A Review of Real-Time Implementable Cooperative Aerial Manipulation Systems

Abstract

1. Introduction

- Ability to navigate in uncertain environments (i.e., poor GPS or GPS denied areas). Real-time SLAM, adaptation to unforeseen events, dynamic collision avoidance, planning and re-planning, and safe flight based on onboard sensor suites are minimum requirements for safe navigation.

- Power and energy requirements (battery consumption), algorithm computational complexity, execution time, effective payload, and maximum takeoff weight (MTOW) must be considered as they affect flight-time, range, and endurance.

- Robust communication among platforms is essential, with minimum or no delays (due to latency, transmission loss, etc.), as well as minimum or no down-time.

- System stability must be tackled since, as stated in [13], wind gusts, random wind profiles, aerodynamic perturbations, and induced, parasitic, and other types of drag may affect accurate manipulation and navigation.

- On the regulation front, regulations dictate that a certified pilot must operate a UAV—this refers to teleoperation as an alternative to semi-autonomous or autonomous functionality (for safety reasons). Obviously, autonomous flight may be needed in certain applications.

2. Search Method

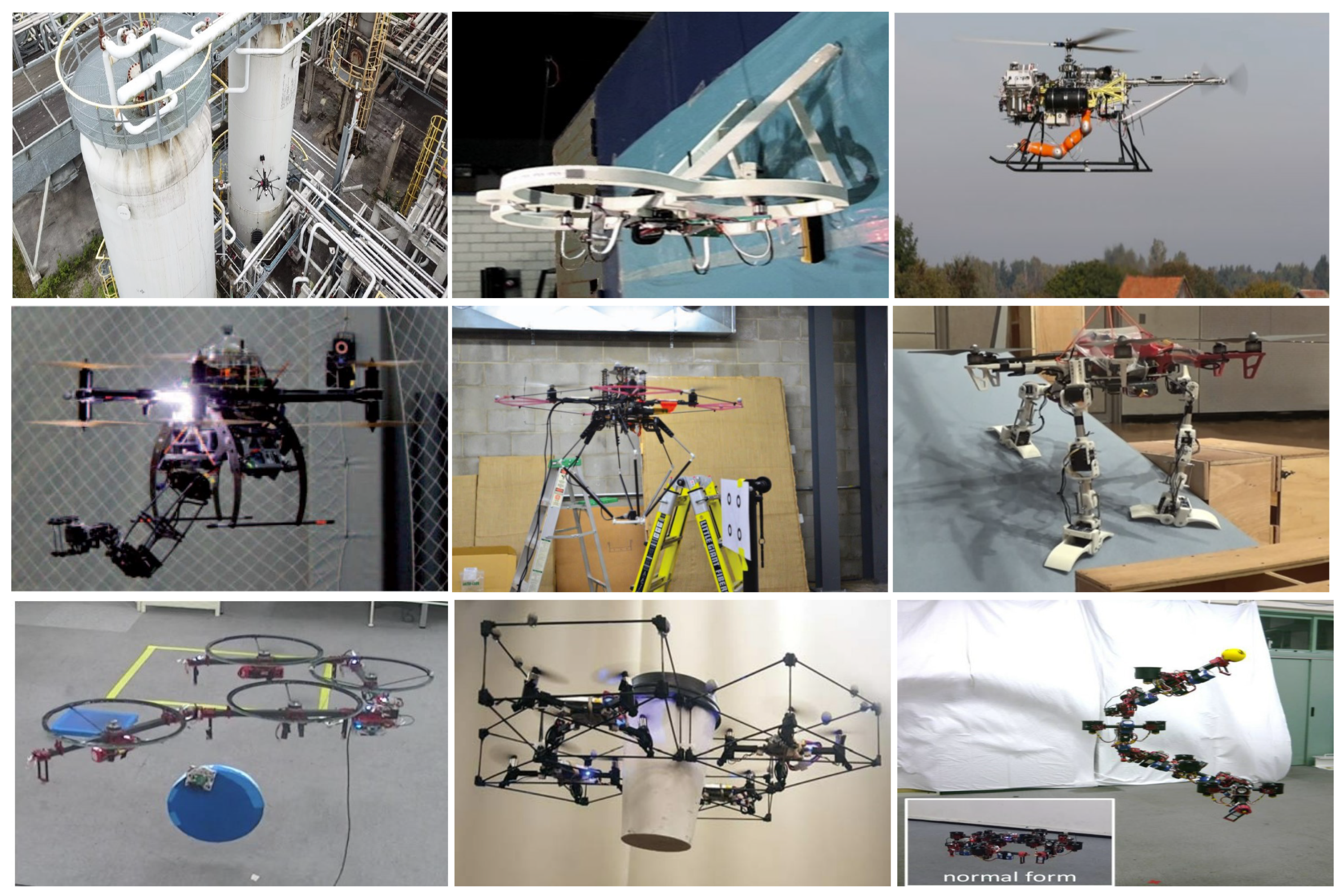

3. Literature Review on Aerial Manipulation

4. Cooperative Aerial Manipulation

4.1. Cable-Driven

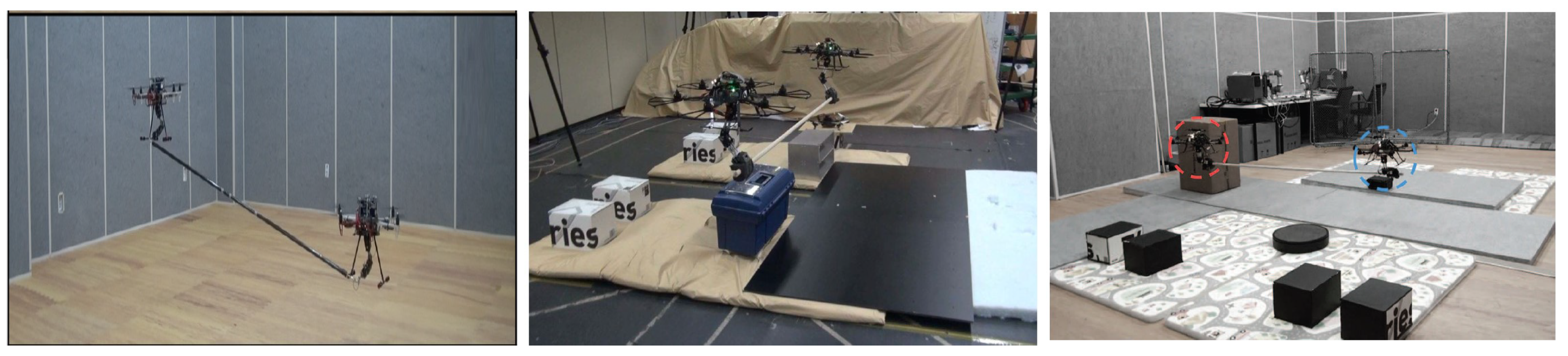

4.2. Aerial Manipulation with Multi-DoF Arms

4.3. Flexible Payload

4.4. Ground–Air

4.5. Rigidly-Attached

5. Modeling Approaches

5.1. Newton–Euler Modeling Formulation

5.2. Euler–Lagrange

5.3. Other Modeling Methods

6. Control

6.1. Manipulation/Transportation

6.2. In the Presence of Wind

6.3. Vision-Based

6.4. Teleoperation

7. Conclusions and Discussion

Future Challenges

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Wu, Y.; Wu, S.; Hu, X. Multi-constrained cooperative path planning of multiple drones for persistent surveillance in urban environments. Complex Intell. Syst. 2021, 7, 1633–1647. [Google Scholar] [CrossRef]

- Almurib, H.; Nathan, P.; Kumar, T. Control and path planning of quadrotor aerial vehicles for search and rescue. In Proceedings of the SICE Annual Conference 2011, Tokyo, Japan, 13–18 September 2011; pp. 700–705. Available online: https://ieeexplore.ieee.org/abstract/document/6060754 (accessed on 27 October 2011).

- Reinoso, J.F.; Gonçalves, J.E.; Pereira, C.; Bleninger, T. Cartography for Civil Engineering Projects: Photogrammetry Supported by Unmanned Aerial Vehicles. Iran. J. Sci. Technol. Trans. Civ. Eng. 2018, 42, 91–96. [Google Scholar] [CrossRef]

- Hu, J.; Niu, H.; Carrasco, J.; Lennox, B.; Arvin, F. Fault-tolerant cooperative navigation of networked UAV swarms for forest fire monitoring. Aerosp. Sci. Technol. 2022, 123, 107494. [Google Scholar] [CrossRef]

- Yuan, W.; Choi, D.; Bolkas, D. GNSS-IMU-assisted colored ICP for UAV-LiDAR point cloud registration of peach trees. Comput. Electron. Agric. 2022, 197, 106966. [Google Scholar] [CrossRef]

- Kim, J.J.; Kim, I.; Hwang, J. A change of perceived innovativeness for contactless food delivery services using drones after the outbreak of COVID-19. Int. J. Hosp. Manag. 2021, 93. [Google Scholar] [CrossRef]

- Ruggiero, F.; Lippiello, V.; Ollero, A. Aerial Manipulation: A Literature Review. IEEE Robot. Autom. Lett. 2018, 3, 1957–1964. [Google Scholar] [CrossRef]

- Aerial Robotics Cooperative Assembly System. EU Res. 2011–2015. Available online: https://cordis.europa.eu/project/id/287617 (accessed on 22 April 2017).

- Lindsey, Q.; Mellinger, D.; Kumar, V. Construction with quadrotor teams. Auton. Robot. 2012, 33, 323–336. [Google Scholar] [CrossRef]

- Ollero, A.; Tognon, M.; Suarez, A.; Lee, D.; Franchi, A. Past, Present and Future of Aerial Robotic Manipulators. IEEE Trans. Robot. 2021, 38, 626–645. Available online: https://ieeexplore.ieee.org/document/9462539 (accessed on 22 June 2021). [CrossRef]

- Khamseh, H.B.; Janabi-Sharifi, F.; Abdessameud, A. Aerial manipulation-A literature survey. Robot. Auton. Syst. 2018, 107, 221–235. [Google Scholar] [CrossRef]

- Ramalepa, L.P.; Jamisola, R.S., Jr. A Review on Cooperative Robotic Arms with Mobile or Drones Bases. Int. J. Autom. Comput. 2021, 18, 536–555. [Google Scholar] [CrossRef]

- Ollero, A.; Heredia, G.; Franchi, A.; Antonelli, G.; Kondak, K.; Sanfeliu, A.; Viguria, A.; de Dios, J.M.; Pierri, F.; Cortés, J.; et al. The aeroarms project: Aerial robots with advanced manipulation capabilities for inspection and maintenance. IEEE Robot. Autom. Mag. 2018, 25, 12–13. Available online: https://ieeexplore.ieee.org/document/8435987 (accessed on 14 August 2018). [CrossRef]

- Barakou, S.C.; Tzafestas, C.S.; Valavanis, K.P. Real-Time Applicable Cooperative Aerial Manipulation: A Survey. In Proceedings of the International Conference on Unmanned Aircraft Systems (ICUAS), Warsaw, Poland, 6–9 June 2023; pp. 634–643. [Google Scholar] [CrossRef]

- Ángel Trujillo, M.; de Dios, J.R.M.; Martín, C.; Viguria, A.; Ollero, A. Novel Aerial Manipulator for Accurate and Robust Industrial NDT Contact Inspection: A New Tool for the Oil and Gas Inspection Industry. Sensors 2019, 19, 1305. [Google Scholar] [CrossRef] [PubMed]

- Albers, A.; Trautmann, S.; Howard, T.; Nguyen, T.A.; Frietsch, M.; Sauter, C. Semi-autonomous flying robot for physical interaction with environment. In Proceedings of the IEEE Conference on Robotics, Automation and Mechatronics, Singapore, 28–30 June 2010; pp. 441–446. Available online: https://ieeexplore.ieee.org/document/5513152 (accessed on 19 July 2010).

- Mellinger, D.; Lindsey, Q.; Shomin, M.; Kumar, V. Design, modeling, estimation and control for aerial grasping and manipulation. In Proceedings of the IEEE/RSJ International Conference on Intelligent Robots and Systems, San Francisco, CA, USA, 25–30 September 2011; pp. 2668–2673. Available online: https://ieeexplore.ieee.org/document/6094871 (accessed on 5 December 2011).

- Fumagalli, M.; Naldi, R.; Macchellia, A.; Forte, F.; Keemink, A.Q.; Stramigioli, S.; Carloni, R.; Marconi, L. Developing an Aerial Manipulator Prototype: Physical Interaction with the Environment. IEEE Robot. Autom. Mag. 2014, 21, 41–50. Available online: https://ieeexplore.ieee.org/document/6875943 (accessed on 11 August 2014). [CrossRef]

- Marconi, L.; Naldi, R.; Gentili, L. Modelling and control of a flying robot interacting with the environment. Automatica 2011, 47, 2571–2583. [Google Scholar] [CrossRef]

- Korpela, C.M.; Danko, T.W.; Oh, P.Y. MM-UAV: Mobile Manipulating Unmanned Aerial Vehicle. J. Intell. Robot. Syst. 2012, 65, 93–101. [Google Scholar] [CrossRef]

- Bernard, M.; Kondak, K.; Maza, I.; Ollero, A. Autonomous Transportation and Deployment with Aerial Robots for Search and Rescue Missions. J. Field Robot. 2011, 28, 914–931. [Google Scholar] [CrossRef]

- Pounds, P.; Bersak, D.; Dollar, A. Grasping From the Air: Hovering Capture and Load Stability. In Proceedings of the IEEE International Conference on Robotics and Automation, Shanghai, China, 9–13 May 2011; pp. 2491–2498. Available online: https://ieeexplore.ieee.org/document/5980314 (accessed on 18 August 2011).

- Morton, K.; Toro, L.F.G. Development of a Robust Framework for an Outdoor Mobile Manipulation UAV. In Proceedings of the IEEE Aerospace Conference, Big Sky, MT, USA, 5–12 March 2016; pp. 1–8. Available online: https://ieeexplore.ieee.org/document/7500576 (accessed on 30 June 2016).

- Jimenez-Cano, A.E.; Martin, J.; Heredia, G.; Ollero, A.; Cano, R. Control of an aerial robot with multi-link arm for assembly tasks. In Proceedings of the IEEE International Conference on Robotics and Automation (ICRA), Karlsruhe, Germany, 6–10 May 2013; pp. 4916–4921. Available online: https://ieeexplore.ieee.org/document/6631279 (accessed on 17 October 2013).

- Kondak, K.; Huber, F.; Schwarzbach, M.; Laiacker, M.; Sommer, D.; Bejar, M.; Ollero, A. Aerial manipulation robot composed of an autonomous helicopter and a 7 degrees of freedom industrial manipulator. In Proceedings of the IEEE International Conference on Robotics and Automation (ICRA), Hong Kong, China, 31 May–7 June 2014; pp. 2107–2112. Available online: https://ieeexplore.ieee.org/document/6907148 (accessed on 29 September 2014).

- Danko, T.W.; Oh, P.Y. A hyper-redundant manipulator for mobile manipulating unmanned aerial vehicles. In Proceedings of the International Conference on Unmanned Aircraft Systems (ICUAS), Atlanta, GA, USA, 28–31 May 2013; pp. 974–981. Available online: https://ieeexplore.ieee.org/document/6564784 (accessed on 22 July 2013).

- Lippiello, V.; Cacace, J.; Santamaria-Navarro, A.; Andrade-Cetto, J.; Ángel Trujillo, M.; Esteves, Y.R.; Viguria, A. Hybrid Visual Servoing with Hierarchical Task Composition for Aerial Manipulation. IEEE Robot. Autom. Lett. 2016, 1, 259–266. Available online: https://ieeexplore.ieee.org/document/7361979 (accessed on 22 December 2015). [CrossRef]

- Kanellakis, C.; Terreran, M.; Kominiak, D.; Nikolakopoulos, G. On Vision Enabled Aerial Manipulation for Multirotors. In Proceedings of the IEEE International Conference on Emerging Technologies and Factory Automation (ETFA), Limassol, Cyprus, 12–15 September 2017; pp. 1–7. Available online: https://ieeexplore.ieee.org/document/8247653 (accessed on 8 January 2018).

- Danko, T.W.; Chaney, K.P.; Oh, P.Y. A Parallel Manipulator for Mobile Manipulating UAVs. In Proceedings of the IEEE International Conference on Technologies for Practical Robot Applications (TePRA), Woburn, MA, USA, 11–12 May 2015; pp. 1–6. Available online: https://ieeexplore.ieee.org/document/7219682 (accessed on 27 August 2015).

- Kamel, M.; Alexis, K.; Siegwart, R. Design and Modeling of Dexterous Aerial Manipulator. In Proceedings of the IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Daejeon, Republic of Korea, 9–14 October 2016; pp. 4870–4876. Available online: https://ieeexplore.ieee.org/document/7759715 (accessed on 1 December 2016).

- Pumarola, A.; Vakhitov, A.; Agudo, A.; Moreno-Noguer, F.; Sanfeliu, A. Relative Localization for Aerial Manipulation with PL-SLAM. In Aerial Robotic Manipulation; Springer: Berlin/Heidelberg, Germany, 2019; pp. 239–248. [Google Scholar] [CrossRef]

- Paneque, J.; de Dios, J.M.; Ollero, A. Multi-Sensor 6-DoF Localization for Aerial Robots In Complex GNSS-Denied Environments. In Proceedings of the IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Macau, China, 3–8 November 2019; pp. 1978–1984. Available online: https://ieeexplore.ieee.org/document/8967686 (accessed on 28 January 2020).

- Zhang, X.; Zhang, Y.; Liu, P.; Zhao, S. Robust Localization of Occluded Targets in Aerial Manipulation Via Range-Only Mapping. IEEE Robot. Autom. 2022, 27, 2921–2928. Available online: https://ieeexplore.ieee.org/document/9691791 (accessed on 25 January 2022). [CrossRef]

- Bodie, K.; Brunner, M.; Pantic, M.; Walser, S.; Pfändler, P.; Angst, U.; Siegwart, R.; Nieto, J. Active Interaction Force Control for Contact-Based Inspection with a Fully Actuated Aerial Vehicle. IEEE Trans. Robot. 2021, 37, 709–722. Available online: https://ieeexplore.ieee.org/document/9295362 (accessed on 15 December 2020). [CrossRef]

- Ryll, M.; Muscio, G.; Pierri, F.; Cataldi, E.; Antonelli, G.; Caccavale, F.; Bicego, D.; Franchi, A. 6D interaction control with aerial robots: The flying end-effector paradigm. Int. J. Robot. Res. 2019, 38, 1045–1062. [Google Scholar] [CrossRef]

- Tognon, M.; Chávez, H.A.T.; Gasparin, E.; Sablé, Q.; Bicego, D.; Mallet, A.; Lany, M.; Santi, G.; Revaz, B.; Cortés, J.; et al. A Truly-Redundant Aerial Manipulator System with Application to Push-and-Slide Inspection in Industrial Plants. IEEE Robot. Autom. 2019, 4, 1045–1062. Available online: https://ieeexplore.ieee.org/document/8629273 (accessed on 29 January 2019). [CrossRef]

- Santamaria-Navarro, A.; Grosch, P.; Lippiello, V.; Solà, J.; Andrade-Cetto, J. Uncalibrated Visual Servo for Unmanned Aerial Manipulation. IEEE/ASME Trans. Mechatronics 2017, 22, 1610–1621. Available online: https://ieeexplore.ieee.org/document/7879365 (accessed on 15 March 2017). [CrossRef]

- Suarez, A.; Salmoral, R.; Garofano-Soldado, A.; Heredia, G.; Ollero, A. Aerial Device Delivery for Power Line Inspection and Maintenance. In Proceedings of the International Conference on Unmanned Aircraft Systems (ICUAS), Dubrovnik, Croatia, 21–24 June 2022; pp. 30–38. Available online: https://ieeexplore.ieee.org/document/9836039 (accessed on 26 July 2022).

- Suarez, A.; Heredia, G.; Ollero, A. Design of an anthropomorphic, compliant, and lightweight dual arm for aerial manipulation. IEEE Access 2018, 6, 29173–29189. Available online: https://ieeexplore.ieee.org/document/8354886 (accessed on 4 May 2018). [CrossRef]

- Paul, H.; Miyazaki, R.; Ladig, R.; Shimonomura, K. Landing of a multirotor aerial vehicle on an uneven surface using multiple on-board manipulators. In Proceedings of the IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Macau, China, 3–8 November 2019; pp. 1926–1933. Available online: https://ieeexplore.ieee.org/document/8968529 (accessed on 28 January 2020).

- Anzai, T.; Zhao, M.; Chen, X.; Shi, F.; Kawasaki, K.; Okada, K.; Inaba, M. Multilinked multirotor with internal communication system for multiple objects transportation based on form optimization method. In Proceedings of the IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Vancouver, BC, Canada, 24–28 September 2017; pp. 5977–5984. Available online: https://ieeexplore.ieee.org/document/8206493 (accessed on 14 December 2017).

- Gabrich, B.; Saldana, D.; Kumar, V.; Yim, M. A Flying Gripper Based on Cuboid Modular Robots. In Proceedings of the IEEE International Conference on Robotics and Automation (ICRA), Brisbane, QLD, Australia, 21–25 May 2018; pp. 7024–7030. Available online: https://ieeexplore.ieee.org/document/8460682 (accessed on 13 September 2018).

- Zhao, M.; Shi, F.; Anzai, T.; Okada, K.; Inaba, M. Online Motion Planning for Deforming Maneuvering and Manipulation by Multilinked Aerial Robot Based on Differential Kinematics. IEEE Robot. Autom. 2020, 5, 1602–1609. Available online: https://ieeexplore.ieee.org/document/8962166 (accessed on 17 January 2020). [CrossRef]

- Yang, H.; Park, S.; Lee, J.; Ahn, J.; Son, D.; Lee, D. LASDRA: Large-Size Aerial Skeleton System with Distributed Rotor Actuation. In Proceedings of the IEEE International Conference on Robotics and Automation (ICRA), Brisbane, QLD, Australia, 21–25 May 2018; pp. 7017–7023. Available online: https://ieeexplore.ieee.org/document/8460713 (accessed on 13 September 2018).

- Gioioso, G.; Mohammadi, M.; Franchi, A.; Prattichizzo, D. A Force-based Bilateral Teleoperation Framework for Aerial Robots in Contact with the Environment. In Proceedings of the IEEE International Conference on Robotics and Automation (ICRA), Seattle, WA, USA, 26–30 May 2015; pp. 318–324. Available online: https://ieeexplore.ieee.org/abstract/document/7139018 (accessed on 2 July 2015).

- Gioioso, G.; Franchi, A.; Salvietti, G.; Scheggi, S.; Prattichizzo, D. The Flying Hand: A Formation of UAVs for Cooperative Aerial Tele-Manipulation. In Proceedings of the IEEE International Conference on Robotics and Automation (ICRA), Hong Kong, China, 31 May–7 June 2014; pp. 4335–4341. Available online: https://ieeexplore.ieee.org/document/6907490 (accessed on 29 September 2014).

- Lee, J.; Balachandran, R.; Sarkisov, Y.S.; Stefano, M.D.; Coelho, A.; Shinde, K.; Kim, M.J.; Triebel, R.; Kondak, K. Visual-Inertial Telepresence for Aerial Manipulation. In Proceedings of the IEEE International Conference on Robotics and Automation (ICRA), Paris, France, 31 May–31 August 2020; pp. 1222–1229. Available online: https://ieeexplore.ieee.org/document/9197394 (accessed on 15 September 2020).

- Sarkisov, Y.S.; Kim, M.J.; Bicego, D.; Tsetserukou, D.; Ott, C.; Franchi, A.; Kondak, K. Development of SAM: Cable-suspended aerial manipulator. In Proceedings of the International Conference on Robotics and Automation (ICRA), Montreal, QC, Canada, 20–24 May 2019; pp. 5323–5329. Available online: https://ieeexplore.ieee.org/document/8793592 (accessed on 12 August 2019).

- Michael, N.; Fink, J.; Kumar, V. Cooperative manipulation and transportation with aerial robots. Auton. Robot. 2010, 30, 73–86. [Google Scholar] [CrossRef]

- Fink, J.; Michael, N.; Kim, S.; Kumar, V. Planning and control for cooperative manipulation and transportation with aerial robots. Int. J. Robot. Res. 2011, 30, 324–334. [Google Scholar] [CrossRef] [PubMed]

- Sanalitro, D.; Savino, H.J.; Tognon, M.; Cortés, J.; Franchi, A. Full-Pose Manipulation Control of a Cable-Suspended Load with Multiple UAVs under Uncertainties. IEEE Robot. Autom. 2020, 5, 2185–2191. Available online: https://ieeexplore.ieee.org/document/8972607 (accessed on 28 January 2020). [CrossRef]

- Sreenath, K.; Kumar, V. Dynamics, Control and Planning for Cooperative Manipulation of Payloads Suspended by Cables from Multiple Quadrotor Robots. Robot. Sci. Syst. 2013. [Google Scholar] [CrossRef]

- Bernard, M.; Kondak, K.; Hommel, G. Load transportation system based on autonomous small size helicopters. Aeronaut. J. 2010, 114, 191–198. [Google Scholar] [CrossRef]

- Paola, V.D.; Goldsztejn, A.; Zoppi, M.; Caro, S. Design of a Sliding Mode-Adaptive PID Control for Aerial Systems with a Suspended Load Exposed to Wind Gusts. J. Comput. Nonlinear Dyn. 2023, 18, 1–15. [Google Scholar] [CrossRef]

- Mechali, O.; Xu, L.; Xie, X. Formation Flight Control of Networked-Delayed Quadrotors for Cooperative Slung Load Transportation. In Proceedings of the IEEE International Conference on Mechatronics and Automation (ICMA), Guilin, China, 7–10 August 2022; pp. 526–531. Available online: https://ieeexplore.ieee.org/document/9856271 (accessed on 22 August 2022).

- Bulka, E.; He, C.; Wehbeh, J.; Sharf, I. Experiments on Collaborative Transport of Cable-suspended Payload with Quadrotor UAVs. In Proceedings of the International Conference on Unmanned Aircraft Systems (ICUAS 22), Dubrovnik, Croatia, 21–24 June 2022; pp. 1465–1473. Available online: https://ieeexplore.ieee.org/document/9836163 (accessed on 26 July 2022).

- Michael Gassner, T.C.; Scaramuzza, D. Dynamic Collaboration without Communication: Vision-Based Cable-Suspended Load Transport with Two Quadrotors. In Proceedings of the IEEE International Conference on Robotics and Automation (ICRA), Singapore, 29 May–3 June 2017; pp. 5196–5202. Available online: https://ieeexplore.ieee.org/document/7989609 (accessed on 24 July 2017).

- Bacelara, T.; Madeirasa, J.; Melicioa, R.; Cardeiraa, C.; Oliveiraa, P. On-board implementation and experimental validation of collaborative transportation of loads with multiple UAVs. Aerosp. Sci. Technol. 2020, 107, 106284. [Google Scholar] [CrossRef]

- Li, G.; Ge, R.; Loianno, G. Cooperative Transportation of Cable Suspended Payloads with MAVs Using Monocular Vision and Inertial Sensing. IEEE Robot. Autom. 2021, 6, 5316–5323. Available online: https://ieeexplore.ieee.org/abstract/document/9376103 (accessed on 11 March 2021). [CrossRef]

- Li, G.; Loianno, G. Nonlinear Model Predictive Control for Cooperative Transportation and Manipulation of Cable Suspended Payloads with Multiple Quadrotors. In Proceedings of the IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Detroit, MI, USA, 1–5 October 2023; pp. 5034–5041. Available online: https://ieeexplore.ieee.org/document/10341785 (accessed on 13 December 2023).

- Xie, H.; Dong, K.; Chirarattananon, P. Cooperative Transport of a Suspended Payload via Two Aerial Robots with Inertial Sensing. IEEE Access 2022, 10, 81764–81776. Available online: https://ieeexplore.ieee.org/document/9844732 (accessed on 29 July 2022). [CrossRef]

- Geng, J.; Langelaan, J.W. Cooperative Transport of a Slung Load Using Load-Leading Control. J. Guid. Control. Dyn. 2020, 43, 1313–1331. [Google Scholar] [CrossRef]

- Klausen, K.; Meissen, C.; Fossen, T.I.; Arcak, M.; Johansen, T.A. Cooperative Control for Multirotors Transporting an Unknown Suspended Load Under Environmental Disturbances. IEEE Trans. Control. Syst. Technol. 2018, 28, 653–660. Available online: https://ieeexplore.ieee.org/document/8567931 (accessed on 7 December 2018). [CrossRef]

- Spurny, V.; Petrlik, M.; Vonasek, V.; Saska, M. Cooperative Transport of Large Objects by a Pair of Unmanned Aerial Systems using Sampling-based Motion Planning. In Proceedings of the IEEE International Conference on Emerging Technologies and Factory Automation (ETFA), Zaragoza, Spain, 10–13 September 2019; pp. 955–962. Available online: https://ieeexplore.ieee.org/document/8869298 (accessed on 17 October 2019).

- Jackson, B.E.; Howell, T.A.; Shah, K.; Schwager, M.; Manchester, Z. Scalable Cooperative Transport of Cable-Suspended Loads with UAVs Using Distributed Trajectory Optimization. IEEE Robot. Autom. 2020, 5, 3368–3374. Available online: https://ieeexplore.ieee.org/document/9007450 (accessed on 24 February 2020). [CrossRef]

- Jiang, Q.; Kumar, V. The Inverse Kinematics of Cooperative Transport with Multiple Aerial Robots. IEEE Trans. Robot. 2013, 29, 136–145. Available online: https://ieeexplore.ieee.org/document/6329450 (accessed on 11 October 2012). [CrossRef]

- Tognon, M.; Gabellieri, C.; Pallottino, L.; Franchi, A. Aerial Co-Manipulation with Cables: The Role of Internal Force for Equilibria, Stability, and Passivity. IEEE Robot. Autom. 2018, 3, 2577–2583. Available online: https://ieeexplore.ieee.org/document/8286868 (accessed on 8 February 2018). [CrossRef]

- Ping, Y.; Wang, M.; Qi, J.; Wu, C.; Guo, J. Collaborative Control Based on Payload-leading for the Multi-quadrotor Transportation Systems. In Proceedings of the IEEE International Conference on Robotics and Automation (ICRA 2023), London, UK, 29 May–2 June 2023; pp. 5304–5309. Available online: https://ieeexplore.ieee.org/document/10161414 (accessed on 4 July 2023).

- Liu, Y.; Zhang, F.; Huang, P.; Zhang, X. Analysis, planning and control for cooperative transportation of tethered multi-rotor UAVs. Aerosp. Sci. Technol. 2021, 113. [Google Scholar] [CrossRef]

- Arab, F.; Shirazi, F.A.; Reza, M.; Yazdi, H. Planning and distributed control for cooperative transportation of a non-uniform slung-load by multiple quadrotors. Aerosp. Sci. Technol. 2021, 117, 106917. [Google Scholar] [CrossRef]

- Zhang, X.; Zhang, F.; Huang, P. Formation Planning for Tethered Multirotor UAV Cooperative Transportation with Unknown Payload and Cable Length. In IEEE Transactions on Automation Science and Engineering; IEEE: Piscataway, NJ, USA, 2023; pp. 1–12. Available online: https://ieeexplore.ieee.org/document/10144367 (accessed on 5 June 2023).

- Han, X.; Miyazaki, R.; Gao, T.; Tomita, K.; Kamimura, A. Controller Design and Disturbance Rejection of Multi-Quadcopters for Cable Suspended Payload Transportation Using Virtual Structure. IEEE Access 2022, 10, 122197–122210. Available online: https://ieeexplore.ieee.org/document/9950250 (accessed on 14 November 2022). [CrossRef]

- Lee, T.; Sreenath, K.; Kumar, V. Geometric Control of Cooperating Multiple Quadrotor UAVs with a Suspended Payload. In Proceedings of the IEEE Conference on Decision and Control, Firenze, Italy, 10–13 December 2013; pp. 5510–5515. Available online: https://ieeexplore.ieee.org/document/6760757 (accessed on 10 March 2014).

- Lee, T. Geometric Control of Quadrotor UAVs Transporting a Cable-Suspended Rigid Body. IEEE Trans. Control. Syst. Technol. 2017, 26, 255–264. Available online: https://ieeexplore.ieee.org/document/7843619 (accessed on 6 February 2017). [CrossRef]

- Goodarzi, F.A.; Lee, T. Dynamics and Control of Quadrotor UAVs Transporting a Rigid Body Connected via Flexible Cables. In Proceedings of the American Control Conference, Chicago, IL, USA, 1–3 July 2015; pp. 4677–4682. Available online: https://ieeexplore.ieee.org/document/7172066 (accessed on 30 July 2015).

- Goodarzi, F.A.; Lee, T. Stabilization of a Rigid Body Payload with Multiple Cooperative Quadrotors. J. Dyn. Syst. Meas. Control. 2015, 138, 121001. [Google Scholar] [CrossRef]

- Sharma, M.; Sundaram, S. A geometric control approach for multi-UAV cooperative payload transfer. Nonlinear Dyn. 2023, 111, 10077–10096. [Google Scholar] [CrossRef]

- Masone, C.; Bülthoff, H.H.; Stegagno, P. Cooperative Transportation of a Payload using Quadrotors: A Reconfigurable Cable-Driven Parallel Robot. In Proceedings of the IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Daejeon, Korea (South), 9–14 October 2016; pp. 1623–1630. Available online: https://ieeexplore.ieee.org/document/7759262 (accessed on 1 December 2016).

- Cardona, G.A.; D’Antonio, D.S.; Fierro, R.; Saldana, D. Adaptive Control for Cooperative Aerial Transportation Using Catenary Robots. In Proceedings of the Aerial Robotic Systems Physically Interacting with the Environment (AIRPHARO), Biograd na Moru, Croatia, 4–5 October 2021; Available online: https://ieeexplore.ieee.org/document/9571068 (accessed on 26 October 2021).

- de Marina, H.G.; Smeur, E. Flexible collaborative transportation by a team of rotorcraft. In Proceedings of the International Conference on Robotics and Automation (ICRA), Montreal, QC, Canada, 20–24 May 2019; pp. 1074–1080. Available online: https://ieeexplore.ieee.org/document/8794316 (accessed on 12 August 2019).

- Villa, D.K.D.; Brandão, A.S.; Carelli, R.; Sarcinelli-Filho, M. Cooperative Load Transportation with Two Quadrotors Using Adaptive Control. IEEE Access 2021, 9, 129148–129160. Available online: https://ieeexplore.ieee.org/document/9540662 (accessed on 16 September 2021). [CrossRef]

- Liang, X.; Zhang, Z.; Yu, H.; Wang, Y.; Fang, Y.; Han, J. Antiswing Control for Aerial Transportation of the Suspended Cargo by Dual Quadrotor UAVs. IEEE/ASME Trans. Mechatronics 2022, 27, 5159–5172. Available online: https://ieeexplore.ieee.org/document/9784110 (accessed on 27 May 2022). [CrossRef]

- Hung, T.K.; Liu, Y.C.; Lee, C.E. Null-Space-Based Adaptive Control for Aerial Manipulators on Cooperatively Transporting Cable-Suspended Objects. In Proceedings of the IEEE/ASME International Conference on Advanced Intelligent Mechatronics (AIM), Seattle, WA, USA, 28–30 June 2023; pp. 466–472. Available online: https://ieeexplore.ieee.org/document/10196282 (accessed on 2 August 2023).

- Zhang, X.; Yang, Q.; Yu, R.; Wu, D.; Wei, S.; Cui, J.; Fang, H. Design and Analysis of Truss Aerial Transportation System (TATS): The Lightweight Bar Spherical Joint Mechanism. In Proceedings of the IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Kyoto, Japan, 23–27 October 2022; pp. 10501–10507. Available online: https://ieeexplore.ieee.org/document/9981191 (accessed on 26 December 2022).

- Wu, P.X.; Yang, C.C.; Cheng, T.H. Cooperative Transportation of UAVs without Inter-UAV Communication. IEEE/ASME Trans. Mechatronics 2023, 28, 2340–2351. Available online: https://ieeexplore.ieee.org/document/10020177 (accessed on 18 January 2023). [CrossRef]

- Xu, L.; Lu, H.; Wang, J.; Guo, X.; Guo, L. Force-Coordination Control for Aerial Collaborative Transportation Based on Lumped Disturbance Separation and Estimation. 2023. Available online: https://arxiv.org/pdf/2304.00193.pdf (accessed on 1 April 2023).

- Kim, S.; Seo, H.; Shin, J.; Kim, H.J. Cooperative Aerial Manipulation Using Multirotors with Multi-DOF Robotic Arms. IEEE/ASME Trans. Mechatronics 2018, 23, 702–713. Available online: https://ieeexplore.ieee.org/document/8253830 (accessed on 11 January 2018). [CrossRef]

- Beard, R.W.; McLain, T.W.; Kingston, D.D.; Johanson, D. Hierarchical cooperative control framework of multiple quadrotor-manipulator systems. In Proceedings of the 2015 IEEE International Conference on Robotics and Automation (ICRA), Seattle, WA, USA, 26–30 May 2015; pp. 4656–4662. Available online: https://ieeexplore.ieee.org/document/7139844 (accessed on 2 July 2015).

- Caccavale, F.; Giglio, G.; Muscio, G.; Pierri, F. Cooperative impedance control for multiple UAVs with a robotic arm. In Proceedings of the 2015 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Hamburg, Germany, 28 September–2 October 2015; pp. 2366–2371. Available online: https://ieeexplore.ieee.org/document/7353697 (accessed on 17 December 2015).

- Lee, H.; Kim, H.; Kim, W.; Kim, H.J. An Integrated Framework for Cooperative Aerial Manipulators in Unknown Environments. IEEE Robot. Autom. Lett. 2018, 3, 2307–2314. Available online: https://ieeexplore.ieee.org/document/8294245 (accessed on 19 February 2018). [CrossRef]

- Lee, H.; Kim, H.; Kim, H.J. Path planning and control of multiple aerial manipulators for a cooperative transportation. In Proceedings of the 2015 IEEE/RSJ International Conference on Intelligent Robots and Systems, Hamburg, Germany, 28 September–2 October 2015; pp. 2386–2391. Available online: https://ieeexplore.ieee.org/document/7353700 (accessed on 17 December 2015).

- Lee, H.; Kim, H.; Kim, H.J. Planning and Control for Collision-Free Cooperative Aerial Transportation. IEEE Trans. Autom. Sci. Eng. 2016, 15, 189–201. Available online: https://ieeexplore.ieee.org/document/7589023 (accessed on 12 October 2016). [CrossRef]

- Kim, H.; Seo, H.; Son, C.Y.; Lee, H.; Kim, S.; Kim, H.J. Cooperation in the Air: A Learning-Based Approach for the Efficient Motion Planning of Aerial Manipulators. IEEE Robot. Autom. Mag. 2018, 25, 76–85. Available online: https://ieeexplore.ieee.org/abstract/document/8485637 (accessed on 8 October 2018). [CrossRef]

- Lee, H.; Son, C.Y.; Kim, H.J. Collision-Free Path Planning for Cooperative Aerial Manipulators Under Velocity and Curvature Constraints. IEEE Access 2019, 7, 171153–171162. Available online: https://ieeexplore.ieee.org/document/8862842. (accessed on 8 October 2019). [CrossRef]

- Lee, H.; Kim, U. Estimation and Control of Cooperative Aerial Manipulators for a Payload with an Arbitrary Center-of-Mass. Sensors 2021, 21, 6452. Available online: https://www.mdpi.com/1424-8220/21/19/6452 (accessed on 27 September 2021). [CrossRef] [PubMed]

- Thapa, S.; Bai, H.; Acosta, J.A. Cooperative Aerial Manipulation with Decentralized Adaptive Force-Consensus Control. J. Intell. Robot. Syst. 2020, 97, 171–183. [Google Scholar] [CrossRef]

- Gkountas, K.; Tzes, A. Leader/Follower Force Control of Aerial Manipulators. IEEE Access 2021, 9, 17584–17595. Available online: https://ieeexplore.ieee.org/document/9333576 (accessed on 22 January 2021). [CrossRef]

- Chaikalis, D.; Evangeliou, N.; Tzes, A.; Khorrami, F. Decentralized Leader-Follower Visual Cooperative Package Transportation using Unmanned Aerial Manipulators. In Proceedings of the European Control Conference (ECC), Bucharest, Romania, 13–16 June 2023; pp. 1–5. Available online: https://ieeexplore.ieee.org/document/10178351 (accessed on 17 July 2023).

- Ritz, R.; D’Andrea, R. Carrying a Flexible Payload with Multiple Flying Vehicles. In Proceedings of the IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Tokyo, Japan, 3–7 November 2013; pp. 3465–3471. Available online: https://ieeexplore.ieee.org/document/6696850 (accessed on 2 January 2014).

- Yang, H.; Kim, M.S.; Lee, D. Distributed Rotor-Based Vibration Suppression for Flexible Object Transport and Manipulation. In Proceedings of the IEEE International Conference on Robotics and Automation (ICRA), Paris, France, 31 May–31 August 2020; pp. 1230–1236. Available online: https://ieeexplore.ieee.org/document/9196908 (accessed on 15 September 2020).

- Chen, T.; Shan, J.; Liu, H.H.T. Cooperative Transportation of a Flexible Payload Using Two Quadrotors. J. Guid. Control. Dyn. 2021, 44, 2099–2107. [Google Scholar] [CrossRef]

- Yang, H.; Staub, N.; Franchi, A.; Lee, D.J. Modeling and Control of Multiple Aerial-Ground Manipulator System (MAGMaS) with Load Flexibility. In Proceedings of the IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Madrid, Spain, 1–5 October 2018; pp. 4840–4847. Available online: https://ieeexplore.ieee.org/document/8593834 (accessed on 6 January 2019).

- Staub, N.; Mohammadi, M.; Bicego, D.; Prattichizzo, D.; Franchi, A. Towards Robotic MAGMaS: Multiple Aerial-Ground Manipulator Systems. In Proceedings of the IEEE International Conference on Robotics and Automation (ICRA), Singapore, 29 May–3 June 2017; pp. 1307–1312. Available online: https://ieeexplore.ieee.org/document/7989154 (accessed on 24 July 2017).

- Staub, N. The tele-MAGMaS: An aerial-ground comanipulator system. IEEE Robot. Autom. Mag. 2018, 25, 66–75. Available online: https://ieeexplore.ieee.org/document/8511046 (accessed on 26 October 2018). [CrossRef]

- Kotaru, P.; Sreenath, K. Multiple Quadrotors Carrying a Flexible Hose: Dynamics, Differential Flatness and Control. IFAC-PapersOnLine 2020, 53, 8832–8839. [Google Scholar] [CrossRef]

- Nguyen, T.W.; Catoire, L.; Garone, E. Control of a quadrotor and a ground vehicle manipulating an object. Automatica 2019, 105, 384–390. [Google Scholar] [CrossRef]

- Staub, N.; Bicego, D.; Sablé, Q.; Arellano-Quintana, V.; Mishra, S.; Franchi, A. Towards a flying assistant paradigm: The OTHex. In Proceedings of the IEEE International Conference on Robotics and Automation (ICRA), Brisbane, QLD, Australia, 21–25 May 2018; pp. 6997–7002. Available online: https://ieeexplore.ieee.org/abstract/document/8460877 (accessed on 13 September 2018).

- Lissandrini, N.; Verginis, C.K.; Roque, P.; Cenedese, A.; Dimarogonas, D.V. Decentralized Nonlinear MPC for Robust Cooperative Manipulation by Heterogeneous Aerial-Ground Robots. In Proceedings of the IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Las Vegas, NV, USA, 24 October 2020–24 January 2021; pp. 1531–1536. Available online: https://ieeexplore.ieee.org/document/9341023 (accessed on 10 February 2021).

- Xu, M.; Hu, A.; Wang, H. Visual-Impedance-Based Human–Robot Cotransportation with a Tethered Aerial Vehicle. IEEE Trans. Ind. Inform. 2023, 19, 10356–10365. Available online: https://ieeexplore.ieee.org/document/10032095 (accessed on 30 January 2023). [CrossRef]

- Prajapati, P.; Vashista, V. Aerial Physical Human Robot Interaction for Payload Transportation. IEEE Robot. Autom. Lett. 2023, 8, 2377–3766. Available online: https://ieeexplore.ieee.org/document/10168218 (accessed on 29 June 2023). [CrossRef]

- Mellinger, D.; Shomin, M.; Michael, N.; Kumar, V. Cooperative Grasping and Transport Using Multiple Quadrotors. Distrib. Auton. Robot. Syst. 2013, 83, 545–558. [Google Scholar] [CrossRef] [PubMed]

- Loianno, G.; Kumar, V. Cooperative Transportation using Small Quadrotors using Monocular Vision and Inertial Sensing. IEEE Robot. Autom. 2017, 3, 680–687. Available online: https://ieeexplore.ieee.org/document/8120115 (accessed on 27 November 2017). [CrossRef]

- Oishi, K.; Amano, Y.; Jimbo, T. Cooperative Transportation using Multiple Single-Rotor Robots and Decentralized Control for Unknown Payloads. In Proceedings of the International Conference on Robotics and Automation (ICRA)), Philadelphia, PA, USA, 23–27 May 2022; pp. 2024–2030. Available online: https://ieeexplore.ieee.org/document/9811768 (accessed on 12 July 2022).

- Oishi, K.; Jimbo, T. Autonomous Cooperative Transportation System involving Multi-Aerial Robots with Variable Attachment Mechanism. In Proceedings of the IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Prague, Czech Republic, 27 September–1 October 2021; pp. 6322–6328. Available online: https://ieeexplore.ieee.org/document/9636145 (accessed on 16 December 2021).

- Chen, T.; Shan, J.; Liu, H.H.T. Transportation of Payload Using Multiple Quadrotors via Rigid Connection. Int. J. Aerosp. Eng. 2022, 2022, 2486561. [Google Scholar] [CrossRef]

- Nguyen, H.N.; Park, S.; Lee, D. Aerial Tool Operation System using Quadrotors as Rotating Thrust Generators. In Proceedings of the IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Hamburg, Germany, 28 September–2 October 2015; pp. 1285–1291. Available online: https://ieeexplore.ieee.org/abstract/document/7353534 (accessed on 17 December 2015).

- Nguyen, H.; Park, S.; Park, J.; Lee, D. A Novel Robotic Platform for Aerial Manipulation Using Quadrotors as Rotating Thrust Generators. IEEE Trans. Robot. 2018, 34, 353–369. Available online: https://ieeexplore.ieee.org/document/8294249 (accessed on 28 February 2018). [CrossRef]

- Tagliabue, A.; Kamel, M.; Siegwart, R.; Nieto, J. Robust collaborative object transportation using multiple MAVs. Int. J. Robot. Res. 2019, 38, 1020–1044. [Google Scholar] [CrossRef]

- Mohammadi, M.; Franchi, A.; Barcelli, D.; Prattichizzo, D. Cooperative aerial tele-manipulation with haptic feedback. In Proceedings of the IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Daejeon, Korea (South), 9–14 October 2016; pp. 5092–5098. Available online: https://ieeexplore.ieee.org/document/7759747 (accessed on 1 December 2016).

- Estevez, J.; Garate, G.; Lopez-Guede, J.M.; Larrea, M. Review of Aerial Transportation of Suspended-Cable Payloads with Quadrotors. Drones 2024, 8, 35. [Google Scholar] [CrossRef]

- Mohammadi, K.; Sirouspour, S.; Grivani, A. Passivity-Based Control of Multiple Quadrotors Carrying a Cable-Suspended Payload. IEEE/ASME Trans. Mechatronics 2022, 27, 2390–2400. Available online: https://ieeexplore.ieee.org/document/9508879 (accessed on 6 August 2021). [CrossRef]

- Erhart, S.; Hirche, S. Model and Analysis of the Interaction Dynamics in Cooperative Manipulation Tasks. IEEE Trans. Robot. 2016, 32, 672–683. Available online: https://ieeexplore.ieee.org/document/7480959 (accessed on 31 May 2016). [CrossRef]

- Ma, S.; Zong, X. Multi-UAV Cooperative Formation Flight Control System for Cascade Active Disturbance Rejection Control. In Proceedings of the 3rd International Conference on Electrical Engineering and Control Technologies (CEECT), Macau, China, 16–18 December 2021; pp. 93–97. Available online: https://ieeexplore.ieee.org/document/9672641 (accessed on 19 January 2022).

- Men, T.; Liu, D.; Zhu, X.; Fei, B.; Xiao, Z.; Xiao, W. Cooperative Localization Method of UAVs for a Persistent Surveillance Task. In Proceedings of the 7th International Conference on Big Data and Information Analytics (BigDIA), Chongqing, China, 29–31 October 2021; pp. 456–463. Available online: https://ieeexplore.ieee.org/document/9619751 (accessed on 6 December 2021).

- Pritzl, V.; Vrba, M.; Štĕpán, P.; Saska, M. Cooperative Navigation and Guidance of a Micro-Scale Aerial Vehicle by an Accompanying UAV using 3D LiDAR Relative Localization. In Proceedings of the International Conference on Unmanned Aircraft Systems (ICUAS), Dubrovnik, Croatia, 21–24 June 2022; pp. 526–535. Available online: https://ieeexplore.ieee.org/document/9836116 (accessed on 26 July 2022).

| Criteria | Data |

|---|---|

| Scientific Database | IEEE Xplore, Google Scholar, Science Direct, Engineering Village, arXiv, manual search |

| Publication Period | From 2010 to October 2023 |

| Keywords | (“aerial” OR “cooperative aerial” OR “survey” OR “review”) AND (“manipulation” OR “transportation” OR “load transportation”) |

| Reference | Dynamic Modeling |

|---|---|

| Rigidly Attached | |

| [111,112,113,115,116,117,118] | Newton–Euler |

| [119] | Euler–Lagrange |

| Flexible object | |

| [99] | Newton–Euler |

| [101] | Euler–Lagrange |

| [100,102] | Euler–Bernoulli, Euler–Lagrange |

| Ground–Air | |

| [103,104,106,108,110] | Euler–Lagrange |

| [109] | Newton–Euler |

| Multi DoF-Arms | |

| [87,88,89,90,91,92,93,94,95] | Euler–Lagrange |

| [96] | Newton–Euler |

| [97,98] | Recursive Newton–Euler |

| Cable-Driven | |

| [49,50,52,55,60,62,65,67,68,81,85,86,121] | Newton–Euler |

| [21,53] | Kane method |

| [54,57,58,59,61,73,74,75,76,77,82,83] | Euler–Lagrange |

| [63,69,70] | Newton–Euler, Udwadia–Kalaba |

| [78,79] | Newton–Euler, Euler–Lagrange |

| Ref. | Fixed/Tilted | Arms | Gripper Type | Platform | Implementation | UAV Weight | Payload Weight | Payload | Controller Design | Motion Planning Technique | Fully Autonomous | Experiment Task |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| RIGIDLY ATTACHED | ||||||||||||

| [118] | Fixed | Gripper with spherical joint | Magnetic | Hexacopter | Outdoor experiment | 1 kg | 2.46 kg | Wooden structure | Admittance controller with force estimator | - | Onboard sensors | Transportation |

| [112] | Gripper | Quadcopter | Lab experiment | 610 gr | Carbon fiber rod | Non-Linear Controller | Onboard camera and IMU | |||||

| [111] | Penetrative | 500 gr | 320 gr | Wooden bar | Two norm optimal control, partially decentralized | - | Pick/Transportation | |||||

| [113] | - | Fixed position on the payload | Mono-rotor | 2.7 kg | Long rectangular object | Decentralized controller based ASSC | Transportation | |||||

| [114] | Variable attachment mechanism on the payload | 3.2 kg | Long rectangular object | Cascaded PID | ||||||||

| [119] | Passive tool | Adhesive tooltip | Quadcopter | Simulation with Hardware in the loop | 0.7 kg | 2.4 kg | Barrel | Haptic feedback control | Manipulation | |||

| [117] | Spherically connected frame with attached rigid tool | - | Lab experiment | 2.31 kg (3 quads) | 1.2 kg | Box | Dynamics-Based Control | Point-Contact/Push | ||||

| [115] | - | Magnets | 1.121 kg | 0.453 kg | Wooden board | Hierarchical control with command allocation | Transportation | |||||

| FLEXIBLE OBJECTS | ||||||||||||

| [99] | Fixed | - | Attached to the payload | Quadcopter | Lab experiment | 0.47 kg | 0.54 kg | Aluminum ring | LQR | - | Transportation | |

| [101] | Attached to the payload via magnets | Octocopter | 1.121 kg | Beam | LQR | |||||||

| [102] | Attached link to payload through passive rotational joint | Quadcopter | Simulation | Not reported | 0.61 kg | Wooden bar | Collaborative control with vibration suspension | Manipulation | ||||

| [100] | Tilted | Attached to the payload | Two-rotor | Lab experiment | Not reported | Aluminum bar | LQR | |||||

| GROUND-AIR | ||||||||||||

| [106] | Fixed | - | Attached to the payload | Birotor | Lab experiment | 100 gr | 30 gr | Carbon rod | PD | - | Manipulation | |

| [103] | Attached link to payload through passive rotational joint | Quadcopter | Not reported | 0.61 kg | Wooden bar | Augmented nonlinear with disturbance observer | ||||||

| [108] | 2-DOF arm (×1) | Gripper | Hexacopter | Not reported | Not reported | Plastic bar | Model Predictive Control | Manipulation/Transportation | ||||

| [104] | Tilted | 1-DOF arm (×1) with passive joint | Gripper (×2) | Indoor experiment | 2.48 kg | 1.42 kg | Rod | Centralized controller and haptic feedback | Pick/Manipulation | |||

| [110] | Fixed | Cable | - | Quadcopter | Outdoor experiment | 1.236 kg | 0.26 kg | Rod | Collaborative control | - | GPS, IMU, custom sensors system | Pick/Manipulation/Transportation |

| [109] | Hexacopter | Lab experiment | 4.05 kg | 1.12 kg | Bar | Visual Impedance control | Onboard camera and IMU | Manipulation/Transportation | ||||

| MULTI-DOF ARMS | ||||||||||||

| [87] | Fixed | 3-DOF arm (×1) | Connected to the object using ball joints | Hexacopter | Lab experiment | 3 kg | 500 gr | Rod | Robust controller with disturbance observer | - | Manipulation | |

| [91] | 2-DOF arm (×1) | Hook | Not reported | 150 gr | RRT* | - | ||||||

| [92] | 2-DOF arm (×1) | Gripper | 280 gr | Augmented adaptive sliding mode controller | RRT* with Bezier Curves and DMPs | - | ||||||

| [93] | 2-DOF arm (×1) | Rigidly attached | 280 gr | High-level augmented adaptive sliding mode controller and low-level robust controller with DOB | Learning-based PDMPs | - | ||||||

| [90] | 2-DOF arm (×1) | Gripper | 280 gr | Wooden rod | Adaptive controller | DMPs | RGB-D camera for object detection | |||||

| [94] | 2-DOF arm (×1) | Rigidly attached | 2.5 kg | 280 gr | Rod | Augmented adaptive sliding mode controller | Velocity and curvature constraints | - | ||||

| [95] | 2-DOF arm (×1) | Quadcopter | Simulation | Not reported | 50 gr | Rod/triangular object | Sliding mode controller with SOSM observer | |||||

| [88] | 2-DOF arm (×1) | 2 kg | 0.4 kg | Box/cylinder | Hierarchical with admittance force control | - | Push/Transportation | |||||

| [89] | 6-DOF arm (×1) | Gripper | Octocopter | 2.7 kg | 1 kg | Rod | Impedance control | - | - | Transportation | ||

| [98] | 2-DOF arm (×1) | Virtual extension | Quadcopter | Gazebo simulation | Not reported | Not reported | Not reported | Compliant controller | - | RGB-camera (visual feedback using markers) | Manipulation/Transportation | |

| [96] | Rigid extension | Rigidly attached | Simulation | 0.75 kg | 1.5 kg | Spherical object | Decentralized adaptive force control | - | Transportation | |||

| [97] | 2-DOF arm (×1) | Gripper | Gazebo simulation | 1.2 kg | 0.8 kg | Beam | Leader/Follower model-based force control | |||||

| CABLE-DRIVEN | ||||||||||||

| [49] | - | Quadcopter | Lab experiment | Not reported | 0.25 kg | Triangular object | PID | |||||

| [51] | 1.03 kg | 0.338 kg | Platform of carbon fiber bars | Robust controller | - | Lift/Manipulation/Transportation | ||||||

| [21] | Helicopter | Outdoor experiment | 12.5 kg | 4 kg | Camera | Orientation controller | - | IMU, GPS, Compass | Lift/Transportation | |||

| [57] | - | Magnetic grippers | Quadcopter | Lab experiment | 800 gr | 263 gr | Aluminum rod | LQR | - | Monocular camera, IMU | Pick/Transportation | |

| [70] | - | Simulation | 1 kg | 2.65 kg | Rectangular object | Distributed adaptive control | RRT* with B-Spline curve | - | Transportation | |||

| [69] | Outdoor experiment | Not reported | 1 kg | Box | Fixed-time ESO based output feedback control | - | IMU, GPS | Lift/Transportation | ||||

| [63] | Hexacopter | 2.3 kg | 2.2 kg | Cylindrical object | Passivity-based decentralized control | IMU, GNSS | ||||||

| [79] | - | Wrapping the cable around the object | Catenary quadcopter | Simulation | Not reported | 0.1 kg | Box | Adaptive control | - | Wrap and Pull/Lift/ Manipulation/Transportation | ||

| [64] | - | Attached grippers | Hexacopter | Outdoor experiment | 70 gr | Not reported | Beam | Model predictive control | RRTc | Camera, Rangefinder, GPS, Compass | Transportation | |

| [78] | Fixed | - | Reconfigurable quadcopter | Physical Simulation with human in the loop | Not reported | Rectangular object | Dual space control approach with tension distribution | - | Manipulation/Transportation | |||

| [62] | Quadcopter | Outdoor experiment | 1.282 kg | 0.815 kg | Custom built with hardware setup | Load-leading control | - | GPS, Compass | Lift/Manipulation/Transportation | |||

| [59] | Lab experiment | Not reported | 250 gr | Triangular object | Distributed vision-based control | Monocular camera, IMU | Manipulation | |||||

| [77] | Gazebo simulation | 2.02 kg | 1.0 kg | Cuboid object | Geometric control | - | Transportation | |||||

| [73] | Simulation | 0.755 kg | 0.4 kg | Spherical pendulum | ||||||||

| [74] | 1.5 kg | Rectangular box | ||||||||||

| [75] | 0.5 kg | Lift/Transportation | ||||||||||

| [76] | Lab experiment | 0.52 kg | Rod | Stabilization | ||||||||

| [80] | 400 gr | 400 gr | Cubic object | Incremental Nonlinear Dynamic Inversion controller and robust formation | Lift/Transportation/Manipulation | |||||||

| [65] | 1 kg | 0.9 kg | Custom | Distributed trajectory optimization control | Transportation | |||||||

| [81] | 500 gr | 575 gr | Aluminum bar | Adaptive control | Manipulation/Transportation | |||||||

| [67] | Simulation | 1 kg | 0.9 kg | Beam | Admittance controller | |||||||

| [56] | - | Carabiner-harness | Outdoor experiment | 1 kg | 3 kg | Custom built with hardware setup | Cascaded PID | GPS | Lift/Manipulation/Transportation | |||

| [82] | - | Lab experiment | 1.43 kg | 0.355 kg | Cargo | Nonlinear hierarchical controller | - | Cargo delivery | ||||

| [83] | 3-DOF arm (×1) | Gripper | Simulation | 1.2 kg (with manipulator) | 0.1 kg | Slung load | Null-Space-Based Adaptive Control | - | Transportation | |||

| [68] | - | Outdoor experiment | 1.46 kg | 1.5 kg | Rectangular aluminum frame | Collaborative Control | - | GPS, IMU | Lift/Transportation/Land | |||

| [121] | Lab experiment | 0.67 kg | 0.4 kg | Spherical object | Passivity-based control | - | Transportation | |||||

| [54] | Simulation | 1.15 kg | 0.5 kg | Spherical object | Sliding Mode-Adaptive PID control | |||||||

| [84] | - | Spherical Joint | Lab experiment | 1.18 kg and 80.4 kg structure | 2.5 kg | Box | - | Lift/Transportation | ||||

| [58] | - | Not reported | Rectangular bar | LQR | - | IMU, Camera, Ultrasound sensor | Transportation | |||||

| [61] | Outdoor experiment | 73 gr | 30 gr | Circular object | Linear controller with EKF-based estimator | IMU | ||||||

| [71] | Lab experiment | Not reported | 0.39 kg | Circular object | Estimation-based formation tracking control | Formation Planning | - | |||||

| [72] | 800 gr | 300 gr | Circular object | Backstepping force controller and force disturbance observer | - | IMU | ||||||

| [60] | Not reported | 232 gr | Triangular object | Nonlinear Model Predictive Control | - | Manipulation/Transportation | ||||||

| [85] | Not reported | Bar | Backstepping (leader), Switching Controller (follower) | Transportation | ||||||||

| [86] | 0.831 kg and 0.832 kg | 0.248 kg and 0.252 kg | Steel pipe | Force Coordination Control | Hovering/Transportation | |||||||

| Ref. | Category | Control Technique | 3D Trajectories | Velocity–Accel. | Payload Tracking Precision | Payload Orientation | Tested Against Uncertainties | Tested Against Wind | Tested Outdoors | Robust Against Disturbances | Implem. Complexity |

|---|---|---|---|---|---|---|---|---|---|---|---|

| [81] | Cable-Driven | Adaptive | Yes | 1.6 m/s2 | Low | 2DoF | Yes | Yes | No | No | Low |

| [51] | H∞ | No | QS | High | 3DoF | Yes | No | No | No | Med | |

| [62] | Load-leading (Optimal) | No | QS | High | 3DoF | Yes | Yes | Yes | No | High | |

| [56] | Cascaded PID | No | 1 m/s | Low | No | Yes | No | Yes | No | Low | |

| [61] | Linear controller with EKF-based estimator | Yes | 1.4 m/s | Med | No | Yes | Yes | Yes | Yes | Med | |

| [72] | Backstepp. force control and force DO | Yes | QS | Med | No | Yes | Yes | No | Yes | High | |

| [69] | ESO | No | QS | Low | No | Yes | Yes | Yes | Yes | Med | |

| [121] | Passivity-based | No | QS | Low | No | Yes | Yes | No | Yes | Low | |

| [60] | MPC | No | <1 m/s | High | 6DoF | No | No | No | No | High | |

| [101] | Flexible Object | LQR | No | 0.13 m/s | Med | No | Yes | No | No | Yes | Low |

| [94] | Multi-DoF Arms | Augmented adaptive sliding mode | Yes | <1 m/s | Med | No | Yes | No | No | Yes | High |

| [109] | Human-UAV | Visual Impedance | No | 0.3 m/s | High | No | Yes | No | No | Yes | Med |

| [118] | Rigidly-Attached | Admittance with force estimation | No | <1 m/s | Med | No | Yes | Yes | Yes | Yes | Med |

| [115] | Hierarchical with command allocation | No | 0.1 m/s | High | No | No | No | No | No | High |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Barakou, S.C.; Tzafestas, C.S.; Valavanis, K.P. A Review of Real-Time Implementable Cooperative Aerial Manipulation Systems. Drones 2024, 8, 196. https://doi.org/10.3390/drones8050196

Barakou SC, Tzafestas CS, Valavanis KP. A Review of Real-Time Implementable Cooperative Aerial Manipulation Systems. Drones. 2024; 8(5):196. https://doi.org/10.3390/drones8050196

Chicago/Turabian StyleBarakou, Stamatina C., Costas S. Tzafestas, and Kimon P. Valavanis. 2024. "A Review of Real-Time Implementable Cooperative Aerial Manipulation Systems" Drones 8, no. 5: 196. https://doi.org/10.3390/drones8050196

APA StyleBarakou, S. C., Tzafestas, C. S., & Valavanis, K. P. (2024). A Review of Real-Time Implementable Cooperative Aerial Manipulation Systems. Drones, 8(5), 196. https://doi.org/10.3390/drones8050196