Independent Control Spraying System for UAV-Based Precise Variable Sprayer: A Review

Abstract

1. Introduction

2. Application Development for an Independent Control System

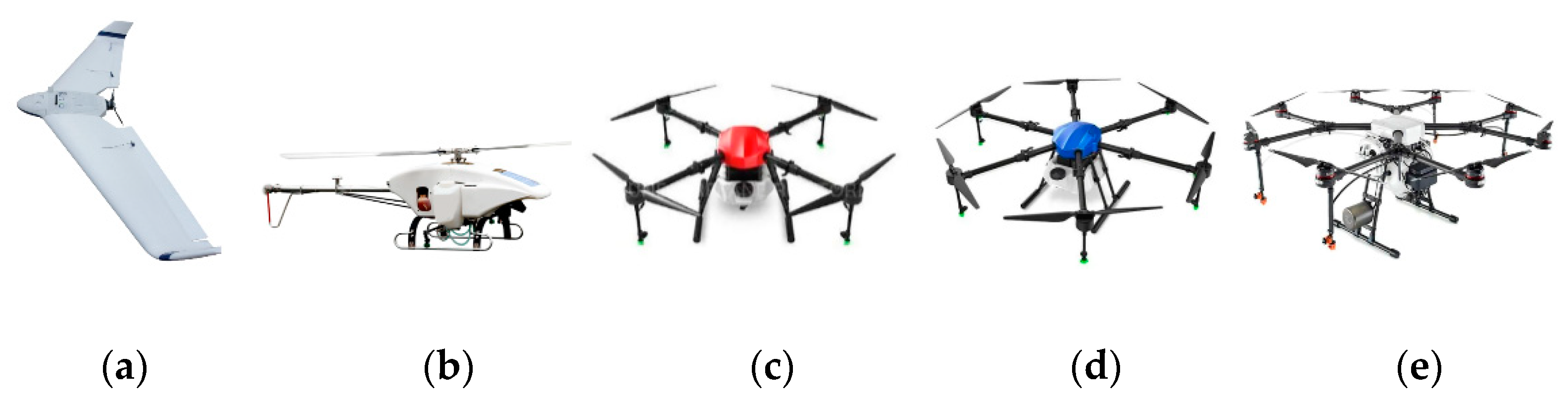

2.1. Unmanned Aerial Vehicle (UAV) in Agriculture Area

- Speed: Much faster than their competitors and capable of reaching greater altitudes.

- Control: Exceptional control that is less impeded by wind and rain and is stronger and more dependable.

- Safety: Even if one motor malfunctions, the octocopter can be flown just as well as a hexacopter. Furthermore, depending on the position and overall payload, two or three motors could be dysfunctional without the craft crashing. Furthermore, they are very stable and perform better in harsh weather conditions.

2.2. UAV Drone Sprayer Basic Components

2.3. Spraying and Nozzle Systems

2.4. The Use of the Spraying Method

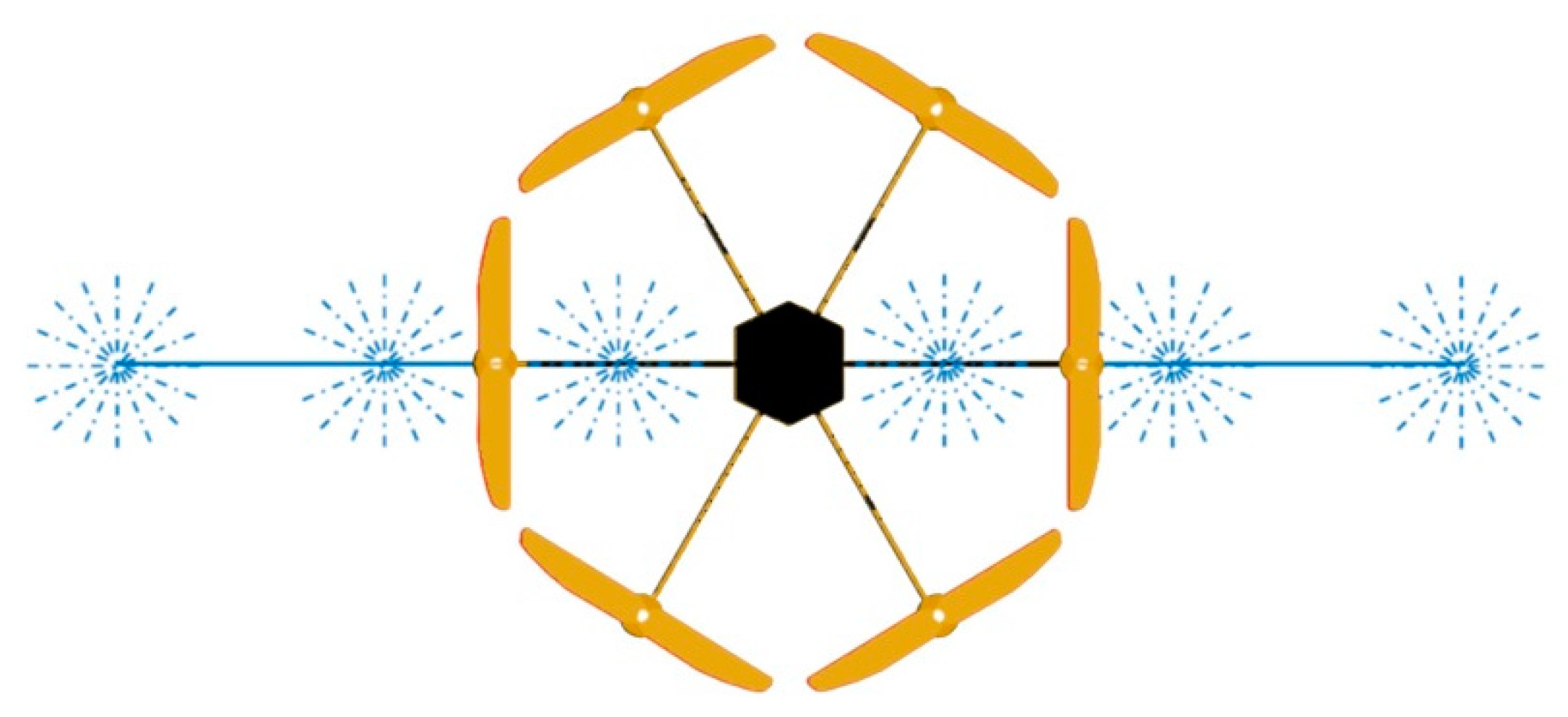

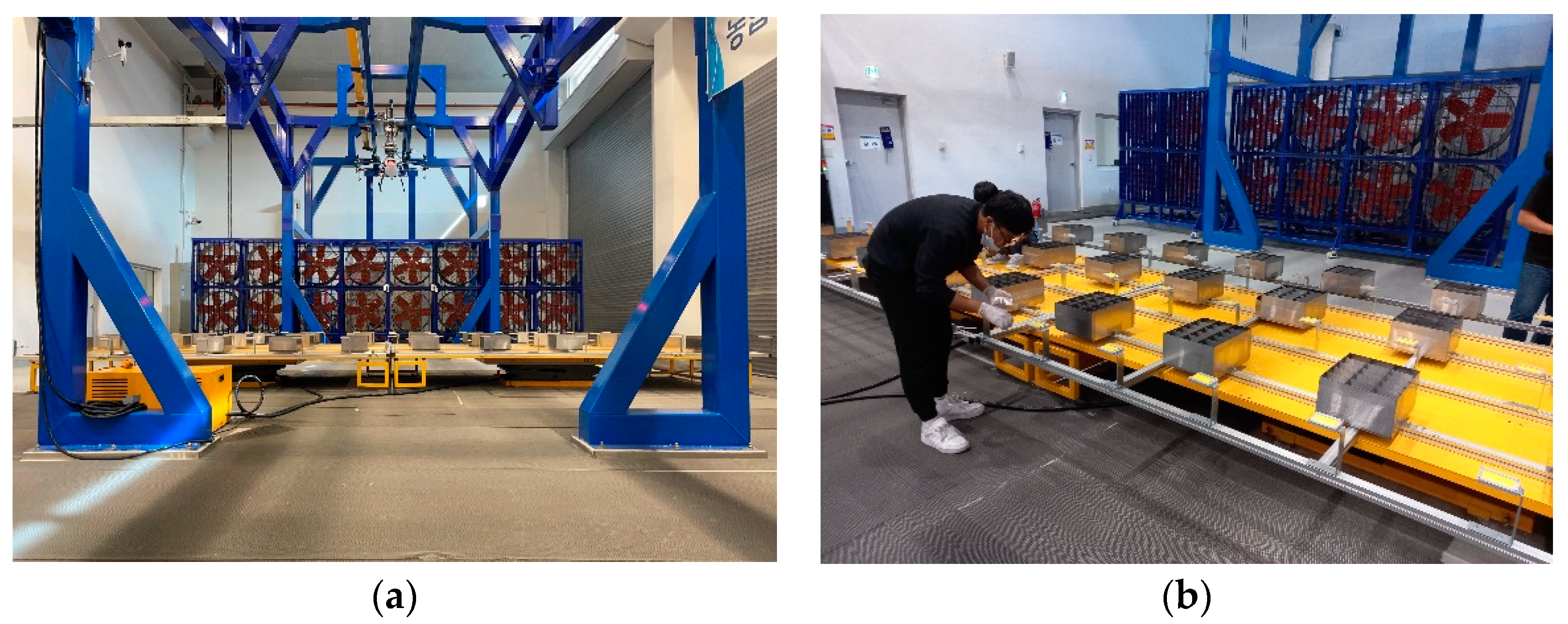

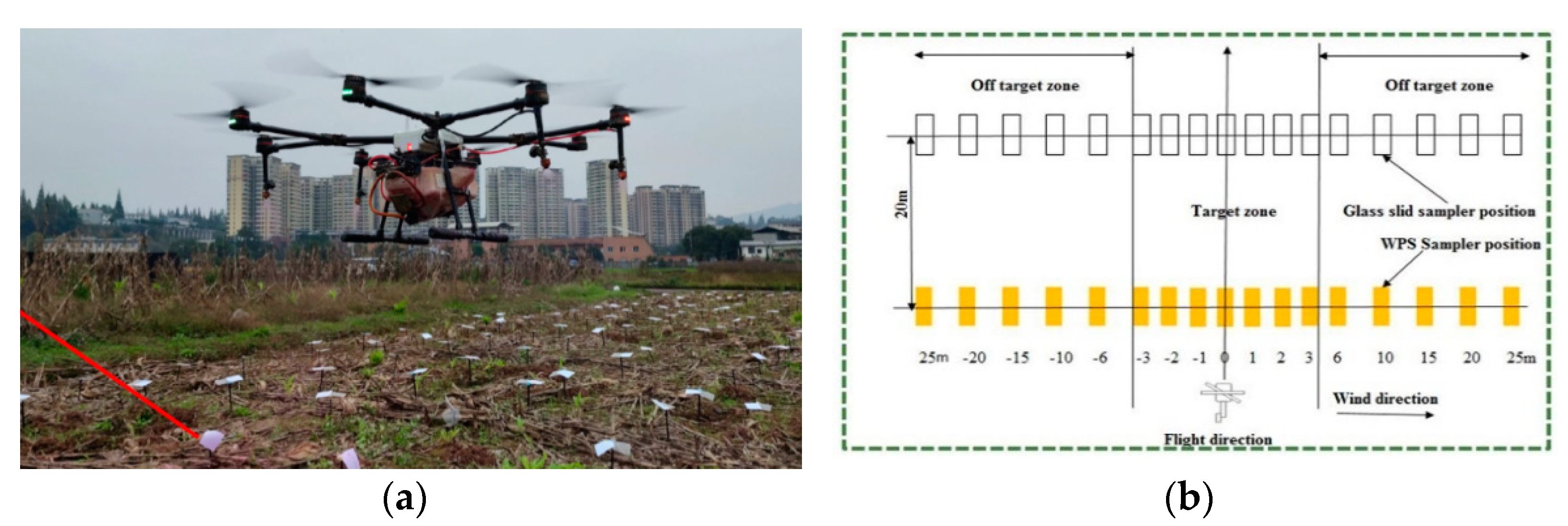

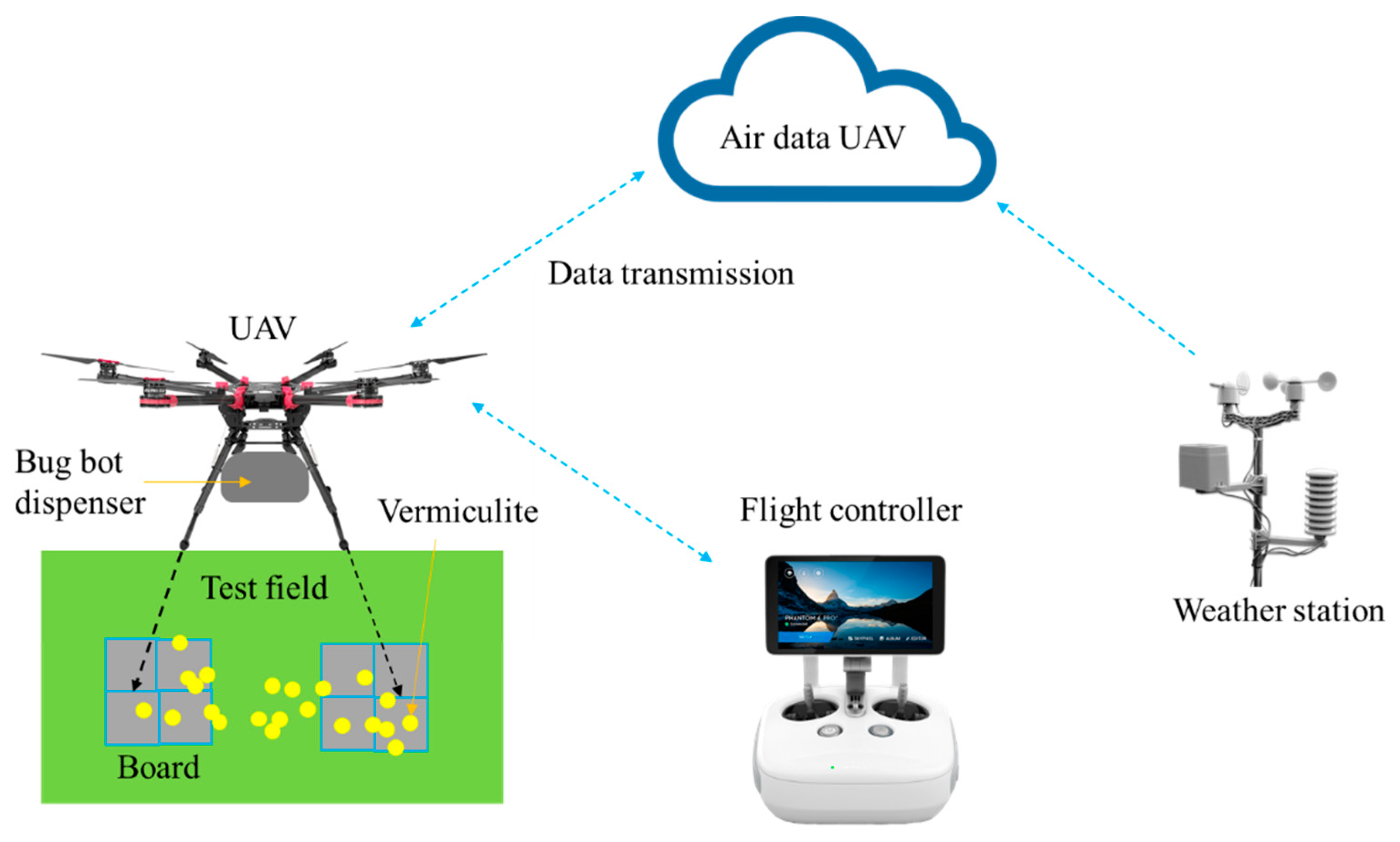

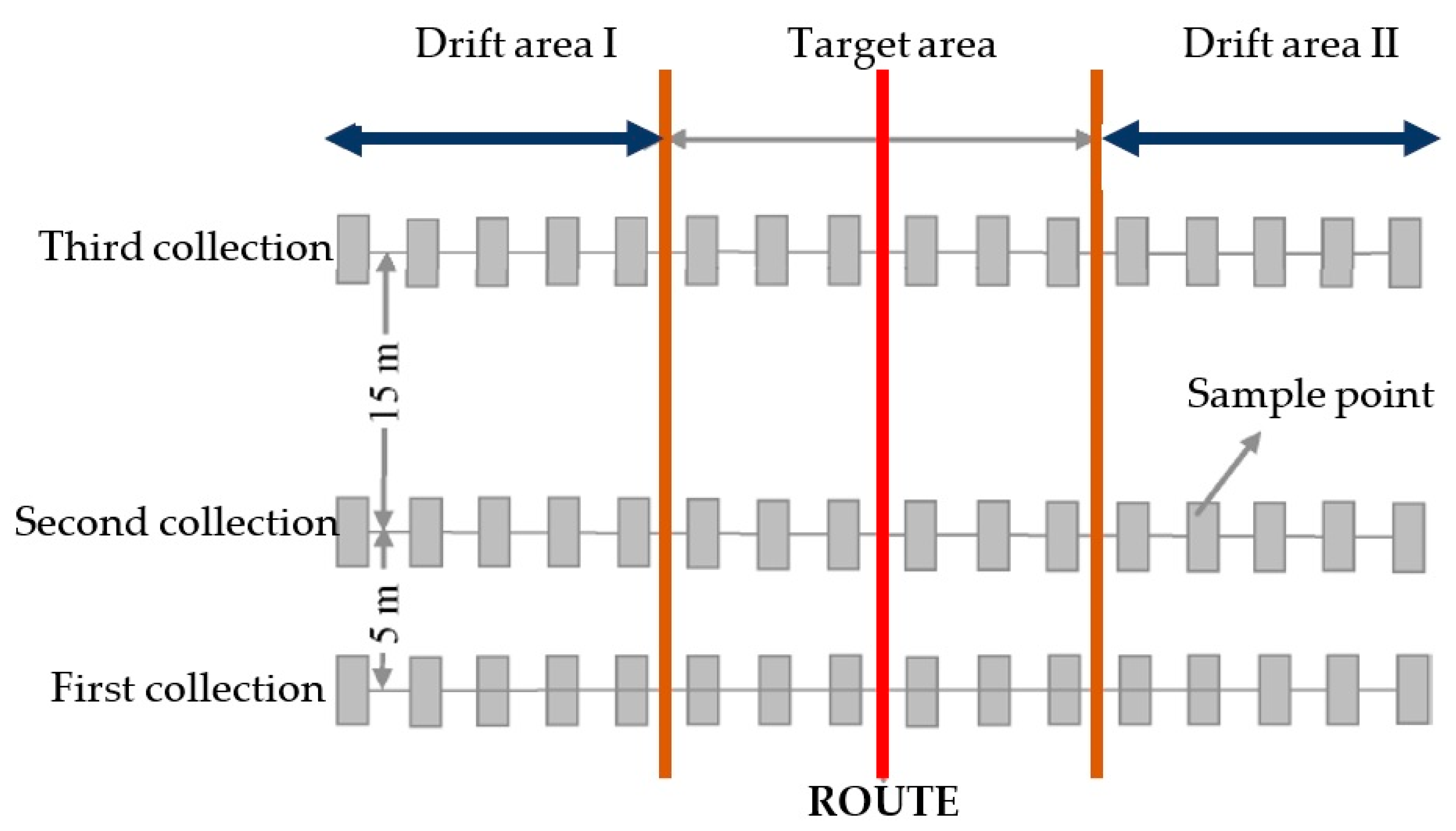

2.5. Spraying Deposition Data Acquisition Methods

2.6. WSP Data Processing Methods

2.7. Expectation of Results and Development of a Control System

3. Benchmarks and Evaluations for Existing Research

3.1. Platform Development and Manufacturing

3.2. Precision Spraying System Effectiveness

4. Future Scope and Considerations

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Lee, C.H.S.; Phang, S.K.; Mun, H.K. Design and Implementation of an Agricultural UAV with Optimized Spraying Mechanism. MATEC Web. Conf. 2021, 335, 02002. [Google Scholar] [CrossRef]

- Yang, S.; Yang, X.; Mo, J. The Application of Unmanned Aircraft Systems to Plant Protection in China. Precis. Agric. 2018, 19, 278–292. [Google Scholar] [CrossRef]

- Morley, C.; Braodley, J.; Hartley, R.; Herries, D.; MacMorran, D. The Potential of Using Unmanned Aerial Vehicles (UAVs) for Precision Pest Control of Possums (Trichosurus vulpecula). Rethink. Ecol. 2017, 2, 27–39. [Google Scholar] [CrossRef]

- Lou, Z.; Xin, F.; Han, X.; Lan, Y.; Duan, T.; Fu, W. Effect of Unmanned Aerial Vehicle Flight Height on Droplet Distribution, Drift and Control of Cotton Aphids and Spider Mites. Agronomy 2018, 8, 187. [Google Scholar] [CrossRef]

- Phang, S.K.; Li, K.; Chen, B.M.; Lee, T.H. Systematic Design Methodology and Construction of Micro Aerial Quadrotor Vehicles. In Handbook of Unmanned Aerial Vehicles; Valavanis, K.P., Vachtsevanos, G.J., Eds.; Springer: Dordrecht, The Netherlands, 2015; pp. 181–206. ISBN 978-90-481-9706-4. [Google Scholar]

- Heong, K.L.; Hardy, B.; Heong, K.L.; Hardy, B. Planthoppers: New Threats to the Sustainability of Intensive Rice Production Systems in Asia; International Rice Research Institute (IRRI): Los Banos, Philippines, 2009. [Google Scholar] [CrossRef]

- Jena, K.K.; Kim, S.-M. Current Status of Brown Planthopper (BPH) Resistance and Genetics. Rice 2010, 3, 161–171. [Google Scholar] [CrossRef]

- Jeevanandham, N.; Raman, R.; Ramaiah, D.; Senthilvel, V.; Mookaiah, S.; Jegadeesan, R. Rice: Nilaparvata Lugens Stal Interaction—Current Status and Future Prospects of Brown Planthopper Management. J. Plant Dis. Prot. 2022, 1–17. [Google Scholar] [CrossRef]

- Hardin, M.R.; Benrey, B.; Coll, M.; Lamp, W.O.; Roderick, G.K.; Barbosa, P. Arthropod Pest Resurgence: An Overview of Potential Mechanisms. J. Crop Prot. 1995, 14, 3–18. [Google Scholar] [CrossRef]

- Garrood, W.T.; Zimmer, C.T.; Gorman, K.J.; Nauen, R.; Bass, C.; Davies, T.G. Field-evolved Resistance to Imidacloprid and Ethiprole in Populations of Brown Planthopper Nilaparvata lugens Collected from across South and East Asia. Pest. Manag. Sci. 2016, 72, 140–149. [Google Scholar] [CrossRef]

- Wu, S.-F.; Zeng, B.; Zheng, C.; Mu, X.-C.; Zhang, Y.; Hu, J.; Zhang, S.; Gao, C.-F.; Shen, J.-L. The Evolution of Insecticide Resistance in the Brown Planthopper (Nilaparvata lugens Stål) of China in the Period 2012–2016. Sci. Rep. 2018, 8, 4586. [Google Scholar] [CrossRef]

- Liao, X.; Xu, P.; Gong, P.; Wan, H.; Li, J. Current Susceptibilities of Brown Planthopper Nilaparvata lugens to Triflumezopyrim and Other Frequently Used Insecticides in China. Insect Sci. 2021, 28, 115–126. [Google Scholar] [CrossRef]

- Panizzi, A.R. Wild Hosts of Pentatomids: Ecological Significance and Role in Their Pest Status on Crops. Annu. Rev. Entomol. 1997, 42, 99–122. [Google Scholar] [CrossRef] [PubMed]

- Medrano, E.G.; Esquivel, J.F.; Bell, A.A. Transmission of Cotton Seed and Boll Rotting Bacteria by the Southern Green Stink Bug (Nezara viridula L.). J. Appl. Microbiol. 2007, 103, 436–444. [Google Scholar] [CrossRef] [PubMed]

- Cruvinel, P.E.; Oliveira, V.A.; Mercaldi, H.V.; Peñaloza, E.A.G.; Felizardo, K.R. An Advanced Sensors-Based Platform for the Development of Agricultural Sprayers. IFSA Indianap. 2016, 181–204. [Google Scholar] [CrossRef]

- Hewitt, A.J. Droplet Size Spectra Classification Categories in Aerial Application Scenarios. J. Crop Prot. 2008, 27, 1284–1288. [Google Scholar] [CrossRef]

- Aissaoui, A.E. A Feasibility Study of Direct Injection Spraying Technology for Small Scale Farming: Modeling and Design of A Process Control System. ULiège 2019, 176. Available online: https://orbi.uliege.be/bitstream/2268/185844/1/Dissertation_elaissaoui_abdellah_sept2015.pdf (accessed on 27 August 2022).

- Zhang, Y.; Li, Y.; He, Y.; Liu, F.; Cen, H.; Fang, H. Near Ground Platform Development to Simulate UAV Aerial Spraying and Its Spraying Test under Different Conditions. Comput. Electron. Agric. 2018, 148, 8–18. [Google Scholar] [CrossRef]

- Deng, W.; Zhao, C.; Chen, L.; Wang, X. Constant Pressure Control for Variable-Rate Spray Using Closed-Loop Proportion Integration Differentiation Regulation. J. Agric. Eng. Res. 2016, 47, 148. [Google Scholar] [CrossRef]

- Wang, L.; Chen, D.; Yao, Z.; Ni, X.; Wang, S. Research on the Prediction Model and Its Influencing Factors of Droplet Deposition Area in the Wind Tunnel Environment Based on UAV Spraying. IFAC-PapersOnLine 2018, 51, 274–279. [Google Scholar] [CrossRef]

- Wang, S.; Song, J.; He, X.; Song, L.; Wang, X.; Wang, C.; Wang, Z.; Ling, Y. Performances Evaluation of Four Typical Unmanned Aerial Vehicles Used for Pesticide Application in China. Int. J. Agric. Biol. Eng. 2017, 10, 22–31. [Google Scholar] [CrossRef]

- Wen, S.; Zhang, Q.; Deng, J.; Lan, Y.; Yin, X.; Shan, J. Design and Experiment of a Variable Spray System for Unmanned Aerial Vehicles Based on PID and PWM Control. Appl. Sci. 2018, 8, 2482. [Google Scholar] [CrossRef]

- Cai, X.; Walgenbach, M.; Doerpmond, M.; Schulze Lammers, P.; Sun, Y. Closed-Loop Control of Chemical Injection Rate for a Direct Nozzle Injection System. Sensors 2016, 16, 127. [Google Scholar] [CrossRef] [PubMed]

- Kundak, N.; Mettler, B. Experimental Framework for Evaluating Autonomous Guidance and Control Algorithms for Agile Aerial Vehicles. In Proceedings of the 2007 European Control Conference (ECC), IEEE, Kos, Greece, 2–5 July 2007; pp. 293–300. [Google Scholar]

- Valenti, M.; Bethke, B.; Fiore, G.; How, J.; Feron, E. Indoor Multi-Vehicle Flight Testbed for Fault Detection, Isolation, and Recovery. In Proceedings of the AIAA Guidance, Navigation, and Control Conference and Exhibit; American Institute of Aeronautics and Astronautics, Keystone, Colorado, 21 August 2006; pp. 1–18. [Google Scholar]

- Tang, Q.; Zhang, R.; Chen, L.; Xu, M.; Yi, T.; Zhang, B. Droplets Movement and Deposition of an Eight-Rotor Agricultural UAV in Downwash Flow Field. Int. J. Agric. Biol. Eng. 2017, 10, 10. [Google Scholar] [CrossRef]

- Cai, G.; Chen, B.M.; Lee, T.H. An Overview on Development of Miniature Unmanned Rotorcraft Systems. Front. Electr. Electron. Eng. China 2010, 5, 1–14. [Google Scholar] [CrossRef]

- Xinyu, X.; Kang, T.; Weicai, Q.; Lan, Y.; Zhang, H. Drift and Deposition of Ultra-Low Altitude and Low Volume Application in Paddy Field. Int. J. Agric. Biol. Eng. 2014, 7, 6. [Google Scholar] [CrossRef]

- Huang, Y.; Hoffman, W.C.; Lan, Y.; Fritz, B.K.; Thomson, S.J. Development of a Low-Volume Sprayer for an Unmanned Helicopter. J. Agric. Res. 2014, 7, 148. [Google Scholar] [CrossRef]

- Giles, D.; Billing, R. Deployment and Performance of a Uav for Crop Spraying. Chem. Eng. Trans. 2015, 44, 307–312. [Google Scholar] [CrossRef]

- Xue, X.; Lan, Y.; Sun, Z.; Chang, C.; Hoffmann, W.C. Develop an Unmanned Aerial Vehicle Based Automatic Aerial Spraying System. Comput. Electron. Agric. 2016, 128, 58–66. [Google Scholar] [CrossRef]

- Huang, Y.; Hoffmann, W.C.; Lan, Y.; Wu, W.; Fritz, B.K. Development of a Spray System for an Unmanned Aerial Vehicle Platform. Appl. Eng. Agric. 2009, 25, 803–809. [Google Scholar] [CrossRef]

- Zhu, H.; Lan, Y.; Wu, W.; Hoffmann, W.C.; Huang, Y.; Xue, X.; Liang, J.; Fritz, B. Development of a PWM Precision Spraying Controller for Unmanned Aerial Vehicles. J. Bionic Eng. 2010, 7, 276–283. [Google Scholar] [CrossRef]

- Sarghini, F.; Vivo, A.D. Interference Analysis of an Heavy Lift Multirotor Drone Flow Field and Transported Spraying System. Chem. Eng. Trans. 2017, 58, 631–636. [Google Scholar] [CrossRef]

- Simelli, I.; Tsagaris, A. The Use of Unmanned Aerial Systems (UAS) in Agriculture. HAICTA 2015, 730–736. Available online: https://ceur-ws.org/Vol-1498/HAICTA_2015_paper83.pdf (accessed on 29 August 2022).

- Berner, B.; Chojnacki, J. Use of Drones in Crop Protection. In Proceedings of the Farm Machinery and Processes Management in Sustainable Agriculture, IX International Scientific Symposium, Lublin, Poland, 22–24 November 2017; pp. 46–51. [Google Scholar]

- Zhang, Y.; Lian, Q.; Zhang, W. Design and Test of a Six-Rotor Unmanned Aerial Vehicle (UAV) Electrostatic Spraying System for Crop Protection. Int. J. Agric. Biol. Eng. 2017, 10, 68–76. [Google Scholar] [CrossRef]

- Bendig, J.; Bolten, A.; Bareth, G. Introducing A Low-Cost Mini-UAV for Thermal and Multispectral-Imaging. Int. Arch. Photogramm. Remote Sens. Spatial Inf. Sci. 2012, XXXIX-B1, 345–349. [Google Scholar] [CrossRef]

- Faiçal, B.S.; Costa, F.G.; Pessin, G.; Ueyama, J.; Freitas, H.; Colombo, A.; Fini, P.H.; Villas, L.; Osório, F.S.; Vargas, P.A.; et al. The Use of Unmanned Aerial Vehicles and Wireless Sensor Networks for Spraying Pesticides. J. Syst. Archit. 2014, 60, 393–404. [Google Scholar] [CrossRef]

- Tang, Y.; Hou, C.J.; Luo, S.M.; Lin, J.T.; Yang, Z.; Huang, W.F. Effects of Operation Height and Tree Shape on Droplet Deposition in Citrus Trees Using an Unmanned Aerial Vehicle. J. Integr. Agric. 2018, 148, 1–7. [Google Scholar] [CrossRef]

- Spoorthi, S.; Shadaksharappa, B.; Suraj, S.; Manasa, V.K. Freyr Drone: Pesticide/Fertilizers Spraying Drone—An Agricultural Approach. In Proceedings of the 2017 2nd International Conference on Computing and Communications Technologies (ICCCT), IEEE, Chennai, India, 23–24 February 2017; pp. 252–255. [Google Scholar]

- Primicerio, J.; Di Gennaro, S.F.; Fiorillo, E.; Genesio, L.; Lugato, E.; Matese, A.; Vaccari, F.P. A Flexible Unmanned Aerial Vehicle for Precision Agriculture. Precis. Agric. 2012, 13, 517–523. [Google Scholar] [CrossRef]

- Anthony, D.; Elbaum, S.; Lorenz, A.; Detweiler, C. On Crop Height Estimation with UAVs. In Proceedings of the 2014 IEEE/RSJ International Conference on Intelligent Robots and Systems, IEEE, Chicago, IL, USA, 14–18 September 2014; pp. 4805–4812. [Google Scholar]

- Yallappa, D.; Veerangouda, M.; Maski, D.; Palled, V.; Bheemanna, M. Development and Evaluation of Drone Mounted Sprayer for Pesticide Applications to Crops. In Proceedings of the 2017 IEEE Global Humanitarian Technology Conference (GHTC), IEEE, San Jose, CA, 19–22 October 2017; pp. 1–7. [Google Scholar]

- Pederi, Y.A.; Cheporniuk, H.S. Unmanned Aerial Vehicles and New Technological Methods of Monitoring and Crop Protection in Precision Agriculture. In Proceedings of the 2015 IEEE International Conference Actual Problems of Unmanned Aerial Vehicles Developments (APUAVD), IEEE, Kyiv, Ukraine, 13–15 October 2015; pp. 298–301. [Google Scholar]

- Herwitz, S.; Johnson, L.; Arvesen, J.; Higgins, R.; Leung, J.; Dunagan, S. Precision Agriculture as a Commercial Application for Solar-Powered Unmanned Aerial Vehicles. In Proceedings of the 1st UAV Conference; American Institute of Aeronautics and Astronautics, Portsmouth, Virginia, 20–23 May 2002; pp. 1–7. [Google Scholar]

- Herwitz, S.R.; Johnson, L.F.; Dunagan, S.E.; Higgins, R.G.; Sullivan, D.V.; Zheng, J.; Lobitz, B.M.; Leung, J.G.; Gallmeyer, B.A.; Aoyagi, M.; et al. Imaging from an Unmanned Aerial Vehicle: Agricultural Surveillance and Decision Support. Comput. Electron. Agric. 2004, 44, 49–61. [Google Scholar] [CrossRef]

- Ghazali, M.H.M.; Azmin, A.; Rahiman, W. Drone Implementation in Precision Agriculture—A Survey. Int. J. Emerg. Technol. Adv. Eng. 2022, 12, 67–77. [Google Scholar] [CrossRef]

- Vanitha, N.; Vinodhini, V.; Rekha, S. A Study on Agriculture UAV for Identifying the Plant Damage after Plantation. Int. J. Eng. Res. 2016, 6, 310–313. [Google Scholar]

- Kurkute, S.R. Drones for Smart Agriculture: A Technical Report. Int. J. Appl. Sci. Eng. 2018, 6, 341–346. [Google Scholar] [CrossRef]

- Patel, P.N.; Patel, M.A.; Faldu, R.M.; Dave, Y.R. Quadcopter for Agricultural Surveillance. Indian J. Sci. Res. 2013, 3, 6. [Google Scholar]

- Achtelik, M.C.; Stumpf, J.; Gurdan, D.; Doth, K.-M. Design of a Flexible High Performance Quadcopter Platform Breaking the MAV Endurance Record with Laser Power Beaming. In Proceedings of the 2011 IEEE/RSJ International Conference on Intelligent Robots and Systems, IEEE, San Francisco, CA, USA, 25–30 September 2011; pp. 5166–5172. [Google Scholar]

- Unal, B.; Savas, T.; Yazar, I. Design of a Pesticide Spraying Quadcopter. Int. J. Aerosp. Sci. Technol. 2020, vm01, 9–13. [Google Scholar] [CrossRef]

- Qasim, M.; Susanto, E.; Wibowo, A.S. PID Control for Attitude Stabilization of an Unmanned Aerial Vehicle Quad-Copter. In Proceedings of the 2017 5th International Conference on Instrumentation, Control, and Automation (ICA), IEEE, Yogyakarta, Indonesia, 9–11 August 2017; pp. 109–114. [Google Scholar]

- Kedari, S.; Lohagaonkar, P.; Nimbokar, M.; Palve, G.; Yevale, P. Quadcopter—A Smarter Way of Pesticide Spraying. Int. J. Impot. Res. 2016, 2, 5. [Google Scholar]

- Qin, W.; Xue, X.; Zhang, S.; Gu, W.; Wang, B. Droplet Deposition and Efficiency of Fungicides Sprayed with Small UAV against Wheat Powdery Mildew. Int. J. Agric. Biol. Eng. 2018, 11, 27–32. [Google Scholar] [CrossRef]

- Gill, R.; D’Andrea, R. An Annular Wing VTOL UAV: Flight Dynamics and Control. Drones 2020, 4, 14. [Google Scholar] [CrossRef]

- Kim, K. User Preferences in Drone Design and Operation. Drones 2022, 6, 133. [Google Scholar] [CrossRef]

- Hafeez, A.; Husain, M.A.; Singh, S.P.; Chauhan, A.; Khan, M.T.; Kumar, N.; Chauhan, A.; Soni, S.K. Implementation of Drone Technology for Farm Monitoring & Pesticide Spraying: A Review. Inf. Process. Agric. 2022. [Google Scholar] [CrossRef]

- Mallick, T.C.; Bhuyan, M.A.I.; Munna, M.S. Design & Implementation of an UAV (Drone) with Flight Data Record. In Proceedings of the 2016 International Conference on Innovations in Science, Engineering and Technology (ICISET), IEEE, Dhaka, Bangladesh, 28–29 October 2016; pp. 1–6. [Google Scholar]

- Nayak, S.; Nalini, J. Development of Gesture Controlled Robot Using 3-Axis Accelerometer. J. Control. Instrum. 2016, 7, 23–34. [Google Scholar]

- Sohail, S.; Nasim, S.; Khan, N.H. Modeling, Controlling and Stability of UAV Quad Copter. In Proceedings of the 2017 International Conference on Innovations in Electrical Engineering and Computational Technologies (ICIEECT), IEEE, Karachi, Pakistan, 5–7 April 2017; pp. 1–8. [Google Scholar]

- Vardhan, P.D.P.R.; Dheepak, S.; Aditya, P.T.; Sanjivi, A. Development of Automated Aerial Pesticide Sprayer. Int. J. Eng. Res. Technol. 2014, 3, 856–861. [Google Scholar] [CrossRef][Green Version]

- Kabra, T.S.; Kardile, A.V.; Bhosale, P.R.; Belekar, A.M. Design, Development & Optimization of a Quad-Copter for Agricultural Applications. Int. J. Eng. Res. 2017, 4, 6. [Google Scholar]

- Faiçal, B.S.; Freitas, H.; Gomes, P.H.; Mano, L.Y.; Pessin, G.; de Carvalho, A.C.P.L.F.; Krishnamachari, B.; Ueyama, J. An Adaptive Approach for UAV-Based Pesticide Spraying in Dynamic Environments. Comput. Electron. Agric. 2017, 138, 210–223. [Google Scholar] [CrossRef]

- Costa, F.G.; Ueyama, J.; Braun, T.; Pessin, G.; Osorio, F.S.; Vargas, P.A. The Use of Unmanned Aerial Vehicles and Wireless Sensor Network in Agricultural Applications. In Proceedings of the 2012 IEEE International Geoscience and Remote Sensing Symposium, IEEE, Munich, Germany, 22–27 July 2012; pp. 5045–5048. [Google Scholar]

- Rouse, J.W., Jr.; Haas, R.H.; Schell, J.A.; Deering, D.W. Monitoring Vegetation Systems in the Great Plains with Erts. NASA Spec. Publ. 1974, 351, 309. [Google Scholar]

- Huang, Y.; Thomson, S.J.; Hoffmann, W.C.; Lan, Y.; Fritz, B.K. Development and Prospect of Unmanned Aerial Vehicle Technologies for Agricultural Production Management. Int. J. Agric. Biol. Eng. 2013, 6, 11. [Google Scholar]

- Maurya, P. Hardware Implementation of a Flight Control System for an Unmanned Aerial Vehicle. Int. J. Comput. Sci. Eng. Technol. 2015, 1, 6. [Google Scholar]

- Yu, S.-H.; Kim, Y.-K.; Jun, H.-J.; Choi, I.S.; Woo, J.-K.; Kim, Y.-H.; Yun, Y.-T.; Choi, Y.; Alidoost, R.; Lee, J. Evaluation of Spray Characteristics of Pesticide Injection System in Agricultural Drones. J. Biosyst. Eng. 2020, 45, 272–280. [Google Scholar] [CrossRef]

- Guler, H.; Zhu, H.; Ozkan, E.; Derksen, R.; Krause, C. Wind Tunnel Evaluation of Drift Reduction Potential and Spray Characteristics with Drift Retardants at High Operating Pressure. J. ASTM Int. 2006, 3, 13527. [Google Scholar] [CrossRef]

- Pereira, L.S.; Paredes, P.; Melton, F.; Johnson, L.; Wang, T.; López-Urrea, R.; Cancela, J.J.; Allen, R.G. Prediction of Crop Coefficients from Fraction of Ground Cover and Height. Background and Validation Using Ground and Remote Sensing Data. Agric. Water Manag. 2020, 241, 106197. [Google Scholar] [CrossRef]

- Maulana, F.A.; Amalia, E.; Moelyadi, M.A. Computational Fluid Dynamics (CFD) Based Propeller Design Improvement for High Altitude Long Endurance (HALE) UAV. Int. J. Intell. Unmanned Syst. 2022. [Google Scholar] [CrossRef]

- Chen, H.; Lan, Y.; Fritz, B.K.; Clint Hoffmann, W.; Liu, S. Review of Agricultural Spraying Technologies for Plant Protection Using Unmanned Aerial Vehicle (UAV). Int. J. Agric. Biol. Eng. 2021, 14, 38–49. [Google Scholar] [CrossRef]

- Sinha, R.; Johnson, J.; Power, K.; Moodie, A.; Warhurst, E.; Barbosa, R. Understanding Spray Attributes of Commercial UAAS as Impacted by Operational and Design Parameters. Drones 2022, 6, 281. [Google Scholar] [CrossRef]

- Zhou, X.; Xing, H.; Ji, X. Multifunctional Automatic Weather Station Control and Management System: Multifunctional Automatic Weather Station Control and Management System. J. Instrum. 2011, 25, 348–354. [Google Scholar] [CrossRef]

- Tomažič, S.; Logar, V.; Kristl, Ž.; Krainer, A.; Škrjanc, I.; Košir, M. Indoor-Environment Simulator for Control Design Purposes. Build Environ. 2013, 70, 60–72. [Google Scholar] [CrossRef]

- Kharim, M.N.A.; Wayayok, A.; Mohamed Shariff, A.R.; Abdullah, A.F.; Husin, E.M. Droplet Deposition Density of Organic Liquid Fertilizer at Low Altitude UAV Aerial Spraying in Rice Cultivation. Comput. Electron. Agric. 2019, 167, 105045. [Google Scholar] [CrossRef]

- Ahmad, F.; Zhang, S.; Qiu, B.; Ma, J.; Xin, H.; Qiu, W.; Ahmed, S.; Chandio, F.A.; Khaliq, A. Comparison of Water Sensitive Paper and Glass Strip Sampling Approaches to Access Spray Deposit by UAV Sprayers. Agronomy 2022, 12, 1302. [Google Scholar] [CrossRef]

- Woldt, W.; Martin, D.; Lahteef, M.; Kruger, G.; Wright, R.; McMechan, J.; Proctor, C.; Jackson-Ziems, T. Field Evaluation of Commercially Available Small Unmanned Aircraft Crop Spray Systems. In Proceedings of the 2018 Detroit, Detroit, MI, USA, 29 July–1 August 2018; American Society of Agricultural and Biological Engineers: St. Joseph, MI, USA, 2018. [Google Scholar]

- Sies, M.F.; Madzlan, N.F.; Asmuin, N.; Sadikin, A.; Zakaria, H. Determine Spray Droplets on Water Sensitive Paper (WSP) for Low Pressure Deflector Nozzle Using Image J. IOP Conf. Ser. Mater. Sci. Eng. 2017, 243, 12047. [Google Scholar] [CrossRef]

- Fox, R.D.; Derksen, R.C.; Cooper, J.A.; Krause, C.R.; Ozkan, H.E. Visual and Image System Measurement of Spray Deposits Using Water–Sensitive Paper (WSP). Appl. Eng. Agric. 2003, 19, 549–552. [Google Scholar] [CrossRef]

- Sánchez-Hermosilla, J.; Medina, R. Adaptive Threshold for Droplet Spot Analysis Using Water-Sensitive Paper. Appl. Eng. Agric. 2004, 20, 547–551. [Google Scholar] [CrossRef]

- Chen, H.; Fritz, B.K.; Lan, Y.; Zhou, Z.; Zheng, J. Overview of Spray Nozzles for Plant Protection from Manned Aircrafts: Present Research and Prospective. Int. J. Precis. Agric. Aviat. 2018, 1, 1–12. [Google Scholar] [CrossRef]

- Fritz, B.K.; Hoffmann, W.C. Measuring Spray Droplet Size from Agricultural Nozzles Using Laser Diffraction. J. Vis. Exp. 2016, 115, e54533. [Google Scholar] [CrossRef] [PubMed]

- Cunha, M.; Carvalho, C.; Marcal, A.R.S. Assessing the Ability of Image Processing Software to Analyse Spray Quality on Water-Sensitive Papers Used as Artificial Targets. Biosyst. Eng. 2012, 111, 11–23. [Google Scholar] [CrossRef]

- Nansen, C.; Ferguson, J.C.; Moore, J.; Groves, L.; Emery, R.; Garel, N.; Hewitt, A. Optimizing Pesticide Spray Coverage Using a Novel Web and Smartphone Tool, SnapCard. Agron. Sustain. Dev. 2015, 35, 1075–1085. [Google Scholar] [CrossRef]

- Muenzer, C.; Shea, K. Simulation-Based Computational Design Synthesis Using Automated Generation of Simulation Models From Concept Model Graphs. J. Mech. Des. 2017, 139, 071101. [Google Scholar] [CrossRef]

- Tian, Z.; Xue, X.; Cui, L.; Chen, C.; Peng, B. Droplet Deposition Characteristics of Plant Protection UAV Spraying at Night. Int. J. Precis. Agric. Aviat. 2018, 1, 18–23. [Google Scholar] [CrossRef]

- Hill, B.D.; Inaba, D.J. Use of Water-Sensitive Paper to Monitor the Deposition of Aerially Applied Insecticides. J. Econ. Entomol. 1989, 82, 974–980. [Google Scholar] [CrossRef]

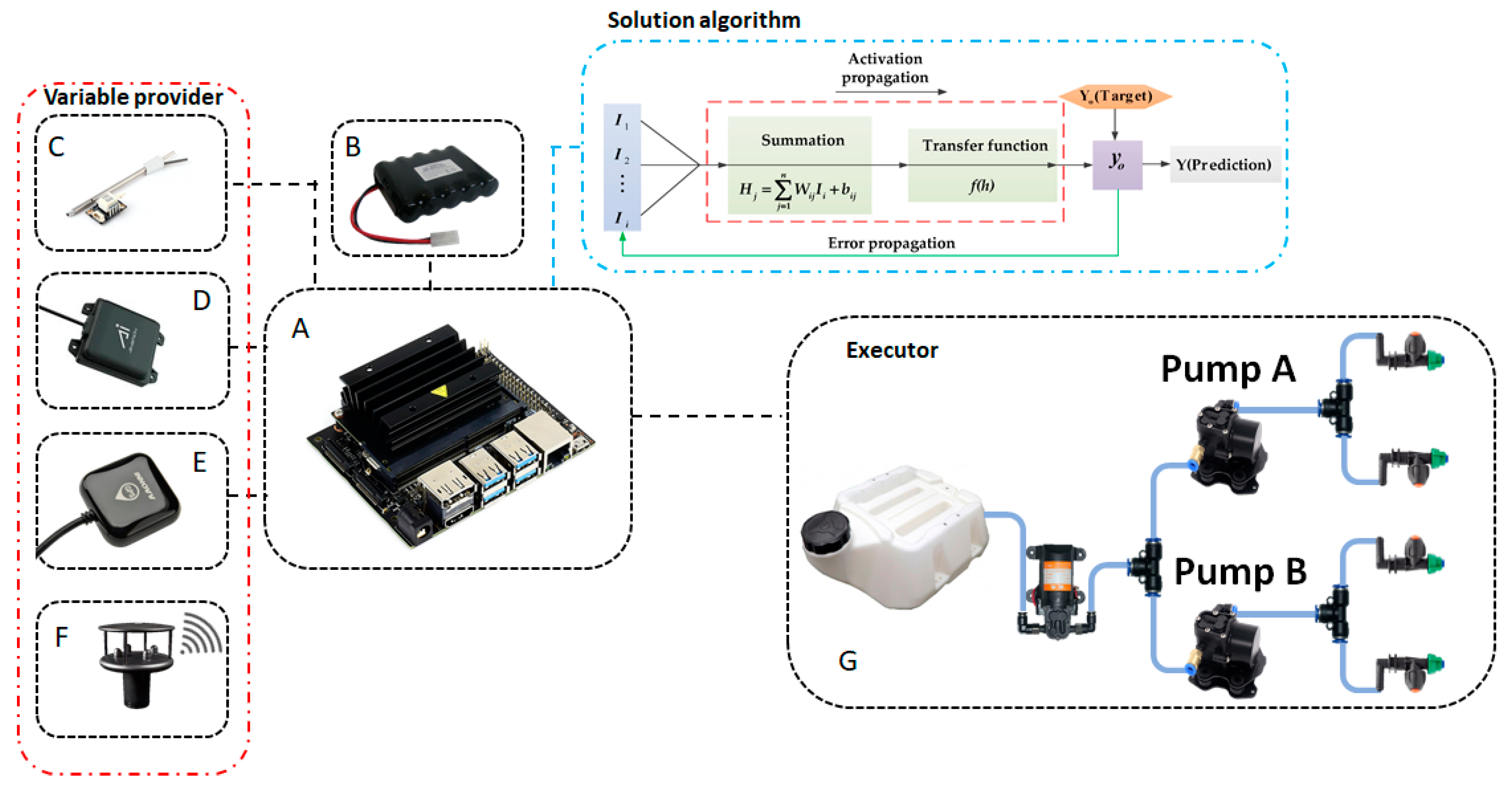

- Wen, S.; Zhang, Q.; Yin, X.; Lan, Y.; Zhang, J.; Ge, Y. Design of Plant Protection UAV Variable Spray System Based on Neural Networks. Sensors 2019, 19, 1112. [Google Scholar] [CrossRef]

- Dou, Z.; Fang, Z.; Han, X.; Liu, Y.; Duan, L.; Zeeshan, M.; Arshad, M. Comparison of the Effects of Chemical Topping Agent Sprayed by a UAV and a Boom Sprayer on Cotton Growth. Agronomy 2022, 12, 1625. [Google Scholar] [CrossRef]

- Dou, H.; Zhai, C.; Chen, L.; Wang, S.; Wang, X. Field Variation Characteristics of Sprayer Boom Height Using a Newly Designed Boom Height Detection System. IEEE Access 2021, 9, 17148–17160. [Google Scholar] [CrossRef]

- Solanelles, F.; Escolà, A.; Planas, S.; Rosell, J.R.; Camp, F.; Gràcia, F. An Electronic Control System for Pesticide Application Proportional to the Canopy Width of Tree Crops. Biosyst. Eng. 2006, 95, 473–481. [Google Scholar] [CrossRef]

- Balsari, P.; Doruchowski, G.; Marucco, P.; Tamagnone, M.; de Zande, J.V.; Wenneker, M. A System for Adjusting the Spray Application to the Target Characteristics. Int. J. Eng. 2008, 10, 12. Available online: https//edepot.wur.nl/2242 (accessed on 12 September 2022).

- Rosell, J.R.; Sanz, R. A Review of Methods and Applications of the Geometric Characterization of Tree Crops in Agricultural Activities. Comput. Electron. Agric. 2012, 81, 124–141. [Google Scholar] [CrossRef]

- Salcedo, R.; Garcera, C.; Granell, R.; Molto, E.; Chueca, P. Description of the Airflow Produced by an Air-Assisted Sprayer during Pesticide Applications to Citrus. Span. J. Agric. Res. 2015, 13, e0208. [Google Scholar] [CrossRef]

- Palleja Cabre, T.; Llorens, J.; Landers, A.J. Measuring Crop Canopy—The Development of a Dynamic System for Precision Fruit Crop Spraying. Adv. Anim. Vet. Sci. 2017, 8, 250–254. [Google Scholar] [CrossRef]

- Escolà, A.; Rosell-Polo, J.R.; Planas, S.; Gil, E.; Pomar, J.; Camp, F.; Llorens, J.; Solanelles, F. Variable Rate Sprayer. Part 1—Orchard Prototype: Design, Implementation and Validation. Comput. Electron. Agric. 2013, 95, 122–135. [Google Scholar] [CrossRef]

- Gil, E.; Llorens, J.; Llop, J.; Fàbregas, X.; Escolà, A.; Rosell-Polo, J.R. Variable Rate Sprayer. Part 2—Vineyard Prototype: Design, Implementation, and Validation. Comput. Electron. Agric. 2013, 95, 136–150. [Google Scholar] [CrossRef]

- Du, Q.; Chang, N.-B.; Yang, C.; Srilakshmi, K.R. Combination of Multispectral Remote Sensing, Variable Rate Technology and Environmental Modeling for Citrus Pest Management. J. Environ. Manag. Today 2008, 86, 14–26. [Google Scholar] [CrossRef]

- Teske, A.L.; Chen, G.; Nansen, C.; Kong, Z. Optimised Dispensing of Predatory Mites by Multirotor UAVs in Wind: A Distribution Pattern Modelling Approach for Precision Pest Management. Biosyst. Eng. 2019, 187, 226–238. [Google Scholar] [CrossRef]

- Lim, J.-T. Development of Spray Calculation Algorithm Using the Pest Control Drones. J. Converg. Inf. Technol. 2020, 10, 135–142. [Google Scholar] [CrossRef]

- Chen, S.; Lan, Y.; Zhou, Z.; Ouyang, F.; Wang, G.; Huang, X.; Deng, X.; Cheng, S. Effect of Droplet Size Parameters on Droplet Deposition and Drift of Aerial Spraying by Using Plant Protection UAV. Agronomy 2020, 10, 195. [Google Scholar] [CrossRef]

- Huang, Y.; Reddy, K.N.; Fletcher, R.S.; Pennington, D. UAV Low-Altitude Remote Sensing for Precision Weed Management. Weed Technol. 2018, 32, 2–6. [Google Scholar] [CrossRef]

- Weiss, M.; Baret, F. Using 3D Point Clouds Derived from UAV RGB Imagery to Describe Vineyard 3D Macro-Structure. Remote Sens. 2017, 9, 111. [Google Scholar] [CrossRef]

- Campos, J.; Llop, J.; Gallart, M.; García-Ruiz, F.; Gras, A.; Salcedo, R.; Gil, E. Development of Canopy Vigour Maps Using UAV for Site-Specific Management during Vineyard Spraying Process. Precis. Agric. 2019, 20, 1136–1156. [Google Scholar] [CrossRef]

- Ballesteros, R.; Ortega, J.F.; Hernández, D.; Moreno, M.Á. Characterization of Vitis vinifera L. Canopy Using Unmanned Aerial Vehicle-Based Remote Sensing and Photogrammetry Techniques. Am. J. Enol. Vitic. 2015, 66, 120–129. [Google Scholar] [CrossRef]

- Liu, H.; Zhu, H.; Shen, Y.; Chen, Y.; Ozkan, H.E. Development of Digital Flow Control System for Multi-Channel Variable-Rate Sprayers. Trans. ASABE 2014, 57, 273–281. [Google Scholar] [CrossRef]

- Yang, D.; Zhang, L.; Yan, X.; Wang, Z.; Yuan, H. Effects of Droplet Distribution on Insecticide Toxicity to Asian Corn Borers (Ostrinia furnaealis) and Spiders (Xysticus ephippiatus). J. Integr. Agric. 2014, 13, 124–133. [Google Scholar] [CrossRef]

- Qin, W.-C.; Qiu, B.-J.; Xue, X.-Y.; Chen, C.; Xu, Z.-F.; Zhou, Q.-Q. Droplet Deposition and Control Effect of Insecticides Sprayed with an Unmanned Aerial Vehicle against Plant Hoppers. J. Crop Prot. 2016, 85, 79–88. [Google Scholar] [CrossRef]

- Zhang, P.; Deng, L.; Lyu, Q.; He, S.; Yi, S.; Liu, Y.; Yu, Y.; Pan, H. Effects of Citrus Tree-Shape and Spraying Height of Small Unmanned Aerial Vehicle on Droplet Distribution. Int. J. Agric. Biol. Eng. 2016, 9, 45–52. [Google Scholar] [CrossRef]

- Chen, P.; Ouyang, F.; Zhang, Y.; Lan, Y. Preliminary Evaluation of Spraying Quality of Multi-Unmanned Aerial Vehicle (UAV) Close Formation Spraying. Agriculture 2022, 12, 1149. [Google Scholar] [CrossRef]

- Chen, P.; Lan, Y.; Huang, X.; Qi, H.; Wang, G.; Wang, J.; Wang, L.; Xiao, H. Droplet Deposition and Control of Planthoppers of Different Nozzles in Two-Stage Rice with a Quadrotor Unmanned Aerial Vehicle. Agronomy 2020, 10, 303. [Google Scholar] [CrossRef]

- Kadam, S.S.; Kulkarni, S.R.; Salunkhe, S.S.; Salunkhe, M.M. Fabrication of Automatic Agricultural Fertilizers Spraying Machine. Int. J. Eng. Res. 2022, 9, 6. [Google Scholar]

- Lan, Y.; Hoffmann, W.C.; Fritz, B.K.; Martin, D.E.; Lopez, J.D., Jr. Spray Drift Mitigation with Spray Mix Adjuvants. Appl. Eng. Agric. 2008, 24, 5–10. [Google Scholar] [CrossRef]

- Hentschke, M.; Pignaton de Freitas, E.; Hennig, C.; Girardi da Veiga, I. Evaluation of Altitude Sensors for a Crop Spraying Drone. Drones 2018, 2, 25. [Google Scholar] [CrossRef]

| Type | Advantage | Disadvantage | Reference |

|---|---|---|---|

| Single rotor helicopter | Long endurance | More dangerous | [21,23,26,27,28,29,30,31,32,33] |

| Octocopter | Greater redundancy and lifting capacity | Several components to keep track of | [21,26,34,35,36,37,38] |

| Quadcopter | Simplest mechanical structure, opposite force stays balanced | Light lifting capacity | [39,40,41] |

| Hexacopter | Greater redundancy | Insufficient performance and battery capacity | [21,34,35,36,37,42,43,44] |

| Fixed wing | Fly faster and longer distances | Reduce mapping efficiency, inflexible take-off and landing | [45,46,47] |

| Controller | Framework | Load | Speed | Reference |

|---|---|---|---|---|

| Ardu 2.8 FC | RC transmitter | - | - | [21] |

| UAV ZHKU-0404 | - | 1–15 dm3 | 3.5 m/s | [40] |

| Arduino mega 2560 | WIFI module | - | - | [41] |

| FC | RC Transmitter | 5 dm3 | 1 m/s | [44] |

| Arduino At mega 328, | Radio receiver | - | - | [28,39,49] |

| Hexa-II Atmega1284p | WIFI | 1 kg (camera) | - | [42] |

| Atom board processor | - | 0.6 kg (Laser scanner) | - | [43] |

| DJIs 900 model | - | - | 1.3 m/s | [36] |

| ARM processor | - | 1 kg | 8.33 m/s | [38] |

| TTA M8A | TR-PIV | 10 kg | 0–15 m/s | [26] |

| Aero drone PAM-20 | Radio Link | 25 kg | 22.22 m/s | [45] |

| Pathfinder-plus | Radio link | 67.5 kg | 13.89 m/s | [46,47] |

| Z-3 | - | 20 dm3 | 3 m/s | [28] |

| Yamaha RMAX | - | 100 kg | 5.56 m/s | [30] |

| MSP430 single-chip | RC transmitter | 25 kg | 3–6 m/s | [31] |

| Rotomotion’s SR200 | RC Transmitter | 22.7 kg (5 kg) | - | [29,32,33] |

| KK v5.5 Atmega 168 | RC Transmitter, WSN | - | - | [50] |

| Atmega 8bit AVR | - | - | - | [51] |

| LLP & HLP | Radio Link | 1 kg | - | [52] |

| Arduino | Radio frequency | 8 kg | 5 m/s | [53,54,55] |

| N-3 type | - | 25 dm3 | 4 m/s | [56] |

| Components | Purpose | Reference |

|---|---|---|

| Accelerometer | Acceleration measurement | [38,39,41,42,44,49,52,60,61] |

| Gyro | Rotational movement | [29,31,32,38,39,44,49,52,54,60,62] |

| BLDC (brushless DC) | Motion control | [39,41,42,44,49,50,51,53,54,60,62,63] |

| ESC (electronic speed control) | BLDC’s speed control | [39,41,42,44,49,50,51,53,54,60,64] |

| Water sensitive paper | Assessing spray coverage | [40,56] |

| Anemometer | Wind speed measurement | [40] |

| Filter papers | Fine substances separator | [40] |

| Digital Temperature | Temperature detectors | [28,40,56] |

| Humidity indicator | Air moisture measurement | [28,40,56] |

| Magnetometer | Magnetic field measurement | [29,31,32,33,42,52,60] |

| WSN | Sensing environmental conditions | [39,49,65,66] |

| IMU | Angular rate and forces measurement | [29,32,33,43,51,52,54,55,60,62] |

| GPS | Provides geo location of an object | [29,31,32,33,38,39,41,42,44,45,50,52,53,56,60,62,63,67,68] |

| Telemetry | Obtain real-time data from a UAV | [31,33] |

| Altimeter | Altitude measurement | [31] |

| Air Pressure Sensor | Gases or liquids measurement | [38,52,69] |

| Barometer | Atmospheric pressures | [28,60] |

| PWM controller | Signal pulse provider | [32,33,54] |

| Nozzle and Pump Type | Operating Speed | Operating Pressure | Reference |

|---|---|---|---|

| Singflo Flo-2203 a (pump) | 2.6 dm3/min | 0.483 MPa | [70] |

| BPP-25 b (pump) | 3.5 dm3/min | 1 MPa | [70] |

| Unbranded/generic c (pump) | 5.5 dm3/min | 0.9 MPa | [70] |

| XR80015-VS d | 0.57 dm3/min | 0.103–0.41 MPa | [44,70] |

| AI11002 e | 0.76 dm3/min | 0.27–0.69 MPa | [30,70] |

| Micron air–A+ | 27.22 g/min | - | [33] |

| TX VK-08 f | 0.5 dm3/min | 0.207–2 MPa | [21,70] |

| Rotary atomizer | 0.85 dm3/min | - | [56] |

| TP800067-VS g | 0.25 dm3/min | 0.207–0.414 MPa | [40,70] |

| Method | Data Type | References |

|---|---|---|

| Spectrometer-fluorometer (Model USB2000+, Ocean optics, Inc., Dunedin, FL) | Number of droplets, spray pattern | [80] |

| Image J | Spray droplet size (SMD) | [81,82,83] |

| DropletScan™ | Spray droplet size (SMD), coverage, spray application rate | [84,85] |

| StainAnalysis | Coverage, droplet density, number of droplets | [86,87] |

| AgroScan | Spray droplet size (SMD), coverage, number of droplets | [86] |

| SnapCard | Spray droplet size (SMD), coverage | [87] |

| Gotas | Spray droplet size (SMD), coverage, Number of droplets | [86] |

| StainMaster | Spray droplet size (SMD), coverage | [86] |

| ImageTool | Spray droplet size (SMD) | [81,82,86] |

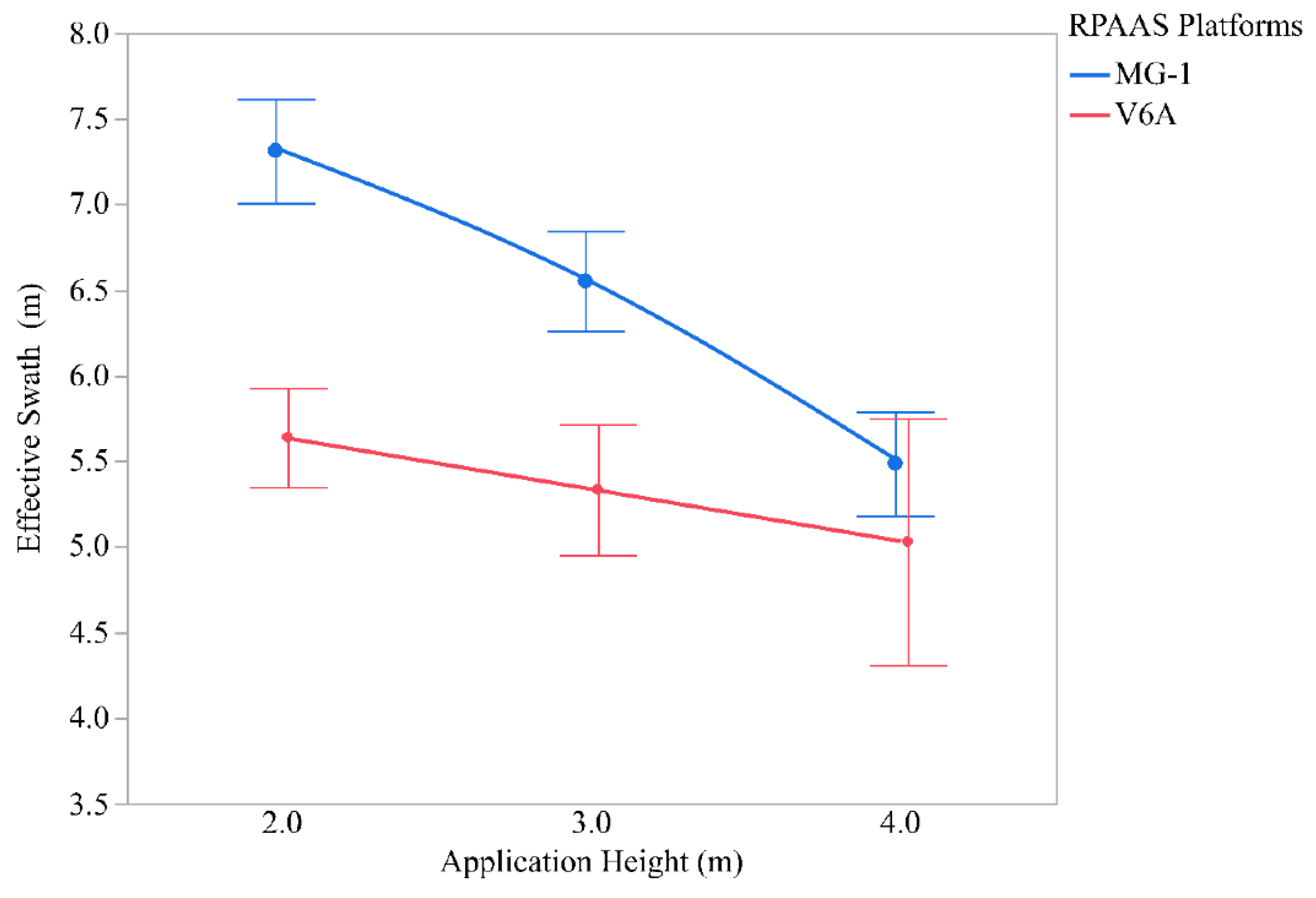

| Platform | Speed (m/s) | Application Height (m) | Effective Swath (m) | Theoretical Application (L/ha) | Measured Application (L/ha) | Spray Efficiency (%) |

|---|---|---|---|---|---|---|

| V6A | 1 | 2 | 5.2 | 25.3 | 14.9 | 58.8 |

| V6A | 1 | 3 | 6.4 | 20.6 | 14.9 | 72.6 |

| V6A | 1 | 4 | 4.0 | 32.9 | 6.4 | 19.3 |

| V6A | 3 | 2 | 5.8 | 7.6 | 6.4 | 84.6 |

| V6A | 3 | 3 | 4.6 | 9.5 | 4.7 | 49.2 |

| V6A | 3 | 4 | 5.2 | 8.4 | 2.0 | 23.8 |

| V6A | 5 | 2 | 6.4 | 4.1 | 5.3 | 129.9 |

| V6A | 5 | 3 | 5.2 | 5.1 | 2.2 | 42.5 |

| V6A | 5 | 4 | 4.0 | 6.6 | 1.5 | 22.5 |

| V6A | 7 | 2 | 5.2 | 3.6 | 1.7 | 47.0 |

| V6A | 7 | 3 | 5.2 | 3.6 | 1.2 | 32.9 |

| V6A | 7 | 4 | 7.0 | 2.7 | 1.0 | 37.2 |

| MG-1 | 1 | 2 | 7.6 | 31.1 | 39.9 | 128.1 |

| MG-1 | 1 | 3 | 6.4 | 36.9 | 33.3 | 90.0 |

| MG-1 | 1 | 4 | 5.8 | 40.8 | 29.3 | 71.8 |

| MG-1 | 3 | 2 | 7.6 | 10.4 | 11.3 | 108.9 |

| MG-1 | 3 | 3 | 7.0 | 11.3 | 6.3 | 56.2 |

| MG-1 | 3 | 4 | 5.8 | 13.6 | 8.9 | 65.6 |

| MG-1 | 5 | 2 | 6.4 | 7.4 | 6.5 | 87.8 |

| MG-1 | 5 | 3 | 7.0 | 6.8 | 18.7 | 276.8 |

| MG-1 | 5 | 4 | 4.6 | 10.3 | 5.8 | 55.9 |

| MG-1 | 7 | 2 | 7.6 | 4.4 | 4.9 | 110.5 |

| MG-1 | 7 | 3 | 5.8 | 5.8 | 5.5 | 95.1 |

| MG-1 | 7 | 4 | 5.8 | 5.8 | 3.6 | 62.2 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hanif, A.S.; Han, X.; Yu, S.-H. Independent Control Spraying System for UAV-Based Precise Variable Sprayer: A Review. Drones 2022, 6, 383. https://doi.org/10.3390/drones6120383

Hanif AS, Han X, Yu S-H. Independent Control Spraying System for UAV-Based Precise Variable Sprayer: A Review. Drones. 2022; 6(12):383. https://doi.org/10.3390/drones6120383

Chicago/Turabian StyleHanif, Adhitya Saiful, Xiongzhe Han, and Seung-Hwa Yu. 2022. "Independent Control Spraying System for UAV-Based Precise Variable Sprayer: A Review" Drones 6, no. 12: 383. https://doi.org/10.3390/drones6120383

APA StyleHanif, A. S., Han, X., & Yu, S.-H. (2022). Independent Control Spraying System for UAV-Based Precise Variable Sprayer: A Review. Drones, 6(12), 383. https://doi.org/10.3390/drones6120383