A Universal Method for the Evaluation of In Situ Process Monitoring Systems in the Laser Powder Bed Fusion Process

Abstract

1. Introduction

- First standardized cross-system evaluation method: Unlike previous studies that focus on individual IPMS performance, this work introduces the first systematic methodology for comparing different IPMS technologies.

- Universal test specimen design: ESC represents a paradigm shift from specific test methods for each IPMS to a universal approach that can be applied across different AM systems with different IMPS installed and materials while protecting proprietary process parameters.

- Vendor-independent assessment framework: The methodology enables objective performance comparison without requiring disclosure of proprietary algorithms or system specifications, addressing a major barrier to IPMS adoption in industry.

- Foundation for standardization: This work provides the technical foundation for developing international standards for IPMS evaluation, potentially accelerating widespread adoption of in situ monitoring technologies.

2. Methodology and Comparative Analysis of In Situ Process Monitoring Systems (IPMSs)

- Binding defect pores are amorphous cavities filled with unmelted powder and process gas and range in size from ten to several hundred micrometers. These pores occur when the process energy is insufficient to completely melt the material. This can occur stochastically when splashes with a larger diameter than the powder particles fall onto the powder bed, or systematically when the process parameters are set incorrectly [27].

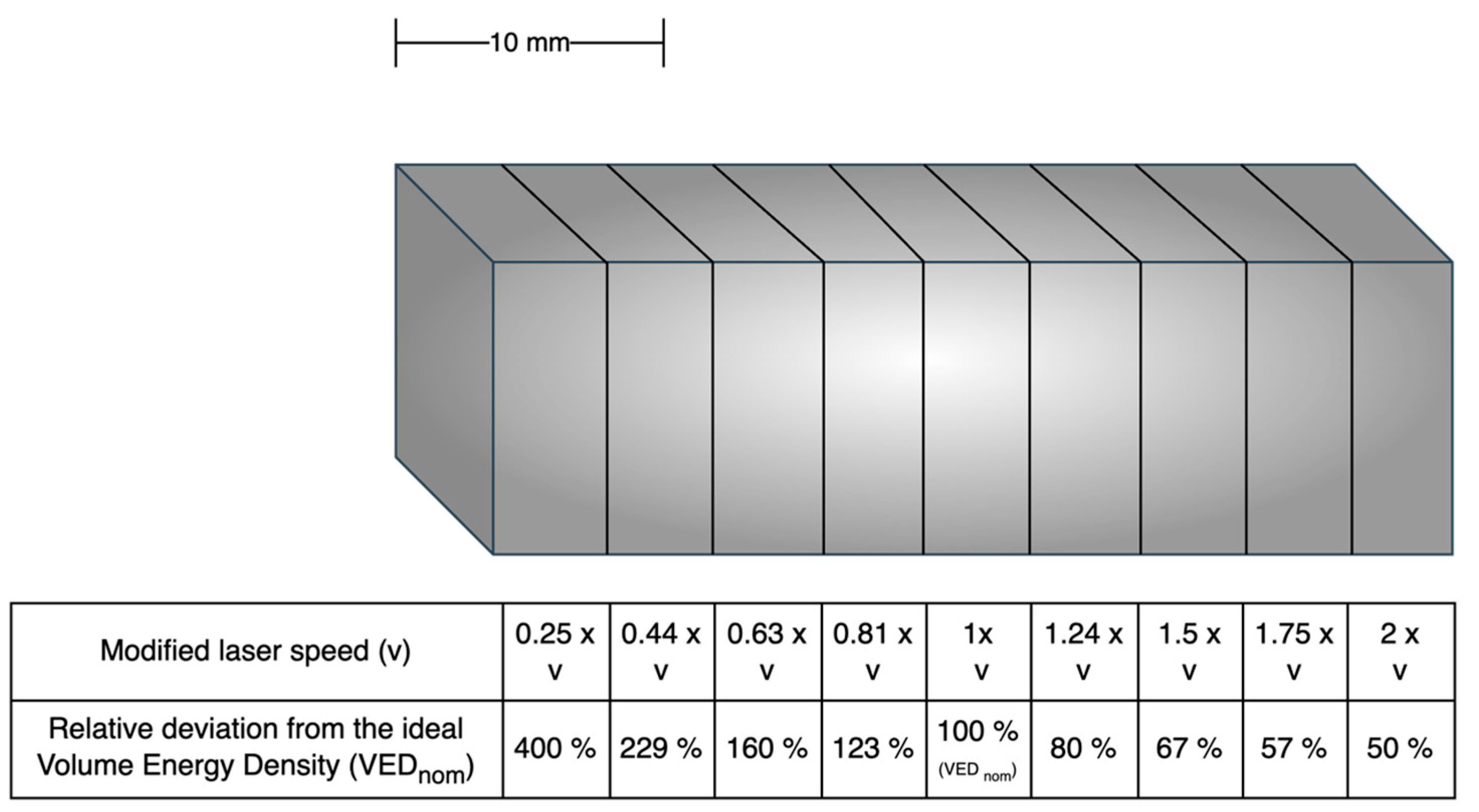

2.1. Design of the Test Specimen “Energy Step Cube” (ESC) [37,38]

- The speeds range from 0.25 × v to 2 × v.

- This results in relative VED deviations of 400% (far left) to 50% (far right) compared to the nominal value.

- VED: Volume energy density [J/mm3];

- PL: Laser power [W];

- h: Track spacing [mm];

- d: Layer thickness [mm];

- v: Scanning speed [mm/s].

2.2. Evaluation Methodology

2.3. Advantages of the Methodology

- Universal applicability: The approach is applicable to every emission-based sensor signature that aims to detect deviations in the printing process. This enables cross-sensor comparisons, which is particularly relevant as there is still no consensus on universal test methods for assessing the sensitivity of individual IPMSs [2,3,15].

3. Experimental Investigation and Comparison of IPMSs

3.1. Experiment

- The integrated IPMS from the system manufacturer Trumpf;

- The equipment-independent PrintRite3D system from Divergent (formerly SigmaLabs or Sigma Additive Solutions).

3.2. Results Analysis

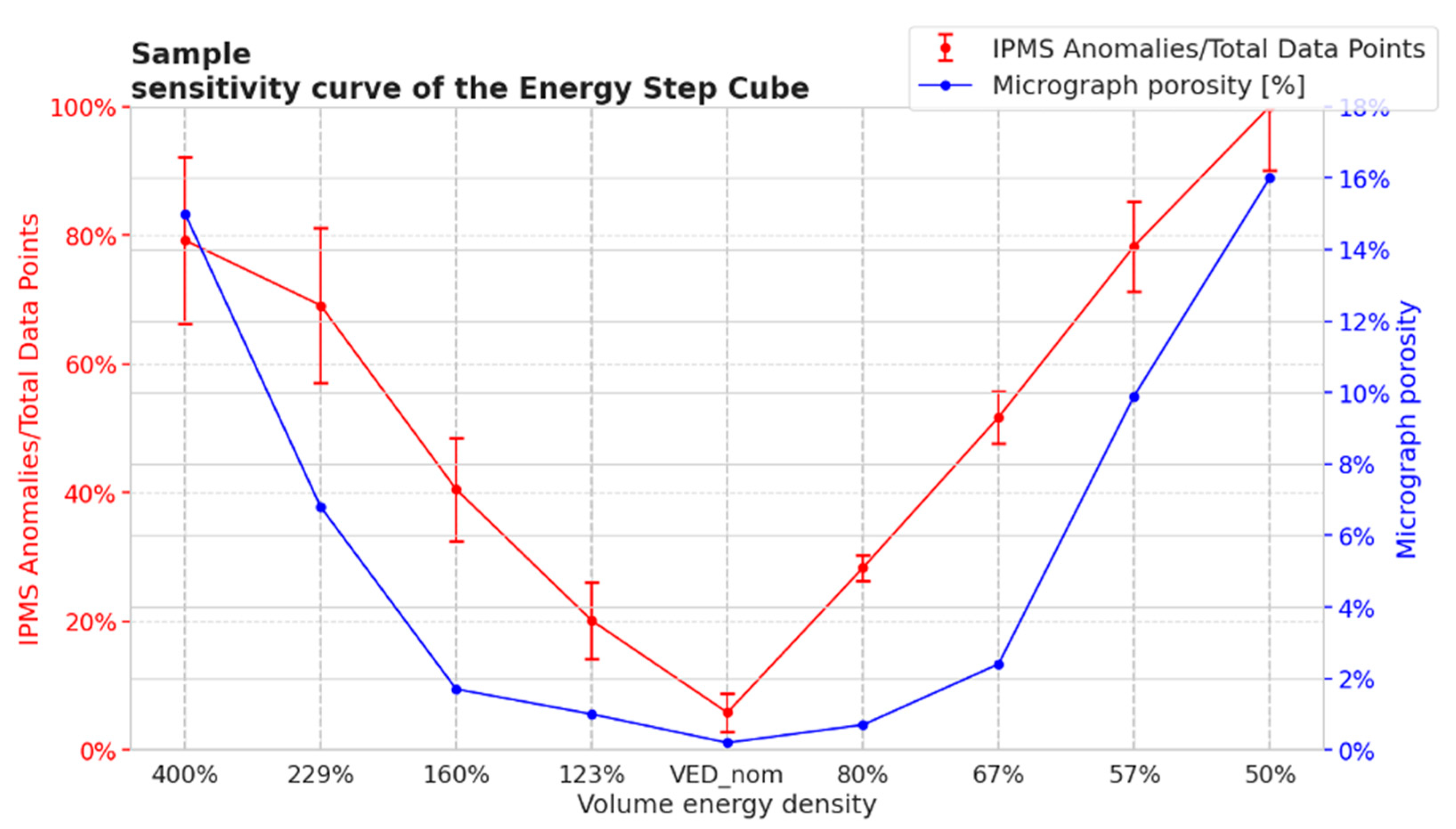

- Lowest porosity at 123% VEDnom, VEDnom and 80% VEDnom, corresponding to the lowest IPMS anomalies (37%, 21% and 28%).

- Porosity increases above 2% at >160% VEDnom and 67% VEDnom.

- Increased anomalies at VED > 123% VEDnom or <80% VEDnom.

- At VEDnom, the anomaly level was 20%, indicating a configuration for detecting slight changes in a wide process window.

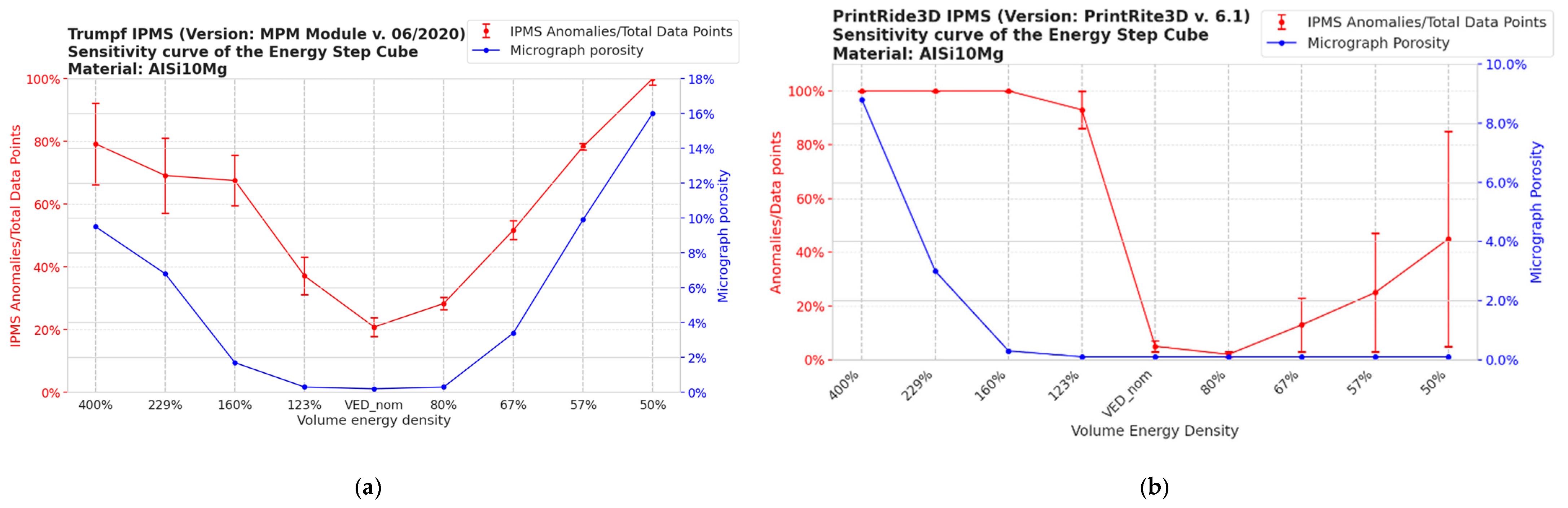

- Minimal porosity (<0.2%) was observed in VEDnom, 80% VEDnom and 67% VEDnom.

- Significant increase in porosity to 2.85% at 229% VEDnom, slight increase to 0.08% at 57% VEDnom with a high dispersion of anomaly values.

- The IPMS showed the lowest percentage of anomalies (2.45%) at 80%VED.

- Strong increase in anomalies to 93.83% at 123% VEDnom and a dispersion of the anomaly values with a reduction in VED.

- Low correlation between porosity and anomalies, as porosity only fluctuates with high energy input: this indicates a narrow process window.

3.3. Comparative Analysis

- Sensitivity:

- PrintRite3D shows higher sensitivity in the nominal range with stronger deflections in the event of VED deviations.

- Trumpf IPMS has a stable process window for high energy input, but is less sensitive to VED changes, as sensitivity in the nominal range is relatively inaccurate (see Figure 3a).

- Process window observation:

- PrintRite3D is optimized for a narrower process window, resulting in faster responses to deviations.

- Trumpf IPMS allows for greater VED variations before significant anomalies are detected. It is important to question whether the sensitivity in the nominal range is sufficiently accurate.

- Correlation with porosity:

- Both systems show a general correlation between detected anomalies and actual porosity.

- PrintRite3D shows a stronger response to small changes in VED (Figure 3b), which could potentially lead to a higher false positive rate.

4. Critical Analysis and Outlook

4.1. Methodological Advances and Limitations

- Developments in various IPMSs can be compared objectively.

- Advances in IPMS technology can be quantified more accurately.

- Manufacturer-independent performance comparisons can be carried out.

- The selection of suitable IPMSs for specific applications is made easier.

- A better basis for regulatory decisions and certifications is created.

4.2. Summary of Contributions

- Methodological Innovation: The ESC methodology represents a paradigm shift from vendor-specific evaluation approaches to a universal framework that enables direct comparison of IPMS performance while protecting proprietary process parameters.

- Empirical Validation: Comparative analysis of two industrially relevant IPMSs (PrintRite3D and Trumpf) revealed significant performance differences in sensitivity and observation windows, demonstrating the methodology’s effectiveness in identifying system-specific characteristics.

- Standardization: The proposed ESC methodology contributes to the ongoing efforts toward standardization of IPMS evaluation by providing a conceptual framework and initial experimental evidence that can inform future inter-laboratory and inter-material studies.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References and Notes

- Seifi, M.; Salem, A.; Beuth, J.; Harrysson, O.; Lewandowski, J.J. Overview of Materials Qualification Needs for Metal Additive Manufacturing. JOM 2016, 68, 747–764. [Google Scholar] [CrossRef]

- Everton, S.K.; Hirsch, M.; Stravroulakis, P.; Leach, R.K.; Clare, A.T. Review of In-Situ Process Monitoring and in-Situ Metrology for Metal Additive Manufacturing. Mater. Des. 2016, 95, 431–445. [Google Scholar] [CrossRef]

- Spears, T.G.; Gold, S.A. In-Process Sensing in Selective Laser Melting (SLM) Additive Manufacturing. Integr. Mater. Manuf. Innov. 2016, 5, 16–40. [Google Scholar] [CrossRef]

- Colosimo, B.M.; Huang, Q.; Dasgupta, T.; Tsung, F. Opportunities and Challenges of Quality Engineering for Additive Manufacturing. J. Qual. Technol. 2018, 50, 233–252. [Google Scholar] [CrossRef]

- Chen, L.; Bi, G.; Yao, X.; Su, J.; Tan, C.; Feng, W.; Benakis, M.; Chew, Y.; Moon, S.K. In-Situ Process Monitoring and Adaptive Quality Enhancement in Laser Additive Manufacturing: A Critical Review. J. Manuf. Syst. 2024, 74, 527–574. [Google Scholar] [CrossRef]

- ASTM F2792-12a; Standard Terminology for Additive Manufacturing Technologies. ASTM: West Conshohocken, PA, USA, 2015. [CrossRef]

- Taherkhani, K.; Ero, O.; Liravi, F.; Toorandaz, S.; Toyserkani, E. On the Application of In-Situ Monitoring Systems and Machine Learning Algorithms for Developing Quality Assurance Platforms in Laser Powder Bed Fusion: A Review. J. Manuf. Process. 2023, 99, 848–897. [Google Scholar] [CrossRef]

- Grasso, M.; Colosimo, B.M. Process Defects and in Situ Monitoring Methods in Metal Powder Bed Fusion: A Review. Meas. Sci. Technol. 2017, 28, 044005. [Google Scholar] [CrossRef]

- Seifi, M.; Gorelik, M.; Waller, J.; Hrabe, N.; Shamsaei, N.; Daniewicz, S.; Lewandowski, J.J. Progress Towards Metal Additive Manufacturing Standardization to Support Qualification and Certification. JOM 2017, 69, 439–455. [Google Scholar] [CrossRef]

- Jamshid, M.; Huff, R.; Kowen, J.; Fidan, I.; Pei, E.; Enrique, P.; Ng, J.L.; Diegel, O. Wohlers Report 2025; Wohlers Associates: Washington, DC, USA, 2025. [Google Scholar]

- Ni, C.; Zhu, J.; Zhang, B.; An, K.; Wang, Y.; Liu, D.; Lu, W.; Zhu, L.; Liu, C. Recent Advance in Laser Powder Bed Fusion of Ti–6Al–4V Alloys: Microstructure, Mechanical Properties and Machinability. Virtual Phys. Prototyp. 2025, 20, e2446952. [Google Scholar] [CrossRef]

- Yap, C.Y.; Chua, C.K.; Dong, Z.L.; Liu, Z.H.; Zhang, D.Q.; Loh, L.E.; Sing, S.L. Review of Selective Laser Melting: Materials and Applications. Appl. Phys. Rev. 2015, 2, 041101. [Google Scholar] [CrossRef]

- Gong, G.; Ye, J.; Chi, Y.; Zhao, Z.; Wang, Z.; Xia, G.; Du, X.; Tian, H.; Yu, H.; Chen, C. Research Status of Laser Additive Manufacturing for Metal: A Review. J. Mater. Res. Technol. 2021, 15, 855–884. [Google Scholar] [CrossRef]

- Schmidt, M.; Merklein, M.; Bourell, D.; Dimitrov, D.; Hausotte, T.; Wegener, K.; Overmeyer, L.; Vollertsen, F.; Levy, G.N. Laser Based Additive Manufacturing in Industry and Academia. CIRP Ann. 2017, 66, 561–583. [Google Scholar] [CrossRef]

- McCann, R.; Obeidi, M.A.; Hughes, C.; McCarthy, É.; Egan, D.S.; Vijayaraghavan, R.K.; Joshi, A.M.; Acinas Garzon, V.; Dowling, D.P.; McNally, P.J.; et al. In-Situ Sensing, Process Monitoring and Machine Control in Laser Powder Bed Fusion: A Review. Addit. Manuf. 2021, 45, 102058. [Google Scholar] [CrossRef]

- Gisario, A.; Kazarian, M.; Martina, F.; Mehrpouya, M. Metal Additive Manufacturing in the Commercial Aviation Industry: A Review. J. Manuf. Syst. 2019, 53, 124–149. [Google Scholar] [CrossRef]

- Evans, R.; Walker, J.; Middendorf, J.; Gockel, J. Modeling and Monitoring of the Effect of Scan Strategy on Microstructure in Additive Manufacturing. Met. Mater. Trans. A 2020, 51, 4123–4129. [Google Scholar] [CrossRef]

- Zhang, Y.; Hong, G.S.; Ye, D.; Zhu, K.; Fuh, J.Y.H. Extraction and Evaluation of Melt Pool, Plume and Spatter Information for Powder-Bed Fusion AM Process Monitoring. Mater. Des. 2018, 156, 458–469. [Google Scholar] [CrossRef]

- Foster, B.K.; Reutzel, E.W.; Nassar, A.R.; Hall, B.T.; Brown, S.W.; Dickman, C.J. Optical, Layerwise Monitoring of Powder Bed Fusion. In Proceedings of the 26th Annual International Solid Freeform Fabrication Symposium—An Additive Manufacturing Conference, SFF 2015, Austin, TX, USA, 10–12 August 2015; pp. 295–307. [Google Scholar]

- Lane, B.; Moylan, S.; Whitenton, E.P.; Ma, L. Thermographic Measurements of the Commercial Laser Powder Bed Fusion Process at NIST. RPJ 2016, 22, 778–787. [Google Scholar] [CrossRef] [PubMed]

- ISO/ASTM 52953:2025; ISO/ASTM International Additive Manufacturing for Metals—General Principles—Registration of Data Acquired from Process Monitoring and for Quality Control. ASTM: West Conshohocken, PA, USA, 2025.

- Mani, M.; Lane, B.; Donmez, A.; Feng, S.; Moylan, S.; Fesperman, R. Measurement Science Needs for Real-Time Control of Additive Manufacturing Powder Bed Fusion Processes; National Institute of Standards and Technology: Gaithersburg, MD, USA, 2015; p. NIST IR 8036. [Google Scholar]

- ISO/ASTM 52920:2023; ISO/ASTM International Qualification Principles—Requirements for Industrial Additive Manufacturing Processes and Production Sites. ASTM: West Conshohocken, PA, USA, 2023.

- Feng, S.C.; Lu, Y.; Jones, A.T. Meta-Data for In-Situ Monitoring of Laser Powder Bed Fusion Processes. In Proceedings of the ASME 2020 15th International Manufacturing Science and Engineering Conference, Virtual Online, 3 September 2020. V001T01A026. [Google Scholar]

- Scime, L.; Beuth, J. Anomaly Detection and Classification in a Laser Powder Bed Additive Manufacturing Process Using a Trained Computer Vision Algorithm. Addit. Manuf. 2018, 19, 114–126. [Google Scholar] [CrossRef]

- Mohr, G.; Altenburg, S.J.; Ulbricht, A.; Heinrich, P.; Baum, D.; Maierhofer, C.; Hilgenberg, K. In-Situ Defect Detection in Laser Powder Bed Fusion by Using Thermography and Optical Tomography—Comparison to Computed Tomography. Metals 2020, 10, 103. [Google Scholar] [CrossRef]

- Coeck, S.; Bisht, M.; Plas, J.; Verbist, F. Prediction of Lack of Fusion Porosity in Selective Laser Melting Based on Melt Pool Monitoring Data. Addit. Manuf. 2019, 25, 347–356. [Google Scholar] [CrossRef]

- Frye, R.; Yu, C.X.; Betts, S.; Jacquemetton, L.; Anderson, K.C. PrintRite3D® Machine Learning Case Study. 2020.

- Lane, B.; Jacquemetton, L.; Piltch, M.; Beckett, D. Thermal Calibration of Commercial Melt Pool Monitoring Sensors on a Laser Powder Bed Fusion System; National Institute of Standards and Technology: Gaithersburg, MD, USA, 2020; NIST AMS 100-35. [Google Scholar]

- Ladewig, A.; Zenzinger, G.; Bamberg, J.; Carl, V. Materialcharakterisierung Bei Der Additiven Fertigung Mittels Optischer Tomografie. In Proceedings of the Syposium Zerstörungsfreie Materialcharakterisierung 2017, München, Germany, 28 November 2017. [Google Scholar]

- Khairallah, S.A.; Anderson, A.T.; Rubenchik, A.; King, W.E. Laser Powder-Bed Fusion Additive Manufacturing: Physics of Complex Melt Flow and Formation Mechanisms of Pores, Spatter, and Denudation Zones. Acta Mater. 2016, 108, 36–45. [Google Scholar] [CrossRef]

- Hooper, P.A. Melt Pool Temperature and Cooling Rates in Laser Powder Bed Fusion. Addit. Manuf. 2018, 22, 548–559. [Google Scholar] [CrossRef]

- Peng, X.; Kong, L.; An, H.; Dong, G. A Review of In Situ Defect Detection and Monitoring Technologies in Selective Laser Melting. 3D Print. Addit. Manuf. 2023, 10, 438–466. [Google Scholar] [CrossRef]

- Khairallah, S.; Anderson, A.; Rubenchik, A. Laser Powder-Bed Fusion Additive Manufacturing: Effects of Main Physical Processes on Dynamical Melt Flow and Pore Formation from Mesoscopic Powder Simulation. Acta Mater. 2016, 108, 36–45. [Google Scholar] [CrossRef]

- Ray, N.; Bisht, M.; Thijs, L.; Vaerenbergh, J.V.; Coeck, S. DMP Monitoring as a Process Optimization Tool for Direct Metal Printing (DMP) of Ti-6Al-4V. In Solid Freeform Fabrication 2018, Proceedings of the 29th Annual International Solid Freeform Fabrication Symposium—An Additive Manufacturing Conference, Austin, TX, USA, 13–15 August 2018; Elsevier: Amsterdam, The Netherlands, 2018; pp. 2244–2253. [Google Scholar]

- Kolb, T.; Müller, L.; Tremel, J.; Schmidt, M. Melt Pool Monitoring for Laser Beam Melting of Metals: Inline-Evaluation and Remelting of Surfaces. Procedia CIRP 2018, 74, 111–115. [Google Scholar] [CrossRef]

- Bisht, M.; Ray, N.; Verbist, F.; Coeck, S. Correlation of Selective Laser Melting-Melt Pool Events with the Tensile Properties of Ti-6Al-4V ELI Processed by Laser Powder Bed Fusion. Addit. Manuf. 2018, 22, 302–306. [Google Scholar] [CrossRef]

- Alberts, D.; Schwarze, D.; Witt, G. In Situ Melt Pool Monitoring and the Correlation to Part Density of Inconel® 718 For Quality Assurance in Selective Laser Melting. In Solid Freeform Fabrication 2017, Proceedings of the 28th Annual International Solid Freeform Fabrication Symposium—An Additive Manufacturing Conference, Austin, TX, USA, 7–9 August 2017; Texas Scholarworks: Austin, TX, USA, 2018; pp. 1481–1494. [Google Scholar]

- Smith, C.; Hommer, G.; Keeler, M.; Gockel, J.; Findley, K.; Brice, C.; Clarke, A.; Klemm-Toole, J. Assessing Volumetric Energy Density as a Predictor of Defects in Laser Powder Bed Fusion 316L Stainless Steel. JOM 2025, 77, 737–748. [Google Scholar] [CrossRef]

- Beckett, D.; Cola, M. Evaluation of Quality SignaturesTM Using In-Situ Process Control during Additive Manufacturing with Aluminum Alloy AlSi10Mg.

- America Makes; ANSI. Standardization Roadmap for Additive Manufacturing Version 3.0; America Makes & ANSI Additive Manufacturing Standardization Collaborative; America Makes: Youngstown, OH, USA; ANSI: Washington, DC, USA, 2022. [Google Scholar]

- Craeghs, T.; Bechmann, F.; Berumen, S.; Kruth, J.-P. Feedback Control of Layerwise Laser Melting Using Optical Sensors. Phys. Procedia 2010, 5, 505–514. [Google Scholar] [CrossRef]

- Berumen, S.; Bechmann, F.; Lindner, S.; Kruth, J.-P.; Craeghs, T. Quality Control of Laser- and Powder Bed-Based Additive Manufacturing (AM) Technologies. Phys. Procedia 2010, 5, 617–622. [Google Scholar] [CrossRef]

- Mitchell, J.A.; Ivanoff, T.A.; Dagel, D.; Madison, J.D.; Jared, B. Linking Pyrometry to Porosity in Additively Manufactured Metals. Addit. Manuf. 2020, 31, 100946. [Google Scholar] [CrossRef]

- Ladewig, A.; Schlick, G.; Fisser, M.; Schulze, V.; Glatzel, U. Influence of the Shielding Gas Flow on the Removal of Process By-Products in the Selective Laser Melting Process. Addit. Manuf. 2016, 10, 1–9. [Google Scholar] [CrossRef]

- Kolb, T.; Gebhardt, P.; Schmidt, O.; Tremel, J.; Schmidt, M. Melt Pool Monitoring for Laser Beam Melting of Metals: Assistance for Material Qualification for the Stainless Steel 1.4057. Procedia CIRP 2018, 74, 116–121. [Google Scholar] [CrossRef]

- Yadav, P.; Rigo, O.; Arvieu, C.; Singh, V.K.; Lacoste, E. Data Processing Techniques for In-Situ Monitoring in L-PBF Process. J. Manuf. Process. 2022, 81, 155–165. [Google Scholar] [CrossRef]

- Megahed, M.; Mindt, H.-W.; Willems, J.; Dionne, P.; Jacquemetton, L.; Craig, J.; Ranade, P.; Peralta, A. LPBF Right the First Time—The Right Mix Between Modeling and Experiments. Integr. Mater. Manuf. Innov. 2019, 8, 194–216. [Google Scholar] [CrossRef]

- Molotnikov, A.; Jurg, M. Additive Assurance. Quality Assurance for Additive Manufacturing. 2020. Available online: https://www.additiveassurance.com (accessed on 15 June 2021).

- Alberts, D.; Schwarze, D.; Witt, G. Neural Networks for Modeling an In-Situ Melt Pool Monitoring System for Selective Laser Melting. Procedia CIRP 2020, 94, 409–413. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lindecke, P.N.J.; Castillo, J.M.D.d.; Tarhini, H. A Universal Method for the Evaluation of In Situ Process Monitoring Systems in the Laser Powder Bed Fusion Process. J. Manuf. Mater. Process. 2025, 9, 359. https://doi.org/10.3390/jmmp9110359

Lindecke PNJ, Castillo JMDd, Tarhini H. A Universal Method for the Evaluation of In Situ Process Monitoring Systems in the Laser Powder Bed Fusion Process. Journal of Manufacturing and Materials Processing. 2025; 9(11):359. https://doi.org/10.3390/jmmp9110359

Chicago/Turabian StyleLindecke, Peter Nils Johannes, Juan Miguel Diaz del Castillo, and Hussein Tarhini. 2025. "A Universal Method for the Evaluation of In Situ Process Monitoring Systems in the Laser Powder Bed Fusion Process" Journal of Manufacturing and Materials Processing 9, no. 11: 359. https://doi.org/10.3390/jmmp9110359

APA StyleLindecke, P. N. J., Castillo, J. M. D. d., & Tarhini, H. (2025). A Universal Method for the Evaluation of In Situ Process Monitoring Systems in the Laser Powder Bed Fusion Process. Journal of Manufacturing and Materials Processing, 9(11), 359. https://doi.org/10.3390/jmmp9110359