Effect of Type of Curing and Metakaolin Replacement on Air Lime Mortars for the Durability of Masonries

Abstract

:1. Introduction

| Study | Mortars Analyzed | Tests | Results |

|---|---|---|---|

| Faria [23] | Binder(CL+Mk):Sand 1:2 with CL:Mk:sand (vol.) 1:0.5:3, 1:1:4, 1:1.5:5, submitted to dry and humid curing, tested at 60 d | Consistency (EN 1015-3) | 167–177 mm |

| FStr (EN 1015-11) | 0.08–1.07 MPa | ||

| CStr (EN 1015-11) | 0.36–8 MPa | ||

| Op (EN 1936) | 29–36% | ||

| Faria et al. [25] | Binder:sand 1:3 (vol.), with 0%, 30% and 50% substitutions of CL by Mk, submitted to standard and humid curing tested at 28 d | Consistency (EN 1015-3) | 132–144 mm |

| Ed (EN 14146) | 729–6690 MPa | ||

| FStr (EN 1015-11) | 0.08–1.09 MPa | ||

| CStr (EN 1015-11) | 0.13–2.82 MPa | ||

| Op (EN 1936) | 29–31% | ||

| CS (EN 15801) | 13.6–24.9 kg/m2 | ||

| CC (EN 15801) | 0.84–1.43 kg/(m2·min0.5) | ||

| Andrejkovičová et al. [20] | Binder:sand 1:3 (vol.) with 0% and 20% of Mk, submitted to weathering cycles, tested at 28, 90 and 180 d | Ed (BS 1881-209) | 2.8–4.0 MPa |

| FStr (EN 1015-11) | 0.125–0.175 MPa | ||

| CStr (EN 1015-11) | 0.40–0.55 MPa | ||

| Cardoso et al. [22] | Binder:sand 1:3 (vol.) with 0% and 9% substitutions of air lime by Mk, submitted to six different curing conditions, tested at 28, 90 and 365 d | Consistency (EN 1015-3) | 150 ± 10 mm |

| FStr (EN 1015-11) | 0.05–0.15 MPa | ||

| CStr (EN 1015-11) | 0.1–0.6 MPa | ||

| Faria & Martins [24] | Binder:sand 1:3 (vol.), with 0% and 20% substitutions of Mk, cured under different conditions of RH and CO2 content and tested at 60 d for mechanical tests and 120 d for capillarity and drying | Consistency (EN 1015-3) | 154–155 mm |

| Ed (EN 14146) | 2822–3691 MPa | ||

| FStr (EN 1015-11) | 0.3–0.7 MPa | ||

| CStr (EN 1015-11) | 0.4–1.3 MPa | ||

| CS (EN 15801) | 13.85–16.91 kg/m2 | ||

| CC (EN 1015-18) | 0.92–1.07 kg/(m2·min0.5) | ||

| Ferraz et al. [26] | Binder:sand 1:3 (vol.), with 0%, 10%, 20% and 30% substitutions of CL by Mk, tested at 28, 90 and 180 d | Consistency (EN 1015-3) | 130–140 mm |

| Ed (EN 14146) | 2.38–3.85 GPa | ||

| FStr (EN 1015-11) | 0.22–0.36 MPa | ||

| CStr (EN 1015-11) | 0.30–0.68 MPa | ||

| Gameiro et al. [19] | Binder:sand 1:1, 1:2 and 1:3 (vol.), with 0%, 30% and 50% substitutions of CL by Mk, tested at 28 and 90 d | Consistency (EN 1015-3) | 139–144 mm |

| FStr (EN 1015-11) | 0.50–2.6 MPa | ||

| CStr (EN 1015-11) | 1–15 MPa | ||

| Pavlík & Užáková, [27] | Binder:sand 1:1 (vol.), with 50% substitutions of CL by Mk, tested at 28, 90, 180 and 365 d | Consistency (EN 1015-3) | 152–150 mm |

| CStr (EN 1015-11) | 1.6–9 MPa | ||

| Arizzi & Cultrone [28] | Binder:sand 1:3 (vol.), with 0%, 10%, 15% and 20% substitutions of CL by Mk, tested at 28 and 120 d | Consistency (EN 1015-3) | 133–148 mm |

| FStr (EN 1015-11) | 1.69–2.93 MPa | ||

| CStr (EN 1015-11) | 2.36–9.12 MPa | ||

| Op (not specified) | 31–32% | ||

| Loureiro et al. [21] | Binder:sand 1:1, 1:2 and 1:3 (vol.), with 0%, 25% and 50% substitutions of CL by Mk, tested at 90 d | Consistency (NBR 13276) | 195–210 mm |

| Ed (EN 14146) | 6771–10485 MPa | ||

| FStr (EN 1015-11) | 0.81–2.72 MPa | ||

| CStr (EN 1015-11) | 2.02–12.63 MPa | ||

| Porosity (EN 1936) | 26–30% | ||

| Drying rate D1 (EN 16322) | 0.0042–0.0051 kg/(m2·min0.5) | ||

| Drying rate D2 (EN 16322) | 0.0391–0.0467 kg/(m2·min0.5) |

2. Experimental Programme

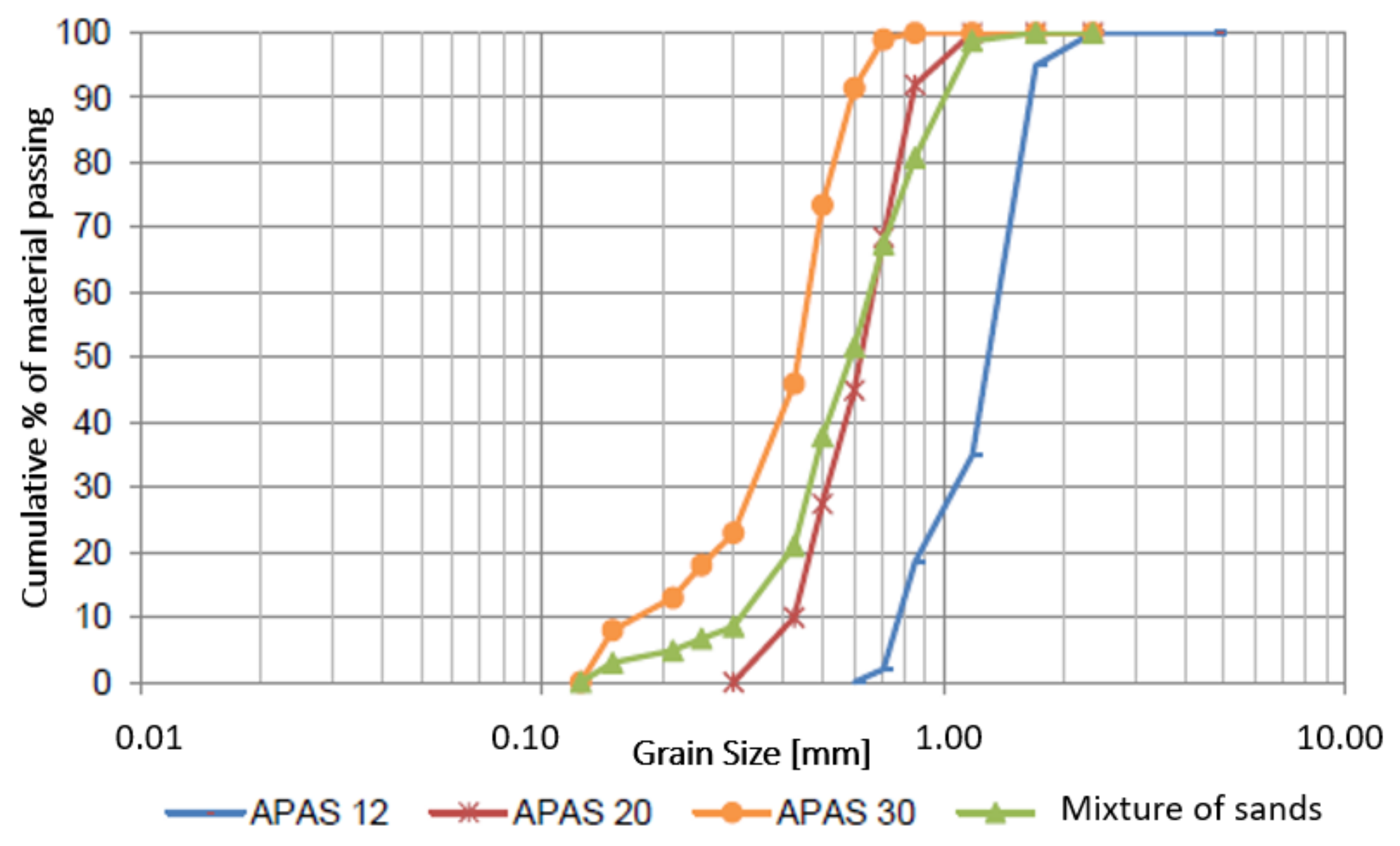

2.1. Materials

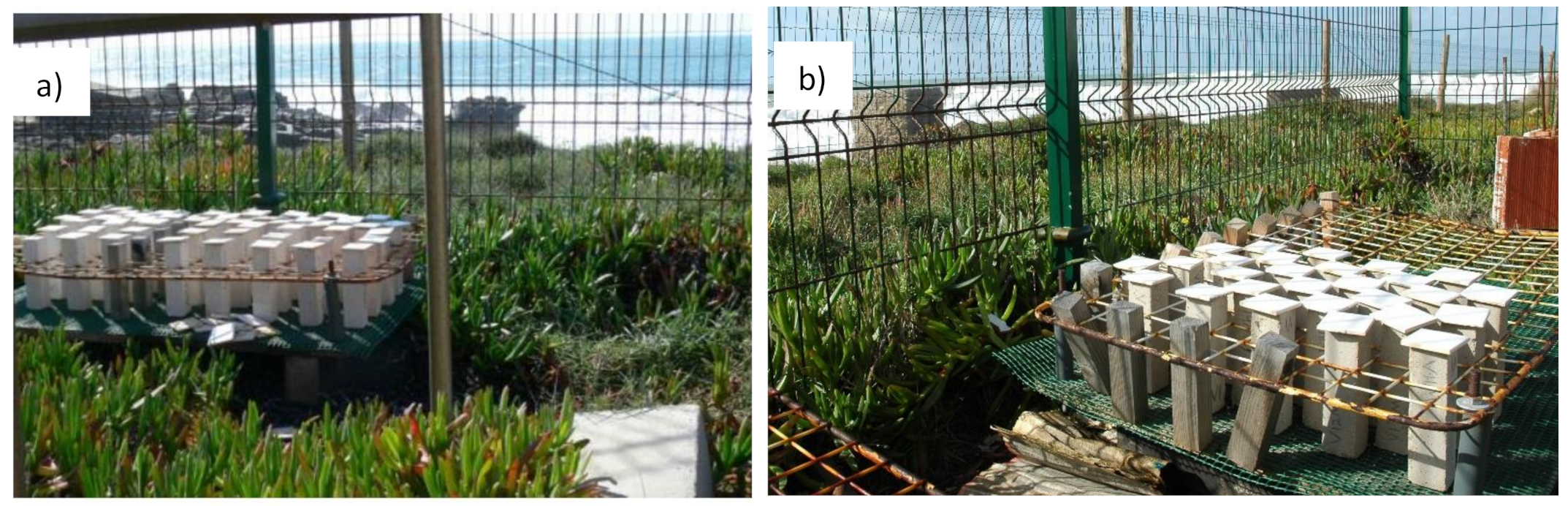

2.2. Mortars Preparation, Fresh State Characterization and Curing

2.3. Hardened State Characterization

3. Results and Analysis

3.1. Characteristics of Fresh Mortars

3.2. Characteristics of the Hardened Mortars

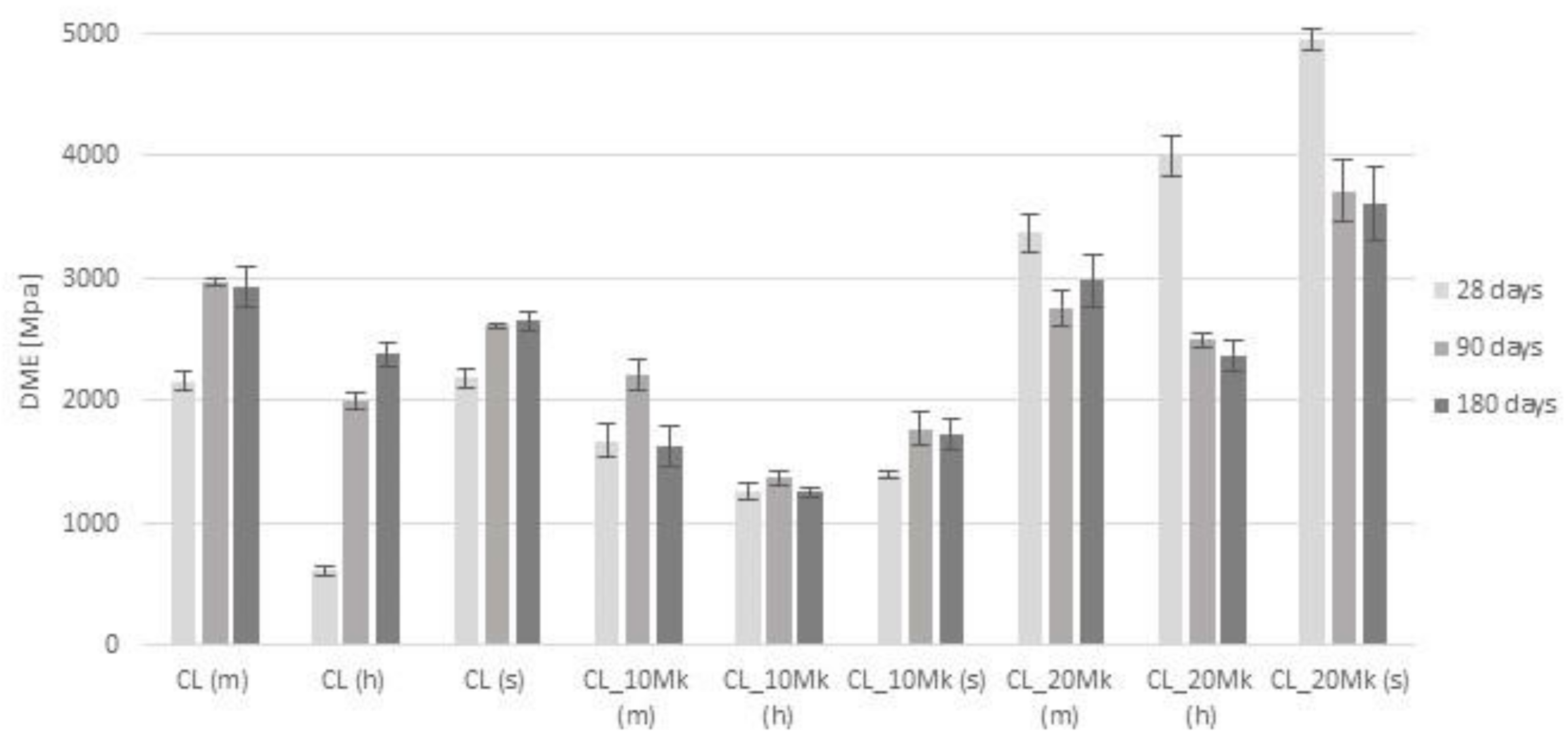

3.2.1. Dynamic Modulus of Elasticity

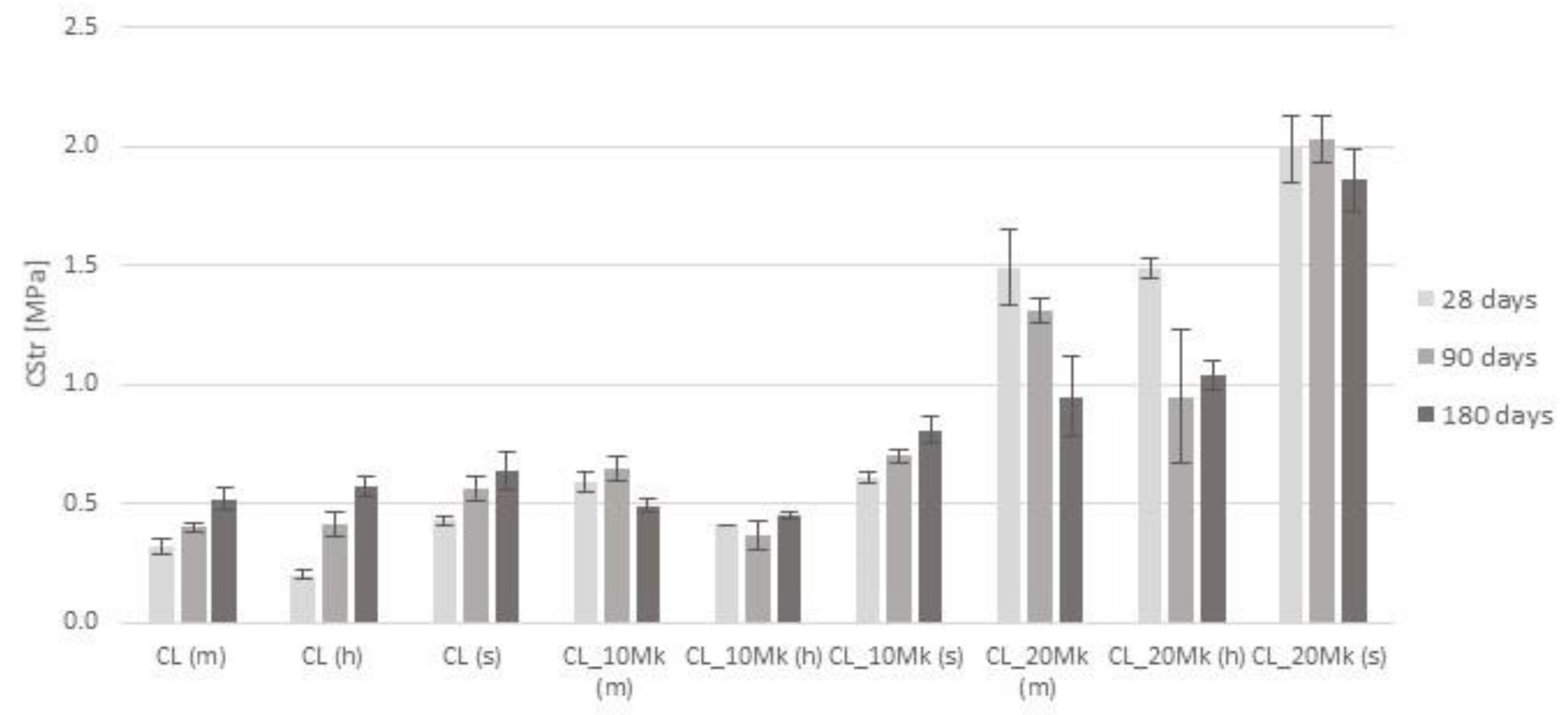

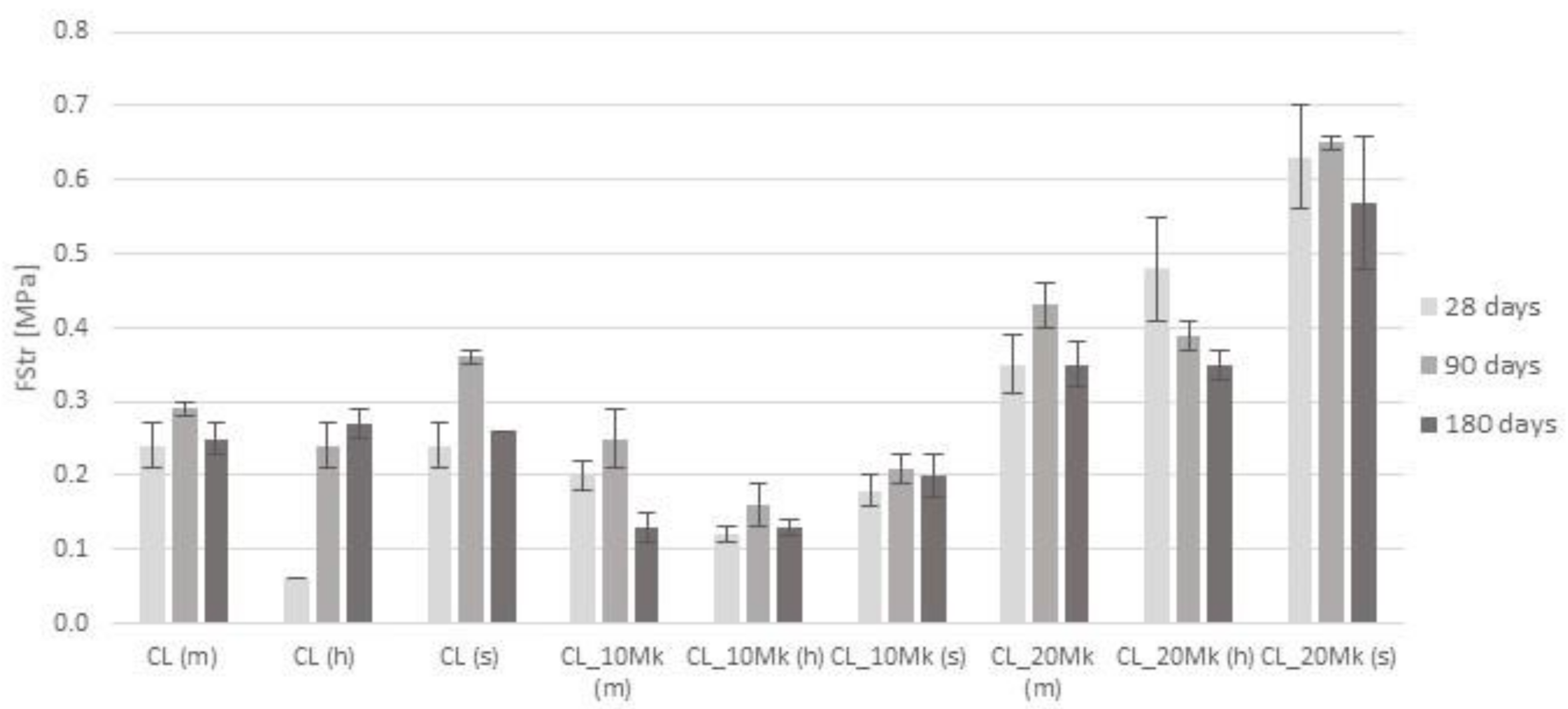

3.2.2. Flexural and Compressive Strength

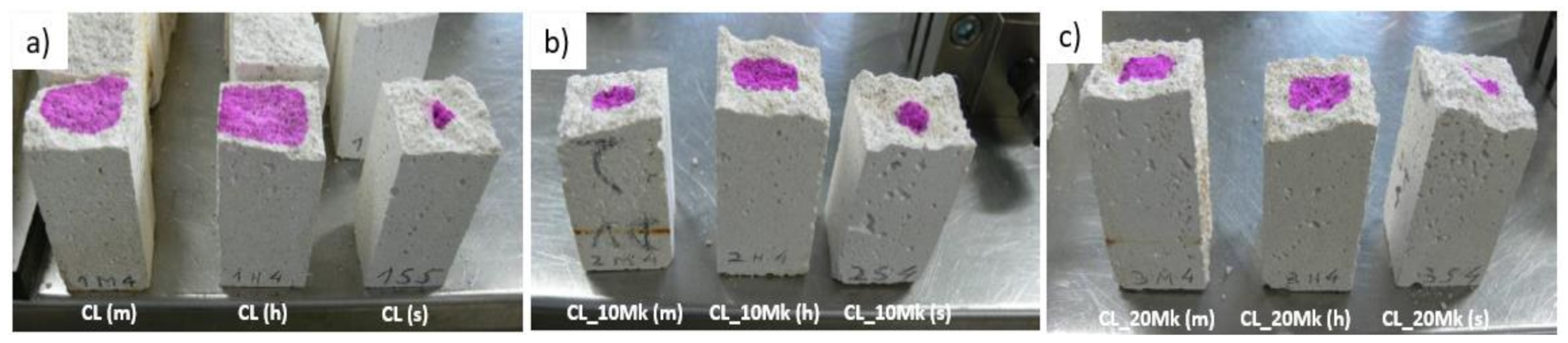

3.2.3. Carbonation

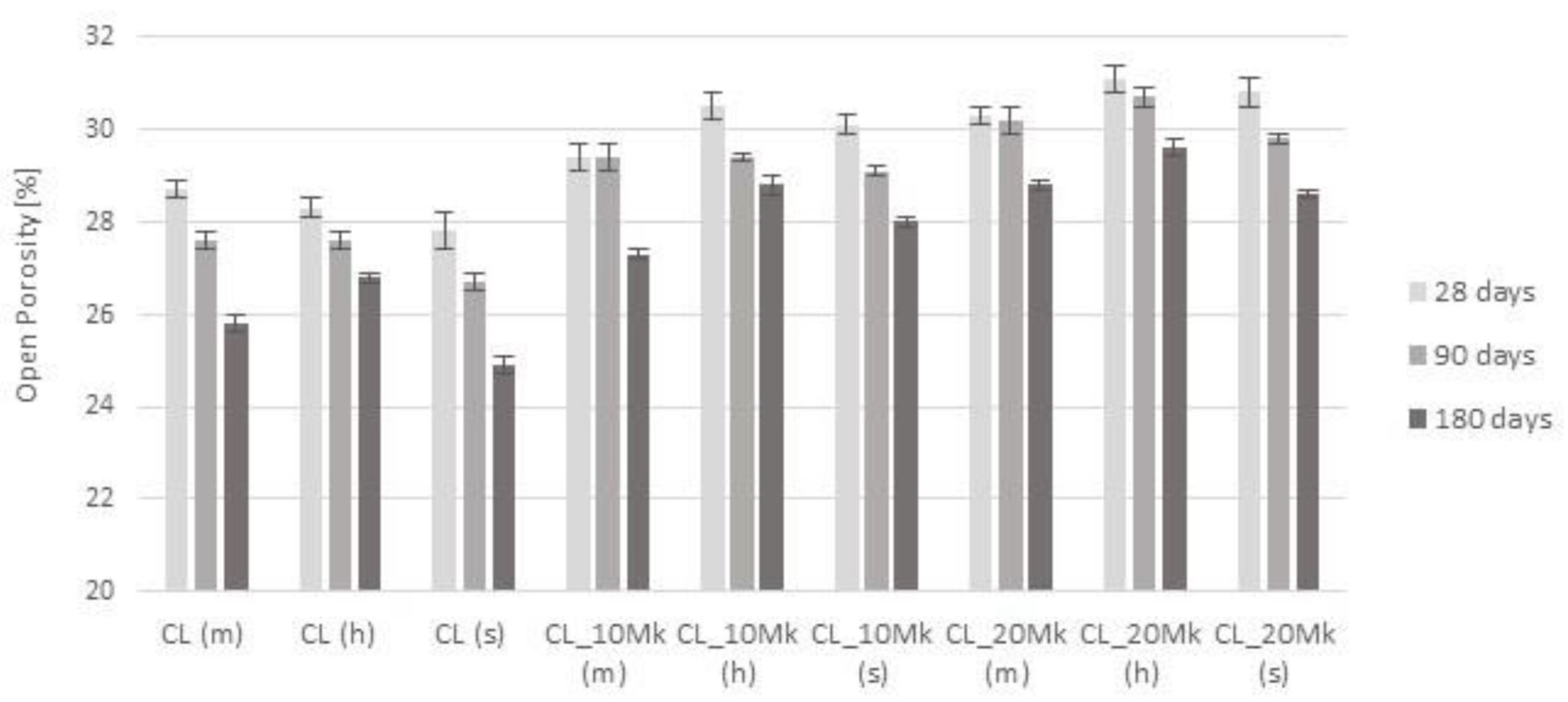

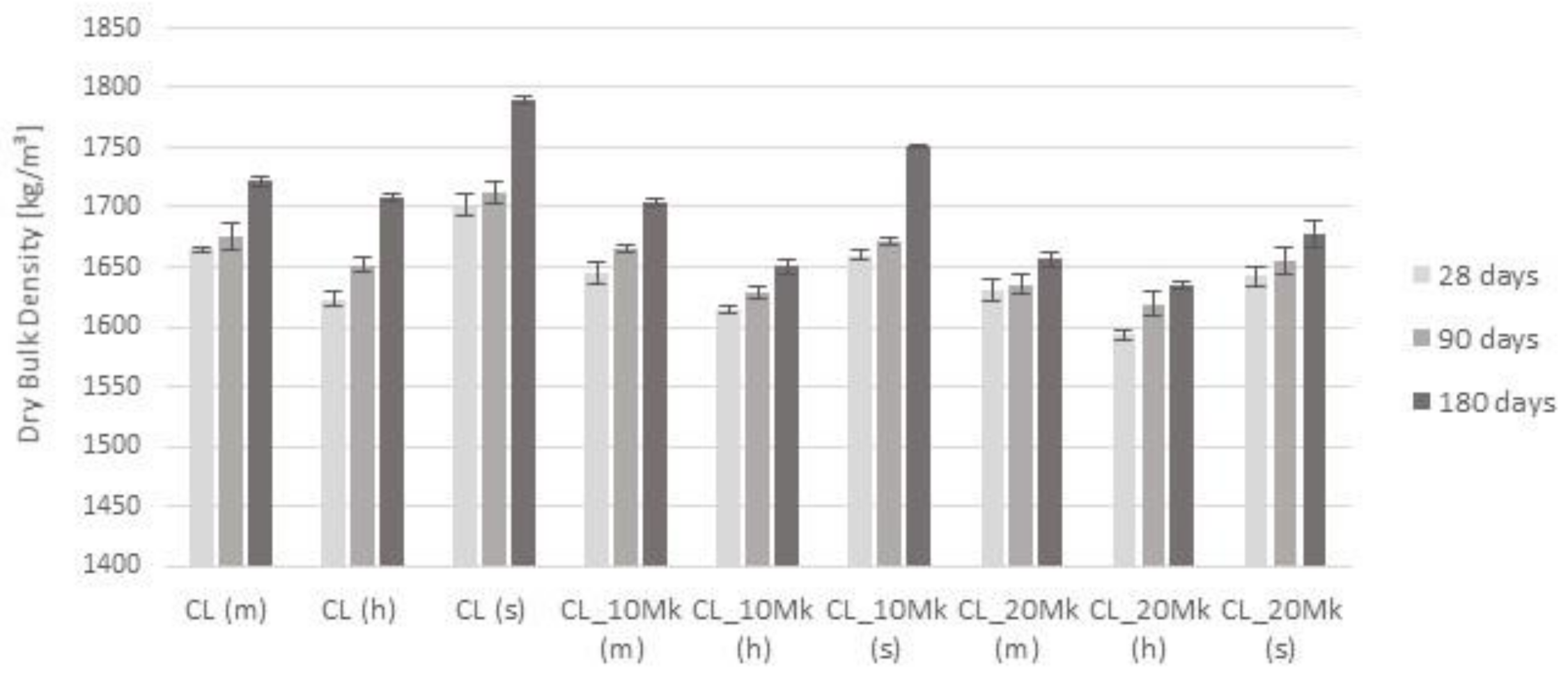

3.2.4. Open Porosity and Dry Bulk Density

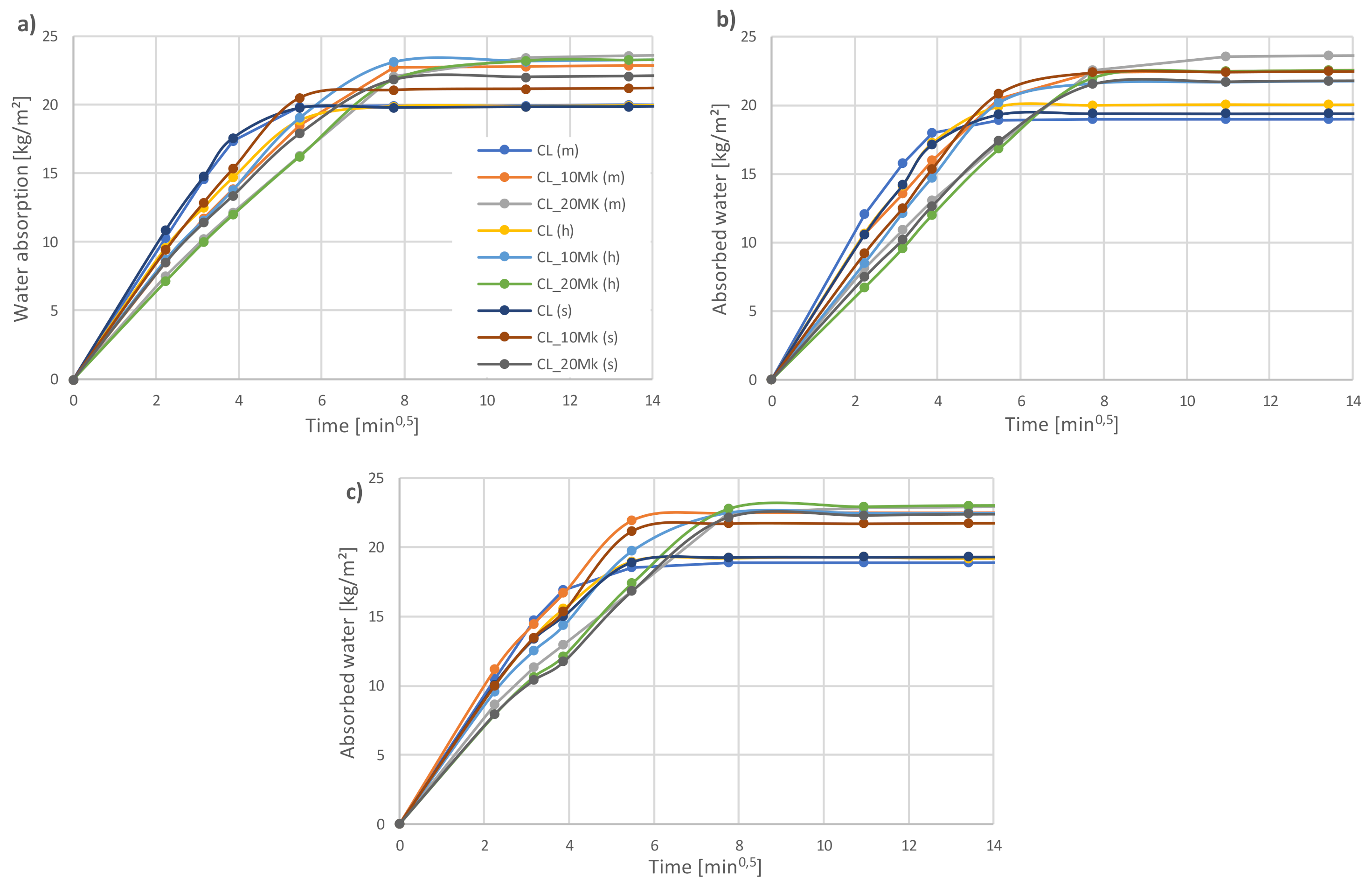

3.2.5. Capillary Water Absorption

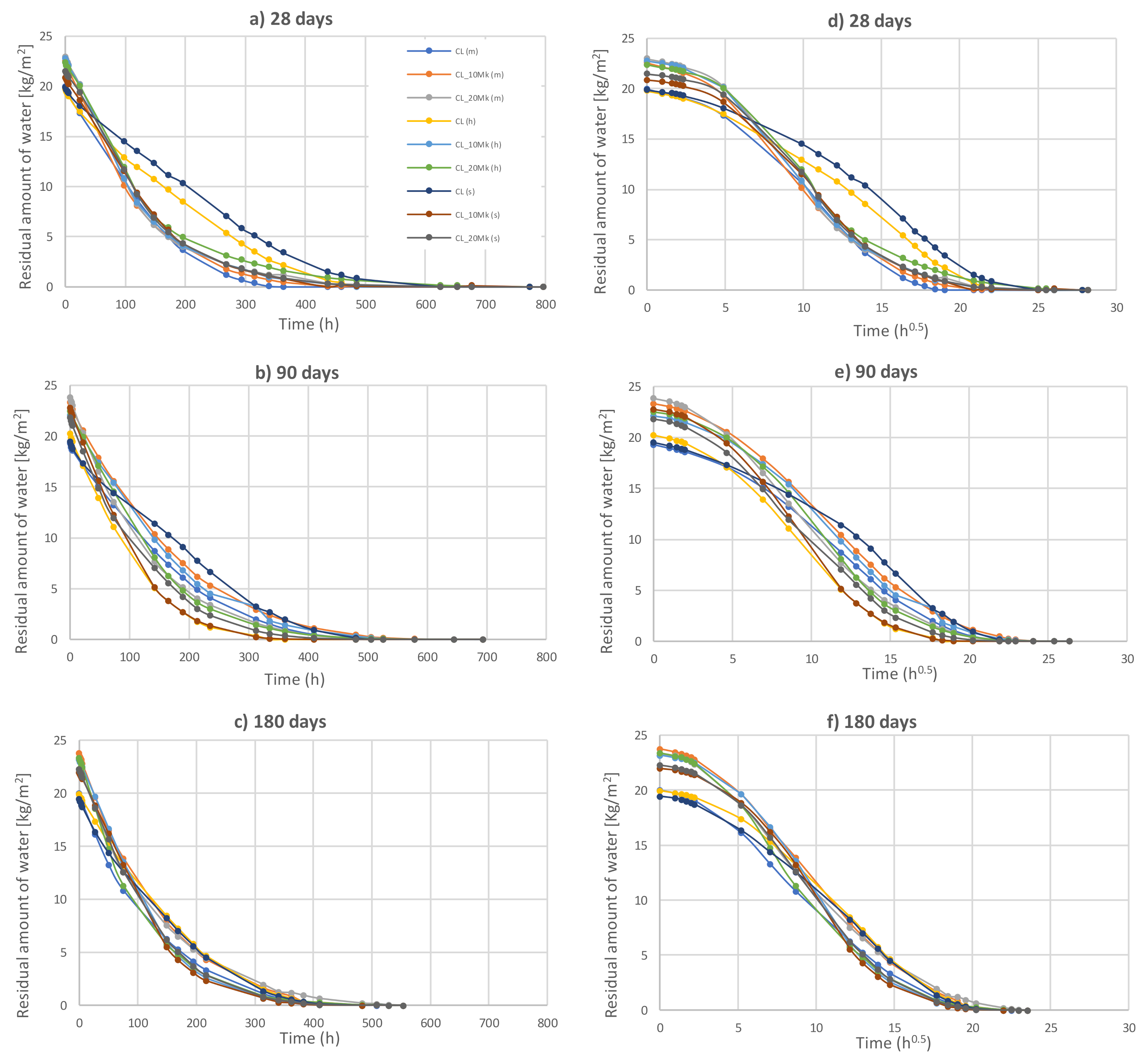

3.2.6. Drying

| Mortar (Curing) | Drying Rate, 1st Phase (D1) (kg/m2·h) | Drying Rate, 2nd Phase (D2) (kg/m2·h0.5) | ||||

|---|---|---|---|---|---|---|

| 28 Days | 90 Days | 180 Days | 28 Days | 90 Days | 180 Days | |

| CL (m) | 0.144 | 0.162 | 0.178 | 1.710 | 1.335 | 1.326 |

| CL_10Mk (m) | 0.163 | 0.166 | 0.176 | 1.472 | 1.534 | 1.639 |

| CL_20Mk (m) | 0.138 | 0.193 | 0.173 | 1.822 | 1.695 | 1.473 |

| CL (h) | 0.123 | 0.183 | 0.112 | 1.075 | 1.736 | 1.374 |

| CL_10Mk (h) | 0.124 | 0.147 | 0.133 | 1.779 | 1.642 | 2.080 |

| CL_20Mk (h) | 0.116 | 0.141 | 0.183 | 1.910 | 1.840 | 1.606 |

| CL (s) | 0.098 | 0.167 | 0.143 | 1.033 | 1.399 | 1.262 |

| CL_10Mk (s) | 0.113 | 0.176 | 0.112 | 1.759 | 1.960 | 2.066 |

| CL_20Mk (s) | 0.095 | 0.184 | 0.143 | 1.805 | 1.474 | 1.759 |

3.3. Application for New Construction and for Rehabilitation and Conservation Purposes

4. Conclusions

- ▪ As the replacement level in air lime mortars increased, compressive and flexural strengths also increased. However, the 10% substitution (CL_10Mk) proved not to be optimized and revealed inconsistent results. The lack of consistency in the results meant that, in most cases, the properties of these mortars were worse than the reference ones (CL), which may justify further investigation.

- ▪ From the studied percentages, it could be concluded that in air lime mortars with proportions of 1:2 (vol.), only replacements of 20% of lime by Mk effectively improved the overall behaviour.

- ▪ Standard curing at (65 ± 5)% RH had a positive influence on mechanical strength parameters but a negative influence on water behaviour.

- ▪ Humid curing, close to saturated RH, showed a negative influence in mechanical strength tests, mainly durinb the initial ages of some mortars, but it had superior performance related to water. This could be due to the hydration between calcium hydroxide and the Mk silicates, which is slow, competing with the carbonation of the calcium hydroxide itself, which may be blocked by water layers at the mortar surface.

- ▪ Curing by the Atlantic Ocean, with salts contamination, had a negative impact on longer-term mechanical strength values (tested up to 180 days) and a negative effect on water behaviour, especially on drying. However, it will be important to continue assessing the mortar’s performance after further ageing and, if possible, on experimental rendered panels and case studies.

- ▪ From the present study and in comparison with results from literature, mortars with 20% Mk seem promising and should be further studied.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Veiga, M.D.R.; Fragata, A.; Velosa, A.; Magalhães, A.C.; Margalha, G. Lime-Based Mortars: Viability for Use as Substitution Renders in Historical Buildings. Int. J. Arch. Herit. 2010, 4, 177–195. [Google Scholar] [CrossRef]

- Veiga, R. Air lime mortars: What else do we need to know to apply them in conservation and rehabilitation interventions? A review. Constr. Build. Mater. 2017, 157, 132–140. [Google Scholar] [CrossRef]

- Botas, S.; Veiga, R.; Velosa, A.; Silva, A.S. Compatible Air Lime Mortars for Historical Tiled Facades: Bond and Mechanical Strength versus Tile–Mortar Interface Microstructure. J. Mater. Civ. Eng. 2020, 32, 04020112. [Google Scholar] [CrossRef]

- da Fonseca, B.S.; Pinto, A.F.; Silva, D.V. Compositional and textural characterization of historical bedding mortars from rubble stone masonries: Contribution for the design of compatible repair mortars. Constr. Build. Mater. 2020, 247, 118627. [Google Scholar] [CrossRef]

- Forster, A.M.; Válek, J.; Hughes, J.; Pilcher, N. Lime binders for the repair of historic buildings: Considerations for CO2 abatement. J. Clean. Prod. 2019, 252, 119802. [Google Scholar] [CrossRef]

- Nogueira, R.; Pinto, A.P.F.; Gomes, A. Design and behavior of traditional lime-based plasters and renders. Review and critical appraisal of strengths and weaknesses. Cem. Concr. Compos. 2018, 89, 192–204. [Google Scholar] [CrossRef]

- Válek, J.; Hughes, J.J.; Pique, F.; Gulotta, D.; Van Hees, R.; Papayiani, I. Recommendation of RILEM TC 243-SGM: Functional requirements for surface repair mortars for historic buildings. Mater. Struct. 2019, 52, 28. [Google Scholar] [CrossRef]

- Damas, A.L.; Veiga, M.D.R.; Faria, P.; Silva, A.S. Characterisation of old azulejos setting mortars: A contribution to the conservation of this type of coatings. Constr. Build. Mater. 2018, 171, 128–139. [Google Scholar] [CrossRef] [Green Version]

- Segura, J.; Aponte, D.; Pelà, L.; Roca, P. Influence of recycled limestone filler additions on the mechanical behaviour of commercial premixed hydraulic lime based mortars. Constr. Build. Mater. 2019, 238, 117722. [Google Scholar] [CrossRef]

- Pachta, V.; Marinou, P.; Stefanidou, M. Development and testing of repair mortars for floor mosaic substrates. J. Build. Eng. 2018, 20, 501–509. [Google Scholar] [CrossRef]

- Pozo-Antonio, J. Evolution of mechanical properties and drying shrinkage in lime-based and lime cement-based mortars with pure limestone aggregate. Constr. Build. Mater. 2015, 77, 472–478. [Google Scholar] [CrossRef]

- Papayianni, I.; Stefanidou, M. Durability aspects of ancient mortars of the archeological site of Olynthos. J. Cult. Herit. 2007, 8, 193–196. [Google Scholar] [CrossRef]

- Matias, G.; Faria, P.; Torres, I. Lime mortars with ceramic wastes: Characterization of components and their influence on the mechanical behaviour. Constr. Build. Mater. 2014, 73, 523–534. [Google Scholar] [CrossRef]

- Mansour, M.S.; Kadri, E.-H.; Kenai, S.; Ghrici, M.; Bennaceur, R. Influence of calcined kaolin on mortar properties. Constr. Build. Mater. 2010, 25, 2275–2282. [Google Scholar] [CrossRef]

- Borsoi, G.; Silva, A.S.; Menezes, P.; Candeias, A.; Mirão, J. Analytical characterization of ancient mortars from the archaeological roman site of Pisões (Beja, Portugal). Constr. Build. Mater. 2019, 204, 597–608. [Google Scholar] [CrossRef] [Green Version]

- Alvarez, J.I.; Veiga, R.; Martínez-Ramírez, S.; Secco, M.; Faria, P.; Maravelaki, P.N.; Ramesh, M.; Papayianni, I.; Válek, J. RILEM TC 277-LHS report: A review on the mechanisms of setting and hardening of lime-based binding systems. Mater. Struct. 2021, 54, 1–30. [Google Scholar] [CrossRef]

- Elavarasan, S.; Priya, A.; Ajai, N.; Akash, S.; Annie, T.; Bhuvana, G. Experimental study on partial replacement of cement by metakaolin and GGBS. Mater. Today: Proc. 2020, 37, 3527–3530. [Google Scholar] [CrossRef]

- Raheem, A.; Abdulwahab, R.; Kareem, M. Incorporation of metakaolin and nanosilica in blended cement mortar and concrete—A review. J. Clean. Prod. 2021, 290, 125852. [Google Scholar] [CrossRef]

- Gameiro, A.; Silva, A.S.; Faria, P.; Grilo, J.; Branco, T.; Veiga, R.; Velosa, A. Physical and chemical assessment of lime–metakaolin mortars: Influence of binder:aggregate ratio. Cem. Concr. Compos. 2014, 45, 264–271. [Google Scholar] [CrossRef] [Green Version]

- Andrejkovičová, S.; Velosa, A.L.; Rocha, F. Air lime–metakaolin–sepiolite mortars for earth based walls. Constr. Build. Mater. 2013, 44, 133–141. [Google Scholar] [CrossRef]

- Loureiro, A.; Paz, S.P.A.; Veiga, M.D.R.; Angélica, R.S. Assessment of compatibility between historic mortars and lime-METAKAOLIN restoration mortars made from amazon industrial waste. Appl. Clay Sci. 2020, 198, 105843. [Google Scholar] [CrossRef]

- Cardoso, D.; Gameiro, A.; Silva, A.S.; Faria, P.; Vieira, R.; Veiga, R.; Velosa, A. Influence of curing conditions in lime-metakaolin blended mortars—A mineralogical and mechanical study. In Proceedings of the HMC2013—Historic Mortars Conference, University of West Scotland, Glasgow, UK, 11–13 September 2013. [Google Scholar]

- Faria, P. Resistance to salts of lime and pozzolan mortars. In RILEM Proceedings pro067—International RILEM Workshop on Repair Mortars for Historic Masonry; Groot, C., Ed.; RILEM Publications: Paris, France, 2009; pp. 99–110. [Google Scholar]

- Faria, P.; Martins, A. Influence of air lime type and curing conditions on lime and lime-metakaolin mortars. In Durability of Building Materials and Components Building Pathology and Rehabilitation; de Freitas, V.P., Delgado, J.M.P.Q., Eds.; Springer: Berlin Heidelberg, 2013; Volume 3, pp. 105–126. [Google Scholar] [CrossRef]

- Faria, P.; Branco, T.; Carneiro, J.; Veiga, R.; Santos Silva, A. Argamassas com base em cal para a reabilitação de rebocos. In Proceedings of the 4º Congreso de Patología y Rehabilitación de Edificios. PATORREB 2012 Grupo, Santiago de Compostela, Spain, 12–14 April 2012. CD-ROM. [Google Scholar]

- Ferraz, E.; Andrejkovičová, S.; Velosa, A.L.; Silva, A.S.; Rocha, F. Synthetic zeolite pellets incorporated to air lime–metakaolin mortars: Mechanical properties. Constr. Build. Mater. 2014, 69, 243–252. [Google Scholar] [CrossRef]

- Pavlík, V.; Užáková, M. Effect of curing conditions on the properties of lime, lime–metakaolin and lime–zeolite mortars. Constr. Build. Mater. 2016, 102, 14–25. [Google Scholar] [CrossRef]

- Arizzi, A.; Cultrone, G. Comparing the pozzolanic activity of aerial lime mortars made with metakaolin and fluid catalytic cracking catalyst residue: A petrographic and physical-mechanical study. Constr. Build. Mater. 2018, 184, 382–390. [Google Scholar] [CrossRef]

- CEN. EN 459-1:2015. Building lime. Part 1: Definitions, Specifications and Conformity Criteria; CEN: Brussels, Belgium, 2015. [Google Scholar]

- CEN. EN 1097-3:1998. Tests for Mechanical and Physical Properties of Aggregates. Part 3: Determination of Loose Bulk Density and Voids; CEN: Brussels, Belgium, 1998. [Google Scholar]

- CEN. EN 1015-2:1998. Methods of Test for Mortars for Masonry. Part 2: Bulk Sampling of Mortars and Preparation of Test Mortars; 1998/A1:2006; CEN: Brussels, Belgium, 1998. [Google Scholar]

- CEN. EN 1015-3:1999. Methods of Test for Mortars for Masonry, Part 3: Determination of Consistency of Fresh Mortars; 1999/A1:2004/A2:2006; CEN: Brussels, Belgium, 1999. [Google Scholar]

- CEN. EN 1015-6:1998. Methods of Test for Mortars for Masonry, Part 6: Determination of Bulk Density of Fresh Mortars; 1998/A1:2006; CEN: Brussels, Belgium, 1998. [Google Scholar]

- CEN. EN 1015-7:1999. Methods of Test for Mortar for Masonry. Determination of Air Content of Fresh Mortar; CEN: Brussels, Belgium, 1999. [Google Scholar]

- CEN. EN 1015-8:1998. Methods of Test for Mortar for Masonry, Part 8: Determination of Water Retentivity of Fresh Mortar; CEN: Brussels, Belgium, 1998. [Google Scholar]

- CEN. EN 14146:2006. Natural Stone Test Methods. Determination of the Dynamic Modulus of Elasticity (By Measuring the Fundamental Resonance Frequency); CEN: Brussels, Belgium, 2006. [Google Scholar]

- CEN. EN 1015-11:2019. Methods of Test for Mortar for Masonry, Part 11: Determination of Flexural and Compressive Strength of Hardened Mortar; CEN: Brussels, Belgium, 2019. [Google Scholar]

- CEN. EN 1936:2008. Natural Stone Test Methods. Determination of Real Density and Apparent Density, and of Total and Open Porosity; CEN: Brussels, Belgium, 2008. [Google Scholar]

- CEN. EN 15801:2009. Determination of Water Absorption by Capillarity; CEN: Brussels, Belgium, 2009. [Google Scholar]

- Brito, V.; Gonçalves, T.D.; Faria, P. Coatings applied on damp building substrates: Performance and influence on moisture transport. J. Coat. Technol. Res. 2011, 8, 513–525. [Google Scholar] [CrossRef] [Green Version]

- CEN. EN 16322:2013. Conservation of Cultural Heritage—Test, Methods—Determination of Drying Properties; CEN: Brussels, Belgium, 2013. [Google Scholar]

- Arizzi, A.; Cultrone, G. Aerial lime-based mortars blended with a pozzolanic additive and different admixtures: A mineralogical, textural and physical-mechanical study. Constr. Build. Mater. 2012, 31, 135–143. [Google Scholar] [CrossRef]

- Lawrence, M.; Mays, T.J.; Rigby, S.; Walker, P.; D’Ayala, D. Effects of carbonation on the pore structure of non-hydraulic lime mortars. Cem. Concr. Res. 2007, 37, 1059–1069. [Google Scholar] [CrossRef]

- Salomão, M.C.D.F.; Bauer, E.; Kazmierczak, C.D.S. Drying parameters of rendering mortars. Ambiente Construído 2018, 18, 7–19. [Google Scholar] [CrossRef]

- Comité Européen de Normalisation. EN 998-1:2017. Specification for Mortar for Masonry—Part 1: Rendering and Plastering Mortar; Comité Européen de Normalisation: Brussels, Belgium, 2017. [Google Scholar]

- Nunes, C.; Slížková, Z. Freezing and thawing resistance of aerial lime mortar with metakaolin and a traditional water-repellent admixture. Constr. Build. Mater. 2016, 114, 896–905. [Google Scholar] [CrossRef]

- González-Sánchez, J.; Fernández, J.; Navarro-Blasco, Í.; Alvarez, J. Improving lime-based rendering mortars with admixtures. Constr. Build. Mater. 2020, 271, 121887. [Google Scholar] [CrossRef]

| Material | Air Lime (CL) | Metakaolin (Mk) | Sands | Mixture of Sands | ||

|---|---|---|---|---|---|---|

| APAS12 | APAS20 | APAS30 | ||||

| Loose bulk density [kg/dm3] | 0.361 | 0.294 | 1.412 | 1.405 | 1.388 | 1.463 |

| Mortar | Volume | Weight | Mk | Quantities | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| CL (g) | Mk (g) | Sand (g) | Water (mL) | ||||||||

| CL:Mk:S | B:S | CL:Mk:S | B:S | (wt.% of CL) | APAS12 | APAS20 | APAS30 | ||||

| CL | 1:0:2 | 1:2 | 1:0:7.75 | 1:7.75 | 0 | 578.1 | 0.0 | 1129.6 | 1686 | 1665.6 | 1000 |

| CL_10Mk | 1:0.14:2.22 | 1:2 | 1:0.11:8.61 | 1:7.75 | 10 | 520.3 | 57.8 | ||||

| CL_20Mk | 1:0.31:2.50 | 1:2 | 1:0.25:9.69 | 1:7.75 | 20 | 462.5 | 115.6 | ||||

| Mortar | Flow (mm) | Water Retention (%) | Air Content (%) | Fresh Bulk Density (kg/m3) |

|---|---|---|---|---|

| CL | 141 ± 3 | 93.9 | 4.2 | 1952.2 |

| CL_10Mk | 134 ± 3 | 92.4 | 4.3 | 1965.1 |

| CL_20Mk | 137 ± 2 | 92.8 | 4.1 | 1961.7 |

| Mortar (Curing) | Cs (kg/m2) | CC (kg/(m2·min0.5)) | ||||

|---|---|---|---|---|---|---|

| 28 Days | 90 Days | 180 Days | 28 Days | 90 Days | 180 Days | |

| CL (m) | 20.4 | 19.7 | 20.3 | 4.5 | 4.7 | 4.4 |

| CL_10Mk (m) | 23.4 | 23.7 | 24.2 | 3.6 | 4.2 | 4.4 |

| CL_20Mk (m) | 24.0 | 24.4 | 23.7 | 3.2 | 3.4 | 3.4 |

| CL (h) | 20.2 | 20.6 | 20.4 | 3.8 | 4.5 | 4.1 |

| CL_10Mk (h) | 23.7 | 22.6 | 23.6 | 3.6 | 3.8 | 3.8 |

| CL_20Mk (h) | 23.6 | 23.1 | 24.2 | 3.1 | 3.1 | 3.2 |

| CL (s) | 20.3 | 19.8 | 20.1 | 4.6 | 4.4 | 4.0 |

| CL_10Mk (s) | 21.6 | 23.0 | 22.6 | 4.0 | 4.0 | 4.0 |

| CL_20Mk (s) | 22.4 | 22.2 | 23.1 | 3.5 | 3.3 | 3.1 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Monteiro, J.; Silva, V.; Faria, P. Effect of Type of Curing and Metakaolin Replacement on Air Lime Mortars for the Durability of Masonries. Infrastructures 2021, 6, 143. https://doi.org/10.3390/infrastructures6100143

Monteiro J, Silva V, Faria P. Effect of Type of Curing and Metakaolin Replacement on Air Lime Mortars for the Durability of Masonries. Infrastructures. 2021; 6(10):143. https://doi.org/10.3390/infrastructures6100143

Chicago/Turabian StyleMonteiro, João, Vitor Silva, and Paulina Faria. 2021. "Effect of Type of Curing and Metakaolin Replacement on Air Lime Mortars for the Durability of Masonries" Infrastructures 6, no. 10: 143. https://doi.org/10.3390/infrastructures6100143

APA StyleMonteiro, J., Silva, V., & Faria, P. (2021). Effect of Type of Curing and Metakaolin Replacement on Air Lime Mortars for the Durability of Masonries. Infrastructures, 6(10), 143. https://doi.org/10.3390/infrastructures6100143