Lightweight 3D-Printed Fractal Gradient-Index Lens Antenna with Stable Gain Performance

Abstract

1. Introduction

2. 3D-Printed Lens and Source Antenna Design

2.1. 3D-Printed Fractal GRIN Lens Design with Honeycomb Cells

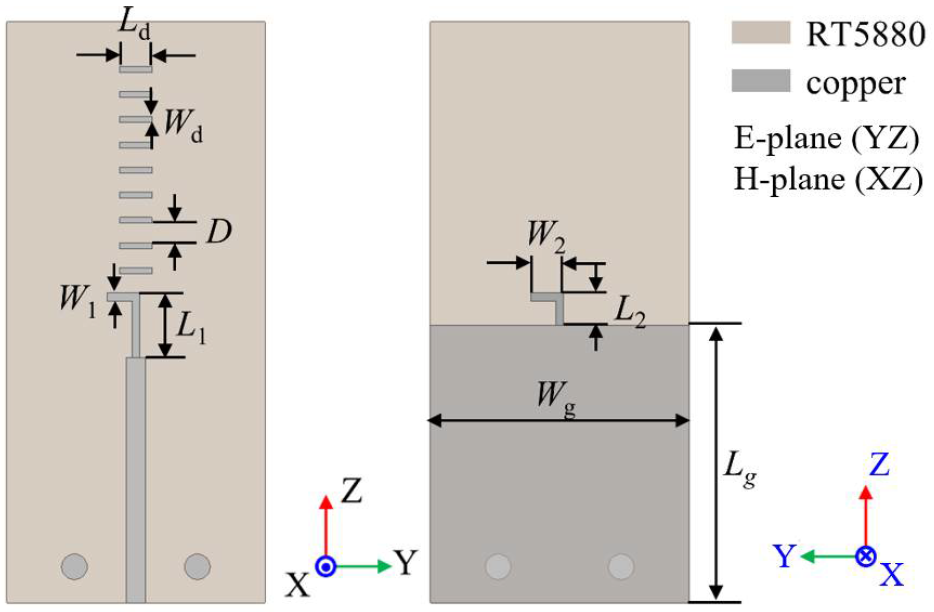

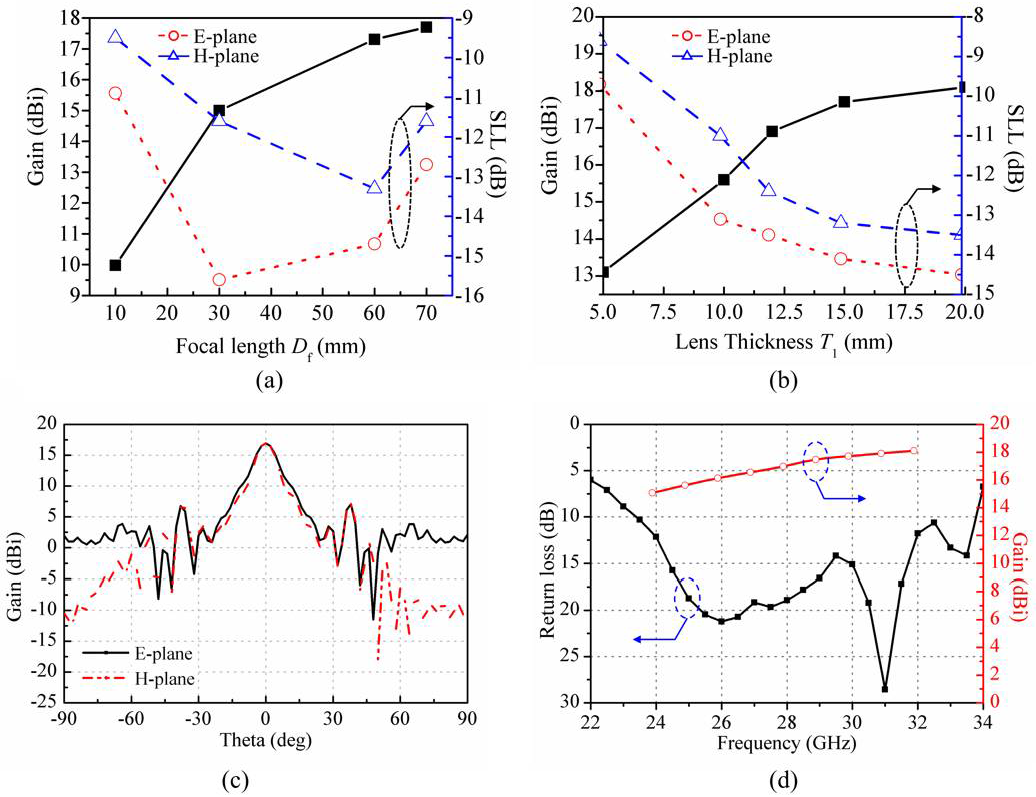

2.2. Source Antenna Design

2.3. Source Antenna Integrated with Fractal GRIN Lens Using Honeycomb Cells

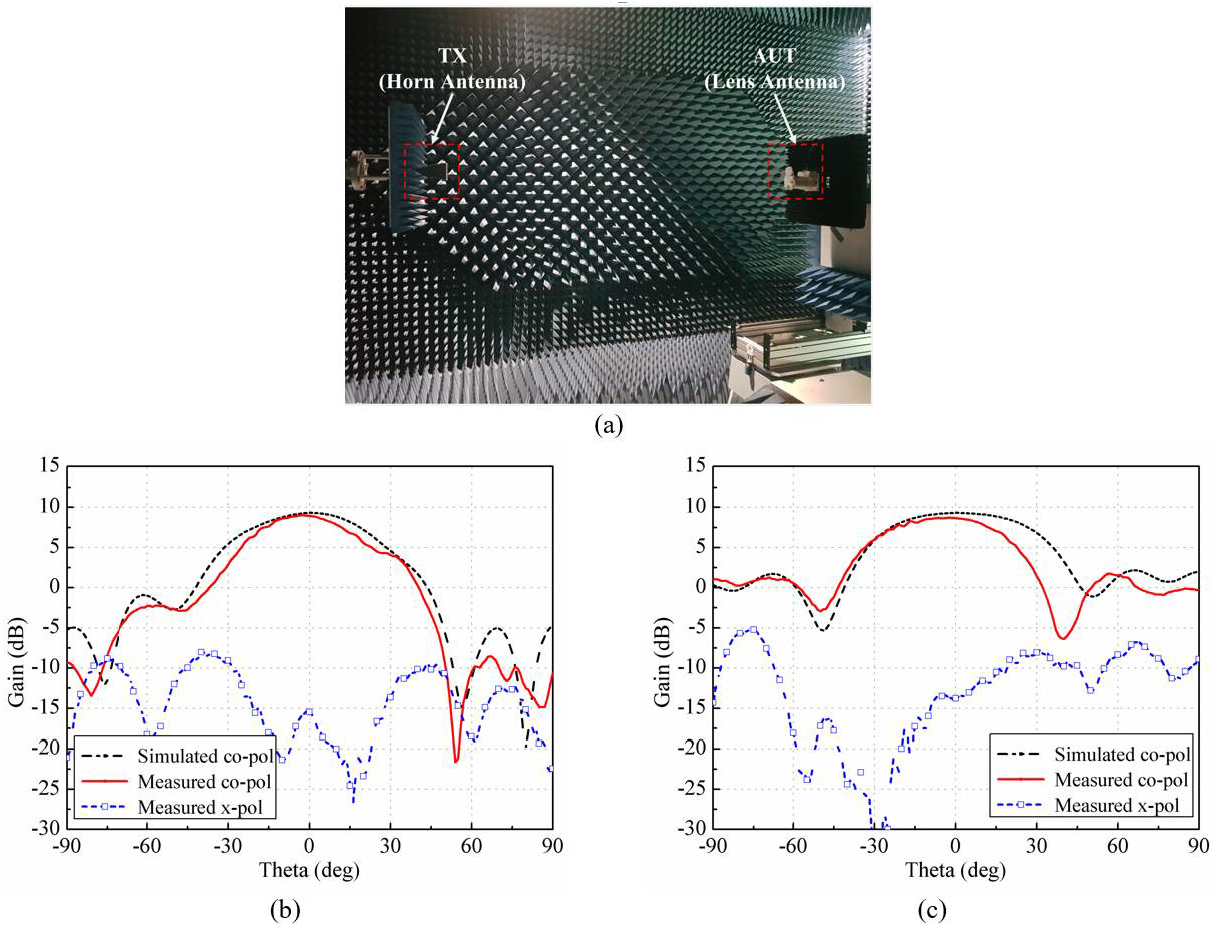

3. Experimental Investigation and Discussion

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Vallappil, A.K.; Khawaja, B.A.; Rahim, M.K.A.; Iqbal, M.N.; Chattha, H.T.; Ali, M.F. bin M. A compact triple-band UWB inverted triangular antenna with dual-notch band characteristics using SSRR metamaterial structure for use in next-generation wireless systems. Fractal Fract. 2022, 6, 422. [Google Scholar] [CrossRef]

- Tubbal, F.; Matekovits, L.; Raad, R. Antenna designs for 5G/IoT and space applications. Electronics 2022, 11, 2484. [Google Scholar] [CrossRef]

- Paun, M.-A.; Nichita, M.-V.; Paun, V.-A.; Paun, V.-P. Minkowski’s loop fractal antenna dedicated to sixth generation (6G) communication. Fractal Fract. 2022, 6, 402. [Google Scholar] [CrossRef]

- Lee, J.-G. Compact and robust Fabry-perot cavity antenna with PEC wall. J. Electromagn. Eng. Sci. 2021, 21, 184–188. [Google Scholar] [CrossRef]

- Lim, J.-H.; Lee, J.W.; Lee, T.-K.; Ryu, S.-B.; Lee, H.-C.; Lee, S.-G. Optimal design of the reflector antenna to improve performance of C-band quad-pol ScanSAR systems. J. Electromagn. Eng. Sci. 2020, 20, 155–157. [Google Scholar] [CrossRef]

- Pham, D.A.; Park, E.; Lee, H.L.; Lim, S. High gain and wideband metasurfaced magnetoelectric antenna for WiGig applications. IEEE Trans. Antennas Propag. 2021, 69, 1140–1145. [Google Scholar] [CrossRef]

- Pham, D.A.; Lee, M.; Lim, S. High-gain conical-beam planar antenna for millimeter-wave drone applications. IEEE Trans. Antennas Propag. 2021, 69, 6959–6964. [Google Scholar] [CrossRef]

- Sarkar, A.; Pham, D.A.; Lim, S. 60 GHz Electronically tunable leaky-wave antenna based on annular surface plasmon polariton media for continuous azimuth scanning. IEEE Trans. Antennas Propag. 2022. [Google Scholar] [CrossRef]

- Sarkar, A.; Pham, D.A.; Lim, S. Tunable higher order mode-based dual-beam CRLH microstrip leaky-wave antenna for V-band backward–broadside–forward radiation coverage. IEEE Trans. Antennas Propag. 2020, 68, 6912–6922. [Google Scholar] [CrossRef]

- Zhang, Y.S.; Hong, W. A millimeter-wave gain enhanced multi-beam antenna based on a coplanar cylindrical dielectric lens. IEEE Trans. Antennas Propag. 2012, 60, 3485–3488. [Google Scholar] [CrossRef]

- Liang, M.; Ng, W.-R.; Chang, K.; Gbele, K.; Gehm, M.E.; Xin, H. A 3-D Luneburg lens antenna fabricated by polymer jetting rapid prototyping. IEEE Trans. Antennas Propag. 2014, 62, 1799–1807. [Google Scholar]

- Su, Y.; Chen, Z.N. A flat dual-polarized transformation-optics beamscanning Luneburg lens antenna using PCB-stacked gradient index metamaterials. IEEE Trans. Antennas Propag. 2018, 66, 5088–5097. [Google Scholar] [CrossRef]

- Erfani, E.; Niroo-Jazi, M.; Tatu, S. A high-gain broadband gradient refractive index metasurface lens antenna. IEEE Trans. Antennas Propag. 2016, 64, 1968–1973. [Google Scholar] [CrossRef]

- Pfeiffer, C.; Grbic, A. Planar lens antennas of subwavelength thickness: Collimating leaky-waves with metasurfaces. IEEE Trans. Antennas Propag. 2015, 63, 3248–3253. [Google Scholar] [CrossRef]

- Papathanasopoulos, A.; Rahmat-Samii, Y.; Garcia, N.C.; Chisum, J.D. A novel collapsible flat-layered metamaterial gradient-refractive-index lens antenna. IEEE Trans. Antennas Propag. 2020, 68, 1312–1321. [Google Scholar] [CrossRef]

- Yi, H.; Qu, S.-W.; Ng, K.-B.; Chan, C.H.; Bai, X. 3-D printed millimeter-wave and terahertz lenses with fixed and frequency scanned beam. IEEE Trans. Antennas Propag. 2016, 64, 442–449. [Google Scholar] [CrossRef]

- Qu, Z.; Qu, S.-W.; Zhang, Z.; Yang, S.; Chan, C.H. Wide-angle scanning lens fed by small-scale antenna array for 5G in millimeter-wave band. IEEE Trans. Antennas Propag. 2020, 68, 3635–3643. [Google Scholar]

- Zhang, Y.-X.; Jiao, Y.-C.; Liu, S.-B. 3-D-printed comb mushroom-like dielectric lens for stable gain enhancement of printed log-periodic dipole array. IEEE Antennas Wirel. Propag Lett. 2018, 17, 2099–2103. [Google Scholar]

- Wang, K.X.; Wong, H. Design of a wideband circularly polarized millimeter-wave antenna with an extended Hemispherical lens. IEEE Trans. Antennas Propag. 2018, 66, 4303–4308. [Google Scholar] [CrossRef]

- Li, Y.; Ge, L.; Chen, M.; Zhang, Z.; Li, Z.; Wang, J. Multibeam 3-D-printed Luneburg lens fed by magnetoelectric dipole antennas for millimeter-wave MIMO applications. IEEE Trans. Antennas Propag. 2019, 67, 2923–2933. [Google Scholar]

- Goulas, A.; Zhang, S.; McGhee, J.R.; Cadman, D.A.; Whittow, W.G.; Vardaxoglou, J.C.; Engstrøm, D.S. Fused filament fabrication of functionally graded polymer composites with variable relative permittivity for microwave devices. Mater. Des. 2020, 193, 108871. [Google Scholar]

- Kim, Y.; Cui, Y.; Tentzeris, M.M.; Lim, S. Additively manufactured electromagnetic based planar pressure sensor using substrate integrated waveguide technology. Addit. Manuf. 2020, 34, 101225. [Google Scholar]

- Poyanco, J.-M.; Pizarro, F.; Rajo-Iglesias, E. Cost-effective wideband dielectric planar lens antenna for millimeter wave applications. Sci. Rep. 2022, 12, 4204. [Google Scholar] [CrossRef]

- Garcia-Marin, E.; Filipovic, D.S.; Masa-Campos, J.L.; Sanchez-Olivares, P. Low-cost lens antenna for 5G multi-beam communication. Microw. Opt. Technol. Lett. 2020, 62, 3611–3622. [Google Scholar] [CrossRef]

- Werner, D.H.; Haupt, R.L.; Werner, P.L. Fractal antenna engineering: The theory and design of fractal antenna arrays. IEEE Antennas Propag Mag. 1999, 41, 37–58. [Google Scholar]

- Ghaffar, F.A.; Khalid, M.U.; Salama, K.N.; Shamim, A. 24-GHz LTCC fractal antenna array SoP with integrated Fresnel lens. IEEE Antennas Wireless Propag Lett. 2011, 10, 705–708. [Google Scholar] [CrossRef]

- Shookooh, B.R.; Monajati, A.; Khodabakhshi, H. Theory, design, and implementation of a new family of ultra-wideband metamaterial microstrip array antennas based on fractal and fibonacci geometric patterns. J. Electromagn. Eng. Sci. 2020, 20, 53–63. [Google Scholar] [CrossRef]

- Zhang, S.; Arya, R.; Pandey, S.; Vardaxoglou, J.C.; Whittow, W.; Mittra, R. 3D-printed planar graded index lenses. IET Microw. Antennas Propag. 2016, 10, 1411–1419. [Google Scholar]

- Janezic, M.D.; Jargon, J.A. Complex permittivity determination from propagation constant measurements. IEEE Microw. Guided Wave Lett. 1999, 9, 76–78. [Google Scholar] [CrossRef]

- Alhalabi, R.A.; Rebeiz, G.M. High-gain Yagi-Uda antennas for millimeter-wave switched-beam systems. IEEE Trans. Antennas Propag. 2009, 57, 3672–3676. [Google Scholar]

| Parameters | 1 | 2 | 3 | 4 |

|---|---|---|---|---|

| Permittivity | 1.88 | 1.67 | 1.44 | 1.22 |

| Radius (mm) | 16.1 | 22.7 | 27.8 | 32.1 |

| [28] | [24] | [15] | [23] | This work | |

|---|---|---|---|---|---|

| Source Antenna | Horn antenna | Patch antenna | Patch antenna | WG | Yagi |

| Lens volume (W × L × H) (mm) | 6λ0 × 6λ0 × 0.925λ0 | 6.7λ0 × 6.7λ0 × 2.2λ0 | 5λ0 × 5λ0 × 1.1λ0 | 10λ0 × 10λ0 × 1.25λ0 | 6λ0 × 6λ0 × 1.12λ0 |

| Frequency band (GHz) | 12–18 | 24–28 | 13.4–13.6 | 28–40 | 24–32 |

| 1dB gain BW (%) | N/A | <7.7 | <4.7 | <8% * | 23 |

| Impedance bandwidth (%) | N/A | 15.4 | 1.48 | 42.4 | 41 |

| SLL (dB) | −14 * | −11 | −18.5 | 20 * | −17 |

| Radiation Efficiency (%) | N/A | 84.5 | 67.3 | N/A | 92 |

| Lens material | PLA | Plastic resin | RO4350B | ABS1200, ABS1000, ABS650, ABS440, ABS300 | PLA |

| Fabrication method | FDM | SLA | PCB | FDM | FDM |

| Cost | Low | High | Medium | High | Low |

| Weight | Light | Medium | Medium | Light | Very Light |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, Y.; Pham, D.A.; Phon, R.; Lim, S. Lightweight 3D-Printed Fractal Gradient-Index Lens Antenna with Stable Gain Performance. Fractal Fract. 2022, 6, 551. https://doi.org/10.3390/fractalfract6100551

Kim Y, Pham DA, Phon R, Lim S. Lightweight 3D-Printed Fractal Gradient-Index Lens Antenna with Stable Gain Performance. Fractal and Fractional. 2022; 6(10):551. https://doi.org/10.3390/fractalfract6100551

Chicago/Turabian StyleKim, Yeonju, Duc Anh Pham, Ratanak Phon, and Sungjoon Lim. 2022. "Lightweight 3D-Printed Fractal Gradient-Index Lens Antenna with Stable Gain Performance" Fractal and Fractional 6, no. 10: 551. https://doi.org/10.3390/fractalfract6100551

APA StyleKim, Y., Pham, D. A., Phon, R., & Lim, S. (2022). Lightweight 3D-Printed Fractal Gradient-Index Lens Antenna with Stable Gain Performance. Fractal and Fractional, 6(10), 551. https://doi.org/10.3390/fractalfract6100551