1. Introduction

Utilizing reclaimed asphalt pavement (RAP) in hot mix asphalt (HMA) is proven to be a green alternative to produce environment-friendly asphalt mixes. Adding RAP in asphalt mixes is suggested not only to conserve the aggregates and bitumen, but also to have at least the same performance [

1]. Recycling of the existing mineral aggregates and asphalt binder in RAP particles would be of great benefit to the environment by saving the nonrenewable materials. Milled pavements are considered to be valuable materials after reaching the end of pavement service life. At a minimum level, RAP can play the role of virgin mineral aggregates in order to conserve the energy and save the environment. However, the ideal goal is to maximize reusing the waste materials in new pavement construction projects in a way that the same or even better performance as compared to the conventional materials can be achieved.

1.1. High RAP Mixes

Although there is no recognized unanimity about the limit of the maximum amount of RAP in HMA, RAP percentage in HMA has been limited by many agencies, mainly, due to the unproven performance of high RAP mixes and also lack of a unified mix design [

2]. The review of the previous research on RAP indicates use of up to 100% RAP in HMA mixes. However, most of the plant-produced 100% RAP hot mix asphalt projects date back to 1991 and earlier [

3,

4,

5]. In 1997, the Federal Highway Administration’s RAP expert task group developed guidelines for the design of Superpave HMA containing RAP [

6]. In the same year, another study by Kandhal and Foo [

7] recommended a three-tier process to deal with RAP in asphalt concrete, where a RAP content of 25% and more was defined as high RAP mix, requiring detailed evaluations [

7]. RAP limitation was also supported by the findings of the NCHRP research report 9–12 [

8]. In spite of several research projects conducted on RAP incorporated mixes, still there is not a clear vision about the interaction of RAP and virgin materials in details. Different scenarios can be considered about the interaction of virgin and aged binder: (1) there is no interaction between old and virgin materials, so RAP could be assumed as a black rock. In other words, the aged binder in RAP does not significantly contribute the total binder content. As the rheology of RAP may be affected by facing preheated aggregate and hot virgin binder, this assumption would most probably be different from what happens in reality. (2) All of the aged binder in RAP blends into the mix and with virgin materials effectively. Again, it is not clear whether this assumption is close to reality or not. Therefore, further research is needed to figure out the rate of interaction between the used and new materials and the significant parameters affecting this phenomenon. Previous study showed that depending on the RAP size and aggregate gradation, the available binder content in RAP would vary [

9]. They have also concluded that there is a significant difference between large and small particles with respect to transition of the asphalt binder from RAP to virgin aggregates.

There was no guidance until early 1990’s for implementation of RAP in HM, but based on experimental studies, FHWA Asphalt Mixture Expert Task Group defined the interim recommendations [

6]. Based on the performance of Marshal Mixes with RAP, and mixes designed according to the Superpave system, AASHTO Standards MP2 (now M323) describes how to design HMA with RAP [

10].

Recycled asphalt mixes consist of complex bituminous material. Further, sometimes unknown milling processes make it difficult to study RAP with predictable properties. Therefore, many issues arise due to RAP variability when high percentages of RAP are used in a mix. One solution for this issue might be using RAP in different layers of pavement structure. An example of such application is discussed by Pratico et al. who describe the feasibility of building a two-layer porous asphalt (TLPA) by recycling from permeable European mixes (PEM) RAP, when highly variable RAP stockpiles are involved [

11].

1.2. RAP Binder Characteristics

RAP mainly consists of aggregates and aged binder. When incorporating RAP in a new HMA, the aged binder can affect the mix behavior in long-term because of the diffusion of RAP and virgin binder. Generally, adding high RAP contents into new mixes can increase the stiffness significantly [

12]. Asphalt as a petroleum-based product is an organic material which can be subjected to short term chemical oxidation due to the combined effect of heat and atmospheric oxygen during the mixing and hauling process. Characterization of oxidation is of utmost importance because this phenomenon makes the material brittle [

13]. This becomes even more crucial when the RAP content in a mix is more than 25%, which according to the conventional definitions mentioned earlier is known as high RAP mix. Therefore, depending on the RAP content, presence of aged binder can change the mixture performance. During the past few decades, several studies have focused on characterizing RAP and on finding the proper way of using it in producing asphalt mixtures. For example, Cosentino et al. [

14] concluded that the controlling factors in the performance of RAP are dependent on where the RAP is obtained and its gradation. However, there are still several aspects of using RAP in HMA that require further investigation such as the impact of RAP source, content, gradation, conditioning, etc.

According to McDaniel et al. [

8], less than 15% RAP has no impact on the blended binder performance in mix. Between 15% and 25% RAP, the virgin binder grade is commonly decreased by one grade (6 °C) on both ends (e.g., a PG 64-22 is changed to a PG 58-28). For more than 25% of RAP, binder needs to be graded using the performance-graded binder tests. Therefore, for the mixes with high RAP content, full characterization of binder is needed.

The aging level of RAP binder film thickness might be changed according to depth where the mix is placed at and presence of oxygen. Bressi et al. [

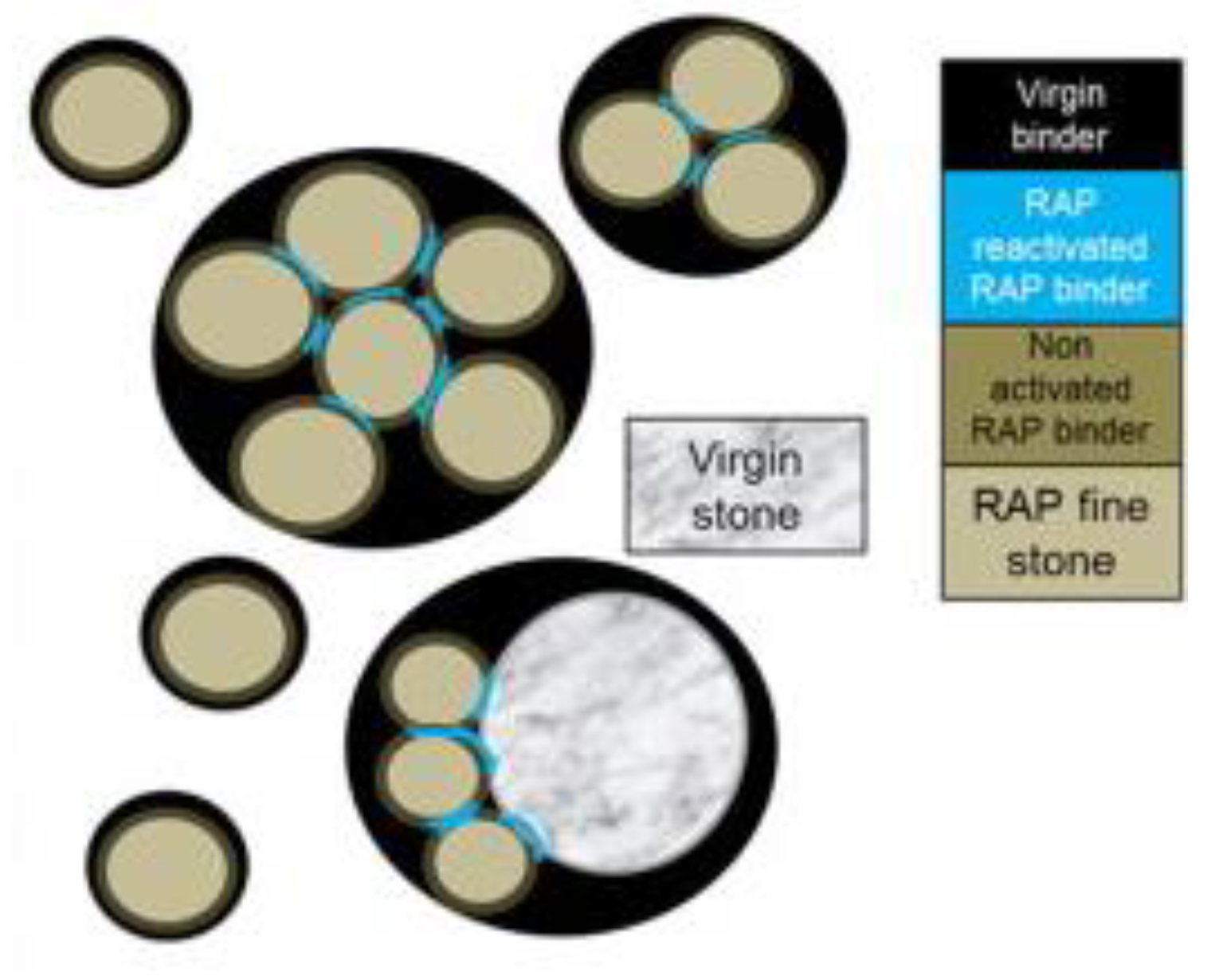

15] proposed a methodology to detect the existence of a cluster phenomenon (

Figure 1) and they also proposed a first approach to show a different aging level in the RAP binder film thickness (i.e., partial differential aging). Stephens et al. [

16] also investigated the asphalt films properties for the coarse aggregates. They concluded that it would be more prone to blending with virgin aggregates than asphalt film around fine aggregates. The aged binder recovered from the coarse and the fine particles was compared by conducting a series of Dynamic Shear Rheometer (DSR) tests. They concluded that there is no correlation between variation in the binder stiffness and the asphalt coating of coarse or fine aggregates. The main issue in this domain was referred to its exposure to heat and air during production, which is a random process and does not correlate with either the aggregate size or related film thickness.

1.3. Effect of RAP Particle Size on Binder-Blending Phenomenon

In addition to the binder rheology in RAP particles several other parameters can affect the final performance of a RAP produced mix. Saliani et al. [

9] showed active binder in coarse RAP is significantly higher than the fine RAP. In their work, Saliani et al. mainly focused on virgin aggregate surface area and correlation with cutting or melting the aged binder from RAP particles. Saliani et al. [

9] concluded that virgin aggregate surface area is another factor that can have an impact on the interaction of recycled and virgin material. In addition to aggregate surface area, film thickness in RAP particles are not the same suggesting that more investigations are needed to characterize the film thickness properties properly.

Gardiner [

17] concluded that the complex modulus is not solely controlled by the stiffness of the binder, whereas several other factors including the gradation and angularity of the aggregate have impact on it. Mixing method, heating temperature, and mixing duration of RAP need to be optimized to ensure the complete blending of the old and new binders so that the plant production process can be better simulated in the lab [

18]. However, all of the aforementioned studies concluded that the stiffness of coarse and fine RAP would be the same, but their binder contribution to the new mix depends on some other factors, such as virgin aggregates surface area, mixing temperature, and RAP preheating temperature (if applicable).

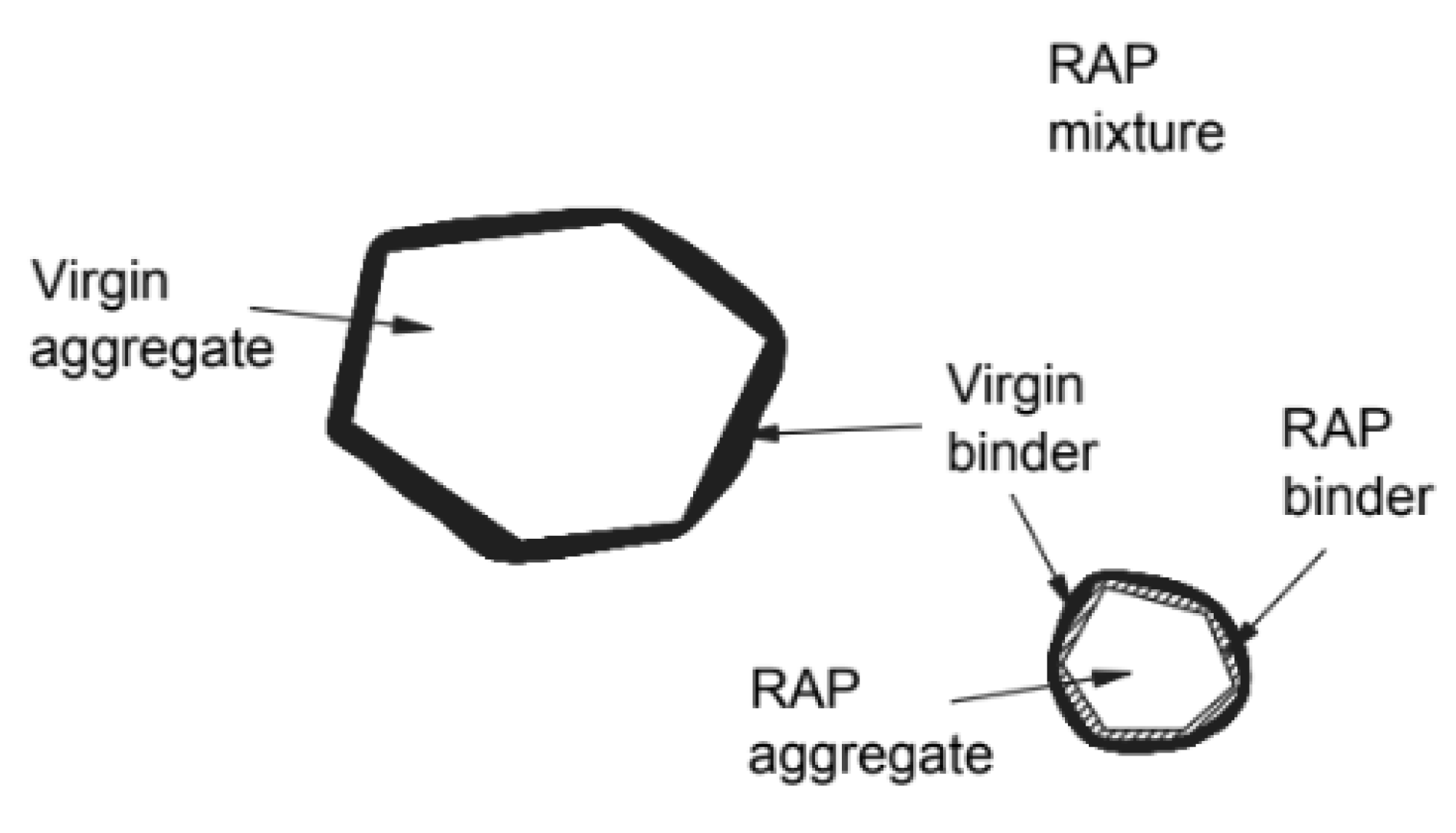

Several researchers studied the blending of RAP and virgin binders. Chen [

19] found that not only RAP does not act like a black rock but also a significant blending occurs between RAP and the virgin binder. However, Huang [

20] studied the blending of RAP with virgin HMA mixtures for a given type of screened RAP. They concluded that aged binder in RAP formed a stiffer layer coating the RAP aggregate particles than the virgin binder (see

Figure 2).

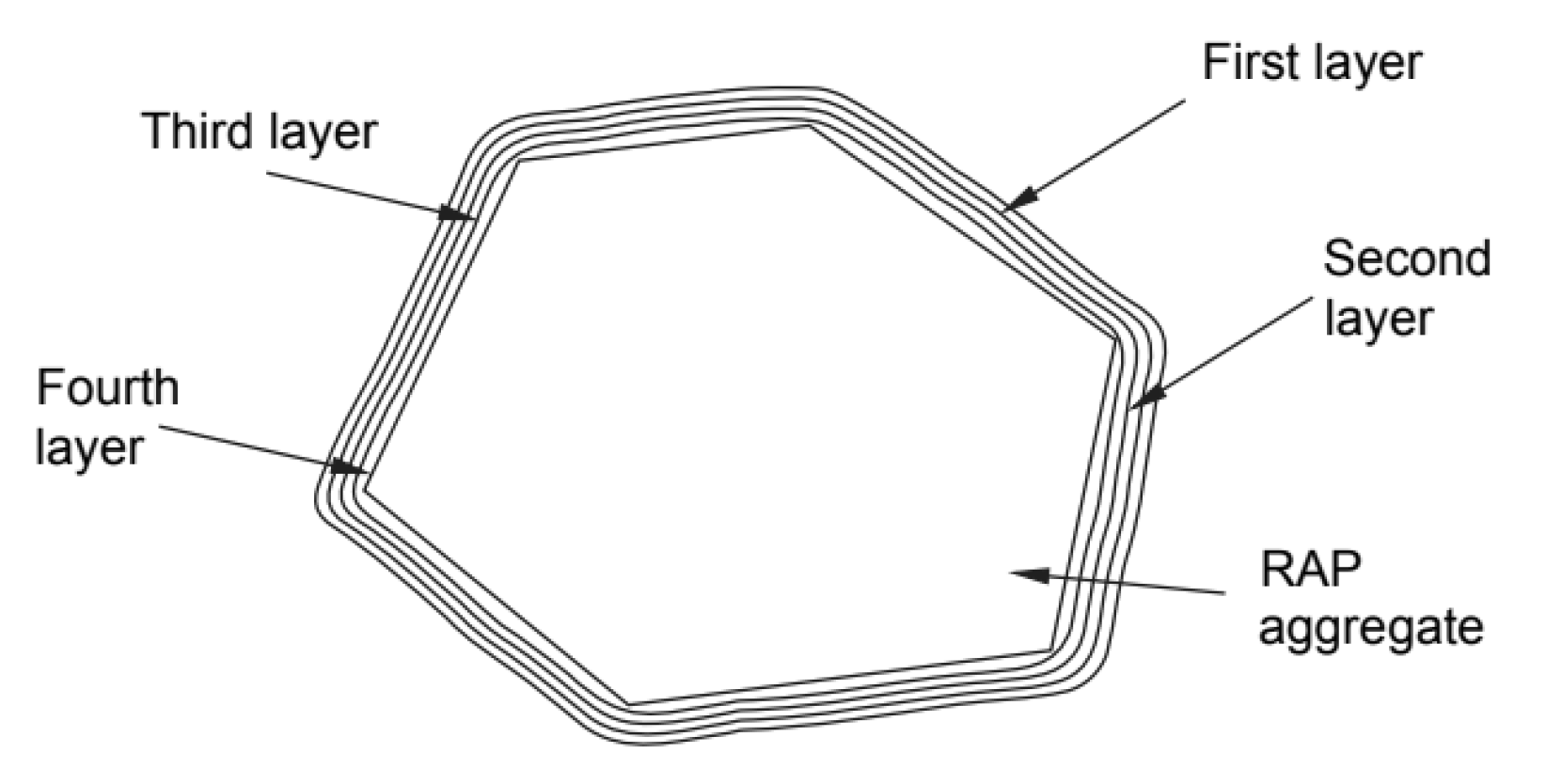

Composite analyses indicated that the layered system in RAP (

Figure 3) helps in reducing the stress concentration in HMA mixtures microstructure. The aged binder mastic layer was actually serving as a cushion layer in between the hard aggregate and the soft binder mastic [

20].

As there is aged binder in RAP particles, bitumen additives might be applied to rehabilitate the aged binder which is not the case in this study. On the other hand, since there is high RAP content in HMA, rejuvenators are recommended [

21,

22,

23]. Additionally, green additives are recommended as cost effective and environmentally friendly alternatives. The green additive is obtained by a simple method from two low-cost and eco-friendly pre-cursors to restore the mechanical properties of the oxidized bitumen, acting on the structure of the bitumen, having a restructuring effect on the altered colloidal network of the aged bitumen binder [

24].

In addition to the binder characterization, mix performance needs to be evaluated when a higher RAP content is used. The indirect tension and semicircular bending test results which were conducted by Huang et al. showed that RAP increases the mixture stiffness [

25]. All RAP materials in Huang et al. study was screened through the No. 4 sieve to acquire a consistent gradation which can compare to the fine aggregates group in this study. There is a possibility to increase the stiffness by adding fine RAP but it depends on job mix formula with inclusion of RAP. Huang et al. assumed that RAP binder totally contributes to the mix, an assumption which still needs to be verified.

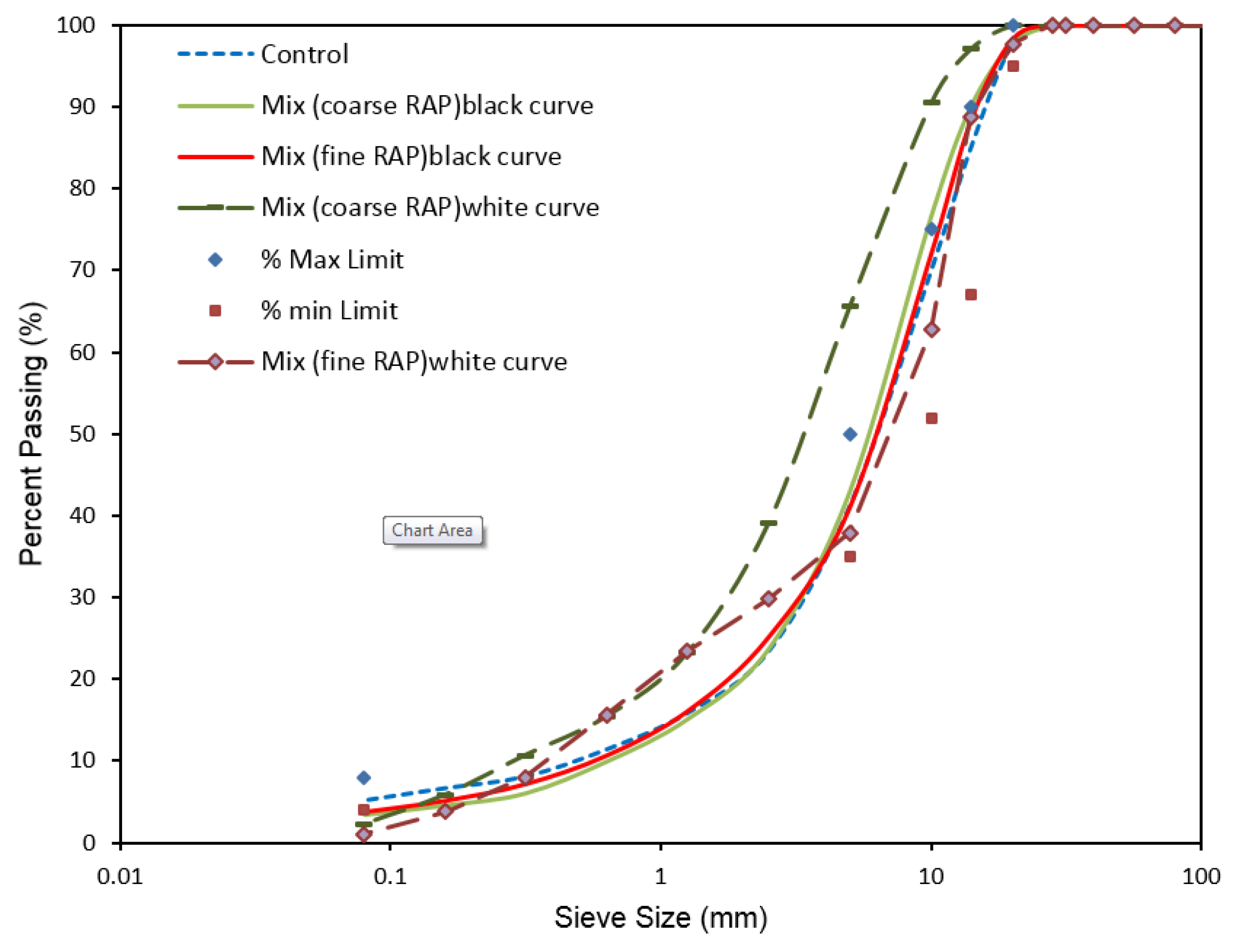

Traditionally, black curves and white curves have been used for sieves analysis of RAP incorporated mixes. Black curves are the gradation of RAP particles from fractioned RAP and white curves are the gradation of recovered RAP aggregate after binder extraction. For a given mix, these two curves are significantly different. Al-Qadi et al. [

26] compared these two curves and concluded that; black curve tends to indicate higher amounts of large particles and lower amounts of fine particles. Therefore, to avoid the detrimental effects caused by unexpected extra fine particles, black curves are not suggested for use in job mix formula calculations. Using the white curve is common practice, however it is not the only approach being used. It should be noted that neither black curve nor white curve represents the actual gradation of the RAP material, and the real gradation lies somewhere in between [

27].

Previous research has shown that the bitumen recovered from coarse particles differ from fine particles [

28]. They concluded that RAP bitumen participation in hot mix process significantly depends on RAP size. The aging rate in fine particles is also faster than coarse particles. Therefore, it can be concluded that the RAP particle size would affect the properties of the RAP incorporated mix and can affect the overall performance of the pavements.

2. Research Goal, Scopes, and Objectives

Review of the literature on RAP indicates that there is not a consensus on several aspects of the RAP binder contribution to the new mix. Therefore, it is difficult to come up with a synthesis of previous work that would be unanimously acceptable. In summary, it can be concluded that the coarse and the fine RAP fractions have relatively similar stiffness, but their contribution to the new mix is different. Therefore, the goal of this project is to understand the interaction of coarse RAP and fine RAP binder in HMA more precisely, through studying mixes prepared with either fine RAP fraction or coarse RAP fraction separately. To this end, various empirical and thermo-mechanical tests are adopted to validate the impact of RAP fractions on the HMA mixes.

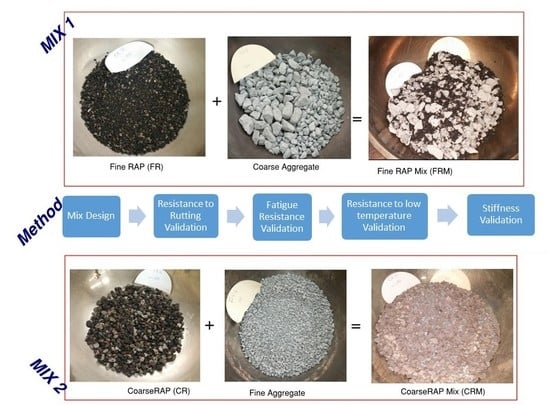

In this study, the RAP particles are separated in two groups by following the LC 21-040 protocol: particles passing sieve number 5 (5 mm), called fine RAP, and those retained on sieve number 5 are considered as the coarse RAP. The main objective of this research is to characterize RAP particles according to the particle sizes used to produce them. Generally, fine RAP is expected to possess a higher binder content, while there has not been any clear evidence to support this claim yet. The presence of such extra amount of binder (as compared to the coarse RAP) may potentially enhance the pavement resistance to cracking. Previous studies showed that in high RAP content mixes, the amount of binder (or mastic) that would diffuse into virgin binder from the fine RAP particles is less than that from the coarse RAP particles. Therefore, it was deemed necessary to further investigate the mix design and mix performance to characterize the fine and coarse RAP mixes more comprehensively. This research aims to characterize the mixes produced using the fine RAP and Coarse RAP in terms of stiffness, fatigue cracking, permanent deformation, and thermal cracking resistance.

3. Materials and Experimental Methods

Generally, limits have been set on the maximum allowable amount of RAP in HMA mixes to avoid the loss of performance due to the impact of more aged binder content, which is present in RAP particles. However, many aspects of RAP incorporated mixes have been investigated by several past studies, the effect of increased RAP content using only coarse or fine RAP particles has not been fully explored. Therefore, in this study it was hypothesized that coarse RAP mix characteristics is different from fine RAP mix and such difference can affect the mix performance. The results might be used to identify the functional class for proper use of RAP mixes in pavement structural design in different layers. Three mixes were designed in this study, including a control mix, a fine RAP mix, and a coarse RAP mix. It was assumed that all of the RAP binder would contribute to the total binder content of the mix. Consequently, it was assumed that all three mixes have the same binder content. Furthermore, the black curve was used for the aggregate gradation in the mix design process.

Four performance tests were used to characterize the mixes in this study. These tests were selected to evaluate the mixes from the major aspects of the pavement materials characteristics, that is, high temperature performance, low temperature cracking, and fatigue cracking. They can be classified as two categories of empirical and thermo-mechanical tests. Resistance to rutting (MLPC wheel tracking rutting tester or French Wheel Tracking Test) is used in this study as the empirical test. The thermo-mechanical tests utilized in this research are as follows:

Complex (dynamic) modulus test,

Uniaxial tension–compression test for resistance to fatigue cracking, and

Thermal stress restrained specimen testing (TSRST) to evaluate resistance to low temperature cracking.

3.1. Mix Design and Volumetrics

A control mix was designed and prepared with only virgin aggregates and virgin asphalt binder. The control mix was a 20 mm-dense graded HMA, commonly used as a base course in Quebec. The design binder content using a PG 64-28 was determined to be 4.5% by the weight of the total mix. A bituminous mixture with a nominal maximum aggregate size of 20 mm, called Grave Bitumen (aka GB20) is mostly used in binder course layer of pavements in Quebec. The selected virgin binder (PG 64-28) is a medium grade asphalt binder that can be used in warm climates. The aggregate size and gradation were selected based on the LC method specifications. This virgin asphalt concrete mix will be referred to as the control mix hereafter in this paper. The LC Test Methods Compendium, produced by the General Directorate of the Pavement Laboratory of the Ministère des Transports du Québec, presents all the test methods used to measure the characteristics of materials used in the construction and maintenance of infrastructures. Additionally, two more mixes (fine and course) were also designed for comparison and validation purposes. Fine RAP mix contained 35% fine RAP content (passing sieve 5 mm) and coarse RAP mix contained 54% coarse RAP content (retained on sieve 5 mm). Initially, it was assumed that all of the aged binder in the RAP could blend into the virgin binder, so that the total binder content could be assumed to be the same for all of the mixes. These mixes would be referred to as Fine RAP (FRM) and Coarse RAP (CRM) in this paper. It should be noted that regardless of the RAP fraction sizes, the target gradation of the mixes were kept the same.

More experimental mixes were initially designed to study the active RAP binder content and their participation in the mixt. The RAP content varied from 0% to 59%. The gradation curves of the experimental mixes were all in accordance with the Ministère des Transports, de la Mobilité durable et de l’Électrification des Transports specification. The mix gradations are shown in

Figure 4. It can be seen that the mixes have the same black curve gradation. First, there was a question of whether to use the white or black curve gradation. With respect to having the same binder content and aggregate gradation as the fixed variable, the black curve was chosen in this research. Consequently, all mixes would have the same binder content, same aged binder content and same black curve, but different RAP content.

The differences between the two RAP mixes are the RAP particle size and content. This experimental program was designed to investigate the impact of RAP size on Hot Mix Asphalt (HMA). It was envisioned that there is no advantage in looking solely into the RAP content by itself, rather considering the RAP binder content and RAP mix gradation. This plan was designed to achieve the same RAP binder content in both mixes, as well as keeping the final mix gradation the same. In this project, RAP content translates to RAP binder content and RAP size, where the former was kept constant in both mixes and studying the effect of the latter was set as the main objective of this research.

The Superpave

TM mix design method was followed in this study. The only design criterion was the binder content at this level of the study (see

Table 1 Design Criterion). Using the design binder content of 4.5%, the control mix was prepared with 4.5% virgin binder content, while for the RAP mixes the RAP binder contribution was considered in determining the needed virgin binder content. The recovered RAP binder from chemical extraction showed that the Coarse RAP (CR) had 4.3% binder, whereas the Fine RAP had 6.7%. In order to do mix design, sufficient amounts of coarse and fine RAP were chosen to have the same recycled binder ratio in the final mixes.

Table 1 presents the summary of the virgin and aged binder contributions in the fine and coarse RAP mixes.

The composition of control and experimental mixes, as well as the values of the volumetric obtained from the mix design, are shown in

Table 2. It can be realized that most of the volumetric values are within the LC method specification.

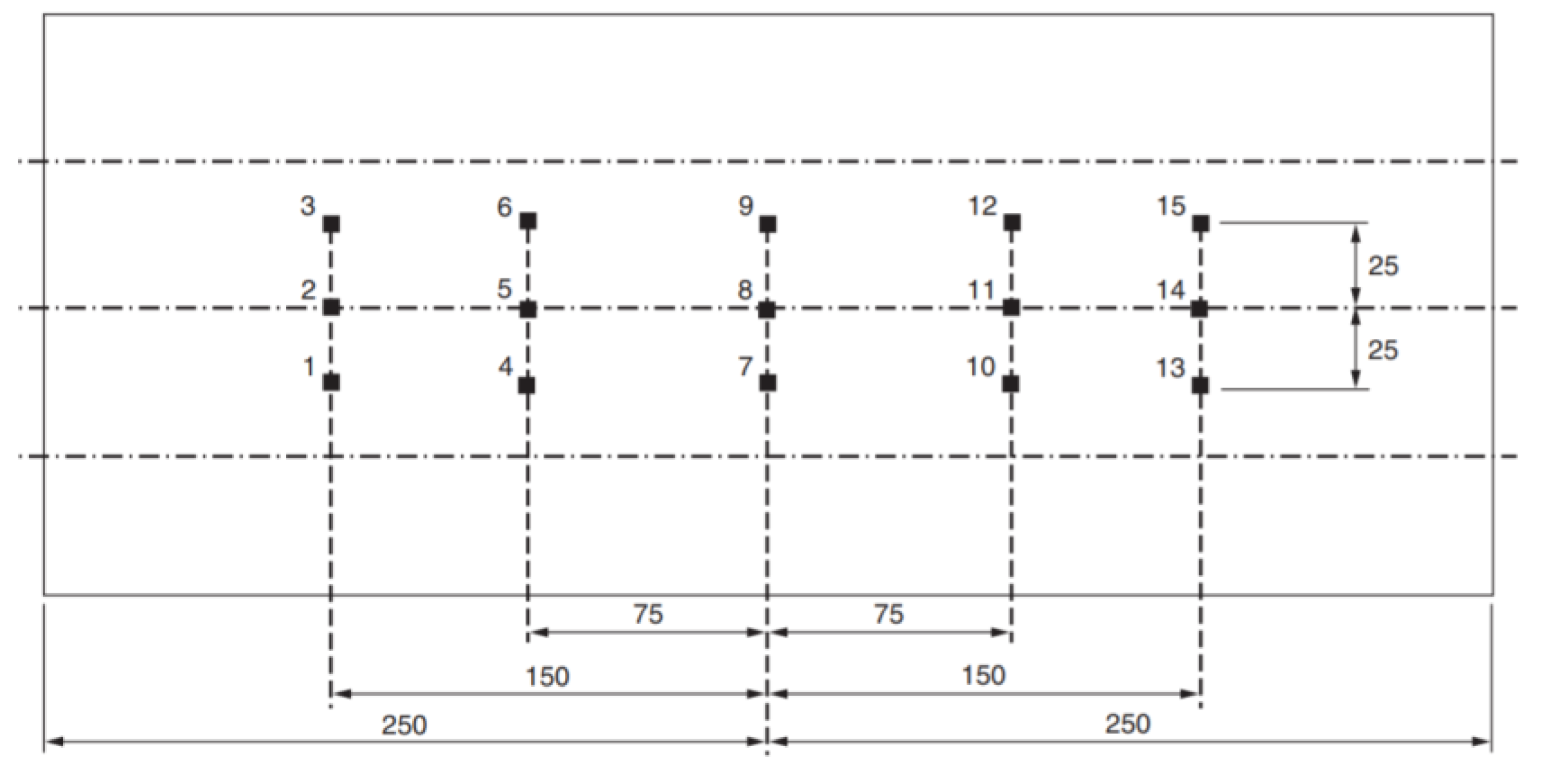

The compaction process was done following to the LC 26-400 Fabrication d’éprouvettes au compacteur LCPC. The laboratory compacted cylindrical specimens were stored for a minimum of one month at room temperature in a sand bed prior to testing. Mechanical tests, including fatigue, and complex modulus were performed on cored specimens extracted from slabs as shown in the schematics in

Figure 5. Samples were compacted by the French MLPC wheel compactor (

Figure 6).

3.2. Resistance to Rutting

All mixes were subjected to laboratory testing for resistance to rutting. The equipment used in this study was developed by France’s Laboratoire Central des Ponts et Chaussées (LCPC) (see

Figure 7 and

Figure 8). The test was standardized in Europe (EN 12697-22A1) and in the province of Quebec, Canada (LC 26-410). It is also commonly used for research purposes by the asphalt industry in other countries [

29,

30].

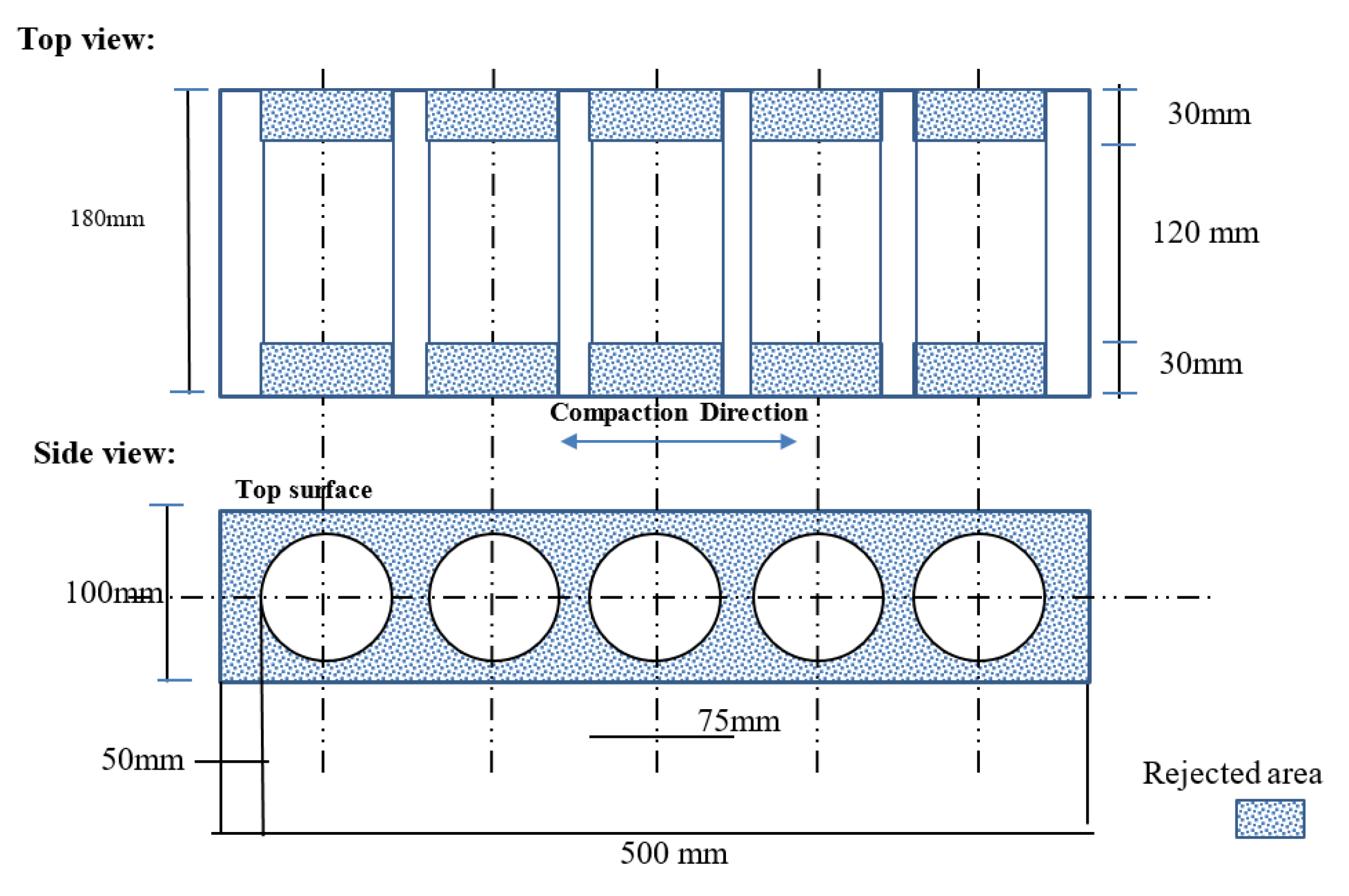

Slab dimensions were 500 mm by 180 mm with a thickness of 100 mm. The level of compaction must correspond to what is obtained in the field. On roadways, the required minimum compaction level is usually 92%. For most hot mixes, laboratory-manufactured specimens at the 92% level may lead to rutting after compaction. Consequently, laboratory-prepared specimens are compacted to a greater value, approximately 95%. At this level, post-compaction is generally negligible [

31]. Heating temperatures for mixing and compaction are indicated in the test method LC 26-003. This laboratory step was done according to AFNOR Standard P98-250-2 Préparation des mélanges hydrocarbonés; Partie 2: Compactage des plaques.

Prior to the rutting test, a preconditioning was done by rolling the pneumatic tire of the rutting tester across the specimen for 1000 cycles at the ambient laboratory temperature. The preconditioning helps with minimizing discrepancies due to the installation of the specimens in the mold. The slabs were then conditioned to reach the testing temperature of 60 °C. Once the temperature of 60 °C was reached, the rutting test was started, and rut depths were measured after 30, 100, 300, 1000, 3000, 10,000, and 30,000 cycles (as applicable). The rut is defined as the mean vertical displacement of the hot mix surface as compared to the mean height of the specimen before starting the test. As described in AFNOR P 98-253-1 Déformation permanente des mélanges hydrocarbonés; Partie 1: Essai d’orniérage, height measurements were taken at 15 locations over the slab area. The stress induced by the tires was maintained at 0.6 MPa during the tests.

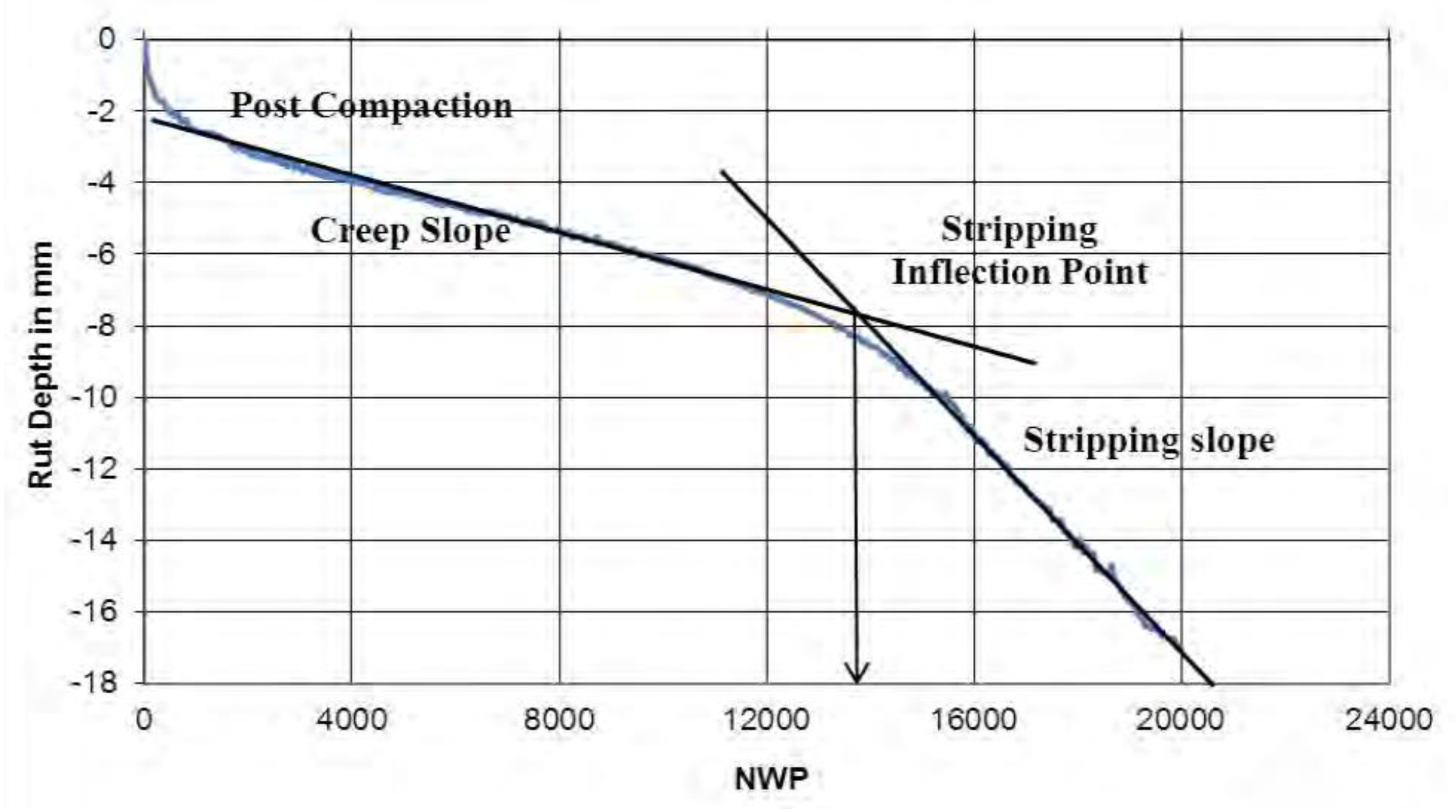

Rutting generally progresses along a straight line when plotted on a logarithmic scale against the number of wheel passes. In order to have an acceptable rutting resistance, the rut depth, expressed as percentage of the specimen thickness, should be less than 10%. Yildirim et al. [

32] characterized the rutting trend by post-compaction consolidation, creep slope, stripping slope, and stripping inflection point by a typical Hamburg Wheel Tracking Device Test (see

Figure 9). Post-compaction consolidation is the deformation (mm) at 1000-wheel passes. Creep slope is the inverse of the rate of deformation in the linear region of plot between post compaction and stripping inflection point (if stripping occurs). Stripping inflection point is the number of wheels passes at the intersection of creep slope and stripping slope. Finally, stripping slope is defined as the inverse rate of deformation after the stripping inflection point.

Meunier [

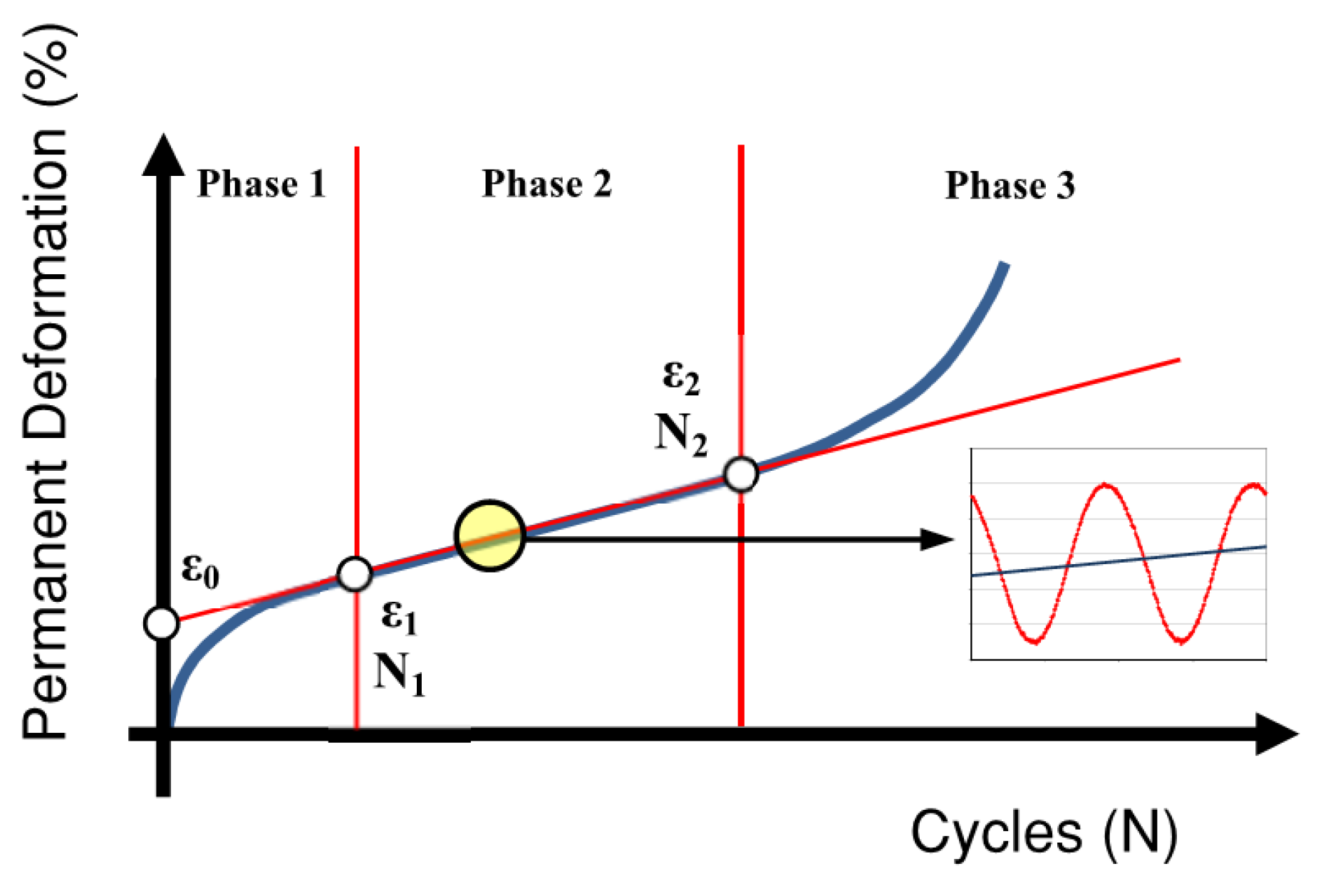

33] characterized the rutting trend from cyclic compression-tension test in three phases as shown in

Figure 10. They concluded that the deformation increases rapidly in first phase. In phase two, the deformation increases by a constant rate per loading cycle. It should be noted that phase three marks the failure of the material and is usually considered less accurate for the purpose of prediction process than the previous two phases.

3.3. Thermo-Mechanical Tests

For the purpose of thermo-mechanical characterization of the mixes in this study, two main tests, namely uniaxial fatigue test and TSRST, were performed by means of a 25 kN servo-hydraulic system.

Figure 11 shows a graphical illustration of the test set-up with the specimen and extensometers. Three extensometers were mounted on the specimens, 120° apart around the sample, to measure the axial strain during the tests.

The set-up was enclosed in an environmentally controlled chamber with three temperature probes, capable of cooling and heating within a range of −40 °C to 80 °C. The following sections provide more details about these two tests.

3.3.1. Fatigue Resistance

Fatigue characterization was performed by means of the uniaxial tension–compression (T–C) tests on cylindrical specimens in this study. The experimental test setup is almost the same as the complex modulus test. The fatigue test was performed at a single loading frequency of 10 Hz at 10 °C. The advantage of using this test over the other conventional fatigue tests is possibility of maintaining the homogeneous state of stress and strain in the sample during the testing process.

The cored samples from slabs were tested under uniaxial T–C condition and the axial strain values were measured using three extensometers. The average of recorded values was considered as the strain level in the sample. Data quality measures were used to ensure that the assumption of homogenous stress/strain condition has not been violated. To this end, reaching a difference of ±25% in the recorded values was considered as an indication of highly non-homogeneous conditions for the strain field within the sample. Therefore, in such cases the test should be considered no longer valid beyond that limit [

34].

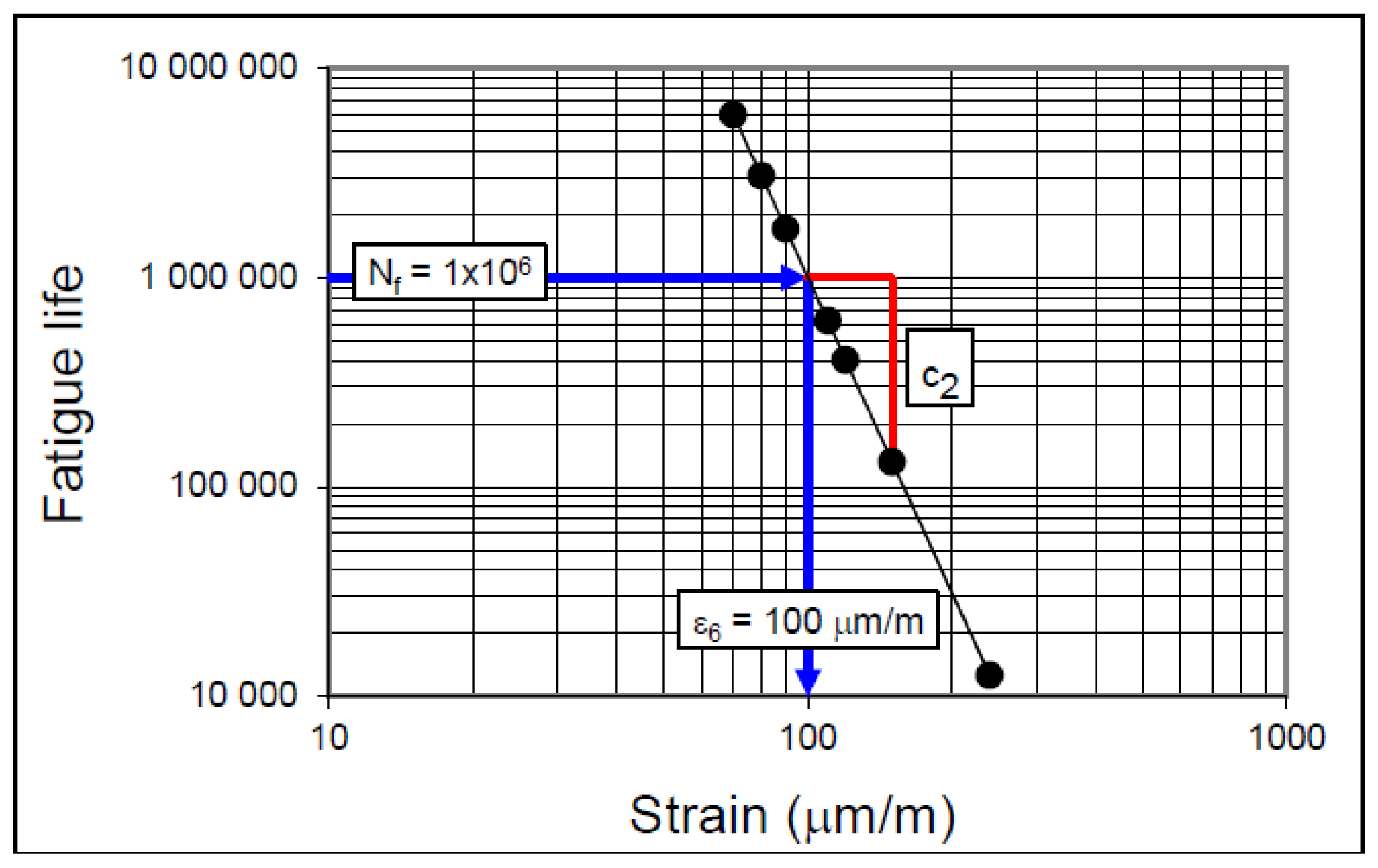

The graphical presentation of the fatigue test results is usually given by Wöhler curve or fatigue curve (see

Figure 12). This curve shows the relation between the fatigue life (N

f) and the level of loading expressed by the initial strain (or stress) amplitude in a bi-logarithmic scale [

35]. A particular value of strain called (ε

6) can be found to correspond to the value of the strain level that would lead to a fatigue life of 1,000,000 cycles. This value is commonly used to characterize the fatigue resistance of the bituminous mixes [

36]. The fatigue resistance is determined through a series of laboratory tests in different magnitudes of solicitation under controlled conditions (temperature and frequency). As demonstrated by the log-log plot in

Figure 12, Wöhler’s Law is associated with a straight line, where fatigue behavior is characterized by two parameters: the slope (c

2) and the Y-intercept (c

1). Coefficients c

1 and c

2 depend on both, the material and the chosen failure criterion [

37]. It should be noted that most of the fatigue-cracking models characterize fatigue failure in three stages: crack initiation, crack propagation, and fatigue induced fracture [

38]. The classical fatigue failure criterion determines the fatigue life as the number of loading cycles that the specimen can take to the point that a 50 percent loss of the initial stiffness for homogeneous tests, or when a 50 percent loss of the initial sample rigidity for non-homogeneous tests is observed [

39,

40].

Based on the Wöhler curve, the fatigue characteristics of asphalt mixtures can be expressed by Equation.

where:

Nf is fatigue life (number of cycles corresponding to the failure point for a given criterion);

ε0 is applied strain amplitude (mm/mm) at a given testing temperature (θi) under a specific testing frequency (f);

C1 is coefficient corresponding to the expected fatigue life for a strain amplitude of 1 mm/mm, at the given testing temperature and loading frequency;

C2 is slope of the Wöhler curve when it is associated with a straight line in the log Nf–log ε0 domain.

3.3.2. Resistance to Low Temperature Cracking

TSRST simulates thermo-mechanical response of flexible pavements during the cooling period. The principle of the test is to restrain the tested specimen from any axial deformation by keeping the total height of the specimen constant throughout the testing period. As a result of decreasing the chamber temperature at a constant cooling rate of 10 °C/h, the magnitude of thermal stress in the specimen would increases until the failure of the specimen. It is also possible to calculate the axial stress as a function of the measured temperature.

Once at failure point, the stress would reach its peak value, referred to as the failure strength (r

f), whereas the corresponding temperature can be defined as the failure temperature (T

f). The slope of the stress-temperature curve increases progressively until a certain temperature where it remains quasi-constant (the stress temperature curve becomes linear). To estimate the value of the quasi-constant slope, the parameter drz/dT is calculated by linear fitting of the curve between the failure temperature and the transition temperature. Tapsoba et al. [

41] assumed transition temperature (T

t) as the temperature where axial stress reaches 50% of the failure strength. It corresponds to the temperature where the material changes from ductile to brittle behavior and vice versa and will be used to evaluate the repeatability of TSRST.

4. Results and Discussion

Three mixes were investigated in this study, including a control mix, an HMA mix with inclusion of fine RAP (FRM) and an HMA mix with inclusion of coarse RAP (CRM). The FRM mix consisted of 35% RAP with 2.2% virgin binder and the CRM mix had 54% RAP and 2.2% virgin binder. The results of the experimental studies on these three mixes are as follow:

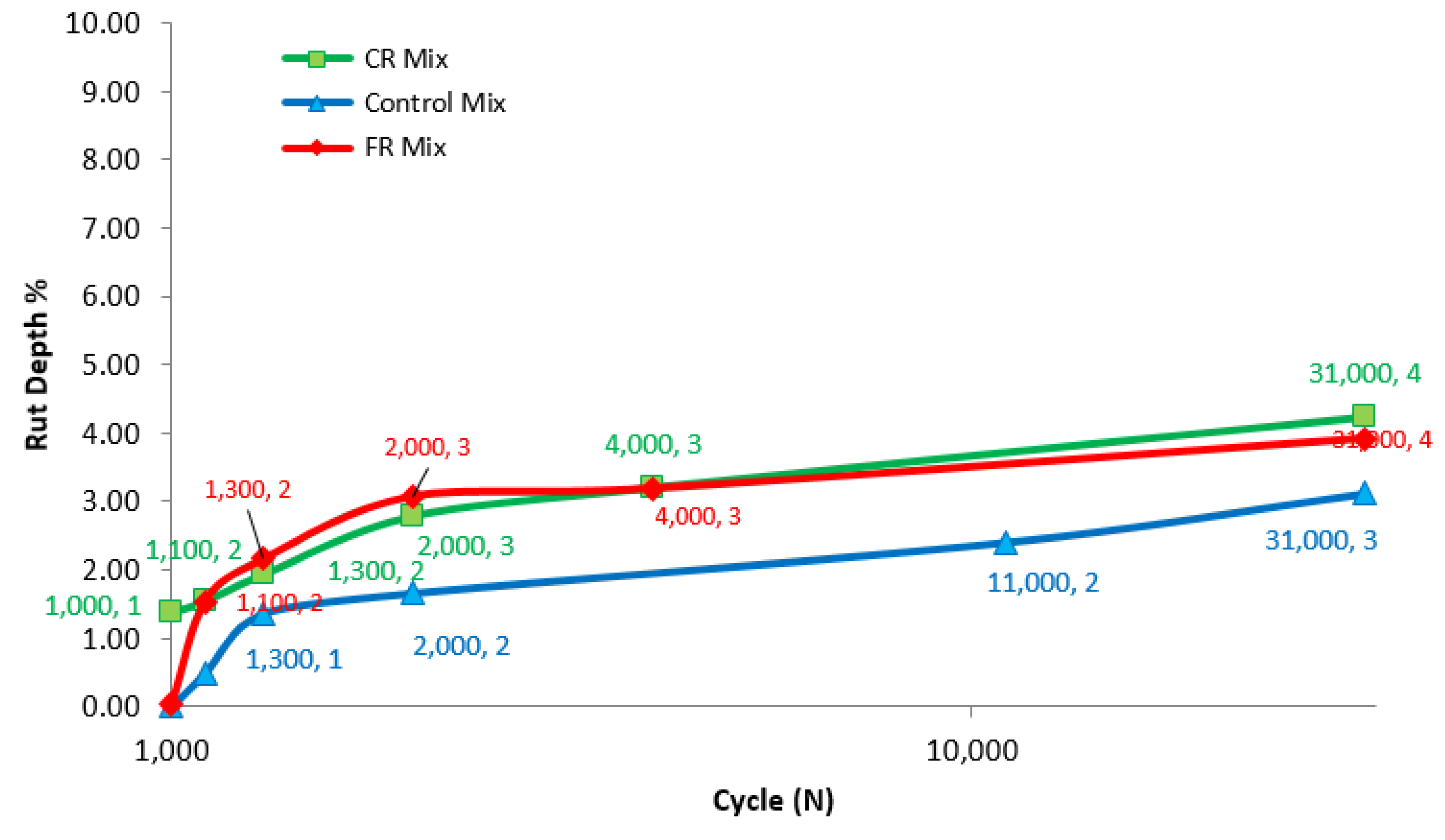

4.1. Rutting Resistance of FRM versus CRM

Permanent deformation of the mixes was evaluated at 60 °C using the French rut tester. All mixes (slabs of 100 × 180 × 500 mm) were subjected to repeated loading of a tire inflated to 0.6 MPa, mounted on a carriage that moves back and forth at 1 Hz with a load magnitude of 5 kN.

Figure 13 and

Figure 14 show the results of rutting tests.

Figure 13 indicates the percentage of permanent deformation by straight line for all mixes in the logarithmic scales. The results confirmed that all of the mixes exhibited deformation magnitudes less than 10% after 30,000 cycles. Therefore, it can be concluded that all of the mixes in this study were strong enough to resist the permanent deformation failure. It should be noted that the mixes had the same black curve gradation, but they showed different behavior under the cyclic wheel load. Therefore, as it was expected the black curve assumption was not found to be a reliable representation of the aggregate skeleton when RAP is incorporated.

A single sample of each mix type was adopted for permanent deformation validation. Basically, the first 1000 preconditioning cycles (aka cold runs) are assumed to capture the continued consolidation stage. There was a significant difference between FRM and CRM mixes. The rest of loading was performed at 60 °C. In addition, the binder exhibits a softer response at 60 °C than the cold cycles temperature. This difference in rutting might be caused by impact of aggregate gradation and air void content.

After 1000 hot cycles (post compactions), FRM was deformed almost as same as CRM. Both RAP mixes deformation were two times higher than control mix. This section could be characterized by S1 and S2. Parameter “S” represents the slope of the permanent deformation in

Figure 13. For the FRM and the control mix, rut depth dramatically increased at first 300 cycles (S1) and continued at a constant slop, whereas for the CRM, these slopes increased at the same rate in both steps (i.e., S1 and S2).

The last stage represents the reaction of material to wheel passes loading which can be translated as rutting values.

Table 3 shows the slop per section of rutting test. It can be seen that the CRM and control mix responded the same way to the load in rutting section, which was two times higher than FRM (see S4 in

Table 3). The aggregate gradation plays the main role in rutting resistance. In this study, black curve was kept the same in all mixes.

CRM white curve showed finer than control mix but the black curve was almost same as control mix. CRM deformed as same as control mix at last stage but it could be compacted more than control mix at the beginning. Large aggregate gradation (D > 5 mm) in FRM black curve was same as the control mix but fine part of FRM white curve showed more fine content in gradation which was expected. However. It cannot be concluded whether it is more appropriate to use white or black curve up to this point.

In conclusion, rutting results can be divided in three phases: deformation at the end of 1000 cold cycles, 1000 hot cycles and 30,000 cycles. First phase which was called continued consolidation earlier, suggests that the CRM gradation and air void were different form FRM mix, which was found to be true; because CRM specimen had 8% air void but FRM specimen had 6%. Second phase which was called post compaction (S1, S2, S3), suggests that the specimen binder is soft enough to indicate the difference in aggregate gradation. Flatter slope can be translated to well packing phenomenon. It was recognized that the CRM could be packed better than FRM. Last section which was called rutting, showed the rutting resistance of mixes. The results indicate that the FRM was more rut-resistant than CRM and also than the control mix. The FRM and the control mix differed only in the fine part in aggregate gradation, especially magnified by the white curve. Thus, FRM mix had stiffer fine skeleton than control mix. According to black curve, CRM and control mix had the same gradation, but considering the white curve, CRM was much finer than control mix. Basically, coarser mixes have better rutting resistance as compared to the CRM. The CRM was expected to be weaker than the control mix but exhibited the same response as the control mix. In both FRM and CRM mixes, better or at least the same resistance as the control mix was recorded in spite of the fact that there is 54% (or 35%) recycle materials in the mix. The results indicate that the FRM prepared with 35% RAP exhibited almost similar performance as the CRM prepared with 54% RAP. It can be concluded that both of the RAP incorporated mixes exhibit satisfactory rutting resistance.

4.2. Fatigue Resistance Results

In this study, the classical method was used among the four types of failure criteria mentioned earlier.

Table 4 provides the specimen details, the actual and target initial strain values, and the number of cycles to failure (aka fatigue life) for each specimen. The fatigue results are sensitive to the air void level, and hence it was attempted to maintain the same level of air void for all the specimens.

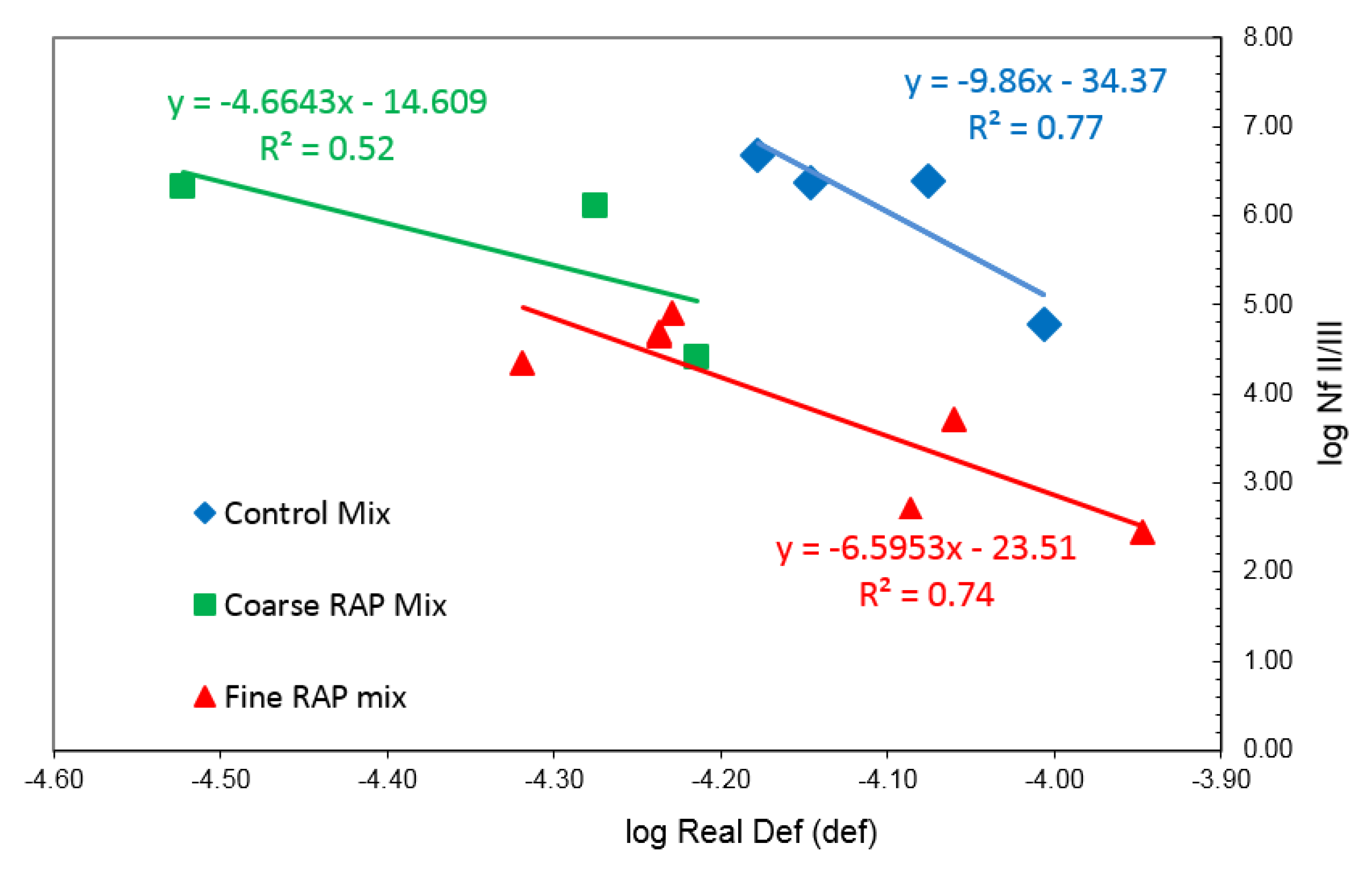

In

Table 5, it should be noted that the classic failure criterion of 50% reduction in the initial stiffness was not found reliable, due to the fact that a significant loss of modulus has occurred during the first phase of the T–C test. In spite of the fact that some researchers use the 50, 100, 200, or even 1000 cycles to calculate the initial modulus, the results were not representative of the fatigue-induced damage. Therefore, the more scientific Wöhler approach was used to study the fatigue performance of the mixes in this study.

Regression based fatigue equations were developed based on the test results to quantitatively characterize the mixes (

Figure 15). In order to develop this chart, various fatigue samples were subjected to sinusoidal load at three different strain levels in order to be able to run a linear regression. The value of ε

6 corresponds to the strain level at which the asphalt mix would reach a fatigue related failure after 1 million cycles. For the sake of comparison, it can be noted that a standard asphalt base course material, made with straight run asphalt cement, usually exhibits ε

6 values in the range of 70 to 90 μm/m. ε

6 in this project is 81 μm/m for control mix. The value of R

2 shows the quality of linear assumption. ε

6 for CR in higher than that of FR. CR failed at 43.57 μm/m and FR failed at 28.94 μm/m. The slope of the trend line shows the degree of sensitivity of mix to deformation. Sharp slope is highly sensitive to deformation, it means that under a small change of deformation there would a huge difference in number of repetition that the mix can take until failure. The CR had less sensitivity to the changes in deformation, and it even surpasses the control mix with this regard.

Basueny et al. [

42] concluded that when the percentage of RAP in the mix is considerably high, the aged RAP binder creates a significant change in the mixture properties. Therefore, it can be concluded that the influence of RAP on the final HMA property also varies with the amount of RAP. The mixes in this study were supposed to have similar recycled binder replacement ratio and black curve gradation, however the CR mix resists to fatigue much better than the FR mix. It can be concluded that black curve assumption is not the best representation of RAP gradation. Virgin binder in CRM is mostly covering the fine natural aggregates and adhesion to CR. More unaged binders in mastic increase the resistance under the tension and compression repeated loads. FRM has more aged binder in fine part of the skeleton that caused weakness of fatigue resistance. Overall, the CRM exhibited a better fatigue performance than the FRM.

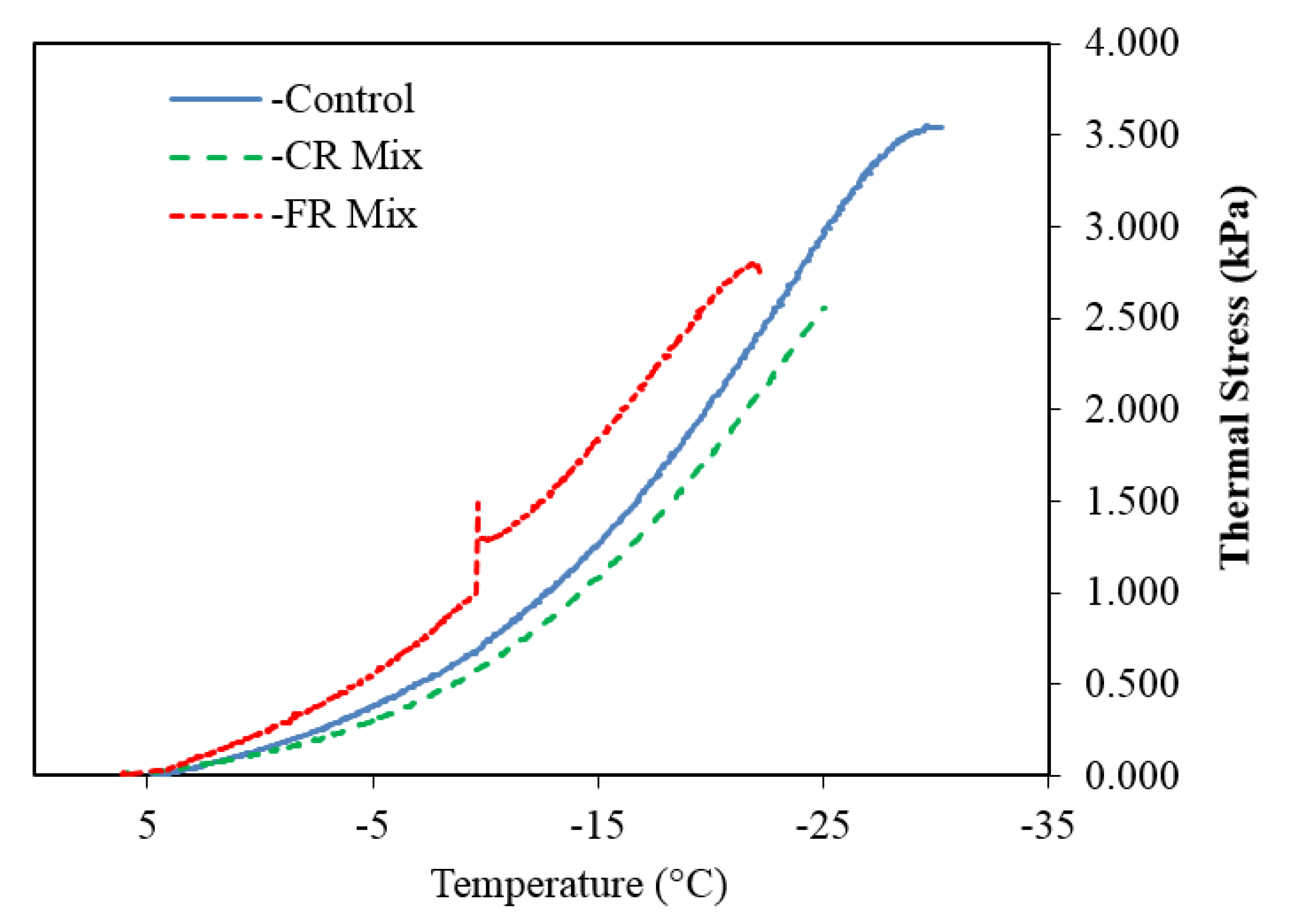

4.3. Resistance to Low Temprature Cracking through TSRST

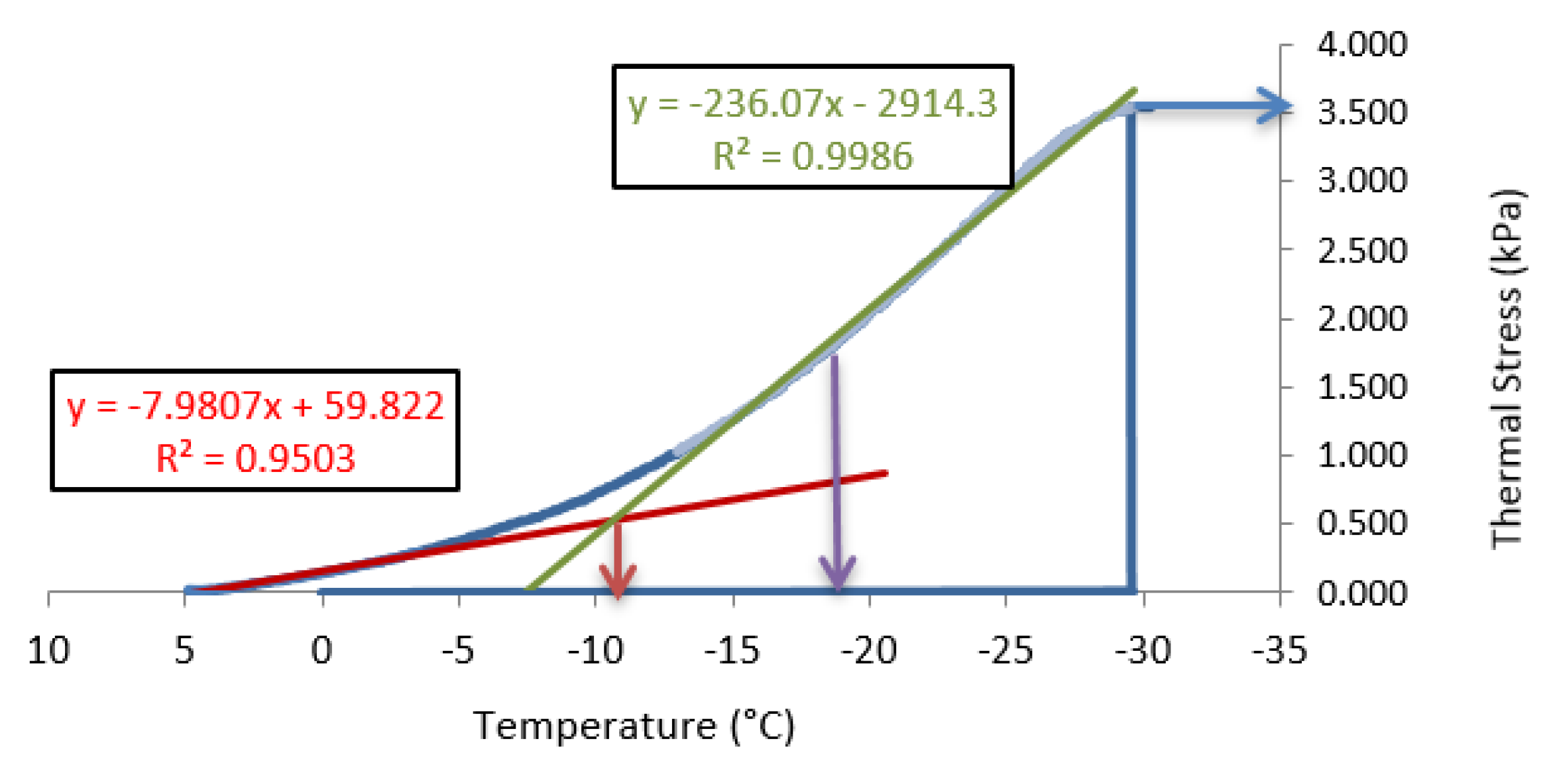

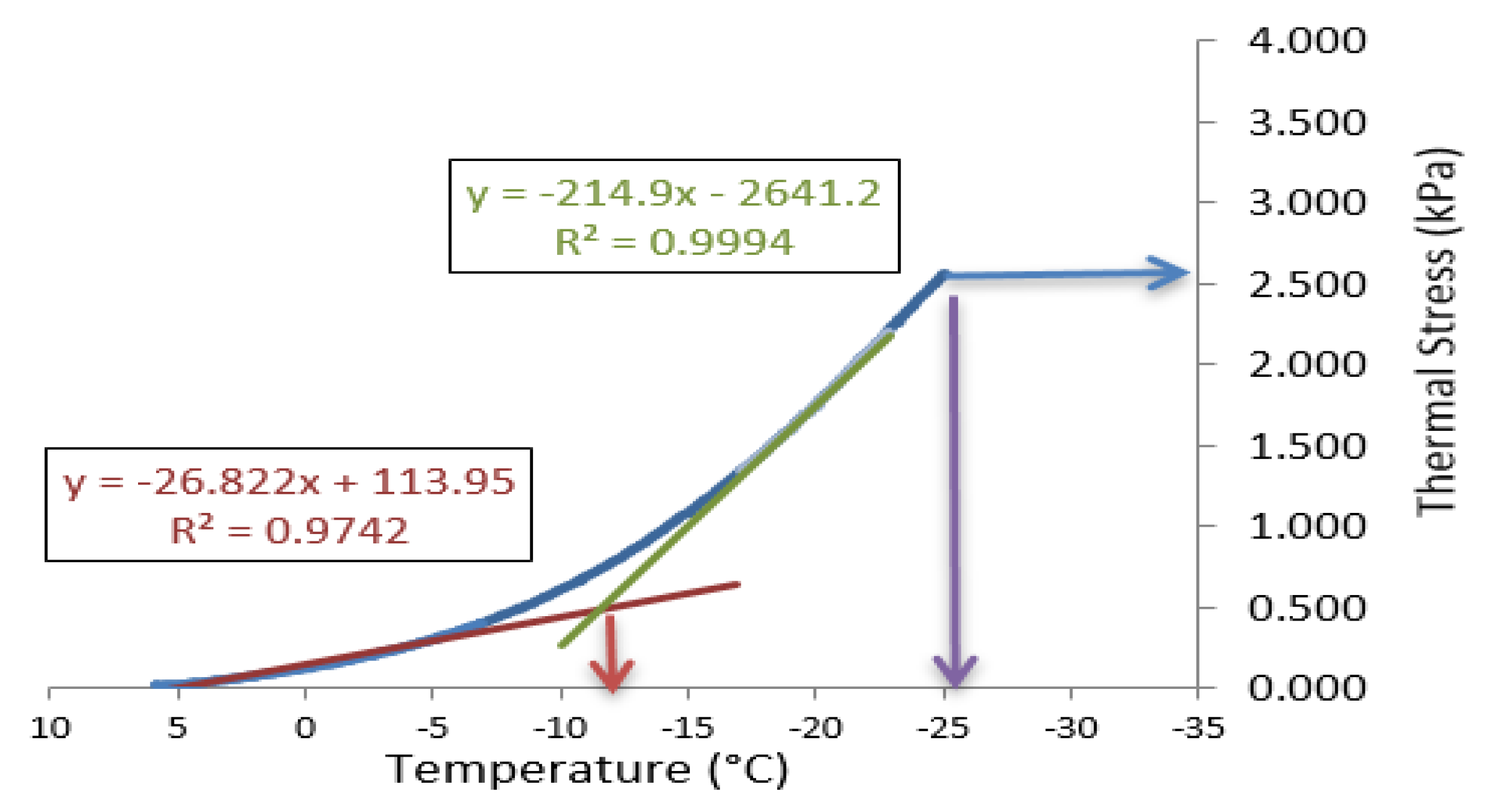

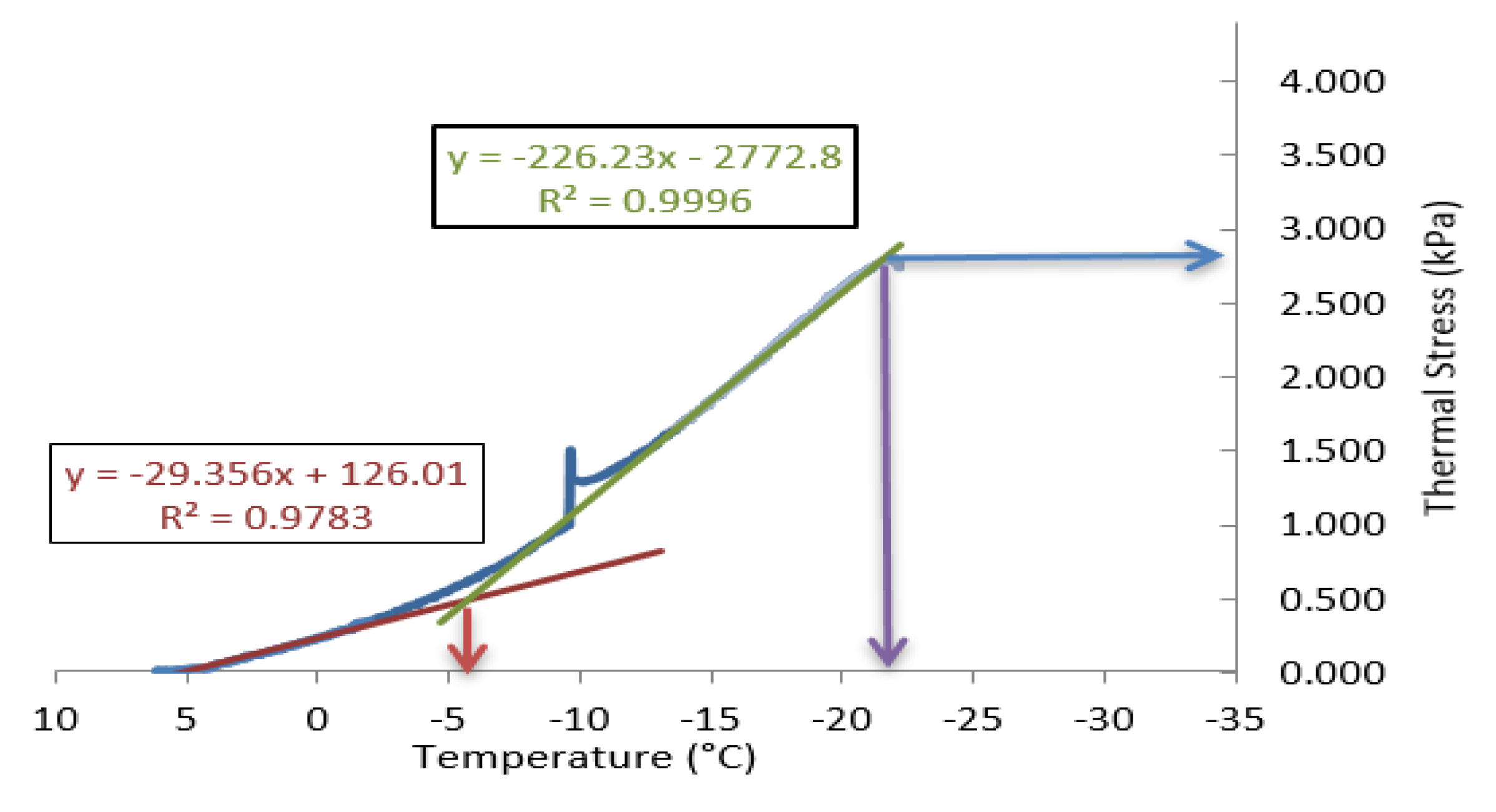

In addition to fatigue cracking, another major concern for HMA mixes with RAP particles is their resistance to low temperature cracking. In general, RAP mixes are stiffer than conventional mixes, due to the highly oxidized nature of the aged binder in RAP particles. The values of the fracture temperature and the corresponding stress at failure, obtained from the TSRST tests for all the tested mixes, are presented in

Figure 16.

The description of the test progress and the associated data collected is as follows [

43]:

Slope no.1: This parameter represents the performance during the relaxation period.

Slope no.2: This slope represents a value analogous to the modulus of elasticity in a diagram of stress versus deformation of an elastic material.

Glass transition temperature (Tg): This temperature represents the end of the relaxation and the beginning of a linear change with temperature.

Transition temperature midpoint: This temperature corresponds to the intersection of the tangent lines in section no.1 and the tangent line fitted to the section no.2 of the curve, and indicates the transition temperature between two stages of the simplified bilinear response of a material.

Maximum tensile strength: This value represents the maximum stress applied to the test specimen just before it fails.

Maximum stress temperature: This temperature is simply the value obtained when the maximum stress is reached.

Figure 17,

Figure 18 and

Figure 19 show the TSRST values derived from the results for the purpose of comparison. The maximum tensile strength values were found to be 3548, 2558 and 2799 kPa for the control, CR and FR mixes, respectively. The maximum stress temperatures were measured as −30, −25, and −22 °C for the control, CR, and FR mixes, respectively. The Transition temperature midpoint of the control and CR mix is almost the same (i.e., −11 °C) but Transition temperature of the FR was very low (i.e., −5 °C). The results indicate that the CR mix performed better than the FR mix with respect to low temperature properties. The CR had lower Tg midpoint and lower failure temperature, however FR failure stress was slightly higher than the CR. In addition, the value of T

t, calculated according to Tapsoba et al. [

41] study, was found to be the same for both mixes.

Void fills with bitumen (VFB) represents the effective bitumen content. The decrease of VFB indicates a decrease of effective bitumen film thickness between aggregates, which will result in higher low-temperature cracking and lower durability of bitumen mixture since bitumen perform the filling and healing effects to improve the flexibility of mixture.

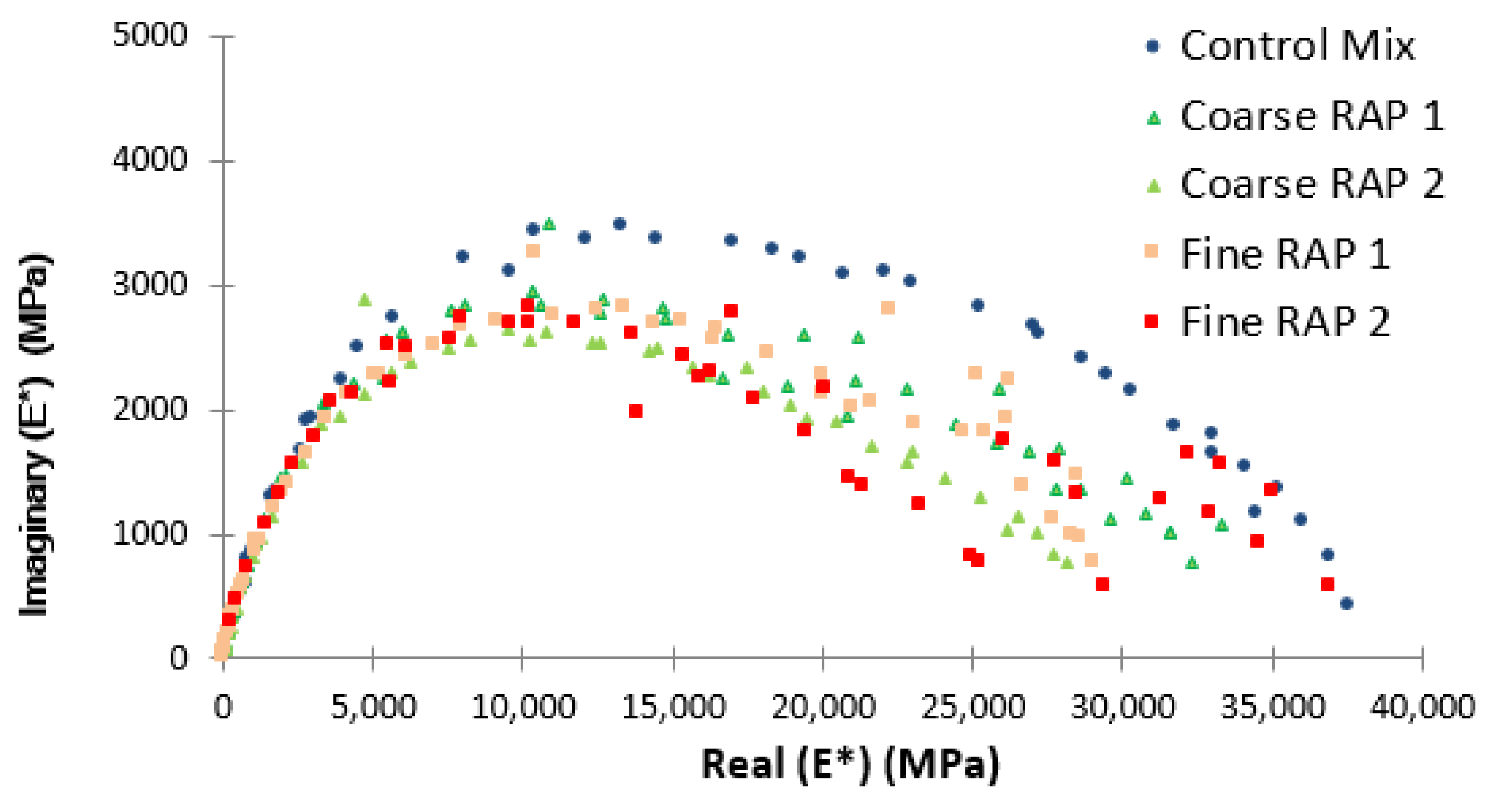

4.4. Complex Modulus

Various criteria are available in order to compare the stiffness of different bituminous materials. Baaj et al. (2013) [

44] suggested to looking into the stiffness of the materials in the following ways:

The stiffness |E*| at −30 °C and 3 Hz: this value gives the material stiffness for a low temperature and a high-frequency condition.

The values of |E*|/sin (ϕ) at 40 °C and 0.03 Hz: this ratio is used as an indicator of rutting resistance.

The stiffness |E*| at 20 °C and 3 Hz frequency: The stiffness of the mix (resilient modulus) at this temperature is used in the AASHTO’93 empirical pavement design method.

In addition, Perraton et al. [

45] also used the stiffness at 15 °C and 3 Hz. typically, standard bituminous base course materials have dynamic modulus values in the range of 5000 to 7000 MPa when tested under the same conditions at 15 °C.

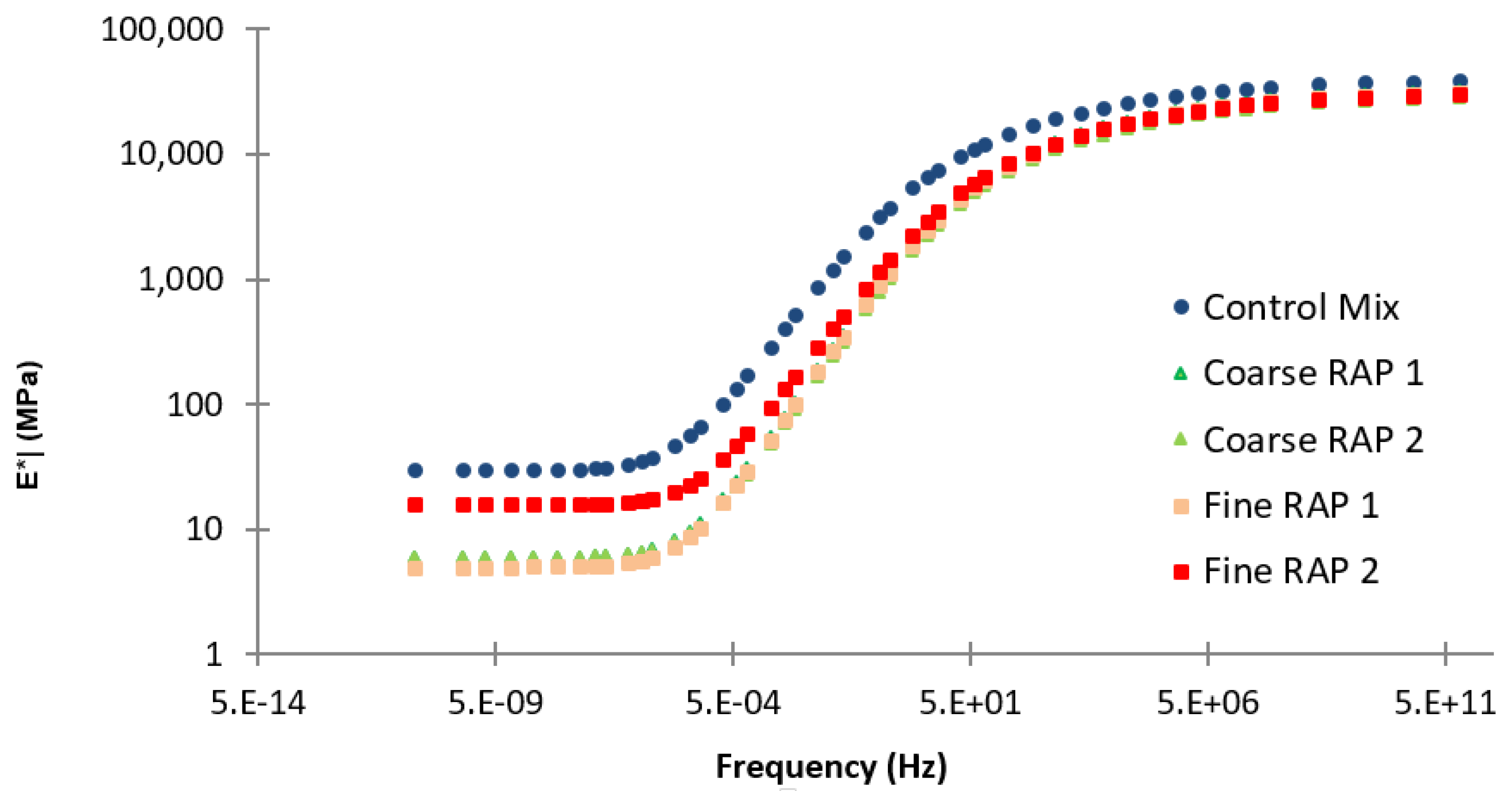

Figure 20 indicates the Cole-Cole plot for all mixes from −35 °C to +35 °C. Two replicate specimens were used for each of the mixes. The measured data was modeled with the 2S2P1D model. There is a notable difference between the control mix and RAP mixes with respect to loss (or so-called imaginary) modulus. Several factors can affect the loss modulus of a bituminous material such as air void level, bitumen content, and bitumen type. The results indicate that, generally, the two RAP mixes are the same according to the Cole-Cole diagram presented in

Figure 20. However, this plot cannot explicitly distinguish the differences in the bitumen characteristics.

The time-temperature superposition principle (TTSP) was applied to analyze the complex modulus test data. This principle was verified by several studies dealing with the unidirectional linear viscoelastic behavior of bituminous materials [

46]. As shown in

Figure 21, at high frequency, RAP mixes have lower stiffness than the control mix, and this difference becomes greater at lower frequencies. According to TTSP principle, high frequency could be translated to low temperature and low frequency could be translated to high temperature. Therefore, in a full range of temperature, RAP mixes were slightly softer than the control mix. However, the RAP content is not the same (i.e., 0%, 35%, and 54%). Therefore, the FRM with inclusion of 35% RAP content has almost the same behavior as the CRM with 54% RAP content. Consequently, it can be inferred that the binder contribution from 54% CR would be almost have the same effect as that of the 35% FR mix used in this study. In addition, FRM stiffness was found to be strongly sensitive to the testing conditions.

Figure 3 shows that the same FRM specimens are variable at low frequency but all CRM mix specimens show consistent response, suggesting that they are less sensitive to the testing conditions.

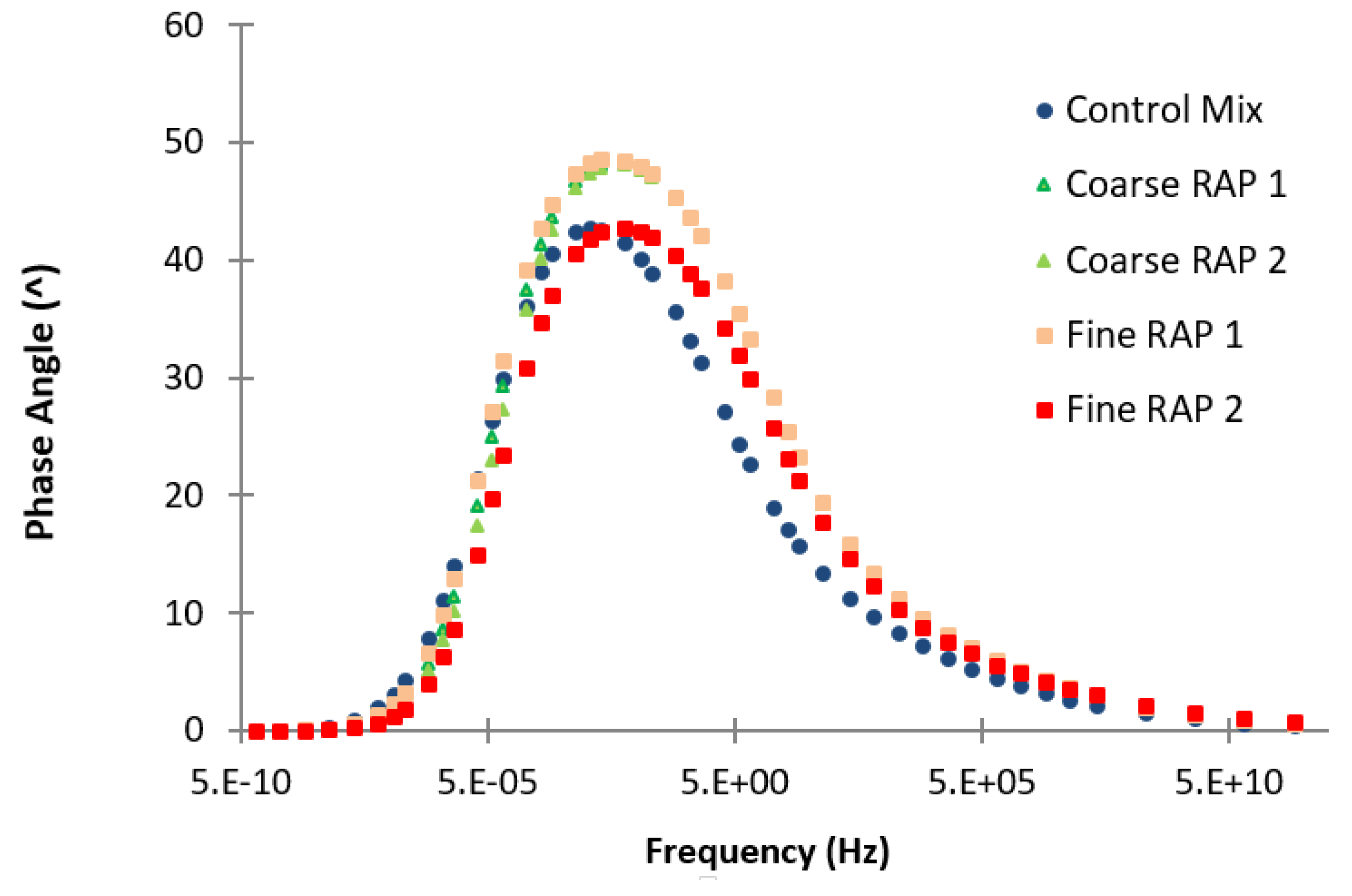

The rheological properties of the mixes can also be expressed in terms of phase angle. A phase angle (δ) value of 0 degrees means a purely elastic material and 90° means a purely viscous material.

Figure 22 shows the master curve of the phase angle for the mixes investigated in this study. The RAP mixes exhibited more viscous response than the control even though they have less virgin bitumen content (i.e., 2.2%). The FR results varied significantly, which might be associated with the higher RAP bitumen content and some unexpected phenomena in the fine RAP particles like clustering and variability in the film thickness of the particles.

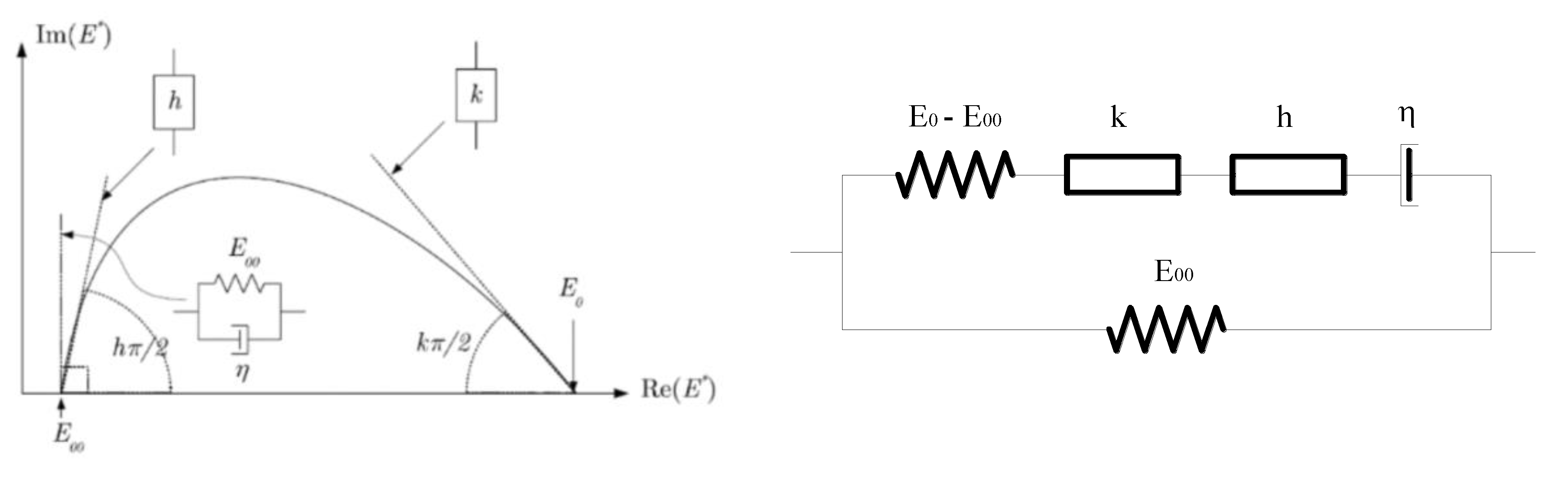

Figure 23 presents a summary of the 2S2P1D model parameters in the Cole-Cole model and the corresponding values of these parameters are listed in

Table 5.

h, k: exponents such as 0 < k < h < 1, related to the ratio EImaginary/EReal when ϖ tends to 0 (resp. to infinity),

E0: the glassy modulus when ϖ ≈ ∞

E00: the static modulus when ϖ ≈ 0

η: Newtonian viscosity

CRM is the same with control mix and FRM in black curve but it has more active aged bitumen. FR bitumen could not increase the FRM stiffness but CR bitumen was more active in mixture and increased the CRM stiffness.

The fact that the same or even better results could be achieved using the coarse RAP at a higher rate, as compared to the fine RAP, offers significant potential advantages in producing high RAP content mixes.

5. Conclusions

Review of the literature indicates that research on producing asphalt concrete mixes with only fine or coarse RAP particles has been scarce. The main goal of this study was to evaluate the effect of fine and coarse RAP fractions on performance of the high RAP content asphalt concrete mixes. Accordingly, three mixes were designed and investigated in this study, including a control HMA prepared with virgin materials, a Fine RAP mix (FRM) with 35% percent RAP, and a Coarse RAP mix (CRM) with 54% RAP. The total binder content considering the different contributions from the RAP particles was maintained the same for all the mixes. The following conclusions can be drawn based on the results of this study:

Black curve and white curve assumptions for the RAP particles were explored and it was concluded that the black rock assumption, which is commonly used, cannot be representative of the RAP contribution to the total binder content and the skeleton of the mix. The actual gradation lies somewhere in between these two extreme cases.

- -

The classifying the RAP particles in HMA is changing the role of virgin binder in the mix. Virgin binder role is covering the natural coarse aggregates and adhesion to aged bitumen of fine part in FRM. On the other hand in CRM, it is covering the natural fine aggregate.

- -

It is important to look into the binder contribution from RAP with respect to the RAP particle sizes, rather than solely considering the RAP content.

- -

The FRM and CRM specimens both passed the rutting resistance evaluation criterion of less than 10% deformation. The rutting performance of these high RAP mixes was found to be at least the same or even better than the control mix.

- -

While the control mix surpassed both the FRM and CRM with respect to fatigue life, it was found to be more sensitive to the changes in deformation.

- -

The transition temperature midpoint and the maximum tensile stress temperature for the CRM was much more desirable as compared to the FRM, and was slightly worse than the control mix.

Overall, the CRM mix, exhibited acceptable performance with respect to rutting, fatigue, and thermal cracking. It can be concluded that the RAP particle size can have a more significant effect on the mix performance than the RAP content. RAP content should be considered along with other important parameters such as RAP particle size and gradation, recycled binder ratio, and RAP binder content.