Additive In-Time Manufacturing of Customised Orthoses

Abstract

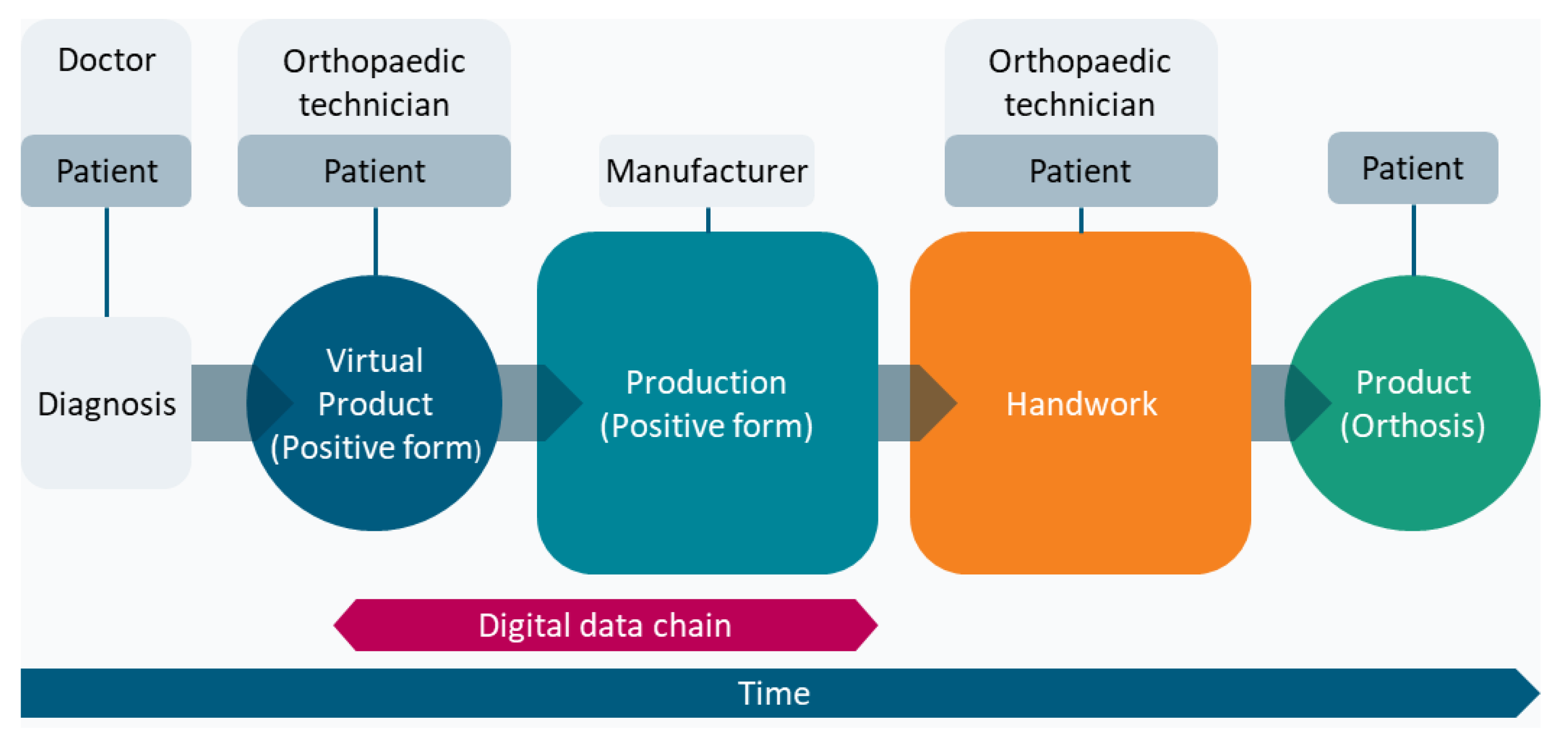

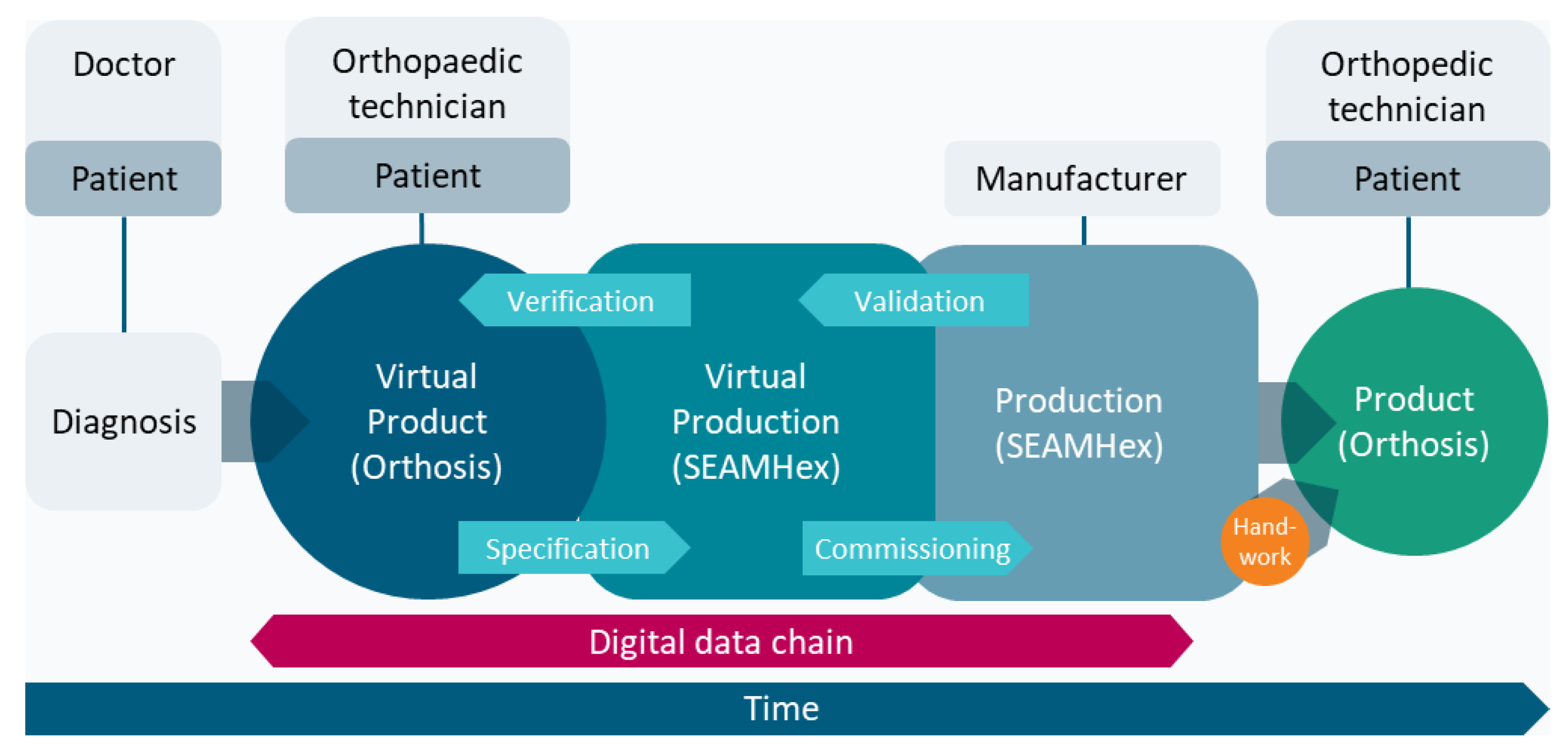

1. Introduction

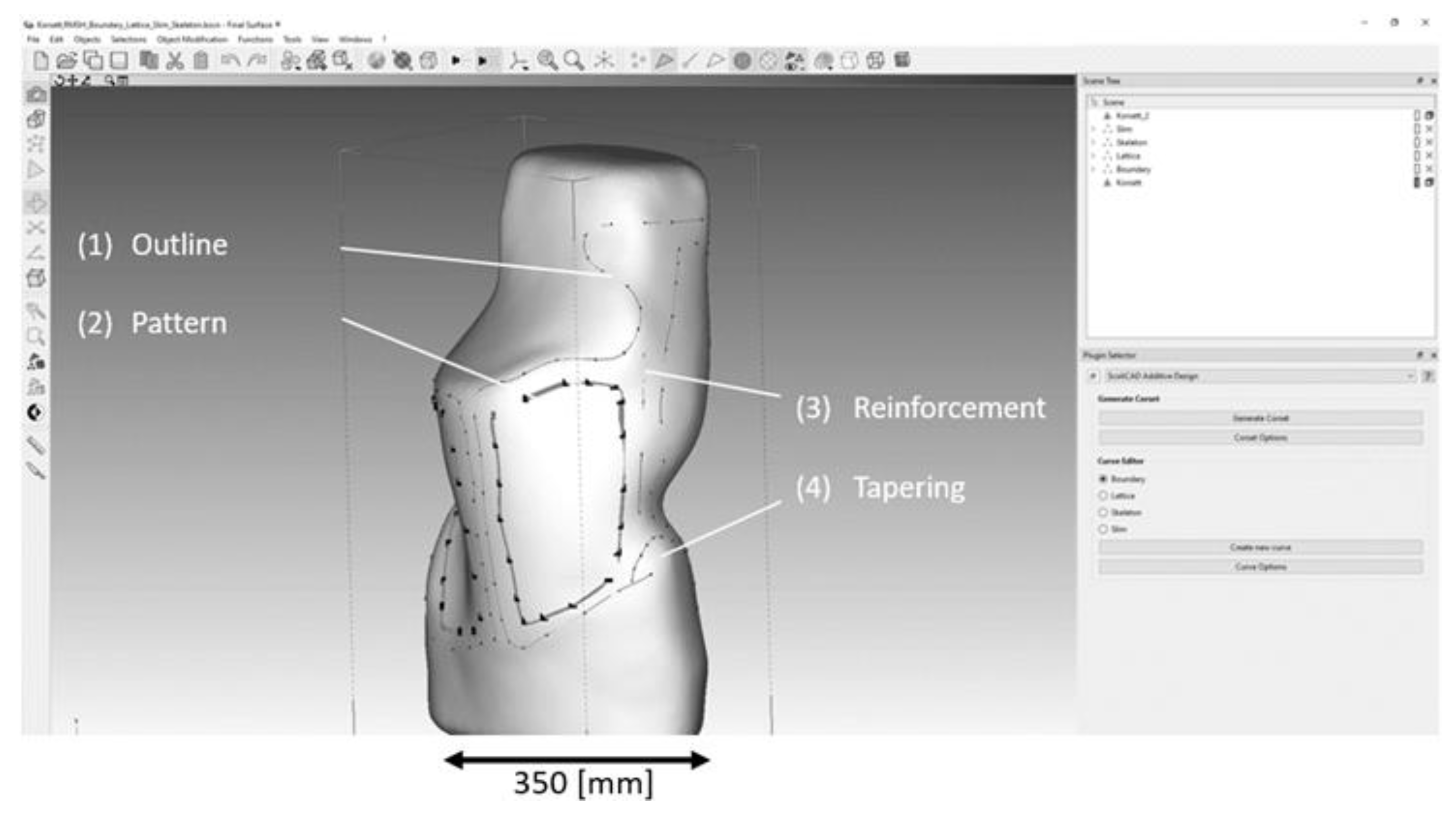

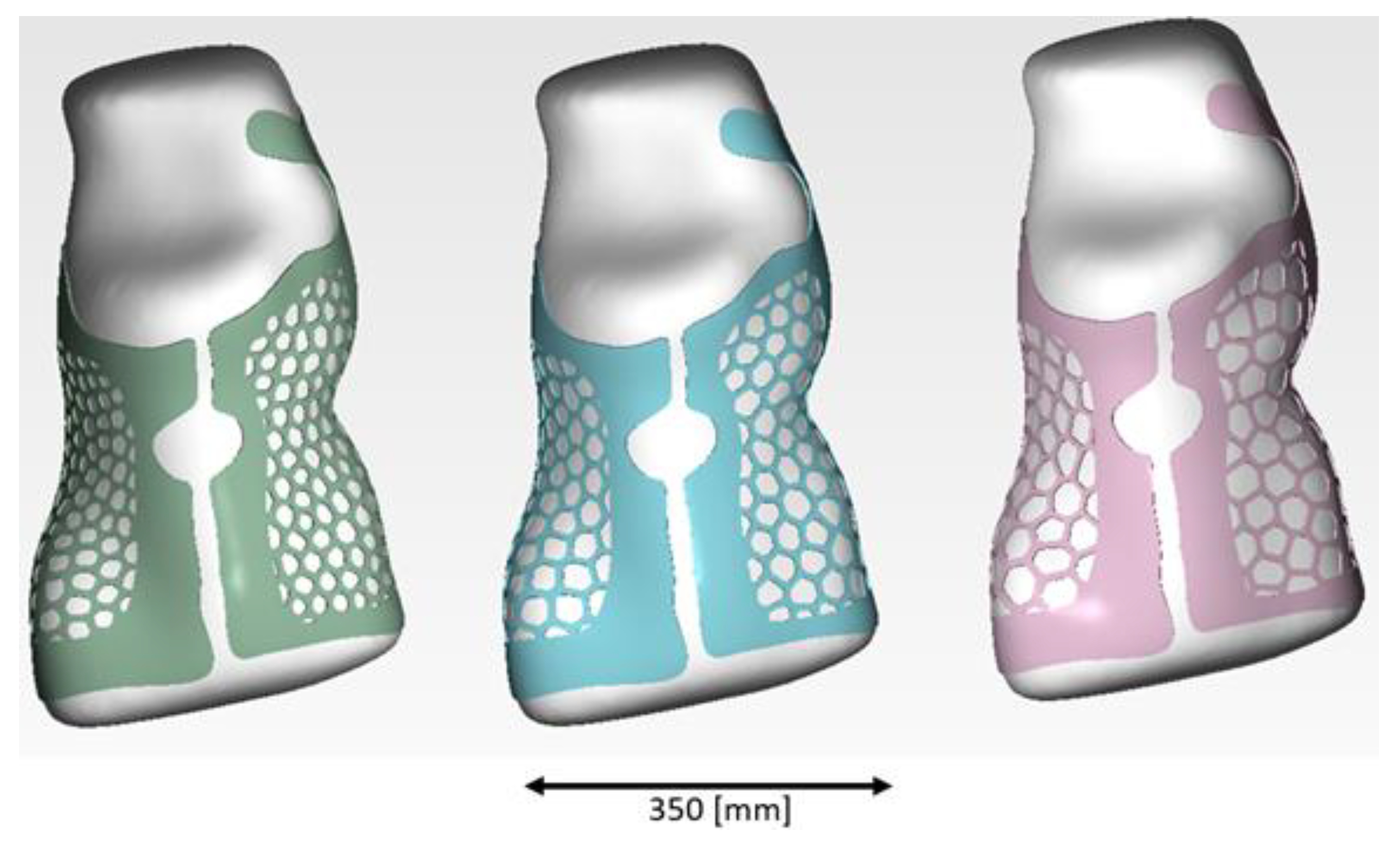

2. Materials and Methods

3. Results

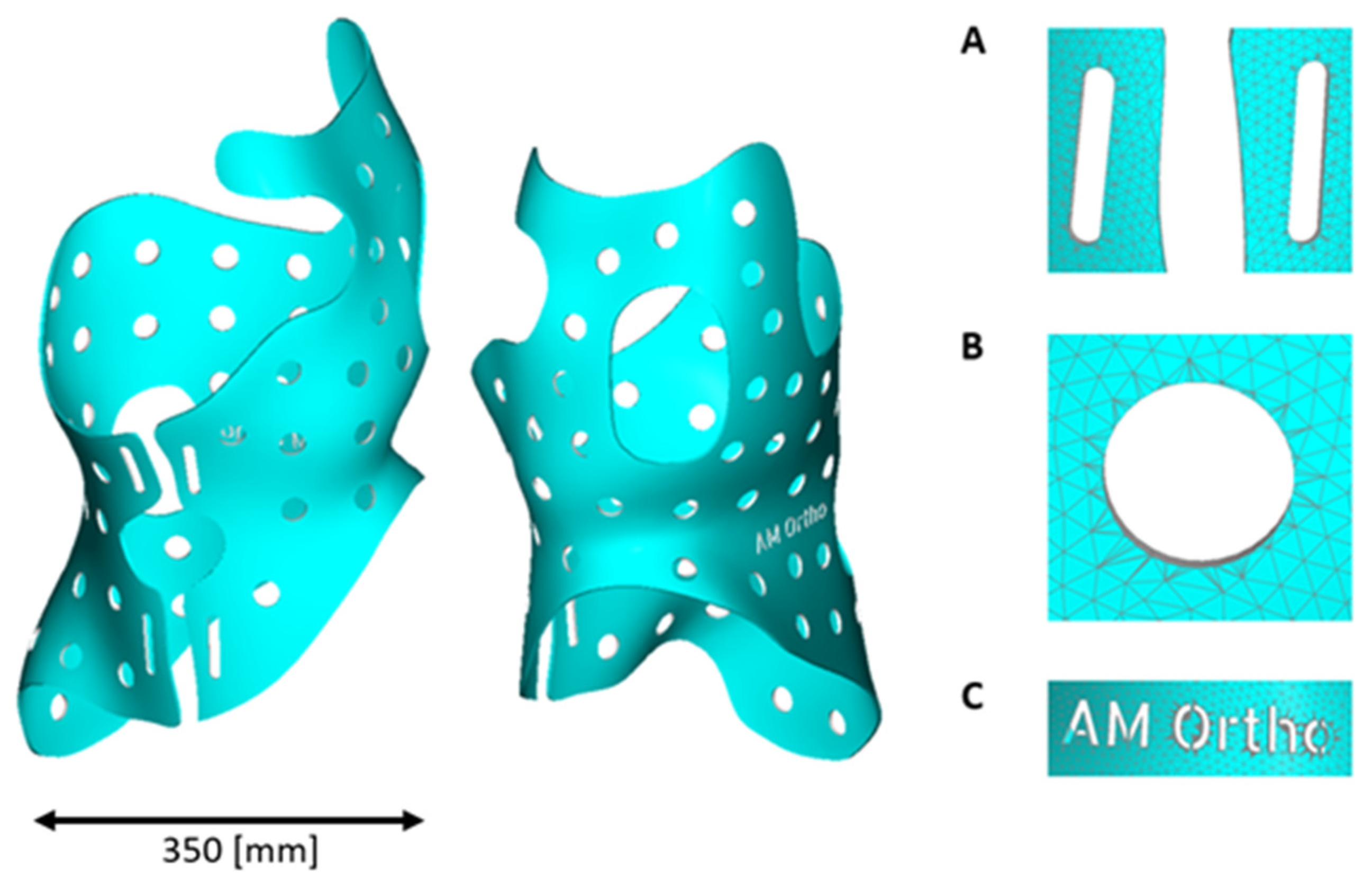

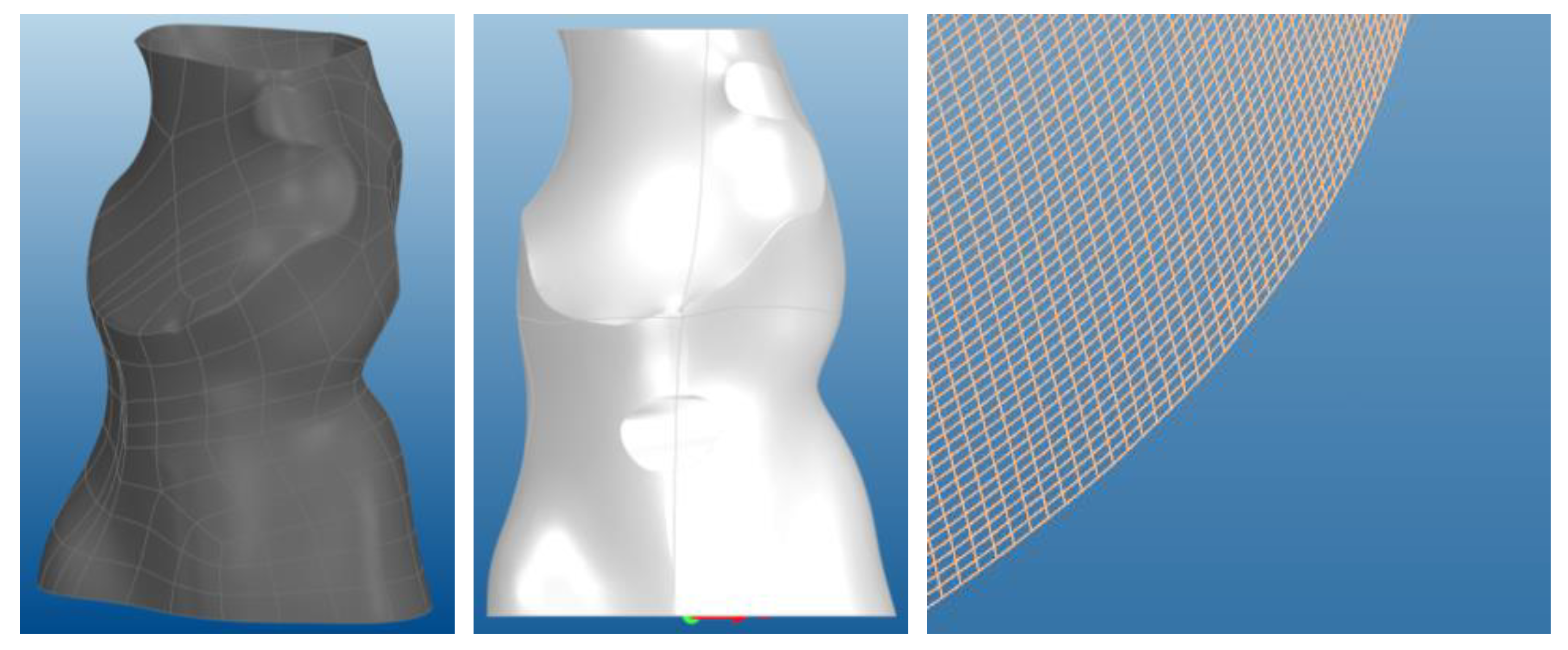

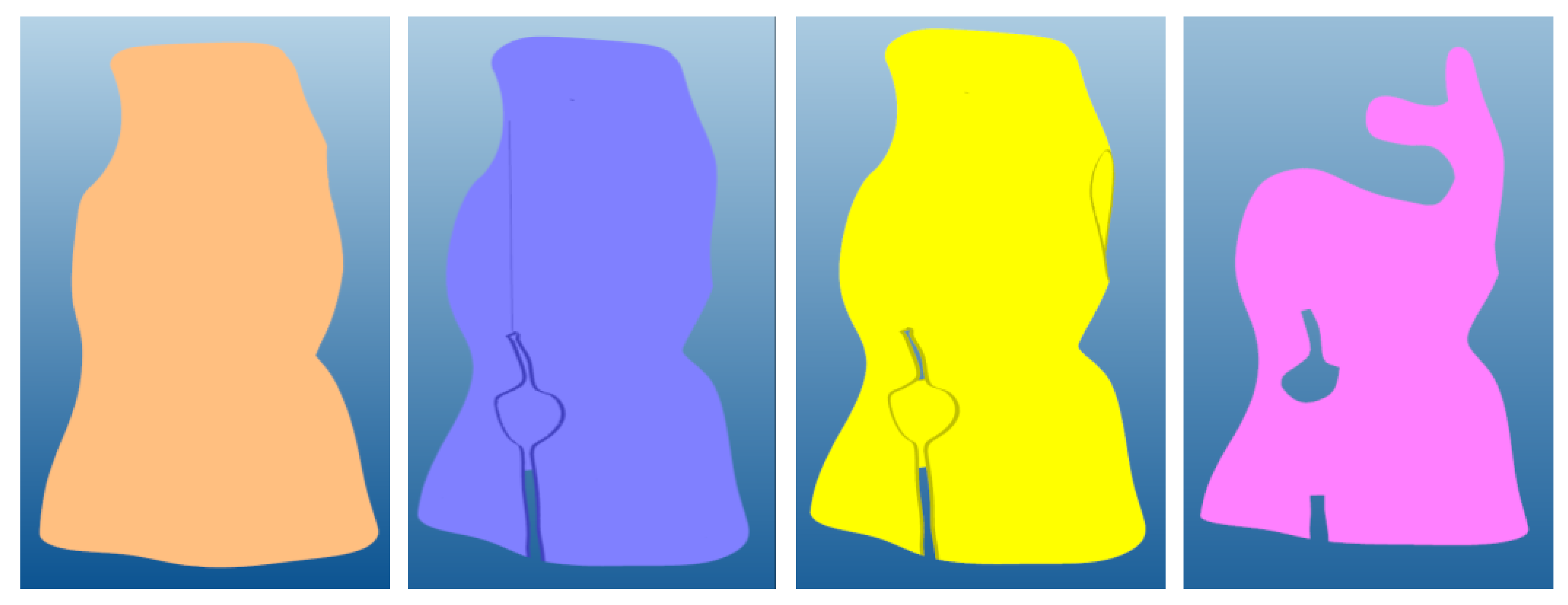

3.1. Model Generation

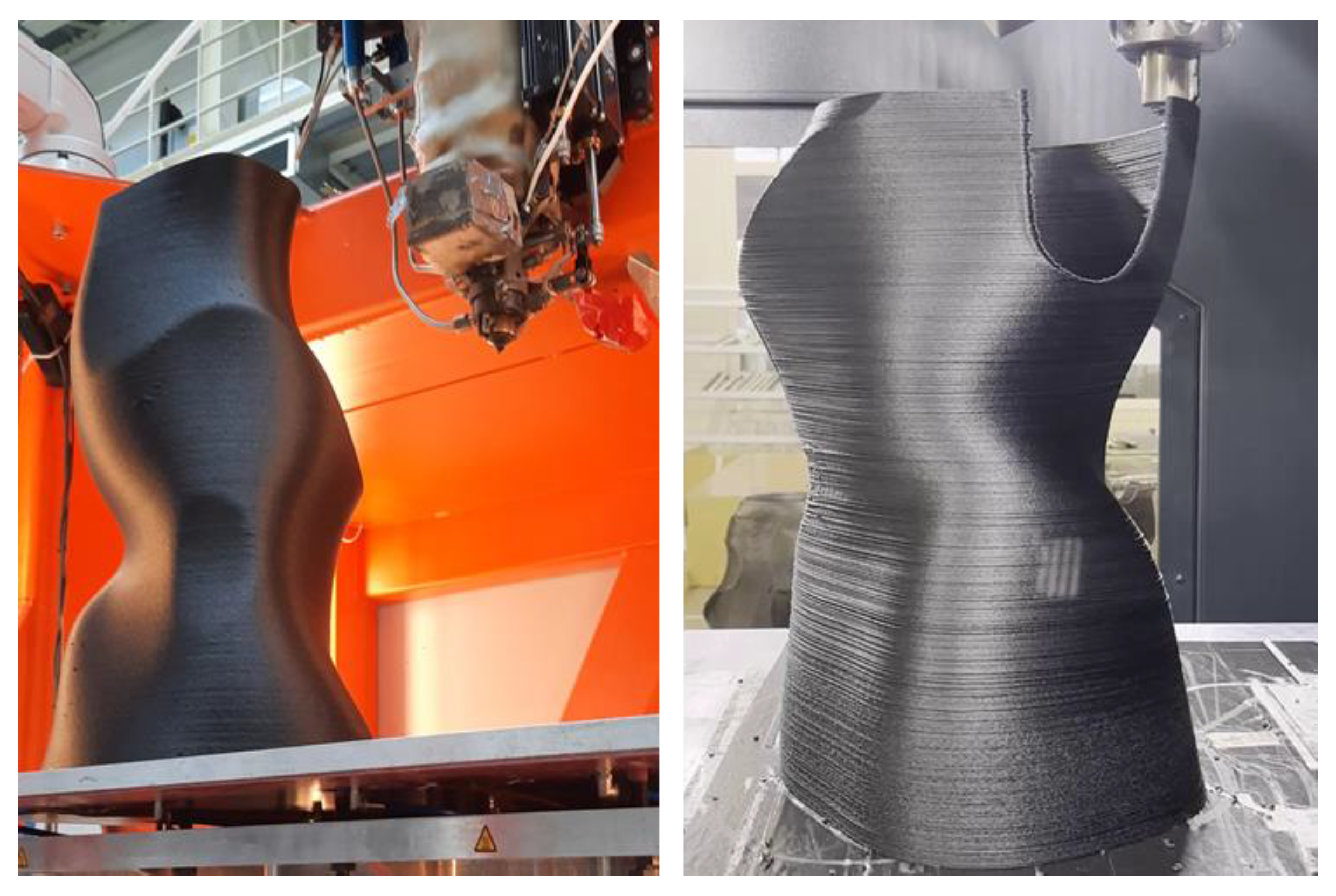

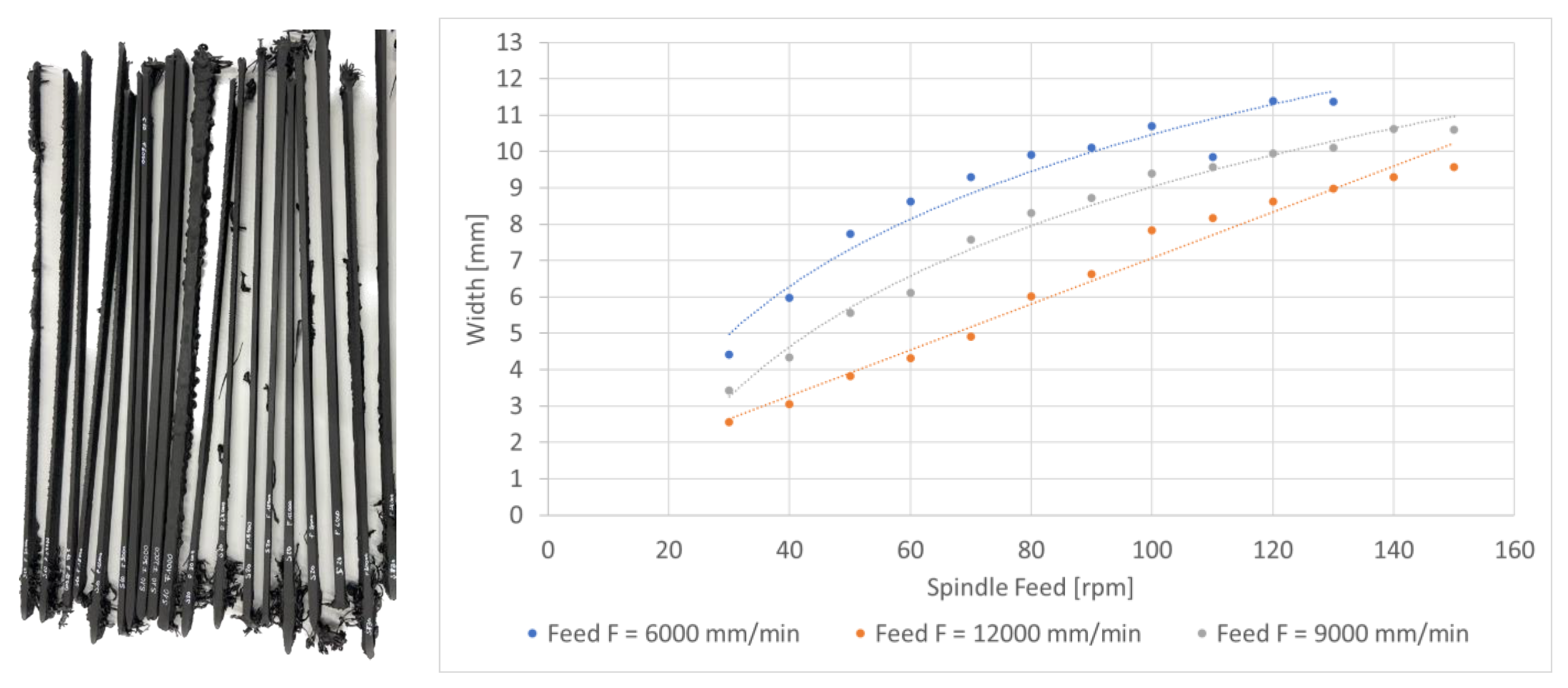

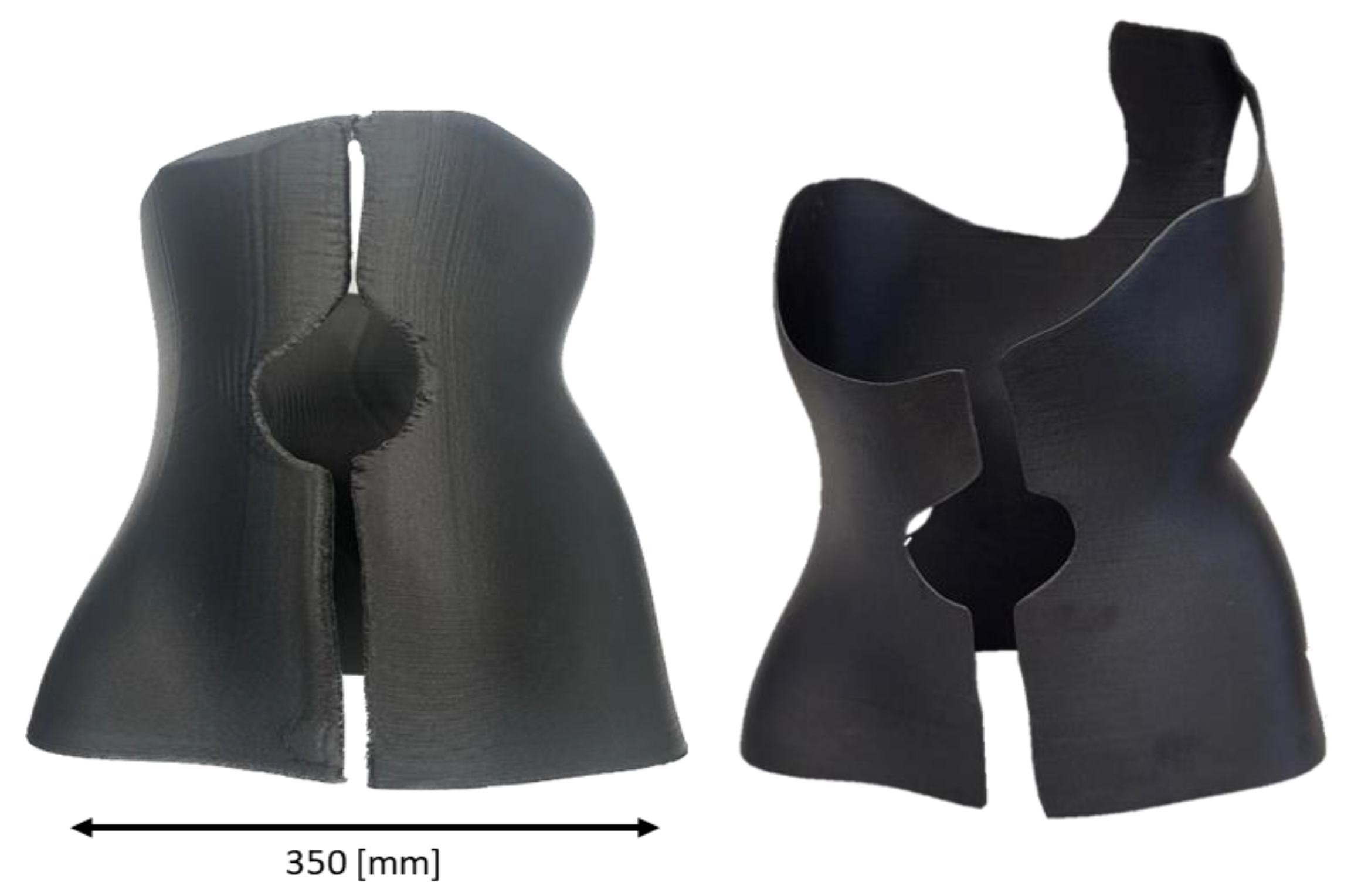

3.2. Manufacturing

4. Conclusions and Outlook

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Asher, M.A.; Burton, D.C. Adolescent idiopathic scoliosis: Natural history and long term treatment effects. Scoliosis 2006, 1, 2. [Google Scholar] [CrossRef] [PubMed]

- Goldberg, C.J.; Moore, D.P.; Fogarty, E.E.; Dowling, F.E. Adolescent idiopathic scoliosis: Natural history and prognosis. In Research into Spinal Deformities 4; IOS Press: Amsterdam, The Netherlands, 2002; pp. 59–63. [Google Scholar]

- Weiss, H.-R.; Lehnert-Schroth, C.; Moramarco, M.; Moramarco, K. Schroth Therapy Advancements in Conservative Scoliosis Treatment, 3rd ed.; Book Publisher International (a part of SCIENCEDOMAIN International): New York, NY, USA, 2022; ISBN 9789355473219. [Google Scholar]

- Weiss, H.-R.; Tournavitis, N.; Nan, X.; Borysov, M.; Paul, L. Workflow of CAD/CAM Scoliosis Brace Adjustment in Preparation Using 3D Printing. Open Med. Inform. J. 2017, 11, 44–51. [Google Scholar] [CrossRef] [PubMed]

- Kaushik, A.; Gahletia, S.; Garg, R.K.; Sharma, P.; Chhabra, D.; Yadav, M. Advanced 3D body scanning techniques and its clinical applications. In Proceedings of the 2022 International Conference on Computational Modelling, Simulation and Optimization (ICCMSO), Pathum Thani, Thailand, 23–25 December 2022; IEEE: Piscataway, NJ, USA, 2022; pp. 352–358, ISBN 979-8-3503-3288-9. [Google Scholar]

- Creaform. HandySCAN 3D Series Metrology-Grade 3D Scanner Optimized for Large Parts. Available online: https://www.creaform3d.com/en (accessed on 20 November 2023).

- Artec3D. Eva Fast Structured Light 3D Scanner for Professionals. Available online: https://www.artec3d.com/de/portable-3d-scanners/artec-eva (accessed on 20 November 2023).

- SMARTTECH 3D. 3D Scanning Technology to Digitizing the Human Body. Available online: https://smarttech3dscanner.com/3d-scanners/smarttech3d-med/ (accessed on 20 November 2023).

- 3D SYSTEMS. Geomagic. Available online: https://de.3dsystems.com/software (accessed on 20 November 2023).

- Helle, R.H.; Lemu, H.G. A case study on use of 3D scanning for reverse engineering and quality control. Mater. Today Proc. 2021, 45, 5255–5262. [Google Scholar] [CrossRef]

- Weiss, H.R.; Seibel, S.; Moramarco, M.; Kleban, A. Bracing scoliosis: The evolution to CAD/CAM for improved in-brace corrections. Hard Tissue 2013, 2, 43. [Google Scholar] [CrossRef][Green Version]

- Rothstock, S.; Weiss, H.-R.; Krueger, D.; Kleban, V.; Paul, L. Innovative Decision Support for Scoliosis Brace Therapy Based on Statistical Modelling of Markerless 3d Trunk Surface Data. Comput. Methods Biomech. Biomed. Eng. 2020, 23, 923–933. [Google Scholar] [CrossRef] [PubMed]

- Rigo, M.; Chêneau, J. Praxis der Chêneau-Korsettversorgung in der Skoliosetherapie; Thieme: Stuttgart, Germany, 2000; ISBN 9783131185419. [Google Scholar]

- Desbiens-Blais, F.; Clin, J.; Parent, S.; Labelle, H.; Aubin, C.-E. New brace design combining CAD/CAM and biomechanical simulation for the treatment of adolescent idiopathic scoliosis. Clin. Biomech. 2012, 27, 999–1005. [Google Scholar] [CrossRef] [PubMed]

- Sankar, W.N.; Albrektson, J.; Lerman, L.; Tolo, V.T.; Skaggs, D.L. Scoliosis in-brace curve correction and patient preference of CAD/CAM versus plaster molded TLSOs. J. Child. Orthop. 2007, 1, 345–349. [Google Scholar] [CrossRef] [PubMed]

- Vorum. CAD/CAM and 3D Printing Solutions for Orthotics and Prosthetics Providers. Available online: https://vorum.com/op-solution-overview/ (accessed on 18 December 2023).

- Rodin 4D. Software and Applications CAD/CAM. Available online: https://www.rodin4d.com/en/logiciel-cfao/ (accessed on 17 March 2024).

- Nathan, P.; Chou, S.M.; Liu, G. A review on different methods of scoliosis brace fabrication. Prosthet. Orthot. Int. 2023, 47, 424–433. [Google Scholar] [CrossRef] [PubMed]

- Lalegani Dezaki, M.; Mohd Ariffin, M.K.A.; Hatami, S. An overview of fused deposition modelling (FDM): Research, development and process optimisation. RPJ 2021, 27, 562–582. [Google Scholar] [CrossRef]

- Rothstock, S.; González-Ruiz, J.M.; Weiss, H.-R.; Turnbull, D.; Krueger, D. Severity and Cobb angle of scoliosis patients quantified with markerless trunk surface topography using k-NN search and multivariate regression analysis. Comput. Methods Biomech. Biomed. Eng. Imaging Vis. 2023, 11, 2433–2439. [Google Scholar] [CrossRef]

- Gefertec GmbH. Die 3DMP®-Prozesskette. Available online: https://www.gefertec.de/3dmp-verfahren/#prozesskette (accessed on 20 November 2023).

- Invet Medical. Company Invet Medical. Available online: https://www.inventmedical.com/de/start/ (accessed on 10 March 2024).

- 3Faktur. Available online: https://3faktur.com/3d-druck-in-der-orthopaedie/ (accessed on 12 March 2024).

- Ahrendt, D.; Schmitt, F.; Krzywinski, S.; Krzywinski, J. Bend-It—Rethinking Customized Orthopaedic Devices Using Additive Manufacturing; CONVERGE Europe: Essen, Germany, 2017. [Google Scholar]

- Hopmann, C.; Hellmich, C.; Lammert, N. Schichtweise vom Granulat zum Bauteil—Additive Fertigung von faserverstärkten PA6-Strukturbauteilen in hoher Geschwindigkeit. Kunststoffe 2018, 11, 22–25. [Google Scholar]

- IceSL. Product page IceSL. Available online: https://icesl.loria.fr/#header (accessed on 20 November 2023).

- Product Page OctoPrint. Available online: https://octoprint.org/ (accessed on 20 November 2023).

- Product Page Slic3r. Available online: http://slic3r.org/ (accessed on 20 November 2023).

- UltiMaker. Product Page Ultimaker Cura. Available online: https://ultimaker.com/software/ultimaker-cura/ (accessed on 20 November 2023).

- Blase, J.; John, C.; Kausch, M.; Witt, M. Ultrafast 3D printing. Kunststoffe Int. 2019, 11, 32–34. [Google Scholar]

- Ihlenfeldt, S.; Drossel, W.-G.; Kausch, M.; Friedrich, C.; Wiese, T.; Jankowsky, L. SEAMHex—Fast 6D Additive Manufacturing using an innovative Screw Extruder applied on a Hexapod Parallel Kinematic. TLS 2022, 5, 1–14. [Google Scholar] [CrossRef]

- Werner Pluta. Fraunhofer-Forscher Entwickeln Sehr Schnellen 3D-Drucker. Available online: https://www.golem.de/news/seam-fraunhofer-forscher-entwickeln-sehr-schnellen-3d-drucker-1904-140472.html (accessed on 20 November 2023).

- Friedrich, C.; Kauschinger, B.; Ihlenfeldt, S. Stiffness evaluation of a hexapod machine tool with integrated force sensors. J. Mach. Eng. 2020, 20, 58–69. [Google Scholar] [CrossRef]

- Wiese, T.; Abicht, J.; Friedrich, C.; Hellmich, A.; Ihlenfeldt, S. Flexible skill-based control for robot cells in manufacturing. Front. Robot. AI 2022, 9, 1014476. [Google Scholar] [CrossRef] [PubMed]

- Kauschinger, B.; Friedrich, C.; Zhou, R.; Ihlenfeldt, S. Fast Evaluation of the Volumetric Motion Accuracy of Multi-Axis Machine Tools using a Double-Ball-Bar. J. Mach. Eng. 2020, 20, 44–62. [Google Scholar] [CrossRef]

- GFaI e., V. Final Surface: 3D-Software zur Professionellen Erfassung, Visualisierung, Bearbeitung und Analyse von Komplexen 3D-Messdaten. Available online: https://www.final-surface.de (accessed on 12 March 2024).

| Property | Part | Conventional Forming | SEAM 5 Axis Additive | Conventional 2.5D Additive |

|---|---|---|---|---|

| Technology | Mould | Milling | - | - |

| Brace | Thermoforming | 3D Printing SEAM | 3D Printing FFF | |

| Material | Mould | Polyurethane | - | - |

| Brace | Polyethylene | PA/PP/PET Granulate | PA/PP Filament | |

| Manual work | Mould | No | - | - |

| Brace | Yes | No | No | |

| Waste | Mould | ca. 50% | - | - |

| Brace | ca. 50% | ca. 1–2% | ca. 1–2% | |

| Warehousing | Mould | Necessary | - | - |

| Wall thickness | Brace | 3 mm | 2.5 mm | 2.5 mm |

| Manufacturing Time | Mould | 30 min | - | - |

| Brace | 2 h | 2.5 h | 12 h | |

| Total | 2.5 h | 2.5 h | 12 h | |

| Costs | Mould | EUR 200 | - | - |

| Brace Machining Brace Material | EUR 500 | 2.5 h × 100 EUR/h = EUR 250 0.9 kg × 7 EUR/kg = EUR 6 | 12 h × 60 EUR/h = EUR 720 0.9 kg × 80 EUR/kg = EUR 72 | |

| Total | EUR 700 | 256 | EUR 792 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Friedrich, C.; Rothstock, S.; Slabon, L.; Ihlenfeldt, S. Additive In-Time Manufacturing of Customised Orthoses. J. Manuf. Mater. Process. 2024, 8, 63. https://doi.org/10.3390/jmmp8020063

Friedrich C, Rothstock S, Slabon L, Ihlenfeldt S. Additive In-Time Manufacturing of Customised Orthoses. Journal of Manufacturing and Materials Processing. 2024; 8(2):63. https://doi.org/10.3390/jmmp8020063

Chicago/Turabian StyleFriedrich, Christian, Stephan Rothstock, Laura Slabon, and Steffen Ihlenfeldt. 2024. "Additive In-Time Manufacturing of Customised Orthoses" Journal of Manufacturing and Materials Processing 8, no. 2: 63. https://doi.org/10.3390/jmmp8020063

APA StyleFriedrich, C., Rothstock, S., Slabon, L., & Ihlenfeldt, S. (2024). Additive In-Time Manufacturing of Customised Orthoses. Journal of Manufacturing and Materials Processing, 8(2), 63. https://doi.org/10.3390/jmmp8020063