1. Introduction and Objective

According to the latest estimates, the expansion levels imposed by modern society will involve a dramatic growth in the size of cities by the middle of this century [

1]. Today, urban areas are formed by multiple paved areas that facilitate people’s daily mobility in different ways. From this perspective, pavements can no longer be considered as simple structures to connect places, since they are composed of roads, special lanes, bike lanes, footpaths and squares in which people spend a great part of their life. This rapid development presents challenges in terms of urban and environmental planning, considering that today 40% of urban areas are covered by pavements. This urban land-cover change is affecting the local ecosystems and the underlying surface conditions, resulting in an important increase in the portion of impervious surfaces. The natural hydrological process may be irreversibly changed [

2,

3], as a consequence of limited rainwater infiltration and the increased surface runoff [

4]. Studies have demonstrated a clear correlation between increased flooding hazard registered in urban areas and the changes in the natural drainage network [

5,

6]. The growth of impervious surfaces has increased the runoff peaks as well as the stormwater runoff accumulation. From an environmental perspective, these impervious areas promote the stagnation of water containing urban pollutants such as road-deposited sediments and potentially toxic metals and metalloids. Studies demonstrated that the presence of contaminants is mainly related to the different land use: high quantities of polycyclic aromatic hydrocarbons were detected in some commercial sites, due to higher vehicle concentrations. Furthermore, heavy metals characterize the stormwater runoff from industrial land-use areas [

7,

8]. The presence of these pollutants can be considered as one of the primary contributors to water quality depletion in natural water bodies [

9]. By 2030 the urban land cover will increase by 1.2 million km

2 and according to recent studies, the global urban land cover is expected to be over 200% if compared to year 2000 [

10].

Engineers from all over the world are facing the new challenges in managing the urban planning for a sustainable future. The importance of taking decisive actions to tackle these problems is obvious. From an environmental point of view, Best Management Practices (BMPs) are today widely applied as runoff control system in urban areas in order to reduce the so-called nonpoint source (NPS) pollution [

11]. BMPs promote the development of detention basins and extended detention basins, which act as storage and water treatment areas. The latest research has highlighted the performance of innovative “smart” BMPs improved with a real-time active control of the stormwater detention basin outflows, able to achieve up to 90% of pollutant removal and considerably reduce the outflows volumes [

12].

As for the increased wash-off volumes in urban areas, some countries have developed a series of guidelines and stormwater management plans and proposed some specific techniques to monitor the urban flooding. To date, the most effective method to control urban runoff is based on the urban design that promotes the development of permeable pavements and surfaces and green areas. This approach is traditionally counted among the infiltration-based technologies to control the urban runoff [

13].

Permeable pavements can be considered as a suitable and sustainable alternative to traditional pavements produced with common asphalt or cement concrete. Considering that paved surfaces represent around the 25% of impervious urban surfaces, the possibility of using porous pavements can be effective in controlling the urban runoff [

14,

15]. Several studies demonstrated that porous pavements are considerably more effective in reducing the wash-off volumes if compared to drainage surfaces [

16]. Moreover, the efficiency of these permeable surfaces is highlighted considering their contribution in decreasing the flood peak and its hysteresis, which is generally related to the thickness of the porous structure [

17]. Starting from the traditional porous asphalts or concretes, some now materials such as modular elements, paving blocks or plastic grid system are today widely used in urban areas to create permeable areas and structures [

18,

19].

The porous layers are also effective against the Urban Heat Island (UHI) effect [

20]. This phenomenon is another consequence of the dramatic development of urbanization and is evaluated as the overheating of urban temperatures compared to the relatively colder conditions of suburban zones and rural areas [

21]. The traditional materials used for pavements and roofs absorb and store most of the solar energy falling on their surface during the day, which is then released in the form of heat during night-time. The albedo is the measure of the sunlight reflection of a surface out of the total solar radiation, and it ranges between zero (corresponding to a full absorption) and 100 (representing a completely reflective surface). The dark surfaces that traditionally distinguish the road pavements and roofs are characterized by a sunlight reflection up to 20% [

22]. Several studies and applications have been carried out to face the UHI through the adoption of innovative materials or simply increasing the solar reflection of surfaces [

23,

24]. Researches verified the mitigation of UHI through the use of porous mixtures and light-colored surfaces [

25].

In the case study presented in this paper, a semi-porous mixture prepared with a polymeric transparent binder and a pale limestone aggregate is proposed. This innovative and eco-friendly material has the dual target of reducing urban runoff and UHI, by coupling a porous structure with a light-colored pavement surface. Moreover, the proposed material can be used as surface layer for the construction of a water-retaining pavement, which is a novel type of cool pavement [

26]. In this case, the reduction in the pavement temperature is promoted by the evaporation cooling of water stored in the thickness of the layer.

Furthermore, the sustainability impact of this material is optimized by the partial substitution of natural aggregates with artificial synthetic aggregate produced through the alkali-activation of waste basalt powder.

3. Mixtures Characterization

3.1. Mixture’s Details

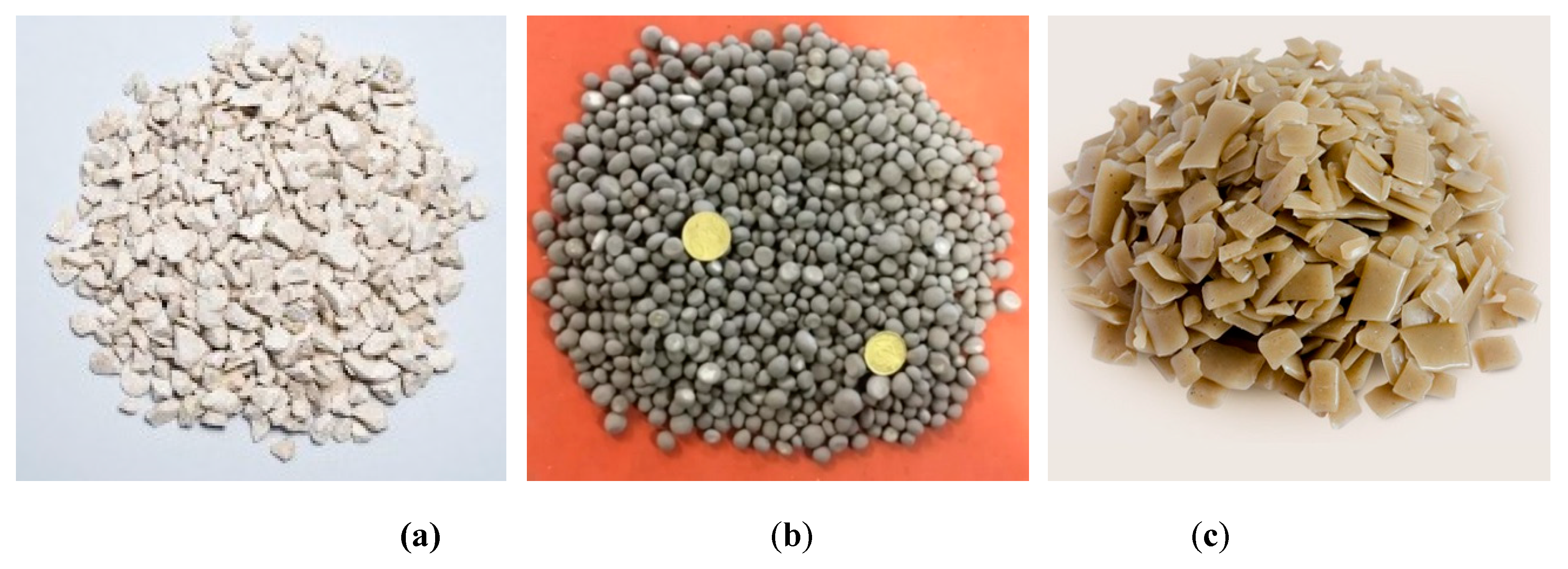

Two mixtures were designed in compliance with a gradation band suggested by Italian technical specifications for semi-porous layers. The SPT mix was produced with 100% pale limestone aggregates. The SPS mix replaced 21% of the natural aggregate with synthetic aggregates (

Figure 2).

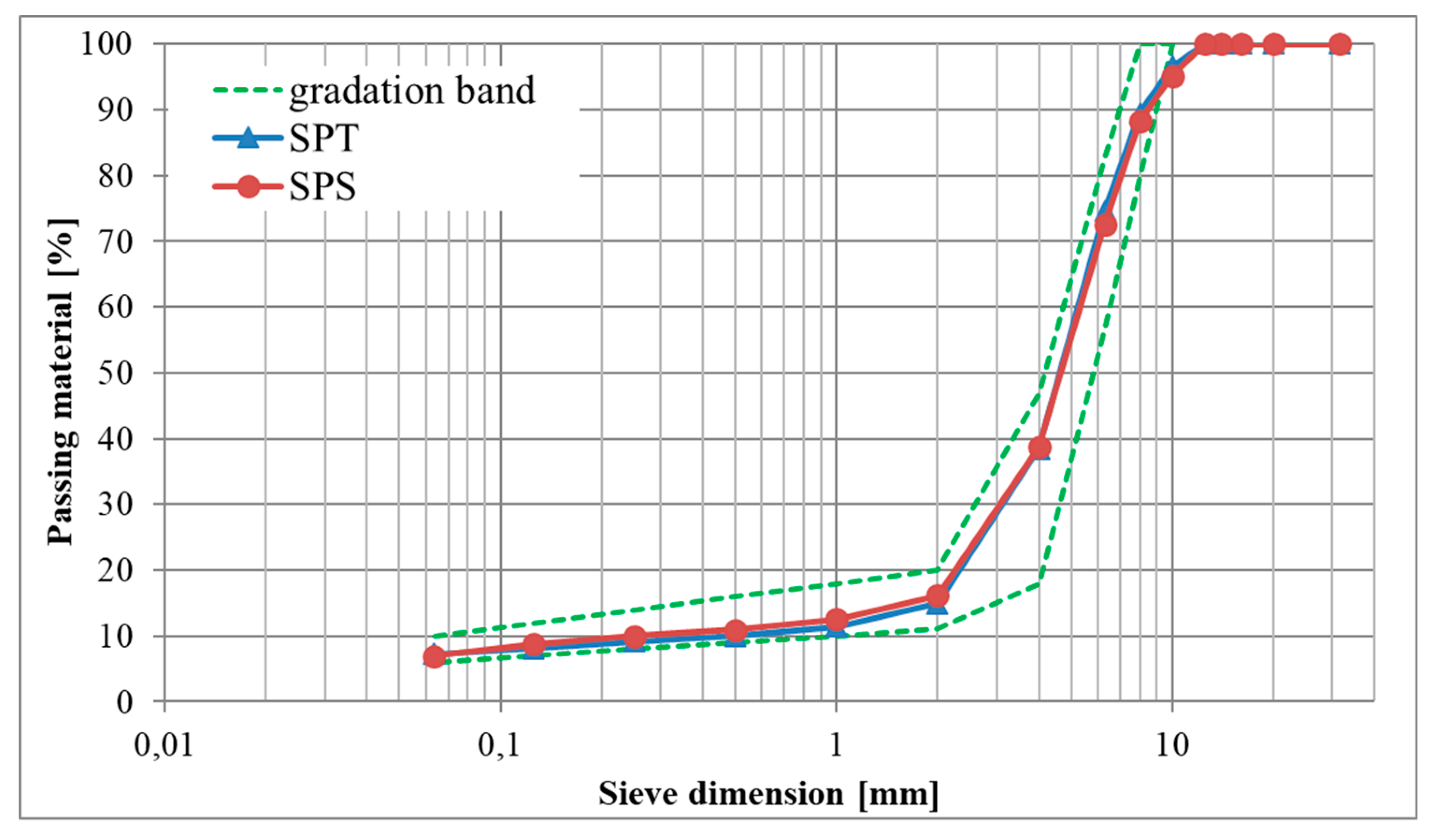

The synthetic aggregates were sieved in order to substitute only the natural aggregate particles with the same dimensions (6.3/12.5 mm). Therefore, the gradations of the two mixtures were kept constant in order to have comparable grading curves (

Figure 3). After several laboratory trials, the optimum binder content was determined to be 5.5% by weight of the aggregates. In this case, the evaluation of the optimum binder content was carried out in compliance with the Marshall mix design method [

40]. The mixing procedure provided for the heating of aggregates at 170 °C and the addition of the polymeric binder chips at ambient temperature directly into the laboratory mixer together with the hot aggregates.

As showed in

Figure 3, both the grading distributions fit the reference gradation band and there is no remarkable difference between the two mixtures.

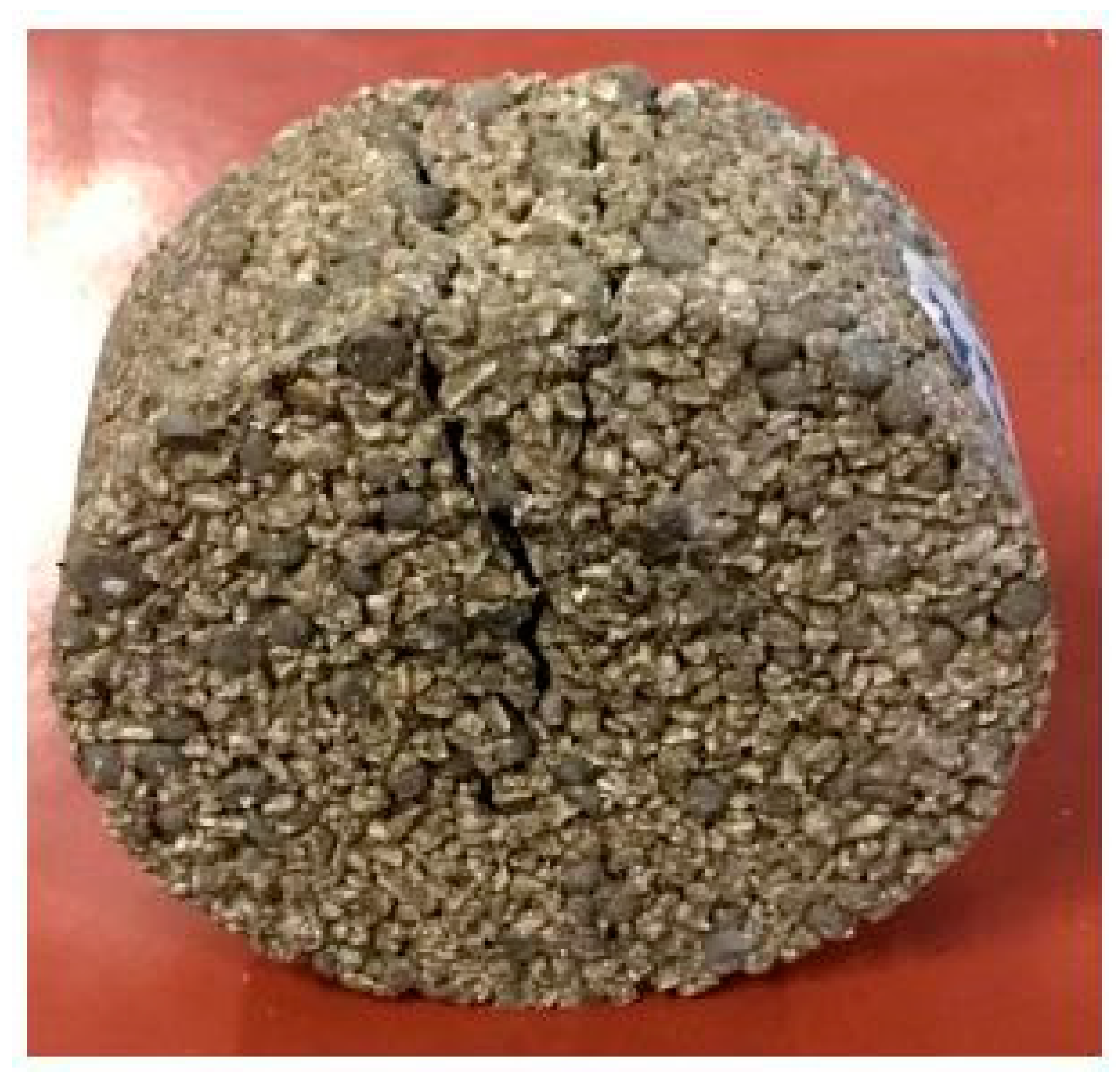

The final aspect of the samples after compaction and its surface texture as well as the porous structure are shown in

Figure 4. From a visual analysis the synthetic aggregates seem to be well distributed into the mixture, highlighting no issues in terms of workability and segregation during the mixing and compaction process.

3.2. Air Voids Content

In order to verify the quality of the mix design, the air voids (Av) content (EN 12697-8) [

41] was evaluated for the two experimental mixtures. Four gyratory samples were produced for each mix in compliance with EN 12697-31 standard (80 gyrations). The bulk density of the specimens was calculated using the geometrical procedure, as suggested by the EN 12697-6 [

42] standard for open graded bituminous mixtures. The results are presented in

Table 3.

Both mixtures show a significant Av content. It is worth noting that the Italian technical specification suggests a lower Av limit of 16% for semi-porous mixtures. The remarkable porosity of the mixture is probably related to the adopted particles size distribution, which was close the lower limit of the gradation band for the material passing the 1 mm sieve and to the upper limit for the retained material at 4 mm sieve. In this case, the obtained aggregates distribution is more open graded.

The higher Av content for the SPS mixture is probably related to the rounded shape of the handcrafted artificial aggregates.

3.3. Mechanical Characterization: ITS and ITSM

The mechanical characterization was based on both static and dynamic tests: Indirect Tensile Strength (ITS) and Indirect Tensile Stiffness Modulus (ITSM).

The ITS test is generally useful for evaluation of the strength of cohesion between aggregates and mastic [

43]. According to EN 12697-23, a load with a constant velocity of 50 mm/min is applied diametrically to a cylindrical specimen until failure.

The test was carried out using 3 gyratory specimens (80 gyrations) conditioned at 25 °C for 4 hours. The results are shown in

Table 4. Both experimental mixtures comply with the minimum ITS value suggested by the reference technical specification (ITS ≥ 0.50 MPa). The SPS mix shows better performance despite its higher porous structure. In wider terms, a suitable ITS is reached despite the considerable amount of air voids content in the mixtures.

These results represent also a further validation of the quality of the mastic formed by the polymeric transparent binder and the finest part of the aggregates distribution.

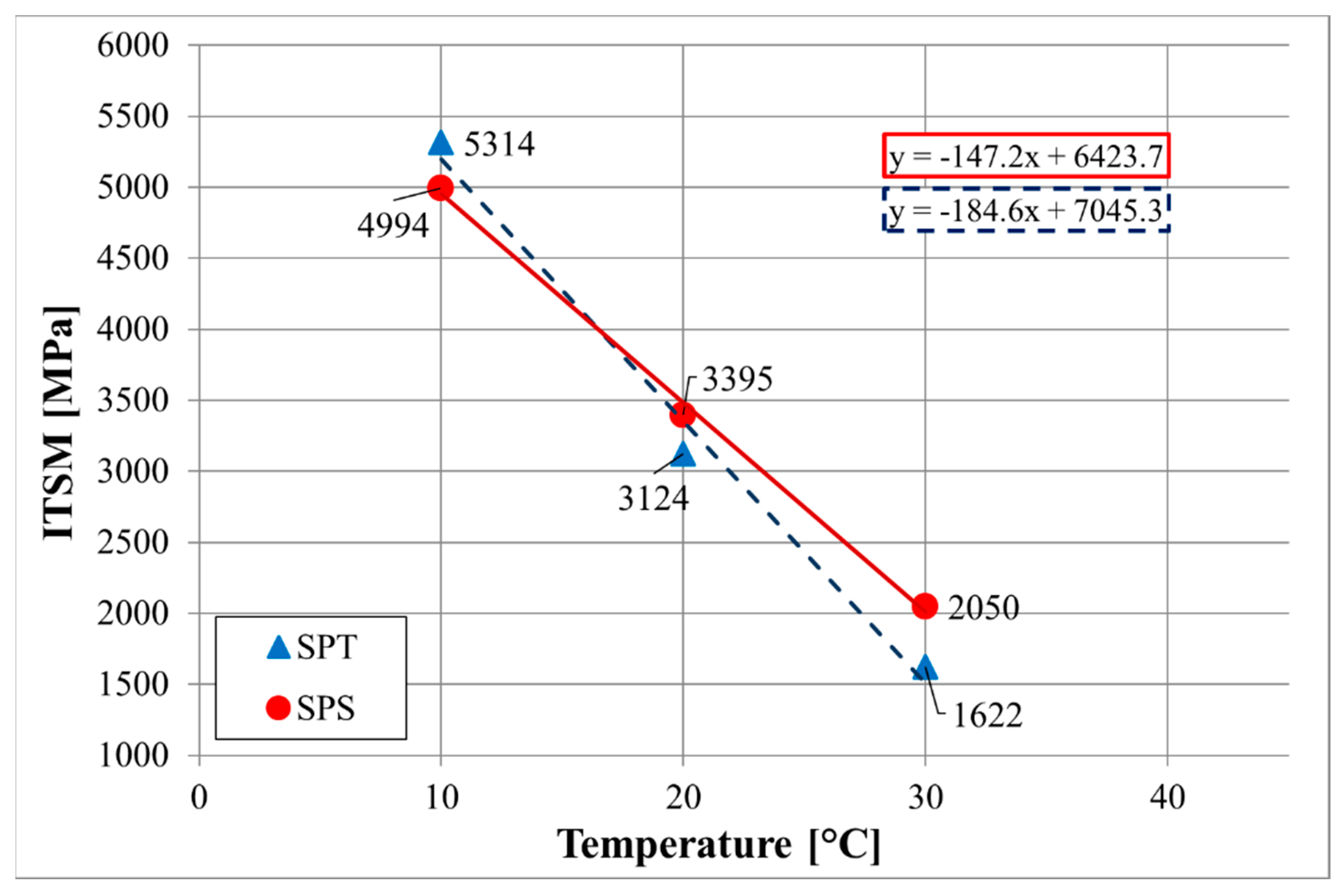

An advanced mechanical characterization was based on evaluation of mixture behavior under dynamic load using the ITSM test carried out on 3 gyratory samples (80 gyrations) for each mixture at 3 different temperatures: 10, 20 and 30 °C. According to the EN 12697-26 part C standard, the Modulus is determined through a pulse loading with a rise-time of 124 ms, to generate a predefined horizontal deformation of 7±2 μm in the core of the cylindrical specimen. The tests were carried out on 3 samples conditioned at 3 temperatures in order to verify the thermal sensitivity of the mixtures and how the presence of synthetic aggregates could affect this property.

As overall results, both mixtures show a consistent stiffness at each test temperature.

If 20 °C is considered as the reference temperature, there are no substantial differences in stiffness between the two mixtures. The adopted technical specification does not suggest any limitations in terms of stiffness moduli. However, according to the scientific literature and real applications, the achievement of 3000 MPa at 20 °C can be considered as a suitable requirement for porous asphalts, considering their relatively weak structure.

In terms of thermal sensitivity, the two mixtures show a different variation in stiffness in relation to test temperature. The SPT mixture would appear to have a mechanical behavior that is more influenced by test temperature than the SPS mixture. Typically, for asphalt concretes an excessive stiffness at low temperatures and a low mechanical response at high temperatures could result in detrimental issues in terms of durability. In light of the above, the experimental mixture shows a positive increase in stiffness at high temperature and this could have a favorable effect in terms of rutting resistance. Still, the SPS mixture shows a stiffness trend line that corresponds to a reduced thermal sensitivity. This might be a consequence of the partial substitution of natural aggregates with synthetic materials. Future testing will assess the level of thermal transmittance for these artificial aggregates in order to validate this speculation.

3.4. Durability Evaluation: ITSR and Cantabro Tests

Considering the porous structure of the material, the durability evaluation was based on the assessment of the water sensitivity of the mixtures, in terms of reduction in ITS and raveling resistance.

In the first case a set of 3 specimens for each mix were subjected to 10 freeze and thaw cycles, from −20 to 20 °C, for 5 days before being tested. In fact, moisture damage can be considered as one of the main forms of pavement deterioration, which is also promoted by the formation of ice [

44]. According to well-established literature, high ITS and ITSR values could guarantee a good resistance to moisture damage [

45]. According to the EN 12697-12, the reduction in ITS is calculated as the ratio between results obtained in wet and normal dry conditions (EN 12697-12).

The Cantabro test is typically used in Europe for evaluating the raveling resistance of porous asphalt concretes (EN 12697-17). The test enables the estimation of the abrasiveness of porous asphalt, as these mixtures have high air voids, the contact areas between aggregates, which guarantee cohesion of the asphalt concrete, are limited. It is worth noting that it does not reflect the abrasive effect by studded tires. Thus, the cohesion is evaluated in terms of particles loss (PL) when a set of Marshall samples (EN 12697-30, 50 blows per side) is placed in a Los Angeles machine for 300 revolutions, with a speed of 30 revolutions per minute. Four Marshall samples were tested for each mixture. In compliance with the standard, the specimens were stored for 2 days at a temperature of 25 °C prior to testing.

Table 6 summarizes the results for ITSR and Cantabro tests.

The technical specifications generally suggest a minimum ITSR value equal to 75%. Both experimental mixtures exceed this threshold value. It is worth noting that the reduction in ITS is generally evaluated for samples kept in a water bath (40 °C) for 72 hours prior testing. In the case under study, the ITSR results are in line with the suggested lower limit even if the mixtures have been subject to a considerable higher deterioration. The lower ITSR results for SPS are probably related to the higher air voids content that might had a detrimental effect during the freeze and thaw cycles.

In terms of particle loss, there is no significant difference between the two mixtures. The most common Italian technical specification suggests a maximum particle loss (PL) value equal to 20%, for porous asphalt, which is substantially higher if compared to test results. This is a further validation of the quality of the cohesion between particles guaranteed by the polymeric transparent binder considering the remarkable porosity of the two mixtures.

3.5. Functional Properties: Skid Resistance and Vertical Permeability Test

Surface friction and vertical permeability are important functional properties for porous layers.

The friction between tires and road pavement involves two components: adhesion and hysteresis. The first phenomenon is connected to the microtexture of the pavement, which is generally evaluated by means of the skid resistance test [

46]. The most common measure of the skid resistance is given in terms of Pendulum Test Value (PTV, EN 13036-4) using the British Portable Pendulum. According to the standard, the frictional force is the force acting tangentially in the contact area and it is measured as the loss of energy of a standard rubber slider that slides across the test surface. The PTV value in given by the average result of five repetitions for each single test point. The final result is adjusted with specific factors depending on the surface temperature. It is worth mentioning that the test surface must be wetted prior to testing.

As for the permeability, it is the most important property for a porous asphalt. According to the EN 12697-19, it can be evaluated in lab in terms of vertical and horizontal permeability: in this research, the former property was assessed. The vertical permeability is considered as the water flowing in a vertical direction through the specimen thickness. The test procedure imposes that a water column of constant height is kept on the surface of the porous sample and the vertical permeability is evaluated in terms of the amount of water flowing through the sample in a specific range of time using the Darcy’s Law.

The results of both tests are shown in

Table 7.

In terms of skid resistance, a small difference was found between the two mixtures. The SPS mixture has a higher friction, possibly related to the different surface texture affected by the higher porosity and the different micro and macro texture of the synthetic aggregates. Both PTV values are acceptable but the surface texture needs to be improved if compared to values generally suggested by technical specifications for asphalt pavements (PTV ≥ 50). However, an increase in PTV is expected after a primary polishing of the binder film that covers the aggregates by the traffic. Nevertheless, an optimization of the grading distribution might improve the macro-texture of the material.

No significant difference was found in terms of vertical permeability for the two mixtures. It is worth noting that the reference standard suggests a minimum value of 0.5·10−3 m/s for traditional porous layers. The obtained values are remarkable, considering that the adopted gradation band is suggested for semi-porous layers. Nevertheless, taking into account the significant porosity of the two mixtures, the air voids interconnection must be improved. Future imaging tests with e.g. Nuclear Magnetic Resonance (NMR) technology will evaluate the inner structure of the samples in order to verify the interconnectivity and tortuosity of air voids.

4. Conclusions

In the present research, a low impact semi-porous concrete produced with transparent polymeric binder and pale limestone aggregates is proposed. To improve the sustainability of the material, an experimental mixture was produced with the partial substitution of natural aggregates with artificial ones obtained through the alkali-activation of waste basalt powder. The research program provided for a physical and mechanical laboratory characterization.

On the basis of the presented results, the following conclusions can be drawn:

The adopted particles size distribution and polymeric binder amount allow the achievement of good workability and a higher porosity if compared to traditional semi-porous asphalt concretes. The presence of synthetic aggregates did not affect the mixing procedure and the workability properties of the mixture. The visual analysis of the samples and their inner structure highlighted a correct distribution of the artificial aggregates within the mixture.

The increased air voids content for the SPS mixture is more likely related to the rounded shape of the handcrafted particles, which limited the aggregates interlocking resulting in a more open structure.

The mechanical characterization and durability evaluation highlighted how both mixtures exceed the threshold limits imposed by the technical specifications for semi-porous asphalt layer, despite the significant porosity of the materials. Consistent properties were registered in terms of water susceptibility considering the severe conditioning given by the freeze and thaw cycles. Furthermore, both mixtures revealed a ravelling resistance considerably lower than the threshold limit for porous asphalts, as a further confirmation of the good cohesion between particles guaranteed by the polymeric binder.

The most relevant difference between the mixtures is related to the low thermal sensitivity of SPS. The experimental mixture showed a favourable increase in stiffness at high temperature and a slight decrease at the lowest ones. This phenomenon might be attributed to the presence of artificial aggregates. Future tests will assess the thermal transmittance of the synthetic aggregates in order to validate this conclusion.

The two experimental mixtures showed a good vertical permeability which is in line with the lowest values suggested for porous layers. However, considering the high porosity of the mixture, most of the air voids may be not fully connected. In terms of skid resistance, both mixtures should be optimized to improve this parameter in their early life, despite the adoption of synthetic aggregates led to higher PTVs. As a general statement, the optimization of the mix design might improve the texture properties of the material as well as the interconnection of air voids.

In the light of the above, the use of transparent polymeric binder seems to be a viable solution for the production of low impact semi-porous layers for use in urban areas. Future studies will investigate the possible substitution of higher quantities of natural aggregate with synthetic material aiming to the production of 100% synthetic mixtures. Furthermore, the use of a centrifugal granulator can improve the quality of the synthetic aggregates and convert the production from the laboratory to the industrial scale.