Abstract

The present study demonstrates the roller burnishing process of aluminum alloy 6061-T6 by using a combination of aluminum oxide and vegetable oil as a lubricant. Machining parameters were explored, varying speed (v) (range 100–300 rpm), feed (f) (range 0.1–0.3 mm), and number of passes (nop) (range 1 to 3). However, performance was measured in terms of surface roughness, microhardness, and roundness. According to the results obtained from experiments, it was found that lubrication had a significant impact on performance in terms of surface roughness, mmicrohardness and roundness. Under lubricated conditions, surface roughness ranged from 0.012 µm to 1.7 µm. However, an increase in mimicrohardnessrom 92 HV to 96 HV and an improvement in roundness from 0.07 mm up to 0.05 mm were observed. Additionally, the findings indicated that high speeds with low feed rates yielded the best results: for instance, at a feed of 0.1 mm/rev, speed (v) of 300 rpm, and number of passes of three, a surface roughness of about 0.8 µm, microhardness of approximately 94 HV, and roundness of about 0.02 mm were recorded when applying lubrication. This study demonstrates how minimal lubrication techniques can be used to improve the roller burnishing process, thereby achieving better mechanical properties and surface finishes while extending the lifespan of the burnishing tool. The study has brought about a conclusion that optimizing v and f during burnishing while including relevant lubricant helps manufacturers to realize significant product quality improvements and enhance production efficiency.

1. Introduction

The pursuit of the best surface finishes and mechanical qualities in manufacturing has generated significant interest in the application of cutting-edge finishing techniques. Among these, roller burnishing is particularly noteworthy as it aims to enhance the accuracy and surface quality of different metals. In this process surface irregularities are levelled using a sturdy roller, leaving a glossy finish. At a microscopic level, it may also make the material stronger [1]. Because of its lightness, strength, and excellent corrosion resistance, Al 6061-T6 is used in many different industries [2].

However, it is challenging to achieve an optimal surface finish and mechanical performance for Al 6061-T6 using conventional finishing operations. A method which has shown promise in overcoming such issues is roller burnishing. It improves size consistency through a reduction in surface roughness [3]. In the cutting-edge MQL (minimum quantity lubrication) technique, the roller is lubricated using a minute amount of lubricant [4].

MQL reduces the surface roughness of workpiece, enhances the range of tool usage, and minimizes friction; all these outcomes are accomplished simultaneously without creating environmental problems or economic losses caused by excessive consumption of lubricant [5]. Certain satisfactory results have been exhibited in recent studies when MQL is utilized in conjunction with several machining processes, including milling and turning [6].

With improved lubrication and reduced friction, use of MQL in roller burnishing offers a strong potential for process improvement. The present investigation assesses the effectiveness of roller burnishing Al 6061-T6 using MQL to determine the best method for attaining a more resistant surface metal finish with precise dimensions. Past research has shown that parameters such as feed rate (f), burnishing speed (v), and lubricant flow rate are particularly important in influencing the final result of the burnishing process [7].

In the present work, a mathematical model that aids in identifying the factors needed to achieve maximum production in roller burnishing using MQL predicts the optimal configuration. For investigating Ra and Central Composite Design (CCD) matrix optimization, and determining the correlation coefficient through analysis of variance (ANOVA) and quadratic analysis, researchers have employed the Response Surface Methodology (RSM) method with AL63400. They attempted to optimize force (F), v, and f, and achieved results in terms of feed-induced Ra [8,9]. Other studies employed RSM and a desirability approach to maximize roller burnishing process parameters. These studies aimed to improve surface characteristics such as Ra and microhardness (Hv). Critical parameters such as burnishing force, feed rate, and number of passes were evaluated systematically for their effect on output responses. The desirability function was able to determine the optimal combination of parameters.

The outcomes displayed tremendous enhancements in surface quality, validating the effectiveness of RSM in capturing optimal machining results for improved product performance. Several parameters, such as depth of cut, f, v, and Nop, were experimented with to remove peaks and troughs on the AA6351 surface post-burnishing. Because of its high stiffness, roller burnishing presents a classical flexible tool to reduce or even eliminate these imperfections and enhance surface properties.

The experiment was based on a CCD offered for the technique of response surface testing. According to the results, v and nop have an effect on Hv but are not as crucial as depth of cut for Ra [10]. Another study investigated the improvement in surface integrity in Inconel 718 through the roller burnishing process [11]. The major areas of focus involved the enhancement of Ra, Hv, and surface integrity as a whole. The study proved that burnishing greatly improves surface characteristics, and it is therefore a good technique for enhancing the performance of high-strength alloys [11]. The researchers applied the RSM to optimize external roller burnishing parameters in magnesium silicon carbide metal–matrix composites. F, v, Nop were some of the parameters examined for their influence on the Ra and Hv of the surface. The study attained a better combination of parameters, achieving better surface finish and mechanical properties of the composite material [12].

The outcome indicated that at 171 rpm, 0.18 mm/rev, 21 N force, and with three passes, the Ra is reduced. The total of all the elements applied to the workpiece surface under various conditions is referred to as surface integrity. Surface and metallurgical texture are the two categories. Burnishing is a machining process where, after machining, a roller is run over the surface of the workpiece. This results in the generation of contact stresses between the workpiece and the tool, which increases the workpiece’s Ra, alters the surface and metallurgical textures, and promotes plastic deformation of the surface layer of the component [8,13]. The authors analyzed Ra with the RSM method to calculate the coefficient of correlation and maximize the CCD matrix with material AL63400. Quadratic analysis and ANOVA were used in the analysis. The factors studied were F, v, and nop, and the Ra of the f was the result. Ref. [14] studied roller burnishing’s influence on the hardness and wear resistance of 316L stainless steel. The research analyzed the impact of process parameters, including v and F, on surface hardness and wear characteristics. The results showed that roller burnishing significantly impacted the enhancement of the surface hardness and also wear resistance, and thus that the material could be utilized more effectively in applications requiring superior surface performance.

The study underscored the potential of roller burnishing as an economic way of enhancing the mechanical and tribological properties of stainless steel [15]. The influence of roller burnishing on 316L stainless steel hardness and Ra was investigated, and there was a 45% increase in the surface hardness to 0.8 mm. Hardness was also enhanced to 57.9996 Hv by adjusting parameters such as v, f, Nop, and F [13]. Ref. [8] investigated microhardness of AL63400 through RSM optimized via CCD. Analysis of variance and quadratic analysis were utilized to find the correlation coefficient, and force and microhardness were found to be the key parameters. In [16], low-lubrication roller burnishing properties were compared across carbon steel and an aluminum alloy, with an increase in hardness from 126 to 323 HV shown. In addition, the surface roughness has been examined in terms of variables such as burnishing f, v, penetration depth, and nop by researchers. Ref. [17] examined surface properties of Al7075-T7451 discs under dry and cryogenic burnishing conditions, revealing the effect of lubrication on surface quality and hardness. Using a liquid nitrogen coolant, a specific roller burnishing head was designed and was experimentally tested on the workpiece. The results suggest that, in comparison with dry burnishing, the surface hardness is increased by over 25%. The Ra and Hv of AA6351 were investigated with the use of kerosene as a coolant [18,19]. The findings showed an improvement in both Ra and Hv by 60%. ANOVA and regression analysis were used to analyze the effect of using a coolant on decreasing heat during operation.

Researchers also studied the influence of process parameters including burnishing force, feed, width, and number of passes on Ra, Hv, and residual stresses in high-strength aluminum alloys, with microhardness increasing from 144.9 Hv to 150.1 Hv. Utilizing lubricants like soluble oil and kerosene, the surface characteristics of AA6082-T6 and AA603 alloys were analyzed. Another investigation explored the effectiveness of the burnishing process under different lubrication conditions, highlighting how lubricants influence surface integrity. For instance, applying a cryogenic process enhances hardness, while minimum quantity lubrication significantly reduces Ra [20]. The use of coated tools and cryogenic coolants was identified as essential for improving hardness and reducing wear resistance. Refs. [21,22] investigated the surface integrity of the Ti-6Al-4V alloy by analyzing variables such as coolants, v, f, and nop. The study utilized four distinct coolant types—flood cooling, minimum quantity lubrication (MQL), cryogenic cooling, and hybrid cooling/lubrication—to evaluate their effects on the burnishing process.

The findings provided insights into how different cooling methods influence surface characteristics, highlighting the importance of coolant selection in optimizing the process for enhanced material performance. The coolants were examined and ranked according to their relative relevance. According to these experiments, hybrid coolants reduce Ra, while cryogenic procedures increase material hardness. Every lubricant has been improved to address the microhardness problems mentioned above. When burnishing is completed with little flood cooling, marks will become visible.

2. Materials and Methods

Al6061-T6, which is widely used in general-purpose applications, was used in this investigation. This alloy is renowned for its high strength-to-weight ratio, corrosion resistance, and weldability, making it suitable for various structural components and popular in manufacturing processes. It is an aluminum alloy that has been precipitation-hardened. Magnesium and silicon are the two most important constituents. The main advantage of aluminum 6061 is its weldability. The selected specimen measures 30 mm in diameter, 160 mm in length, and 50 mm in length on each surface. It is often included in aircraft structures. Properties and chemical makeup of aluminum alloy 6061 (as supplied by All Metal India Pvt Ltd., Pune, India) are shown in Table 1.

Table 1.

Chemical composition of Al6061 alloy.

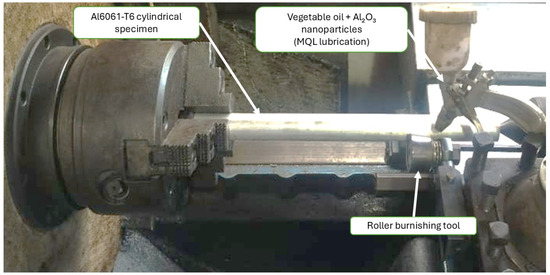

In the current study, as shown in Figure 1, a single roller burnishing tool with a carbide roller was employed. During the burnishing process, the carbide roller is spring-loaded in both axial directions with the proper pressure. Long tool life can be achieved by regrinding or lapping a worn-out carbide roller [23]. The carbide roller tool can be used on CNC lathes, turrets, or traditional lathes and is appropriate for all external shaft surfaces, including taper shafts, radii, shoulders, and more. It is possible to burnish the turned surface up to 0.1 to 0.2 µm.

Figure 1.

Experimental setup for roller burnishing.

Experiments were conducted at a constant depth of penetration of 0.5 mm while adjusting the f, v, and nop (refer Table 2). To comprehend the key elements influencing the sustainability indicators (Ra, microhardness, and error in roundness), a design of experiment (DOE) technique was employed. In this study, nine roller burnishing experiments were performed with varying process parameters to develop Ra, microhardness, and error in roundness (roundness error) models [7,24]. Nanofluids are advanced fluids made by dispersing nanoparticles (typically 1–100 nm) into base fluids like water, oil, or ethylene glycol. They exhibit significantly enhanced thermal properties, such as increased thermal conductivity and heat transfer efficiency, compared to traditional fluids. The most significant factors that affect their performance are the nanoparticle size, concentration, and form, and the characteristics of the base fluid. Nanofluids find applications in heat exchangers, cooling systems, and solar energy systems.

Table 2.

Machining parameters and their different levels.

Although nanofluids are advantageous, there are still challenges of stability, viscosity, and expense that need to be addressed by further research for industrial-scale applications. A base fluid is the major liquid medium in which nanoparticles are suspended to form a nanofluid. Water, oils, and ethylene glycol are some of the common base fluids. Properties of the base fluid, such as thermal conductivity, viscosity, and stability, have a great impact on the resultant nanofluid’s performance and efficiency [25,26,27].

Al2O3 nanoparticles dispersed in vegetable oil yield a nanofluid that has good thermal characteristics. Aluminum oxide has a very high thermal conductivity value and is able to enhance the heat transfer efficiency of vegetable oil. The blend is usually studied for the possibility of application in heat exchangers, cooling systems, and lubrication where thermal management is vital. This oil-based vegetable fluid possesses advantages, such as low toxicity and biodegradability, over the traditional base fluid options. However, stability and nanoparticle agglomeration inhibition in such mixtures are important for optimal performance [28].

One important element that affects the efficiency of the cooling and lubrication process in minimum quantity lubrication (MQL) is the lubricant concentration. MQL is accomplished by applying a little amount of compressed air and lubricant, typically in the form of a fine mist. The concentration of the lubricant affects the cooling capacity, lubrication efficiency, and surface finish [29]. Higher concentrations may enhance lubrication but result in too much residue, while lower concentrations may reduce tool wear but compromise lubrication. Optimal concentration must balance cooling, and lubrication needs to minimize wear, friction, and environmental impact while enhancing machining performance and tool life. The investigations of López de Lacalle et al. [1] show the potential of the burnishing process to increase the degree of automation and efficiency by substituting polishing processes on complex geometries.

In this study, a systematic approach was adopted to evaluate surface roughness, material microhardness, and dimensional accuracy (in terms of roundness) following the roller burnishing process. Surface roughness was measured using a precision surface tester (Model: SJ-210, 4 mN type). It is capable of capturing finer variations in surface texture with reliable accuracy. To evaluate the material’s microhardness, a Vickers microhardness tester was employed, utilizing a diamond-shaped indenter with a 136° angle. The test was carried out under a consistent load of 100 g and a dwell time of 20 s, ensuring reproducible results across all specimens. Dimensional accuracy was examined with the aid of a bridge-type coordinate-measuring machine (CMM). It provided high-resolution measurement of geometric features, detecting any deviations from the intended specifications. This combination of instruments ensured comprehensive and accurate evaluation of the effect of burnishing parameters on the workpiece.

3. Results and Discussion

Table 3 presents the results of surface roughness (Ra), microhardness (Hv), and roundness error (Re) obtained from the experimental runs of the L9 Taguchi orthogonal array. For each run, three replicates were conducted, and the average values along with their corresponding Standard Deviations are reported in this table. The experimental results from Table 3 illuminate the effect of different process parameters and lubrication conditions during the roller burnishing process on the surface finish, microhardness, and roundness of the aluminum alloy. The remainder of this section will provide a further discussion on how the parameters affected the performance of the burnishing process.

Table 3.

Roller burnishing experimental matrix (dry and lubricated conditions).

3.1. Surface Roughness (Ra)

Surface roughness varied between 1.1 and 1.7 µm when lubrication was not used. It is crucial to note that when burnishing speed increases and feed rate lowers, surface roughness reduces. For example, the surface roughness is reduced to 1.1 µm at 300 rpm with a feed rate of 0.1 mm/rev, compared at 100 rpm when it was 1.7 µm. This clearly indicates that a smoother finish will be achieved at higher speeds and lower feed rates. Furthermore, when compared to the lubricated circumstances, the surface roughness values continue to be comparatively high. Moreover, using vegetable oil and aluminum oxide combined as lubricants improves the surface roughness, reaching the range of 0.8 to 1.2 µm. A smoother surface results from the lubrication’s significant reduction in heat production and friction. For example, the surface roughness is decreased to 0.8 µm at 300 rpm with an input rate of 0.1 mm/rev using lubrication, which is far less than what was seen in dry conditions. By lowering friction and providing efficient cooling for the roller, this results in a fine finish [8].

3.2. Microhardness (HV)

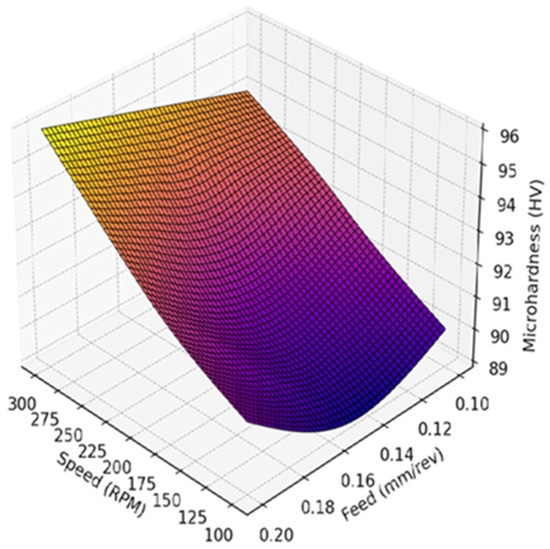

Microhardness values vary from 84 HV to 92 HV in the case of unlubricated scenarios. At high speeds and lower feed rates, the hardness appears to increase, meaning these set conditions improve material hardness since they exhibit better burnishing effects. However, this increase is far less than the value found in the lubricated condition, since in the lubricated condition, the values of microhardness are considerably high and range between 90 HV and 96 HV. The presence of lubrication improves the burnishing effects due to reduced friction and tool wear, thus producing more uniform and consistent hardening on the surface [29]. For instance, 0.1 mm/rev, and speed at 300 rpm, microhardness can reach 96 HV, demonstrating that lubrication efficiently raises hardness because of better process conditions. Considering the STDEV (Standard Deviation) and RSD (Relative Standard Deviation) of the microhardness results, they were 2.34 and 2.54%, respectively, in the lubricated version, and 2.73 and 3.11% in the non-lubricated one.

3.3. Roundness

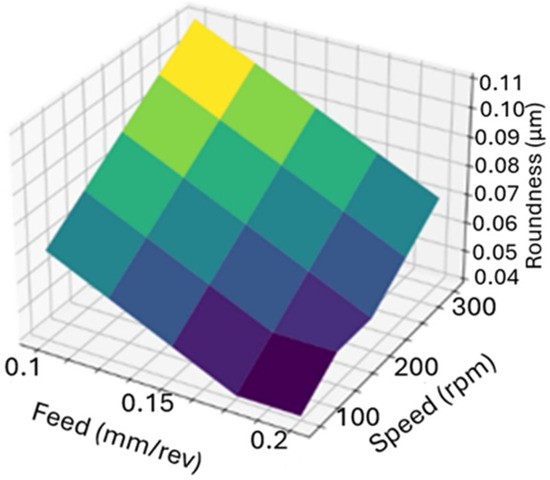

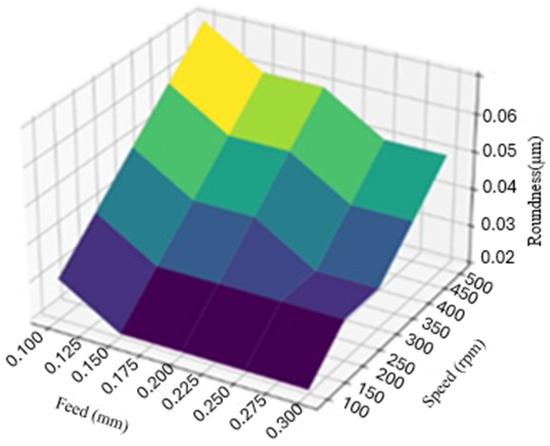

Measurements in dry conditions are between 0.04 mm and 0.07 mm regarding the roundness of the treated specimen. With increased speeds and decreased feed rates, roundness is improved, which means that with such process conditions, the burnishing process is more effective in maintaining dimensional accuracy. Nevertheless, some effects from the lack of lubrication will still be noted, and thus the roundness will vary to some small degree. Lubrication further leads to improved roundness, with values varying between 0.02 mm and 0.05 mm. It is because of reduced friction and smoother operation that the dimensionally accurate component may be better controlled under lubricated conditions, and hence a considerable reduction in roundness deviations occurs. For example, the roundness is reduced to 0.02 mm at 300 rpm with a feed rate of 0.1 mm/rev, demonstrating unequivocally that lubrication aids in dimensional precision. The results show that, as compared to dry conditions, the application of MQL with aluminum oxide and vegetable oil greatly improves the surface quality, microhardness, and roundness of aluminum alloy 6061-T6. This lubrication helps lubricate, reduces friction between the processes, lowers the temperature during burnishing, and provides a smoother finish.

Under lubrication, the surface is significantly smoother than under dry conditions. This is mainly due to the reduced friction and effective cooling, leading to the increased hardness of the material due to more uniform burnishing effects and reduced tool wear. Lubrication contributes to better dimensional accuracy by minimizing roundness deviations. These findings support the conclusion that incorporating lubrication into the roller burnishing process can lead to superior surface quality and mechanical properties, making it a valuable technique for improving the performance and durability of aluminum alloy 6061-T6 components in various industrial applications.

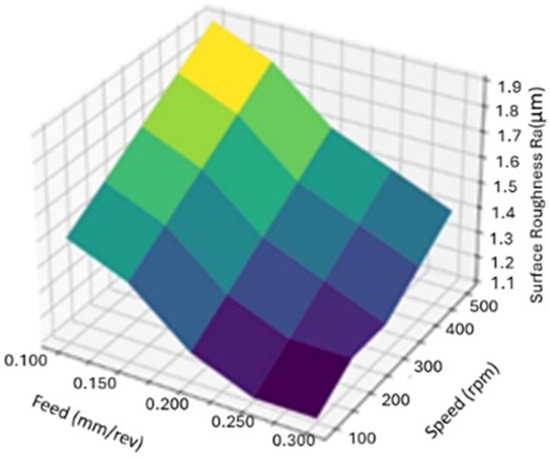

3.3.1. Dry Condition: Surface Roughness

The analysis of surface roughness under dry conditions reveals the following trends, as shown in Figure 2:

- The surface roughness is 1.5 µm at 100 rpm, 0.1 mm/rev f, and one pass.

- The surface roughness is decreased by 1.3 µm when the speed is increased to 200 rpm, f is 0.1 mm/rev, and two passes are performed.

- The surface roughness further reduces to 1.1 µm at 300 rpm, 0.1 mm/rev f, and three passes.

Overall, surface roughness improves (i.e., decreases) with higher speeds and more passes. The feed rate also influences the surface finish, with a smaller feed rate generally yielding a smoother surface.

Figure 2.

Dry condition: Surface roughness.

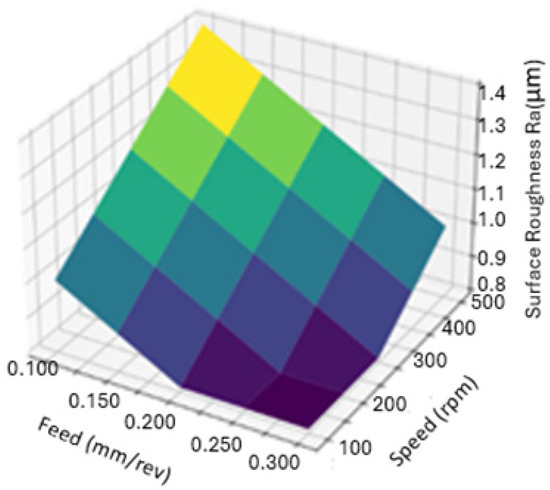

3.3.2. Lubricated Condition: Surface Roughness

For the lubricated condition using aluminum oxide and vegetable oil, as shown in Figure 3, the results are as follows:

- The surface roughness is 1.0 µm at 100 rpm, 0.1 mm/rev f, and one pass.

- A surface roughness reduction of 0.9 µm is achieved by increasing the speed to 200 rpm, f at 0.1 mm/rev, and making two passes.

- The surface roughness further reduces to 0.8 µm 0.1 mm/rev feed, at 300 rpm, and three passes.

The use of lubrication significantly improves surface finish compared to dry conditions. As in the dry condition, increasing the speed and number of passes contributes to a better surface quality.

Figure 3.

Effect of process parameters on surface quality metrics. Lubricated condition: Surface roughness.

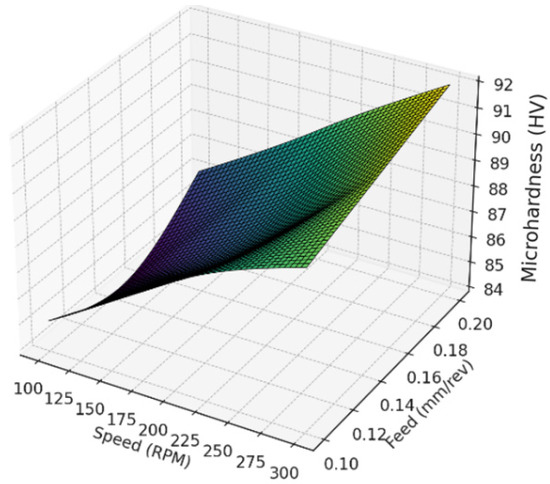

3.3.3. Dry Condition: Microhardness

The microhardness results under dry conditions are as follows, as shown in Figure 4:

- The microhardness is 85 HV at 100 rpm, one pass, and an f of 0.1 mm/rev.

- A microhardness of 88 HV is achieved by increasing the speed to 200 rpm and making two passes at an f of 0.1 mm/rev.

- The microhardness reaches 90 HV after three passes at 300 rpm and 0.1 mm/rev f.

Microhardness improves with increased speed and more passes, indicating a strengthening of the material’s surface layer due to the microplastic deformation of it.

Figure 4.

Dry condition: Microhardness.

3.3.4. Lubricated Condition: Microhardness

Under lubricated conditions, as shown in Figure 5, the following results are achieved:

- At an f of 0.1 mm/rev, speed of 100 rpm, and one pass, the microhardness is 90 HV.

- Increasing speed to 200 rpm with an f of 0.1 mm/rev and two passes results in a microhardness of 92 HV.

- At 300 rpm, when the f is 0.1 mm/rev and the number of passes is three, the microhardness increases to 94 HV.

The microhardness further increases with lubrication as compared to under dry condition, which indicates that lubrication provides better formation of a hard surface layer.

Figure 5.

Lubricated condition microhardness.

3.3.5. Dry Condition: Roundness

Results of the roundness in dry conditions are as follows:

- Roundness is 0.05 mm at a f 0.1 mm/rev, v 100 rpm, and one pass.

- At a speed of 200 rpm with two passes and an f of 0.1 mm/rev, the roundness is 0.04 mm.

- When a f of 0.1 mm/rev, a speed increased to 300 rpm, and three passes, the roundness is 0.04 mm.

Some slight improvement in roundness with increased speed and number of passes is shown in Figure 6.

Figure 6.

Dry condition: Roundness.

3.3.6. Lubricated Condition: Roundness

For lubricated conditions, the roundness results are as follows:

- At 100 rpm, with one pass and an f of 0.1 mm/rev1, the roundness is 0.03 mm.

- With an increase in speed to 200 rpm, two passes, and an f of 0.1 mm/rev, the roundness is 0.02 mm.

- Further with an f of 0.1 mm/rev, increase in speed to 300 rpm, and three passes, and the roundness is still 0.02 mm.

The improvement in roundness with lubrication, compared to dry conditions, is very significant and indicative of a more accurate and uniform surface finish. More specifically, lubrication improves all surface quality metrics related to surface roughness, microhardness, and roundness, as shown in Figure 7. For a better surface finish, increase the number of passes and speed. Lubrication helps to achieve a finer surface finish and higher microhardness, and also improves roundness as compared to dry conditions.

Figure 7.

Lubricated condition: Roundness.

4. Conclusions

From the study, the following conclusions are drawn, and key limitations are also provided.

- Lubrication using aluminum oxide and vegetable oil significantly enhanced the performance of roller burnishing on aluminum alloy 6061-T6.

- Significant improvements were observed in surface finish, microhardness, and roundness when compared to dry conditions:

- –

- Surface roughness was reduced from 1.7 µm to 0.012 µm under lubricated conditions;

- –

- Microhardness increased from 92 HV to 96 HV under lubricated conditions;

- –

- Roundness improved from 0.07 mm to 0.05 mm under lubricated conditions.

- Optimal performance was achieved with higher speeds and lower feed rates.

- At a 0.1 mm/rev feed rate, 300 rpm, and three passes, the lubricated process resulted in a surface roughness of 0.8 µm, a microhardness of 94 HV, and a roundness of 0.02 mm.

- The findings validate the effectiveness of minimal lubrication in enhancing roller burnishing.

- Optimization of burnishing parameters and lubrication can lead to significant improvements in the surface quality and mechanical properties of aluminum alloy components, providing valuable insights for the manufacturing industry.

This study is limited to Al6061-T6 and a specific aluminum oxide–vegetable oil MQL lubricant under selected process parameters, and future work could explore other alloys, alternative nanofluid lubricants, and industrial-scale applications to further validate the findings. Rt and Rz measurements can be included in future studies to further characterize the surface profile.

5. Limitations

- Our findings are based on aluminum alloy 6061-T6 and may not apply to other alloys or materials.

- The study focused on limited process parameters (feed rate, speed, and number of passes), excluding factors like tool geometry, lubrication quantity, and environmental conditions.

- The long-term effects on tool wear and surface integrity were not examined.

- The environmental impact and economic feasibility of scaling up the lubrication with aluminum oxide and vegetable oil for mass production were not assessed.

- Our findings are based on a specific nanofluid mixture of aluminum oxide and vegetable oil as the lubrication liquid.

Author Contributions

Conceptualization, A.S., A.K. and P.A.; methodology, A.S., A.K. and P.A.; software, A.S. and P.A.; validation, A.D. and A.K.; formal analysis, A.S. and P.A.; investigation, A.S., A.K. and P.A.; resources, A.S. and J.K.; data curation, A.S. and J.K.; writing—original draft preparation, A.S. and P.A.; writing—review and editing, A.K. and J.K.; visualization, A.K.; supervision, A.K. and J.K.; funding acquisition, A.K. and J.K. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

Data are contained within the article.

Acknowledgments

This research was supported by the “University of Debrecen Program for Scientific Publication”.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Rodríguez, A.; López de Lacalle, L.N.; Celaya, A.; Fernández, A.; Lamikiz, A. Ball burnishing application for finishing sculptured surfaces in multi-axis machines. Int. J. Mechatron. Manuf. Syst. 2011, 4, 220–237. [Google Scholar] [CrossRef]

- Pak, A.; Mahmoodi, M.; Safari, M. Experimental investigation of the effects of initial surface roughness on ultrasonic assisted ball burnishing of Al6061-T6. Modares Mech. Eng. 2020, 20, 87–95. [Google Scholar]

- Saffar, S.; Eslami, H. Increasing the fatigue life and surface improvement of AL7075 alloy T6 by using ultrasonic ball burnishing process. Int. J. Surf. Sci. Eng. 2022, 16, 181–206. [Google Scholar] [CrossRef]

- Somatkar, A.A. Enhancing Surface Integrity and Quality through Roller Burnishing: A Comprehensive Review of Parameters Optimization, and Applications. Commun. Appl. Nonlinear Anal. 2024, 31, 151–169. [Google Scholar] [CrossRef]

- Nguyen, T.T.; Nguyen, T.A.; Trinh, Q.H.; Le, X.B.; Pham, L.H.; Le, X.H. Artificial neural network-based optimization of operating parameters for minimum quantity lubrication-assisted burnishing process in terms of surface characteristics. Neural Comput. Appl. 2022, 34, 7005–7031. [Google Scholar] [CrossRef]

- Nguyen, T.T. Multi-response performance optimization of burnishing operation for improving hole quality. J. Braz. Soc. Mech. Sci. Eng. 2021, 43, 560. [Google Scholar] [CrossRef]

- Shirsat, U.; Ahuja, B.; Dhuttargaon, M. Effect of burnishing parameters on surface finish. J. Inst. Eng. Ser. C 2017, 98, 431–436. [Google Scholar] [CrossRef]

- Kurkute, V.; Chavan, S.T. Modeling and Optimization of surface roughness and microhardness for roller burnishing process using response surface methodology for Aluminum 63400 alloy. Procedia Manuf. 2018, 20, 542–547. [Google Scholar] [CrossRef]

- Patel, K.A.; Brahmbhatt, P.K. Response surface methodology-based desirability approach for optimization of roller burnishing process parameter. J. Inst. Eng. Ser. C 2018, 99, 729–736. [Google Scholar] [CrossRef]

- Maheshwari, A.S.; Gawande, R.R. Improving Surface Quality of AA 6351 by the Stiff Burnishing Technique. Jordan J. Mech. Ind. Eng. 2016, 10, 245–251. [Google Scholar]

- Yaman, N.; Sunay, N.; Kaya, M.; Kaynak, Y. Enhancing surface integrity of additively manufactured Inconel 718 by roller burnishing process. Procedia CIRP 2022, 108, 681–686. [Google Scholar] [CrossRef]

- Prasad, K.A.; John, M.S. Optimization of external roller burnishing process on magnesium silicon carbide metal matrix composite using response surface methodology. J. Braz. Soc. Mech. Sci. Eng. 2021, 43, 342. [Google Scholar] [CrossRef]

- Tadic, B.; Todorovic, P.M.; Luzanin, O.; Miljanic, D.; Jeremic, B.M.; Bogdanovic, B.; Vukelic, D. Using specially designed high-stiffness burnishing tool to achieve high-quality surface finish. Int. J. Adv. Manuf. Technol. 2013, 67, 601–611. [Google Scholar] [CrossRef]

- El-Khabeery, M.M.; El-Axir, M.H. Experimental techniques for studying the effects of milling roller-burnishing parameters on surface integrity. Int. J. Mach. Tools Manuf. 2001, 41, 1705–1719. [Google Scholar] [CrossRef]

- Tugay, I.O.; Hosseinzadeh, A.; Yapici, G.G. Hardness and wear resistance of roller burnished 316L stainless steel. Mater. Today Proc. 2021, 47, 2405–2409. [Google Scholar] [CrossRef]

- Okada, M.; Suenobu, S.; Watanabe, K.; Yamashita, Y.; Asakawa, N. Development and burnishing characteristics of roller burnishing method with rolling and sliding effects. Mechatronics 2015, 29, 110–118. [Google Scholar] [CrossRef]

- Huang, B.; Kaynak, Y.; Sun, Y.; Jawahir, I.S. Surface layer modification by cryogenic burnishing of Al 7050-T7451 alloy and validation with FEM-based burnishing model. Procedia CIRP 2015, 31, 1–6. [Google Scholar] [CrossRef]

- Kanovic, Z.; Vukelic, D.; Simunovic, K.; Prica, M.; Saric, T.; Tadic, B.; Simunovic, G. The Modelling of Surface Roughness after the Ball Burnishing Process with a High-Stiffness Tool by Using Regression Analysis, Artificial Neural Networks, and Support Vector Regression. Metals 2022, 12, 320. [Google Scholar] [CrossRef]

- Mahmood, N.Q.; Tahir, Y.F.; Hikmat, M.; Abdulsatar, M.S.; Baumli, P. Experimental investigation of the surface roughness for aluminum alloy AA6061 in milling operation by taguchi method with the anova technique. J. Eng. 2024, 30, 1–14. [Google Scholar] [CrossRef]

- Casarin, S.J.; De Angelo Sanchez, L.E.; Bianchi, E.C.; Scalon, V.L.; Fragelli, R.L.; De Godoi, E.L.; Cindra Fonseca, M.D.P. Effect of burnishing on Inconel 718 workpiece surface heated by infrared radiation. Mater. Manuf. Process. 2021, 36, 1853–1864. [Google Scholar] [CrossRef]

- Caudill, J.; Schoop, J.; Jawahir, I.S. Correlation of surface integrity with processing parameters and advanced interface cooling/lubrication in burnishing of Ti-6Al-4V alloy. Adv. Mater. Process. Technol. 2019, 5, 53–66. [Google Scholar] [CrossRef]

- Rotella, G.; Rinaldi, S.; Filice, L. Roller burnishing of Ti6Al4V under different cooling/lubrication conditions and tool design: Effects on surface integrity. Int. J. Adv. Manuf. Technol. 2020, 106, 431–440. [Google Scholar] [CrossRef]

- Elsamanty, M.E.; Youssef, W.F.; Abdelsalam, M.; Ibrahim, A.A. Investigating the Impact of Tool Type on Optimizing Burnishing Parameters for AISI 1035 Steel: A Taguchi and RSM Approach. Eng. Res. J. 2023, 180, 119–146. [Google Scholar] [CrossRef]

- Modi, M.A.; Patel, T.M. Predictive modeling of specific fuel consumption in compression ignition engines using neural networks: A comparative analysis across diesel and polymer-based fuels. Eng. Res. Express 2024, 6, 035519. [Google Scholar] [CrossRef]

- Albadr, J.; Tayal, S.; Alasadi, M. Heat transfer through heat exchanger using Al2O3 nanofluid at different concentrations. Case Stud. Therm. Eng. 2013, 1, 38–44. [Google Scholar] [CrossRef]

- Bahmani, M.H.; Sheikhzadeh, G.; Zarringhalam, M.; Akbari, O.A.; Alrashed, A.A.; Shabani, G.A.S.; Goodarzi, M. Investigation of turbulent heat transfer and nanofluid flow in a double pipe heat exchanger. Adv. Powder Technol. 2018, 29, 273–282. [Google Scholar] [CrossRef]

- Pourhoseini, S.H.; Naghizadeh, N.; Hoseinzadeh, H. Effect of silver-water nanofluid on heat transfer performance of a plate heat exchanger: An experimental and theoretical study. Powder Technol. 2018, 332, 279–286. [Google Scholar] [CrossRef]

- Sadat, A. Residual stresses and surface damage when micromachining 6061-T6 aluminum alloy. Int. J. Adv. Manuf. Technol. 2024, 130, 4469–4477. [Google Scholar] [CrossRef]

- Akkaya, M.; Menlik, T.; Sözen, A.; Gürü, M. Experimental investigation of nanolubricant usage in a cooling system at different nanoparticle concentrations. Heat Transf. Res. 2020, 51, 949–965. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).