Application of Carbon Dioxide Snow in Machining of CGI using an Additively Manufactured Turning Tool

Abstract

:1. Introduction

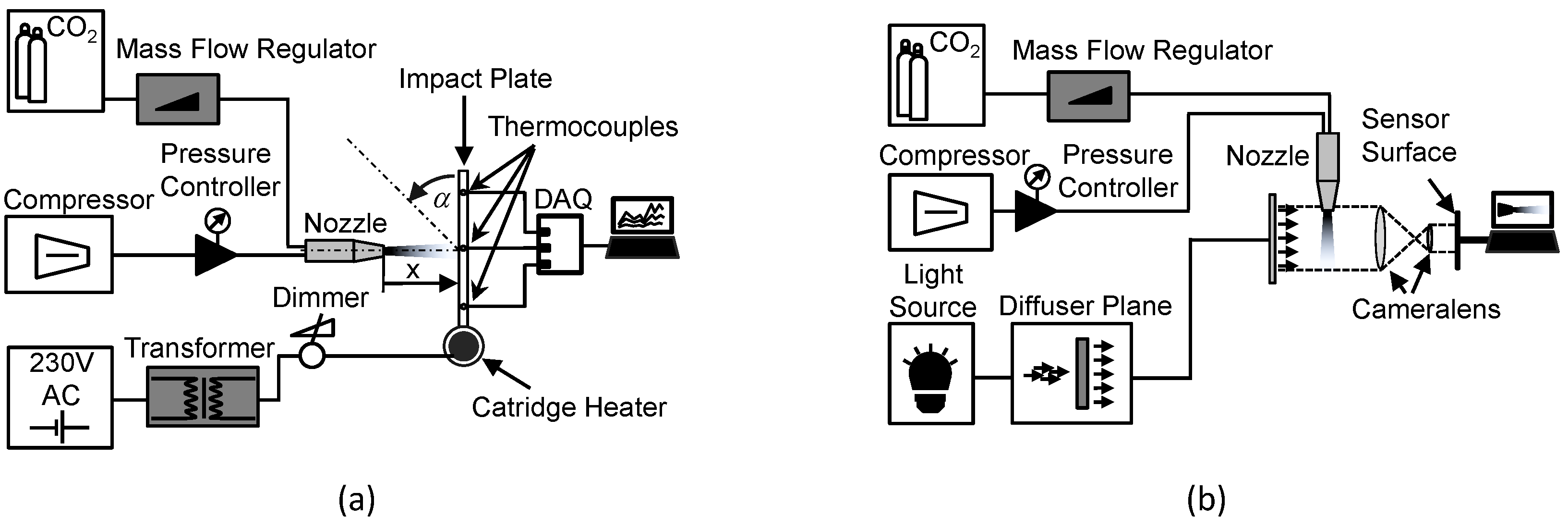

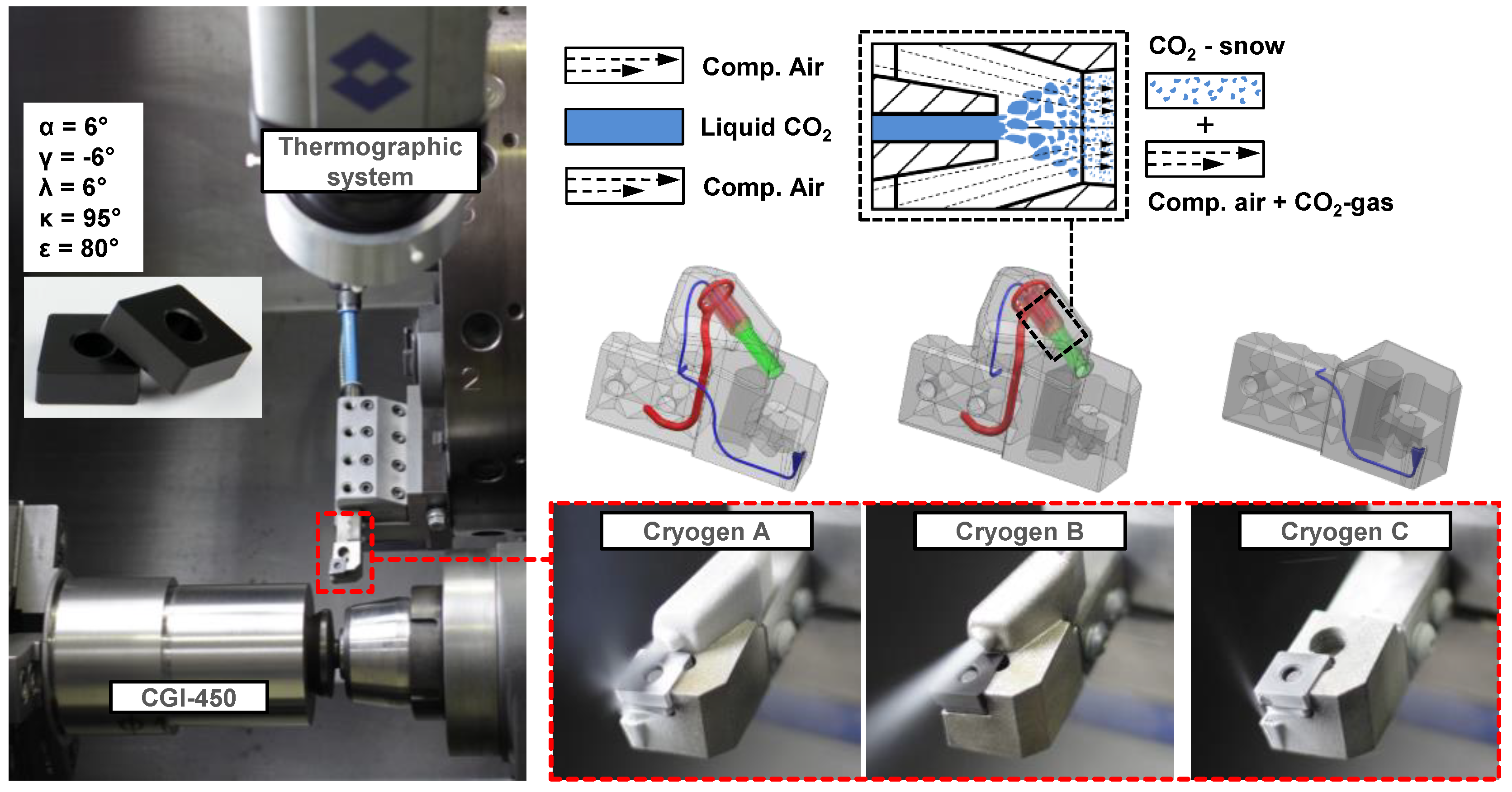

2. Materials and Methods

3. Results and Discussion

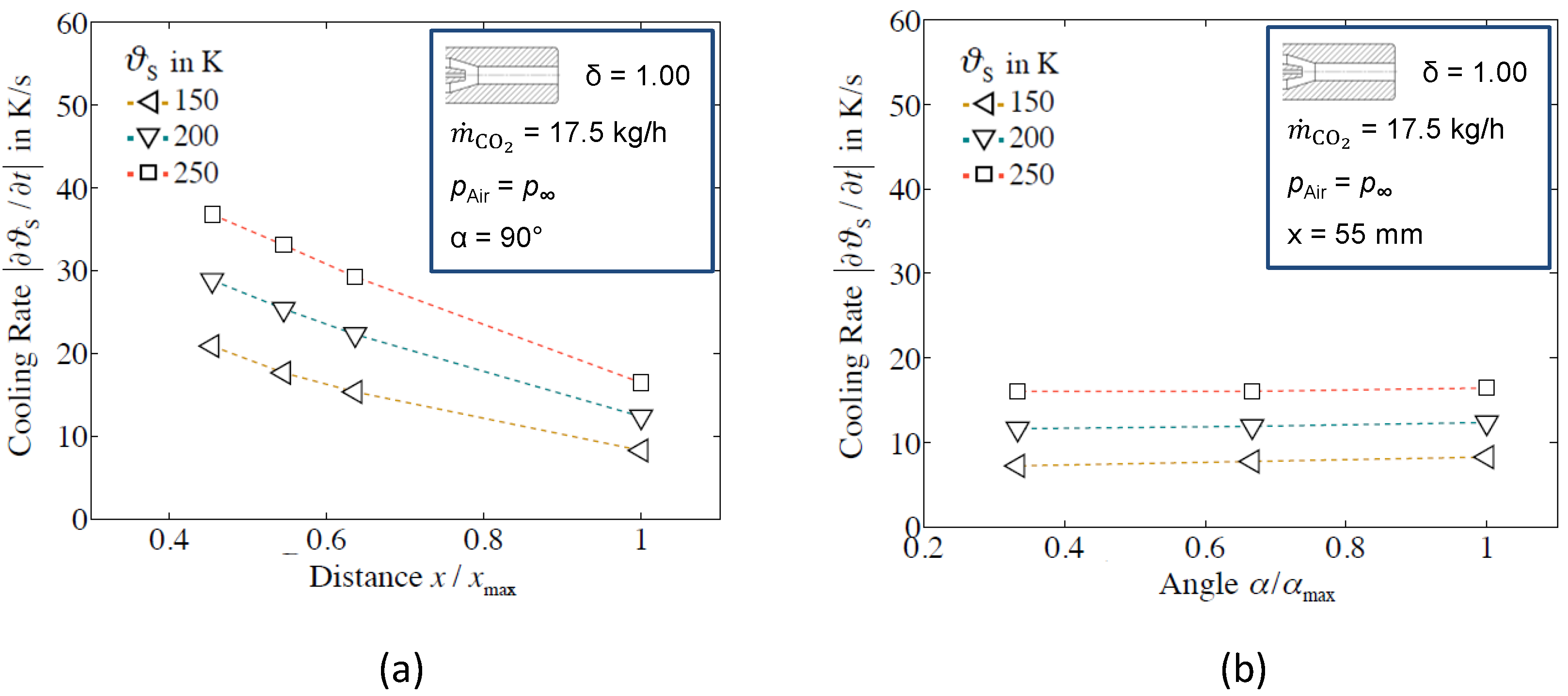

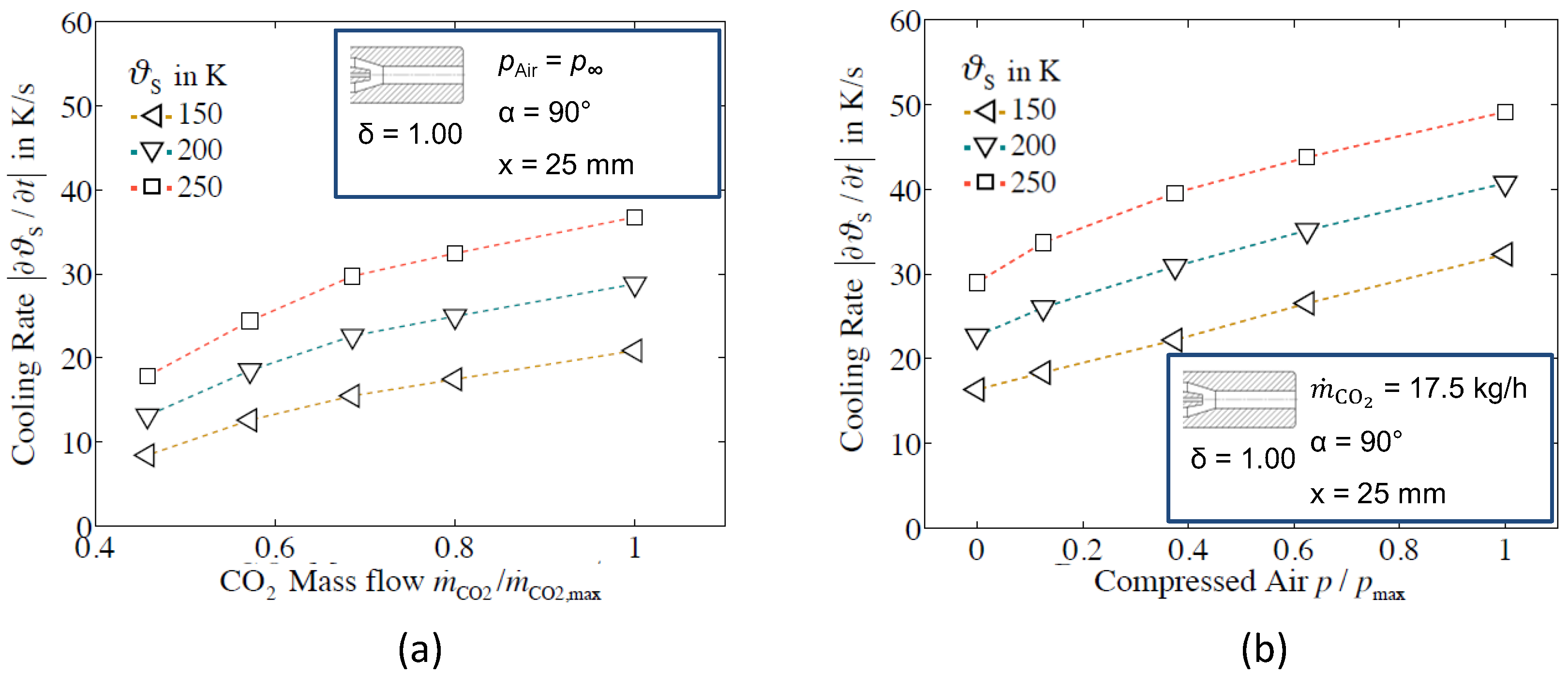

3.1. Examination of the Cooling Rate under Varying Nozzle Alignment and Operating Parameters

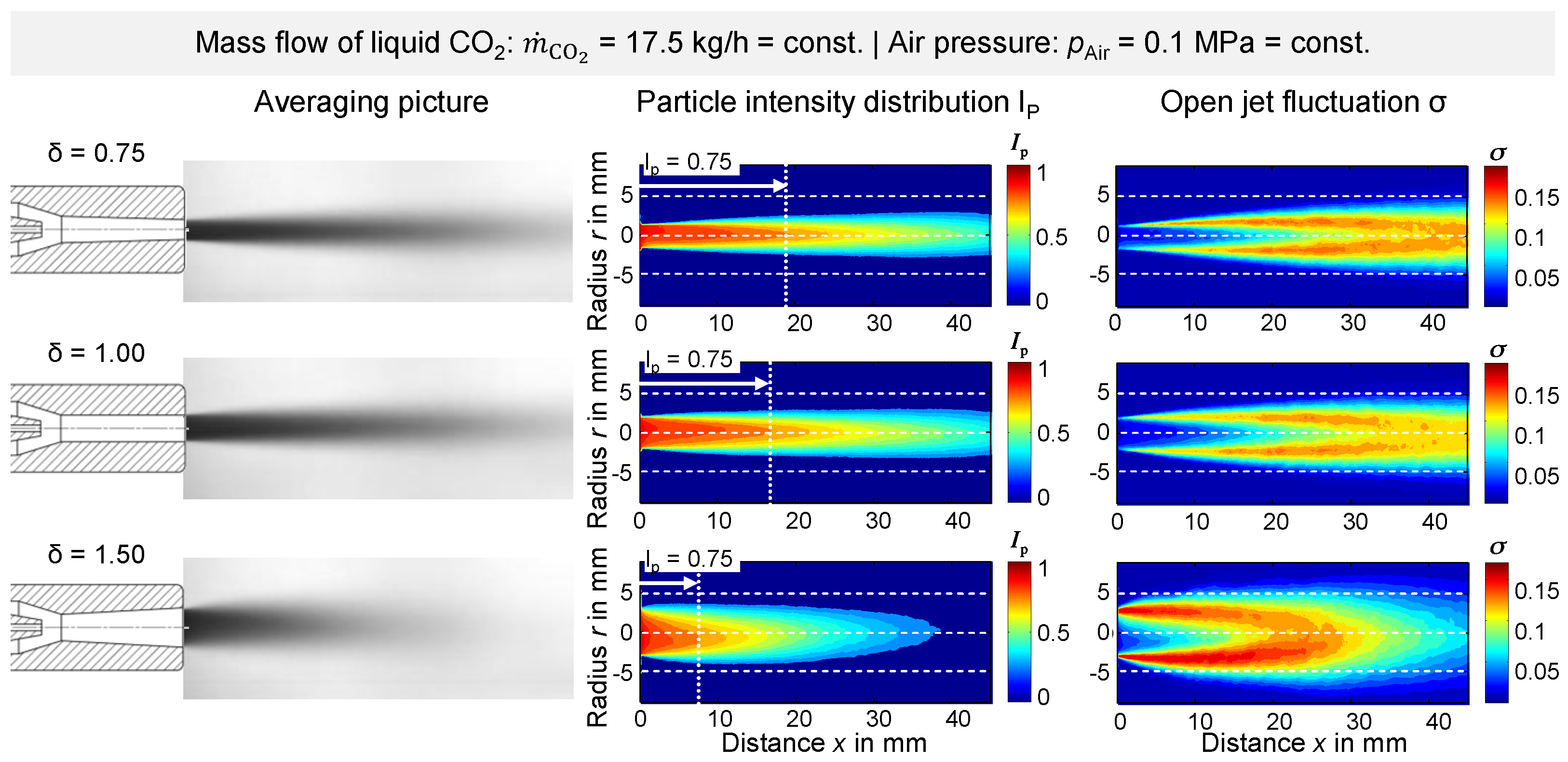

3.2. Influence of the Nozzle Opening Geometry on the Open Jet Behaviour

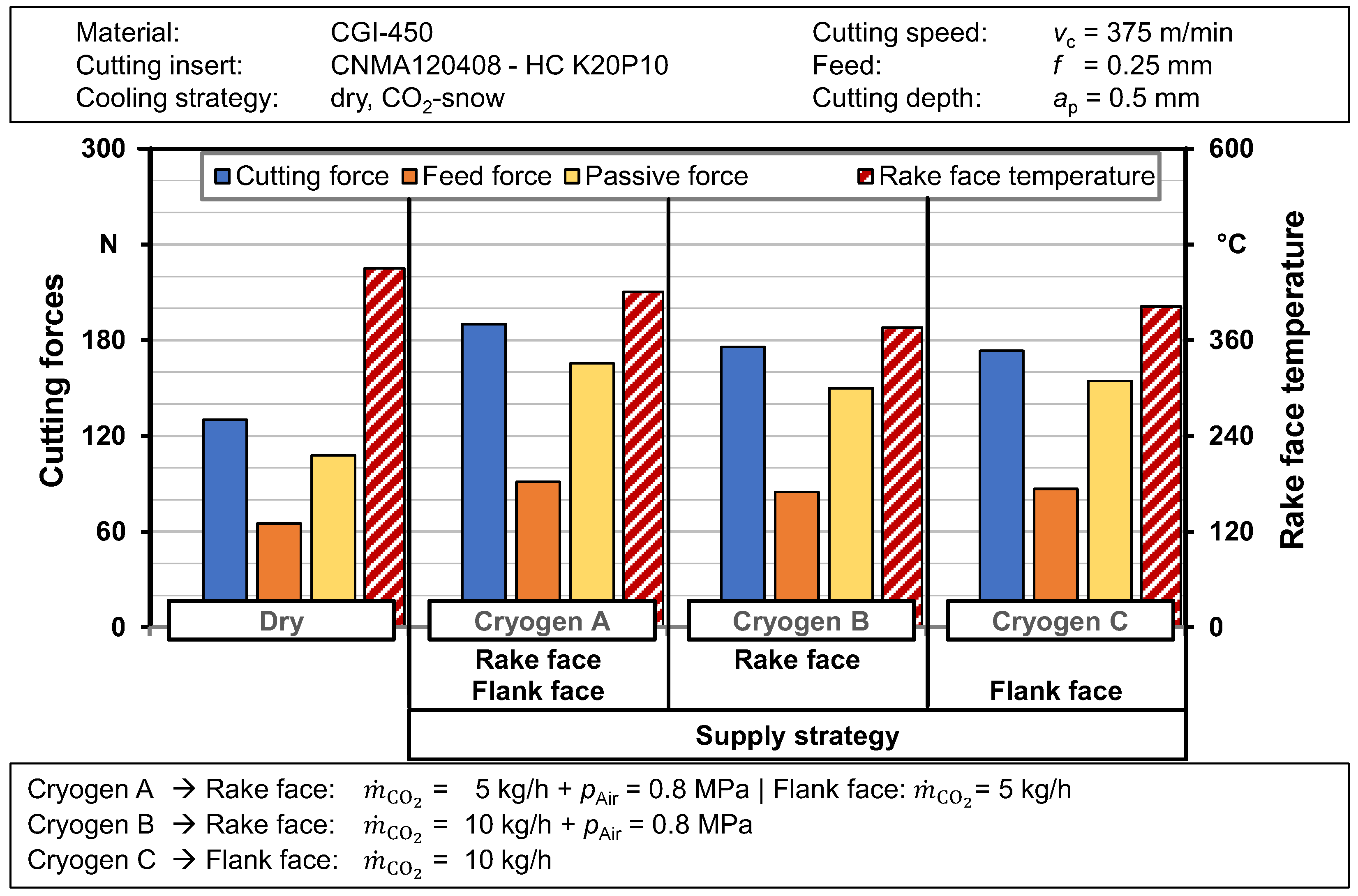

3.3. Influence of the Supply Strategy on the Thermomechanical Tool Load

4. Conclusions

- The nozzle distance affects the ability to achieve cutting edge cooling more strongly than the angular alignment of the nozzle.

- The cooling rate for cryogenic CO2-snow jet cooling is increased by 32% with an additional air-mass flow.

- The long-term behavior regarding process-reliability (protecting the nozzle against ice formation) was improved significantly using CO2-snow jets with dual nozzles compared to a single-component nozzle.

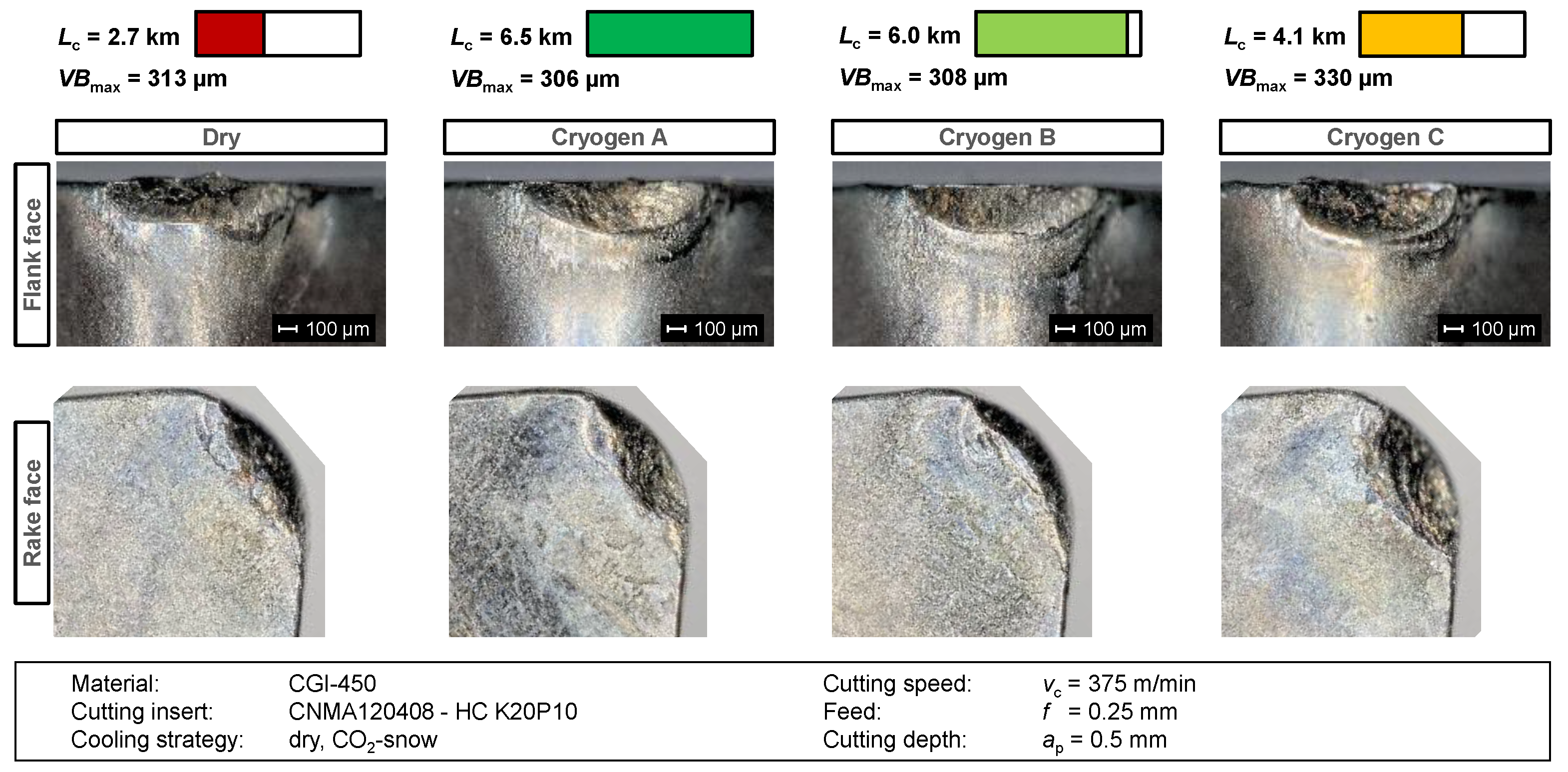

- Efficient rake face cooling is essential for the reduction of thermal tool loads and has a significant effect on the crater wear behavior.

- The wear development on the flank face can be further reduced by targeted flank face cooling.

- Compared to dry machining, the tool life Lc could be increased by a factor of 2.4 with combined rake face and flank face cooling using CO2-snow.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Bordin, A.; Sartori, S.; Bruschi, S.; Ghiotti, A. Experimental investigation on the feasibility of dry and cryogenic machining as sustainable strategies when turning Ti6Al4V produced by Additive Manufacturing. J. Clean. Prod. 2017, 142, 4142–4151. [Google Scholar] [CrossRef]

- Pfeiffer, P. Technologische Prozessauslegung für die Zerspanung von Gusseisen mit Vermiculargrafit unter kontinuierlichen Schnittbedingungen. Ph.D. Thesis, TU Darmstadt, Darmstadt, Germany, 2014. [Google Scholar]

- Biermann, D.; Abrahams, H.; Metzger, M. Experimental investigation of tool wear and chip formation in cryogenic machining of titanium alloys. Adv. Manuf. 2015, 3, 292–299. [Google Scholar] [CrossRef]

- Hong, S.Y.; Ding, Y.; Jeong, W. Friction and cutting forces in cryogenic machining of Ti-6Al-4V. Int. J. Mach. Tools Manuf. 2001, 41, 2271–2285. [Google Scholar] [CrossRef]

- Weinert, K.; Hesterberg, S.; Wittkop, S. Den Span eiskalt erwischt. Werkstatt und Betr. Wb 2003, 136, 74–76. [Google Scholar]

- Ueda, T.; Hosokawa, A.; Yamada, K. Effect of Oil Mist on Tool Temperature in Cutting. J. Manuf. Sci. Eng. 2006, 128, 130–135. [Google Scholar] [CrossRef]

- Bermingham, M.J.; Palanisamy, S.; Kent, D.; Dargusch, M.S. A comparison of cryogenic and high pressure emulsion cooling technologies on tool life and chip morphology in Ti-6Al-4V cutting. J. Mater. Process. Technol. 2012, 212, 752–765. [Google Scholar] [CrossRef]

- Abele, E.; Schramm, B. Using PCD for machining CGI with a CO2 coolant system. Prod. Eng. 2008, 2, 165–169. [Google Scholar] [CrossRef]

- Kaynak, Y.; Gharibi, A. Progressive Tool Wear in Cryogenic Machining: The Effect of Liquid Nitrogen and Carbon Dioxide. J. Manuf. Mater. Process. 2018, 2, 31. [Google Scholar] [CrossRef]

- Blau, P.; Busch, K.; Dix, M.; Hochmuth, C.; Stoll, A.; Wertheim, R. Flushing Strategies for High Performance, Efficient and Environmentally Friendly Cutting. Procedia CIRP 2015, 26, 361–366. [Google Scholar] [CrossRef]

- Jawahir, I.S.; Attia, H.; Biermann, D.; Duflou, J.; Klocke, F.; Meyer, D.; Newman, S.T.; Pusavec, F.; Putz, M.; Rech, J.; et al. Cryogenic manufacturing processes. CIRP Ann. 2016, 65, 713–736. [Google Scholar] [CrossRef]

- Gross, D.; Heinz, A.; Ebner, M.; Hanenkamp, N. Assessment of Process Improvement Potential of Carbon Dioxide as a Cryogenic for Machining Operations. Appl. Mech. Mater. 2017, 856, 151–158. [Google Scholar] [CrossRef]

- Tapoglou, N.; Lopez, M.I.A.; Cook, I.; Taylor, C.M. Investigation of the influence of CO2 cryogenic coolant application on tool wear. Procedia CIRP 2017, 63, 745–749. [Google Scholar] [CrossRef]

- Lin, T.-C.; Hong, C.Y.; Shen, Y.L.; Wang, M.R. Effects of Bypass Flow on CO2 Snow Formation for Cryogenic Application. J. Aeronaut. Astronaut. Aviat. 2012, 44, 193–200. [Google Scholar]

- Pereira, O.; Rodriguez, A.; Barreiro, J.; Fernández-Abia, A.I.; López de Lacalle, L.N. Nozzle Design for Combined Use of MQL and Cryogenic Gas in Machining. Int. J. Precis. Eng. Manuf. Green Technol. 2017, 4, 87–95. [Google Scholar] [CrossRef]

- Montandon, J. Energiesparen mit 3D-gedruckten KSS-Düsen. In Proceedings of the Schweizer Schleif-Symposium, Zurich, Switzerland, 19–20 January 2016. [Google Scholar]

- Wegener, K.; Bleicher, F.; Krajnik, P.; Hoffmeister, H.; Brecher, C. Recent developments in grinding machines. CIRP Ann. 2017, 66, 779–802. [Google Scholar] [CrossRef]

- Bourell, D.; Kruth, J.P.; Leu, M.; Levy, G.N.; Rosen, D.; Beese, A.M.; Clare, A. Materials for additive manufacturing. CIRP Ann. 2017, 66, 659–681. [Google Scholar] [CrossRef]

- Schmidt, M.; Merklein, M.; Bourell, D.; Dimitrov, D.; Hausotte, T.; Wegener, K.; Overmeyer, L.; Vollertsen, F.; Levy, G.N. Laser based additive manufacturing in industry and academia. CIRP Ann. 2017, 66, 561–583. [Google Scholar] [CrossRef]

- Kress, D. Mittels eines Lasersinterverfahrens hergestellter Bohrer. Patent WO2015/166065 A1, 5 November 2015. [Google Scholar]

- Ach, E.; Gey, C. Zerspanungswerkzeug sowie Verfahren zum Herstellen eines Zerspanungswerkzeugs. Patent DE102014207507 A1, 22 October 2015. [Google Scholar]

- Donisi, S.; Graf, G. Scheibenfräser und Herstellverfahren. Patent DE102014012481 A1, 3 March 2016. [Google Scholar]

- Kappmeyer, G. Verfahren zur Herstellung eines Zerspanwerkzeugs. Patent DE102006026967 A1, 13 December 2007. [Google Scholar]

- Biermann, D.; Meier, H.; Haberland, C.; Abrahams, H.; Metzger, M.; Steiner, M. Einsatz additiv gefertigter Werkzeughalter—Optimierungspotentiale bei der Drehbearbeitung von Titan durch strahlgeschmolzene Werkzeugaufnahmen. wt Werkstattstech. online 2013, 103, 481–484. [Google Scholar]

- Seidel, C.; Kamps, T.; Riss, F.K.E. Bio TRIZ—Process know-how, design methodologies and software tools for enhanced additive manufacturing. In Proceedings of the Symposium of Additive Manufacturing and Innovative Technologies (Add+it), Linz, Austria, 10–11 September 2015. [Google Scholar]

- Uhlmann, E.; Peukert, B.; Thom, S.; Prasol, L.; Fürstmann, P.; Sammler, F.; Richarz, S. Solutions for Sustainable Machining. J. Manuf. Sci. Eng. 2017, 139, 051009-1–051009-7. [Google Scholar] [CrossRef]

- Denkena, B.; Grove, T.; Kuhlemann, P. Geschlossenes Kühlsystem vermeidet Osteonekrose. Werkstatt und Betr. WB 2016, 149, 42–45. [Google Scholar]

- Ward, H.; Burger, M.; Chang, Y.; Fürstmann, P.; Neugebauer, S.; Radebach, A.; Sproesser, G.; Pittnerac, A.; Rethmeier, M.; Uhlmann, E.; et al. Assessing carbon dioxide emission reduction potentials of improved manufacturing processes using multiregional input output frameworks. J. Clean. Prod. 2017, 163, 154–165. [Google Scholar] [CrossRef]

- Abele, E.; Heep, T. Feinbearbeitung von Vermicularguss bei Einsatz eines additiv gefertigten Drehhalters für die Prozesskühlung mit CO2-Schnee. In Spanende Fertigung—Prozesse, Innovationen, Werkstoffe; Biermann, D., Ed.; Vulkan-Verlag GmbH: Essen, Germany, 2017; Volume 7, pp. 48–56. ISBN 978-3-8027-2989-8. [Google Scholar]

- Heep, T.; Abele, E. Additively manufactured turning tool solution for the application of cryogenic CO2-cooling. In Proceedings of the 14th Powertrain Manufacturing Conference, Darmstadt, Germany, 21–22 November 2017. [Google Scholar]

- Gibson, I.; Rosen, D.W.; Stucker, B. Additive Manufacturing Technologies; Springer Science + Business Media: New York, NY, USA, 2010; ISBN 978-1-4419-1119-3. [Google Scholar]

- Stoffregen, H.A. Strukturintegration piezoelektrischer Vielschichtaktoren mittels selektiven Laserschmelzens. Ph.D. Thesis, TU Darmstadt, Darmstadt, Germany, 2015. [Google Scholar]

- Kraemer, A. Gestaltungsmodell der kryogenen Prozesskühlung in der Zerspanung. Ph.D. Thesis, RWTH Aachen, Aachen, Germany, 2015. [Google Scholar]

- Liu, Y. Analysis of Production Process of Fine Dry Ice Particles and Application for Surface Cleaning. Ph.D. Thesis, Kyoto University, Kyoto, Japan, 2012. [Google Scholar]

- Aguilar, G.; Vu, H.; Nelson, J.S. Influence of angle between the nozzle and skin surface on the heat flux and overall heat extraction during cryogen spray cooling. Phys. Med. Biol. 2004, 49, N147–N153. [Google Scholar] [CrossRef] [PubMed]

- Spurk, J.H.; Aksel, N. Fluid Mechanics, 2nd ed.; Springer: Berlin/Heidelberg, Germany, 2008; ISBN 978-3-540-73536-6. [Google Scholar]

- Kumar, K.K.; Choudhury, S.K. Investigation of tool wear and cutting force in cryogenic machining using design of experiments. J. Mater. Process. Technol. 2008, 203, 95–101. [Google Scholar] [CrossRef]

- Jerold, B.D.; Kumar, M.P. Experimental comparison of carbon-dioxide and liquid nitrogen cryogenic coolants in turning of AISI 1045 steel. Cryogenics 2012, 52, 569–574. [Google Scholar] [CrossRef]

- Machai, C.; Biermann, D. Machining of beta-titanium-alloy Ti-10V-2Fe-3Al under cryogenic conditions: Cooling with carbon dioxide snow. J. Mater. Process. Technol. 2011, 211, 1175–1183. [Google Scholar] [CrossRef]

δ = 1.00 | Varied | Constant | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| x | α | |||||||||||

| alignment | x | mm | 25 | 30 | 35 | - | 55 | - | 90 | 17.5 | 5.7 | |

| α | ° | 30 | 60 | - | - | 90 | 55 | - | 17.5 | 5.7 | ||

| loading | kg/h | 7.7 | 11.1 | 13.6 | 14.7 | 17.5 | 25 | 90 | - | - | ||

| MPa | 0.0 | 0.1 | 0.3 | 0.5 | 0.8 | 25 | 90 | 17.5 | 5.7 | - | ||

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Heep, T.; Bickert, C.; Abele, E. Application of Carbon Dioxide Snow in Machining of CGI using an Additively Manufactured Turning Tool. J. Manuf. Mater. Process. 2019, 3, 15. https://doi.org/10.3390/jmmp3010015

Heep T, Bickert C, Abele E. Application of Carbon Dioxide Snow in Machining of CGI using an Additively Manufactured Turning Tool. Journal of Manufacturing and Materials Processing. 2019; 3(1):15. https://doi.org/10.3390/jmmp3010015

Chicago/Turabian StyleHeep, Thomas, Christian Bickert, and Eberhard Abele. 2019. "Application of Carbon Dioxide Snow in Machining of CGI using an Additively Manufactured Turning Tool" Journal of Manufacturing and Materials Processing 3, no. 1: 15. https://doi.org/10.3390/jmmp3010015

APA StyleHeep, T., Bickert, C., & Abele, E. (2019). Application of Carbon Dioxide Snow in Machining of CGI using an Additively Manufactured Turning Tool. Journal of Manufacturing and Materials Processing, 3(1), 15. https://doi.org/10.3390/jmmp3010015