Abstract

The excessive production of construction waste is a significant concern as it requires proper disposal and may become economically unfeasible. Reusing construction waste in producing new concrete can substantially reduce the disposal requirements of construction waste. In addition, this results in a sustainable solution for the rapidly depleting natural resources of concrete. Pervious concrete may contain up to 80% coarse aggregates and could be an exceptional host for reusing construction waste. This study aimed to investigate the mechanical properties of pervious concrete constructed with natural and recycled aggregates. The substandard properties of recycled aggregates were improved by adding natural fibers from sackcloth. This study presents an experimental program on 45 samples of pervious concrete with air void ratios and the size of coarse aggregates as the parameters of interest. The compressive strength of the pervious concrete decreased by increasing the air void ratio regardless of the size of the aggregates. The type of aggregates did not influence the permeability of pervious concrete, and the maximum temperature in pervious concrete increased as the quantity of air void ratios increased. The decrease in compressive strength was 40–60% as the void ratio was increased from 10–30% for all types of concrete mixes, such as natural and recycled aggregates. The permeability of small-size aggregates with 10% designed air void ratios for natural and recycled aggregates with sackcloth was 0.705 cm/s.

1. Introduction

In recent years, the reuse of construction waste in new construction works has been a topic of interest [1,2,3,4,5,6,7,8]. The use of recycled aggregates as an alternative to natural aggregates in the production of concrete addresses two key issues: (1) It eases the handling and proper disposal requirements of construction waste, and (2) the demand for the rapidly depleting natural resources may be reduced [9,10,11,12,13,14]. It has been estimated that the annual use of concrete will increase to 18 billion tons by the year 2050 [15]. Thus, effective ways of minimizing the excessive use of depleting natural resources for concrete production must be devised.

Porous Portland cement concrete (PPCC), also known as pervious concrete, is differentiated from Portland cement concrete (PCC) due to the presence of a large volume of air voids [16]. PPCC mainly finds its applications in permeable pavements and infiltration beds [17]. One of the best ways to utilize recycled aggregates could be in the production of PPCC. This is because PPCC comprises up to 80% of coarse aggregates with little or no fine aggregates [18]. Recycled aggregates typically possess lower density, higher porosity, and higher water absorption characteristics than natural aggregates. This may be attributed to the mortar adhered to the surface of recycled aggregates [19,20,21]. Consequently, recycled aggregates are mainly recommended for non-structural applications [22,23]. Thus, the use of recycled aggregates in porous pavements is subjected to the mechanical properties of the resulting mix as the pavements are designed to bear traffic loads. Natural sources, such as solar radiation, air temperature, and wind, are the catalyst to vary pavement temperatures periodically. The properties of comprising constituents in PPCC also influence the pavement temperature. As a result, pavements may exhibit different temperatures under the same environmental conditions. Hassan et al. [24] concluded that the temperature at the top and bottom surface of pavements increased with the increase in air void ratios. Albedo is a property that characterizes the amount of heat absorbed by the pavement. Li et al. [25] found that an increased albedo resulted in a decreased heat absorption characteristic of the pavement. Studies have shown that PPCC has lower albedo than PCC and demonstrates higher heat absorption characteristics [26,27]. It has been suggested that pavement temperature affects the surrounding environment, and an increased temperature variation may disturb the comfort of human bodies [28]. A strong correlation between air temperature and surface temperature has been observed [29].

Although in the past, many studies have been conducted on the mechanical properties of pervious concrete with natural stone aggregates [30,31,32,33,34,35,36,37,38]; however, no studies were found on mechanical properties of pervious recycled aggregate concrete reinforced with sackcloth fibers (SF). The mechanical properties of concrete constructed with recycled aggregates differ substantially from those constructed with natural aggregates. The present study aims to investigate the presence of recycled aggregates in pervious concrete, focusing on mechanical properties, such as compressive strength, permeability, and temperature variation inside the resulting PPCC. By acknowledging the substandard characteristics of the concrete constructed with recycled aggregates, natural fibers originating from sackcloth (sackcloth fibers SF) with a weight of 3% of the cement content were added to the concrete mix in the presence of recycled aggregates. Therefore, the mechanical properties of PPCC with natural aggregates, recycled aggregates, and recycled aggregates strengthened with sackcloth natural fibers were investigated in the present study.

2. Materials and Methods

2.1. Test Matrix

In this study, three groups of specimens were tested. Each group was comprised of fifteen specimens. Specimens in Group 1 were constructed with pervious Portland cement concrete with 100% natural aggregates, whereas 100% of natural coarse aggregates in Group 2 specimens were replaced with recycled aggregates. The recycled aggregates were obtained from locally available construction waste. Specimens in Group 3 were also comprised of 100% recycled coarse aggregates. In Thailand, usually sackcloth bags are used for the curing of concrete at the construction site. In this study, used sackcloth bags were collected and cut into small lengths to develop natural sackcloth fibers (SF). The sackcloth fibers (SF) were added to the concrete mix to enhance the mechanical properties of the PPCC mix. The weight of the natural sackcloth fibers was kept as 3% of the weight of the cement used. The air void ratios in each group varied from 10% to 30%, with an increment of 5%. Thus, five samples in each group were constructed with air void ratios of 5%, 10%, 15%, 20%, and 25% each. Further, three samples were tested corresponding to each air void ratio. Three samples corresponding to each void ratio were differentiated depending on the size of coarse aggregates. Three sizes of coarse aggregates were used, namely large (L), medium (M), and small (S). The large coarse aggregates referred to the size retained on sieve #3/8 inches. The medium size referred to the aggregates with 50% passing through the sieve #3/8 inches and 50% retained on no. 4 sieve, whereas small aggregates were the ones that passed 100% from the no. 4 sieve. The details of the test specimens are presented in Table 1. Specimen name in each group was differentiated depending on the type of coarse aggregates and the presence of sackcloth. Natural, recycled, and recycled aggregates strengthened with sackcloth were recognized as “NA”, “RA”, and “RA-SF”, respectively. Further, specimens within each group were differentiated depending on the air void contents. For instance, Vv10 represented a specimen with a 10% air void ratio.

Table 1.

Details of test specimens.

All specimens were constructed using a water-to-cement ratio of 0.30. The volume of cement paste was constant at 20% in all specimens. The mix details are provided in Table 2. Further, type-I Portland cement was used in the construction of all specimens. Locally available natural aggregates from Saraburi province in Thailand were used to construct Group 1 specimens. The recycled aggregates were acquired from recycled structural concrete with compressive strength ranging from 23.5 MPa to 40.0 MPa. Various tests were performed to obtain the mechanical properties of coarse aggregates. Figure 1 shows the process of obtaining recycled aggregates from the structural concrete waste. A typical sackcloth is shown in Figure 2.

Table 2.

Details of mix components (kg).

Figure 1.

Acquisition of recycled aggregates in process.

Figure 2.

Typical sackcloth.

2.2. Unit Weight and Water Absorption

The unit weight and water absorption of the aggregates were determined by following the recommendations of ASTM C29 [39]. Table 3 presents the details of the process to determine the unit weight and water absorption characteristics of natural and recycled aggregates. Three trials were performed for both natural and recycled aggregates. The average values of unit weight and water absorption are reported in Table 3. The average unit weight of natural coarse aggregates was 1493.9 kg/m3, whereas the unit weight of recycled aggregates was estimated at 1358.2 kg/m3, which is 9.81% lower than the unit of natural aggregates. Similarly, the water absorption of recycled aggregates was 4.52%, which was 511% higher than the water absorption of natural aggregates.

Table 3.

Unit weight and water absorption characteristics of natural and recycled aggregates.

2.3. Sieve Analysis of Coarse Aggregates

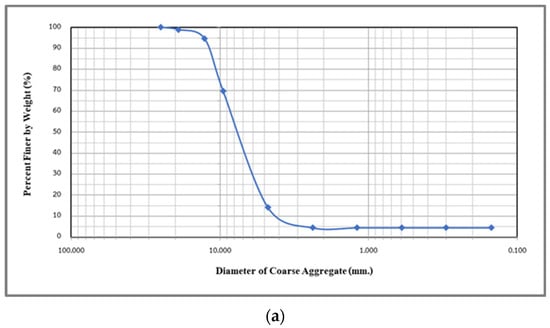

The determination of fineness modulus through sieve analysis results in the average size of the aggregates. Sieve analysis was performed in accordance with ASTM C136/C136M-19 [40]. Figure 3a,b presents the sieve analysis results performed on recycled and natural aggregates, respectively. The fineness modulus of recycled and natural aggregates was estimated at 6.003 and 6.350, respectively. This suggests that the average size of both recycled and natural aggregates was between 4.75 mm and 10 mm.

Figure 3.

Results of sieve analysis on (a) recycled coarse aggregates and (b) natural coarse aggregates.

2.4. Resistance to Abrasion and Impact

The relative quality of natural and recycled aggregates was determined by performing the Los Angeles test in accordance with ASTM C131/C131M-20 [41]. The results of the Los Angeles test performed on recycled and natural aggregates are shown in Table 4. The abrasion values of natural and recycled aggregates were 23.45% and 30.86%, respectively. This suggests that recycled aggregates exhibited a 31.60% higher abrasion tendency than natural aggregates.

Table 4.

Unit weight and water absorption characteristics of natural and recycled aggregates.

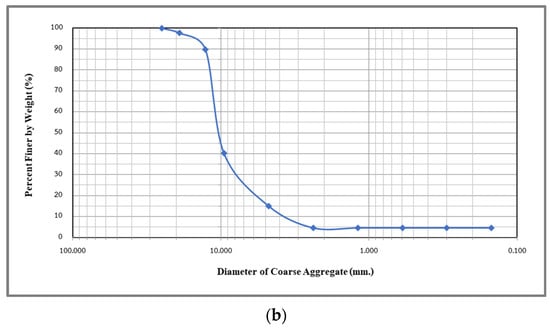

2.5. Temperature Measurement

The present study investigated the temperature of porous concrete by using thermocouples. To replicate the actual conditions of pavement, specimens were embedded inside the ground, as shown in Figure 4. The temperature at the top surface, mid-height, and bottom of specimens was monitored. The temperature corresponding to the mid-height represented the temperature inside the specimen. Thermocouple wires were attached to the outer surfaces at the top and bottom of specimens. Thermocouples were connected to a logger to record continuous temperature measurements. The measured temperatures reported in this study are the average of the temperatures recorded at three positions.

Figure 4.

Temperature measurement scheme.

3. Results

3.1. Compressive Strength Results

Compressive strength for each specimen was determined on the 7th and 28th day of casting, as per the recommendations of ASTM C39/C39M [42]. A summary of the results of compressive strength is presented in Table 5. The typical failure modes of specimens are shown in Figure 5. All specimens experienced sudden failure due to the crushing of concrete. The aggregates started peeling off the specimen with a gentle sound near the ultimate load. The crushing resulted in the separation of coarse aggregates that is considerably different from the splitting and cone formations in PCC. A similar failure was observed in pervious concrete elsewhere [43].

Table 5.

Unit weight and water absorption characteristics of natural and recycled aggregates.

Figure 5.

Ultimate failure modes of cube specimens.

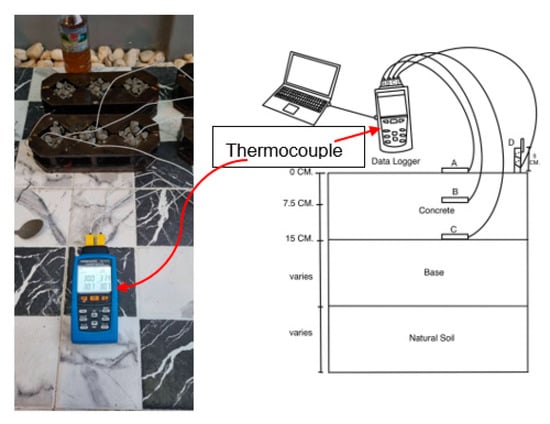

The variation of the compressive strength of test specimens with air void ratios for different aggregate sizes is shown in Figure 6. It is evident that the compressive strength decreased as the air void ratio increased, regardless of the size of the aggregates. Aggregates corresponding to small and large size referred to the size retained on the #3/8-inch and no. 4 sieves, respectively. Hence, a uniform grading was achieved in small- and large-size aggregates. On the contrary, medium-size aggregates referred to the combination of sizes with 50% retained on the #3/8-inch sieve and remaining retained on the no. 4 sieve. As a result, a better grading was achieved in medium-size aggregates. This is reflected in the compressive strength results of the medium-size aggregates as compared to the large- and small-size aggregates, as shown in Figure 6. It is observed that the compressive strength of medium-size aggregates was highest among small- and large-size aggregates at all air void ratios and irrespective of the type of aggregates. For uniformly graded aggregates, the strength of PPCC decreased as the size of coarse aggregates increased. A similar trend was also observed in existing studies on pervious concrete [44,45,46]. Zhong and Wille [47] suggested that an increased aggregate size increased the pore size. As a larger pore size reduces the number of pores per unit volume for a constant porosity, the bonding area of the coarse aggregates reduces, which results in a lower compressive strength.

Figure 6.

Variation of compressive strength (at 28th day) of PPCC with an air void ratio: (a) natural aggregate PPCC, (b) recycled aggregate PPCC, and (c) recycled aggregate PPCC strengthened with sackcloth fibers.

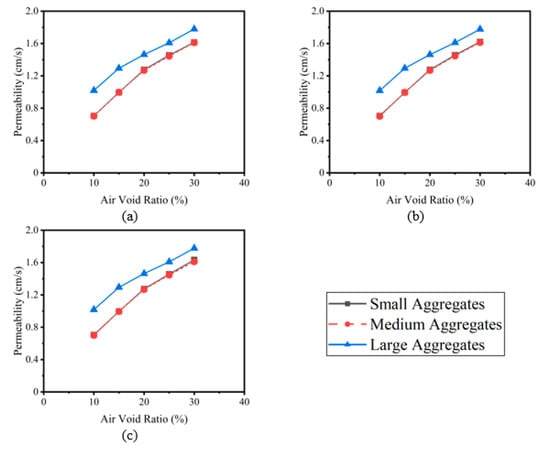

3.2. Permeability Results

An adequate permeability is desired from pervious concrete when used in pavements. Permeability tests were performed by following the recommendations of ASTM D5084-16a [48]. The calculated air void ratios and permeabilities are presented in Table 6 for different aggregate sizes. Figure 7 shows a relationship between the permeability and air void ratios for different aggregate sizes and types. It is interesting to observe that the type of aggregates did not influence the permeability of PPCC. For instance, the permeability of small-size aggregates with 10% designed air void ratios for natural, recycled, and recycled aggregates with sackcloth was 0.705 cm/s. It was found that the permeability increased with the air void ratios in all aggregate types and sizes. Further, the permeability of large-size aggregates was highest for a specific specimen type. The permeability of small- and medium-size aggregates did not differ considerably. This can be attributed to the better grading of medium-size aggregates as compared to that of small- and large-size aggregates.

Table 6.

Unit weight and water absorption characteristics of natural and recycled aggregates.

Figure 7.

Variation of permeability of PPCC with an air void ratio: (a) natural aggregate PPCC, (b) recycled aggregate PPCC, and (c) recycled aggregate PPCC strengthened with sackcloth fibers.

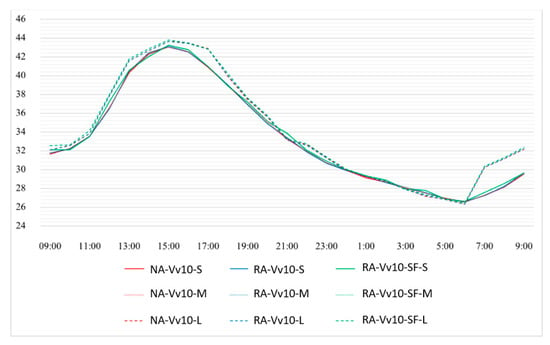

3.3. Temperature Variation of PPCC

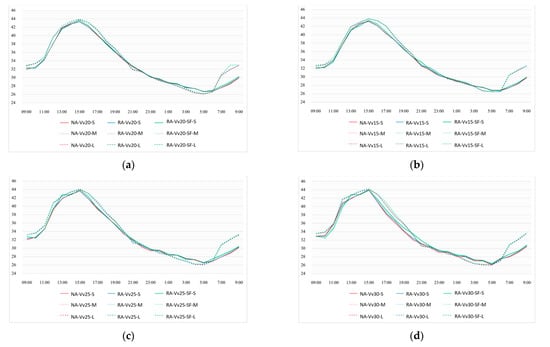

The temperature variation of PPCC was recorded for 24 h starting from 9:00 A.M. Table 7 presents the hourly temperature measurements for specimens with 10% air void ratios. Figure 8 plots the temperature variation at different time intervals. It is evident that the temperature variation trend was identical in all aggregate types and sizes. The upper bound on temperature was created by large-size aggregates, whereas the temperature in small- and medium-sized aggregate PPCC could not be separated. A similar observation on temperature measurement in PPCC was also reported elsewhere [28]. The maximum temperature was recorded at 15:00 h for all specimen types. The minimum temperature was reported around 6:00 h for all specimen types. It is interesting to observe that the increase in temperature was sudden beyond 6:00 h for specimens with large-size aggregate. Figure 9 provides the temperature variation of specimens with void ratios ranging from 15% to 30%. The temperature variation trend was identical for all void ratios with large-size aggregate specimens creating the upper and lower bounds of the recorded temperature.

Table 7.

Unit weight and water absorption characteristics of natural and recycled aggregates.

Figure 8.

Variation of temperature in specimens with a 10% air void ratio.

Figure 9.

Temperature variation in PPCC specimens with (a) a 15% air void ratio, (b) a 20% air void ratio, (c) a 25% air void ratio, and (d) a 30% air void ratio.

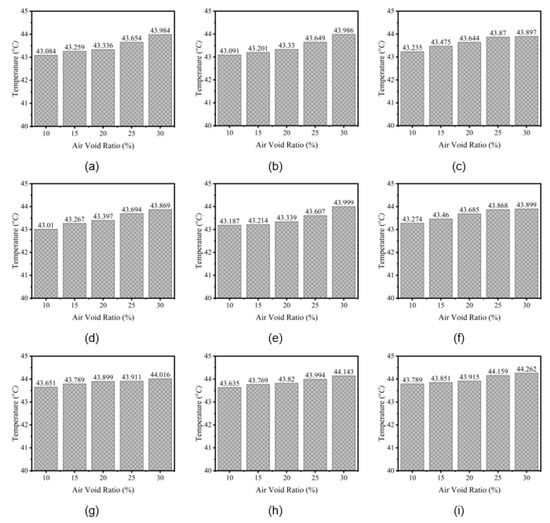

The variation of peak temperature with air void ratios is shown in Figure 10. It is interesting to observe that the maximum temperature of PPCC increased with the air void ratio. This trend was the same in all specimen types, irrespective of the type and size of the aggregates.

Figure 10.

Effect of air void ratios on the maximum temperature of PPCC: (a) NA-S, (b) RA-S, (c) RA-SF-S, (d) NA-M, (e) RA-M, (f) RA-SF-M, (g) NA-L, (h) RA-L, and (i) RA-SF-L.

4. Conclusions

This study aimed to investigate the mechanical properties of pervious concrete constructed with natural and recycled aggregates. The substandard properties of recycled aggregates were improved by adding natural fibers from sackcloth. This study presents an experimental program on 45 samples of pervious concrete with air void ratios and the size of coarse aggregates as the parameters of interest. Experimental results in terms of compressive strength, permeability, and temperature variation were reported. The following important conclusions can be deduced.

1. The compressive strength decreased as the air void ratio increased, irrespective of the size of aggregates. Three sizes of aggregates were tested, namely small, medium, and large. The compressive strength of PPCC specimens with large-size aggregates was consistently lower than that of specimens with small-size aggregates. A better grading of aggregates was used in medium-size aggregates as compared to the uniform grading in small and large-size aggregates. As a result, the compressive strength of PPCC specimens with medium-size aggregates was the highest.

2. The type of aggregates did not influence the permeability of PPCC. For instance, the permeability of small-size aggregates with 10% designed air void ratios for natural, recycled, and recycled aggregates with sackcloth was 0.705 cm/s. It was found that the permeability increased with air void ratios in all aggregate types and sizes.

3. The temperature variation trend was identical in all aggregate types and sizes. The upper bound on temperature was created by large-size aggregates, whereas the temperature in small- and medium-sized aggregate PPCC could not be separated.

4. The maximum temperature of PPCC increased as the quantity of air void ratios increased. This trend was same in all specimen types, irrespective of the type and size of aggregates.

Author Contributions

Conceptualization, A.S., N.S., T.R., K.D. and P.J.; Methodology, A.S., N.S., T.R., K.D. and P.J.; Resources, T.R.; Writing–original draft, A.S., N.S., T.R. and K.D; Writing–review & editing, A.S., N.S. and K.D. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

Not applicable.

Acknowledgments

This research was successfully accomplished with the assistance of government officials’ officers of the Directorate of civil engineering, Royal Thai Air Force that has facilitated access to the sackcloth testing tool, including thanks to the Department of Civil Engineering, Nawaminthakasatriyathirat Air Force Academy for the funding and the location that includes the compression testing tool for cube concrete blocks. The researcher would like to thank everyone for this opportunity.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Poon, C.S.; Kou, S.C.; Lam, L. Use of Recycled Aggregates in Molded Concrete Bricks and Blocks. Constr. Build. Mater. 2002, 16, 281–289. [Google Scholar] [CrossRef]

- Tabsh, S.W.; Abdelfatah, A.S. Influence of Recycled Concrete Aggregates on Strength Properties of Concrete. Constr. Build. Mater. 2009, 23, 1163–1167. [Google Scholar] [CrossRef]

- Thomas, C.; Setién, J.; Polanco, J.A.; Alaejos, P.; Sánchez De Juan, M. Durability of Recycled Aggregate Concrete. Constr. Build. Mater. 2013, 40, 1054–1065. [Google Scholar] [CrossRef]

- Gao, C.; Huang, L.; Yan, L.; Kasal, B.; Li, W. Behavior of Glass and Carbon FRP Tube Encased Recycled Aggregate Concrete with Recycled Clay Brick Aggregate. Compos. Struct. 2016, 155, 245–254. [Google Scholar] [CrossRef]

- Nováková, I.; Mikulica, K. Properties of Concrete with Partial Replacement of Natural Aggregate by Recycled Concrete Aggregates from Precast Production. Procedia Eng. 2016, 151, 360–367. [Google Scholar] [CrossRef]

- Hamad, B.S.; Dawi, A.H. Sustainable Normal and High Strength Recycled Aggregate Concretes Using Crushed Tested Cylinders as Coarse Aggregates. Case Stud. Constr. Mater. 2017, 7, 228–239. [Google Scholar] [CrossRef]

- Reza, F.; Wilde, W.J.; Izevbekhai, B. Sustainability of Using Recycled Concrete Aggregates as Coarse Aggregate in Concrete Pavements. Transp. Res. Rec. J. Transp. Res. Board 2018, 2672, 99–108. [Google Scholar] [CrossRef]

- Ohemeng, E.A.; Ekolu, S.O. Comparative Analysis on Costs and Benefits of Producing Natural and Recycled Concrete Aggregates: A South African Case Study. Case Stud. Constr. Mater. 2020, 13, e00450. [Google Scholar] [CrossRef]

- Noguchi, T.; Kitagaki, R.; Tsujion, M. Minimizing Environmental Impact and Maximizing Performance in Concrete Recycling. Struct. Concr. 2011, 12, 36–46. [Google Scholar] [CrossRef]

- Zeybek, Ö.; Özkılıç, Y.O.; Karalar, M.; Çelik, A.İ.; Qaidi, S.; Ahmad, J.; Burduhos-Nergis, D.D.; Burduhos-Nergis, D.P. Influence of replacing cement with waste glass on mechanical properties of concrete. Materials 2022, 15, 7513. [Google Scholar] [CrossRef]

- Karalar, M.; Bilir, T.; Çavuşlu, M.; Özkiliç, Y.O.; Sabri, M.M.S. Use of recycled coal bottom ash in reinforced concrete beams as replacement for aggregate. Front. Mater. 2022, 9, 1064604. [Google Scholar] [CrossRef]

- Qaidi, S.; Najm, H.M.; Abed, S.M.; Özkılıç, Y.O.; Al Dughaishi, H.; Alosta, M.; Sabri, M.M.S.; Alkhatib, F.; Milad, A. Concrete containing waste glass as an environmentally friendly aggregate: A review on fresh and mechanical characteristics. Materials 2022, 15, 6222. [Google Scholar] [CrossRef]

- Çelik, A.İ.; Özkılıç, Y.O.; Zeybek, Ö.; Karalar, M.; Qaidi, S.; Ahmad, J.; Burduhos-Nergis, D.D.; Bejinariu, C. Mechanical Behavior of Crushed Waste Glass as Replacement of Aggregates. Materials 2022, 15, 8093. [Google Scholar] [CrossRef]

- Karalar, M.; Özkılıç, Y.O.; Aksoylu, C.; Sabri MM, S.; Alexey, N.B.; Sergey, A.S.; Evgenii, M.S. Flexural behavior of reinforced concrete beams using waste marble powder towards application of sustainable concrete. Front. Mater. 2022, 701. [Google Scholar] [CrossRef]

- Meng, T.; Zhang, J.; Wei, H.; Shen, J. Effect of Nano-Strengthening on the Properties and Microstructure of Recycled Concrete. Nanotechnol. Rev. 2020, 9, 79–92. [Google Scholar] [CrossRef]

- Lian, C.; Zhuge, Y.; Beecham, S. The Relationship between Porosity and Strength for Porous Concrete. Constr. Build. Mater. 2011, 25, 4294–4298. [Google Scholar] [CrossRef]

- Beecham, S. Water Sensitive Urban Design: A Technological Assessment. J. Stormwater Ind. Assoc. 2003, 17, 5–13. [Google Scholar]

- Aamer Rafique Bhutta, M.; Hasanah, N.; Farhayu, N.; Hussin, M.W.; Tahir, M.B.M.; Mirza, J. Properties of Porous Concrete from Waste Crushed Concrete (Recycled Aggregate). Constr. Build. Mater. 2013, 47, 1243–1248. [Google Scholar] [CrossRef]

- Li, X. Recycling and Reuse of Waste Concrete in China: Part I. Material Behaviour of Recycled Aggregate Concrete. Resour. Conserv. Recycl. 2008, 53, 36–44. [Google Scholar] [CrossRef]

- Etxeberria, M.; Vázquez, E.; Marí, A.; Barra, M. Influence of Amount of Recycled Coarse Aggregates and Production Process on Properties of Recycled Aggregate Concrete. Cem. Concr. Res. 2007, 37, 735–742. [Google Scholar] [CrossRef]

- Henry, M.; Pardo, G.; Nishimura, T.; Kato, Y. Balancing Durability and Environmental Impact in Concrete Combining Low-Grade Recycled Aggregates and Mineral Admixtures. Resour. Conserv. Recycl. 2011, 55, 1060–1069. [Google Scholar] [CrossRef]

- Courard, L.; Michel, F.; Delhez, P. Use of Concrete Road Recycled Aggregates for Roller Compacted Concrete. Constr. Build. Mater. 2010, 24, 390–395. [Google Scholar] [CrossRef]

- Leite, F.D.C.; Motta, R.D.S.; Vasconcelos, K.L.; Bernucci, L. Laboratory Evaluation of Recycled Construction and Demolition Waste for Pavements. Constr. Build. Mater. 2011, 25, 2972–2979. [Google Scholar] [CrossRef]

- Hassn, A.; Aboufoul, M.; Wu, Y.; Dawson, A.; Garcia, A. Effect of Air Voids Content on Thermal Properties of Asphalt Mixtures. Constr. Build. Mater. 2016, 115, 327–335. [Google Scholar] [CrossRef]

- Li, H.; Harvey, J.T.; Holland, T.J.; Kayhanian, M. The Use of Reflective and Permeable Pavements as a Potential Practice for Heat Island Mitigation and Stormwater Management. Environ. Res. Lett. 2013, 8, 015023. [Google Scholar] [CrossRef]

- Haselbach, L.; Boyer, M.; Kevern, J.T.; Schaefer, V.R. Cyclic Heat Island Impacts on Traditional versus Pervious Concrete Pavement Systems. Transp. Res. Rec. J. Transp. Res. Board 2011, 2240, 107–115. [Google Scholar] [CrossRef]

- Zhang, R.; Jiang, G.; Liang, J. The Albedo of Pervious Cement Concrete Linearly Decreases with Porosity. Adv. Mater. Sci. Eng. 2015, 2015, 746592. [Google Scholar] [CrossRef]

- Hu, L.; Li, Y.; Zou, X.; Du, S.; Liu, Z.; Huang, H. Temperature Characteristics of Porous Portland Cement Concrete during the Hot Summer Session. Adv. Mater. Sci. Eng. 2017, 2017, 2058034. [Google Scholar] [CrossRef]

- Benrazavi, R.S.; Binti Dola, K.; Ujang, N.; Sadat Benrazavi, N. Effect of Pavement Materials on Surface Temperatures in Tropical Environment. Sustain. Cities Soc. 2016, 22, 94–103. [Google Scholar] [CrossRef]

- Karalar, M.; Özkılıç, Y.O.; Deifalla, A.F.; Aksoylu, C.; Arslan, M.H.; Ahmad, M.; Sabri, M.M.S. Improvement in bending performance of reinforced concrete beams produced with waste lathe scraps. Sustainability 2022, 14, 12660. [Google Scholar] [CrossRef]

- Çelik A, İ.; Özkılıç, Y.O.; Zeybek, Ö.; Özdöner, N.; Tayeh, B.A. Performance assessment of fiber-reinforced concrete produced with waste lathe fibers. Sustainability 2022, 14, 11817. [Google Scholar] [CrossRef]

- Amin, M.N.; Khan, K.; Saleem, M.U.; Khurram, N.; Niazi MU, K. Influence of mechanically activated electric arc furnace slag on compressive strength of mortars incorporating curing moisture and temperature effects. Sustainability 2017, 9, 1178. [Google Scholar] [CrossRef]

- Zeybek, Ö.; Özkılıç, Y.O.; Çelik, A.İ.; Deifalla, A.F.; Ahmad, M.; Sabri Sabri, M.M. Performance evaluation of fiber-reinforced concrete produced with steel fibers extracted from waste tire. Front. Mater. 2022, 692. [Google Scholar] [CrossRef]

- Beskopylny, A.N.; Shcherban’, E.M.; Stel’makh, S.A.; Meskhi, B.; Shilov, A.A.; Varavka, V.; Evtushenko, A.; Özkılıç, Y.O.; Aksoylu, C.; Karalar, M. Composition Component Influence on Concrete Properties with the Additive of Rubber Tree Seed Shells. Appl. Sci. 2022, 12, 11744. [Google Scholar] [CrossRef]

- Shcherban’, E.M.; Stel’Makh, S.A.; Beskopylny, A.N.; Mailyan, L.R.; Meskhi, B.; Shilov, A.A.; Chernil’Nik, A.; Özkılıç, Y.O.; Aksoylu, C. Normal-Weight Concrete with Improved Stress–Strain Characteristics Reinforced with Dispersed Coconut Fibers. Appl. Sci. 2022, 12, 11734. [Google Scholar] [CrossRef]

- Khan, K.; Ahmad, W.; Amin, M.N.; Aslam, F.; Ahmad, A.; Al-Faiad, M.A. Comparison of Prediction Models Based on Machine Learning for the Compressive Strength Estimation of Recycled Aggregate Concrete. Materials 2022, 15, 3430. [Google Scholar] [CrossRef]

- Amin, M.N.; Iqtidar, A.; Khan, K.; Javed, M.F.; Shalabi, F.I.; Qadir, M.G. Comparison of machine learning approaches with traditional methods for predicting the compressive strength of rice husk ash concrete. Crystals 2021, 11, 779. [Google Scholar] [CrossRef]

- Sakib, N.; Bhasin, A.; Islam, M.K.; Khan, K.; Khan, M.I. A review of the evolution of technologies to use sulphur as a pavement construction material. Int. J. Pavement Eng. 2021, 22, 392–403. [Google Scholar] [CrossRef]

- ASTM C29/C29M-17a; Standard Test Method for Bulk Density (“Unit Weight”) and Voids in Aggregate. ASTM International: West Conshohocken, PA, USA, 2017.

- ASTM C136/C136M-19; Standard Test Method for Sieve Analysis of Fine and Coarse Aggregates. ASTM International: West Conshohocken, PA, USA, 2020.

- ASTM C131/C131M-20; Standard Test Method for Resistance to Degradation of Small-Size Coarse Aggregate by Abrasion and Impact in the Los Angeles Machine. ASTM International: West Conshohocken, PA, USA, 2020.

- ASTM ASTM C39/C39M-21; Standard Test Method for Compressive Strength of Cylindrical Concrete Specimens 1. ASTM International: West Conshohocken, PA, USA, 2018.

- Yu, F.; Sun, D.; Wang, J.; Hu, M. Influence of Aggregate Size on Compressive Strength of Pervious Concrete. Constr. Build. Mater. 2019, 209, 463–475. [Google Scholar] [CrossRef]

- Yang, J.; Jiang, G. Experimental Study on Properties of Pervious Concrete Pavement Materials. Cem. Concr. Res. 2003, 33, 381–386. [Google Scholar] [CrossRef]

- Bhutta, M.A.R.; Tsuruta, K.; Mirza, J. Evaluation of High-Performance Porous Concrete Properties. Constr. Build. Mater. 2012, 31, 67–73. [Google Scholar] [CrossRef]

- Huang, B.; Wu, H.; Shu, X.; Burdette, E.G. Laboratory Evaluation of Permeability and Strength of Polymer-Modified Pervious Concrete. Constr. Build. Mater. 2010, 24, 818–823. [Google Scholar] [CrossRef]

- Zhong, R.; Wille, K. Compression Response of Normal and High Strength Pervious Concrete. Constr. Build. Mater. 2016, 109, 177–187. [Google Scholar] [CrossRef]

- ASTM D5084-16a; Standard Test Methods for Measurement of Hydraulic Conductivity of Saturated Porous Materials Using a Flexible Wall Permeameter. ASTM International: West Conshohocken, PA, USA, 2016.

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).