Abstract

The strength of the soil–structure interface can be mobilised when subjected to cyclic loading. To capture the cyclic mobilisation of the soil–structure interface, an advanced elastoplastic constitutive model is developed within the framework of fractional plasticity, where no additional use of an additional plastic potential is required. Considering the influence of material state and soil fabric on the plastic response of the soil–structure interface, the state-dependent fractional order and hardening modulus are proposed. Further numerical simulation of the developed model shows that it can reasonably capture the mobilised strength and deformation of the soil–structure interface under cyclic loads.

1. Introduction

Geotechnical engineering usually encounters the interaction between soil and structure [1]. Due to the abrupt change in the stiffness of soil and structure, an interface with reduced stiffness and strength usually exists [2,3]. The load–displacement behaviour, e.g., stiffness degradation by in-situ cyclic loading [4], of the soil–structure interface can significantly influence the ultimate bearing capacity of the geotechnical infrastructures, e.g., tunnels, onshore foundations, and other underground space structures [5,6], especially under earthquake loading [7,8]. To understand the strength and deformation behaviour of the soil–structure interface, many experimental and numerical studies have been carried out [9,10,11,12,13,14]. For example, Zhang and Zhang [11] carried out a series of direct interface shear tests on a gravelly soil–steel interface under various loading conditions, e.g., constant normal load (CNL) and constant normal stiffness (CNS) shearing. Lashkari and Jamali [15] conducted a series of interface shear tests on different sand–geosynthetic interfaces, with the aid of digital particle image velocimetry to track the local particle movement. From these studies, it was found that the interface thickness increased with the mean particle size of soil; the interface strength mobilised with the cyclic loading path and was influenced by the initial relative density, particle shape, particle size, normal stiffness and effective normal stress. Moreover, through a comprehensive three-dimensional discrete element simulation using spheres with contact moments and walls with varying topography, Grabowski et al. [14] observed significant effects of the contact roughness and sand fabric on the mobilised strength and displacement of the sand–structure interface. Such effect of fabric has also been reported by Wang et al. [16] when evaluating the liquefaction and instability behaviour of sands. In addition, Zhang et al. [17] reported a remarkable 3D effect of the turning corner on the stability of geosynthetic-reinforced soil structures.

It can be found that the strength and deformation of the soil–structure interface are complex and influenced by many physical and mechanical factors. In order to properly instruct the engineering design and construction of geotechnical structures, a sophisticated constitutive model that can consider different influencing factors is of critical importance [18]. In fact, a variety of constitutive models have been developed for different soil–structure interfaces. For example, Saberi et al. [19] developed a unified constitutive model to capture the stress path dependence of a sandy and gravelly soil interface by using the framework of the bounding surface plasticity. Despite the elegant model performance, an additional plastic potential function was required, which resulted in the complexity in their model. Stutz and Mašín [20] developed a hypoplastic interface model for fine-grained soils via reduced incremental stress–strain vectors and redefined tensorial operations. However, their model did not consider the effect of particle breakage and soil fabric on the stress–displacement response of the soil–structure interface. By extending the original fractional plasticity for granular and soft soils [21,22], Sun et al. [18,23] proposed a family of fractional plastic models to capture the load–displacement behaviour of the granular soil–structure interface. Nonetheless, these models did not consider the effect of soil fabric on the cyclic mobilisation of the interface, as well. In engineering practice, a natural deposition or construction process can refabricate the soil by imprinting it with a certain structure. Upon shearing, such structure or fabric can evolve with strain level, which in turn influences the strength and deformation of the interface. To better interpret the load–displacement response of the granular soil–structure interface, a refined constitutive model by adopting the fabric-dependent fractional plastic flow rule will be developed within the framework of fractional plasticity. It is noted that this study only addresses the cyclic mobilisation problem during the soil–structure interaction, where the interface between soil and structure exists. When the soil and structure start to separate from each other, the developed interface model is no longer applicable.

2. Constitutive Model in the Framework of Fractional Plasticity

2.1. Constitutive Relation

This study only deals with soil–structure interfaces under a direct two-dimensional interface or simple shearing state. The constitutive relation for the soil–structure interface can be formulated using the elastoplastic equation as:

where i, j = 1, 2; and are the incremental stress vector and incremental displacement vector, respectively; the elastoplastic stiffness can be expressed as [23]:

where is the thickness of the soil–structure interface; and are the elastic modulus and plastic modulus, respectively. can be decomposed and expressed as:

where and are material constants; is the normal stress applied on the interface; Pa is the atmospheric pressure. can be obtained through algebraic calculation as:

where i, k, l, j, r, s = 1, 2; , , and are the plastic flow vector, plastic loading vector, and hardening modulus, respectively, which will be provided in the following section after developing the constitutive model.

2.2. Model Development

To characterise the cyclic mobilisation of the soil–structure interface, the framework of the fractional plasticity [24,25,26] is adopted. Then, the model will be developed by using three main components, i.e., the plastic loading vector, the fractional plastic loading vector, and the hardening modulus. To obtain the plastic loading vector, one can use the following Cam-clay loading/unloading surface (f):

where is the size of f; t = +1 or −1, for loading or unloading, respectively; M is a material constant, defining the residual stress ratio of the interface in the plane. Upon loading/unloading, each current stress step should be on the loading/unloading surface.

Then, the plastic loading vector, , can be obtained by solving Equation (7), such that:

where the superscript, 1, indicates first-order differentiation; stress ratio .

Apart from the loading vector, the plastic flow vector, , should also be defined. In this study, is obtained by conducting fractional order differentiation of the Cam-clay surface, f, such that:

where the superscript, , denotes the fractional order; stress ratio ; , in which is the digamma function. Details for deriving Equations (10) and (11) can be found in Sun et al. [23] and, thus, are not repeated here for simplicity. As the fractional order defines the contraction and dilation responses of the soil–structure interface during loading/unloading, Sun et al. [23] suggested using the following plastic work-dependent fractional order to properly represent the cyclic normal displacement after stress reversal:

where and are material constants; and Wir are the state parameter and plastic work, respectively, which can be expressed as:

where and are material constants that depict the residual state line of the interface; denotes the shift stress that describes the effect of particle breakage on the downward bending of the residual state line [27]; e is the current void ratio that obeys the following evolution law: , in which denotes the initial void ratio calculated from the initial density of the interface; and are the irreversible tangential displacement and normal displacement, respectively, as shown in Figure 1. denotes the McCauley bracket. In order to account for the fabric-dependence of the plastic flow of the soil–structure interface, a fabric variable, z, by analogous to Dafalias and Manzari [28], is introduced into Equation (11), such that:

where z obeys the following evolution law, i.e., .

Figure 1.

Irreversible displacements of the soil–structure interface.

In addition, the hardening modulus, , can be defined as:

where and are material constants.

2.3. Model Constants

The developed model requires eleven model constants to completely describe the cyclic mobilisation of the soil–structure interface under shearing. tn is the thickness of the interface, which can be assumed to be 5d50 of the interface. and are the elastic constants, describing the degree of difficulty in elastic deformation of the interface; and can be obtained by fitting the initial stress–displacement curve, as clearly shown in [18]. M indicates the strength of the interface at the residual state; is the intercept of the residual state line at () = 1 kPa; is the gradient of the residual state line in the plane; indicates the effect of particle breakage on the residual state of the interface; M, , and can be obtained by fitting the residual state data of the interface. defines the phase transition state of the interface at first loading, which can be obtained from the phase transition state data at first loading. defines the phase transition state of the interface at subsequent cyclic loading, which can be obtained by fitting the first unloading stress–displacement curve. is an empirical parameter, which can be assumed to be 0.01 for general application. defines the hardening ability of the interface, which is determined by trial and error. For a schematic representation of the parameter identification, one can refer to [18,23]. Table 1 lists the model constant used in this study.

Table 1.

Model constants.

3. Numerical Simulations and Discussions

This section provides the numerical simulations of the cyclic load–displacement behaviour of the Zipingpu rockfill–steel interface [11] tested under CNS and CNL loading conditions. Discussions are to be made on the overall performance in regards to the cyclic mobilisation of the soil–structure interface in the framework of fractional plasticity. Note that the Zipingpu rockfill was reported to have a dry density of 17.5 kg/m3. All the samples were prepared with an initial size of 500 mm in length, 360 mm in width and 300 mm in height. Then, the TsingHua-20 tonne Cyclic Shear Apparatus for the Soil–Structure Interface (TH-20t CSASSI) was adopted to carry out the interface shear test. During shearing, the length and width of the samples were kept constant whilst the height was variable. Two boundary conditions, i.e., CNS and CNL, were used for the test. The CNS test was carried out under an initial normal load of 400 kPa, while the CNL test was conducted at a constant normal load of 700 kPa. Displacement-controlled shearing at a loading rate of 1 mm/min was applied, where the corresponding stress and displacement of the interface in tangential and normal directions were automatically measured using preinstalled force or displacement sensors. According to the measured data, the interface exhibited strength degradation or stress–normal dilation/contraction during cyclic loading

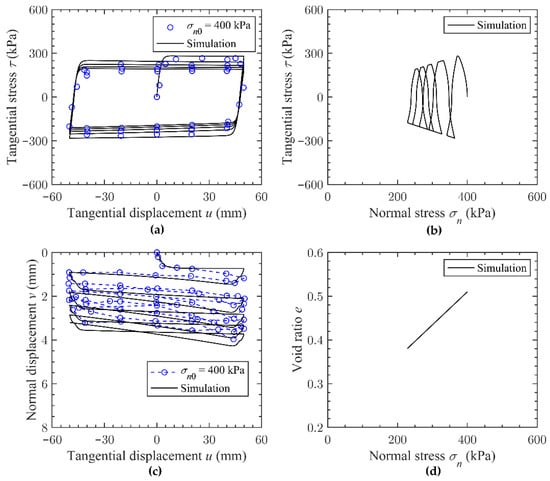

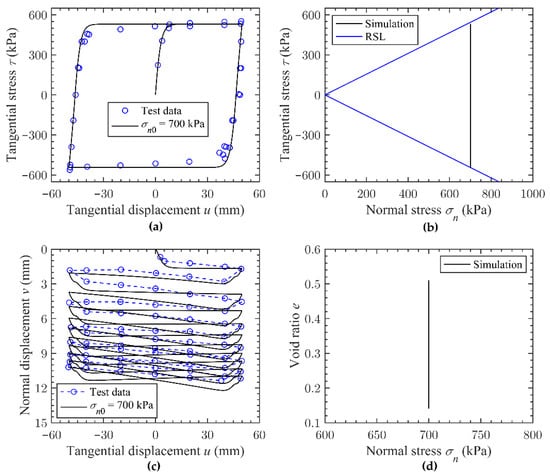

According to Zhang and Zhang [9], the Zipingpu rockfill–steel interface had a thickness of 50 mm and an initial void ratio of 0.51. Figure 2 and Figure 3 show the model simulations of the load–displacement behaviour subjected to different initial normal stresses, i.e., 400 and 700 kPa. It can be observed that the fractional plastic interface model can capture the load–displacement loops (Figure 2a and Figure 3a) and normal displacement (Figure 2c and Figure 3c) of the Zipingpu rockfill–steel interface with mobilised tangential displacement in a reasonable manner. At both CNS and CNL loading conditions, the model can characterise the unloading and reloading-induced contraction and dilation response of the interface. After several cycles of mobilisation, a general normal contraction of the interface under CNS loading conditions can be observed, which induces a reduction in the normal stress. Specifically speaking, at the CNS loading condition shown in Figure 2b, the tangential stress as well as the normal stress mobilises towards a smaller value, indicating a reduced resistance of the interface to the cyclic loads. The engineering design in terms of the seismic loads should consider such strength reduction. However, at the CNL loading condition shown in Figure 3b, the tangential stress fluctuates between the residual state line (RSL), while the normal stress remains constant. There is no obvious strength reduction in the interface, since the normal stress was not changed through the entire loading process. The interface resists the cyclic loads through densified normal displacement.

Figure 2.

Zipingpu rockfill–steel interface [11] under CNS: (a) tangential displacement vs. tangential stress; (b) normal stress vs. tangential stress; (c) tangential displacement vs. normal displacement; (d) normal stress vs. void ratio.

Figure 3.

Zipingpu rockfill-steel interface [11] under CNL: (a) Tangential displacement v.s. tangential stress; (b) Normal stress v.s. tangential stress; (c) Tangential displacement v.s. normal displacement; (d) Normal stress v.s. void ratio.

In addition to the load–displacement responses, the void ratio–displacement responses of the interface are also different under CNS and CNL loading conditions, as shown in Figure 2d and Figure 3d. The void ratio of the interface mobilises and decreases with the decreasing normal stress at the CNS loading condition. However, at the CNL loading condition, the normal stress remains constant; even so, the void ratio of the interface mobilises towards a smaller value due to the variation of the normal displacement.

Compared to other existing models using generalised plasticity [19] or a nonlinear incremental approach [29], this model does not require additional plastic potential to capture the nonassociated plastic flow of the soil–structure interface, where the dilatant volumetric response can be well simulated. Even though similar models using fractional plasticity was also developed in [18], their model cannot accurately simulate the strength mobilisation along with the contraction and dilation of the interface under cyclic loading, as shown in Figure 2 and Figure 3.

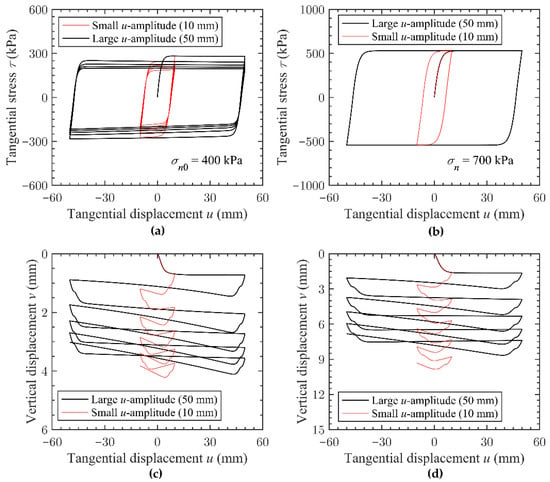

Figure 4 further evaluates the effect of shear displacement amplitude on the stress–displacement behaviour of the Zipingpu rockfill–steel interface. It can be observed from Figure 4a that the strength of the interface under CNS mobilises negatively under cyclic loads. With the increase in the displacement amplitude, the extent of strength reduction decreases due to the higher extent of normal dilation of the interface, as shown in Figure 4c. This is in accord with the critical state soil mechanics that dilation would contribute to the material strength. In addition, it can be observed from Figure 4b that displacement amplitude has an insignificant influence on strength mobilisation of the interface under CNL. However, a decrease the displacement amplitude would also increase the normal contraction of the interface, as shown in Figure 4d.

Figure 4.

Effect of displacement amplitude on the stress–displacement behaviour of the Zipingpu rockfill–steel interface [11]: (a) tangential displacement vs. tangential stress under CNS; (b) tangential displacement vs. tangential stress under CNL; (c) tangential displacement vs. normal displacement under CNS; (d) tangential displacement vs. normal displacement under CNL.

4. Conclusions

This study made an attempt to develop an advanced elastoplastic model for characterising cyclic mobilisation of the granular soil–structure interface by adopting the framework of fractional plasticity. The main conclusions can be drawn as follows:

- (a)

- Without using an additional plastic potential function, the method developed can consider the nonassociated plastic flow response of the soil–structure interface by using fractional order derivatives of the plastic yielding function.

- (b)

- By incorporating the effect of material state and soil fabric on the plastic response of the soil–structure interface, a fabric-enriched state-dependent fractional stress-dilatancy equation and a state-dependent hardening modulus were suggested.

- (c)

- The developed model contained eleven parameters, which can be all determined from laboratory test results. Numerical simulations of cyclic mobilisation of the Zipingpu rockfill–steel interface revealed that the model can characterise the mobilised strength and displacement of the soil–structure interface under different boundary conditions in a reasonable manner.

- (d)

- The variations of tangential stress and void ratio with the normal stress were different under CNS and CNL conditions. The strength of the interface under CNS conditions reduced with the number of load cycles. As the displacement amplitude increased, the extent of the strength reduction decreased. However, displacement amplitude had a limited impact on strength mobilisation of the interface under CNL.

- (e)

- The current model can only simulate the two-dimensional stress-displacement of the soil–structure interface. Further work on developing a multiaxial fractional plastic model for capturing the true three-dimensional response of the interface needs to be carried out.

Author Contributions

Conceptualisation and methodology, Y.S. (Yifei Sun) and Y.S. (Yang Shen); software, validation and data curation, J.X.; writing—original draft preparation, J.X. and Y.S. (Yang Shen); writing—review and editing, Y.S. (Yifei Sun). All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Natural Science Foundation of Jiangsu Province (No. BK20180776).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data presented in this study are available on request from the corresponding author. The data are not publicly available due to intellectual property.

Acknowledgments

The third author appreciates Wen Chen for his invaluable inspiration.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Raheem, S.A.; Hayashikawa, T.; Hashimoto, I. Effects of soil–foundation–superstructure interaction on seismic response of cable-stayed bridges tower with spread footing foundation. J. Struct. Eng. 2003, 49, 475–486. [Google Scholar]

- Zaman, M.M.; Desai, C.S.; Drumm, E.C. Interface model for dynamic soil-structure interaction. J. Geotech. Eng. 1984, 110, 1257–1273. [Google Scholar] [CrossRef]

- Desai, C.S. Mechanics of Materials and Interfaces: The Disturbed State Concept; CRC Press: Boca Raton, FL, USA, 2000. [Google Scholar]

- Kamura, A.; Kazama, M. Assessment of stiffness degradation of soil by in-situ cyclic loading using pressuremeter. In Proceedings of the 6th International Conference on Geotechnical and Geophysical Site Characterization, Budapest, Hungary, 26–29 September 2021. [Google Scholar]

- Gao, Y.; Zhang, N.; Li, D.; Liu, H.; Cai, Y.; Wu, Y. Effects of topographic amplification induced by a U-Shaped canyon on seismic waves. Bull. Seismol. Soc. Am. 2012, 102, 1748–1763. [Google Scholar] [CrossRef]

- Zhang, N.; Gao, Y.; Cai, Y.; Li, D.; Wu, Y. Scattering of SH waves induced by a non-symmetrical V-shaped canyon. Geophys. J. Int. 2012, 191, 243–256. [Google Scholar] [CrossRef] [Green Version]

- Gao, Y.; Wu, Y.; Li, D.; Liu, H.; Zhang, N. An improved approximation for the spectral representation method in the simulation of spatially varying ground motions. Probabilistic Eng. Mech. 2012, 29, 7–15. [Google Scholar] [CrossRef]

- Gao, Y.; Wu, Y.; Cai, Y.; Liu, H.; Li, D.; Zhang, N. Error assessment for spectral representation method in random field simulation. J. Eng. Mech. 2012, 138, 711–715. [Google Scholar] [CrossRef]

- Maghsoodi, S.; Cuisinier, O.; Masrouri, F. Non-isothermal soil-structure interface model based on critical state theory. Acta Geotech. 2021, 16, 2049–2069. [Google Scholar] [CrossRef]

- Kishida, H.; Uesugi, M. Tests of the interface between sand and steel in the simple shear apparatus. Géotechnique 1987, 37, 45–52. [Google Scholar] [CrossRef]

- Zhang, G.; Zhang, J. Monotonic and cyclic tests of interface between structure and gravelly soil. Soils Found. 2006, 46, 505–518. [Google Scholar] [CrossRef] [Green Version]

- Martinez, A.; Frost, J.D. Undrained behavior of sand–structure interfaces subjected to cyclic torsional shearing. J. Geotech. Geoenviron. Eng. 2018, 144, 04018063. [Google Scholar] [CrossRef]

- Wang, H.; Zhou, W.; Yin, Z.; Jie, X. Effect of grain size distribution of sandy soil on shearing behaviors at soil–structure interface. J. Mater. Civ. Eng. 2019, 31, 04019238. [Google Scholar] [CrossRef]

- Grabowski, A.; Nitka, M.; Tejchman, J. 3D DEM simulations of monotonic interface behaviour between cohesionless sand and rigid wall of different roughness. Acta Geotech. 2021, 16, 1001–1026. [Google Scholar] [CrossRef]

- Lashkari, A.; Jamali, V. Global and local sand–geosynthetic interface behaviour. Géotechnique 2021, 71, 346–367. [Google Scholar] [CrossRef]

- Wang, R.; Dafalias, Y.F.; Fu, P.; Zhang, J.M. Fabric evolution and dilatancy within anisotropic critical state theory guided and validated by DEM. Int. J. Solids Struct. 2019, 188–189, 210–222. [Google Scholar] [CrossRef] [Green Version]

- Zhang, F.; Gao, Y.; Leshchinsky, D.; Yang, S.; Dai, G. 3D effects of turning corner on stability of geosynthetic-reinforced soil structures. Geotext. Geomembr. 2018, 46, 367–376. [Google Scholar] [CrossRef]

- Sun, Y.; Sumelka, W.; Gao, Y. Reformulated fractional plasticity for soil-structure interface. Mech. Res. Commun. 2020, 108, 103580. [Google Scholar] [CrossRef]

- Saberi, M.; Annan, C.D.; Konrad, J.M. A unified constitutive model for simulating stress-path dependency of sandy and gravelly soil–structure interfaces. Int. J. Non-Linear Mech. 2018, 102, 1–13. [Google Scholar] [CrossRef]

- Stutz, H.; Mašín, D. Hypoplastic interface models for fine-grained soils. Int. J. Numer. Anal. Meth. Geomech. 2017, 41, 284–303. [Google Scholar] [CrossRef]

- Sun, Y.; Gao, Y.; Zhu, Q. Fractional order plasticity modelling of state-dependent behaviour of granular soils without using plastic potential. Int. J. Plast. 2018, 102, 53–69. [Google Scholar] [CrossRef]

- Sun, Y.; Sumelka, W. Multiaxial stress-fractional plasticity model for anisotropically overconsolidated clay. Int. J. Mech. Sci. 2021, 205, 106598. [Google Scholar] [CrossRef]

- Sun, Y.; Sumelka, W.; Gao, Y.; Nimbalkar, S. Phenomenological fractional-order stress-dilatancy model for granular soil and soil-structure interface under monotonic and cyclic loads. Acta Geotech. 2021, 16, 3115–3132. [Google Scholar] [CrossRef]

- Sun, Y.; Gao, Y.; Song, S.; Chen, C. Three-dimensional state-dependent fractional plasticity model for soils. Int. J. Geomech. 2020, 20, 04019161. [Google Scholar] [CrossRef]

- Lu, D.; Liang, J.; Du, X.; Ma, C.; Gao, Z. Fractional elastoplastic constitutive model for soils based on a novel 3D fractional plastic flow rule. Comput. Geotech. 2019, 105, 277–290. [Google Scholar] [CrossRef] [Green Version]

- Lu, D.; Zhou, X.; Du, X.; Wang, G. A 3D fractional elastoplastic constitutive model for concrete material. Int. J. Solids Struct. 2019, 165, 160–175. [Google Scholar] [CrossRef]

- Sun, Y.; Sumelka, W.; Gao, Y. Bounding surface plasticity for sand using fractional flow rule and modified critical state line. Arch. Appl. Mech. 2020, 90, 2561–2577. [Google Scholar] [CrossRef]

- Dafalias, Y.F.; Manzari, M.T. Simple plasticity sand model accounting for fabric change effects. J. Eng. Mech. 2004, 130, 622–634. [Google Scholar] [CrossRef]

- Yang, J.; Yin, Z.Y. Soil-structure interface modeling with the nonlinear incremental approach. Int. J. Numer. Anal. Meth. Geomech. 2021, 45, 1381–1404. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).