AI-Driven Innovations in 3D Printing: Optimization, Automation, and Intelligent Control

Abstract

1. Introduction

2. Challenges of Additive Manufacturing

3. AI-Driven Innovations in 3D Printing: The Role of AI and Its Benefits

3.1. AI in Manufacturing: Types of AI Used in 3D Printing

3.1.1. Machine Learning (ML)

3.1.2. Deep Learning (DL)

3.1.3. Computer Vision

3.1.4. Reinforcement Learning (RL)

3.1.5. Natural Language Processing (NLP) and AI Assistants

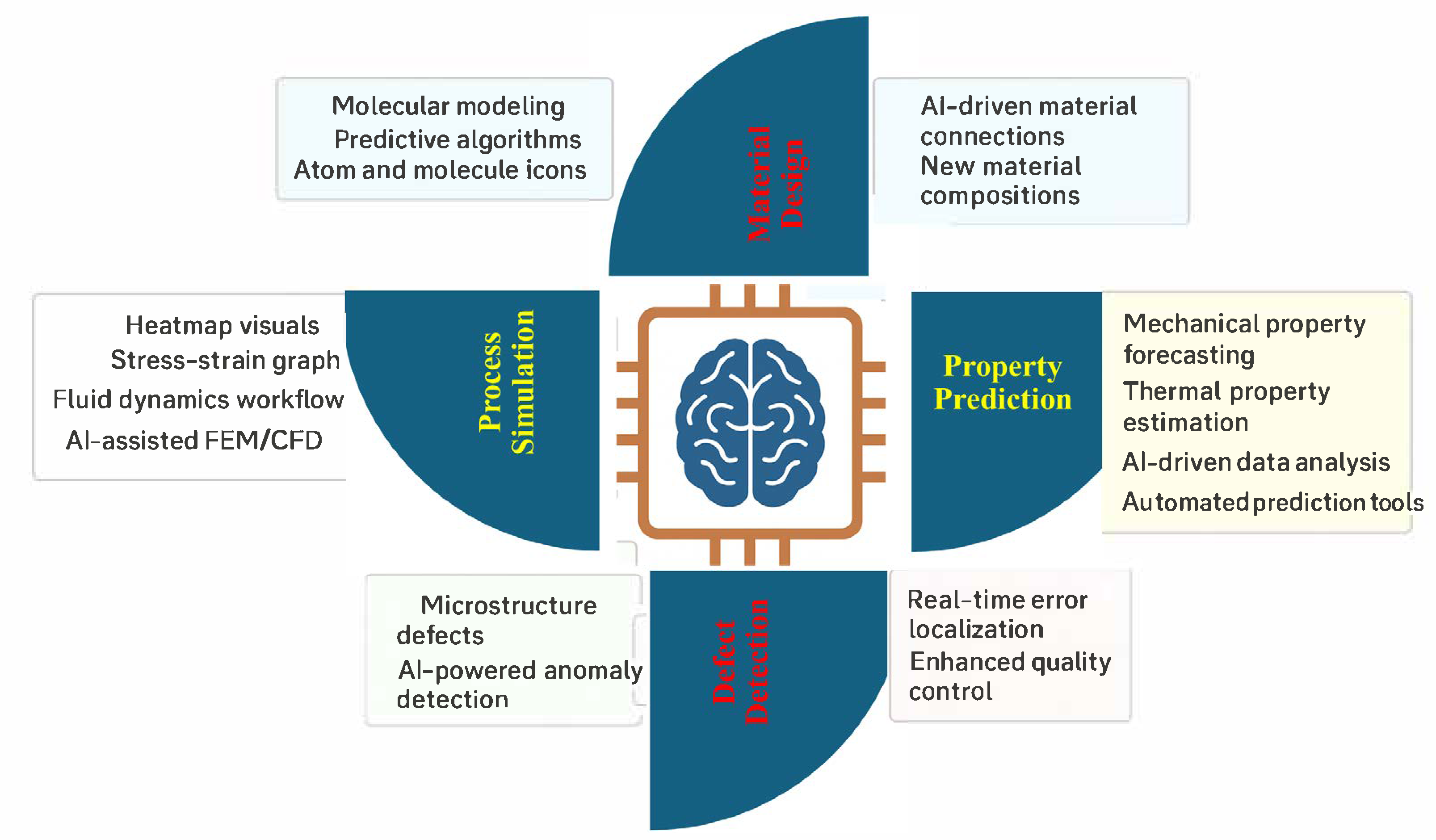

4. Applications of AI in 3D Printing

4.1. Real-Time Process Optimization

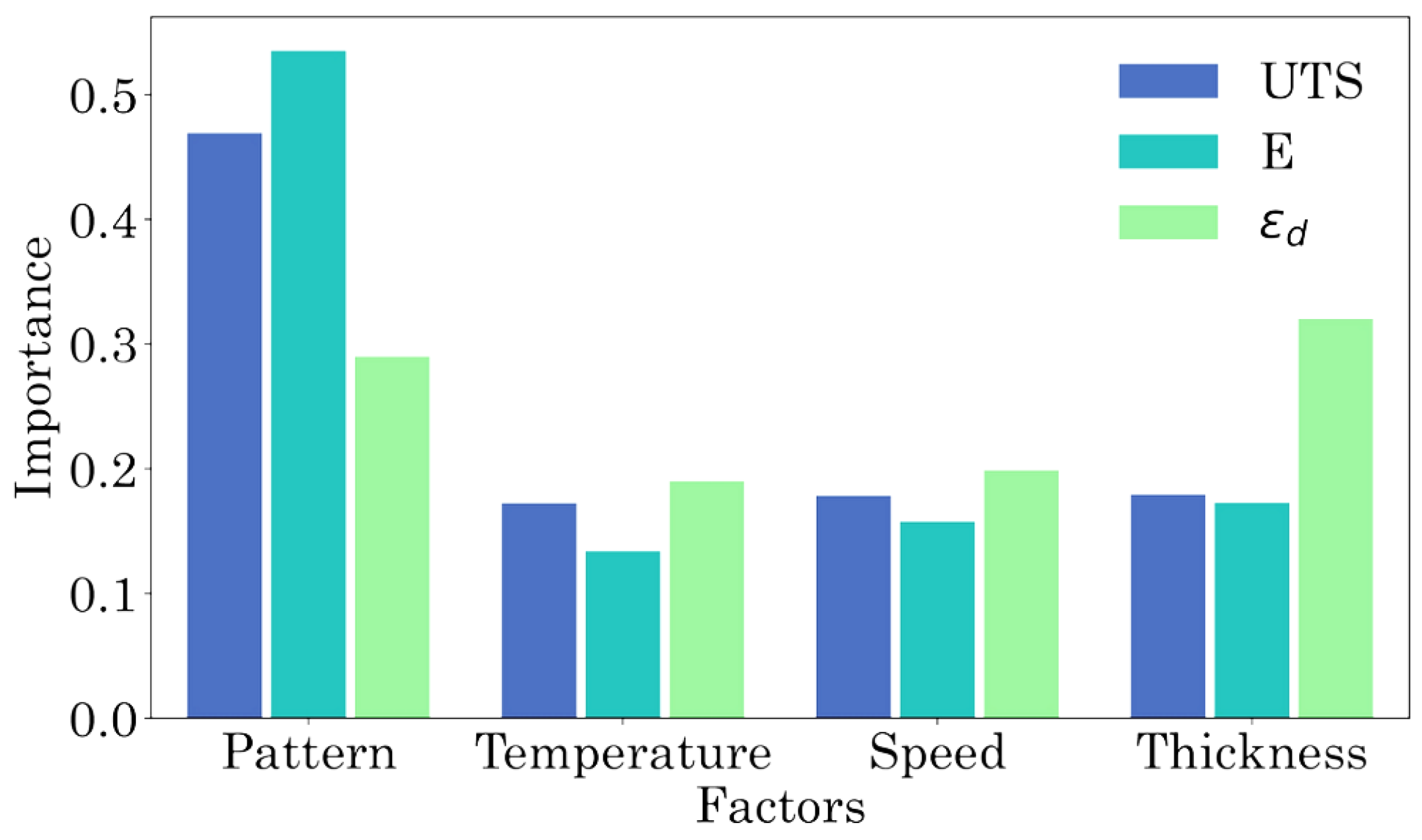

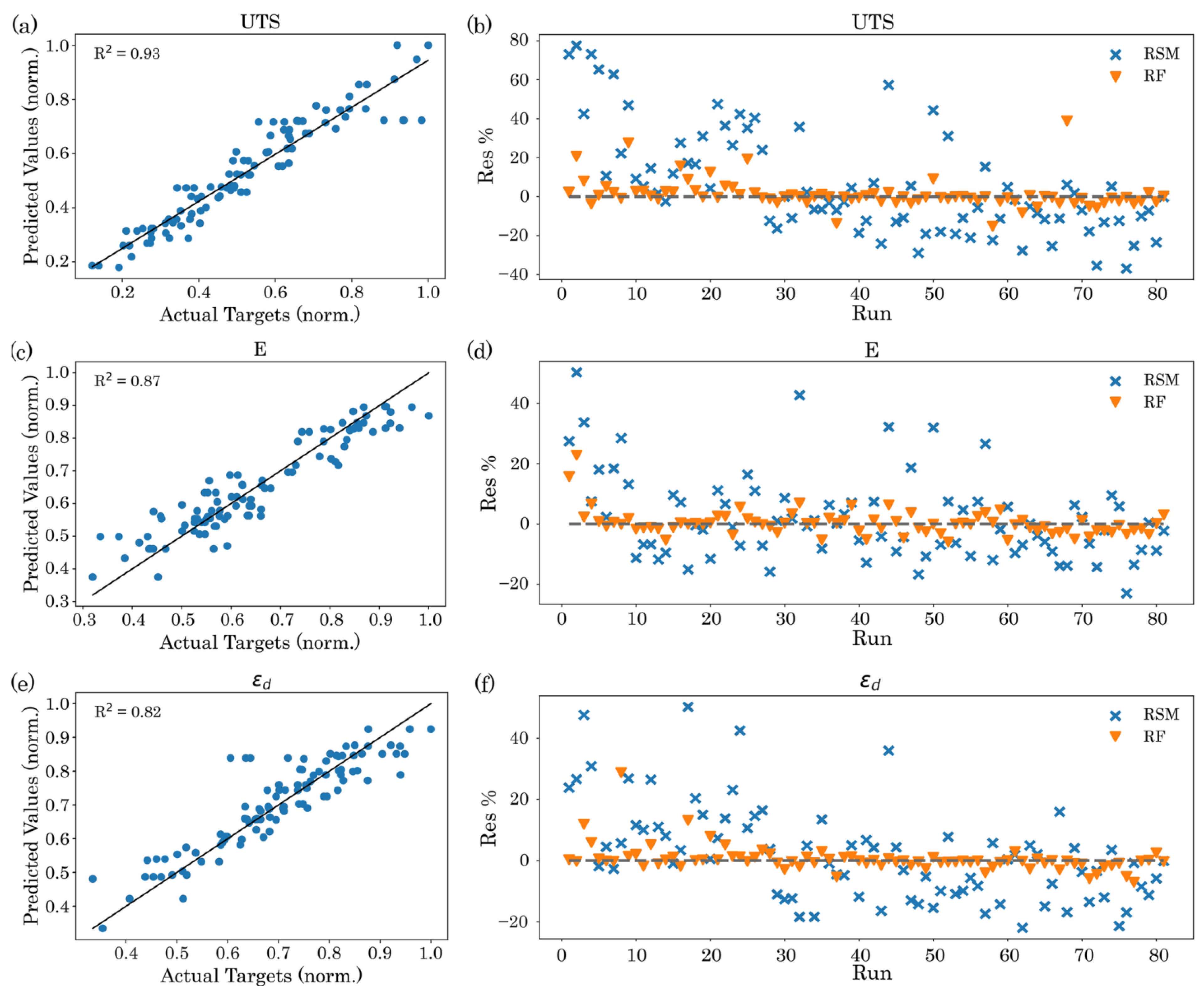

4.2. Material Behavior Prediction

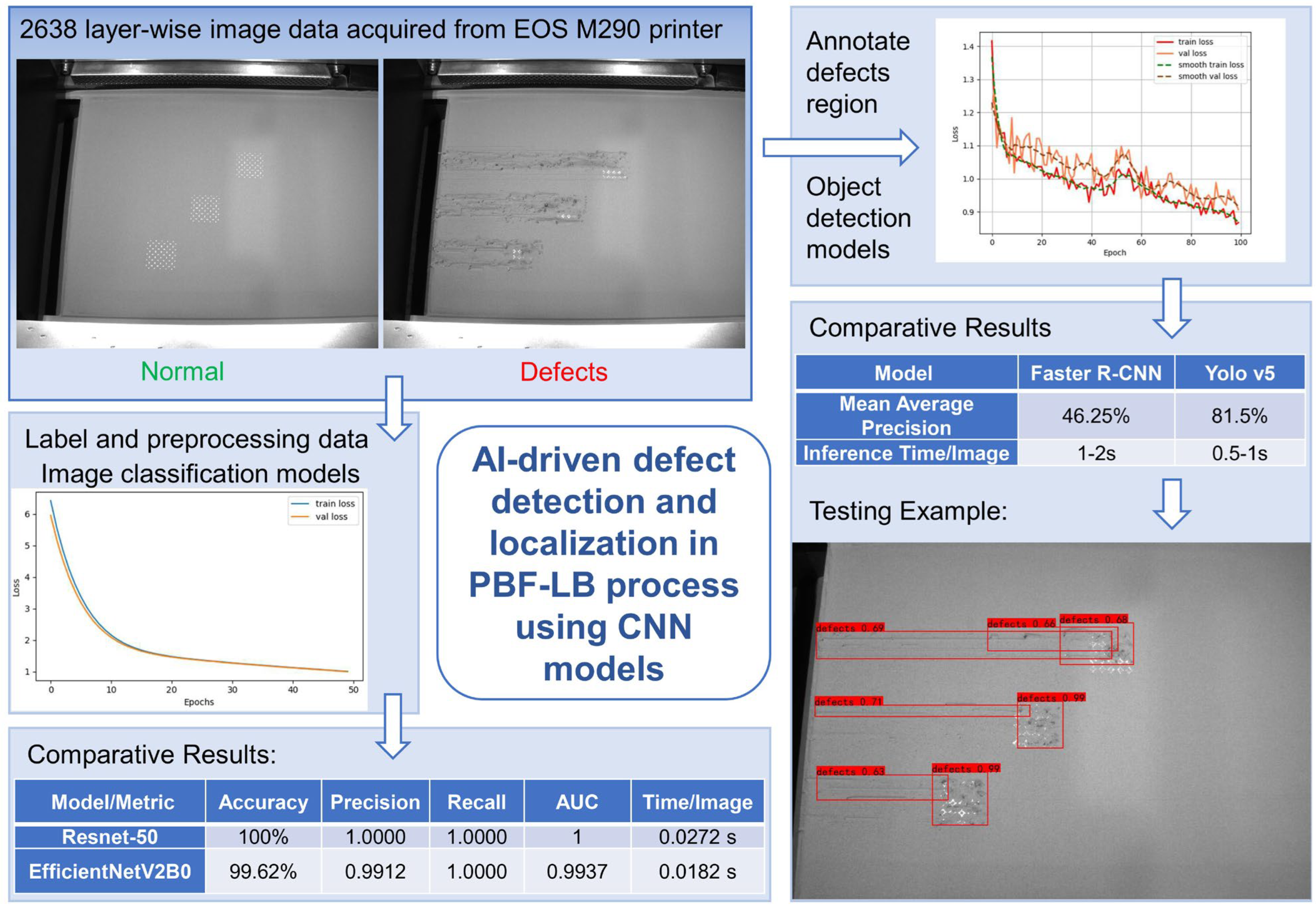

4.3. Defect Detection and Quality Assurance

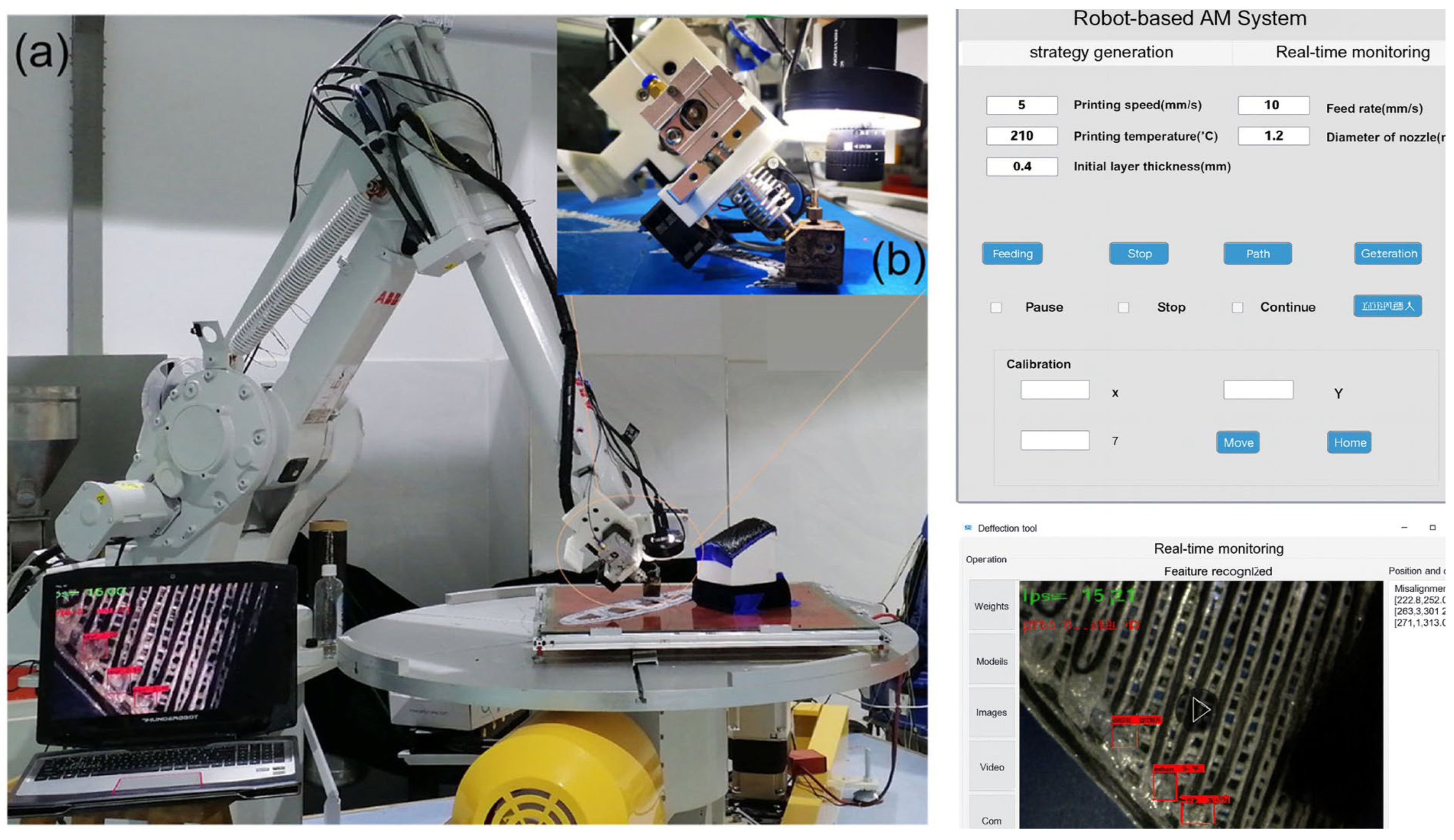

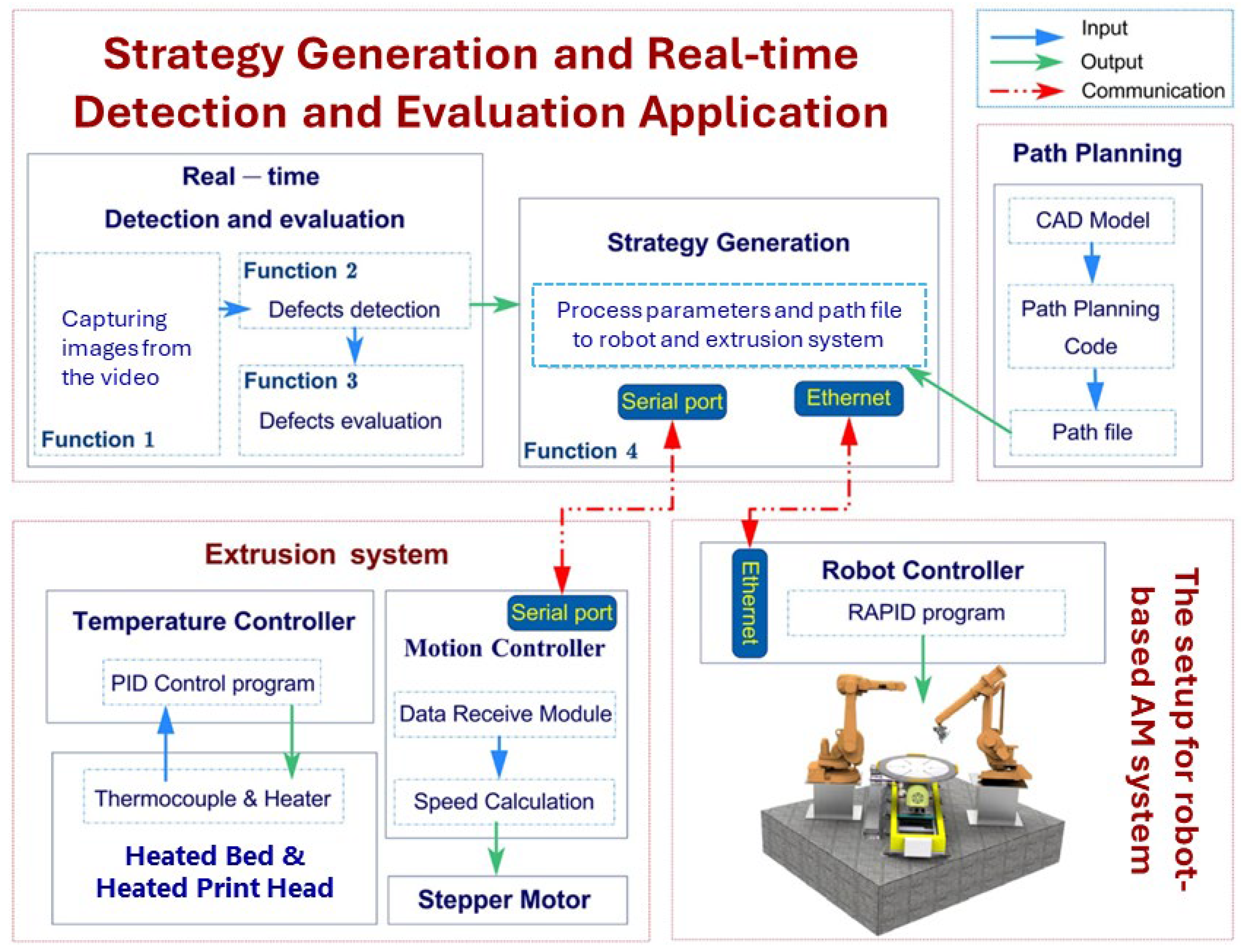

4.4. Automation in Design and AM Workflow

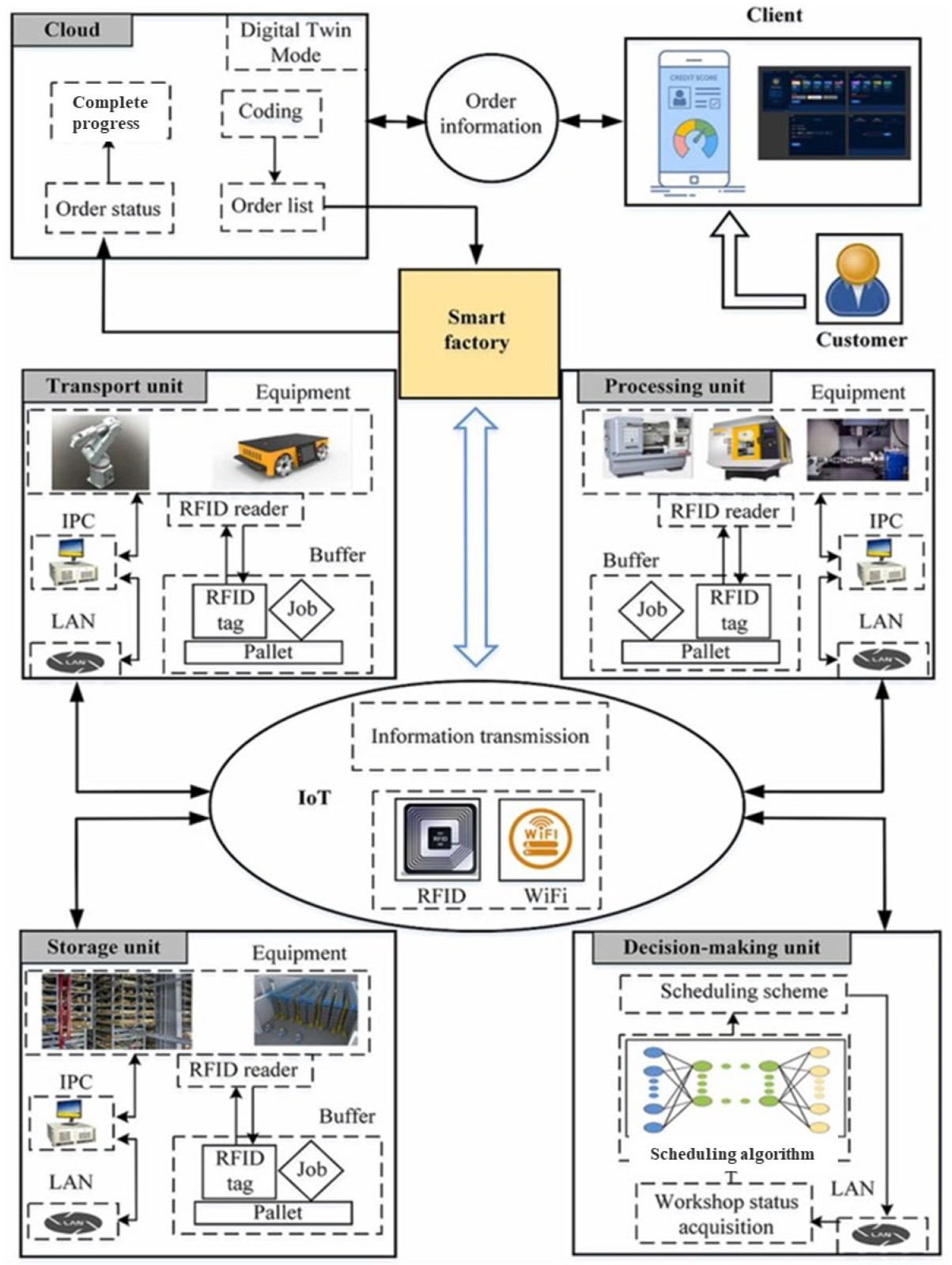

5. Smart Manufacturing Systems

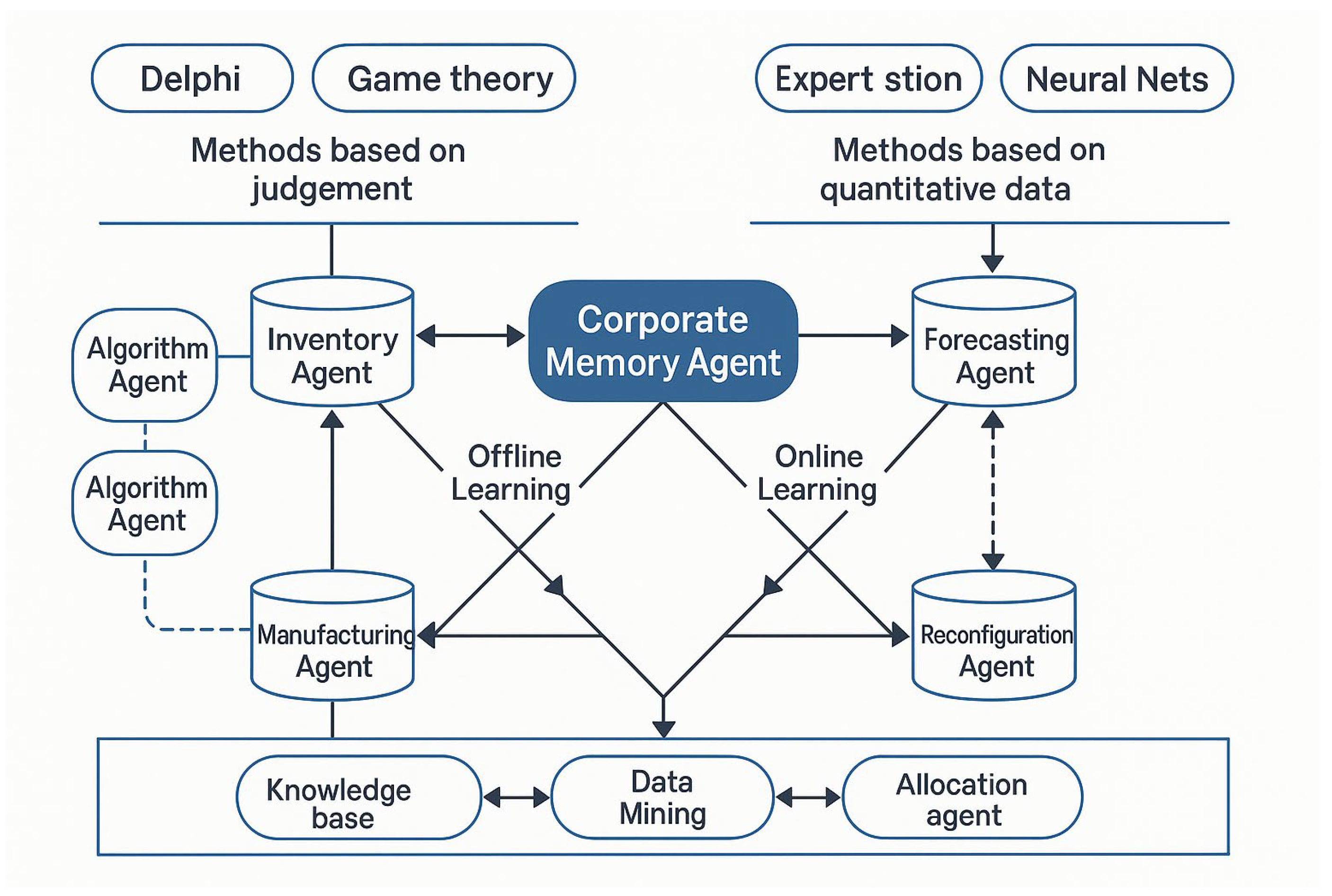

5.1. Development of Self-Learning, Self-Correcting Systems

5.2. Integration of AI with IoT and Digital Twins

5.3. Case Studies and Current Implementations

6. Industrial Impact and Future Potential

6.1. Aerospace

6.2. Healthcare

6.3. Construction

6.4. Consumer Products

7. Data Governance, Adaptability, and Standards

8. Conclusions

Funding

Conflicts of Interest

References

- Habib, M.A.; Subeshan, B.; Kalyanakumar, C.; Asmatulu, R.; Rahman, M.M.; Asmatulu, E. Current Practices in Recycling and Reusing of Aircraft Materials and Equipment. Mater. Circ. Econ. 2025, 7, 12. [Google Scholar] [CrossRef]

- Hamzat, A.K.; Murad, M.S.; Adediran, I.A.; Asmatulu, E.; Asmatulu, R. Fiber-reinforced composites for aerospace, energy, and marine applications: An insight into failure mechanisms under chemical, thermal, oxidative, and mechanical load conditions. Adv. Compos. Hybrid Mater. 2025, 8, 152. [Google Scholar] [CrossRef]

- Subeshan, B.; Atayo, A.; Asmatulu, E. Machine learning applications for electrospun nanofibers: A review. Mater. Sci. 2024, 59, 14095–14140. [Google Scholar] [CrossRef]

- Altun, F.; Altuntas, G.; Asmatulu, E.; Asmatulu, R. Additive Manufacturing of Ti-6Al-4V: Influence of Cryogenic and Stress-Relief Heat Treatments on Electrical Conductivity. In Proceedings of the 7th International Trakya Scientific Research Congress, Edirne, Türkiye, 28–29 August 2025; Trakya University: Edirne, Türkiye, 2025; pp. 219–226. [Google Scholar]

- Altun, F. Mechanical and Surface Properties of 3D-Printed Ti6Al4V Alloy Parts Fabricated by Selective Laser Melting Under Extreme Conditions. Master’s Thesis, Wichita State University, Wichita, KS, USA, 2025. [Google Scholar]

- Al’Aref, S.J. 3D Printing Applications in Cardiovascular Medicine; Elsevier: Amsterdam, The Netherlands, 2018. [Google Scholar]

- Thomas, D.J. Advanced active-gas 3D printing of 436 stainless steel for future rocket engine structure manufacture. J. Manuf. Process. 2022, 74, 256–265. [Google Scholar] [CrossRef]

- Boretti, A. A techno-economic perspective on 3D printing for aerospace propulsion. J. Manuf. Process. 2024, 109, 607–614. [Google Scholar] [CrossRef]

- Metal AM. The Convergence of Additive Manufacturing and Artificial Intelligence: Envisioning a Future That is Closer Than You Think; Metal AM: Shrewsbury, UK, 2023. [Google Scholar]

- Srivastava, M.; Aftab, J.; Tyll, L. The influence of artificial intelligence and additive manufacturing on sustainable manufacturing practices and their effect on performance. Sustain. Futures 2025, 10, 100820. [Google Scholar] [CrossRef]

- Wang, G.; Chen, Y.; An, P.; Hong, H.; Hu, J.; Huang, T. UAV-YOLOv8: A small-object-detection model based on improved YOLOv8 for UAV aerial photography scenarios. Sensors 2023, 23, 7190. [Google Scholar] [CrossRef]

- Thompson, M.K.; Moroni, G.; Vaneker, T.; Fadel, G.; Campbell, R.I.; Gibson, I.; Bernard, A.; Schulz, J.; Graf, P.; Ahuja, B.; et al. Design for Additive Manufacturing: Trends, opportunities, considerations, and constraints. CIRP Ann. 2016, 65, 737–760. [Google Scholar] [CrossRef]

- Lewandowski, J.J.; Seifi, M. Metal additive manufacturing: A review of mechanical properties. Annu. Rev. Mater. Res. 2016, 46, 151–186. [Google Scholar] [CrossRef]

- Yadollahi, A.; Shamsaei, N. Additive manufacturing of fatigue resistant materials: Challenges and opportunities. Int. J. Fatigue 2017, 98, 14–31. [Google Scholar] [CrossRef]

- Ngo, T.D.; Kashani, A.; Imbalzano, G.; Nguyen, K.T.Q.; Hui, D. Additive manufacturing (3D printing): A review of materials, methods, applications and challenges. Compos. Part B Eng. 2018, 143, 172–196. [Google Scholar] [CrossRef]

- Brillinger, M.; Pendl, K.A. Non newtonian material behaviour in extrusion based 3D printing: Investigation of critical process parameters. In Proceedings of the 6th World Congress on Mechanical, Chemical, and Material Engineering, Prague, Czech Republic, 16–18 August 2020; pp. 1–10. [Google Scholar]

- Freeman, S.; Calabro, S.; Williams, R.; Jin, S.; Ye, K. Bioink formulation and machine learning-empowered bioprinting optimization. Front. Bioeng. Biotechnol. 2022, 10, 913579. [Google Scholar] [CrossRef] [PubMed]

- Chen, H.; Liu, Y.; Balabani, S.; Hirayama, R.; Huang, J. Machine learning in predicting printable biomaterial formulations for direct ink writing. Research 2023, 6, 197. [Google Scholar] [CrossRef] [PubMed]

- Arriaga-Dávila, J.; Rosero-Arias, C.; Jonker, D.; Córdova-Castro, M.; Zscheile, J.; Kirchner, R.; Aguirre-Soto, A.; Boyd, R.; De Leon, I.; Gardeniers, H. From Single to Multi-Material 3D Printing of Glass-Ceramics for Micro-Optics. Small Methods 2025, 9, 2401809. [Google Scholar] [CrossRef]

- Yeshiwas, T.A.; Tiruneh, A.B.; Sisay, M.A. A review article on the assessment of additive manufacturing. J. Mater. Sci. Mater. Eng. 2025, 20, 85. [Google Scholar] [CrossRef]

- Zhou, L.; Miller, J.; Vezza, J.; Mayster, M.; Raffay, M.; Justice, Q.; Al Tamimi, Z.; Hansotte, G.; Sunkara, L.D.; Bernat, J. Additive manufacturing: A comprehensive review. Sensors 2024, 24, 2668. [Google Scholar] [CrossRef]

- Opoz, T.T.; Burgess, A.; Ahuir-Torres, J.I.; Kotadia, H.R.; Tammas-Williams, S. The effect of surface finish and post-processing on mechanical properties of 17-4 PH stainless steel produced by the atomic diffusion additive manufacturing process (ADAM). Int. J. Adv. Manuf. Technol. 2024, 130, 4053–4066. [Google Scholar] [CrossRef]

- Wang, W.; Wang, P.; Zhang, H.; Chen, X.; Wang, G.; Lu, Y.; Chen, M.; Liu, H.; Li, J. A real-time defect detection strategy for additive manufacturing processes based on deep learning and machine vision technologies. Micromachines 2023, 15, 28. [Google Scholar] [CrossRef]

- Sturm, L.D. Cyber-Physical Security for Additive Manufacturing Systems; Virginia Tech: Blacksburg, VA, USA, 2020. [Google Scholar]

- Yampolskiy, M.; Bates, P.; Seifi, M.; Shamsaei, N. State of Security Awareness in the Additive Manufacturing Industry: 2020 Survey. Prog. Addit. Manuf. 2022, 2021, 192–212. [Google Scholar] [CrossRef]

- Haque, A.N.M.A.; Naebe, M. Tensile properties of natural fibre-reinforced FDM filaments: A short review. Sustainability 2023, 15, 16580. [Google Scholar] [CrossRef]

- Kennedy, S.M.; Wilson, L.A.; Rb, J.R. Natural fiber filaments transforming the future of sustainable 3D printing. MethodsX 2025, 14, 103385. [Google Scholar] [CrossRef] [PubMed]

- Hassan, M.; Misra, M.; Taylor, G.W.; Mohanty, A.K. A review of AI for optimization of 3D printing of sustainable polymers and composites. Compos. Part C Open Access 2024, 15, 100513. [Google Scholar] [CrossRef]

- Hamzat, A.K.; Salman, U.T.; Murad, M.S.; Altay, O.; Bahceci, E.; Asmatulu, E.; Bakir, M.; Asmatulu, R. Development of robust machine learning models for predicting flexural strengths of fiber-reinforced polymeric composites. Hybrid Adv. 2025, 8, 100385. [Google Scholar] [CrossRef]

- Sun, H.-B.; Kawata, S. Two-Photon Photopolymerization and 3D Lithographic Microfabrication. In NMR—3D Analysis—Photopolymerization; Springer: Berlin/Heidelberg, Germany, 2004; Volume 170, pp. 169–273. [Google Scholar] [CrossRef]

- Johnson, J.E.; Jamil, I.R.; Pan, L.; Lin, G.; Xu, X. Bayesian optimization with Gaussian-process-based active machine learning for improvement of geometric accuracy in projection multi-photon 3D printing. Light. Sci. Appl. 2025, 14, 56. [Google Scholar] [CrossRef]

- Panico, A.; Corvi, A.; Collini, L.; Sciancalepore, C. Multi objective optimization of FDM 3D printing parameters set via design of experiments and machine learning algorithms. Sci. Rep. 2025, 15, 16753. [Google Scholar] [CrossRef]

- Piovarci, M.; Foshey, M.; Xu, J.; Erps, T.; Babaei, V.; Didyk, P.; Rusinkiewicz, S.; Matusik, W.; Bickel, B. Closed-loop control of direct ink writing via reinforcement learning. arXiv 2022, arXiv:2201.11819. [Google Scholar] [CrossRef]

- Hunt, K.A.; Ebel, A.B.; Rose, E.S.; Zylich, S.C.; Jensen, B.D.; Wise, K.E.; Siochi, E.J.; Gardner, J.M.; Sauti, G. Machine Learning to Increase the Quality and Repeatability of 3D Printing-Workflow; NASA STI: Washington, DC, USA, 2023. [Google Scholar]

- Garboczi, E.; Henry, T.; Phillips, F.; Cole, D.; Haynes, R.; Johnson, T. In situ fatigue monitoring investigation of additively manufactured maraging steel. Int. J. Adv. Manuf. Technol. 2020, 107, 3499–3510. [Google Scholar] [CrossRef]

- Biswas, K.; Rose, J.; Eikevik, L.; Guerguis, M.; Enquist, P.; Lee, B.; Love, L.; Green, J.; Jackson, R. Additive manufacturing integrated energy—Enabling innovative solutions for buildings of the future. J. Sol. Energy Eng. 2017, 139, 015001. [Google Scholar] [CrossRef]

- Rojek, I.; Mikołajewski, D.; Macko, M.; Szczepański, Z.; Dostatni, E. Optimization of extrusion-based 3D printing process using neural networks for sustainable development. Materials 2021, 14, 2737. [Google Scholar] [CrossRef]

- Kadauw, A.A.A. Neural Network Optimization of Mechanical Properties of ABS-like Photopolymer Utilizing Stereolithography (SLA) 3D Printing. J. Manuf. Mater. Process. 2025, 9, 116. [Google Scholar] [CrossRef]

- Zhang, Z.; Mativenga, P.; Zhang, W.; Huang, S. Deep Learning-Driven Prediction of Mechanical Properties of 316L Stainless Steel Metallographic by Laser Powder Bed Fusion. Micromachines 2024, 15, 1167. [Google Scholar] [CrossRef]

- Hespeler, S.; Dehghan-Niri, E.; Juhasz, M.; Luo, K.; Halliday, H.S. Deep learning for in-situ layer quality monitoring during laser-based directed energy deposition (LB-DED) additive manufacturing process. Appl. Sci. 2022, 12, 8974. [Google Scholar] [CrossRef]

- Brion, D.A.J.; Pattinson, S.W. Generalisable 3D printing error detection and correction via multi-head neural networks. Nat. Commun. 2022, 13, 4654. [Google Scholar] [CrossRef] [PubMed]

- Mieszczanek, P.; Corke, P.; Mehanian, C.; Dalton, P.D.; Hutmacher, D.W. Towards industry-ready additive manufacturing: AI-enabled closed-loop control for 3D melt electrowriting. Commun. Eng. 2024, 3, 158. [Google Scholar] [CrossRef] [PubMed]

- Felbrich, B.; Schork, T.; Menges, A. Autonomous robotic additive manufacturing through distributed model-free deep reinforcement learning in computational design environments. Constr. Robot. 2022, 6, 15–37. [Google Scholar] [CrossRef] [PubMed]

- Ganitano, G.S.; Wallace, S.G.; Maruyama, B.; Peterson, G.L. A hybrid metaheuristic and computer vision approach to closed-loop calibration of fused deposition modeling 3D printers. Prog. Addit. Manuf. 2024, 9, 767–777. [Google Scholar] [CrossRef]

- Akbari, P.; Ogoke, F.; Kao, N.-Y.; Meidani, K.; Yeh, C.-Y.; Lee, W.; Farimani, A.B. MeltpoolNet: Melt pool characteristic prediction in Metal Additive Manufacturing using machine learning. Addit. Manuf. 2022, 55, 102817. [Google Scholar] [CrossRef]

- Dharmadhikari, S.; Menon, N.; Basak, A. A Reinforcement Learning Approach for Process Parameter Optimization in Additive Manufacturing. arXiv 2022, arXiv:2211.09545. [Google Scholar] [CrossRef]

- Sun, M.; Ding, J.; Zhao, Z.; Chen, J.; Huang, G.Q.; Wang, L. Out-of-order execution enabled deep reinforcement learning for dynamic additive manufacturing scheduling. Robot. Comput. Integr. Manuf. 2025, 91, 102841. [Google Scholar] [CrossRef]

- Fabbaloo. Ai Build’s AiSync: A GPT-4 Powered AI Copilot for 3D Printing. Available online: https://www.fabbaloo.com/news/ai-builds-natural-language-processing-in-3d-printing-software (accessed on 24 September 2025).

- Faruqi, F.; Katary, A.; Hasic, T.; Abdel-Rahman, A.; Rahman, N.; Tejedor, L.; Leake, M.; Hofmann, M.; Mueller, S. Style2Fab: Functionality-Aware Segmentation for Fabricating Personalized 3D Models with Generative AI. In Proceedings of the 36th Annual ACM Symposium on User Interface Software and Technology, San Francisco, CA, USA, 29 October–1 November 2023; ACM: New York, NY, USA, 2023; pp. 1–13. [Google Scholar] [CrossRef]

- Rosenberger, J.E. Simplifying 3D Printing Using Natural Language Processing. Bachelor’s Thesis, Bellarmine University, Louisville, KY, USA, 2025. [Google Scholar]

- Jasche, F.; Weber, P.; Liu, S.; Ludwig, T. PrintAssist—A conversational human-machine interface for 3D printers. I-Com 2023, 22, 3–17. [Google Scholar] [CrossRef]

- Jadhav, Y.; Pak, P.; Farimani, A.B. Llm-3D print: Large language models to monitor and control 3D printing. arXiv 2024, arXiv:2408.14307. [Google Scholar] [CrossRef]

- Lee, J.A.; Park, J.; Sagong, M.J.; Ahn, S.Y.; Cho, J.-W.; Lee, S.; Kim, H.S. Active learning framework to optimize process parameters for additive-manufactured Ti-6Al-4V with high strength and ductility. Nat. Commun. 2025, 16, 931. [Google Scholar] [CrossRef] [PubMed]

- Herzog, T.; Brandt, M.; Trinchi, A.; Sola, A.; Molotnikov, A. Process monitoring and machine learning for defect detection in laser-based metal additive manufacturing. J. Intell. Manuf. 2024, 35, 1407–1437. [Google Scholar] [CrossRef]

- Yin, X.; Akmal, J.; Salmi, M. Artificial intelligence-driven defect detection and localization in metal 3D printing using convolutional neural networks. Mater. Sci. Addit. Manuf. 2025, 4, 025150022. [Google Scholar] [CrossRef]

- Dritsas, E.; Trigka, M. Exploring the Intersection of Machine Learning and Big Data: A Survey. Mach. Learn. Knowl. Extr. 2025, 7, 13. [Google Scholar] [CrossRef]

- Koul, P. A Review of Generative Design Using Machine Learning for Additive Manufacturing. Adv. Mech. Mater. Eng. 2024, 41, 145–159. [Google Scholar] [CrossRef]

- Khan, A.A.; Chaudhari, O.; Chandra, R. A review of ensemble learning and data augmentation models for class imbalanced problems: Combination, implementation and evaluation. Expert Syst. Appl. 2024, 244, 122778. [Google Scholar] [CrossRef]

- Xie, X.; Bennett, J.; Saha, S.; Lu, Y.; Cao, J.; Liu, W.K.; Gan, Z. Mechanistic data-driven prediction of as-built mechanical properties in metal additive manufacturing. NPJ Comput. Mater. 2021, 7, 86. [Google Scholar] [CrossRef]

- Ziadia, A.; Habibi, M.; Kelouwani, S. Machine Learning Study of the Effect of Process Parameters on Tensile Strength of FFF PLA and PLA-CF. Eng 2023, 4, 2741–2763. [Google Scholar] [CrossRef]

- Alldredge, J.; Slotwinski, J.; Storck, S.; Kim, S.; Goldberg, A.; Montalbano, T. In-Situ monitoring and modeling of metal additive manufacturing powder bed fusion. AIP Conf. Proc. 2018, 1949, 020007. [Google Scholar] [CrossRef]

- Yuan, C.; Moghaddam, M. Attribute-Aware Generative Design With Generative Adversarial Networks. IEEE Access 2020, 8, 190710–190721. [Google Scholar] [CrossRef]

- Kwon, O.; Kim, H.G.; Ham, M.J.; Kim, W.; Kim, G.-H.; Cho, J.-H.; Kim, N.I.; Kim, K. A deep neural network for classification of melt-pool images in metal additive manufacturing. J. Intell. Manuf. 2020, 31, 375–386. [Google Scholar] [CrossRef]

- DebRoy, T.; Wei, H.L.; Zuback, J.S.; Mukherjee, T.; Elmer, J.W.; Milewski, J.O.; Beese, A.M.; Wilson-Heid, A.; De, A.; Zhang, W. Additive manufacturing of metallic components—Process, structure and properties. Prog. Mater. Sci. 2018, 92, 112–224. [Google Scholar] [CrossRef]

- Gu, S.; Choi, M.; Park, H.; Jeong, S.; Doh, J.; Park, S. Application of artificial intelligence in additive manufacturing. JMST Adv. 2023, 5, 93–104. [Google Scholar] [CrossRef]

- Everton, S.K.; Hirsch, M.; Stravroulakis, P.; Leach, R.K.; Clare, A.T. Review of in-situ process monitoring and in-situ metrology for metal additive manufacturing. Mater. Des. 2016, 95, 431–445. [Google Scholar] [CrossRef]

- Chen, L.; Yao, X.; Chew, Y.; Weng, F.; Moon, S.K.; Bi, G. Data-driven adaptive control for laser-based additive manufacturing with automatic controller tuning. Appl. Sci. 2020, 10, 7967. [Google Scholar] [CrossRef]

- Narayana, P.L.; Kim, J.H.; Lee, J.; Choi, S.W.; Lee, S.; Park, C.H.; Yeom, J.T.; Reddy, N.G.S.; Hong, J.K. Optimization of process parameters for direct energy deposited Ti-6Al-4V alloy using neural networks. Int. J. Adv. Manuf. Technol. 2021, 114, 3269–3283. [Google Scholar] [CrossRef]

- Mezaache, M.; Babes, B.; Chaouch, S. Optimization of Welding Input Parameters Using PSO Technique for Minimizing HAZ Width in GMAW. Period. Polytech. Mech. Eng. 2022, 66, 99–108. [Google Scholar] [CrossRef]

- Wang, C.; Tan, X.P.; Tor, S.B.; Lim, C.S. Machine learning in additive manufacturing: State-of-the-art and perspectives. Addit. Manuf. 2020, 36, 101538. [Google Scholar] [CrossRef]

- Kats, D.; Wang, Z.; Gan, Z.; Liu, W.; Wagner, G.; Lian, Y. A physics-informed machine learning method for predicting grain structure characteristics in directed energy deposition. Comput. Mater. Sci. 2022, 202, 110958. [Google Scholar] [CrossRef]

- Zhang, X.; Kuang, X.; Wang, F.; Wang, S. Strength indices and conversion relations for basalt fiber-reinforced recycled aggregate concrete. DYNA 2019, 94, 82–87. [Google Scholar] [CrossRef]

- Lv, N.; Xu, Y.; Li, S.; Yu, X.; Chen, S. Automated control of welding penetration based on audio sensing technology. J. Mater. Process. Technol. 2017, 250, 81–98. [Google Scholar] [CrossRef]

- Mu, H.; Pan, Z.; Li, Y.; He, F.; Polden, J.; Xia, C. MIMO Model Predictive Control of Bead Geometry in Wire Arc Additive Manufacturing. In Proceedings of the 2021 IEEE 11th Annual International Conference on CYBER Technology in Automation, Control, and Intelligent Systems (CYBER), Jiaxing, China, 27–31 July 2021; pp. 169–174. [Google Scholar] [CrossRef]

- Scime, L.; Beuth, J. Anomaly detection and classification in a laser powder bed additive manufacturing process using a trained computer vision algorithm. Addit. Manuf. 2018, 19, 114–126. [Google Scholar] [CrossRef]

- Djenouri, Y.; Srivastava, G.; Lin, J. Applied AI in Defect Detection for Additive Manufacturing: Current Literature, Metrics, Datasets, and Open Challenges. IEEE Instrum. Meas. Mag. 2024, 27, 46–53. [Google Scholar] [CrossRef]

- Fu, Y.; Whetham, M.; Downey, A.R.J.; Yuan, L.; Comert, G. A study of online melt pool, plume, and spatter tracking in laser powder bed fusion using DBSCAN. In Digital Twins, AI, and NDE for Industry Applications and Energy Systems 2025; Niezrecki, C., Farhangdoust, S., Eds.; SPIE: Vancouver, BC, Canada, 2025; p. 21. [Google Scholar] [CrossRef]

- Chowdhury, S.; Tschopp, M.; Doude, H.; Marufuzzaman, M.; Bian, L. In-Situ Monitoring of Melt Pool Images for Porosity Prediction in Directed Energy Deposition Processes. IISE Trans. 2017, 51, 437–455. [Google Scholar] [CrossRef]

- Nele, L.; Mattera, G.; Vozza, M. Deep Neural Networks for Defects Detection in Gas Metal Arc Welding. Appl. Sci. Switz. 2022, 12, 3615. [Google Scholar] [CrossRef]

- Pan, H.; Pang, Z.; Wang, Y.; Wang, Y.; Chen, L. A New Image Recognition and Classification Method Combining Transfer Learning Algorithm and MobileNet Model for Welding Defects. IEEE Access 2020, 8, 119951–119960. [Google Scholar] [CrossRef]

- Trivedi, C.; Bhattacharya, P.; Prasad, V.K.; Patel, V.; Singh, A.; Tanwar, S.; Sharma, R.; Aluvala, S.; Pau, G.; Sharma, G. Explainable AI for industry 5.0: Vision, architecture, and potential directions. IEEE Open J. Ind. Appl. 2024, 5, 177–208. [Google Scholar] [CrossRef]

- Soori, M.; Jough, F.K.G.; Dastres, R.; Arezoo, B. Additive manufacturing modification by artificial intelligence, machine learning, and deep learning: A review. Addit. Manuf. Front. 2025, 4, 200198. [Google Scholar] [CrossRef]

- Erboz, G. How To Define Industry 4.0: Main Pillars Of Industry 4.0. In Proceedings of the 7th International Scientific Conference on Managerial Trends in the Development of Enter Prises in Globalization Era (ICoM)—Managerial Trends in the Development of Enterprises in Globalization Era, Nitra, Slovakia, 1–2 June 2017; pp. 761–767. [Google Scholar]

- Jasperneite, J.; Sauter, T.; Wollschlaeger, M. Why we need automation models: Handling complexity in industry 4.0 and the internet of things. IEEE Ind. Electron. Mag. 2020, 14, 29–40. [Google Scholar] [CrossRef]

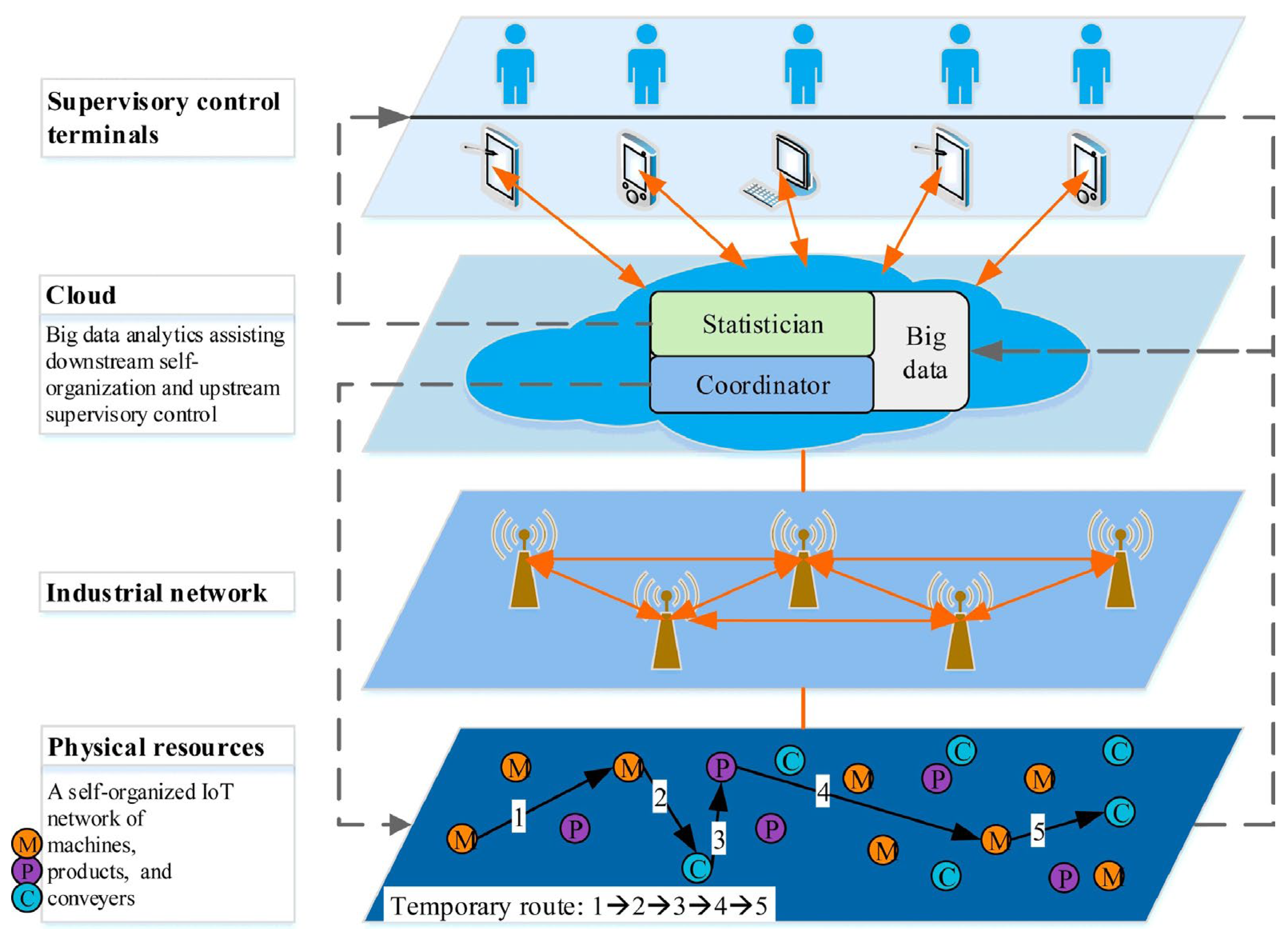

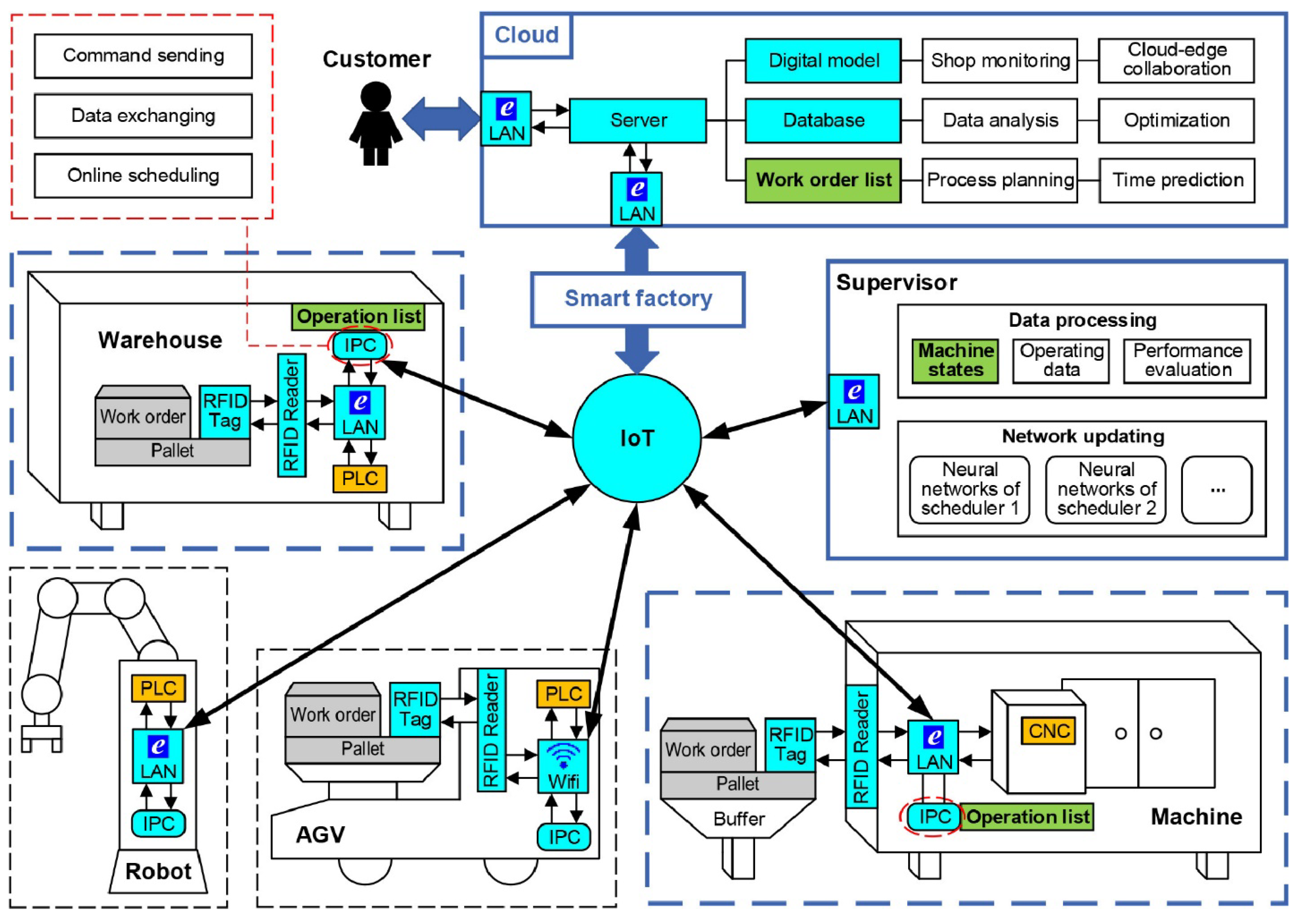

- Zheng, P.; Wang, H.; Sang, Z.; Zhong, R.Y.; Liu, Y.; Liu, C.; Mubarok, K.; Yu, S.; Xu, X. Smart manufacturing systems for Industry 4.0: Conceptual framework, scenarios, and future perspectives. Front. Mech. Eng. 2018, 13, 137–150. [Google Scholar] [CrossRef]

- Chen, B.; Wan, J.; Shu, L.; Li, P.; Mukherjee, M.; Yin, B. Smart factory of industry 4.0: Key technologies, application case, and challenges. IEEE Access 2017, 6, 6505–6519. [Google Scholar] [CrossRef]

- Zhong, R.Y.; Xu, X.; Klotz, E.; Newman, S.T. Intelligent manufacturing in the context of industry 4.0: A review. Engineering 2017, 3, 616–630. [Google Scholar] [CrossRef]

- Kusiak, A. Smart manufacturing. Int. J. Prod. Res. 2018, 56, 508–517. [Google Scholar] [CrossRef]

- Didaskalou, E.; Manesiotis, P.; Georgakellos, D. Smart Manufacturing and Industry 4.0: A preliminary approach in structuring a conceptual framework. WSEAS Trans. Adv. Eng. Educ. 2021, 18, 27–36. [Google Scholar] [CrossRef]

- Çınar, Z.M.; Zeeshan, Q.; Korhan, O. A framework for industry 4.0 readiness and maturity of smart manufacturing enterprises: A case study. Sustainability 2021, 13, 6659. [Google Scholar] [CrossRef]

- Valaskova, K.; Nagy, M.; Zabojnik, S.; Lăzăroiu, G. Industry 4.0 wireless networks and cyber-physical smart manufacturing systems as accelerators of value-added growth in Slovak exports. Mathematics 2022, 10, 2452. [Google Scholar] [CrossRef]

- Resman, M.; Pipan, M.; Šimic, M.; Herakovič, N. A new architecture model for smart manufacturing: A performance analysis and comparison with the RAMI 4.0 reference model. Adv. Prod. Eng. Manag. 2019, 14, 153–165. [Google Scholar] [CrossRef]

- Qi, Q.; Tao, F. Digital twin and big data towards smart manufacturing and industry 4.0: 360 degree comparison. IEEE Access 2018, 6, 3585–3593. [Google Scholar] [CrossRef]

- Xu, J.; Kovatsch, M.; Mattern, D.; Mazza, F.; Harasic, M.; Paschke, A.; Lucia, S. A review on AI for smart manufacturing: Deep learning challenges and solutions. Appl. Sci. 2022, 12, 8239. [Google Scholar] [CrossRef]

- Lăzăroiu, G.; Andronie, M.; Iatagan, M.; Geamănu, M.; Ștefănescu, R.; Dijmărescu, I. Deep learning-assisted smart process planning, robotic wireless sensor networks, and geospatial big data management algorithms in the internet of manufacturing things. ISPRS Int. J. Geo Inf. 2022, 11, 277. [Google Scholar] [CrossRef]

- Visconti, P.; Rausa, G.; Del-Valle-Soto, C.; Velázquez, R.; Cafagna, D.; De Fazio, R. Machine learning and IoT-based solutions in industrial applications for Smart Manufacturing: A critical review. Future Internet 2024, 16, 394. [Google Scholar] [CrossRef]

- Frankó, A.; Hollósi, G.; Ficzere, D.; Varga, P. Applied machine learning for IIOT and smart production—Methods to improve production quality, safety and sustainability. Sensors 2022, 22, 9148. [Google Scholar] [CrossRef] [PubMed]

- Iqbal, A.; Dar, N.U.; He, N.; Hammouda, M.M.I.; Li, L. Self-developing fuzzy expert system: A novel learning approach, fitting for manufacturing domain. J. Intell. Manuf. 2010, 21, 761–776. [Google Scholar] [CrossRef]

- Kumar, V.; Mishra, N. A multi-agent self correcting architecture for distributed manufacturing supply chain. IEEE Syst. J. 2011, 5, 6–15. [Google Scholar] [CrossRef]

- Henke, M.; Besenfelder, C.; Kaczmarek, S.; Fiolka, M. A Vision of Digitalization in Supply Chain Management and Logistics; Hannover House: Fayetteville, AR, USA, 2020. [Google Scholar]

- Vaidya, S.; Ambad, P.; Bhosle, S. Industry 4.0–A glimpse. Procedia Manuf. 2018, 20, 233–238. [Google Scholar] [CrossRef]

- Vogel-Heuser, B.; Hess, D. Guest editorial Industry 4.0–prerequisites and visions. IEEE Trans. Autom. Sci. Eng. 2016, 13, 411–413. [Google Scholar] [CrossRef]

- Tomiyama, T.; Lutters, E.; Stark, R.; Abramovici, M. Development capabilities for smart products. CIRP Ann. 2019, 68, 727–750. [Google Scholar] [CrossRef]

- Lu, L.; Hou, J.; Yuan, S.; Yao, X.; Li, Y.; Zhu, J. Deep learning-assisted real-time defect detection and closed-loop adjustment for additive manufacturing of continuous fiber-reinforced polymer composites. Robot. Comput. Integr. Manuf. 2023, 79, 102431. [Google Scholar] [CrossRef]

- Kong, L.; Peng, X.; Chen, Y.; Wang, P.; Xu, M. Multi-sensor measurement and data fusion technology for manufacturing process monitoring: A literature review. Int. J. Extrem. Manuf. 2020, 2, 22001. [Google Scholar] [CrossRef]

- Garcia Plaza, E.; Nunez Lopez, P.J.; Beamud Gonzalez, E.M. Multi-sensor data fusion for real-time surface quality control in automated machining systems. Sensors 2018, 18, 4381. [Google Scholar] [CrossRef]

- Zhang, Z.; Liu, Q.; Wu, D. Predicting stress–strain curves using transfer learning: Knowledge transfer across polymer composites. Mater. Des. 2022, 218, 110700. [Google Scholar] [CrossRef]

- Gim, J.; Yang, H.; Turng, L.-S. Transfer learning of machine learning models for multi-objective process optimization of a transferred mold to ensure efficient and robust injection molding of high surface quality parts. J. Manuf. Process. 2023, 87, 11–24. [Google Scholar] [CrossRef]

- Lockner, Y.; Hopmann, C.; Zhao, W. Transfer learning with artificial neural networks between injection molding processes and different polymer materials. J. Manuf. Process. 2022, 73, 395–408. [Google Scholar] [CrossRef]

- Murugaiyan, S.; Maranco, M.; Krishnaraj, N.; Reddy, U.S. Data Analytics and Visualization in Smart Manufacturing Using AI-based Digital Twins. In Artificial Intelligence-Enabled Digital Twin for Smart Manufacturing; Wiley: Hoboken, NJ, USA, 2024; pp. 240–268. [Google Scholar] [CrossRef]

- Boltaboyeva, A.; Baigarayeva, Z.; Postolache, O.; Mansurova, M.; Karymssakova, N.; Belgibayev, B. Smart sensors and IoT applied in Digital Twin for Industry 4.0. In Proceedings of the 2024 International Symposium on Sensing and Instrumentation in 5G and IoT Era (ISSI), Lagoa, Portugal, 29–30 August 2024; IEEE: New York, NY, USA, 2024; Volume 1, pp. 1–6. [Google Scholar]

- Tyagi, A.K.; Richa, R. Smart manufacturing using internet of things, artificial intelligence, and digital twin technology. In Global Perspectives on Robotics and Autonomous Systems: Development and Applications; IGI Global: Hershey, PA, USA, 2023; pp. 184–205. [Google Scholar]

- Dmitrieva, E.; Krishna, G.; Chhabra, S.; Pavithra, A.; Sharma, K. IoT and AI integration: An experiment on smart manufacturing efficiency in industry 5.0. BIO Web Conf. 2024, 86, 1062. [Google Scholar] [CrossRef]

- Tyagi, A.K.; Tiwari, S.; Arumugam, S.K.; Sharma, A.K. Artificial Intelligence-Enabled Digital Twin for Smart Manufacturing; John Wiley & Sons: Hoboken, NJ, USA, 2024. [Google Scholar]

- Lavanya, R.; Bhavani, G.; Santhiya, C.; Chakkaravarthy, G.V.; Kumar, P. Digital Twins and IoT for Sustainable Manufacturing: A Survey of Current Practices and Future Directions. In Handbook of Intelligent and Sustainable Manufacturing; CRC Press: Boca Raton, FL, USA, 2024; pp. 80–94. [Google Scholar]

- Rajendran, S.; Palani, G.; Sanjeevi, S.; Veerasimman, A.; Trilaksana, H.; Sundaram, V.; Marimuthu, U.; Yang, Y.-L.; Shanmugam, V. A review on AI integration with FDM printing to enhance precision, efficiency, and process optimization. J. Reinf. Plast. Compos. 2024, 07316844251358587. [Google Scholar] [CrossRef]

- Gu, W.; Liu, S.; Zhang, Z.; Li, Y. A distributed physical architecture and data-based scheduling method for smart factory based on intelligent agents. J. Manuf. Syst. 2022, 65, 785–801. [Google Scholar] [CrossRef]

- Wang, S.; Wan, J.; Zhang, D.; Li, D.; Zhang, C. Towards smart factory for industry 4.0: A self-organized multi-agent system with big data based feedback and coordination. Comput. Netw. 2016, 101, 158–168. [Google Scholar] [CrossRef]

- Psarommatis, F.; May, G.; Dreyfus, P.-A.; Kiritsis, D. Zero defect manufacturing: State-of-the-art review, shortcomings and future directions in research. Int. J. Prod. Res. 2020, 58, 1–17. [Google Scholar] [CrossRef]

- Boubaker, N.E.H.; Zarour, K.; Guermouche, N.; Benmerzoug, D. A Comprehensive Survey on Resource Management for IoT Applications in Edge-Fog-Cloud Environments. IEEE Access 2025, 13, 111892–111925. [Google Scholar] [CrossRef]

- Wang, J.; Ma, Y.; Zhang, L.; Gao, R.X.; Wu, D. Deep learning for smart manufacturing: Methods and applications. J. Manuf. Syst. 2018, 48, 144–156. [Google Scholar] [CrossRef]

- Sjödin, D.R.; Parida, V.; Leksell, M.; Petrovic, A. Smart Factory Implementation and Process Innovation: A Preliminary Maturity Model for Leveraging Digitalization in Manufacturing Moving to smart factories presents specific challenges that can be addressed through a structured approach focused on people, processes, and technologies. Res. Technol. Manag. 2018, 61, 22–31. [Google Scholar] [CrossRef]

- Shin, S.-J. A Hybrid Learning-based Predictive Process Planning Mechanism for Cyber-Physical Production Systems. J. Korean Soc. Precis. Eng. 2019, 36, 391–400. [Google Scholar] [CrossRef]

- Martínez-Mireles, J.R.; Rodríguez-Flores, J.; García-Márquez, M.A.; Austria-Cornejo, A.; Figueroa-Diaz, R.A. AI in Smart Manufacturing. In Machine and Deep Learning Solutions for Achieving the Sustainable Development Goals; IGI Global Scientific Publishing: Hershey, PA, USA, 2025; pp. 463–494. [Google Scholar]

- Gao, W.; Zhang, Y.; Ramanujan, D.; Ramani, K.; Chen, Y.; Williams, C.B.; Wang, C.C.L.; Shin, Y.C.; Zhang, S.; Zavattieri, P.D. The status, challenges, and future of additive manufacturing in engineering. CAD Comput. Aided Des. 2015, 69, 65–89. [Google Scholar] [CrossRef]

- 3DNatives. Using AI and 3D Printing to Design a Better Rocket Engine; 3DNatives: Paris, France, 2024. [Google Scholar]

- Envision Tech. 3D Printing for Aerospace; EnvisionTech: Oslo, Norway, 2025. [Google Scholar]

- Materialise. Healthcare. 2020. Available online: https://www.materialise.com/en/academy/healthcare (accessed on 24 September 2025).

- Presnell, S. Use of Bioprinted 3D Human Tissues for the Assessment of Drug Toxicity; Organovo: San Diego, CA, USA, 2022. [Google Scholar]

- Carbon3D. Beyond the Status Quo for Whole Mouth Removable Restorations; Carbon3D: Redwood City, CA, USA, 2021. [Google Scholar]

- Apis Cor. Construction with Robotic Precision; Apis Cor: Melbourne, FL, USA, 2022. [Google Scholar]

- NASA. 3D-Printed Habitat Challenge (2015–2019); NASA: Washington, DC, USA, 2020. [Google Scholar]

- IKEA. IKEA in Collaboration with UNYQ and Area Academy; IKEA: Delft, The Netherlands, 2018. [Google Scholar]

- Formlabs. Gillette Stays Ahead of the Competition by Using 3D Printing to Unlock Consumer Personalization. 2018. Available online: https://formlabs.com/global/blog/gillette-uses-3d-printing-to-unlock-consumer-personalization/?srsltid=AfmBOoo4YRL7isZS1TZuJUPhgmHR7Owtcy9qsATJ7w4SmJtv1-a_MVO_ (accessed on 24 September 2025).

- ISO/ASTM 52904:2024; Additive Manufacturing of Metals—Process Characteristics and Performance—Metal Powder Bed Fusion Process to Meet Critical Applications. International Organization for Standardization: Geneva, Switzerland, 2024.

| Application Area | AI Methods/Models | Key References | Purpose/Functionality | Benefits/Outcomes |

|---|---|---|---|---|

| Real-Time Process Optimization | Reinforcement learning (RL), feed-forward ANN, and Gaussian-process active learning | Dharmadhikari et al., Lee et al., and Rojek et al. [37,46,53] | Dynamically adjust laser power, scan speed, layer thickness, and extrusion rates during printing | Minimizes defects, reduces material waste, improves part quality, and enhances process efficiency |

| Material Behavior Prediction | ANN, SVM, Random Forest, CNN, MechProNet, Hybrid Mechanistic-Data Driven Models | Akbari et al., Xie et al., and Ziadia et al. [45,59,60] | Predict mechanical, thermal, and flow properties of metals and polymers | Speeds up material selection, reduces trial-and-error, improves accuracy and reproducibility, and optimizes mechanical performance |

| Defect Detection and Quality Assurance | CNNs (ResNet, EfficientNet), YOLOv5, and SVM | Yin et al., Herzog et al., and Alldredge et al. [54,55,61] | Detect porosity, cracks, delamination, and warping in real time | Early fault detection, minimizes scrap, improves reliability, and enables certification-critical applications |

| Automation in Design and Workflow | Generative design algorithms, GANs (DA-GAN), GPT-like models, and ANN | Koul, Yuan, and Moghaddam, Dritsas and Trigka [56,57,62] | Automate topology optimization, slicing, and design generation; create innovative structures | Reduces design time, improves structural performance, and enables highly customized and complex designs |

| Vision-Based Monitoring | CNNs, deep learning, and YOLO | Kwon et al. and Yin et al [55,63] | Real-time image analysis for melt-pool or powder bed monitoring | Accurate defect localization, continuous process monitoring, and adaptive feedback control |

| Predictive Analytics and Parameter Optimization | ANN, SVM, k-NN, and gradient boosting | Khan et al. and Rojek et al. [37,58] | Predict process outcomes such as surface roughness, tensile strength, and energy consumption | Optimizes process parameters, improves part quality, and balances multiple production objectives |

| AI Model Selection Guidelines | CNN for vision-based tasks, ANN/SVM for prediction, and hybrid ML models | Multiple studies | Select AI model depending on data availability and task type | Enhances precision, reduces waste, and accelerates design-to-product timelines |

| Aspect | Self-Learning Systems | AI with IoT and Digital Twins | Case Studies |

|---|---|---|---|

| Capabilities | Predictive modeling, autonomous optimization, and energy reduction | Real-time monitoring, predictive maintenance, quality control, and resource optimization | Improved efficiency, quality control, and sustainability |

| Technologies Used | Hybrid learning, machine learning, and transfer learning | AI algorithms, IoT devices, and digital twins | IoT, AI, digital twins |

| Benefits | Enhanced adaptability, reduced energy consumption, and improved machine tool selection | Reduced downtime, proactive maintenance, and increased productivity | Increased production efficiency, effective maintenance practices, and higher quality |

| Challenges | Data integration, ensuring data quality, and managing complex systems | Data security, compatibility concerns, and managing heterogeneous sensor networks | Large-scale transformation, high initial costs, and interoperability issues |

| Examples | Self-learning factory mechanism in metal cutting industries [123] | Concerns like AI-driven digital twins for predictive maintenance and quality control [110,112] | Smart factory implementation in automotive manufacturing [122] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Altun, F.; Bayar, A.; Hamzat, A.K.; Asmatulu, R.; Ali, Z.; Asmatulu, E. AI-Driven Innovations in 3D Printing: Optimization, Automation, and Intelligent Control. J. Manuf. Mater. Process. 2025, 9, 329. https://doi.org/10.3390/jmmp9100329

Altun F, Bayar A, Hamzat AK, Asmatulu R, Ali Z, Asmatulu E. AI-Driven Innovations in 3D Printing: Optimization, Automation, and Intelligent Control. Journal of Manufacturing and Materials Processing. 2025; 9(10):329. https://doi.org/10.3390/jmmp9100329

Chicago/Turabian StyleAltun, Fatih, Abdulcelil Bayar, Abdulhammed K. Hamzat, Ramazan Asmatulu, Zaara Ali, and Eylem Asmatulu. 2025. "AI-Driven Innovations in 3D Printing: Optimization, Automation, and Intelligent Control" Journal of Manufacturing and Materials Processing 9, no. 10: 329. https://doi.org/10.3390/jmmp9100329

APA StyleAltun, F., Bayar, A., Hamzat, A. K., Asmatulu, R., Ali, Z., & Asmatulu, E. (2025). AI-Driven Innovations in 3D Printing: Optimization, Automation, and Intelligent Control. Journal of Manufacturing and Materials Processing, 9(10), 329. https://doi.org/10.3390/jmmp9100329