Abstract

Admixtures are an integral part of modern cementitious materials, as they significantly enhance the rheological, mechanical, and durability properties of the material. Though manufactured admixtures are mainly used in concrete production, they are expensive. Therefore, this research investigated the effect of sugarcane juice (SCJ), as a natural admixture, on the properties of concrete. Various percentages of SCJs were used to investigate the initial and final setting time, workability, compressive strength, and splitting tensile strength of concrete. Furthermore, the effect of different cement-sand ratios (c/s) and water-cement ratios (w/c) on the setting time of different cement mortar mixes was studied. Experimental results have shown that the setting time measured by the Vicat’s apparatus reduces significantly, up to a certain percentage of SCJ in the mortar mixes. Setting time is also reduced as the c/s and w/c ratios are reduced in the mortar mix. From the results, it was found that, based on the c/s ratio, with the addition of 20% SCJ in the mix, the initial setting time of mortar can be reduced to 10% from 79%. In the case of mechanical strength, compared to the control mix (0% SCJ), more than 29% higher compressive strength in concrete was achieved by adding 10% SCJ to the mix. For the splitting strength, this increment was more than 4%. The ANOVA analysis also proved that the higher percentages of SCJ produced a compressive strength that was not statistically different from the control concrete mix. Finally, the research outcome showed that the dosages of SCJ can greatly alter the setting time and mechanical strength of cementitious materials.

1. Introduction

It is common knowledge in the construction industry that concrete is the most used material on earth besides water. Concrete is a composite material typically produced from cement/binder, coarse aggregate, fine aggregate, water, and admixtures. The proportion of the constituent materials influences the fresh and hardened states and durability properties of concrete. Nowadays, a typical concrete mix design would, of necessity, include chemical and mineral admixtures for sustainability and eco-friendliness. Though chemical admixtures are relatively small in volume compared to other concrete constituents, they influence the concrete’s properties, such as setting time (initial and final), consistency, rheology, strength, and durability. Chemical admixtures are chemical substances that improve the quality of cement and concrete, thereby reducing construction costs [1,2]. Based on their functions in concrete, they can be water reducers, high-range water-reducers (superplasticizers), retardants, accelerators, viscous modifying agents, air entraining agents, shrinkage reducing admixtures, and waterproofers, among others [3].

In temperate climates, concreting can be challenging. Hence, retarders are used to slow down the setting time of cement-based materials. Sugar is one retarder whose use in concrete has been discouraged since it is viewed as a “concrete destroyer”, and adding 1% (wt. of cement) to Portland cement paste would cause an endless delay in the hardening process [4]. Khan & Baradan [4] asserted that retardation of cement set was recorded for various cement types and curing regimes investigated in their study. However, the increase in setting time was limited to a sugar content of 0.15%, though retardation occurred at up to 0.25% sugar content. Beyond this limit, the cement set was accelerated at 0.3–0.8% sugar content. Similarly, with admixture contents (sugar) of 0.125%, 0.25%, 0.375 and 0.5%, Khan & Ullah [5] reported that under each of the three curing regimes investigated, the addition of the retarding admixture led each of the three-cement types studied to experience significant retardation, which reduced the rate of hydration and the strength development. In a study by Al Khafaji & Ruddock [6], the effect of four types of sugar (granular, caster, brown and Beet Syrup) on the setting times of cement paste was investigated. Sugar contents investigated, as a percent of cement weight, were 0%, 0.5%, 1.5%, 2.5% and 5%. The initial setting times were reduced for all sugar types, while the final setting times increased to 1.5% sugar content. Cement paste mixes with 2.5% and 5% sugar content showed reduced initial and final setting times, except for samples prepared with 5% Beet Syrup, which showed reduced initial setting time but increased final setting time compared to the control.

More recently, Ahmad et al. [7] reported on the effect of sugarcane juice (SCJ) dosages on the setting time and compressive strength of pastes and mortars produced from Types I and V Portland cements. The sugar was limited to 0.25% by the weight of the cement. The result of their study indicated that both initial and final setting times significantly increased at 0.05% sugar content but thereafter decreased for both cement types. It was concluded that wider cracks are generated in the microstructure at higher dosages, which may lead to lower mechanical strength in the concrete. Other studies have reported similar performances [8,9]. The retarding action of sugar may be primarily brought on by the organic admixtures’ adsorption onto the calcium hydroxide nucleus, which delays the hydration of tricalcium silicate by poisoning their growth [4,10]. Furthermore, another study reported that materials with lignosulfonic acids and their salts, hydroxyl-carboxylic acids and their salts, sucrose and its derivatives, and inorganic salts such as borates, phosphates, zinc, and lead salts are the key components of retarding admixtures [11].

To accelerate cementitious materials, it is necessary to increase the hydration rate of C3S, which leads to the formation of calcium silicate hydrates (C-S-H) gel in the matrix. However, research has also indicated that the increased hydration rate of C3S can have an adverse effect on the strength and durability of cementitious materials [12]. Therefore, a proper accelerating agent with an appropriate amount should be used in concrete. The hydration of cementitious materials can also be influenced by residues such as supplementary cement, aggregates, or chemical admixtures. Some residues can obstruct the crystalline transformation of C-S-H, which may ultimately reduce the strength and durability of cementitious materials [13]. A study by Liu et al. [14] investigated the effect of alkaline accelerators (the main component of sodium meta-aluminate) and non-alkaline, i.e., alkaline-free type accelerators (the main component of aluminum sulfate) on the hydration and microstructural properties of cementitious composites. It was found that, for both accelerators, the hydrated mineral and gypsum were rapidly consumed, forming ettringite crystal, thus reducing the setting time and increasing the early-age strength of cementitious materials [14]. Other scholars have reached a similar conclusion [15]. The presence of fluoride ions (F−) in different accelerator agents may dissolve C3S and accelerate the C3A. Thus, a lower setting time and increased early strength of cementitious materials can be achieved [15]. However, very limited research is available where the hydration and microstructural analysis of cementitious materials were investigated with higher dosages of SCJ [7].

Some studies have reported the effects of sugar as an admixture on the strength performance of cement-based materials. Since the cement-based materials’ set is delayed by sugar, the strength development is also delayed. For example, as sugar content increases up to 0.25%, cement paste and mortar compressive strength decreases relative to the control for up to 28 days [7]. However, at a low sugar content (0.05%), Usman et al. [16] reported a minimal concrete compressive strength gain (3.23%) at 28 days compared to the control. Above this sugar content, the compressive strength of the concrete decreased.

Chemical admixtures are expensive and may not be commonly available in some regions of the world. Hence, one alternative would be investigating the use of natural admixtures, which are cost-effective and eco-friendly. In light of this, a number of researchers have examined a variety of natural admixtures as replacements for conventional ones to modify or control the cement-based material’s behavior [17,18,19]. A recent study by Mahmood et al. [17] investigated the influence of two natural admixtures (grape and mulberry extracts) and poly-carboxylate-ether-based chemical admixtures on the fresh and hardened states properties of concrete. The results of the study showed that both initial and final setting times and workability were significantly reduced compared to the chemical admixture and the control samples; slightly lower water absorption with the natural admixtures was recorded compared to the chemical admixtures and control samples; 28-day compressive strength increased by between 5%–6.8% and 21%–23% over the chemical admixtures and control samples, respectively. However, the natural admixture samples’ split tensile strength and elastic modulus decreased compared to the chemical admixture samples but were higher than the control. These admixtures were used at a low content, a maximum of 0.35% by the weight of the cement. Bio-based admixtures derived from the Dracaena Arborea and Carica papaya were also used as retarding agents in concrete [20]. It was found that as the percentages of these bio-based admixture content increased in the mixes from 0% to 4%, the setting time of concrete reduced significantly.

Another natural admixture that has been used in lieu of chemical admixture is SCJ. Unlike the low content (typically less than 1%) of sugar admixture reported by other studies, Otunyo & Koate [21] replaced water with SCJ up to 15%. Their study reported a decrease in the workability of concrete as the content of SCJ increased, while the setting times increased as SCJ content increased. The 28-day compressive strength decreased from 32 MPa to 5 MPa at SCJ contents by up to 10%. However, at 15% SCJ content, it increased to 18 MPa.

Knowing the setting time for cement-based materials is very important as materials need to be transported from the mixing plant to the construction workplace. This aspect is also important for construction in hot and cold weather. In hot weather, newly mixed fresh concrete requires sufficient time after mixing to be transported and poured in place. Generally, a retarder is used to delay the setting time of concrete. On the other hand, in cold weather, fresh concrete needs to set fast, and therefore an accelerating agent is required.

Generally, it is presumed that the admixtures collected naturally from agricultural waste or renewable sources without much modification require less energy and emit less CO2 to the environment than chemical admixtures that embody high carbon. A study conducted by Maraveas [22] concluded that a novel method of replacing synthetic polymer with a bio-based polymer derived from agricultural waste could save a significant amount of CO2 emissions as well as lower ecological impact. Recent research investigated the effect of natural pigments and synthetic pigments on the environment. It was found that bio-based natural pigments can have more than 94% less impact on the environment through their life cycle compared to synthetic pigments [23]. Nevertheless, bio-based minerals or admixtures are less remarkable than chemical admixtures [24]. Therefore, the user must scrutinize the possible effect of bio-based materials on cementitious materials. Nevertheless, many researchers have already investigated the feasibility of using different bio-based residues in developing different types of mortars [25,26]. It was concluded that the properties of mortar could be improved if the proper amount and residue types could be used.

In this study, a comprehensive investigation of the effects of SCJ on the setting times and mechanical strength of cementitious materials is reported. As the mechanism is not well-investigated in the literature, various percentages of SCJ (up to 20%), and various mix design parameters, such as water/cement ratios and cement/sand ratios, are reported. As a result, natural admixtures in cement-based materials will have the combined benefits of being less expensive and eco-friendly.

2. Materials and Methods

2.1. Initial and Final Setting Time of Mortar Mixes

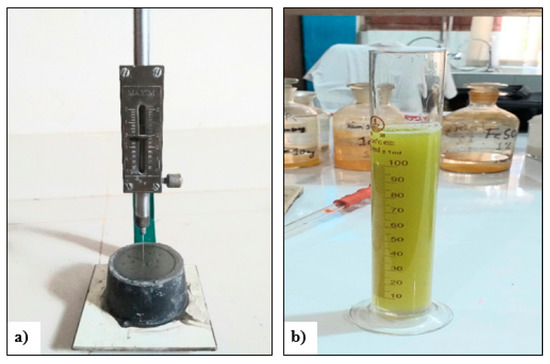

To investigate the initial setting time of cement mortar with sugarcane juice (SCJ), three different cement-to-sand ratios (c/s), water-to-cement ratios (w/c), and a minimum of four to a maximum of eight different percentages of SCJ by weight of water were used. A control mix (i.e., without SCJ) was also fabricated for comparison purposes. The details of the mix compositions for the setting times of mortar mixtures are shown in Table 1. Vicat’s apparatus was used to determine cement mortars’ initial and final setting times. A total of 55 mixes for different SCJ content, c/s, and w/c were tested to determine the setting times according to the ASTM C191-21 [27]. Figure 1 shows the measurement of the setting time using Vicat’s apparatus and SCJ. Penetration readings were collected from several points, as shown in Figure 1a. A maximum of 300 gm of materials (mix of cement and sand), as per the mix design shown in Table 1, was used for each test. All tests were performed at ambient temperature in the concrete laboratory. It is worth mentioning that the SCJ was collected before every mixing by manually crushing the raw sugarcane and then filtering the juice to remove any solid impurities, as shown in Figure 1b. No further treatment was applied to the SCJ. During mixing, raw SCJ was added with water for uniformity in the mix. It is worth mentioning that before SCJ was added, the same amount of water was removed to maintain the correct w/c in the mix. The typical chemical composition of SCJ in Bangladesh is sucrose content of 75%–80%, reduced sugar of 6.5–6.8%, pH of 5.2–6.2, fiber of 15.5–16.8%, and purity of 88.28 [28]. CEM II/A-M cement was used as the main binder, and the typical chemical composition such as CaO, SiO2, Fe2O3, Al2O3, and MgO were about 53.43%, 24.9%, 3.96%, 7.52%, and 2.52%, respectively [29].

Table 1.

Mix compositions of cement mortars to determine the initial setting time.

Figure 1.

Testing setting times of cement mortar using (a) Vicat’s apparatus and (b) sugarcane juice.

2.2. Fresh and Hardened Properties of Concrete

A concrete mix design was also prepared to determine the workability, compressive strength, and splitting tensile strength of concrete with different percentages of SCJ. Table 2 shows the mix composition for the different concrete mixes. The w/c ratio was chosen based on trial mixes with a targeted slump of 80 to 100 mm for all mixes. SCJ and plasticizer were used as water and total concrete mix volume percentages. The total weight of both SCJ and plasticizer from each mix was subtracted from the water weight. Right after mixing, the workability of fresh concrete was checked using a slump cone, also known as an Abrams cone [30]. For mechanical properties, a total of 136 cylindrical samples with a dimension of 100 mm diameter and 200 mm length were prepared to investigate the compressive (ASTM C39) [31] and splitting tensile (ASTM C496) [32] strength of concrete. All the samples were de-molded after 24 hr of mixing and then cured in water at 23 ± 2 °C temperature until the mechanical testing. The compressive strength of concrete samples was determined at 7, 14, and 28 days, and the splitting tensile test was performed at 14 and 28 days only. In all cases, a minimum of four samples were tested, and their average value was reported in the results and discussion section. Finally, investigating the significance of the SCJ dosages in the mechanical strength of the concrete was also examined by statistical analysis, that is, the analysis of variance (ANOVA) at a 95% confidence level.

Table 2.

Mix compositions (kg/m3) of different concrete mixes to determine the workability and mechanical strength.

3. Results and Discussion

3.1. Effect of Sugarcane Juice on Setting Time of Cement Paste

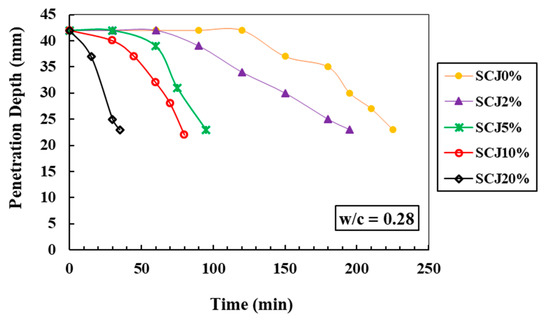

The effect of different percentages of SCJ on the penetration depth of cement paste is shown in Figure 2. In this section, the w/c of 0.28 has been chosen to discuss the effect. As shown in Figure 2, it is obvious that the addition of SCJ can significantly reduce the penetration depth (i.e., setting time) of the cement pastes, and it is more pronounced for the higher percentages of SCJ in the mix. For instance, compared with the control cement paste (0% SCJ), the initial setting time of cement paste is reduced to 33%, 57%, 70%, and 90%, for SCJ content of 2%, 5%, 10%, and 20%, respectively. These outcomes reveal that incorporating SCJ in cement paste works as an accelerator, and this result agrees with the outcome reported in [7]. The authors [7] stated that the setting time of cement pastes increased up to the addition of 0.05% SCJ by weight of cement; after that, a decrease in setting time was observed for the mix containing 0.25% SCJ. It is noteworthy that the present study deals with a higher amount of SCJ than reported in the literature [7,21]. The significant decrease in setting time (i.e., decrease in penetration depths with time) could be due to the acceleration of the hydration process of cement (i.e., it starts losing its plasticity rapidly) and gains adequate strength. Hence, reducing the penetration depth of the Vicat’s apparatus needle in the cement paste compared to the control cement paste.

Figure 2.

Effect of different percentages of SCJ on the penetration depth of cement paste made with w/c of 0.28.

3.2. Effect of Cement to Sand (c/s) and Water to Cement (w/c) Ratio in Setting Time of Mortar

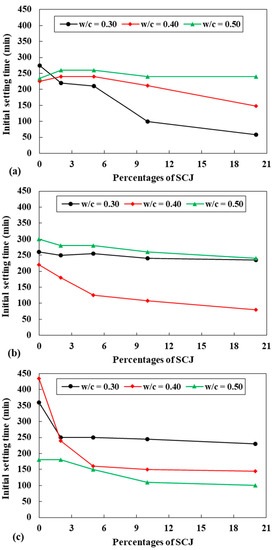

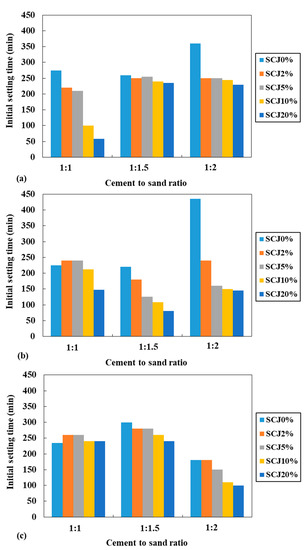

Figure 3 shows the effect of different c/s and w/c ratios on the initial setting time of a cement mortar with varying percentages of SCJ. As in Figure 2, the reduction of the setting time of mortar is also evident here for the increased amount of SCJ content in the three different c/s ratios and the same amount of w/c ratios, i.e., a total of nine different mixes investigated in this study. In the first batch of mortar mixes with a c/s ratio of 1:1, w/c ratio of 0.30, and at SCJ content of 2%, 5%, 10%, and 20%, the initial time of the mixes is reduced to 20%, 23%, 64%, and 79%, respectively, compared to control mix. At the same SCJ content and c/s ratio but w/c of 0.40 and 0.50, these differences range between −7% to +34% and −2% to −11%, respectively. Secondly, the mortar mixes with a c/s ratio of 1:1.5, w/c ratio of 0.30, and at the same SCJ content, the reduction of the initial time of different mixes is 4%, 2%, 8%, and 10%, respectively, in comparison to the control mix. At the same SCJ content and c/s ratio but w/c of 0.40 and 0.50, these differences range between 18% to 64% and 7% to 20%. Lastly, at a c/s ratio of 1:2, in comparison to the control mix, the differences in the initial setting time in different SCJ mixed mortar mixes were 31% to 37% for w/c of 0.30, 45% to 67% for w/c of 0.40, and 17% to 44% for w/c of 0.50. From the above results, it is apparent that the setting time is influenced by the SCJ content and the w/c and c/s ratios of the mortar mixes, which are summarized in Figure 4. The maximum reduction (79%) in the initial setting time is found for SCJ content of 20% at a w/c ratio of 0.30 and c/s ratio of 1:1. At the same SCJ content, this reduction is 10% and 37% for c/s ratios of 1:1.5 and 1:2, respectively. For a w/c ratio of 0.40, the highest reduction of 67% is observed at 20% SCJ content at a c/s ratio of 1:2. And for a w/c ratio of 0.50, the maximum reduction of 44% is found at 20% SCJ content at c/s ratio of 1:2.

Figure 3.

Effect of percentages of SCJ to initial setting time of mortar at c/s ratios of (a) 1:1, (b) 1:1.5, and (c) 1:2.

Figure 4.

Relationship between the initial setting time and c/s ratio of different percentages of SCJ for different w/c ratios of (a) 0.30, (b) 0.40, and (c) 0.50.

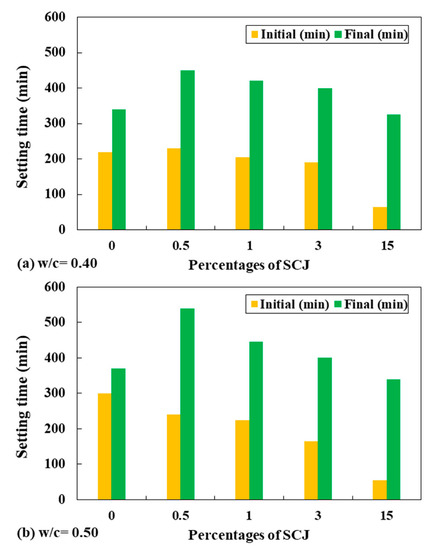

Figure 5 compares the initial and final setting times of cement mortar at different w/c ratios but only for a c/s ratio of 1:1.5. In this regard, the SCJ content ranges from 0.50% to 15%. From the results, it can be seen that, at lower dosages, SCJ in mortar acts as a retarding agent. However, at higher dosages, SCJ acts as an accelerating agent in cementitious materials. Some researchers have also reported this phenomenon in their studies [7,16].

Figure 5.

Comparison of initial and final setting time of mortar at different percentages of SCJ at c/s ratios of 1:1.5 and at (a) w/c = 0.40 and (b) w/c = 0.50.

The significantly lower setting time of cement paste made with 20% SCJ and w/c ratio of 0.30, and c/s ratio of 1:1 could be due to the reduced gap within the cement particles, i.e., hydration started at their surface with less distance, thus ensuring a robust bond [12]. In addition, the presence of higher content of SCJ in the mix may accelerate the overall hydration process of cement, which promotes the early hardening of the cement paste development. These combined actions may shorten the cement paste’s setting time by preventing Vicat’s apparatus needle penetration in the specimen (i.e., providing lower final penetration depth).

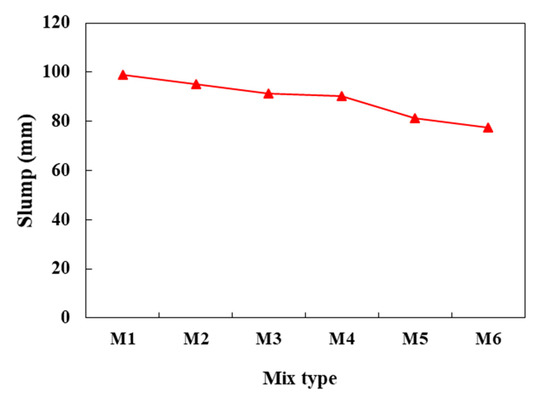

3.3. Slump Value of Concrete with Different SCJ Content

The workability (i.e., slump) of concrete with different SCJ content was measured and reported in Figure 6. Note that it was aimed to have the same workability for different mixes to avoid the impact on the mechanical strength of concrete mixes; therefore, plasticizer was added in varying percentages of concrete volume, as shown in Figure 6. Indeed, it was challenging to have the same slump value in the different mixes. The slump value ranges from 77 to 99 mm, which is considered medium-range workability of concrete [33]. During concrete mixing, it was observed that the mix became sticky with an increase in the percentage of SCJ, which was more pronounced at higher content of SCJ. The highest slump achieved was due to the addition of a superplasticizer, which enhances the movability of the fresh concrete.

Figure 6.

Slump value of concrete mixes with different SCJ content.

The decreasing trend of the concrete slump is linked to the sticky nature of the mix as SCJ increases and the enhanced initial hydration reaction of cement by the SCJ. This process may increase the amount of water required to achieve the desired slump, i.e., decreasing the initial mixing water in the concrete mix, thereby hindering the movability of freshly mixed concrete, thus offering a lower slump. This implies that the SCJ dosage should be precisely regulated in the concrete mix, especially for the lower w/c ratio and the ultra-high performance concrete mixes, to maintain adequate workability.

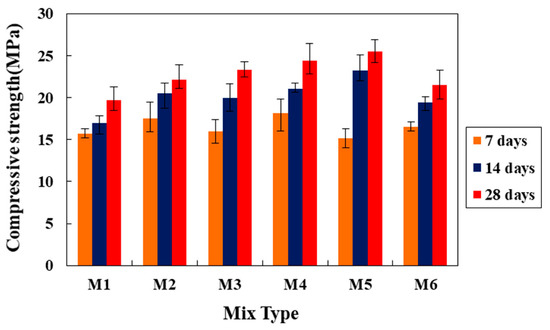

3.4. Compressive and Splitting Tensile Strength of Concrete with Different SCJ Content

The compressive strength development of concrete samples with different SCJ content at different curing ages is shown in Figure 7. The experimental results reveal that almost no significant changes in the compressive strength are observed for the test at an early age curing (i.e., at 7 days) among the mixes with and without SCJ. For example, compared to the control mix, the variation in the compressive strength is a minimum of −3% to a maximum of 16%. In contrast, compared with the control mix, the compressive strength increases at all SCJ content for other ages (14 and 28 days). At 14 days, the increment in the compressive strength ranges from 17% to 37%, and at 28 days, this is 12% to 29%.

Figure 7.

Compressive strength of different concrete mixes at different curing ages.

This significantly higher compressive strength of concrete containing SCJ could be linked with the accelerated hydration of cement minerals, e.g., alite (C3S) and belite (C2S), which is responsible for producing calcium silicate hydrate (C-S-H gel) and believed to be the strength-giving compound of cement-based materials. This process may produce higher content of C-S-H gels (i.e., filled and refined micropores which could reduce the porosity and may leave lower content of unhydrated cement) and dense hydration product (i.e., robust interfacial transition zone-ITZ). Therefore, the concrete mixes with SCJs are more capable of withstanding the uniaxial compressive load, thus ensuring higher compressive strength than the control mix. These results agree with the literature [7,16]. As Arefin et al. [28] reported, the SCJ contains fiber of approximately 15.5–16.8% of the total amount of liquid as well as micro solid particles, which may contribute to the enhancement in compressive strength, and its propensity could be higher for the higher content of SCJ. Though the SCJ was filtered before using it in the concrete mixes, the complete removal of microfibers is quite challenging. Therefore, this micro crusher sugarcane solid particles could fill the microvoids (i.e., lowering porosity), thus fostering a denser microstructure, resulting in an augmented ITZ between the aggregate and cement paste, resulting in improved compressive strength as compared to the control mix. Indeed, the ITZ is the most vulnerable path for concrete failure during mechanical loading. Furthermore, perhaps, the presence of microfibers (around 15.5–16.8% of total liquid [28]) in the SCJ may restrain the development and enlarge the cracks in the concrete matrix by bridging micropores and cracks, bind the other components of concrete (i.e., cement, sand, and coarse aggregate) tightly and construct a strong bond (i.e., provide more promising lateral confinement), and decrease the stress concentration in the concrete matrix. These effects enhance the post-cracking behavior of the specimens and offer better compressive strength to the concrete mix containing SCJ than the control mix. Indeed, the microstructure analysis through scanning electron microscopy and the physicochemical properties of the composites needs to be investigated to confirm the mechanisms, which are not carried out in this study. Furthermore, the microstructure analysis by Ahmad et al. [7] confirmed that the mortar containing SCJ produced a dense hydration product and compacted, thus enhancing the mechanical strength of the mortar. Similarly, Juenger and Jennings [34] concluded that incorporating sugar expanded the surface area and changed the pore size distribution of cement pastes. They [34] also stated that adding sugar accelerates the hydration of cement paste and the microstructure of C-S-H gels.

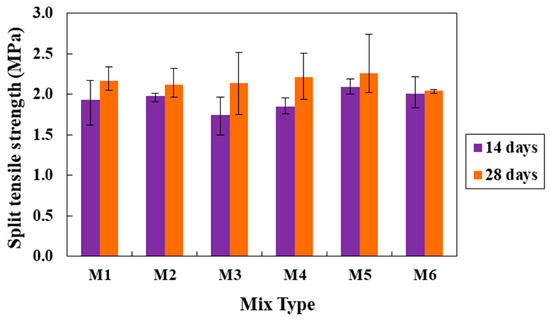

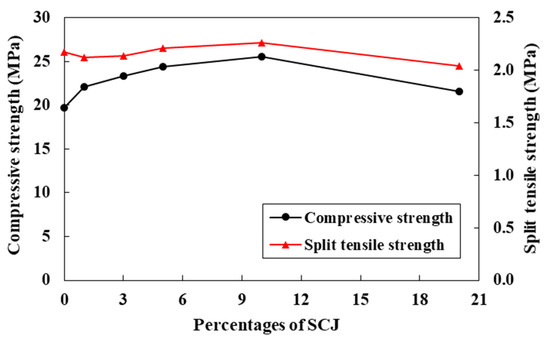

The splitting tensile strength of concrete samples was also investigated for different mixes, and their results are shown in Figure 8. Only 14 days and 28 days curing ages were considered in this case. As shown in the figure, no significant differences in the splitting tensile strength are observed in SCJ mixed concrete compared to the control. At 14 days, a minimum of −9% to a maximum of 8% change in the tensile strength is noticed due to the addition of different content of SCJ. While at 28 days, this difference is only a minimum of −2% to a maximum of 4%. The variations in the results are more pronounced when the SCJ content increases in the mixes. The mechanism behind the enhanced tensile strength should be the same as discussed for the compressive strength test. The large variation in the split tensile test in Figure 8 compared to the compressive strength reported in Figure 7 can be attributed to the applied stress in the samples during testing. Generally, in a split test, the load is applied to a small area of the sample, which may be affected by the presence of uneven pores distribution. Thus, the results may significantly vary from sample to sample. Conversely, a compressive load is applied to a larger sample area, resulting in less variation. A relationship between compressive and splitting tensile strength of SCJ mixed concrete at 28 days is also analyzed and presented in Figure 9. The improvement of the concrete strength is noticeable with the increasing content of SCJ in the mixes.

Figure 8.

Split tensile strength of different concrete mixes at different curing ages.

Figure 9.

Relationship between 28 days compressive and split tensile strength of concrete at different SCJ content.

3.5. Statistical Analysis of the Effect of SCJ on the Strength of Concrete

An analysis of variance (ANOVA) was performed to investigate the statistical significance of the impact of different SCJ content on the compressive and splitting tensile strength of the control mix at a 95% confidence level. Table 3 shows the results obtained from the ANOVA test. Two groups, such as 14 and 28 days compressive and splitting tensile strength data, were considered, and their statistical parameters are shown in Table 3. In the case of compressive strength, the p-value is more than 0.05 (for a 95% confidence level) and less for the splitting tensile strength test. Therefore, it can be concluded that the higher percentages of SCJ can produce a compressive strength that is not statistically different from the control concrete mix (without SCJ). However, this trend is not true for splitting tensile strength, which needs further investigation.

Table 3.

ANOVA test for compressive and split tensile strength results.

4. Discussion

The experiments in this research reveal that the SCJ can be an alternative to chemical admixtures generally used in concrete to control both fresh and mechanical properties. In the cement paste, the inclusion of SCJ content of 2%, 5%, 10%, and 20% reduced the initial setting time by about 33% to 90%. A previous study also reported this trend of reduced setting time [7]. In the case of mortar, the trend of the lower setting time was more noticeable above 5% SCJ content.

Although the increased percentage of SCJ reduced the setting time in both cement paste and mortar, hardening was significantly delayed for the concrete with a sticky nature due to the addition of SCJ. At higher dosages, such as 10% and 20%, concrete samples were demolded after 48 hr of casting. The compressive strength test also revealed that at a lower curing age (i.e., at 7 days), the strength improvement in different SCJ mixed concrete is insignificant compared to the control mix. This could be another reason the samples took longer in demolding as the SCJ content increased in the mixes. In contrast, at longer curing ages (i.e., at 14 and 28 days), the compressive strength increased at all SCJ content. At 14 days, the increment in the compressive strength was in a range of 17% to 37%, and at 28 days, this was 12% to 29%. From the discussion, it can be concluded that the SCJ behaves differently with the compositions of the cementitious materials. In the case of the splitting test, no significant differences in the splitting tensile strength were observed in SCJ mixed concrete than the control. At 14 days, a minimum of −9% to a maximum of 8% changes in the tensile strength were noticed due to the addition of different content of SCJ. While at 28 days, this difference was only a minimum of −2% to a maximum of 4%.

In future research, testing of the micro-structural analysis and physicochemical properties of cement-based materials needs to be conducted to study the in-deep analysis of the mechanism of strength development when SCJ is used. The existing literature concluded that the formation of C-S-H in bio-based cementitious materials could also vary in different curing conditions, which should also be studied further. Also, the long-term effect of SCJ in cementitious materials should be examined to scrutinize the durability properties of (e.g., porosity, permeability, and water absorption) of the concrete. Furthermore, as the properties of SCJ may vary from source to source, a comparative study on the properties of SCJ from various sources would be an interesting area to research.

5. Conclusions

This study investigated experimental research into the effects of sugarcane juice (SCJ) as a chemical admixture in mortar and concrete mixes. The following conclusions can be drawn from the experiments carried out.

- The setting time was reduced with the increased SCJ content in the mix. As an accelerator, the minimum SCJ for cement mortar is 5% by water weight.

- The mix compositions also influenced the setting time of cement mortar. For the cement to sand ratio (c/s) of 1:1, the optimum water-to-cement ratio (w/c) is 0.30. This implies that the initial setting time of mortar reduces significantly at low c/s and w/c ratios. At c/s of 1:1.5 and 1:2, the optimum results can be obtained at w/c ratios of 0.40 and 0.50.

- The compressive strength of concrete increased as the SCJ content increased in the concrete mix. However, the compressive strength development at early curing age, such as at 7 days, is insignificant. The difference in strength was more pronounced at longer curing ages (14 and 28 days). In the case of splitting tensile strength, the differences in the strength were not so significant in SCJ mixed concrete compared to the control mix.

- The ANOVA proved that higher percentages of SCJ produced a compressive strength that was not statistically different from the control concrete mix (without SCJ). However, this trend is not valid for splitting tensile strength.

Author Contributions

Conceptualization, S.C.P.; methodology, S.C.P.; validation, S.C.P., A.J.B., M.J.M., M.A.B. and N.M.S.H.; formal analysis, S.C.P.; investigation, S.C.P., A.J.B. and M.J.M.; resources, S.C.P.; data curation, S.C.P., A.J.B., M.J.M. and S.Y.K.; writing—original draft preparation, S.C.P., A.J.B. and M.J.M.; writing—review and editing, M.A.B., N.M.S.H. and S.Y.K.; visualization, S.Y.K.; supervision, S.C.P. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

This study didn’t report any data.

Acknowledgments

The authors would like to thank Ahadul Islam, K.M. Azmol Hossain Fahim, Kamruzzaman Sarder, Tanvir Islam, Armina Akhter, Inzama Mul Haque and Abdullah for conducting the experiments. This research was conducted at the International University of Business Agriculture and Technology, and it was sponsored by the Miyan Research Institute.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Mohamed, A.K.; Weckwerth, S.A.; Mishra, R.K.; Heinz, H.; Flatt, R.J. Molecular modeling of chemical admixtures; opportunities and challenges. Cem. Concr. Res. 2022, 156, 106783. [Google Scholar] [CrossRef]

- Raju, T.; Ramaswamy, K.P.; Saraswathy, B. A review on the effects of chemical admixtures on alkali activated concrete. Mater. Today Proc. 2022, 65, 846–851. [Google Scholar] [CrossRef]

- Alexander, M. Fulton’s Concrete Technology, 10th ed.; Cement & Concrete SA: Midrand, South Africa, 2021. [Google Scholar]

- Khan, B.; Baradan, B. The effect of sugar on setting-time of various types of cements. Q. Sci. Vis. 2002, 8, 71–78. [Google Scholar]

- Khan, B.; Ullah, M. Effect of a retarding admixture on the setting time of cement pastes in hot weather. Eng. Sci. 2004, 15, 63–79. [Google Scholar]

- Al Khafaji, Z.S.; Ruddock, F. Study the retardant effect of using different sugar’s types on setting time and temperature of cement paste. Int. J. Civ. Eng. Technol. 2018, 9, 519–530. [Google Scholar]

- Ahmad, S.; Lawan, A.; Al-Osta, M. Effect of sugar dosage on setting time, microstructure and strength of Type I and Type V Portland cements. Case Stud. Constr. Mater. 2020, 13, e00364. [Google Scholar] [CrossRef]

- Thomas, N.L.; Birchall, J.D. The retarding action of sugars on cement hydration. Cem. Concr. Res. 1983, 13, 830–842. [Google Scholar] [CrossRef]

- Abalaka, A.E. Comparative effects of cassava starch and simple sugar in cement mortar and concrete. ATBU J. Sci. Technol. 2011, 4, 13–22. [Google Scholar]

- Young, J.F. A review of the mechanisms of set-retardation in Portland cement pastes containing organic admixtures. Cem. Concr. Res. 1972, 2, 415–433. [Google Scholar] [CrossRef]

- Erdoğan, T.Y. Admixtures for Concrete; Middle East Technical University: Ankara, Turkey, 1997; ISBN 975-479-113-6-188. [Google Scholar]

- Aïtcin, P.C. Accelerators. In Science and Technology of Concrete Admixtures, 1st ed.; Woodhead Publishing: Sawston, UK, 2016; pp. 405–413. [Google Scholar] [CrossRef]

- Kunchariyakun, K.; Sinyoung, S.; Kajitvichyanukul, P. Comparative microstructures and mechanical properties of mortar incorporating wood fiber waste from various curing conditions. Case Stud. Constr. Mater. 2022, 16, e00855. [Google Scholar] [CrossRef]

- Luo, B.; Luo, Z.; Wang, D.; Shen, C.; Xia, M. Influence of alkaline and alkali-free accelerators on strength, hydration and microstructure characteristics of ultra-high performance concrete. J. Mater. Res. Technol. 2021, 15, 3283–3295. [Google Scholar] [CrossRef]

- Su, Y.; Luo, B.; Luo, Z.; Huang, H.; Li, J.; Wang, D. Effect of accelerators on the workability, strength, and microstructure of ultra-high-performance concrete. Materials 2021, 15, 159. [Google Scholar] [CrossRef] [PubMed]

- Usman, N.D.; Chom, H.A.; Salisu, C.; Abubakar, H.O.; Gyang, J.B. The impact of sugar on setting-time of ordinary Portland cement (OPC) paste and compressive strength of concrete. FUTY J. Environ. 2016, 10, 107–114. [Google Scholar]

- Mahmood, H.F.; Dabbagh, H.; Mohammed, A.A. Comparative study on using chemical and natural admixtures (grape and mulberry extracts) for concrete. Case Stud. Constr. Mater. 2021, 15, e00699. [Google Scholar] [CrossRef]

- Hazarika, A.; Hazarika, I.; Gogoi, M.; Bora, S.S.; Borah, R.R.; Goutam, P.J.; Saikia, N. Use of a plant based polymeric material as a low cost chemical admixture in cement mortar and concrete preparations. J. Build. Eng. 2018, 15, 194–202. [Google Scholar] [CrossRef]

- Babu, T.R.; Neeraja, D. A experimental study of natural admixture effect on conventional concrete and high volume class F fly ash blended concrete. Case Stud. Constr. Mater. 2017, 6, 43–62. [Google Scholar]

- Ekop, I.E.; Harry, O.A. Influence of Dracaena Aborea and Carica Papaya Leave Extracts on the Strength and Setting Time of Cement Paste and Mortar. IOSR j. Mech. Civ. Eng. (IOSR-JMCE) 2020, 17, 17–20. [Google Scholar]

- Otunyo, A.W.; Koate, I. Sugar cane juice as a retarding admixture in concrete production. Glob. J. Eng. Res. 2015, 14, 17–23. [Google Scholar] [CrossRef]

- Maraveas, C. Production of sustainable and biodegradable polymers from agricultural waste. Polymers 2020, 12, 1127. [Google Scholar] [CrossRef]

- Rosso, F.; Pisello, A.L.; Pigliautile, I.; Cavalaglio, G.; Coccia, V. Natural, bio-based, colored linoleum: Design, preparation, characteristics and preliminary life cycle assessment. J. Clean. Prod. 2020, 267, 122202. [Google Scholar] [CrossRef]

- Huang, H.; Yuan, Q.; Deng, D.; Peng, J.; Huang, Y. Effects of chemical and mineral admixtures on the foam indexes of cement-based materials. Case Stud. Constr. Mater. 2019, 11, e00232. [Google Scholar] [CrossRef]

- Azevedo, A.R.; Marvila, M.T.; Zanelato, E.B.; Alexandre, J.; Xavier, G.C.; Cecchin, D. Development of mortar for laying and coating with pineapple fibers. Rev. Bras. Eng. Agricola Ambient 2020, 24, 187–193. [Google Scholar] [CrossRef]

- Khorasani, F.F.; Kabir, M.Z. Experimental study on the effectiveness of short fiber reinforced clay mortars and plasters on the mechanical behavior of adobe masonry walls. Case Stud. Constr. Mater. 2022, 16, e00918. [Google Scholar] [CrossRef]

- ASTM C191-21; Standard Test Method for Time of Setting of Hydraulic Cement by Vicat Needle. ASTM International: West Conshohocken, PA, USA, 2021.

- Arefin, M.S.; Rahman, M.M.; Alim, M.A. Physico-chemical properties of goor and quality of sugarcane (Saccharum officinarum) as influenced by integrated nutrient management in Bangladesh. MOJ Ecol. Environ. Sci. 2020, 5, 271–278. [Google Scholar] [CrossRef]

- Miah, M.J.; Ali, M.K.; Paul, S.C.; John Babafemi, A.; Kong, S.Y.; Šavija, B. Effect of recycled iron powder as fine aggregate on the mechanical, durability, and high temperature behavior of mortars. Materials 2020, 13, 1168. [Google Scholar] [CrossRef]

- ASTM C143/C143M-12; Standard Test Method for Slump of Hydraulic-Cement Concrete. ASTM International: West Conshohocken, PA, USA, 2012. [CrossRef]

- ASTM C39/C39M-14; Standard Test Method for Compressive Strength of Cylindrical Concrete Specimens. ASTM International: West Conshohocken, PA, USA, 2014. [CrossRef]

- ASTM C496-96; Standard Test Method for Splitting Tensile Strength of Cylindrical Concrete Specimens. ASTM International: West Conshohocken, PA, USA, 1996. [CrossRef]

- Shetty, M.S.; Jain, A.K. Concrete Technology (Theory and Practice), 8th ed.; S. Chand Publishing: New Delhi, India, 2019. [Google Scholar]

- Juenger, M.C.G.; Jennings, H.M. New insights into the effects of sugar on the hydration and microstructure of cement pastes. Cem. Concr. Res. 2002, 32, 393–399. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).