2.2. Scaling Laws from Model to Prototype

The physical model development in this paper followed SDOFO principles [

16] and corresponded to one of the categories summarized in [

9], specifically “small and very small-scale laboratory experiments, usually conducted on soil placed in a strongbox, with the footing undergoing steady-state or transient vibrations”.

Dynamic model tests encompass two groups: tests performed under 1-g and n-g gravitational fields [

17]. The proposed physical model is a small-scale one, so it allows complete control over the model’s details [

18]. However, the extrapolation from model to prototype must respect several rules named scaling laws, which provide the reliability to understand the behavior of prototypes using small-scale models. Ref. [

19] researched the similitude for shaking table tests on the soil-structure-fluid model in a 1-g gravitational field to interpret dynamic model tests and presented two tables that show geotechnical items and their scaling factors (prototype/model). Additionally, Ref. [

19] presented two scale factors,

λ, and

λt, as the geometrical and time scales. Ref. [

20] proposed an approach to the geometric scale factor

λ as the ratio

E/ρ of the scale model to prototype. This scaled factor is known as the “Cauchy condition” [

21]. Based on the research above, Ref. [

10] developed the scaled factors required to develop this work, summarized in

Table 1. The scaling factor adopted in this work was

N = 25, computed as the ratio between the length of the square foundation in the prototype and the model according to the laboratory set-up available (see Equation (1)):

where

Bm is the length of the base of the square footing in the model, and

Bp is the scaled length in the prototype.

The authors used Equation (2) to compute the model’s void ratio and the prototype’s scale based on the scaling laws exposed by [

10] after [

19]. This equation is appropriate if the dilatancy of the sand is kept constant in the model and prototype.

where

em is the void ratio of the soil in the model, and

ep is the scaled void ratio in the prototype.

Ref. [

18] stated that a ratio of structure dimension to particle size would be of the order of ten to assure continuity of mechanical behavior; however, such a ratio “might be too small to guarantee the correct response of the physical model”. The authors assumed the continuity of mechanical behavior, considering that the intrinsic properties of the soil are homogeneous, and the relative density and saturation conditions were constant.

2.3. Test Equipment and Set-Up

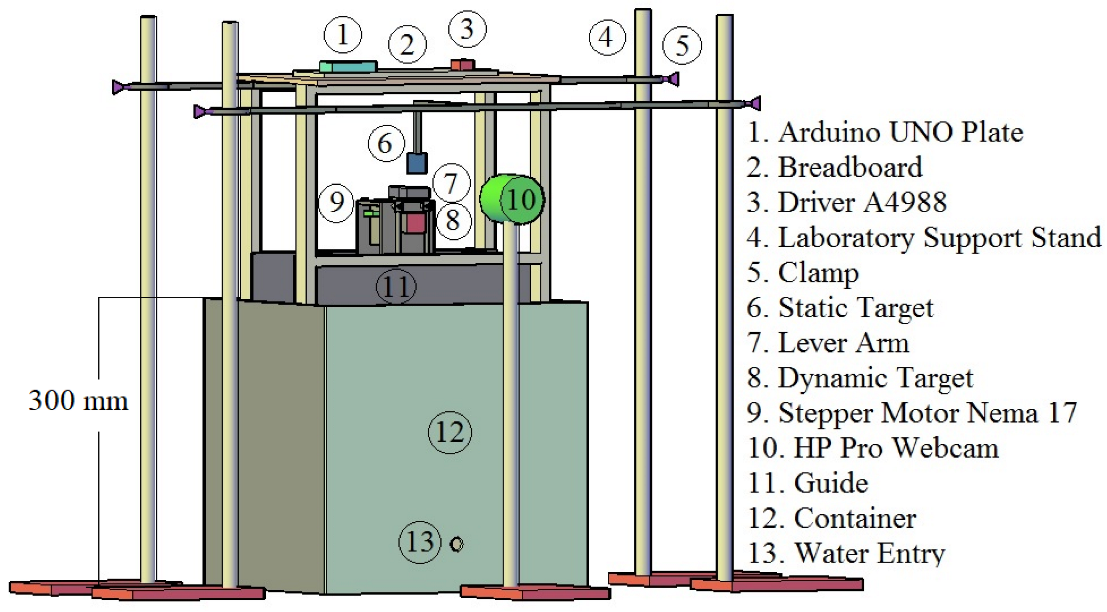

The physical model consists of three parts: (1) the electromechanical oscillator, (2) the experimental set-up around the tests, and (3) the machine vision system.

Figure 1 shows the proposed physical model, and Table 4 summarizes the dimensions of the strongbox.

The electromechanical oscillator was the primary device with mechanical and electronic components. The mechanical component was comprised of a dynamic red target of 20 by 20 mm, bearings, column, lever arm, square footing (shallow foundation), and sandpaper. The electronic component controlled the oscillatory movement of the actuator, and they were a stepper Nema 17 bipolar 0.4 amperes motor, an Arduino UNO plate (microcontroller board), an A4988 driver (micro-stepping motor driver), and a breadboard.

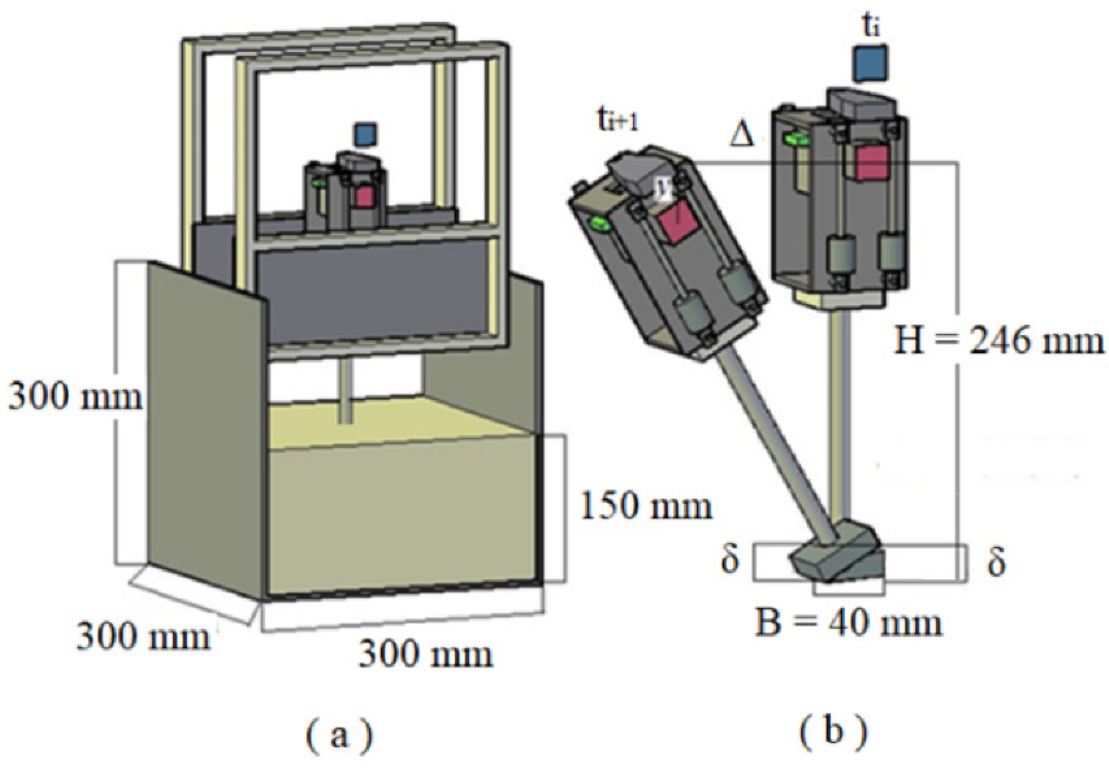

Figure 2 exposes the parts of the electromechanical oscillator.

Although shallow foundations are usually built with reinforced concrete, in physical model experiments, they are usually made with higher-density materials, such as steel, to provide the required contact pressure representing an actual building on the prototype scale, following the similitude laws by [

10]. The authors built the shallow foundation and column with steel to satisfy this requirement. The bottom face of the shallow foundation, which was in direct contact with soil, was roughened with a glued sandpaper sheet to provide friction between the soil and the footing; thus, there was no sliding, as proposed by [

10].

Table 2 summarizes the actuator’s parameters.

The experimental set-up of the test refers to the coupled equipment that supports and hosts the electromechanical oscillator. These are the strongbox employed to store the sand, the box used to store water, a hose to link both boxes, valves to regular water entry, levels, clamps, the laboratory supports stand, guides to lead the oscillatory movement, and a blue static target of 20 mm × 20 mm as a reference to the actuator’s displacement.

The dry air pluviation proposed by [

22] in [

23], i.e., soil deposition at constant fall height using a funnel, was used for sample preparation, ensuring reasonably homogeneous specimens with uniform density. The container filling was performed by rotating and lifting the funnel with dry soil; the fall height was kept constant and minimum as well as possible. This process allowed the uniform depositing of the sand to guarantee that density was constant throughout the strongbox.

The saturation process for the tests was developed using deaerated water obtained by boiling tap water and storing it in a sealed container [

24]. Deaerated water was flushed slowly upward through the sand layer and filled the voids of the soil deposit from the base up to 20 mm above the surface of the sand particles. The total height pressure was approximately 250 mm, guaranteeing a slow flush through the sand. After around 24 h, the surplus water on the soil surface was removed using a sponge. The volume of flushed water into the container up to the sand surface was measured and divided by the required water needed for total saturation. The degree of saturation was calculated according to Equation (3):

where

ω is water content and

ωmax is the maximum water content for the void ratio and the specific gravity of the soil sample.

According to [

10], the threshold of the degree of saturation required to continue with a test is 90%.

Figure 3 shows the saturation process.

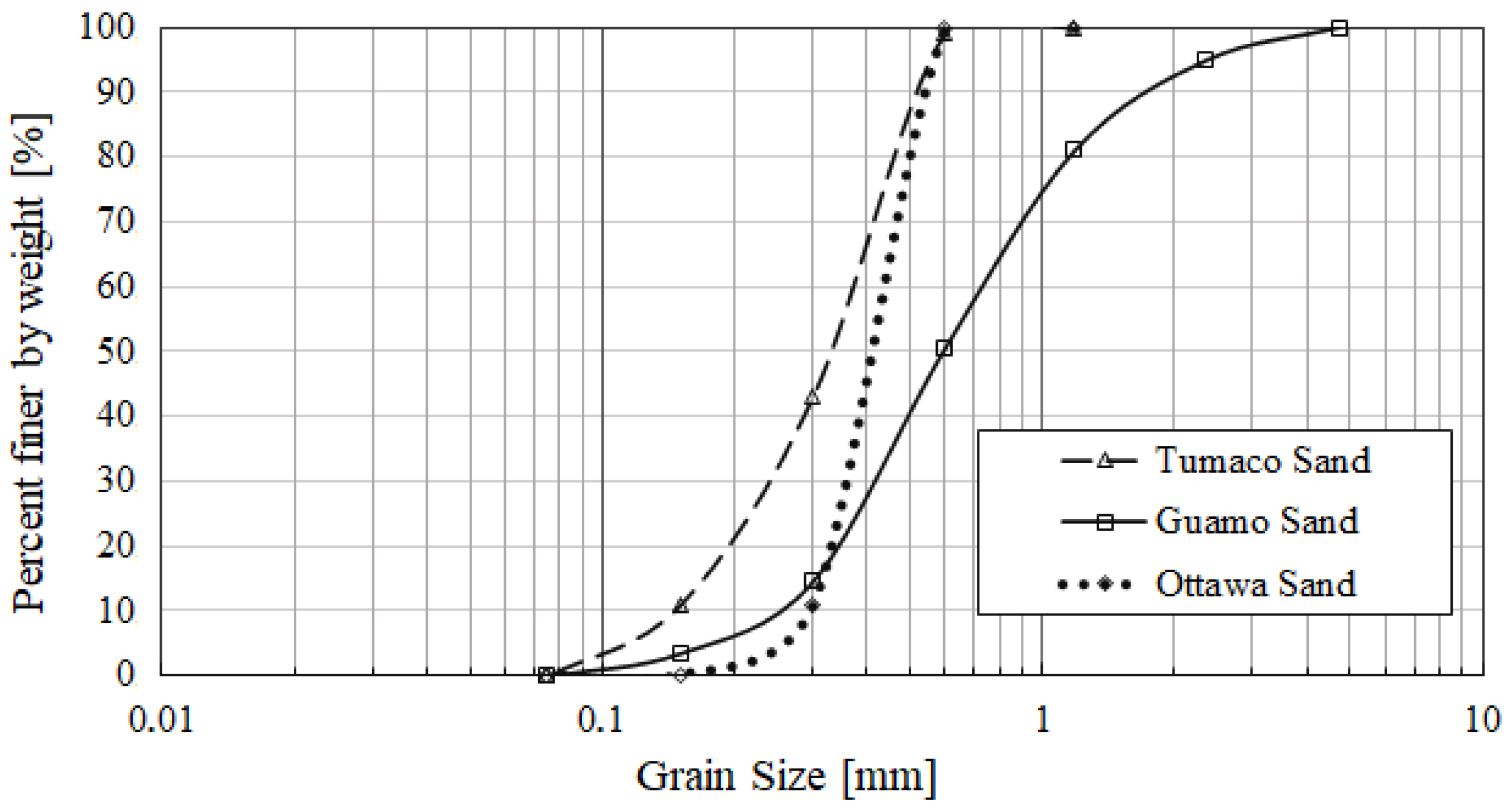

The authors used three types of sands in this study, Ottawa sand, Guamo sand, and Tumaco sand (these two last from Colombia, South America).

Table 3 and Table 6 summarize the parameters of the tested sands. Ref. [

25] concluded that Guamo sand achieved liquefaction flow with

Dr < 25%, and in this state, this soil showed a small contractive behavior. The authors assumed a contractive behavior for the sands due to the low relative density values (less than 0.33).

The acrylic strongbox is classified as a rigid box with fixed-end boundary conditions. The dimensions of the strongbox followed the guidance proposed by [

27] in [

9,

10]. They stated that the free field soil might be realized in a rigid container fulfilling the recommendations summarized in

Table 4.

The electromechanical oscillator was located at the geometrical center of the soil surface with a 40 mm embedment depth, following Terzaghi’s description: “A foundation is considered shallow if its depth is less than or equal to its width” [

28]. Then, the device was installed within the guides so that the bearings slightly touched the guide walls leading the movement. The guides constrained three of the six degrees of freedom experienced by a shallow foundation on a soil medium [

15]; the remaining degrees were lateral, vertical, and rocking motion. In consequence, this small-scale model was a simplified planar problem. Only the rocking motion was analyzed as this was the primary tendency due to the device features considering the actuator as an inverted pendulum with forces applied on top of the structure. The roughness of the bottom of the shallow foundation limited lateral motion by friction with the soil, and the vertical motion was presumed insignificant because the settlement on sand was instantaneous in drained conditions [

29].

Table 4.

Recommendations for experimental tests of shallow foundations in rigid containers.

Table 4.

Recommendations for experimental tests of shallow foundations in rigid containers.

| Parameter | Rule (*) | Reference |

|---|

| Rigid container length | 8 × B | [9] |

| Minimal height from the bottom of the rigid container to the bottom of the shallow foundation | 1.4 × B | [9] |

| Minimal width of the sample to minimize boundary effects | 10 × Dnom | [30] |

| Grain-size effects on soil-structure interaction. Bearing capacity of shallow footings (strip footing) | B/D50 > 35 | [31] |

Following

Table 2, the dimensions of the strongbox were 300 mm × 300 mm × 300 mm (length × width × height), and the sand deposit height reached 150 mm.

Figure 4 shows the dimensions and location of the electromechanical oscillator and its rocking motion between t

i and t

i+1 times, including the operation of the guides.

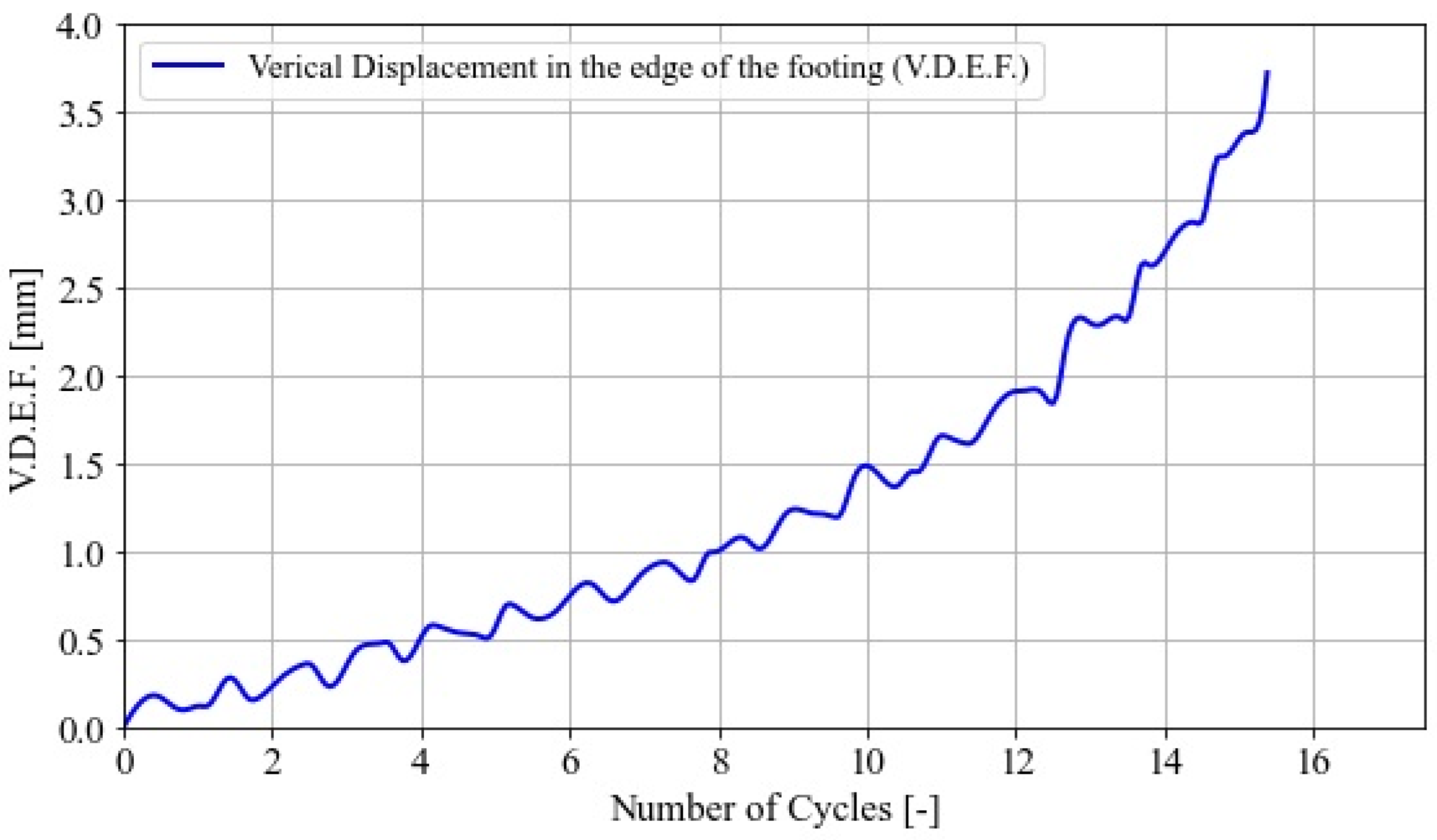

A geometric formulation allowed obtaining the vertical displacement in one of the edges of the SDOFO, which should be the same vertical displacement of the soil per cycle of loading beneath that edge because every cycle of loading pushed the soil deposit under the footing. A conversion factor was necessary to compute the vertical displacement on the edge of the footing by converting the position of the dynamic target centroid related to the static target centroid for every recorded displacement. Based on the similarity of the isosceles triangles, Equation (4) yields:

where

δ is the vertical displacement in one of the edges of the footing; Δ is the horizontal movement of the mobile target related to the static target;

B = width of square footing;

H = effective height of the equivalent SDOF model.

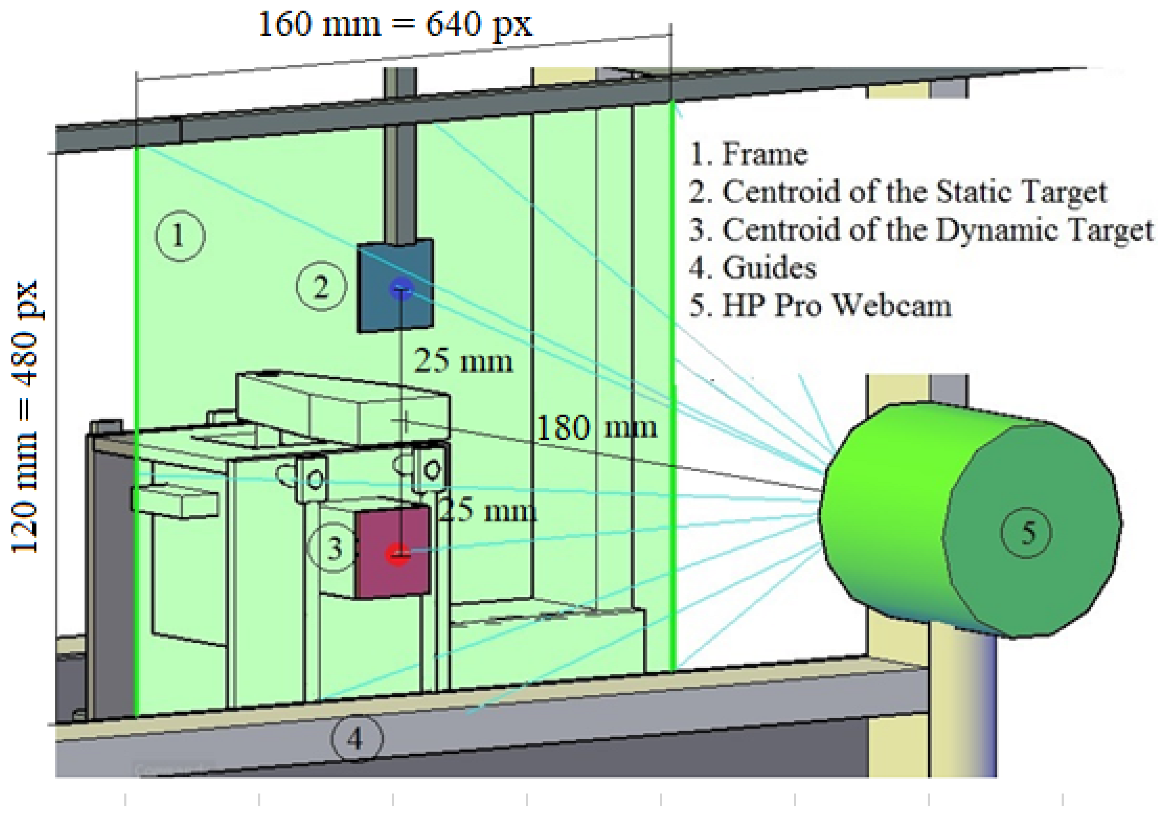

The machine vision system registered the movement between the dynamic target centroid related to the static target centroid. This system allowed indirect measuring of displacements instead of using LVDT sensors, which have a different rigidity than the soil and may affect the test results [

32]. Thus, data recording using images provided a “free movement” of the electromechanical oscillator without sensors directly installed in the device and the soil sample. This “free movement” can reliably represent the behavior of actual structures undergoing cyclical load, as evidenced in numerous seismic events (e.g., San Francisco 1906; Niigata 1964; Turkey 1999; Christchurch 2011, Japan 2011).

The computer vision method applied in this research was morphology, which employs morphological operators to define the shapes of features in an image using non-linear mathematical operators [

33]. Algorithms encoded in Python interpreted the displacement information recorded by the machine vision. Data recording used the OpenCV, NumPy, and Time libraries developed for Python. OpenCV is a well-known Python library for processing images and detecting and rebuilding objects [

34].

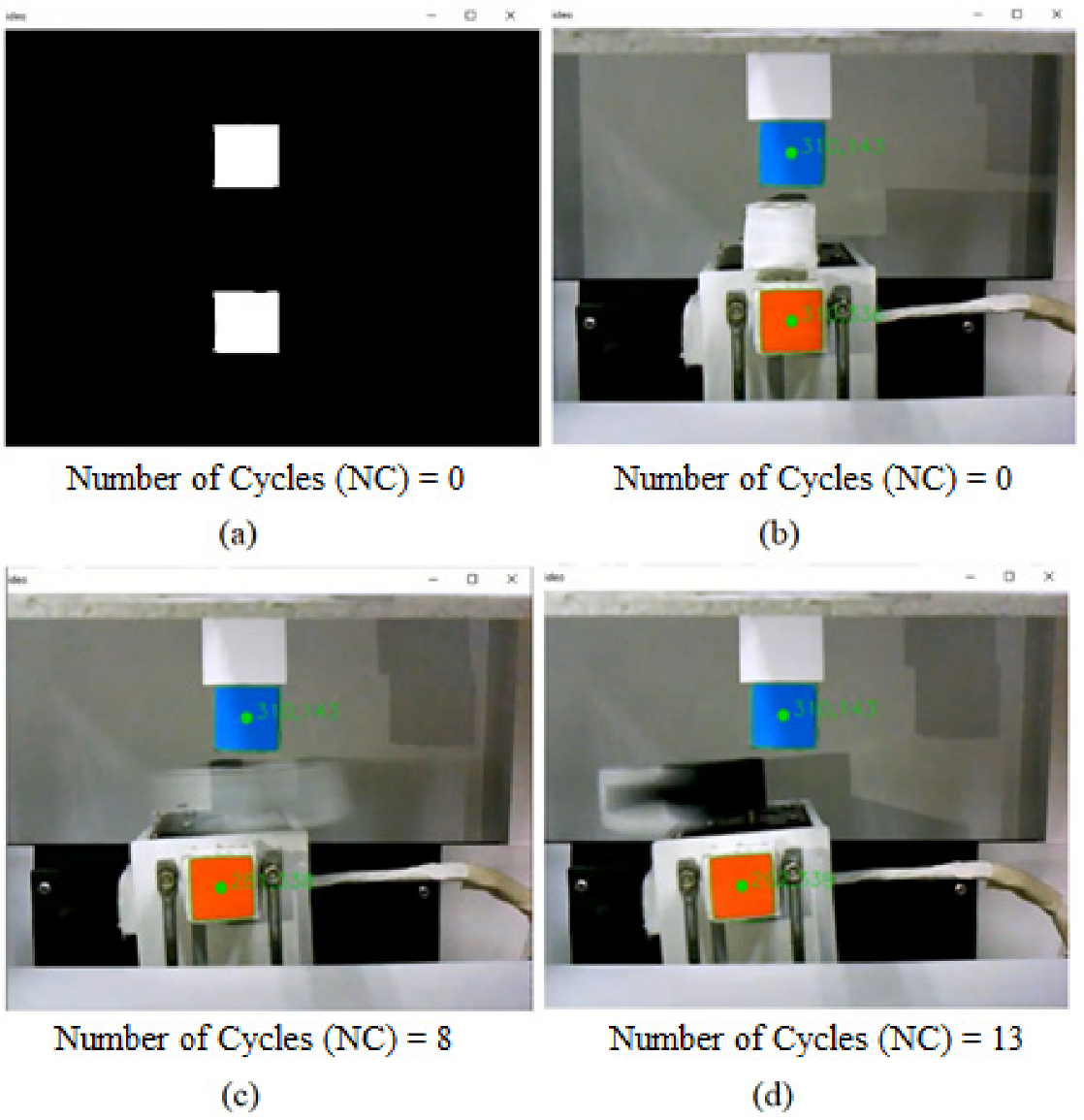

Figure 5 shows how the machine vision system works. The camera used to capture the movement was an HP Pro Webcam with a video resolution of 640 × 480 4:3 at up to 30 frames per second and a power line frequency anti-flicker of 60 Hz. During testing, the lighting conditions remained constant in a lighted room.

The range of frequencies was from 2.92 Hz to 6.05 Hz. Therefore, as the video camera captured thirty frames per second (30 fps), there were between five to ten recorded images per load cycle, enough to capture the features of the loading process. Targets were set up on the same vertical plane but vertically displaced relative to one another; this was accomplished by carefully moving both edges of the static target and aligning them with the respective edges of the dynamic target. Then, the computer vision checked the equality of the

X coordinate (

Figure 6b).

The lever arm on the top of the electromechanical oscillator spins counterclockwise. Once the rotation begins, the electromechanical oscillator loses the static equilibrium showing a brief incline, which increases with every cycle until the device’s downfall.

Figure 6 shows the behavior of the actuator and the operativity of artificial vision.

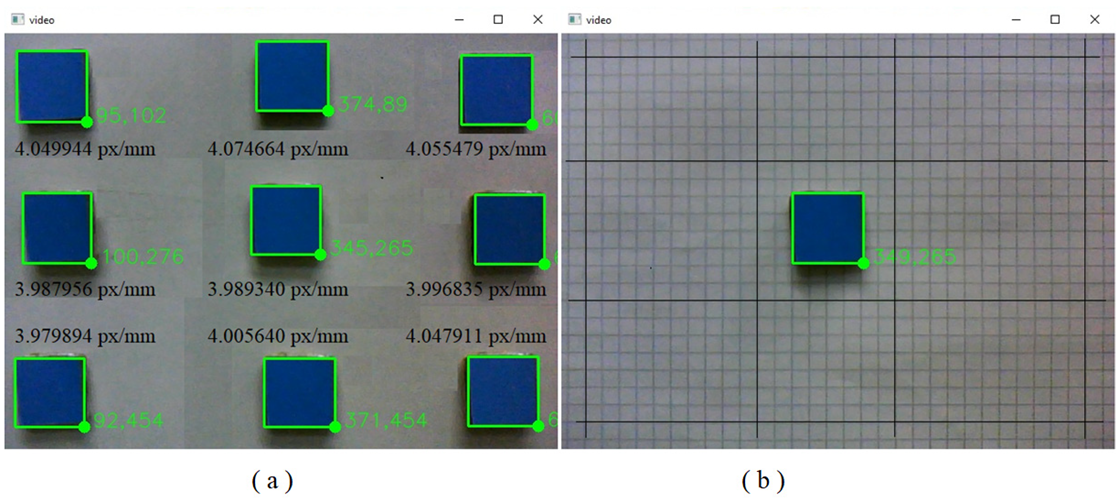

The optical distortion was analyzed by locating the static target in the corners, middle boundaries, and the video frame’s center. Then, the pixel density for every location was determined using the calibration code, as shown in

Figure 7. Additionally, on the right side of this figure, it is possible to observe that straight lines stay parallel to each other in the video frame; therefore, this has no significant optical distortions (barrel, pincushion, and wavy distortion).

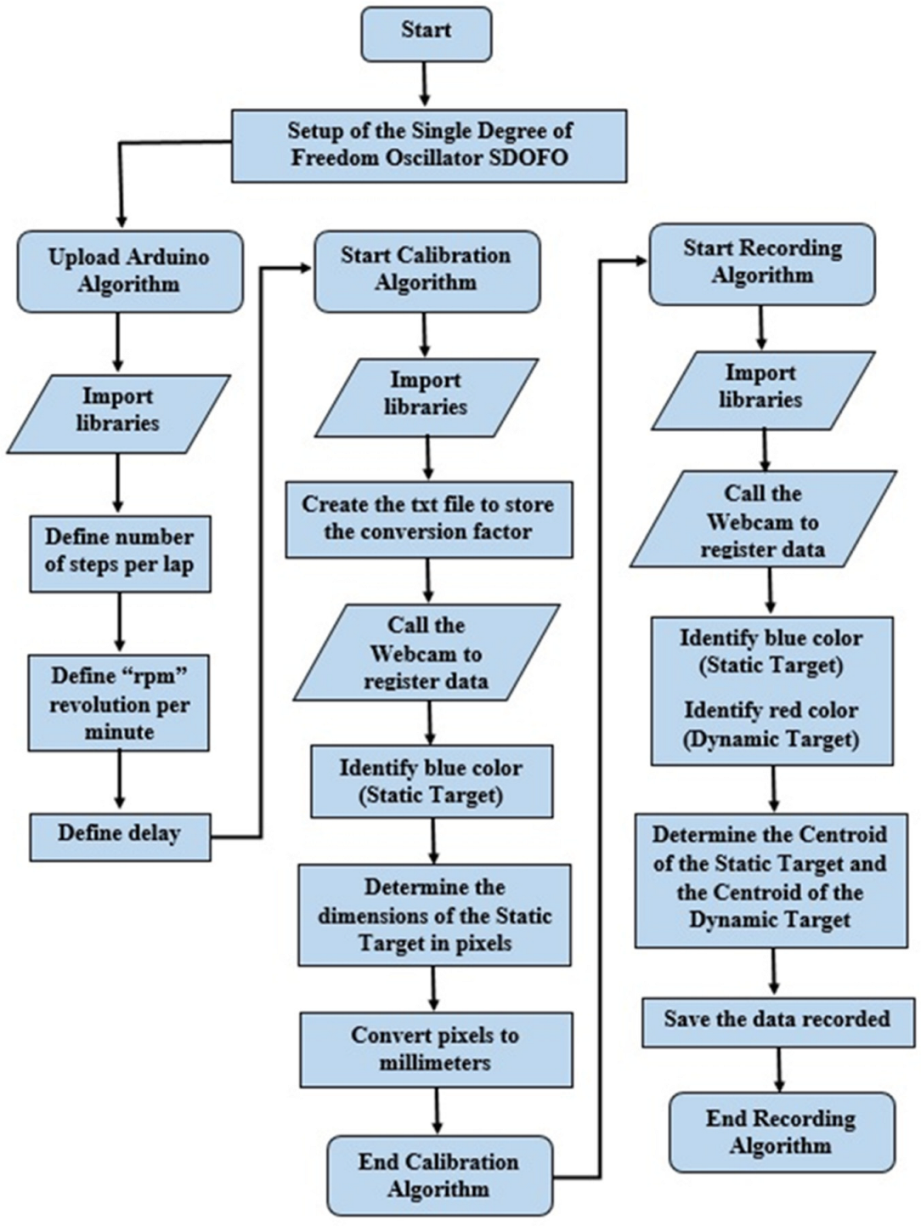

The flow diagrams in

Figure 8 describe the procedures required to obtain displacements and times in each video frame. The first procedure controls the oscillatory movement using an Arduino UNO plate indicating the excitation frequency. The second procedure is a calibration process that creates an adequate factor to convert pixels to millimeters by measuring the static target dimensions; the conversion factor to obtain the pixel density does not change during a particular test.

However, every test has a different conversion factor and, consequently, a distinct pixel density due to the distinct positions of the machine vision system and the SDOFO, i.e., the distance from the focal point to the dynamic target had slight variations. Nevertheless, for every test, this distance was close to 180 mm.

Table 5 summarizes the conversion factors and pixel density variations for the three tests on 23 samples developed for this work (eight tests on Ottawa sand, seven tests on Guamo sand, and nine tests on Tumaco sand).

The third procedure reads and stores data about the position of the dynamic target and static target centroids for each video frame. In this code, the primary functions are “cv2.morphologyEx” to purge every video frame, “cv2.moments” to find targets centroids, and “cv2.convexhull” to assure that the shapes selected were convex.

Supplementary Materials contains the calibration and recording algorithms.