Fractional Modeling and Control of Lightweight 1 DOF Flexible Robots Robust to Sensor Disturbances and Payload Changes

Abstract

:1. Introduction

- More energy consumption due to the bulky structure.

- Higher weight that often impedes their translation if mounted on a mobile platform.

- Higher design cost and operational risk.

- The finite element method: The flexible link is modeled as a combination of a finite number of elements and the deflections are analyzed from the movement of small rigid bodies which leads to an important number of differential equations [9].

- The transfer matrix method: This was originally used in optics and acoustics to analyze the propagation of electromagnetic or acoustic waves. The transfer matrix can represent each element of the flexible link system by transferring a state vector from one end of the element to the other. The whole system transfer matrix is obtained by multiplying the element transfer matrices together [10].

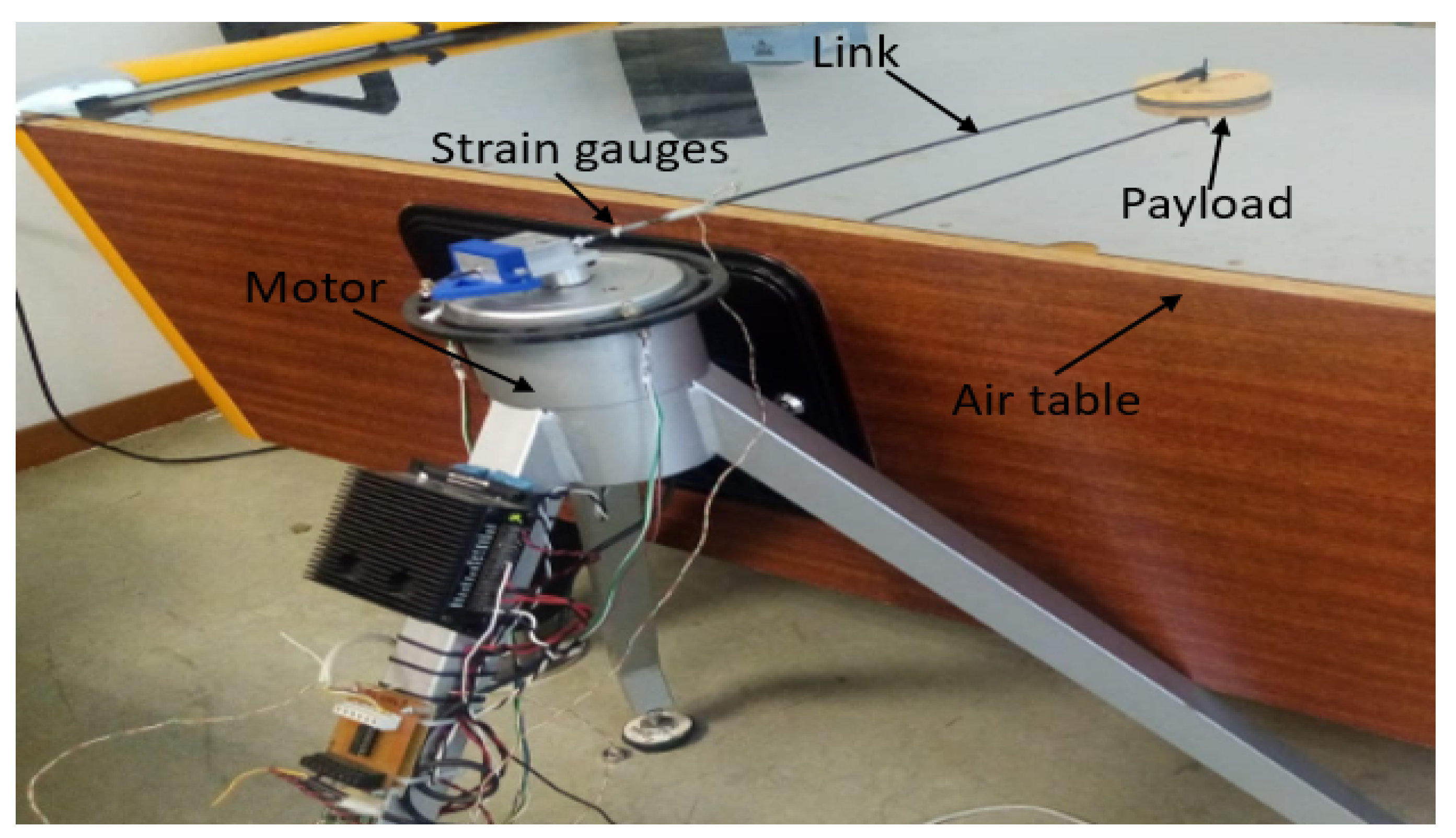

2. Experimental Setup

2.1. Flexible Robot Setup Description

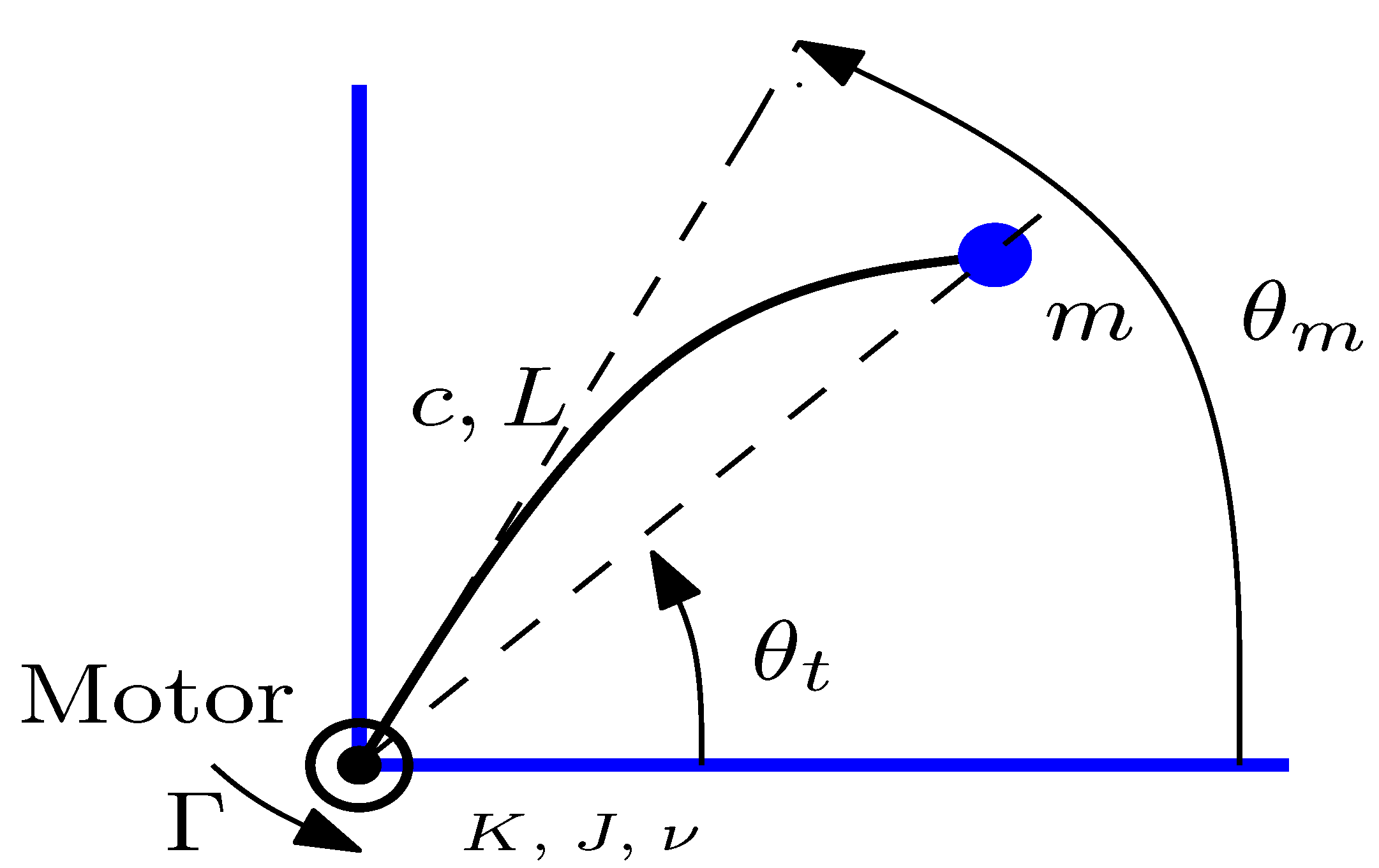

2.2. Robot Dynamics

2.2.1. Actuator Model

2.2.2. Flexible Link Integer Order Model

3. Fractional Order Model of the Flexible Link

3.1. The Fractional Order Model

3.2. The Resonant Frequency

3.3. Experimental Validation of the Dynamic Model

| Algorithm 1 Model-based identification system algorithm |

|

- The of the identified - is kept constant during the payload changes, with a value .

- The frequency changes significantly with the payload, in accordance with expression (5).

- The - models have the lowest compared to the rest of the models.

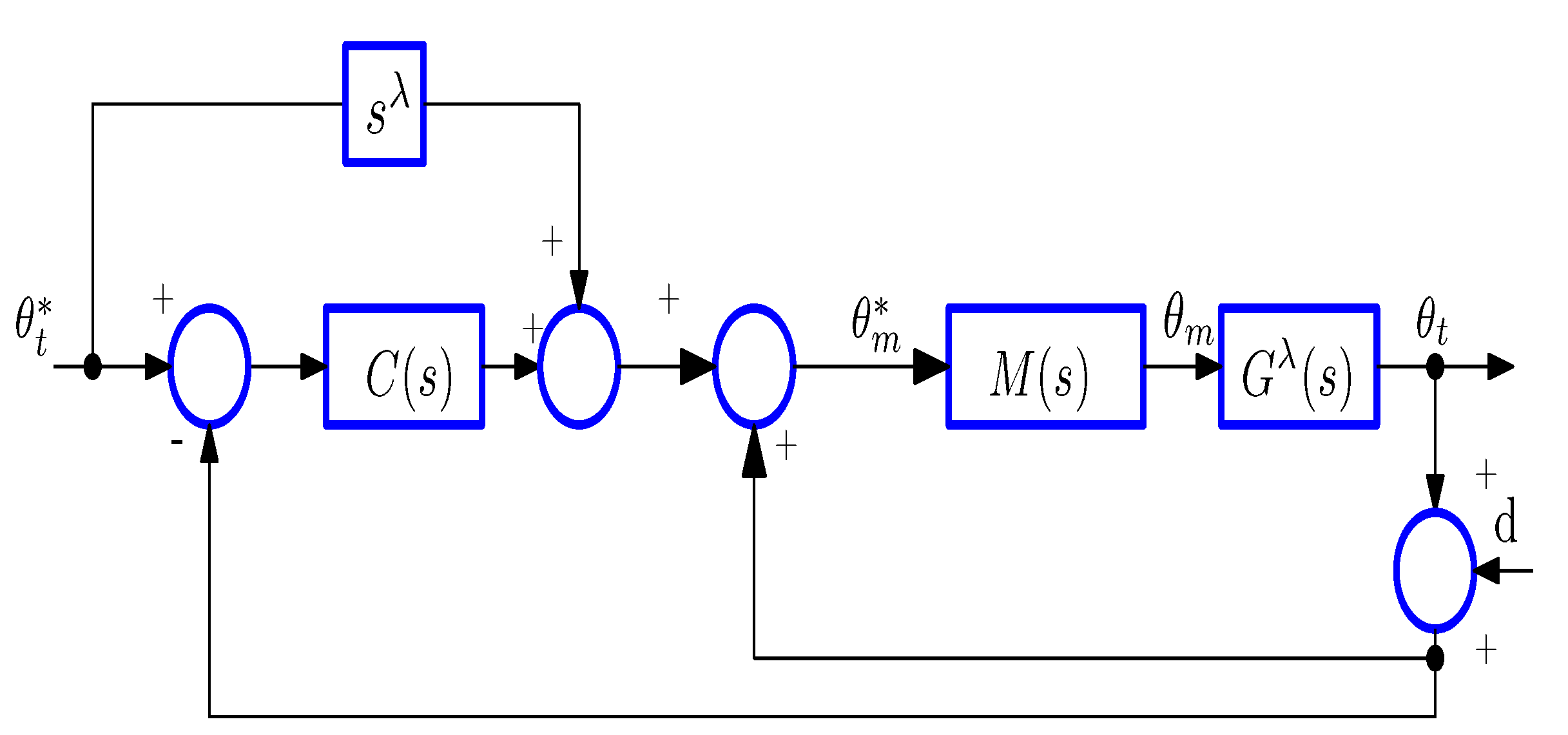

4. General Control Scheme

- The inner loop employs the measured motor angle, , to regulate the motor position. It effectively gets out the effects of non-linear Coulomb friction and time-varying viscous friction. Moreover, in order to ensure a faster dynamic response of the servo-controlled motor compared to the flexible link, this inner loop was implemented with a high-gain controller.

- The outer loop focuses on controlling the position of the payload at the tip to mitigate the occurrence of mechanical vibrations and ensure good trajectory tracking.

4.1. The Inner Loop

4.2. The Outer Loop

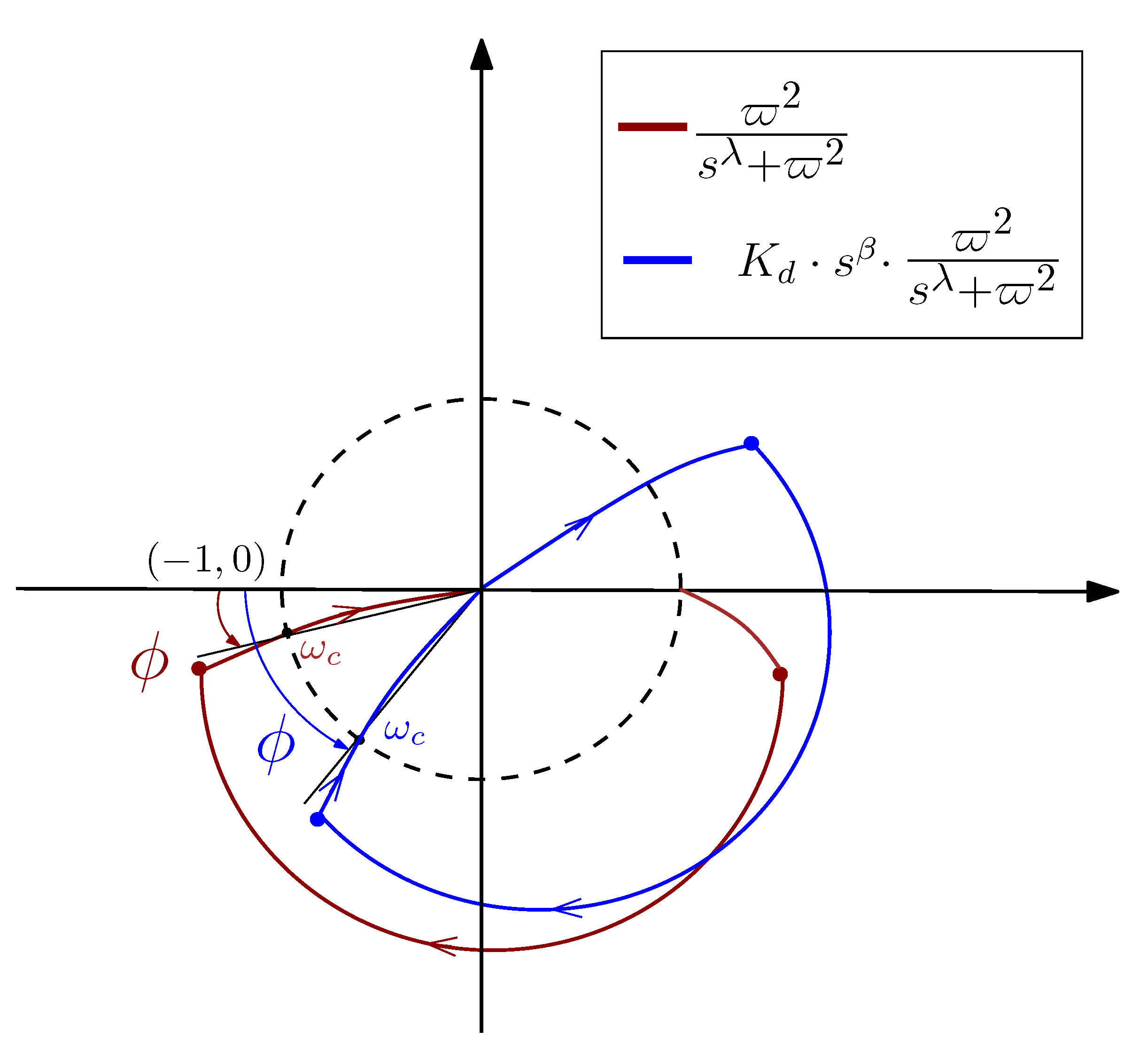

5. Control Robust to Strain Gauge Disturbances

5.1. Strain Gauge Offset Disturbance Removal

5.2. High-Frequency Noise Reduction

6. Control Robust to Payload Changes

- Since , the numerator is less than or equal to zero.

- Choose the gain crossover frequency corresponding to . It must verify condition (39) and, according to Remark 1, it is the minimum achieved in the interval .

- Apply Equation (43) to the pair . This gives the relationThen, to calculate , we need to obtain the value of , which will be done in the next step.

- In accordance with Theorems 1 and 2, the minimum phase margin in the range is located at . This value is represented by . Then, applying condition (42) to and substituting by (54) yieldsThis complex equation can be transformed into two real equations that allow us to obtain the two values and .

- Obtain from the left side equation of (54) using the already calculated and the fractional order calculated in the previous step.

- Then, the designed controller iswhich can be modified aswhere if and if in order to fulfill the high-frequency noise condition (32). In this expression, is chosen small enough to not modify the frequency characteristic of the open-loop transfer function . Since this modification produces a phase lag in , a criterion to design is to choose a value such that the minimum phase margin is reduced by up to of its initially designed value (or, alternatively, increase in a quantity that accounts for the phase margin reduction subsequently caused by introducing ).

7. Application to a Single Lumped Mass Flexible Link Manipulator

7.1. Design of the Controllers

- The gain crossover frequency corresponding to the minimum natural frequency rad·s is chosen as rad·s. Note that the condition of Theorem 2 is verified. Then, it is the minimum achieved in the interval .

- Application of the right side equation of (54) gives .

- The minimum phase margin in all the intervals is chosen as . Then, the solution of (55) is rad·s and .

- Obtain from the left side equation of (54) and the fractional order calculated in the previous step. We obtain .

- The proper controller is designed by choosing and instead of (as stated in the procedure) in order to enhance the filtering of high-frequency noise.

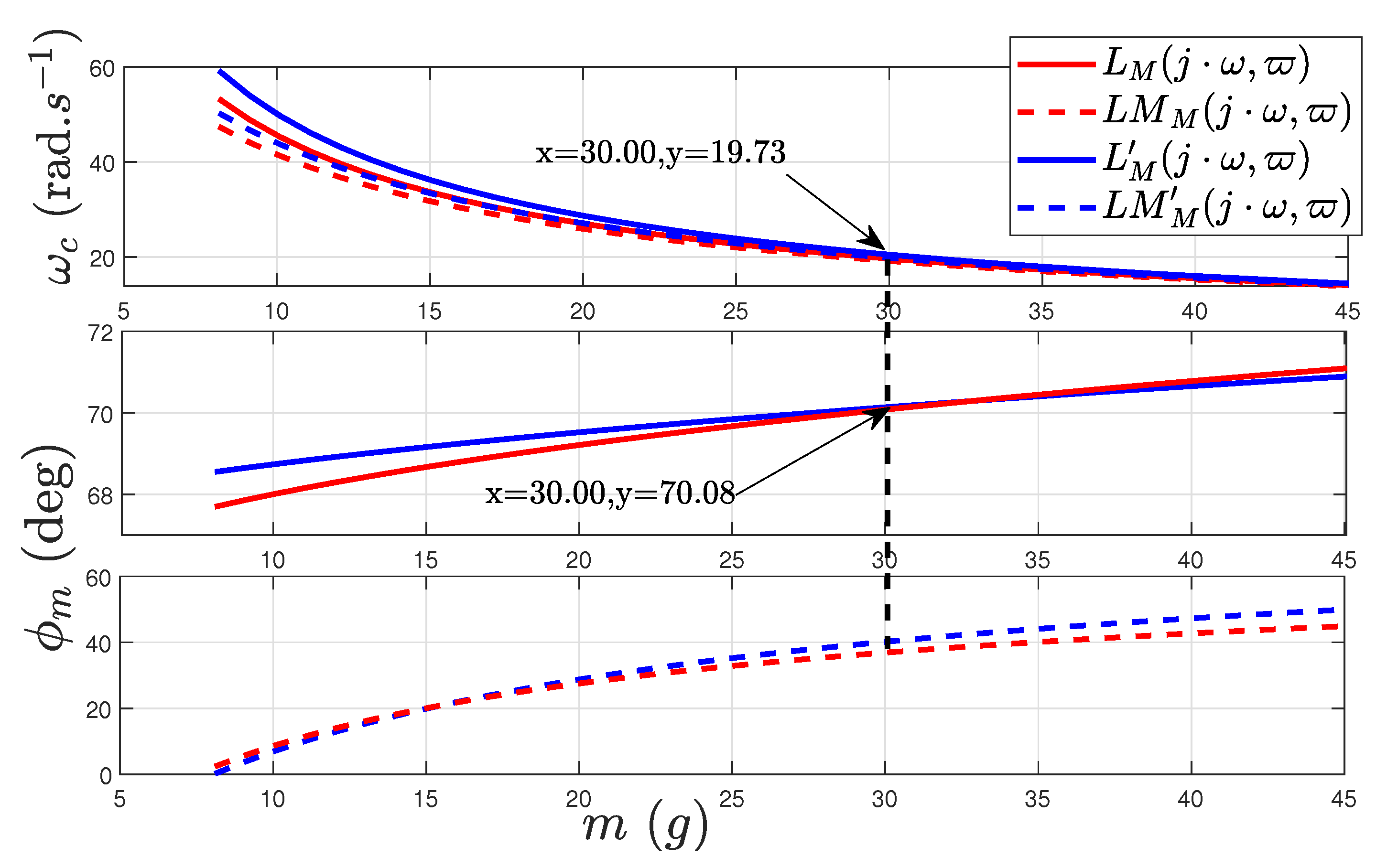

- The plots of and intersect at the nominal payload in the cases of and .

- is decreasing with m (increasing with ) as stated in Remark 1.

- is increasing with m (decreasing with ) as stated in Theorem 1.

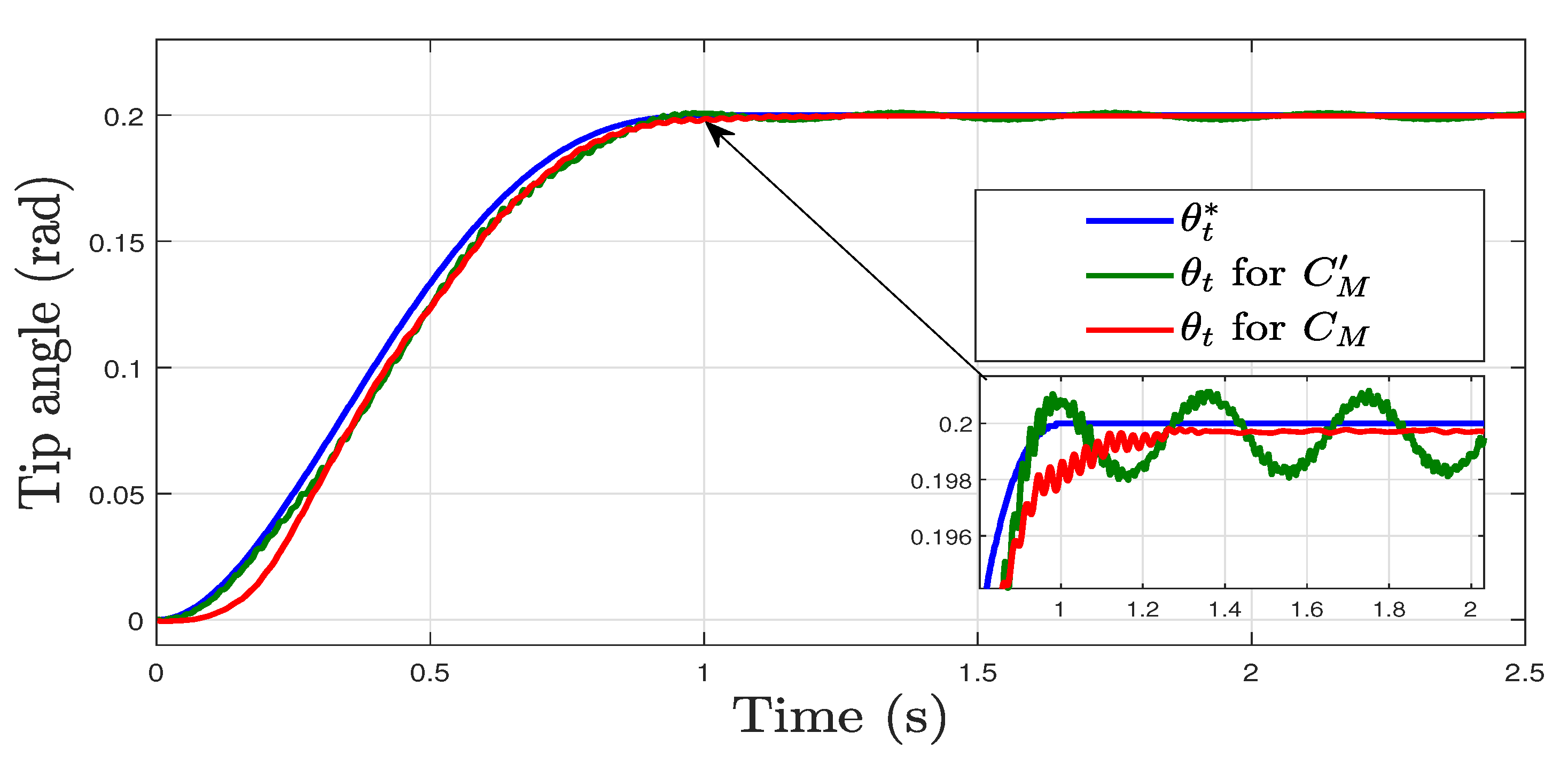

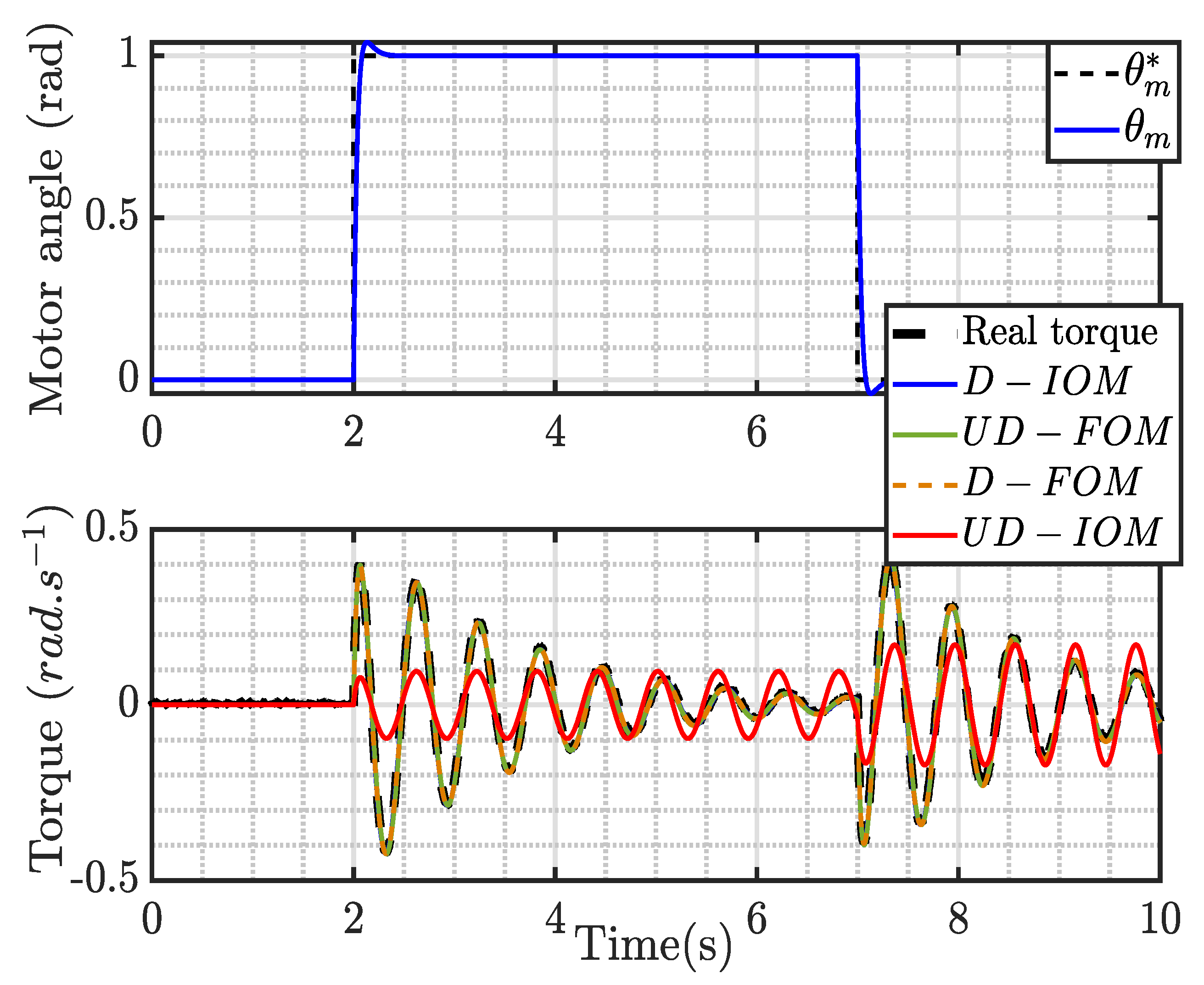

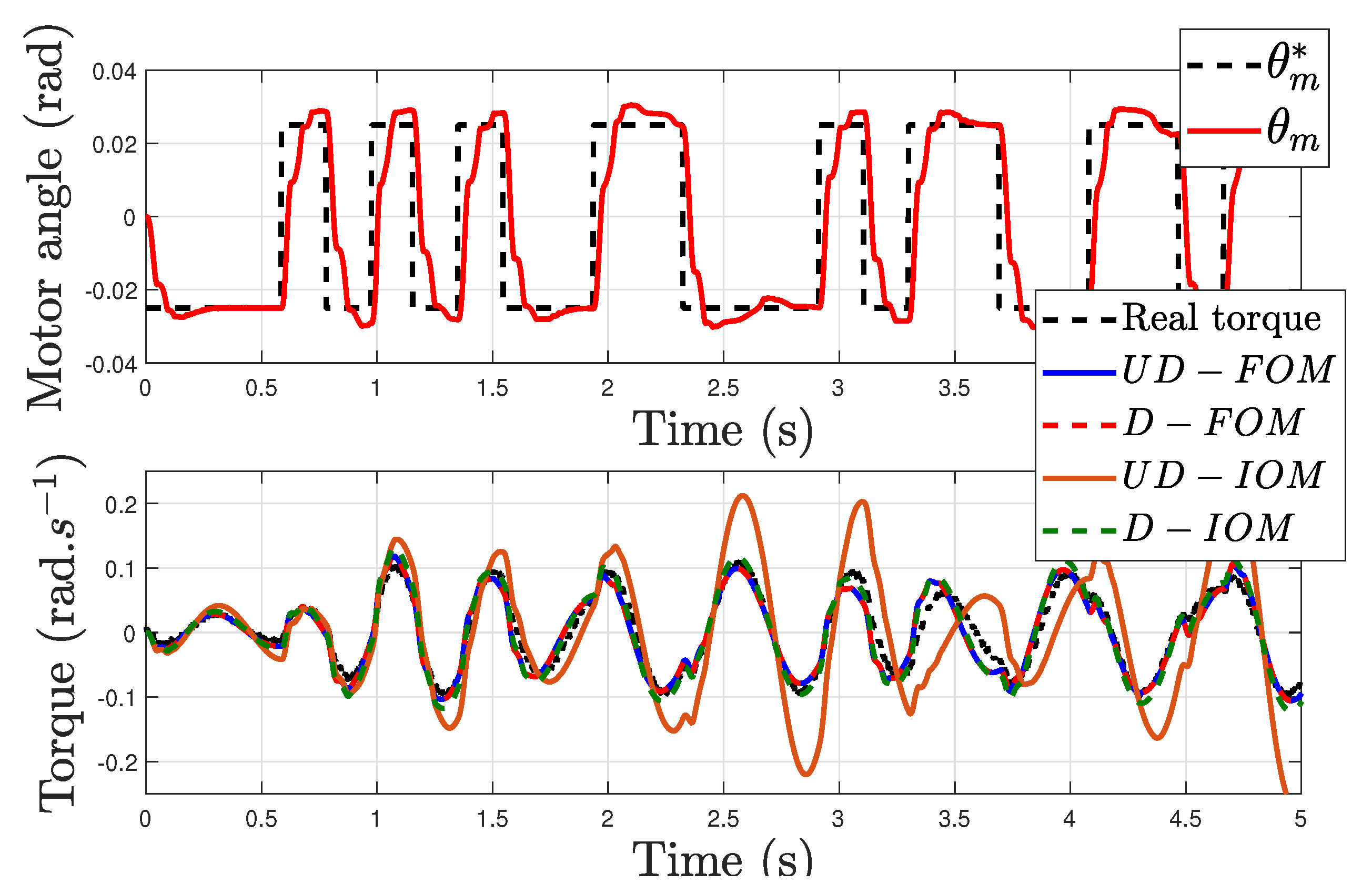

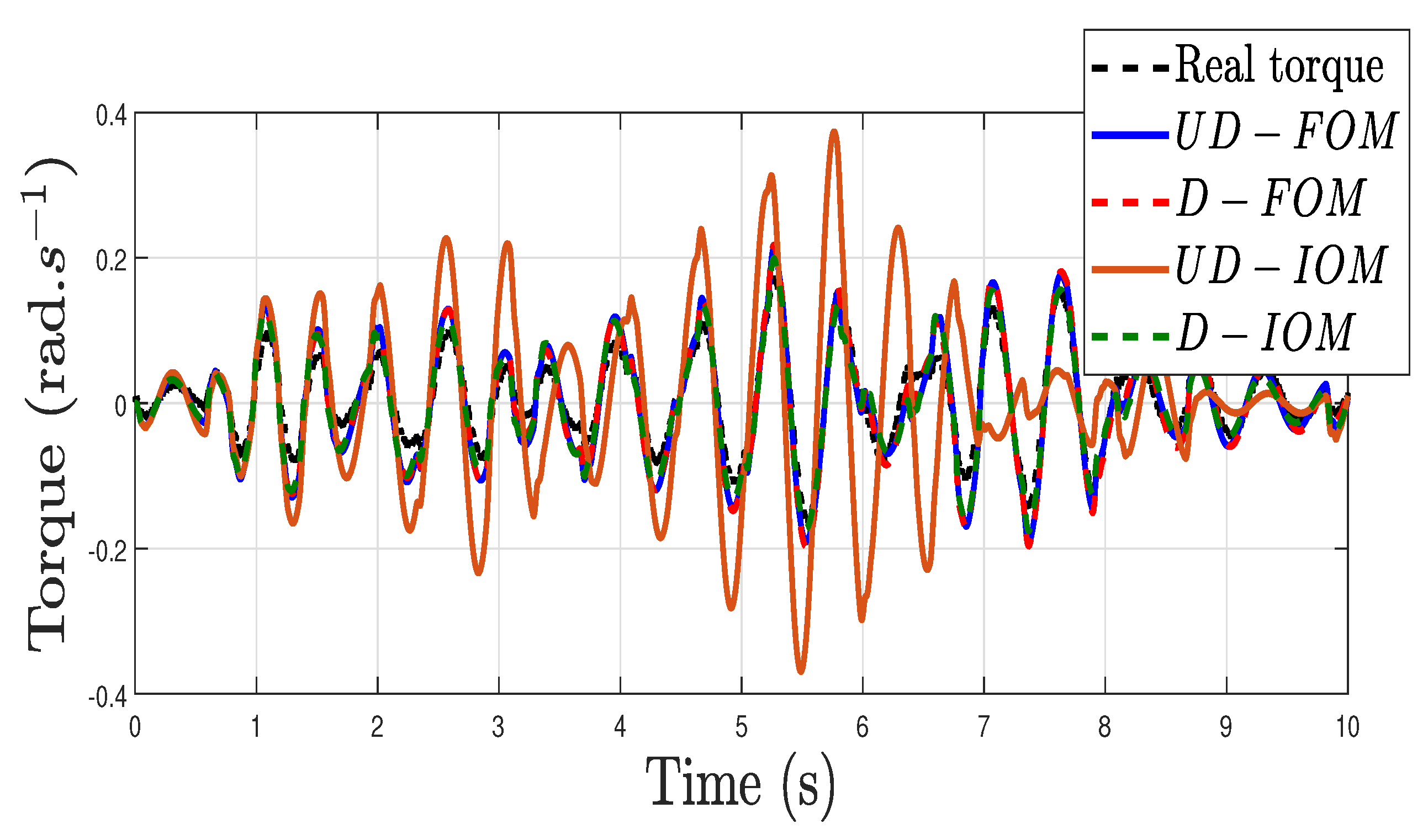

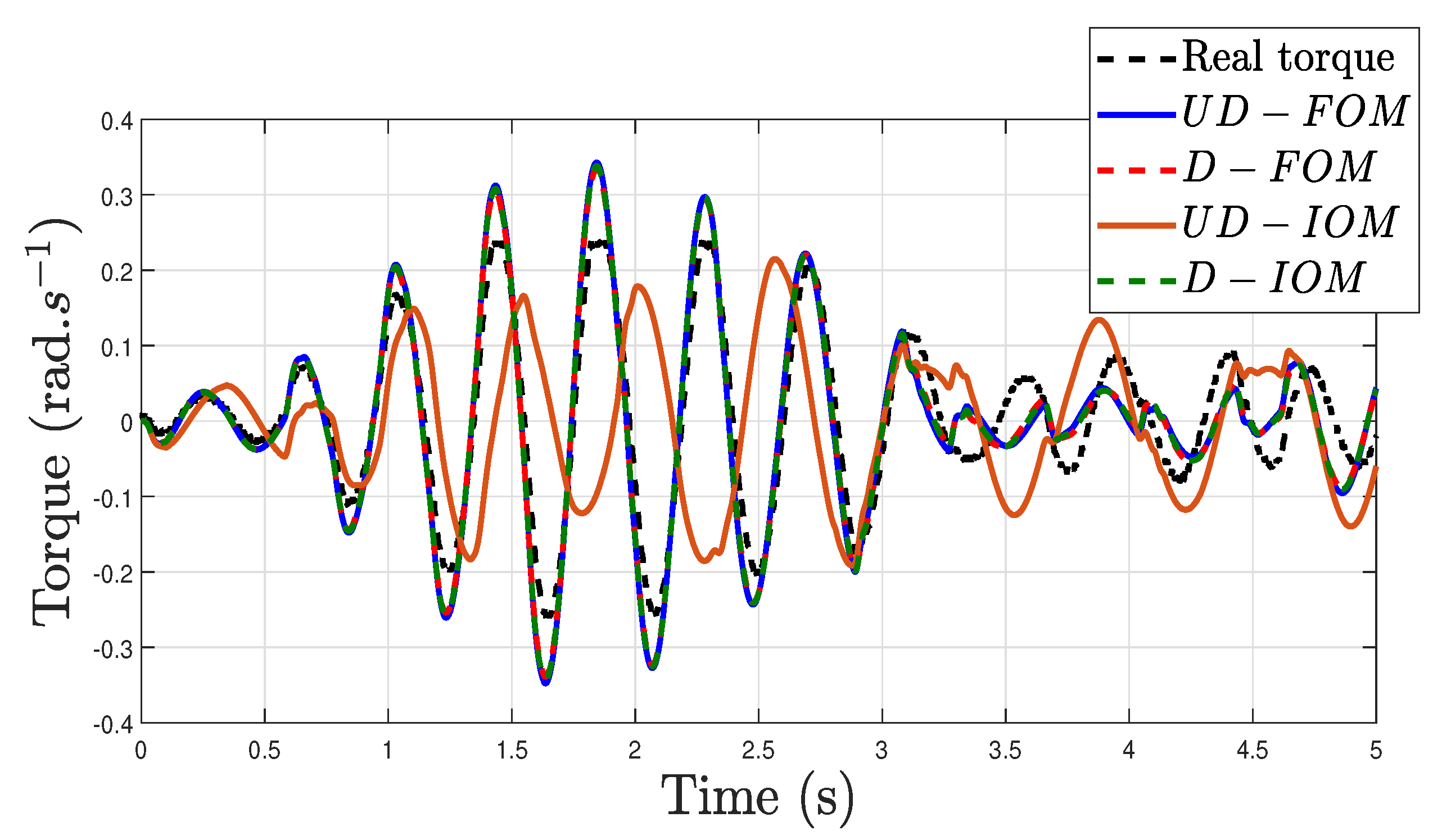

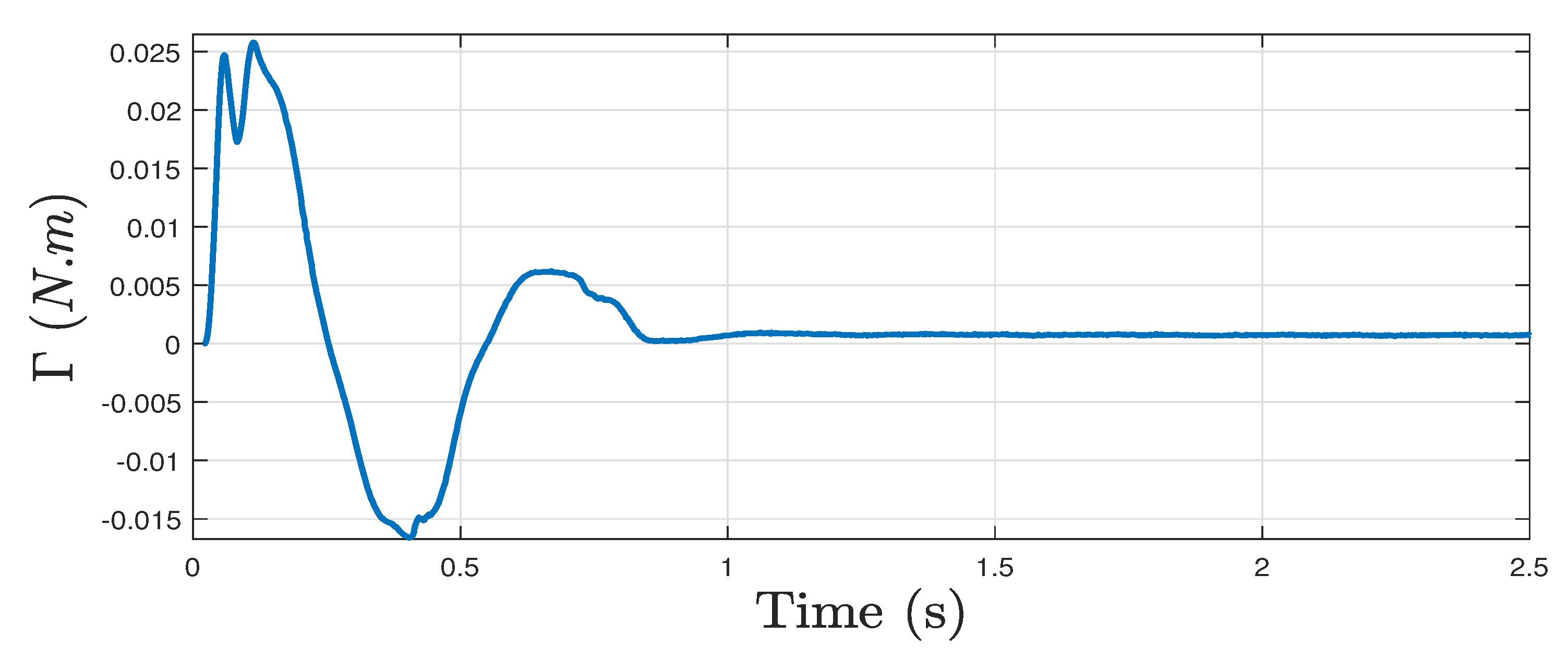

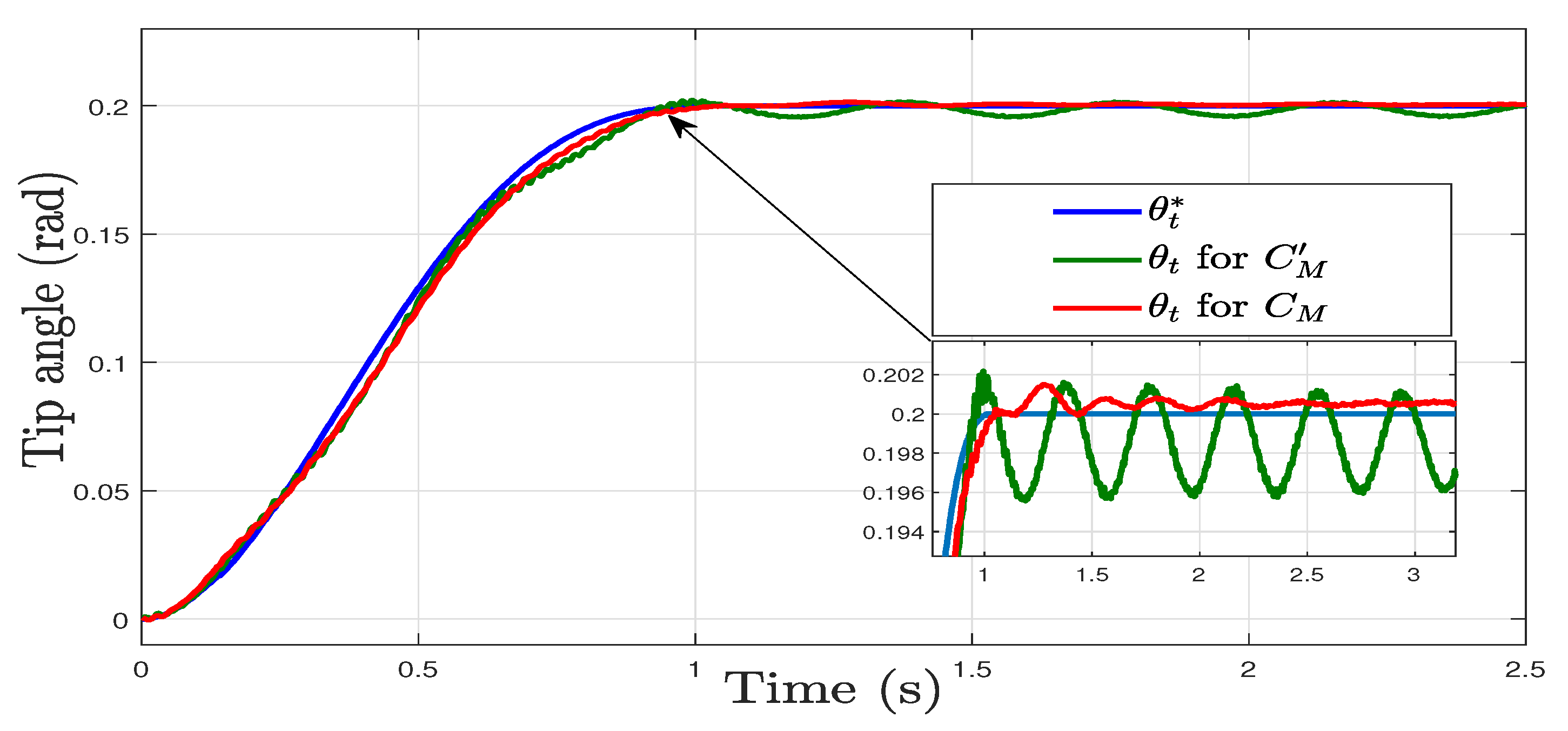

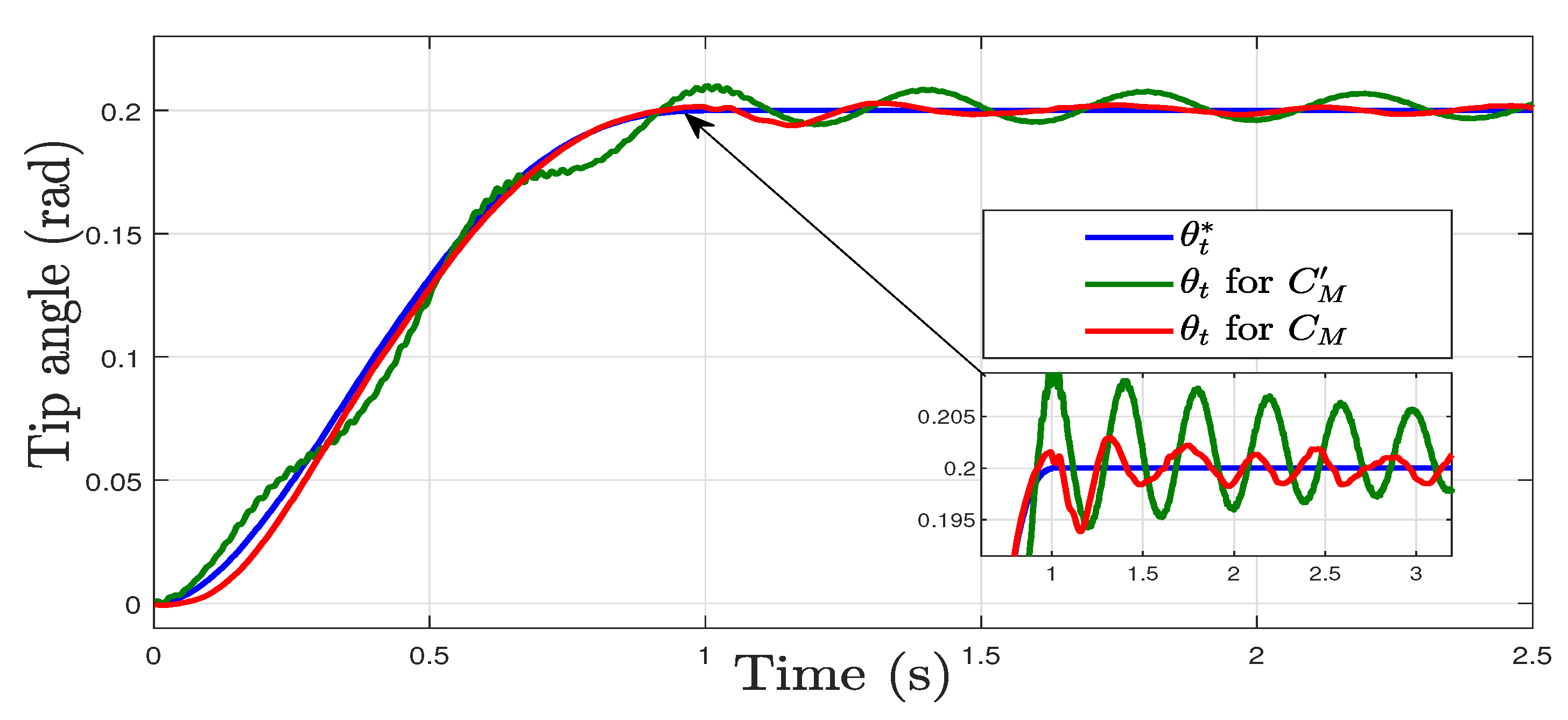

7.2. Experimental Validation of the Controller

7.3. Discussion

- At payloads lower than the nominal payload, the gain crossover frequency of is higher than that of and the gain crossover frequency of is higher than that of .

- At payloads lower than the nominal payload, the gain crossover frequency of is lower than that of and the gain crossover frequency of is lower than that of . This can be easily understood because is a low-pass filter that reduces the amplitudes of and , causing a reduction in the gain crossover frequencies.

- The effect of adding to the open loop is a strong reduction in the phase margin at all the payloads, as a comparison of the middle and lower subplots shows.

- At payloads lower than the nominal payload, the phase margin of is higher than that of .

- However, the lower subplot of Figure 10 shows that, at low payloads, the phase margin of is higher than that of . This is caused by the fact that, according to the higher subplot of Figure 10, the gain crossover frequency of is lower than that of . Then, produces less phase lag on than on . This compensates for the positive difference in the phase margin between and , yielding higher phase margins of at low payloads.

8. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| DC | Direct Current |

| DOF | Degree Of Freedom |

| FO | Fractional Order |

| FOM | Fractional Order Model |

| FLR | Flexible Link Robot |

| FJR | Flexible Joints Robot |

| IOM | Integer Order Model |

| PD | Proportional-Derivative controller |

| PI | Proportional-Integral controller |

| PID | Proportional-Integral-Derivative controller |

References

- Spong, M.W.; Hutchinson, S.; Vidyasagar, M. Robot Modeling and Control; John Wiley & Sons: Hoboken, NJ, USA, 2020. [Google Scholar]

- Monje, C.; Ramos, F.; Feliu, V.; Vinagre, B. Tip position control of a lightweight flexible manipulator using a fractional order controller. IET Control Theory Appl. 2007, 1, 1451–1460. [Google Scholar] [CrossRef]

- Rahimi, H.; Nazemizadeh, M. Dynamic analysis and intelligent control techniques for flexible manipulators: A review. Adv. Robot. 2014, 28, 63–76. [Google Scholar] [CrossRef]

- Subedi, D.; Tyapin, I.; Hovland, G. Review on modeling and control of flexible link manipulators. Model. Identif. Control 2020, 41, 141–163. [Google Scholar] [CrossRef]

- Feliu-Batlle, V.; Rattan, K.; Brown, H. Modelling and Control of Single-Link Flexible Arms with Lumped Masses. ASME J. Dyn. Syst. Meas. Control 1992, 114, 59–69. [Google Scholar] [CrossRef]

- Cambera, J.C.; Feliu-Batlle, V. Input-state feedback linearization control of a single-link flexible robot arm moving under gravity and joint friction. Robot. Auton. Syst. 2017, 88, 24–36. [Google Scholar] [CrossRef]

- Wei, J.; Cao, D.; Liu, L.; Huang, W. Global mode method for dynamic modeling of a flexible-link flexible-joint manipulator with tip mass. Appl. Math. Model. 2017, 48, 787–805. [Google Scholar] [CrossRef]

- Gao, H.; He, W.; Zhou, C.; Sun, C. Neural network control of a two-link flexible robotic manipulator using assumed mode method. IEEE Trans. Ind. Inform. 2018, 15, 755–765. [Google Scholar] [CrossRef]

- Farid, M.; Cleghorn, W.L. Dynamic modeling of multi-flexible-link planar manipulators using curvature–based finite element method. J. Vib. Control 2014, 20, 1682–1696. [Google Scholar] [CrossRef]

- Zhang, X.; Sørensen, R.; Iversen, M.R.; Li, H. Computationally efficient dynamic modeling of robot manipulators with multiple flexible-links using acceleration-based discrete time transfer matrix method. Robot. Comput.-Integr. Manuf. 2018, 49, 181–193. [Google Scholar] [CrossRef]

- Kiang, C.T.; Spowage, A.; Yoong, C.K. Review of control and sensor system of flexible manipulator. J. Intell. Robot. Syst. 2015, 77, 187–213. [Google Scholar] [CrossRef]

- Singh, A.P.; Deb, D.; Agarwal, H. On selection of improved fractional model and control of different systems with experimental validation. Commun. Nonlinear Sci. Numer. Simul. 2019, 79, 104902. [Google Scholar] [CrossRef]

- Singh, A.P.; Deb, D.; Agrawal, H.; Bingi, K.; Ozana, S. Modeling and control of robotic manipulators: A fractional calculus point of view. Arab. J. Sci. Eng. 2021, 46, 9541–9552. [Google Scholar] [CrossRef]

- Li, M. Theory of Fractional Engineering Vibrations; De Gruyter: Berlin, Germany, 2021. [Google Scholar]

- Wang, P.; Wang, Q.; Xu, X.; Chen, N. Fractional Critical Damping Theory and Its Application in Active Suspension Control. Shock Vib. 2017, 2017, 2738976. [Google Scholar] [CrossRef]

- Mattioni, A.; Wu, Y.; Le Gorrec, Y. Infinite dimensional model of a double flexible-link manipulator: The Port-Hamiltonian approach. Appl. Math. Model. 2020, 83, 59–75. [Google Scholar] [CrossRef]

- Baek, J.; Jin, M.; Han, S. A new adaptive sliding-mode control scheme for application to robot manipulators. IEEE Trans. Ind. Electron. 2016, 63, 3628–3637. [Google Scholar] [CrossRef]

- Becedas, J.; Trapero, J.R.; Feliu, V.; Sira-Ramírez, H. Adaptive controller for single-link flexible manipulators based on algebraic identification and generalized Proportional Integral control. IEEE Trans. Syst. Man Cybern. Part B (Cybern.) 2009, 39, 735–751. [Google Scholar] [CrossRef]

- Alandoli, E.A.; Lee, T.S.; Lin, Y.; Vijayakumar, V. Dynamic model and intelligent optimal controller of flexible link manipulator system with payload uncertainty. Arab. J. Sci. Eng. 2021, 46, 7423–7433. [Google Scholar] [CrossRef]

- Ouyang, Y.; He, W.; Li, X.; Liu, J.K.; Li, G. Vibration Control Based on Reinforcement Learning for a Single-link Flexible Robotic Manipulator. IFAC-PapersOnLine 2017, 50, 3476–3481. [Google Scholar] [CrossRef]

- Mamani, G.; Becedas, J.; Feliu, V. Sliding Mode Tracking Control of a Very Lightweight Single-Link Flexible Robot Robust to Payload Changes and Motor Friction. J. Vib. Control 2012, 18, 1141–1155. [Google Scholar] [CrossRef]

- Karimi, H.; Yazdanpanah, M.J.; Patel, R.; Khorasani, K. Modeling and control of linear two-time scale systems: Applied to single-link flexible manipulator. J. Intell. Robot. Syst. 2006, 45, 235–265. [Google Scholar] [CrossRef]

- Nikdel, N.; Badamchizadeh, M.; Azimirad, V.; Nazari, M.A. Fractional-order adaptive backstepping control of robotic manipulators in the presence of model uncertainties and external disturbances. IEEE Trans. Ind. Electron. 2016, 63, 6249–6256. [Google Scholar] [CrossRef]

- Gupta, S.; Singh, A.P.; Deb, D.; Ozana, S. Kalman Filter and Variants for Estimation in 2DOF Serial Flexible Link and Joint Using Fractional Order PID Controller. Appl. Sci. 2021, 11, 6693. [Google Scholar] [CrossRef]

- Dumlu, A.; Erenturk, K. Trajectory tracking control for a 3-dof parallel manipulator using fractional-order PIλDμ control. IEEE Trans. Ind. Electron. 2013, 61, 3417–3426. [Google Scholar] [CrossRef]

- Relaño, C.; Muñoz, J.; Monje, C.A.; Martínez, S.; González, D. Modeling and Control of a Soft Robotic Arm Based on a Fractional Order Control Approach. Fractal Fract. 2022, 7, 8. [Google Scholar] [CrossRef]

- Sabouri, J.; Effati, S.; Pakdaman, M. A neural network approach for solving a class of fractional optimal control problems. Neural Process. Lett. 2017, 45, 59–74. [Google Scholar] [CrossRef]

- Lopes, A.M.; Tenreiro Machado, J.A. Fractional-order sensing and control: Embedding the nonlinear dynamics of robot manipulators into the multidimensional scaling method. Sensors 2021, 21, 7736. [Google Scholar] [CrossRef]

- Mujumdar, A.; Tamhane, B.; Kurode, S. Fractional order modeling and control of a flexible manipulator using sliding modes. In Proceedings of the 2014 American Control Conference, Portland, OR, USA, 4–6 June 2014; pp. 2011–2016. [Google Scholar]

- Bingi, K.; Rajanarayan Prusty, B.; Pal Singh, A. A Review on Fractional-Order Modelling and Control of Robotic Manipulators. Fractal Fract. 2023, 7, 77. [Google Scholar] [CrossRef]

- Gharab, S.; Benftima, S.; Batlle, V.F. Fractional Control of a Lightweight Single Link Flexible Robot Robust to Strain Gauge Sensor Disturbances and Payload Changes. Actuators 2021, 10, 317. [Google Scholar] [CrossRef]

- Feliu-Talegon, D.; Feliu-Batlle, V.; Castillo-Berrio, C. Motion control of a sensing antenna with a nonlinear input shaping technique. Rev. Iberoam. Autom. Inform. Ind. 2016, 13, 162–173. [Google Scholar] [CrossRef] [Green Version]

- Feliu, V.; Pereira, E.; Díaz, I.M. Passivity-based control of single-link flexible manipulators using a linear strain feedback. Mech. Mach. Theory 2014, 71, 191–208. [Google Scholar] [CrossRef]

- Herrmann, R. Fractional Calculus: An Introduction for Physicists; World Scientific: Singapore, 2011. [Google Scholar]

- Chung, W.S. Fractional Newton mechanics with conformable fractional derivative. J. Comput. Appl. Math. 2015, 290, 150–158. [Google Scholar] [CrossRef]

- Feliu-Talegon, D.; Feliu-Batlle, V. Control of very lightweight 2-DOF single-link flexible robots robust to strain gauge sensor disturbances: A fractional-order approach. IEEE Trans. Control Syst. Technol. 2021, 30, 14–29. [Google Scholar] [CrossRef]

- Kashiri, N.; Malzahn, J.; Tsagarakis, N.G. On the sensor design of torque controlled actuators: A comparison study of strain gauge and encoder-based principles. IEEE Robot. Autom. Lett. 2017, 2, 1186–1194. [Google Scholar] [CrossRef]

- Benftima, S.; Batlle, V.F.; Benattia, S.; Salhi, S. A Fast Online Estimator of the Main Vibration Mode of Mechanisms from a Biased Slightly Damped Signal. In Proceedings of the IECON 2022—48th Annual Conference of the IEEE Industrial Electronics Society, Brussels, Belgium, 17–20 October 2022; pp. 1–6. [Google Scholar]

- Fliess, M. Analyse non standard du bruit. C. R. Acad. Sci. Paris Ser. I 2006, 342, 797–802. [Google Scholar] [CrossRef] [Green Version]

- Ogata, K. Modern Control Engineering; Prentice Hall: Hoboken, NJ, USA, 1993. [Google Scholar]

- Feliu-Batlle, V. Robust isophase margin control of oscillatory systems with large uncertainties in their parameters: A fractional-order control approach. Int. J. Robust Nonlinear Control 2017, 27, 2145–2164. [Google Scholar] [CrossRef]

| Symbol | Description | Numerical Values |

|---|---|---|

| J | Motor Inertia | (kg·m) |

| Viscous Friction | (N·m·s) | |

| K | Electromechanical Constant | 0.21 (N·m·V) |

| L | Flexible Beam Length | 0.65 (m) |

| Flexural Rigidity | 0.260 (N·m) | |

| Nominal Tip Load | 0.03 (kg) | |

| Sampling Time | 4 (ms) | |

| d | Diameter | 3 · 10 (m) |

| Nominal Frequency | 11.54 (rad·s) | |

| Minimal Frequency | 9.42 (rad·s) | |

| Maximal Frequency | 14.14 (rad·s) |

| ) | ||||||

|---|---|---|---|---|---|---|

| UD-IOM | xx | 2.00 | xx | 10.20 | 0.05845 | −1.4199 |

| D-IOM | xx | 2.00 | 1.30 | 10.20 | 0.00531 | −2.6192 |

| UD-FOM | xx | 1.92 | xx | 10.02 | 0.00524 | −2.6258 |

| D-FOM | 0.9 | 2.00 | 1.37 | 10.50 | 0.00524 | −2.6256 |

| - | D- | - | D- | ||

|---|---|---|---|---|---|

| 2 | 2 | 2 | |||

| 2 | 2 | 2 | |||

| 2 | 2 | 2 | |||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Benftima, S.; Gharab, S.; Feliu Batlle, V. Fractional Modeling and Control of Lightweight 1 DOF Flexible Robots Robust to Sensor Disturbances and Payload Changes. Fractal Fract. 2023, 7, 504. https://doi.org/10.3390/fractalfract7070504

Benftima S, Gharab S, Feliu Batlle V. Fractional Modeling and Control of Lightweight 1 DOF Flexible Robots Robust to Sensor Disturbances and Payload Changes. Fractal and Fractional. 2023; 7(7):504. https://doi.org/10.3390/fractalfract7070504

Chicago/Turabian StyleBenftima, Selma, Saddam Gharab, and Vicente Feliu Batlle. 2023. "Fractional Modeling and Control of Lightweight 1 DOF Flexible Robots Robust to Sensor Disturbances and Payload Changes" Fractal and Fractional 7, no. 7: 504. https://doi.org/10.3390/fractalfract7070504

APA StyleBenftima, S., Gharab, S., & Feliu Batlle, V. (2023). Fractional Modeling and Control of Lightweight 1 DOF Flexible Robots Robust to Sensor Disturbances and Payload Changes. Fractal and Fractional, 7(7), 504. https://doi.org/10.3390/fractalfract7070504