mm thickness) was achieved, featuring a distinctive S-shaped interface geometry. This configuration promotes mechanical interlocking and facilitates an effective distribution of normal and shear stresses, contributing to joint integrity.

- The IMC layer thickness varied between 0.1 μm and 4.0 μm, influenced by the unique joint geometry and material flow during welding. The dominant IMC phase at the interface was identified as Fe2Al5, with aluminum content ranging between 68% and 72% atomic percent.

- Post-weld heat treatment at elevated temperatures showed an increase in IMC thickness only at 400 °C, while negligible growth occurred at 100 °C and 250 °C, indicating temperature-dependent IMC kinetics.

- Tensile testing revealed a reduction in ultimate failure loads following post-weld heat treatment, even at 100 °C, where IMC growth was minimal; this reduction is explained by the smoothing of IMC protrusions that otherwise act as crack arrestors, thus compromising joint toughness.

- The numerical fracture model effectively captured the experimental failure behavior, highlighting damage initiation in the middle zone of the joint and progression toward the top zone. The bottom zone exhibited considerable plastic deformation, consistent with observed experimental fracture patterns.

- The S-shaped interface geometry mitigates the detrimental impact of the IMC layer on joint strength by altering the stress distribution, as the interface is not aligned perpendicular to the applied loading.

- Variation in activation energies for IMC growth across different interface regions reflects non-uniform thermo-mechanical histories during FSW, underscoring the complex nature of the process.

- The influence of an S-shaped joint interface in different aluminum and steel grades;

- The effect of welding parameters on the formation of the curved (S-shaped) interface;

- The corrosion behavior of the curved interface in dissimilar Al/St FSW joints;

- The creep and fatigue properties of S-shaped dissimilar joints.

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Nonnenmann, T.; Beygi, R.; Carbas, R.; da Silva, L.; Öchsner, A. Feasibility study on hybrid weld-bonding between dissimilar material for automotive industry. Int. J. Adhes. Adhes. 2023, 121, 103316. [Google Scholar] [CrossRef]

- Abhilash; Nunthavarawong, P.; Ratanathavorn, W.; Kowitwarangkul, P. Advances in friction stir welding of dissimilar aluminum and steel: A review on challenges, assisted techniques, and future prospects. Mater. Manuf. Process. 2024, 39, 1639–1672. [Google Scholar] [CrossRef]

- Gohoungodji, P.; N’Dri, A.B.; Latulippe, J.M.; Matos, A.L.B. What is stopping the automotive industry from going green? A systematic review of barriers to green innovation in the automotive industry. J. Clean. Prod. 2020, 277, 123524. [Google Scholar]

- Winkler, M.; Rößler, C.; Harriehausen, N.; Jüttner, S.; Schmicker, D.; Trommer, F. An energetic approach to the statistical analysis and optimization of friction welding processes applied to an aluminum-steel-joint. J. Adv. Join. Process. 2024, 10, 100251. [Google Scholar] [CrossRef]

- Zhang, Y.N.; Cao, X.; Larose, S.; Wanjara, P. Review of tools for friction stir welding and processing. Can. Met. Q. 2012, 51, 250–261. [Google Scholar] [CrossRef]

- Mishra, R.S.; Ma, Z. Friction stir welding and processing. Mater. Sci. Eng. R Rep. 2005, 50, 1–78. [Google Scholar] [CrossRef]

- Chaudhari, R.; Parekh, R.; Ingle, A. Reliability of dissimilar metal joints using fusion welding: A Review. In Proceedings of the International Conference on Machine Learning, Electrical and Mechanical Engineering (ICMLEME: 2014)—2014, Dubai, United Arab Emirates, 8 January 2014. [Google Scholar]

- Munoz, A.C.; Rückert, G.; Huneau, B.; Sauvage, X.; Marya, S. Comparison of TIG welded and friction stir welded Al–4.5 Mg–0.26 Sc alloy. J. Mater. Process. Technol. 2008, 197, 337–343. [Google Scholar] [CrossRef]

- Xue, P.; Xiao, B.L.; Ma, Z.Y. Effect of interfacial microstructure evolution on mechanical properties and fracture behavior of friction stir-welded Al-Cu joints. Met. Mater. Trans. A 2015, 46, 3091–3103. [Google Scholar] [CrossRef]

- Hussein, S.A.; Tahir, A.S.M.; Hadzley, A. Characteristics of aluminum-to-steel joint made by friction stir welding: A review. Mater. Today Commun. 2015, 5, 32–49. [Google Scholar] [CrossRef]

- Singh, J.; Arora, K.S.; Shukla, D.K.; Kumar, H. Mechanical and microstructural characterization of cold metal transfer (CMT) spot aluminium-steel weld-brazed joints. Proc. Inst. Mech. Eng. Part L J. Mater. Des. Appl. 2022, 236, 2506–2515. [Google Scholar] [CrossRef]

- Zhang, C.; Li, H.; Liu, Q.; Huang, C.; Zhou, K. Ultrasonic Welding of Aluminum to Steel: A Review. Metals 2022, 13, 29. [Google Scholar] [CrossRef]

- Penner, S.; Armbrüster, M. Formation of intermetallic compounds by reactive metal–support interaction: A frequently encountered phenomenon in catalysis. ChemCatChem 2015, 7, 374–392. [Google Scholar] [CrossRef]

- Wang, X.; Lados, D.A. Optimization of aluminum-to-steel friction stir lap welding for the fabrication of high-integrity structural components. J. Adv. Join. Process. 2022, 5, 100114. [Google Scholar] [CrossRef]

- Beygi, R.; Mehrizi, M.Z.; Akhavan-Safar, A.; Safaei, S.; Loureiro, A.; da Silva, L.F.M. Design of friction stir welding for butt joining of aluminum to steel of dissimilar thickness: Heat treatment and fracture behavior. Int. J. Adv. Manuf. Technol. 2021, 112, 1951–1964. [Google Scholar] [CrossRef]

- Hesari, M.B.; Beygi, R.; Teixeira, T.O.G.; Marques, E.A.S.; Carbas, R.J.C.; da Silva, L.F.M. Enhancing High-Temperature Durability of Aluminum/Steel Joints: The Role of Ni and Cr in Substitutional Diffusion Within Intermetallic Compounds. Metals 2025, 15, 465. [Google Scholar] [CrossRef]

- Insua, P.; Nakkiew, W.; Wisittipanich, W. Post Weld Heat Treatment Optimization of Dissimilar Friction Stir Welded AA2024-T3 and AA7075-T651 Using Machine Learning and Metaheuristics. Materials 2023, 16, 2081. [Google Scholar] [CrossRef]

- Naumov, A.; Mertin, C.; Korte, F.; Hirt, G.; Reisgen, U. On the growth of intermetallic phases by heat treatment of friction stir welded aluminum steel joints. Prod. Eng. 2017, 11, 175–182. [Google Scholar] [CrossRef]

- Movahedi, M.; Kokabi, A.; Reihani, S.S.; Cheng, W.; Wang, C. Effect of annealing treatment on joint strength of aluminum/steel friction stir lap weld. Mater. Des. 2013, 44, 487–492. [Google Scholar] [CrossRef]

- Dong, H.; Yang, J.; Li, Y.; Xia, Y.; Hao, X.; Li, P.; Sun, D.; Hu, J.; Zhou, W.; Lei, M. Evolution of interface and tensile properties in 5052 aluminum alloy/304 stainless steel rotary friction welded joint after post-weld heat treatment. J. Manuf. Process. 2020, 51, 142–150. [Google Scholar] [CrossRef]

- Cao, F.; Zhang, P.; Zou, J.; Wang, T. The formation and growth of intermetallic compounds during interdiffusion of Al/Cu bimetals. Mater. Res. Express 2022, 9, 056503. [Google Scholar] [CrossRef]

- Beygi, R.; Carbas, R.; Barbosa, A.; Marques, E.; da Silva, L. A comprehensive analysis of a pseudo-brittle fracture at the interface of intermetallic of η and steel in aluminum/steel joints made by FSW: Microstructure and fracture behavior. Mater. Sci. Eng. A 2021, 824, 141812. [Google Scholar] [CrossRef]

- Beygi, R.; Carbas, R.; Marques, E.; Barbosa, A.; Kasaei, M.; da Silva, L. Mechanism of toughness enhancement of brittle fracture by intermittent η-intermetallic in Al/Cu joint made by FSW. Mater. Sci. Eng. A 2024, 890, 145907. [Google Scholar] [CrossRef]

- Hwang, W.-S.; Wu, T.-I.; Sung, W.-C. Effects of heat treatment on mechanical property and microstructure of aluminum/stainless steel bimetal plate. J. Eng. Mater. Technol. 2012, 134, 014501. [Google Scholar] [CrossRef]

- Wang, C.; Deng, J.; Dong, C.; Zhao, Y. Numerical Simulation and Experimental Studies on Stationary Shoulder Friction Stir Welding of Aluminum Alloy T-Joint. Front. Mater. 2022, 9, 898929. [Google Scholar] [CrossRef]

- Koopas, R.N.; Rezaei, S.; Rauter, N.; Ostwald, R.; Lammering, R. Comparative Analysis of Phase-Field and Intrinsic Cohesive Zone Models for Fracture Simulations in Multiphase Materials with Interfaces: Investigation of the Influence of the Microstructure on the Fracture Properties. Appl. Sci. 2025, 15, 160. [Google Scholar] [CrossRef]

- Teixeira, T.O.G.; Beygi, R.; Carbas, R.J.C.; Marques, E.A.S.; Hesari, M.B.; Kasaei, M.M.; da Silva, L.F.M. Aluminium/Steel Joints with Dissimilar Thicknesses: Enhancement of UTS and Ductility Through Making an S-Shaped Interface and a Mixed-Mode Fracture. J. Manuf. Mater. Process. 2025, 9, 120. [Google Scholar] [CrossRef]

- Berković, M.; Stevan, M.; Sedmak, A. Analysis of Welded Joints by Applying the Finite Element Method. ResearchGate.net. Available online: https://www.researchgate.net/profile/A-Sedmak/publication/277153060_Analysis_of_welded_joints_by_applying_the_finite_element_method/links/563ef6be08ae34e98c4dbd9e/Analysis-of-welded-joints-by-applying-the-finite-element-method.pdf (accessed on 4 November 2025).

- ASTM E8/E8M-13a; Standard Test Methods for Tension Testing of Metallic Materials. ASTM International: West Conshohocken, PA, USA, 2013.

- ASTM E384-17; Standard Test Method for Microindentation Hardness of Materials. ASTM International: West Conshohocken, PA, USA, 2017.

- Mitra, R. Structural Intermetallics and Intermetallic Matrix Composites; CRC Press: Boca Raton, FL, USA, 2015. [Google Scholar]

- Wang, T.; Sidhar, H.; Mishra, R.S.; Hovanski, Y.; Upadhyay, P.; Carlson, B. Evaluation of intermetallic compound layer at aluminum/steel interface joined by friction stir scribe technology. Mater. Des. 2019, 174, 107795. [Google Scholar] [CrossRef]

- Jindal, V.; Srivastava, V.; Das, A.; Ghosh, R. Reactive diffusion in the roll bonded iron–aluminum system. Mater. Lett. 2006, 60, 1758–1761. [Google Scholar] [CrossRef]

| St37 Carbon Steel | 1050 Aluminum | |

|---|---|---|

| Tensile strength—370 MPa | Tensile strength—100–135 MPa | |

| Yielding strength—300 MPa | Yielding strength—85 MPa | |

| Vickers hardness—120 HV | Vickers hardness—41 HV | |

| Chemical composition | Chemical composition | |

| Fe: 99.43–99.75% C: 0.08% Mn: 0.25–0.4% S: 0.05% P: 0.04% | Al: 99.5 % Si: 0.25 % Fe: 0.40 % Cu: 0.05 % Mn: 0.05 % | Mg: 0.05 % Zn: 0.07 % Ti: 0.05 % Others: 0.03 % |

| Material | Young’s Modulus [GPa] | Poisson’s Ratio | Mass Density [gr/cm3] |

|---|---|---|---|

| Al1050 | 71 | 0.33 | 2.71 |

| St37 | 207 | 0.28 | 7.80 |

| Zone | Equation | Q (J/k.mol) | K0 (m2/s) | Arrhenius Equation |

|---|---|---|---|---|

| Upper | Y = −404.41x − 34.294 | 3362.26 | 1.27 × 10−15 | k = |

| Middle | Y = −661.94x − 35.223 | 5503.36 | 5.04 × 10−16 | k = |

| Lower | Y = −540.29x − 34.837 | 4491.97 | 7.42 × 10−16 | k = |

| Percentage Reduction in UTS | Reference |

|---|---|

| 41% | [16] |

| 23% | Present study |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Teixeira, T.O.G.; Beygi, R.; Hesari, M.B.; Carbas, R.J.C.; Marques, E.A.S.; Kasaei, M.M.; da Silva, L.F.M. Heat Treatment and Fracture Behavior of Aluminum/Steel FSW Joints: A Comprehensive Analysis of a Curved Interface. J. Manuf. Mater. Process. 2025, 9, 381. https://doi.org/10.3390/jmmp9110381

Teixeira TOG, Beygi R, Hesari MB, Carbas RJC, Marques EAS, Kasaei MM, da Silva LFM. Heat Treatment and Fracture Behavior of Aluminum/Steel FSW Joints: A Comprehensive Analysis of a Curved Interface. Journal of Manufacturing and Materials Processing. 2025; 9(11):381. https://doi.org/10.3390/jmmp9110381

Chicago/Turabian StyleTeixeira, Tiago Oliveira Gonçalves, Reza Beygi, Masih Bolhasani Hesari, Ricardo João Camilo Carbas, Eduardo Andre Sousa Marques, Mohammad Mehdi Kasaei, and Lucas Filipe Martins da Silva. 2025. "Heat Treatment and Fracture Behavior of Aluminum/Steel FSW Joints: A Comprehensive Analysis of a Curved Interface" Journal of Manufacturing and Materials Processing 9, no. 11: 381. https://doi.org/10.3390/jmmp9110381

APA StyleTeixeira, T. O. G., Beygi, R., Hesari, M. B., Carbas, R. J. C., Marques, E. A. S., Kasaei, M. M., & da Silva, L. F. M. (2025). Heat Treatment and Fracture Behavior of Aluminum/Steel FSW Joints: A Comprehensive Analysis of a Curved Interface. Journal of Manufacturing and Materials Processing, 9(11), 381. https://doi.org/10.3390/jmmp9110381