Kinetic Model for Drying in Frame of Generalized Fractional Derivatives

Abstract

1. Introduction

2. Mathematical Background

- i.

- .

- ii.

- .

- iii.

- .

- iv.

- .

3. Main Results

3.1. Lewis Drying Kinetic Model in Fractional Cases

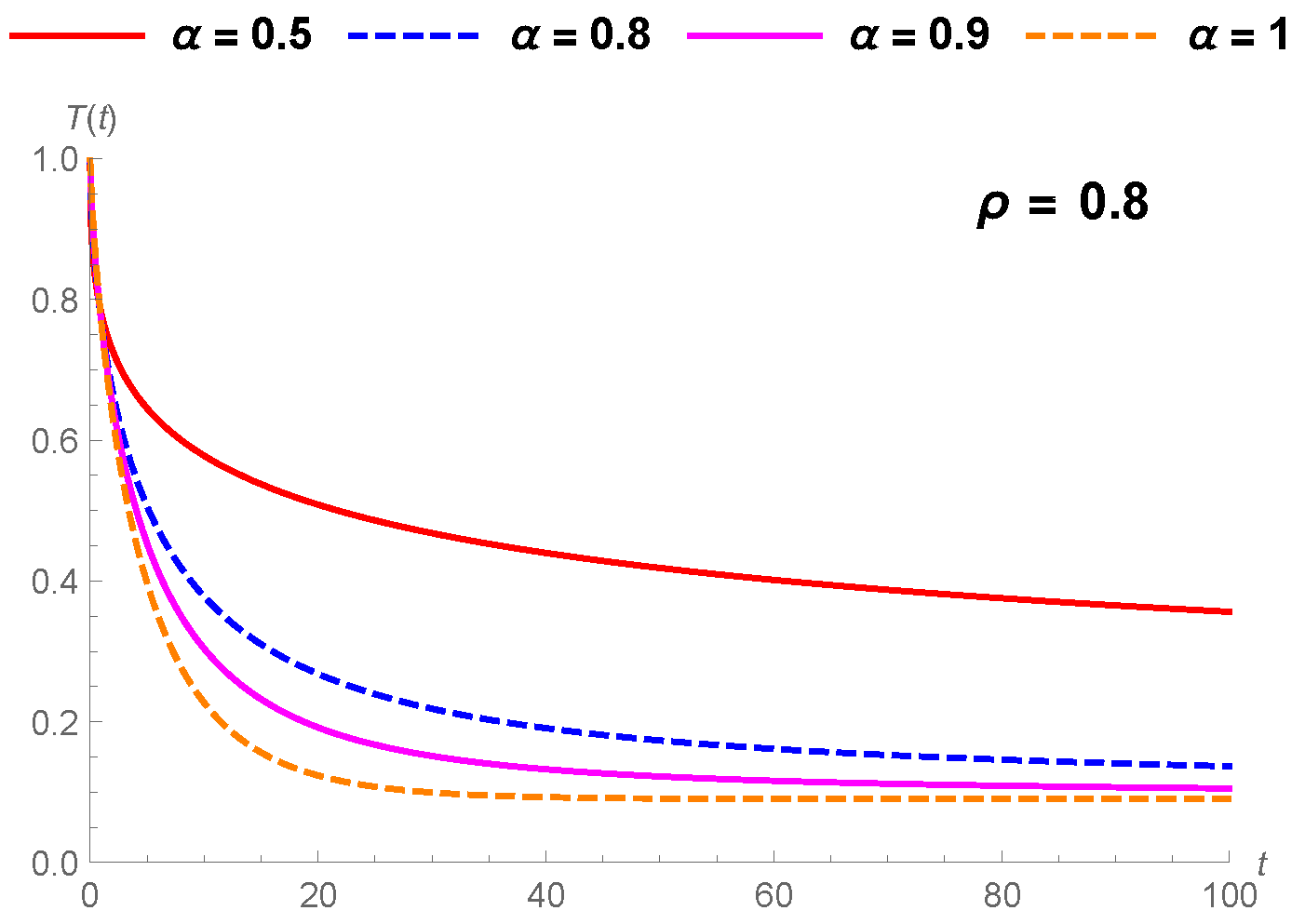

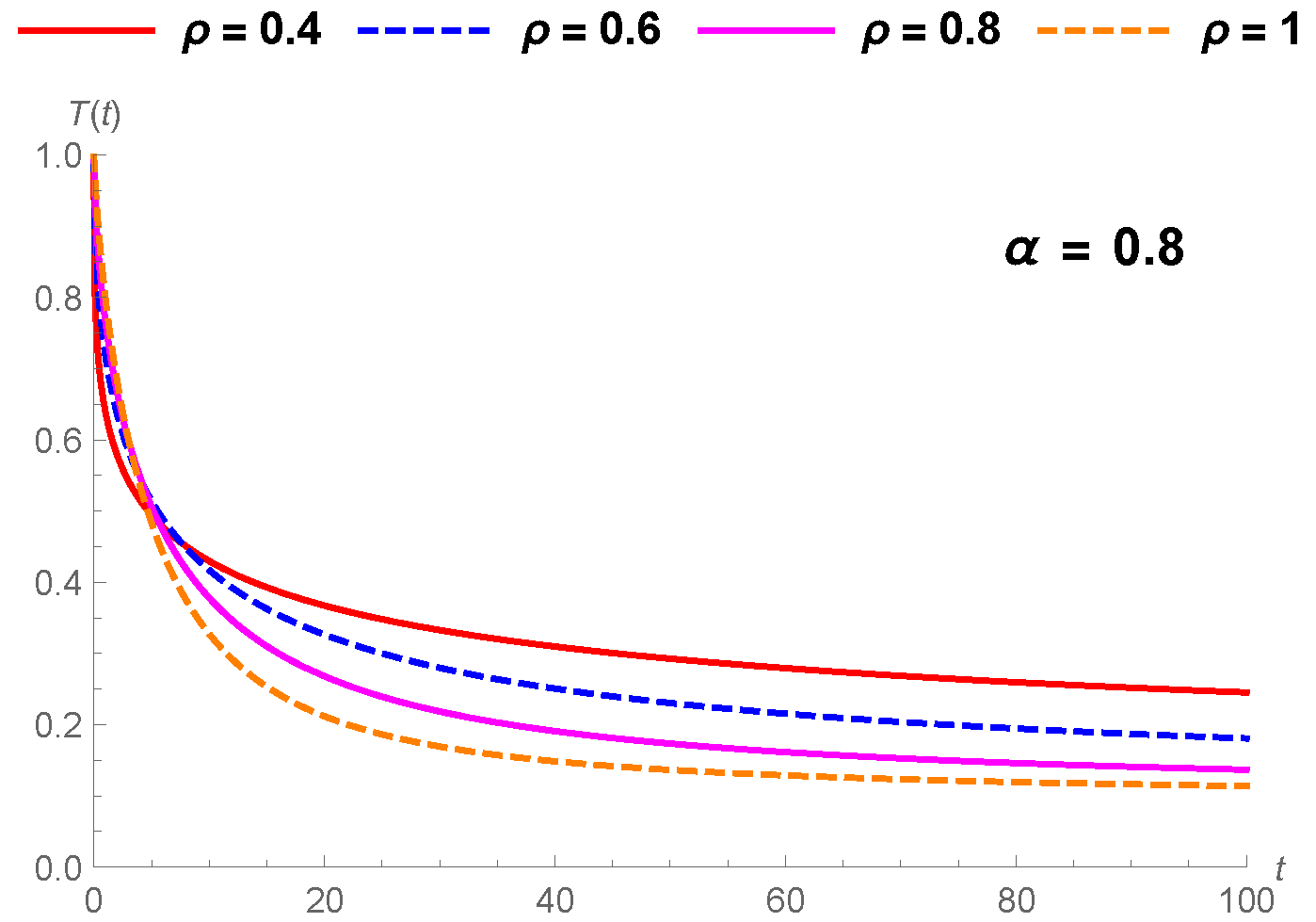

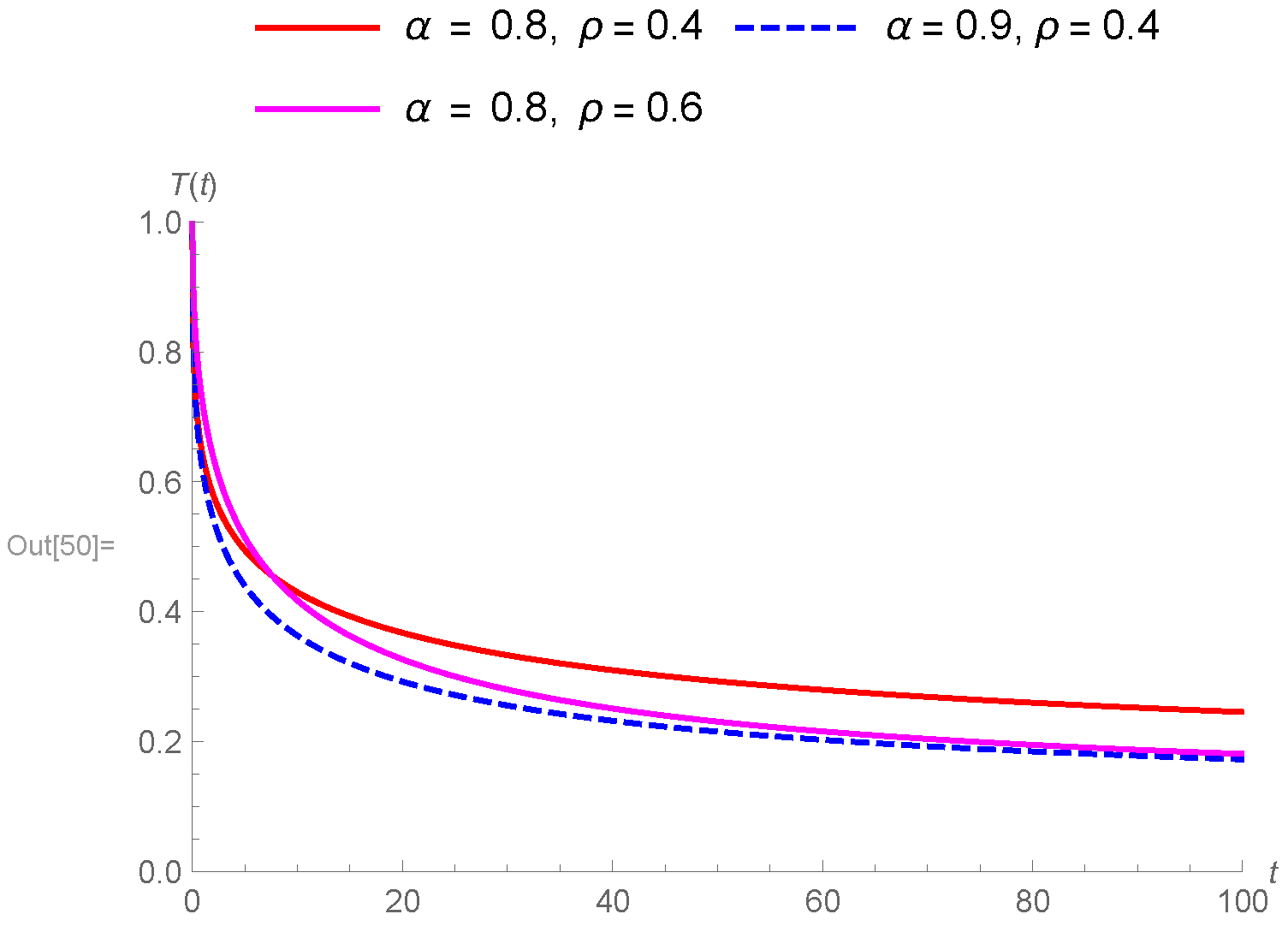

3.1.1. Drying Kinetic with Generalized Fractional Derivative

3.1.2. Drying Kinetic with Caputo Fractional Derivative

4. Comparative Results

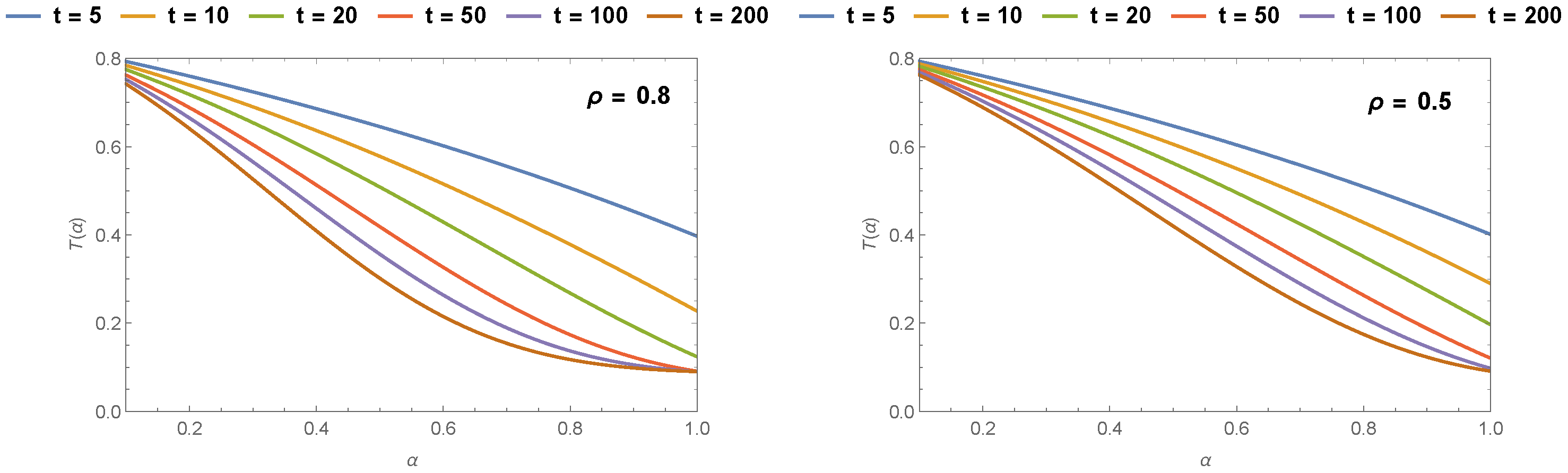

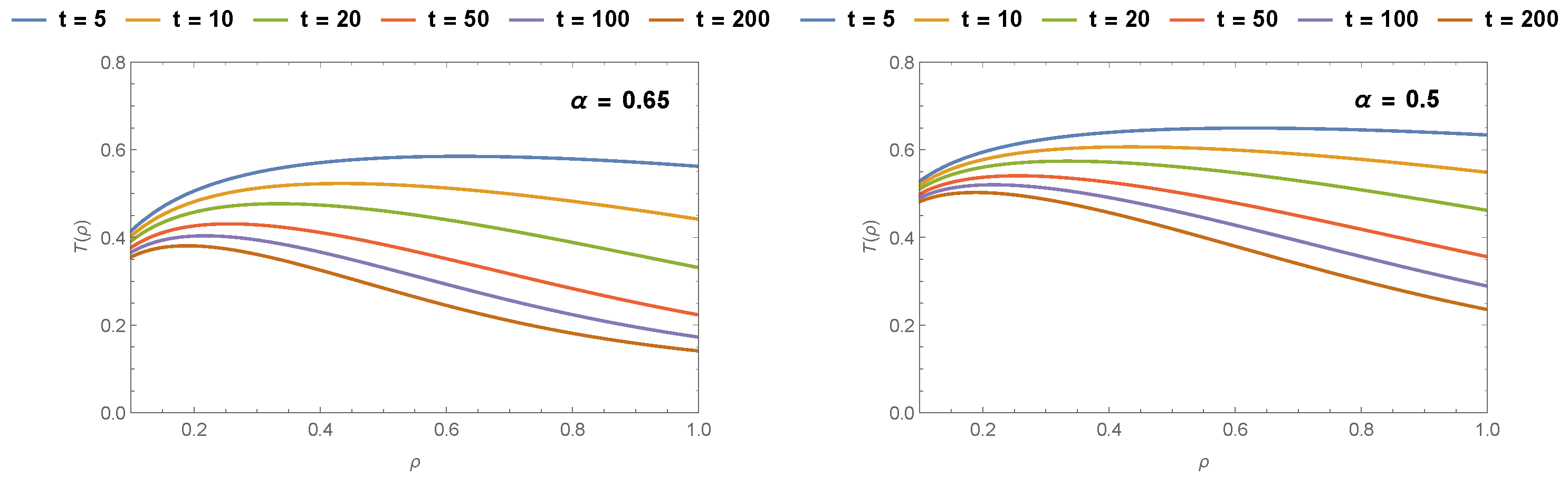

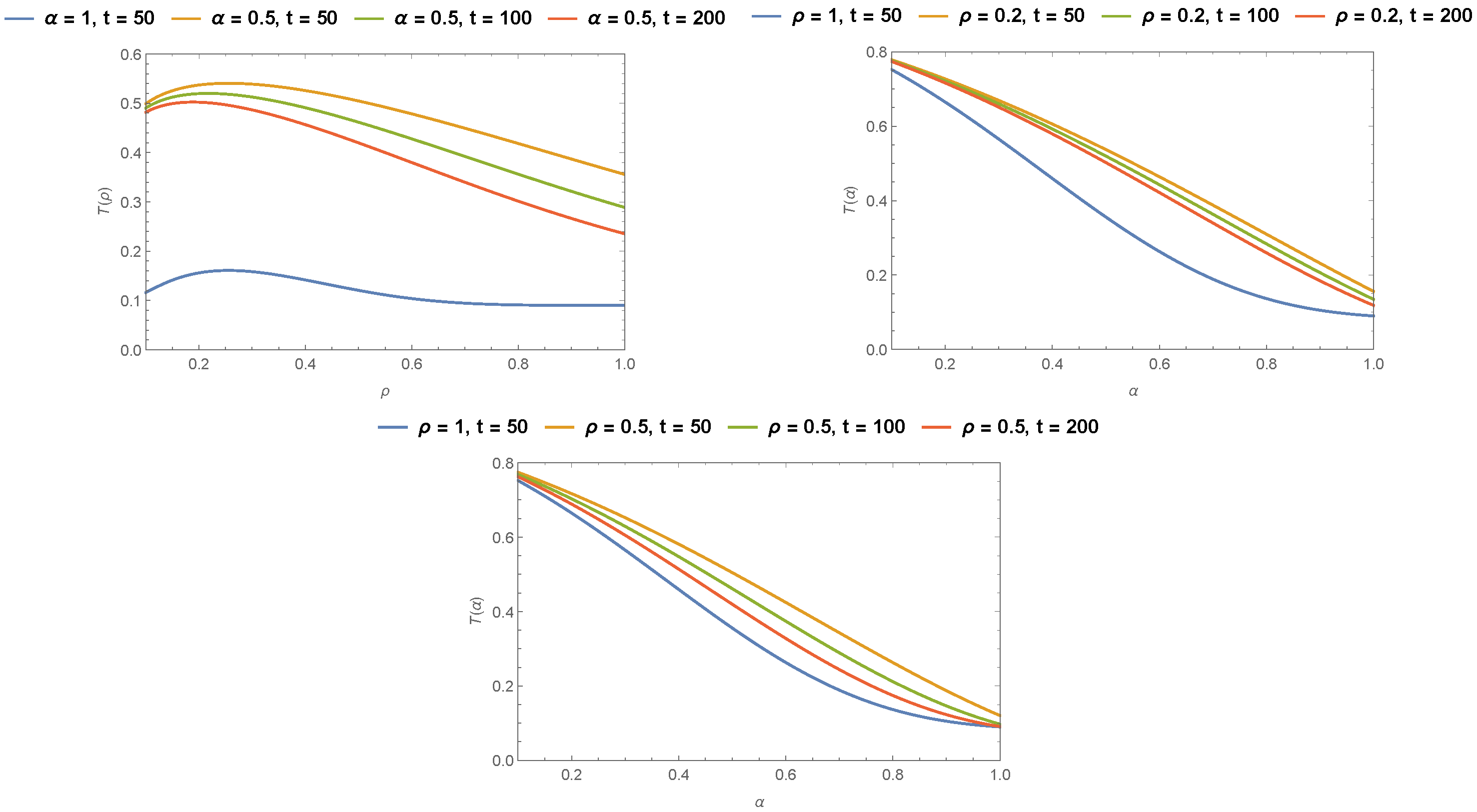

5. Discussion

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Agutter, P.S.; Malone, P.C.; Wheatley, D.N. Diffusion theory in biology: A relic of mechanistic materialism. J. Hist. Biol. 2000, 33, 71–111. [Google Scholar] [CrossRef] [PubMed]

- Garcia, J.R.; Calderon, M.G.; Ortiz, J.M.; Baleanu, D.; de Santiago, C.S.V. Motion of a particle in a resisting medium using fractional calculus approach. Proc. Rom. Acad. A 2013, 14, 42–47. [Google Scholar]

- Diethelm, K. A fractional calculus based model for the simulation of an outbreak of dengue fever. Nonlinear Dyn. 2013, 71, 613–619. [Google Scholar] [CrossRef]

- Simpson, R.; Jaques, A.; Nuńez, H.; Ramirez, C.; Almonacid, A. Fractional calculus as a mathematical tool to improve the modeling of mass transfer phenomena in food processing. Food Eng. Rev. 2013, 5, 45–55. [Google Scholar] [CrossRef]

- Ramírez, C.; Astorga, V.; Nuńez, H.; Jaques, A.; Simpson, R. Anomalous diffusion based on fractional calculus approach applied to drying analysis of apple slices: The effects of relative humidity and temperature. J. Food Process Eng. 2017, 40, e12549. [Google Scholar] [CrossRef]

- Metzler, R.; Klafter, J. The random walk’s guide to anomalous diffusion: A fractional dynamics approach. Phys. Rep. 2000, 339, 1–77. [Google Scholar] [CrossRef]

- Fomin, S.; Chugunov, V.; Hashida, T. Mathematical modeling of anomalous diffusion in porous media. Fract. Differ. Calc. 2011, 1, 1–28. [Google Scholar] [CrossRef]

- Lewis, W.K. The rate of drying of solid materials. Ind. Eng. Chem. 1921, 13, 427–432. [Google Scholar] [CrossRef]

- Page, G.E. Factors Influencing the Maximum Rates of Air Drying Shelled Corn in Thin Layers; Purdue University: West Lafayette, IN, USA, 1949. [Google Scholar]

- Caputo, M.; Fabrizio, M. A new definition of fractional derivative without singular kernel. Prog. Fract. Differ. Appl. 2015, 1, 1–13. [Google Scholar]

- Atangana, A.; Baleanu, D. New fractional derivatives with nonlocal and generalized kernel: Theory and application to heat transfer model. Therm. Sci. 2016, 20, 757–763. [Google Scholar] [CrossRef]

- Abdeljawad, T.; Baleanu, D. On fractional derivatives with generalized Mittag-Leffler kernels. Adv. Differ. Equ. 2018, 2018, 468. [Google Scholar] [CrossRef]

- Fernandez, A.; Özarslan, M.A.; Baleanu, D. On fractional calculus with general analytic kernels. Appl. Math. Comput. 2019, 354, 248–265. [Google Scholar] [CrossRef]

- Bas, E.; Ozarslan, R. Real world applications of fractional models by Atangana-Baleanu fractional derivative. Chaos Solitons Fractals 2018, 116, 121–125. [Google Scholar] [CrossRef]

- Bas, E.; Ozarslan, R.; Baleanu, D.; Ercan, A. Comparative simulations for solutions of fractional Sturm-Liouville problems with generalized operators. Adv. Differ. Equ. 2018, 2018, 350. [Google Scholar] [CrossRef]

- Abdeljawad, T. A Lyapunov type inequality for fractional operators with nonsingular Mittag-Leffler kernel. J. Inequal. Appl. 2017, 2017, 130. [Google Scholar] [CrossRef] [PubMed]

- Sekerci, Y.; Ozarslan, R. Respiration Effect on Plankton–Oxygen Dynamics in view of generalized time fractional derivatives. Phys. A Stat. Mech. Appl. 2019, 123942. [Google Scholar] [CrossRef]

- Sekerci, Y.; Ozarslan, R. Marine system dynamical response to a changing climate in frame of power law, exponential decay and Mittag-Leffler kernel. Math. Methods Appl. Sci. 2020, 43, 5480–5506. [Google Scholar] [CrossRef]

- Sekerci, Y.; Ozarslan, R. Oxygen-plankton model under the effect of global warming with nonsingular fractional order. Chaos Solitons Fractals 2020, 132, 109532. [Google Scholar] [CrossRef]

- Ozarslan, R.; Bas, E.; Baleanu, D.; Acay, B. Fractional physical problems including wind-influenced projectile motion with Mittag-Leffler kernel. AIMS Math. 2020, 5, 467. [Google Scholar] [CrossRef]

- Ozarslan, R. Microbial Survival and Growth Modeling in Frame of Nonsingular Fractional Derivatives. Math. Meth. Appl. Sci. 2020, 1–19. [Google Scholar] [CrossRef]

- Acay, B.; Ozarslan, R.; Bas, E. Fractional physical models based on falling body problem. AIMS Math. 2020, 5, 2608–2628. [Google Scholar] [CrossRef]

- Sekerci, Y.; Ozarslan, R. Dynamic analysis of time fractional order oxygen in a plankton system. Eur. Phys. J. Plus 2020, 135, 88. [Google Scholar] [CrossRef]

- Sekerci, Y. Climate change effects on fractional order prey-predator model. Chaos Solitons Fractals 2020, 134, 109690. [Google Scholar] [CrossRef]

- Kumar, D.; Singh, J.; Al Qurashi, M.; Baleanu, D. A new fractional SIRS-SI malaria disease model with application of vaccines, antimalarial drugs and spraying. Adv. Differ. Equ. 2019, 2019, 278. [Google Scholar] [CrossRef]

- Ullah, S.; Khan, M.A.; Farooq, M.; Hammouch, Z.; Baleanu, D. A fractional model for the dynamics of tuberculosis infection using Caputo-Fabrizio derivative. Discret. Contin. Dyn. Syst. S 2019, 2019, 11–27. [Google Scholar] [CrossRef]

- Singh, J.; Kumar, D.; Al Qurashi, M.; Baleanu, D. A new fractional model for giving up smoking dynamics. Adv. Differ. Equ. 2017, 2017, 88. [Google Scholar] [CrossRef]

- Jajarmi, A.; Hajipour, M.; Baleanu, D. New aspects of the adaptive synchronization and hyperchaos suppression of a financial model. Chaos Solitons Fractals 2017, 99, 285–296. [Google Scholar] [CrossRef]

- Yusuf, A.; Qureshi, S.; Inc, M.; Aliyu, A.I.; Baleanu, D.; Shaikh, A.A. Two-strain epidemic model involving fractional derivative with Mittag-Leffler kernel. Chaos Interdiscip. J. Nonlinear Sci. 2018, 28, 123121. [Google Scholar] [CrossRef]

- Qureshi, S.; Yusuf, A. Fractional derivatives applied to MSEIR problems: Comparative study with real world data. Eur. Phys. J. Plus 2019, 134, 171. [Google Scholar] [CrossRef]

- Qureshi, S.; Atangana, A. Mathematical analysis of dengue fever outbreak by novel fractional operators with field data. Phys. A Stat. Mech. Appl. 2019, 526, 121127. [Google Scholar] [CrossRef]

- Bas, E.; Acay, B.; Ozarslan, R. Fractional models with singular and generalized kernels for energy efficient buildings. Chaos Interdiscip. J. Nonlinear Sci. 2019, 29, 023110. [Google Scholar] [CrossRef] [PubMed]

- Ozarslan, R.; Ercan, A.; Bas, E. Novel Fractional Models Compatible with Real World Problems. Fractal Fract. 2019, 3, 15. [Google Scholar] [CrossRef]

- Ozarslan, R.; Ercan, A.; Bas, E. β-type fractional sturm-liouville coulomb operator and applied results. Math. Meth. Appl. Sci. 2019, 42, 1–12. [Google Scholar] [CrossRef]

- Pinto, C.M.; Carvalho, A.R. A latency fractional order model for HIV dynamics. J. Comput. Appl. Math. 2017, 312, 240–256. [Google Scholar] [CrossRef]

- Jajarmi, A.; Baleanu, D. A new fractional analysis on the interaction of HIV with CD4+ T-cells. Chaos Solitons Fractals 2018, 113, 221–229. [Google Scholar] [CrossRef]

- Katugampola, U.N. New approach to a generalized fractional integral. Appl. Math. Comput. 2011, 218, 860–865. [Google Scholar] [CrossRef]

- Katugampola, U.N. A new approach to generalized fractional derivatives. Bull. Math. Anal. Appl. 2014, 6, 1–15. [Google Scholar]

- Anatoly, A.K. Hadamard-type fractional calculus. J. Korean Math. Soc. 2001, 38, 1191–1204. [Google Scholar]

- Jarad, F.; Abdeljawad, T.; Baleanu, D. On the generalized fractional derivatives and their Caputo modification. J. Nonlinear Sci. Appl. 2017, 10, 2607–2619. [Google Scholar] [CrossRef]

- De Souza, Matias, G.; Bissaro, C.A.; de Matos, Jorge, L.M.; Rossoni, D.F. The fractional calculus in studies on drying: A new kinetic semi-empirical model for drying. J. Food Process Eng. 2019, 42, e12955. [Google Scholar] [CrossRef]

- Nicolin, D.J.; Defendi, R.O.; Rossoni, D.F.; de Matos, Jorge, L.M. Mathematical modeling of soybean drying by a fractional-order kinetic model. J. Food Process Eng. 2018, 41, e12655. [Google Scholar] [CrossRef]

- Podlubny, I. Fractional Differential Equations: An Introduction to Fractional Derivatives, Fractional Differential Equations, to Methods of Their Solution and Some of Their Applications; Elsevier: Amsterdam, The Netherlands, 1998; Volume 198. [Google Scholar]

- Jarad, F.; Abdeljawad, T. A modified Laplace transform for certain generalized fractional operators. Results Nonlinear Anal. 2018, 1, 88–98. [Google Scholar]

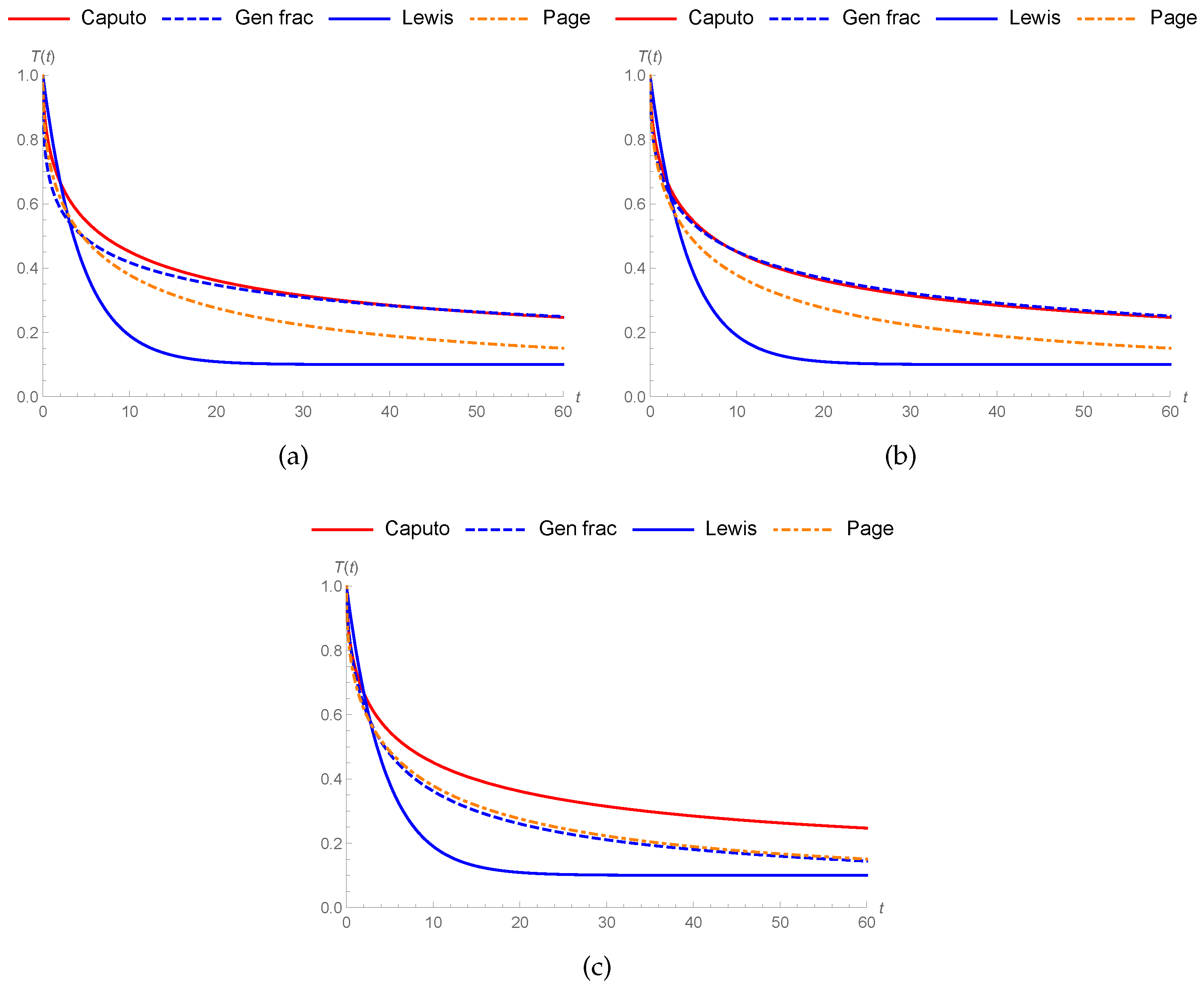

| Figures | Parameters | Page | Lewis Classical | Lewis Caputo | Lewis Gen. Frac. |

|---|---|---|---|---|---|

| k | 0.31 | 0.178 | 0.0835014 | 0.0579262 | |

| Figure 1a | 0.10 | 0.12 | 0.09 | 0.01 | |

| 0.57478 | 0.5 | ||||

| 0.8 | |||||

| n | 0.52 | ||||

| k | 0.31 | 0.178 | 0.0835014 | 0.0430676 | |

| Figure 1b | 0.10 | 0.12 | 0.09 | 0.01 | |

| 0.57478 | 0.6 | ||||

| 0.8 | |||||

| n | 0.52 | ||||

| k | 0.31 | 0.178 | 0.0835014 | 0.0917365 | |

| Figure 1c | 0.10 | 0.12 | 0.09 | 0.01 | |

| 0.57478 | 0.63 | ||||

| 0.8 | |||||

| n | 0.52 | ||||

| k | 0.31 | 0.178 | 0.0835014 | 0.187836 | |

| Figure 1d | 0.10 | 0.12 | 0.09 | 0.01 | |

| 0.57478 | 0.9 | ||||

| 0.8 | |||||

| n | 0.52 |

| Figures | Parameters | Page | Lewis Classical | Lewis Caputo | Lewis Gen. Frac. |

|---|---|---|---|---|---|

| k | 0.39 | 0.23 | 0.109725 | 0.0911242 | |

| Figure 2a | 0.08 | 0.10 | 0.07 | 0.008 | |

| 0.53 | 0.45 | ||||

| 0.85 | |||||

| n | 0.46 | ||||

| k | 0.39 | 0.23 | 0.109725 | 0.065617 | |

| Figure 2b | 0.08 | 0.10 | 0.07 | 0.001 | |

| 0.53 | 0.52 | ||||

| 0.85 | |||||

| n | 0.46 | ||||

| k | 0.39 | 0.23 | 0.109725 | 0.142309 | |

| Figure 2c | 0.08 | 0.10 | 0.07 | 0.01 | |

| 0.53 | 0.65 | ||||

| 0.95 | |||||

| n | 0.46 |

| Figures | Parameters | Page | Lewis Classical | Lewis Caputo | Lewis Gen. Frac. |

|---|---|---|---|---|---|

| k | 0.35 | 0.21 | 0.0785997 | 0.0822175 | |

| Figure 3a | 0.07 | 0.10 | 0.05 | 0.1 | |

| 0.50050 | 0.61 | ||||

| 0.79 | |||||

| n | 0.49 | ||||

| k | 0.35 | 0.21 | 0.0785997 | 0.126885 | |

| Figure 3b | 0.07 | 0.10 | 0.05 | 0.05 | |

| 0.50050 | 0.85 | ||||

| 0.79 | |||||

| n | 0.49 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ozarslan, R.; Bas, E. Kinetic Model for Drying in Frame of Generalized Fractional Derivatives. Fractal Fract. 2020, 4, 17. https://doi.org/10.3390/fractalfract4020017

Ozarslan R, Bas E. Kinetic Model for Drying in Frame of Generalized Fractional Derivatives. Fractal and Fractional. 2020; 4(2):17. https://doi.org/10.3390/fractalfract4020017

Chicago/Turabian StyleOzarslan, Ramazan, and Erdal Bas. 2020. "Kinetic Model for Drying in Frame of Generalized Fractional Derivatives" Fractal and Fractional 4, no. 2: 17. https://doi.org/10.3390/fractalfract4020017

APA StyleOzarslan, R., & Bas, E. (2020). Kinetic Model for Drying in Frame of Generalized Fractional Derivatives. Fractal and Fractional, 4(2), 17. https://doi.org/10.3390/fractalfract4020017