Abstract

Ever-increasing traffic loads, in addition to hot climates, have always been a challenge for both road pavement authorities and engineers. Technically, asphalt binder and concrete modifiers that generally increase the viscosity and provide higher resistance to permanent deformation have been the optimal choice. In this paper, the asphalt layers of a motorway constructed in 2015 were studied. In this pavement, a plastomeric polymeric compound and synthetic-cellulose composite fibers containing plastomeric polymers were used in its binder course and surface course, respectively. The higher performance of the mixtures containing the plastomeric additives allowed a thinner pavement. This study addressed a quality assurance and monitoring plan spanning 7 years, consisting of core mechanical tests, including stiffness moduli and strength tests, in situ structural analysis by means of a falling weight deflectometer (FWD), surface profile characterization by means of IRI and SCRIM, and experts’ visual inspections. Overall, the test results complied with the specifications, and no distress or failure was recorded after 7 years of being under service. This could indicate that plastomers and the dry method can be considered as reliable alternatives for high quality asphalt pavement production.

1. Introduction

1.1. Pavement Challenges and Polymer Applications

Increases in global road freight transport, vehicle weights, tire pressures, and the frequency of extreme climatic events are deteriorating the road network at an anomalously fast rate, bringing it close to the end of its service life and requiring more frequent maintenance operations []. The challenge is exacerbated when these factors come together and road pavements in moderate to hot climates meet heavy traffic loads. As a solution, some improvements in asphalt binder properties have been achieved by selecting the proper base crude oil or tailoring the refinery processes applied to produce asphalt binder. However, there are only a few crudes used in the production of quality asphalt binders, and only a limited number of actions can be taken to control the refining process, and to thereby improve the characteristics of asphalt binders []. Consequently, polymers of different natures have played a key role in providing satisfying properties for the asphalt binders to comply with asphalt concrete specifications. Polymers used for asphalt binder/concrete modification are technically divided into two main groups, i.e., elastomers and plastomers, and the choice of the modifiers is dependent on the design engineering factors, including traffic loads and density, dominant ambient temperature, and the profile of the other pavement layers of the pavement’s structure.

1.2. Plastomer and Elastomer Properties

Elastomers, which provide excellent elastic properties, are suitable for pavements in low to moderate temperature climates and thin asphalt-bonded layers. Plastomers, by providing high strength and modulus, are well-suited for heavy traffic road pavements and those laid in moderate to hot climate regions [,,]. Within the literature, this has been shown by several parameters, either by the rheological properties of the plastomeric-modified bituminous binders or modified asphalt concretes using the additives directly in hot aggregates, i.e., the so-called dry method. However, naturally different plastics perform to different extents. Furthermore, knowledge on the low-temperature properties is still limited. The few available research works show that the addition of plastomers either to asphalt binder or directly to aggregates does not aggravate the low-temperature properties, or has an insignificant effect. This has been shown by means of the Fraass breaking point, low-temperature Semi-Circular Bending (SCB) test, etc. [,]. As expected, the plastomers have a limited effect on the elastic properties. Within the two main groups of asphalt binder/concrete modifiers, elastomers and plastomers, many different polymers have been used. Styrene Butadiene (SB) and Styrene Butadiene Styrene (SBS) block copolymers, which can increase the elasticity of the asphalt, much like a rubber band, and Styrene Butadiene Rubber (SBR) latex polymers, which increase the ductility of asphalt binder, are the most used elastomers.

The latter group has greater variety. Polyethylene (PE), Polypropylene (PP), Polyolefins, etc., either single or hybrid in combination with other polymers, are the most used polymers. Technically, due to the variety of plastomeric additives, it should be considered that not all plastomers are suitable for use for asphaltic targets or even provide the same performance in asphalt concretes []. Nevertheless, within the literature, enhanced strength, modulus, and resistance to permanent deformation have been reported, making plastomers, which are derived mostly from recycled wastes, a sustainable alternative for asphalt binder/concrete modification []. In addition to the performance properties of asphalt, polymers may change the adhesion properties and the level of affinity between aggregates and binder. In a study by Eskandarsefat et al., the effect of elastomers and plastomers on the stripping property of coated aggregates was investigated. Based on the results, the aggregates covered with plastomer-modified binder showed superior resistance to stripping [].

1.3. Polymer-Modified Asphalt (Wet and Dry Methods)

From another point of view, the differences between elastomers and plastomers not only relate to the genuine properties of each group, but also the method of use. Asphalt modification can be undertaken by applying either the wet method or the so-called dry method. During the wet method modification, the additive is added to the bituminous binder and the modified binder is primarily produced. By comparison, in the dry method, the additive is added to the hot aggregates before addition of the asphalt binder to the mix. The dry method has several advantages compared to the wet method. The most important may be due to less fuel consumption; as a result it may be more cost effective and is a green eco-friendly technique. The lower fuel consumption occurs due to the elimination of, first, the need to mix the polymer with asphalt binder, which reduces the process time by around 2 h, and, second, the maturation time, during which the polymer-modified asphalt binder is kept at high temperature for the phase inversion and final stabilization, which consumes a considerable amount of energy []. Although elastomers (mainly SBS) have been used mostly for the production of modified asphalt binders using the well-known wet method, plastomers have been used mostly via the dry method. This enables tackling the problem of poor stability, while also reducing the huge amount of energy consumed in the production of polymer-modified asphalt binders.

1.4. Polymers and Fibers in Asphalt Pavement Performance Standards

Regarding road pavement in situ performance characteristics, Stone Mastic Asphalt (SMA) and semi-dense-graded asphalt concrete are highly engineered but simple and effective solutions for paving durable, silent, and safe roads. Although SMA is an engineering choice in responses to permanent deformation and early-stage failures, semi-dense-graded asphalt concretes are an engineering solution for high-speed roadways in high precipitation climates. SMA concretes are characterized by the high quantity of asphalt binder and stabilizing fibers, which are used to control the binder draindown. The same stabilizing fibers are also suggested for the same target for open-graded and semi-dense-graded asphalt concretes. This is mostly due to the discontinuous grading of the aggregates’ blend. The literature shows that fibers having a different nature, either cellulose, mineral, or synthetic, depending on the type of asphalt concrete, may play other roles, i.e., improving some of its performance properties. In addition to the mentioned conventional types of fibers, recently modified fibers have been also introduced to the asphalt paving industry and shown promising results for asphalt modification, particularly for SMA mixes. Modifying fibers are generally used more than typical stabilizing fibers and, depending on the type, may contain different polymers in addition to one of the three mentioned base fibers. In a previous study, fibers containing plastomeric polymers were examined by comparing SMA mixes made of plastomeric fibers and neat asphalt binder with SMA mixes made of SBS polymer-modified asphalt binder. Based on the results, a comparable performance was recorded, which showed the plastomeric modified fibers to be a viable asphalt modification method [,]. In this research, the addition of plastomeric fibers increased the level of tenacity, stiffness, and Marshall stability [], while low-temperature properties tested by means of the Thermal Stress Restrained Specimen Test (TSRST) were similar []. This is in line with the few previously mentioned research works that studied the low-temperature properties of plastomeric polymer-modified asphalt concretes.

1.5. Objectives

The current study deals with the use of a plastomeric-modified fiber and a plastomeric compound for modification of the asphalt concrete of a project that also contained reclaimed asphalt. The asphalt concretes were the semi-dense-graded asphalt concrete surface and the dense-graded binder course of a heavy traffic motorway, and the additives were used via the dry method. This paper comprises two main sections. The first part discusses the pavement design, mix design, and details of the used materials. The second part of the paper presents results of some of the post-production and monitoring tests of the asphaltic courses during the construction and 6 years of monitoring. Accordingly, the main objective of this study was to provide practical and realistic knowledge about the performance of plastomeric-modified asphalt concretes under actual service conditions. The presence of two types of plastomeric additives in the asphalt courses of this pavement can provide better insights for road sector stakeholders on alternative technologies. In addition, this study highlights the validity of plastomeric polymer-containing fibers, which has not previously been widely presented. It is worth mentioning that the authors did not aim at comparing the technologies; therefore, no control section was constructed or studied. Indeed, given that the pavement has been subjected to the cycles of seasonal temperature variations and performed successfully, the information provided in this paper may show the viability of plastomers in asphalt modification. For this purpose, the test results were compared with the values indicated within the projects and local specifications. Furthermore, monitoring of the pavements was carried out to control the presence of thermal cracking, rutting, and, in particular, raveling, because the surface course was a semi-densegraded asphalt mixture. This distress can be commonly seen in traditional practices.

2. Project Profile

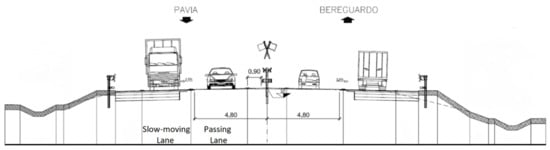

The motorway A53, shown in Figure 1, is located in the northeast of Italy and is a connection between the ring road of the city of Pavia and motorway A7 toward the city of Milan. Having a length of approximately 9.2 km, it also provides access between the city of Pavia and the town of Bereguardo. The project consisted of widening the single carriageway (in each direction) to obtain a double carriageway, shown in Figure 2. Naturally, for this target, the whole pavement structure was designed and constructed from a compacted foundation.

Figure 1.

The location of the A53 motorway in the south of the metropolitan city of Milan.

Figure 2.

The final cross section of the project.

3. Pavement Structure

The project involved a roadway widening, in which the existing pavement structure was composed of a 50 mm surface course, 35 mm binder course, 105 mm asphalt concrete base, and 300 mm of stabilized subbase. Considering the anticipated traffic loads and the properties of the asphalt concretes containing the plastomeric polymers, which were determined by prequalification tests, for the new section a pavement design was carried out following the Mechanistic-empirical Pavement Design Guide (MEPDG). During the pavement’s structural design, 20 years was considered for the service life of the pavement and 10 million passes for the heavy vehicles’ load. The temperature variation in the area was also considered. Based on the climate control statistics, there is a significant difference between the average monthly maximum and minimum temperatures of the location of this highway (Pavia area), which are 30 and −1 °C, respectively.

The pavement design was carried out twice. In the original design (first design with consideration of common materials and properties), the new lanes comprised a 200 mm stabilized course, a 200 mm cement-bound course, a 150 mm HMA base course, a 60 mm HMA binder course, and a 50 mm surface course. However, the second design was carried out after an extensive cost–benefit analysis, where an alternative pavement structure was designed, selected, and executed, replacing the asphalt pavement courses made of SBS PmB with plastomeric additives. Consequently, for the whole project, the new pavement structure allowed a saving of 35% asphalt mass and, accordingly, the environmental impacts were also reduced. The alternative plastomeric polymer solution was comprised of:

- A 300 mm subgrade course;

- A 300 mm polypropylene fiber-reinforced cement-mixed course, see Figure 3;

Figure 3. The installation of the base/binder course and its cross-section on polypropylene fiber-reinforced cement-mixed course. The scale coin is EUR 1; 23.25 mm.

Figure 3. The installation of the base/binder course and its cross-section on polypropylene fiber-reinforced cement-mixed course. The scale coin is EUR 1; 23.25 mm. - An 80 mm high-modulus dense-graded asphalt base binder course containing polymetric compound, anti-stripping agent, and rejuvenator due to the use of 30% reclaimed asphalt (RA);

- Finally, a 90 mm high-modulus semi-dense-graded bituminous surface course containing plastomeric polymer modified fiber, anti-stripping agent, and rejuvenator due to the use of 20% reclaimed asphalt (RA).

Naturally, the old sections were just resurfaced with the new designed surfaced layer.

4. Materials

4.1. Aggregates

The asphalt concretes executed in the project were of dense-graded base/binder course and semi-dense-graded surface course. Accordingly, the properties of the crushed calcareous rock coarse and fine aggregates and the limestone filler were tested, and the values were controlled with the technical specifications. For instance, the Los Angeles abrasion value of the coarse aggregates for the surface materials was 15.2, which complied with the maximum value of 20 in the project’s specification. The aggregates’ particle distributions of both courses, shown in Table 1, were selected from the technical specifications of the project, Raccordo autostradale Pavia-Breguardo, 2014 [].

Table 1.

Aggregates’ particle distributions of the surface and the base/binder course.

4.2. Asphalt Binder

The asphalt binder used in this study was a 50/70 penetration-graded bituminous binder. Table 2 summarizes some of the measured properties based on the European standard testing methods. Given reclaimed asphalt (RA) was also used in the asphaltic courses, in addition to the virgin binder, the RA’s aged binder was previously extracted and analyzed to be considered during the mix design.

Table 2.

Some of the physical properties of the used asphalt binder.

4.3. Additives

In this full-scale project, the two plastomeric asphalt concrete modifiers used, shown in Figure 4, were:

Figure 4.

The cellulose-synthetic fiber containing plastomeric polymers vs. plastomeric polymer compound. The scale coin is EUR 1; 23.25 mm.

- A plastomeric polymeric compound, used for the modification of the base/binder asphalt concrete via dry methods. It was dosed at 4% on mass of the asphalt binder.

- A cellulose–synthetic composite fiber containing plastomeric polymers, used for the modification and stabilization of the semi-dense-graded surface course via dry methods. It was dosed at 0.5% on mass of the aggregates. The polymer in the fiber was a plastomeric compound with 160–170 °C softening point.

Table 3 summarizes some of the physical properties and the aspects of the asphalt concrete modifiers used in this project.

Table 3.

Some of the properties of the additives.

5. Mix Design

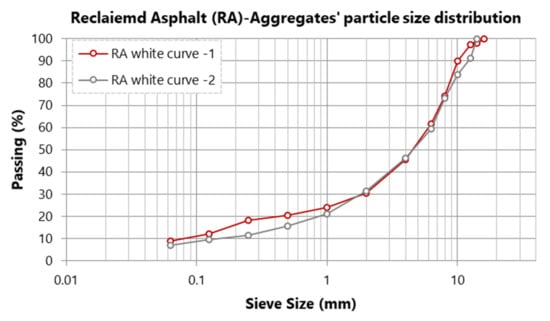

The mixtures were optimized by applying the Marshall method considering the technical specifications of the project, Raccordo autostradale Pavia-Breguardo, 2014 []. For this target, different contents of bituminous binders were tested to identify the optimum Marshall stability values and the corresponding volumetric parameters, which were 3 to 5%, using 75 Marshall blows and a gyration number of 120. Based on the conducted Marshall mix design and prequalification controls by means of additional tests, the optimum asphalt binder contents of 5.3% and 4.7% (on the weight of aggregates) were determined for the surface and base/binder course, respectively. Considering the use of 30% and 20% reclaimed asphalt in the base/binder course and the surface course, respectively, the aged binder was fully analyzed. For this target, the grading curve of the reclaimed asphalt after asphalt binder extraction (white curve) was determined and considered during the mix design and determination of the Job Mix Formulas (JMF). Additionally, the control of the RA grading curve was also continuously carried out to ensure the consistency of the produced mixtures. Figure 5 shows the controlled RA white curves during the mix design and one of the control RA samples during the construction.

Figure 5.

The grading curves of the RA samples after asphalt binder extraction (white curve) during the mix design and execution of the project.

In addition to the grading curve of the RA samples, the asphalt binder content of the RA was also determined and considered during the mix design. Based on the analysis, 4.8 ± 0.2% (by mass of the RA) of the aged asphalt binder content was determined for the RA sources of the project. However, eventually, 4.5% was considered for the mix design. This was due to the probable variation between the RA samples and the reusable amount of the aged binder. Naturally, considering the impacts of the aged asphalt binder within the reclaimed asphalt, 0.2% (on the mass of the reclaimed asphalt) rejuvenator was used during the mix design. Bearing in mind the quantities of the RA in the mixes, the dosage offered by the producer was used for this job and the efficiency was controlled via the performance properties of the asphalt concretes.

6. Post-Production Quality Controls

The quality of the materials during the production and laying was controlled by testing the materials collected from the job site. The testing plan mainly consisted of volumetric property control, indirect tensile strength at 25 °C, and Marshall stability and flow. For this purpose, the asphalt concrete was collected behind the finisher from different points of the job site during the material laying. The materials were then reheated and re-compacted in the laboratory to produce the test specimens. Table 4 and Table 5 summarize the obtained average values for the surface and the base/binder course. Based on the obtained values, the results complied with the values required by the project’s specifications.

Table 4.

The post-production laboratory quality control of the surface course.

Table 5.

The post-production laboratory quality control of the base/binder course.

7. Project Monitoring

Aiming at providing comprehensive knowledge on the long-term service performance of the plastomeric polymers used in the asphalt concretes of this job, the monitoring of the project was divided into four main sections as follows:

- In the first step, cores were taken from the surface and base/binder courses of both directions. Volumetric analysis, indirect tensile stiffness modulus, and indirect tensile strength tests were carried out, representing the mechanical properties of the installed pavements;

- The second step was dedicated to the pavement structural analysis by means of a falling weight deflectometer (FWD), where the elastic moduli of the pavement’s layers were investigated and compared with the data previously obtained from the cores and post-production controls;

- The International Roughness Index (IRI) was also measured and calculated representing the level of the evenness and ride quality;

- As a key factor not only for the safety of any roadway, but also as determinant of ride quality, the surface characteristics of the installed pavement were assessed by means of a Sideway-force Coefficient Routine Investigation Machine (SCRIM);

- Finally, as a common practice, the pavements were visually inspected by experienced pavement experts to detect any recognizable failure.

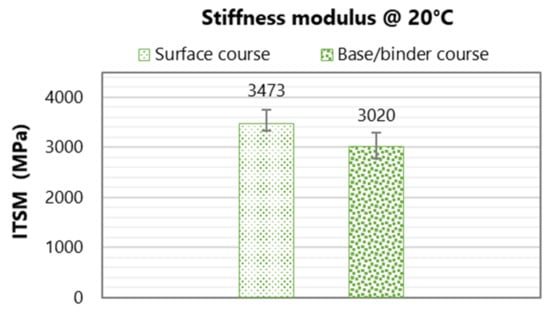

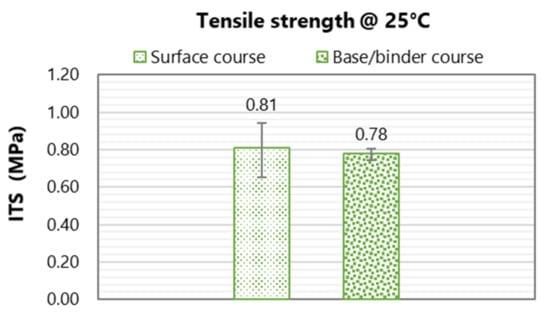

7.1. Cores’ Testing

As shown in Figure 6, the cores were taken 1 year following the opening of the road to traffic in February 2016. The cores were 100 mm in diameter and first subjected to the indirect tensile stiffness modulus (ITSM) test based on EN 12697-26 IT-CY at 20 °C, and then the indirect tensile strength (ITS) test based on EN 12697-23 at 25 °C. Figure 7 and Figure 8 show the obtained stiffness moduli and the tensile strengths, respectively. The moduli obtained from the cores were also compared with the FWD moduli, to ensure the validity of the results. However, considering the semi-dense-graded asphalt concrete and the in-situ air voids that are normally higher than the laboratory highly-compacted specimens (the N2 gyration number was 120), the obtained values complied with the project’s specifications. The average air void contents of the surface and base/binder course were 6–10%.

Figure 6.

Taking cores for the quality assurance and in-place mixtures properties.

Figure 7.

The indirect tensile modulus of cores after 1 year being in service.

Figure 8.

The indirect tensile strength of the cores after 1 year being in service.

7.2. Falling Weight Deflectometer (FWD)

A falling weight deflectometer is a testing device that is primarily used to estimate the pavement’s structural capacity. The load is produced by dropping a large weight onto a set of rubber buffers on a bracket connected to a circular load plate. A load cell mounted on top of the plate measures the imparted load. Deflection sensors (geophones) mounted in and radially from the center of the load plate measure the deformation of the pavement in response to the load []. Using the related analytical software, Elmod 6.1.75 (Dynatest), it is possible to determine the moduli of both the asphalt pavements’ courses and the subgrade soils.

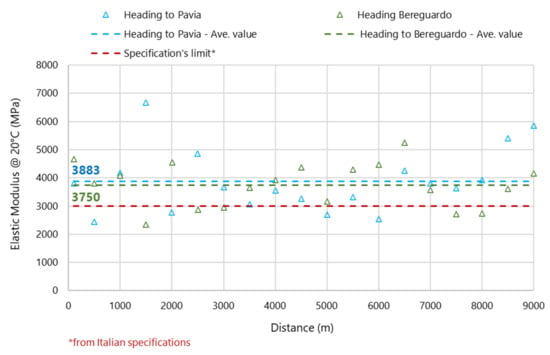

As part of the monitoring phase of the pavement, the FWD tests and analysis were carried out 2 years after the completion of the project. This time span allowed the occurrence of any early changes in the pavement. For this target, the FWD was set considering 500 m spacing along the low-speed carriageway, where the full pavement structure was built. During the test, the pavement temperature was 14 ± 2 °C and the configuration of the equipment used was as follows:

- Masses mounted: 700 kN

- Load plate: 300 mm

- Acquisition sequences: three beats per station point with contact pressures of about 1700 kPa

- Pulse duration: 25–30 ms

- Sensors: nine geophones in line at a distance

The load frequency (f) of FWD is typically defined using the cyclic definition of frequency (f = 1/t), where t (in ms) is the load duration []. However, several other interconversions, such as frequency (f = 1/2πt), have been also introduced and applied in the analysis []. Consequently, considering the applied loading duration of 25 to 30 ms in this job, the corresponding frequency would be either 40 to 33 Hz or 6.4 to 5.3 Hz. Figure 9 shows the back-calculated elastic moduli of the overall bituminous layers (surface + binder course) at the reference temperature of 20 °C. It can be seen that the calculated values for both directions are slightly higher compared to the cores’ moduli shown in Figure 7. This may be either due to the higher frequency of 6.4 to 5.3 Hz of the FWD analysis (6.4 to 5.3 Hz) compared to the laboratory tests, or to the different ages at the time of testing (the core’s stiffness was measured one year earlier). However, the obtained values complied with the considered specifications of the project, i.e., 3000 MPa.

Figure 9.

FWD E1 (asphalt layers) dynamic modulus after two years (2017) of installation of the pavement.

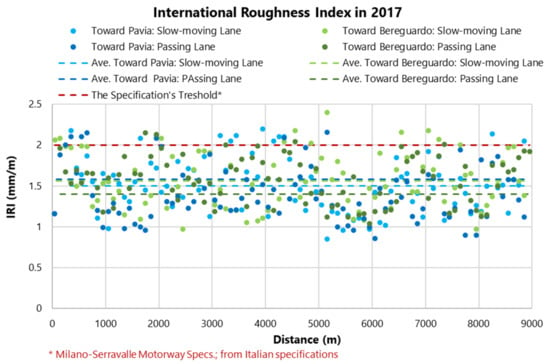

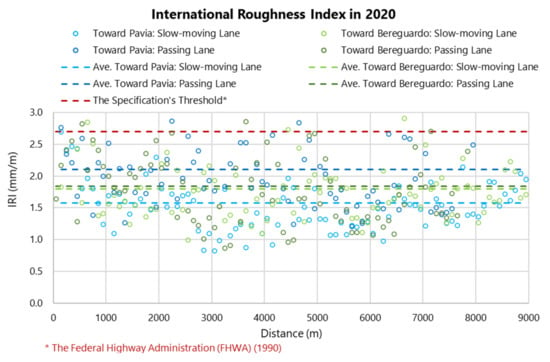

7.3. International Roughness Index (IRI)

Since its introduction in 1986, IRI has become the standard road roughness index and is commonly used worldwide for evaluating and managing road systems. IRI is the roughness index obtained from measured longitudinal road profiles. It is based on the adjusted average slope, which represents the ratio between the accumulated movement of a vehicle’s suspension standard and the distance travelled by the vehicle during the measurement. As one of the surface characteristics and functional properties of the installed pavements, the IRI values of all four lanes were determined after 2 and 5 years of the completion of the project. Figure 10 and Figure 11 represent the recorded IRI index values for the four lanes of this project compared with the specifications of the project, Milano Serravalle—Milano Tangenziali specifications []. Derived from the calculated results, the average values in 2017 were 1.50, 1.4, 1.58, and 1.57 mm/m, and in 2020 were 1.58, 1.8, 2.1, and 1.84 mm/m for the slow lanes and fast lanes, respectively. As expected, the IRI values increased due to the surface’s natural stripping changes; however, both plots show that the values perfectly comply with the specification’s threshold. Since there was no threshold for the pavement after 6 years in service, the FHWA threshold that is 2.7 mm/m was considered for the 2020 analysis [,]. 2014 the threshold of the Milano Serravalle specifications was 2.00 mm/m that was considered for the 2017 analysis.

Figure 10.

The International Roughness Index (IRI) after 2 years of pavement laying.

Figure 11.

The International Roughness Index (IRI) after 5 years of pavement laying.

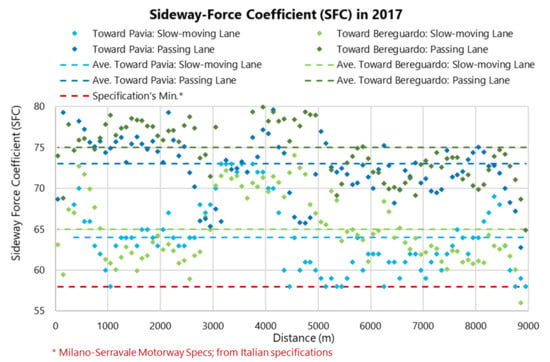

7.4. Sideway-Force Coefficient

The monitoring of the pavement’s skid resistance was performed with a Sideway-force Coefficient Routine Investigation Machine (SCRIM®) by applying the speed of about 60 km/h. SCRIM® is a machine originally developed by TRL Limited in the United Kingdom, in order to measure the wet skidding resistance of a road surface. The SCRIM® machine operates by applying a freely rotating fifth wheel, at an angle of 20° to the direction of travel, onto the road surface under a known load. A controlled jet of water wets the road surface directly in front of the test wheel. The vertical load and the sideway force generated by the frictional resistance to skidding of the test wheel are measured using transducers. Skid resistance measured using the SCRIM is expressed as the SCRIM coefficient, which is typically in the range of 20 to 65.

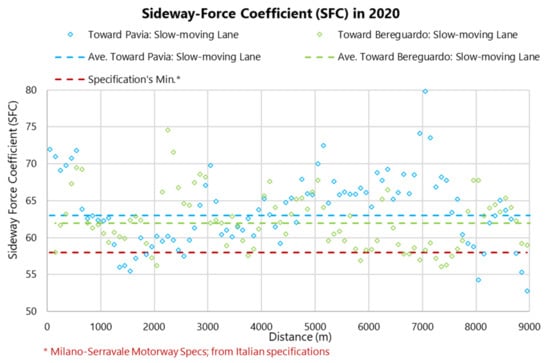

As mentioned earlier, the monitoring plan of the project also included the properties of the surface characteristics to investigate the impact of the used additives on the ride quality and safety parameters. In this context, the sideway-force coefficients (SFCs) of the installed pavements for the four lanes were determined at 2 and 5 years after the construction, in 2017 and 2020. Figure 12 and Figure 13 compare the recorded SFC values along the path to the project’s specification limit, which was 58. It can be seen from the IRI results that the SFC values fully complied with the required specification of the project. The SFC coefficients fulfilled the project’s specification at 3 and 5 years after the pavement’s installation and opening to traffic. Naturally, due to the polishing of the aggregates, the SFC values for the slow-moving lanes, 64 toward Pavia and 65 toward Bereguardo, decreased slightly to 63 and 62, respectively. Nonetheless, the values are far from the limits of the reference value of the Milano Serravalle specifications, which was 58, thus showing the pavement’s safe status.

Figure 12.

Sideway-force coefficient (SFC) in 2017.

Figure 13.

Sideway-force coefficient (SFC) in 2020.

7.5. Visual Inspections

As a fundamental and routine pavement management and maintenance practice, the installed pavements were periodically monitored by a minimum of two pavement experts to control the pavements’ condition and any visible failure. Based upon the last monitoring during the autumn of 2021, as shown in Figure 14, no pavement distress or failure was observed and the semi-dense-graded surface, which provides control of precipitation and noise, was in perfect condition.

Figure 14.

Pavement condition during the annual visual inspections on autumn 2021.The scale coin is EUR 1; 23.25 mm.

In addition to the visual inspections, the rut depth was also investigated. The measurement of the rut depth is best carried out using a standard straight edge and a calibrated wedge. Based on its general use and its ease of handling and transportation, a 2 m straight wedge is the most practical choice. During the last controls in autumn 2021, as shown in Figure 15, despite the heavy-traffic loads of this motorway, no rutting was observed nearly 6 years after the pavements’ installation and its complete opening to traffic. This was expected as the plastomeric polymers used in both surface and base/binder courses can increase the stiffness and strength properties and, consequently, the pavement’s resistance to permanent deformation. From another point of view, this shows the precision of the pavement design and the lack of excessive addition of the rejuvenator.

Figure 15.

Rutting control of the pavement wheel paths. Autumn 2021.

8. Conclusions

This study investigated the feasibility and performance of two types of plastomeric modifiers for asphalt concretes. The modifiers used in the discussed project were chosen due to several reasons, including increasing the service life of the asphalt pavement, reducing the environmental impacts, and optimizing the project costs. In fact, the mentioned items were all assessed during the pavement design and cost–benefit analysis of the project. These plastomeric modifiers were (I) a cellulose and synthetic fiber containing plastomeric polymers, which was used in a semi-dense-graded surface course; (II) a plastomeric polymeric compound, which was used to produce a dense-graded asphalt for the base/binder course of the presented project. The additives introduced in this paper were used via the dry method, which not only results in fewer environmental impacts, but also in a more sustainable asphalt concrete modification practice. In addition, the study of polymeric fibers added to the surface course can highlight the potential additional functions of stabilizing fibers. This study focused on the mixed design, post-production, monitoring lab controls, and in-situ investigations, which all showed the efficiency of plastomers in asphalt concrete modifications.

Based on the results of the laboratory tests on the collected samples from the job site, and on the core and in situ surface characterizations, all of the pavement’s properties complied with the quality control and assurance specifications and requirements. In addition, during the periodic inspections by pavement experts during the 7-year period, no distress or failure was observed at the date of writing this paper (fall 2021), indicating plastomers are a promising solution for durable and resistant asphalt concretes. In line with the literature, regardless of the type of mixture, which was an SDA with high air voids, due to its high strength, the pavement was resistant under the heady-duty traffic loads of this motorway. Regarding the mechanical characteristics of the laid asphalt concretes, the correlation between the test results of the cores and the results obtained from the FWD analysis not only showed the consistency and homogeneity of the laid materials via the dry method, but also the validity of the results of the tests.

In addition to the pavements’ mechanical and performance properties, considering that the plastomeric additives were added by applying the dry method, huge environmental benefits were achieved. This was due to the substitution of SBS PmB (wet process), which not only eliminated the huge carbon footprint during the production of the additive, but also during the transportation and reservation of the PmB. The huge CO2 eq. of SBS PmB has been shown in the latest extensive report of Asphalt Institute [].

It is also worth mentioning that the right choice of rejuvenator also played a key role in this success, where no crack of any kind was seen after 7 years.

Finally, from another point of view, a total re-think of the design of the 9 km long A53 motorway not only led to a more durable pavement structure, but also saved a significant amount of material. In addition, the project was concluded 130 days before the originally scheduled date.

Author Contributions

Conceptualization, L.V., S.E. and, A.C.; methodology, E.S. and I.O.; validation, A.C., I.O. and E.S.; formal analysis, S.E.; investigation, L.V.; data curation, S.E.; writing—original draft preparation, S.E.; writing—review and editing, all contributors.; visualization, S.E.; supervision, L.V.; All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding

Institutional Review Board Statement

Not applicable

Informed Consent Statement

Not applicable

Data Availability Statement

The data used to support the findings of this study are available from the corresponding author upon request.

Acknowledgments

The authors would like to thank Milano Serravalle—Milano Tangenziali S.p.A, Itinera S.p.A, Sina S.p.A, and the laboratory colleagues of Iterchimica S.p.A, for their great contributions to this job.

Conflicts of Interest

The authors declare no conflict of interest.

References

- High-Performance Pavements for Vehicles with Enhanced Road Requirements; EAPA Technical Briefing; European Asphalt Pavement Association: Brussels, Belgium, 2021.

- Becker, Y.; Méndez, M.P.; Rodrìguez, Y. Polymer Modified Asphalt. Vision Tecnol. 2001, 9, 39–50. [Google Scholar]

- Pavement Technology Advisory—Polymer-Modified Hot Mix Asphalt—PTA-D5. Illinois Department of Transportation. 2005. Available online: https://idot.illinois.gov/Assets/uploads/files/Transportation-System/Research/Pavement-Technology-Advisories/Design-Construction-and-Materials-SeriesNew-Folder/PTAD5.pdf (accessed on 21 February 2021).

- Movilla-Quesada, D.; Raposeiras, A.; Silva-Klein, L.; Lastra-González, P.; Castro-Fresno, D. Use of plastic scrap in asphalt mixtures added by dry method as a partial substitute for bitumen. Waste Manag. 2019, 87, 751–760. [Google Scholar] [CrossRef] [PubMed]

- Brasileiro, L.; Navarro, F.M.M.; Tauste-Martínez, R.; De Matos, J.M.; Rubio-Gamez, M.C. Reclaimed Polymers as Asphalt Binder Modifiers for More Sustainable Roads: A Review. Sustainability 2019, 11, 646. [Google Scholar] [CrossRef]

- White, G. Evaluating recycled waste plastic modification and extension of bituminous binder for asphalt. In Proceedings of the 18th Annual International Conference on Pavement Engineering, Asphalt Technology and Infrastructure, Liverpool, UK, 27–28 February 2019. [Google Scholar]

- Lecomte, M.; Hacker, S.; Teymourpour, P.; Bahia, B. Use of plastomeric additives to improve mechanical performance of warm mix asphalt. In Proceedings of the 6th Eurasphalt & Eurobitume Congress, E&E Congress 2016, Prague, Czech Republic, 1–3 June 2016. [Google Scholar] [CrossRef][Green Version]

- Chin, C.; Damen, P. Viability of Using Recycled Plastics in Asphalt and Sprayed Sealing Applications; Austroads Technical Report AP-T351-19; Austroads Ltd: Sydney, NSW, Australia, 2019. [Google Scholar]

- Yin, F.; Moraes, R.; Anand, A. Recycled Plastics in Asphalt Part B: Literature Review; NAPA-IS-142 National Asphalt Pavement Association: Greenbelt, MD, USA, 2020. [Google Scholar]

- Eskandarsefat, S.; Dondi, G.; Sangiorgi, C. Recycled and rubberized SMA modified mixtures: A comparison between polymer modified bitumen and modified fibres. Constr. Build. Mater. 2019, 202, 681–691. [Google Scholar] [CrossRef]

- Venturini, L.; Eskandarsefat, S. High performance PMA: Ffrom polymeric compounds to graphene-based super modifier. In Proceedings of the 26th World Road Congress, Abu Dhabi, United Arab Emirates, 6–10 October 2019. [Google Scholar]

- Eskandarsefat, S.; Hofko, B.; Sangiorgi, C. A comparison study on low-temperature properties of Stone Mastic Asphalts modified with PmBs or modified fibres. Int. J. Pavement Eng. 2018, 21, 1541–1549. [Google Scholar] [CrossRef]

- Raccordo Autostradale Pavia—Bereguardo, Sostituzione Barriere di Sicurezza in Spartitraffico, Specifiche Tecniche Integrative; Itinera S.p.A.: Milan, Italy, 2014.

- FWD Brochure Metric, 8000 Falling Weight Deflectometer (FWD). Available online: https://www.dynatest.com/falling-weight-deflectometer-fwd (accessed on 30 July 2021).

- Dressler Bech, N. Use of Falling Weight Deflectometer Testing in the Pavement me ac/ac Overlay Design Procedure. Master’s Thesis, University of Pittsburgh, Pittsburgh, PA, USA, 2015. [Google Scholar]

- Sullivan, B.; Rickards, I.; Yousefdoost, S. Interconversion of laboratory measured modulus results to field modulus and strain. In Proceedings of the AAPA International Flexible Pavements Conference, Brisbane, Australia, 22–25 September 2013. [Google Scholar]

- Giuseppe, C. Capitolato Speciale D’apalto, Specifiche Tecniche, Auto Strada A50, Tangenziali Ovest di Milano e Pertinenze; Ministero delle Infrastrutture e dei Trasporti.: Milan, Italy, 2016. [Google Scholar]

- Highway Performance Monitoring System, Field Manual, Appendix J; FHWA Publication 5600 1A; U.S. Department of Transportation: Washington, DC, USA, 1990.

- Arhin, S.A.; Noel, E.C.; Ribbiso, A. Acceptable International Roughness Index Thresholds based on Present Serviceability Rating. J. Civ. Eng. Res. 2015, 5, 90–96. [Google Scholar] [CrossRef]

- Thinkstep, A.G. Life Cycle Assessment of Asphalt Binder, Report Version v2.1; Asphalt Institute: Lexington, KY, USA, 2019. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).