Abstract

The paper deals with the issue of obtaining iron-sulfur-containing binders through their mechanochemical treatment using mutual neutralization and detoxification structure formation, and the curing stage of arbolite concrete composites based on industrial waste under long-term loading were also studied. Due to abrasion and impact, the mutual neutralization and detoxification methods of industrial waste toxic components through their mechanochemical treatment on the structures of ball mill LShM-750, were used to obtain iron-sulfur-containing binders. Pyrite cinders acted as oxidizing agents, and elementary technical sulfur had reduced properties. To determine the rate of creep strain growth, the load on prism samples was applied in the form of specially made spring units at stress levels of 0.15 Rbn, 0.44 Rbn, and 0.74 Rbn, where Rbn is the prism strength of iron-sulfur-containing arbolite concrete in compression. The strength and fracture formations of lightweight iron-sulfur concrete were studied using strain gauge apparatus and depth strain gauges glued on shredded reed fibers using adhesive, installed before concreting. It was revealed that the introduction of a sulfur additive within the range from 10 to 13% increases the compressive strength of iron-sulfur-containing concrete composites prepared with that of mortars at a water/solid ratio equal to 0.385 in wet and dry states. It is found that the deformations occurring under applied load growth proportionally to it, and deviation from this regularity was observed for lightweight iron-sulfur-containing concrete only at high compressive stresses. It was also proved that the destruction of iron-sulfur-containing arbolite occurs sequentially. First, the destruction of the mortar component is observed, and then the organic aggregate in the form of crushed reed fiber is destroyed. It was confirmed that arbolite concrete composite can be used as an effective wall material for civil engineering structure, especially in seismic regions of Kazakhstan.

1. Introduction

Due to the constant growth of construction volumes, more and more building materials and products are required. At the same time, there is a tendency to reduce the weight of building structures, particularly enclosing ones, due to the use of lightweight concrete, including lightweight arbolite concrete composites characterized by low density (550–650 kg/m3) and relatively high strength (respectively, 3.0 and 5.0 MPa) with minimal growth of raw materials [1,2,3,4,5]. However, the issue of relatively low strength of the final material at a high consumption of binders has not yet been solved [1,2,3,4,5]. Moreover, the issue of acquisition by the products of demolding strength, due to which the additional holding in a warm room for at least 7 days in summer and more than 7 days in winter is required, still needs an explanation.

At the same time, increasing attention has been paid to the development of technological processes and schemes, the introduction of which would reduce the amount of industrial waste and ensure its maximum utilization, including in the construction materials industry [5,6,7,8,9,10]. It is even more important for regions with abundant industrial and agricultural wastes. Such regions include Kazakhstan’s western and eastern regions, where multi-tonnage toxic waste from the metallurgical, petrochemical, and mining industries are accumulated yearly, polluting the environment [10,11,12]. The utilization of these wastes, in particular, the waste of oil and gas industries—technical sulfur—creates significant interest in studying the possibility of using these secondary raw materials in the production of construction materials. Also, a special place in the production of construction materials in the regions of Kazakhstan with a sharply continental severe hot climate is occupied by lightweight arbolite concrete composites based on waste vegetation, which are abundant in the steppe regions of Kazakhstan. This solution combines lightness, durability, environmental friendliness and high thermal insulation qualities. In this regard, there is a need to analyze the scientific and technical impact of technical sulfur and sulfur-containing additives on the properties of arbolite for the possible use in obtaining structural and heat-insulating arbolite with a density of 550–650 kg/m3 [7,8,9,10,12,13,14,15,16]. These studies have not solved the question about the need for large areas of storage of organic cellulose aggregates for the manufacture of arbolite concrete composites. In addition, the questions on deformability and wave formation in the finished arbolite concrete products have not been answered.

It is known from many researchers’ work presented in the literature [1,14,15,16,17,18,19,20] that crushed powdered types of technical sulfur have a very positive effect on the strength characteristics of concrete as a mineral admixture. At the same time, the optimal compositions, manufacturing methods, and mechanisms of sulfur additives effect on the structure formation of concrete composites have not been determined. The use of sulfurous wastes from oil production as a mineral additive for obtaining effective binders for arbolite concrete composites should positively affect the material’s physical and mechanical properties due to the high activity of sulfurous waste that can lead to the occurrence of a high structure-forming process [1,2,3,4,5,16,17,18,19,20]. The peculiarities of structure formation processes of lightweight concrete are caused by the active participation of organic aggregates in creating structure-forming elements on a large area of contact zones. It should be considered that such processes occur under conditions of intensive adsorption and are associated with the high porosity of organic cellulose aggregates [11,12,13,14,15,20,21,22,23,24,25]. Analysis of the literature sources indicates [1,5,23,24,25,26,27,28] that one of the most promising directions for solving the problem of technical sulfur utilization is its wide application in the production of building materials and products. At the same time, the high compressive strength and high chemical resistance in solutions of acids, salts, alkalis, as well as the low water permeability of sulfur-containing materials are noted. These works do not solve the problem of the need for additional specialized equipment to detoxify toxic industrial waste in the production of construction materials.

It has been shown [7,29,30,31,32,33,34] that the introduction of sulfuric acid production waste additive containing no less than 60% of technical sulfur into the composition of lightweight concrete based on oil shale ash has a positive effect on calcium hydration and the aluminate component of oil shale ash, i.e., on the processes of cement stone formation. Moreover, the amount of the introduced additive, the conditions of hardening of the material, as well as its influence on the properties of the obtained material are not reported. These studies have not solved the question of the difficulty of determining the exact amount of harmful substances in the composition of arbolite concrete products based on vegetable waste.

The processes of detoxification and activation of a binder, as shown in [11,12,13,14,15,16,17,35,36,37,38,39], lead to the improvement of operational and qualitative characteristics of the resulting building materials. The principle of the mutual neutralization of chemically harmful substances in industrial waste is used in the process of combined mechanochemical activation and the detoxification of industrial waste in the presence of water, with the production of raw mixtures to manufacture building materials. References [15,16,17,40,41,42,43,44,45,46] show the possibility of obtaining concrete products with improved physical and technical properties by various methods of the additional activation of the binder. These methods allow for reducing cement consumption by replacing part of it with industrial wastes. According to known concepts of concrete science, with regard to the management of the physical and chemical processes of hardening mineral binders at the stage of hydration, the transformation of the unstable structure of binder dough to a stable structure of stone is realized by the following methods: introduction of chemical additives; mechanical activation and detoxification; and electromagnetic and mechanomagnetic treatment. The results of the realization of the specified regulation methods by physical and chemical processes of hardening binders and the mechanism of the latter hardening are discussed in [17,18,41]. The most common way of activation is to increase the specific surface area of cement particles, and there are two ways of grinding—dry and wet. In works [17,18,19,20,42,43,44,45,46,47], it is noted that dry grinding is carried out up to a certain limit, as further dispersion leads not to grinding, but, on the contrary, to the aggregation of the smallest particles in the grinding bodies due to their electrification in the process of grinding. Fine (colloidal) dispersion is impossible without surfactant and adsorbent additives, which can be introduced in dry and wet grinding. In the latter activation method, the dispersibility of the binder particles in the liquid phase increases, while the chemical and mineralogical compositions do not change; meanwhile, the activity of the substance increases. The effectiveness of grinding in an aqueous medium is studied in [20,21,48,49,50,51,52,53,54], where it is shown that increasing the fineness of grinding promotes the better dispersion of cement grains due to the reduction in their hardness adsorption. The processes of cement gel structure formation as a result of fine grinding are accelerated, and its critical plastic strength increases. At the same time, more dispersed particles participate in structure formation with the construction of coagulation contacts of the system, which is associated with an increase in the number of crystallization centers. It is noted in [21,55,56] that mechanically activated surfaces of the binder are characterized by a change in its surface in the structure of the crystal lattice, and also by the fact that at the moment of destruction, there is a noticeable number of atoms with uncompensated bonds, a saturation of which occurs either at the expense of neighboring atoms or as a result of the rearrangement of atomic shells. In addition, during pulverization, molecular bonds are broken and deformed, changing not the atomic structure of the body but the atomic (subatomic) structure. Many researchers [2,3,4,5,6,7,8,9,10,11,12,13,14,15,16,17,18,19,20,21,22,23,56] agree that the binding properties of materials depend on the surface energy, and the nature and size of the surface determine the magnitudes of surface forces. According to known scientific concepts, the intermolecular interaction of substances is subdivided into physical, determined by the physical characteristics of the interaction of molecules, and chemical, leading to the formation of directed chemical and quasi-chemical bonds, as well as universal and specific interactions [21,53,54,55,56,57]. Jet mills are designed for the superfine grinding of materials. Unlike ball, vibration, and ring mills, they do not have grinding bodies, and the grinding process occurs due to the high speed of particles in the air stream, due to friction and the impact of material particles among themselves and against the walls of the chamber. The most widespread in factories for the production of building products and structures are ball and vibrating mills designed for grinding clinkers, as well as for the production of multi-component cement. The production of the latter consists of the joint grinding of cement and active mineral additives to obtain the required specific surface area of binder components [2,23,24,25,26,27,28,55]. Grinding takes place in a rotating or vibrating drum with the help of loaded grinding bodies due to the impact and abrasion processes between them, arising during operation. The analysis has shown [20,21,22,23,24,25,56] that in the building materials industry, ball mills and vibrating mills are the most common among the known designs of grinding devices. To obtain iron-sulfur-containing binders, the principle of mutual neutralization and detoxification of toxic components of industrial wastes by their mechanochemical treatment at low temperatures was used. It is noted in the works [11,12,13,14,15,16,17] that unlike conventional arbolite based on wood shavings, where organic cellulose aggregate is most often the least strong component, the sulfur-containing components of the mortar part significantly influence its strength and deformation characteristics. The study on the strength, deformability, and creep of lightweight concrete, which immensely affects the performance of load-bearing and enclosing structures, has attracted much attention from scientists of the Commonwealth of Independent States and foreign countries in recent years [17,18,19,20,21,22,23,24,25,55,56,57,58,59]. A variety of recommendations and proposals to consider strength, deformability, and creep in the calculation of individual structures and structures as a whole are presented in the works [8,9,10,11,15,16,17,18,19,59] and those of other authors. The disadvantages of these works include the unresolved issues of the mechanism of strength formation and fracture of iron-sulfur-containing arbolite–concrete composites under a long-term acting load.

These studies mainly consider the linear hereditary theory of strength, deformability, and creep, reducing stress–strain relationships, where the strain at any given moment depends on both the acting and previously acting stresses [20,21,22,23,24,25,57,58,59,60]. It is assumed that the creep strains of concrete are proportional to stresses and their rate of increase depends only on the age of concrete, which decreases with its “aging”, while neglecting the elastic consequence and assuming that the previously acting stresses do not affect the rate of full strain [9,10,11,45,46,47,48,49,50]. The works [18,19,20,25,26,27,28,29,30,55,56,57,58,59,60] discuss the linear theory of “elastic-crawling body”, which is a kind of “aging” theory. This theory considers the age and duration of the load action, as well as the change in the instantaneous deformation modules of concrete over time, making it possible to apply sulfur-containing arbolitic concrete at normal operational stresses. The disadvantages of these works include unresolved questions on the influence of previously acting elastic instantaneous deformations on the stress at the considered moment for sulfur-containing arbolite. The analysis of the literature review and the experimental studies of predecessors indicate the feasibility of studying the possibility of obtaining high-performance building materials on the basis of technical sulfur and the development of technologies for their production. For this reason, it is required to set additional experimental works on the detoxification of sulfur-containing toxic wastes when using them in building materials to investigate the formation of strength and mechanism of its deformation and fracture of iron-sulfur-containing arbolite–concrete composites under a long-term acting load.

Analyzing the issues of unsolved problems, this study aims to develop iron-sulfur-containing binders by the mechanochemical treatment, structure formation, and hardening stages of arbolite concrete composites under long-term load.

In order to achieve this goal, the following objectives were set:

- Development of the composition and study of the properties of iron-sulfur-containing binders by the method of mechanochemical treatment for their use in the composition of arbolite–concrete composites.

- Study the growth rate of creep strains and strength of lightweight iron-sulfur-containing concrete of dense, porous, and large-porous structures.

- Study the curing phase of final strength and fracture of iron-sulfur-containing arbolite concrete composites.

2. Materials and Methods Used in Experimental Work

2.1. Materials Used in Experimental Work

Portland cement of 500 grade from the Chimkent cement plant, corresponding to the Interstate standard GOST 31108-2020 [61], was used for experimental research. Industrial wastes from the enterprises of Kazakhstan in the form of sludge and solids were also used in our research. As an additional additive, pyrite cinders of the former JSC “Phosphochim” were applied. The chemical composition of pyrite cinders, mass %, are as follows: CaO-10.5%; SiO2-19.7%; Fe2O3-66.1%; AI2O3-2.3%; MgO-1.2%; and other various impurities-0.2%.

Technical sulfur, a secondary product of the processing of high-sulfur oil fields in the Atyrau region of the Republic of Kazakhstan, was used as a modifying additive. Its sort was defined as No 9998 according to the Interstate standard GOST 127.1-93 [62]. The chemical composition of technical sulfur is as follows: mass fraction of sulfur-99.060%; mass fraction of ash-0.400%; mass fraction of organic matter-0.053%; mass fraction of water-0.010%. External views of industrial waste used in the research in the form of industrial sulfur (a) and pyrite cinders (b) are shown in Figure 1.

Figure 1.

External views of (a) technical sulfur and (b) burnt sulfur.

To obtain iron-sulfur-containing arbolite–concrete composite as an organic aggregate used crushed reed fibers of the Aktobe region of Kazakhstan (Figure 2). The chemical composition of the crushed cane fiber is: Cellulose-39.1%; Lignin-19.2%; Pentazon-17.7%; Polysaccharides-24%.

Figure 2.

External views of shredded cane.

2.2. Methods

2.2.1. Methods of Mutual Neutralization of Toxic Components of Industrial Wastes

To neutralize toxic components of industrial wastes, the work on their mechanochemical treatment at low temperatures was conducted. In the selected wastes, iron in oxidation degree three (in the form of Fe2O3) functioned as oxidizing agents, and elemental sulfur and iron in oxidation degree two (FeO) had reduced properties. Since in this study the primary method of introduction of sulfur additive in the iron-sulfur-containing mixture considered is the joint grinding of pyrite cinder and sulfur, not only was the specific surface of the resulting iron-sulfur-containing binder determined but also those of pyrite cinder and sulfur separately. The decantation (scouring) method was applied to separate components of the iron-sulfur-containing binder. For this purpose, one liter of iron-sulfur-containing sludge obtained by co-milling pyrite cinder with sulfur addition was used. Additionally, three liters of water were poured into a glass flask with a capacity of five liters. The components were stirred and stood for two hours. After that, the upper layer, which consisted of sulfur and water, was separated and filtered, and water was added to the flask with pyrite cinder. The process was repeated until the visual separation of sulfur was completed. Then, the iron-sulfur mixture was also filtered off. Practice showed that no more than four cycles were sufficient for complete separation. The obtained materials were dried and averaged and the specific surface area was determined. At the same time, the separated sulfur was dried in a desiccator at a temperature no greater than 70 °C and pyrite cinder at a temperature of 500 °C to remove possibly remaining sulfur.

2.2.2. Mechanochemical Activation of Iron-Sulfur-Containing Additives on the Basis of Pyrite Cinders and Technical Sulfur Together with Cement

During research planning, the scientific hypothesis raised that joint grinding applications can give the effect of the additional activation of each particle of additives, resulting in the mutual detoxification of solid wastes with special opposite characteristics on chemical properties. Experimental works on the preliminary determination of composition and activation of iron-sulfur-containing additive grinding were performed on the construction of ball mill LShM-750, due to abrasion and impact. The technical characteristics of the ball mill are as follows: grinding principle—friction; shaft dimensions—d 45 mm, length 170 mm, 370 mm; speed range—100–750 rpm; mass of installed drums—up to 12 kg; power consumption—300 W; overall dimensions—1000 × 325 × 265 mm; mass—35 kg.

To study the possibility of using the method of mechanochemical activation of additives in the form of technical sulfur and pyrite cinder together with cement mortar and its effect on the properties of iron-sulfur-containing dough and the strength of iron-sulfur-containing cement stone, the method of the sequential study of the mortar mixture of the three-component binder was adopted. The analysis of the processes occurring according to this sequence allowed us to find out the reasons for the increase in the activity of the initial binder.

The samples were made in the following technological sequence:

- -

- Preparation and dosing of iron-sulfur-containing additives based on pyrite cinders and technical sulfur by fractional composition and specific surface area;

- -

- Preparation and dosing of Portland cement;

- -

- Preparation and mixing of a certain amount of water from the total mass of binder;

- -

- Loading into the mill iron-sulfur-containing additives on the basis of pyrite cinders and technical sulfur in the ratios 100:200, 100:250, and 150:250 by weight, grinding to a fineness characterized by 8–10% of the residue on the sieve No 008 and mixing for 20 min;

- -

- Subsequent addition of 67–70% of cement to the iron-sulfur-containing dry mix and not enough water up to W/C = 0.6;

- -

- Joint grinding of iron-sulfur-containing additives together with cement for 10 min;

- -

- Stopping the mill and discharging the sulfur containing the binder.

Specific surfaces of the components of iron-sulfur-containing dry mixtures after grinding in a ball mill are given in Table 1.

Table 1.

Specific surfaces of iron-sulfur-containing components.

2.2.3. Methods of Preparation of Iron-Sulfur Binders

To conduct a study to determine the effect of technical sulfur addition on the strength characteristics of iron-sulfur-containing cement, stone samples of size 100 × 100 × 100 mm were made at a water/solid ratio of 0.385, which provided the spreading of iron-sulfur-containing mortar mixture 200 mm on the shaking table. The characteristics of the initial and activated binder were determined in accordance with Interstate standards GOST 30515-97, 31108-2020 and 7473-2010 [63,64] The specimen beams with dimensions 40 × 40 × 160 mm were used to determine the tensile and bending strength of iron-sulfur-containing binders in the device IP 2710. The prototypes of the developed compositions of iron-sulfur-containing binders were made. The developed compositions of iron-sulfur-containing binders are shown in Table 2.

Table 2.

Developed compositions of iron-sulfur binders.

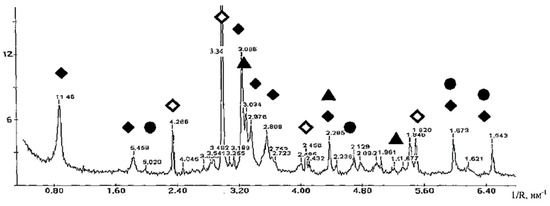

2.2.4. Methods of Evaluating Sulfur Additive Effect on the Strength Characteristics of Iron-Sulfur-Containing Binders by Phase and Mineral Composition

Considering the strength characteristics of iron-sulfur cement stone, which are determined to a large extent by its phase and mineral composition, it was reasonable to consider the influence of sulfur additives on them. For this purpose, samples of dense solutions prepared at a water/solid, W/S, ratio equal to 0.375 with sulfur addition of 10, 12, and 13% of the weight of dry components were studied by X-ray phase analysis. The investigated samples were prepared in the form of fine powders of optimal mass with the further application of a thin layer on the surface of frosted glass. During imaging, the diffraction angle interval from 2 to 32° was selected. The deciphering of X-ray diffraction patterns was performed on the basis of the reference X-ray diffraction patterns of constituent minerals.

2.2.5. Experimental Methods for Investigating the Rate of Creep Strain Growth of Iron-Sulfur-Containing Lightweight Arbolite Concretes at Different Compressive Stresses

The arbolite–concrete mixture was prepared as follows: to the organic aggregate in the form of crushed reed fiber was added a pre-prepared solution of the cement-iron-sulfur-containing component with water, and it was mixed until the formation of a homogeneous mass. The density of cement-iron-sulfur-containing component solutions and solution ratio were varied in broad ranges in order to study the influence of these factors on the physical and mechanical parameters of the arbolite–concrete composite. Then, the arbolite–concrete mixture was placed in a cleaned and machine-oiled mold with dimensions 150 × 150 × 150 mm, bayoneted, compacted, and fixed in accordance with the requirements of Interstate Standard GOST 19222-84 [65].

The physical and mechanical characteristics of the arbolite-concrete composite were determined according to Interstate standards GOST 19222-84 and 25820-2000 [65,66]. The samples were subjected to heat and humidity, as well as curing in natural conditions. The study of the properties of organic aggregates was performed using the standard methods according to state standard 19222-84. The shrinkage strains and creep of iron-sulfur arbolite concrete composite were 28 days after curing in natural conditions. The compression stress of the arbolite-concrete composite was transferred 0.15–0.74 Rbn from the prismatic strength.

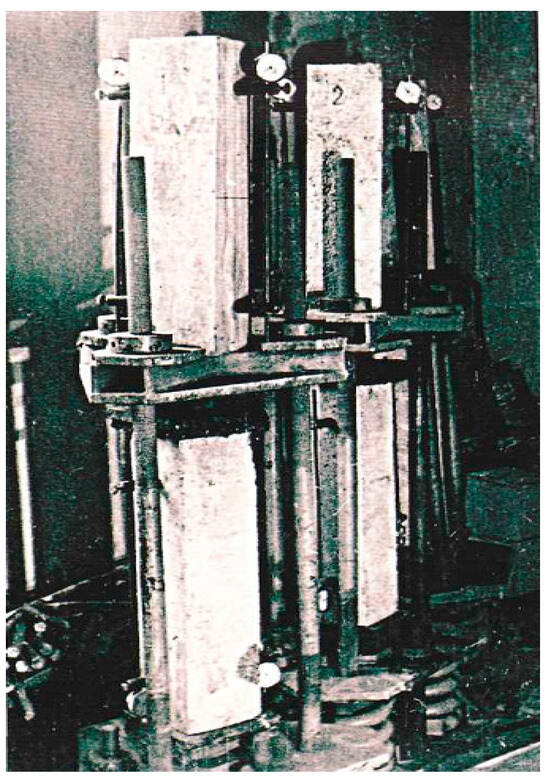

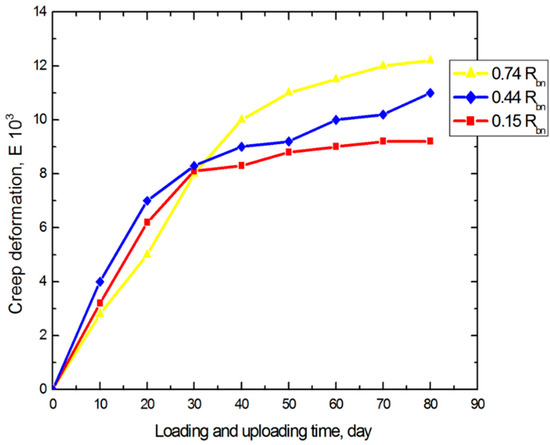

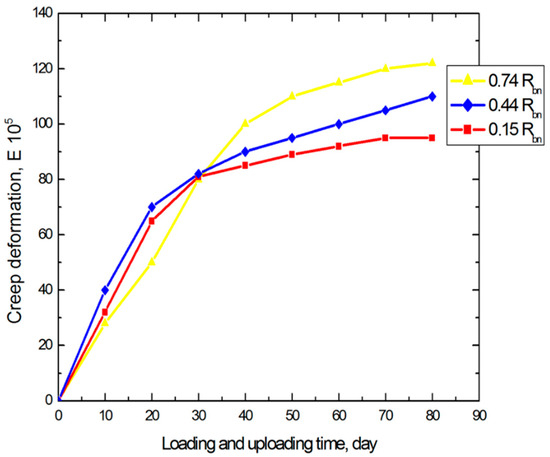

Due to the peculiarity of iron-sulfur-containing arbolite-concrete specimens, the magnitude of the maximum load on the prismatic specimens was limited within the range from 60 to 120 kN, which was determined by the limiting equation of specimen loading equal to σ = 0.15 Rbn, σ = 0.44 Rbn, and σ = 0.75 Rbn, where Rbn is the prismatic compressive strength of iron-sulfur-containing arbolite concrete (Figure 3).

Figure 3.

Loading of iron-sulfur prism samples.

In the course of the study, a total of six series of specimens made of iron-sulfur arbolite concrete and iron-sulfur expanded clay concrete were produced to compare the results. Then, three series of specimens from iron-sulfur-containing arbolite-concrete and three series from iron-sulfur-containing expanded clay concrete were tested. Each series included 9 prisms. The prism samples were loaded in stages corresponding to the stress increment from 0.1 to 0.15 MPa. After each loading step, the samples were held for five minutes. Indicator readings were taken after applying each load step and before applying a new step. Such a test methodology allowed us to isolate extreme instantaneous deformations and determine the value of the initial modulus of elasticity of lightweight concrete. The load on the sample prisms was transferred through a small steel plate with an area of 1 cm2 located in the prism’s center. The specimens were centered on the four faces of the specimen prisms under continuous loading, so that the deformations of the prism by the end of loading were the same. The deformation measurement base was 500 mm. Simultaneously, the production of prism samples for each series of tests from the same composition of lightweight iron-sulfur-containing concrete in steel molds made up to 72 control cubes with dimensions 150 × 150 × 150 mm, which were stored together with the prisms and tested at different times. The deformations of unloaded insulated and uninsulated specimens against moisture loss were also measured.

So, the organic aggregates in the form of reed fiber with sizes from 30 to 50 mm in the composition of iron-sulfur-containing arbolite-concrete samples have special properties, characterized by the higher ultimate tensile strength under long-term loading. Compared to other lightweight concrete, iron-sulfur-containing arbolite samples have a low density (650–700 kg/m3) and low strength (3.0–3.9 MPa). To determine the values of the creep strain coefficient ν2(t, τ) and elastic strain ν1(τ), iron-sulfur-containing arbolite–concrete specimens were loaded with a long-term load, the stress of which was σ = 0.15 Rbn, σ = 0.44 Rbn, and σ = 0.75 Rbn. In the long-term tests, a constant load was applied to the specimens using specially made spring units (Figure 4).

Figure 4.

Installation for testing iron-sulfur-containing arbolite. Prism samples under long-term loading.

2.2.6. Methods for Determining the Curing and Fracture Phase of Iron-Sulfur-Containing Arbolite–Concrete Composites

To study the formation of strength, mechanism of fracture sequence, and deformative properties of arbolite–concrete composites under a long-term acting load, light concrete prisms with a cross-section of 150 × 150 × 600 mm were used. One part of the samples was made of iron-sulfur-containing arbolite, where the cellulose organic filler used was crushed reed fibers; for comparison, the second part of iron-sulfur-containing expanded clay concrete. The compositions of iron-sulfur-containing arbolite concrete composite and iron-sulfur-containing expanded clay concrete are given in Table 3 and Table 4.

Table 3.

Compositions of iron-sulfur-containing arbolite–concrete composite.

Table 4.

Compositions of iron-sulfur-containing expanded clay concrete.

For the compositions investigated, the ratio of compressive strengths of certain prisms with a cross-section of 150 × 150 × 600 mm (Rbn) and cubes with a cross-section of 150 × 150 × 150 × 150 mm (R) is from 0.87 to 0.95, depending on the composition of the lightweight iron-sulfur concrete. In each series consisting of nine prism samples, the first three were isolated from moisture loss and placed under dynamic loading; the second three samples were also isolated but left unloaded. Finally, the remaining three samples were not isolated and subjected to loading. Hence, they were used to determine the axial compressive strength of concrete and to analyze the failure mechanism of iron-sulfur lightweight concrete.

The coefficient of prismatic strength of iron-sulfur-containing arbolite is, on average, 25% greater than that of conventional lightweight concrete, which can be explained by the peculiarities of its deformational properties, characterized by greater ultimate extensibility (Table 5). Therefore, when normalizing the prismatic strength coefficient (Rbn) of iron-sulfur-containing arbolite, it is recommended to apply a 20–25% greater value than for lightweight and cellular concrete.

Table 5.

Relationship between cubic and prismatic strengths of lightweight and cellular concrete R/Rbn.

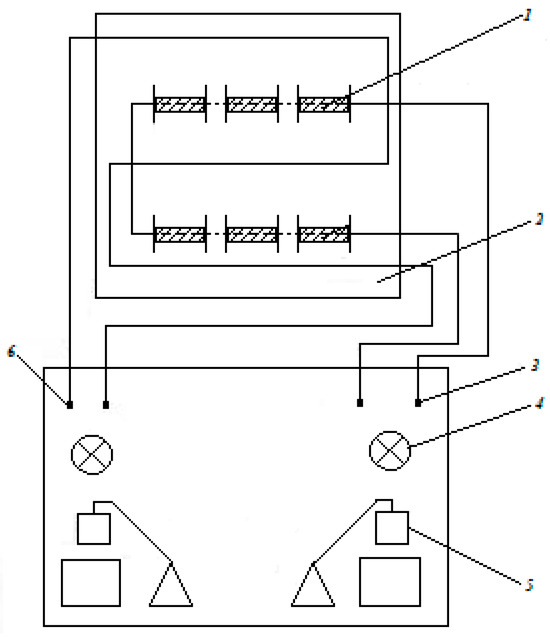

The character of strength formation and fracture of iron-sulfur-containing arbolite concrete composite was studied with the help of strain gauges and depth strain gauges with the base of 10–50 mm, glued on cotton fibers with the help of fast-setting adhesive “Moment”, oriented along and perpendicular to the applied load to the prisms, installed before concreting. The task of the tests was that the depth strain gauges were installed both on the crushed cotton fibers and in the iron-sulfur-containing mortar component of the material, which made it possible to determine the root cause of the sequence of failure of the individual components of the iron-sulfur-containing material (Figure 5).

Figure 5.

Scheme for determining the failure mechanism of iron-sulfur-containing arbolite concrete: 1—strain gauge on fibers of organic aggregate; 2—strain gauge in the iron-sulfur-containing mortar component; 3—terminals of “organic aggregate fibers”; 4—signal lamp; 5—key; 6—terminals of “mortar component”.

3. Results and Discussion in Accordance with the Set Research Objectives

3.1. Development of Composition and Study of Properties of Iron-Sulfur-Containing Binders by the Method of Mechanochemical Treatment for Their Use in the Composition of Arbolite Concrete Composites

3.1.1. Results of Mutual Neutralization of Toxic Components of Industrial Waste

When grinding technical sulfur and pyrite cinder in ratios 10:18; 12:18; and 13:20 by weight by the mutual neutralization of toxic components of industrial wastes within 20 min, reaction products visually differed in color from the initial raw material mixtures. At joint dry grinding of technical sulfur with pyrite cinders, it was established that trivalent iron could oxidize sulfur, passing then to divalent iron, as the color of the processed mixture changed from yellowish to gray–green. In the process of mechanochemical treatment, there was a noticeable increase in the temperature of the reaction medium (about 40 °C). Most likely, the raw mass was heated due to chemical exothermic reactions and due to the transition of mechanical energy into thermal energy. Apparently, the temperature factor of instantaneous local heating of reagents at the moment of mechanical impact plays a significant role in mechanochemical grinding. A notable role in solid-phase reactions induces impurity and non-stoichiometric origin defects in the crystal lattices of iron oxide [18,19,20]. The pyrite cinder initiated the physicochemical process of coagulating the binding mixture in this case. In the coagulation process, there is the polarization of dispersed particles of binder and mutual attraction between them, enhancing the structure formation process. Defects of impurity and non-stoichiometric origin in the crystal lattices of iron oxide play a noticeable role in solid-phase reactions. Ecologically dangerous sulfur oxide in the sludge, when treated with pyrite cinders, is transformed into low-toxic sulfur oxide. Hence, it can be fully utilized as a part of arbolite concrete composites. Such raw material mixtures can be rationally reused by adding vegetable waste such as shredded reed or other organic components to obtain lightweight arbolite concrete. The above results indicate sulfur binding with iron oxides under mechanical action at temperatures close to normal, as evidenced by the absence of a characteristic odor. The addition of organic sawdust and iron nanoparticles to improve sulfur binding may also be an interesting option for the co-disposal of waste.

3.1.2. Developed Compositions and Properties of Iron-Sulfur Binders

Joint mechanochemical treatment of iron-sulfur-containing components with cement positively affects the mechanical properties of the studied iron-sulfur-containing binders. When adding technical sulfur in the amount of 10 and 13%, the compressive strength of iron-sulfur-containing samples increases by 9.2 and 8% in the dry and by 10.8 and 8.8% in the wet state, respectively. From the obtained strength values of sulfur-containing specimens made on the basis of equal-solid mortar mixtures, it can be seen that the same regularity is observed for them as for specimens prepared at the same water/solid ratio. This is probably due to the reduction in capillary porosity and the increase in the density of the samples as a result of the reduction in the water/solid ratio at the introduction of technical sulfur. It is established that introducing technical sulfur additives in the amount of 10–13% increases the compressive strength of samples prepared from solutions with a water/solid ratio equal to 0.385 in wet and dry states. The strength of the developed iron-sulfur binders of specimens at 90 days of age increased from 64.7 MPa to 73.5 MPa. The developed compositions and properties of sulfur-containing binders are given in Table 6.

Table 6.

Compositions and properties of iron-sulfur binders.

3.1.3. Phase and Mineral Compositions and Properties of Iron-Sulfur Binders

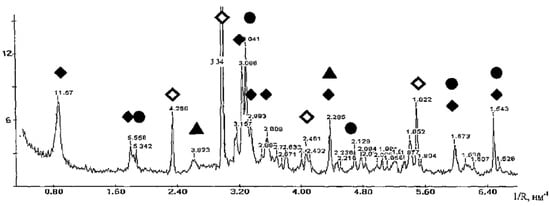

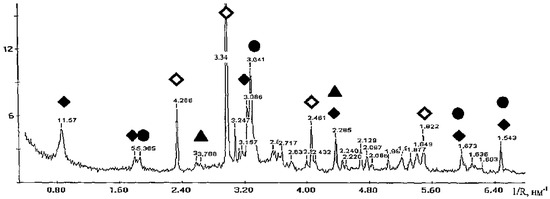

A decrease in the strength of the iron-sulfur binder depends on the decrease in the concentration of cementitious formations in the structure of iron-sulfur cement stone because of a decrease in the total amount of binder. It is established that the greatest values of iron-sulfur-containing binder strength are observed at conducting additives of technical sulfur 10–13% from the weight of dry components. Considering that the strength characteristics of iron-sulfur cement stone are mainly determined by its phase and mineral composition, it is necessary to consider the influence of technical sulfur additives on them. The results of the X-ray phase analysis are given in Figure 6, Figure 7 and Figure 8.

Figure 6.

X-ray phase analyses of iron-sulfur cement stone samples with 10% sulfur addition ♦−1.1 nm tobermorite; ●—hydrosilicates; ◊—quartz; ▲—calcite.

Figure 7.

X-ray phase analyses of samples of iron-sulfur cement stone with 12% sulfur addition ♦−1.1 nm tobermorite; ●—hydrous silicates; ◊—quartz; ▲—calcite.

Figure 8.

X-ray phase analyses of iron-sulfur cement stone samples with 13% sulfur addition ♦−1.1 nm tobermorite; ●—hydrous silicates; ◊—quartz; ▲—calcite.

According to the obtained results of X-ray phase analysis in samples from iron-sulfur cement mortar with sulfur additives (Figure 6, Figure 7 and Figure 8), the main tobermorite group minerals formed are as follows: 1.1 nm tobermorite and low-base hydrous silicates. The composition of the basic binding minerals also includes a significant amount of amorphous phase, which is represented by gel-like hydrosilicates. Also, in the composition of iron-sulfur-containing cement, the cement stone is a source of minerals such as quartz and calcite. A significant change in the diffraction reflections of hydrosilicates is observed, which suggests their quantitative and phase change. In samples with additions of sulfur in the amount of 10% (p¬is. 6), the relative content of tobermorite is 45% greater than in the initial samples, which suggests the increased formation in the structure of iron-sulfur cement stone for this mineral. An increase in its diffraction maxima also indicates the increased content of tobermorite. The increase in the width of these peaks, as well as a decrease in the calculated values of the size of the coherent scattering region (CSR) of the tobermorite by 33% in samples with the addition of technical sulfur compared to the original samples, indicates a decrease in the degree of crystallization of this mineral. The results of the work allow us to assert that due to the increase in the structure of crystals tobermorite’s small size, the content of the amorphous phase in this material increases by 3.8%. In samples with additions of technical sulfur in the amount of 12% (Figure 7), the relative content of tobermorite is greater by 31%. However, the value of the size of the coherent scattering area (CSA) is 42% lower, and the content of the amorphous phase increases by 8.8%. In samples with the addition of technical sulfur in the amount of 13% (Figure 8), the content of tobermorite is greater by 12% than in samples without sulfur. In comparison, the value of the size of the coherent scattering region (CSR) decreases by 49%, and the content of the amorphous phase is greater by 16%. In iron-sulfur-containing samples, with the addition of technical sulfur in the amount of 10 to 13%, the intensity of the diffraction maximum at d-0.3041 increases significantly, which agrees with the studies [25,26] and shows the presence of relatively well-crystallized hydrosilicates. It suggests an increase in the degree of crystallization of cement stone depending on the increase in the addition of technical sulfur. The increase in the relative content of 1.1 nm tobermorite in the composition of binder cement stone at the introduction of technical sulfur additive, according to established ideas and the obtained results of works [21,25,27], is explained by the formation in its structure of an increased number of “abnormal” varieties, which require much less energy input compared to the index for “normal” compounds. As a result, they are very close to calcium hydrosilicates by the degree of crystallization.

3.2. Results of Creep Strain Growth and Strength of Iron-Sulfur Lightweight Concretes

The conducted experimental studies have established that the analysis of the growth of deformation of prism samples of iron-sulfur-containing arbolite on the basis of shredded reed, depending on the curing period indicates some deviations from the general regularity. Thus, the deformation of specimens under stress σ = 0.15 Rbn of iron-sulfur arbolite was slower than the same deformation of specimens under greater stress σ = 0.44 Rbn and σ = 0.74 Rbn (Figure 9). It seems to be due to the greater heterogeneity of iron-sulfur-containing arbolite-concrete based on shredded reed. No such deviations were observed in the samples from iron-sulfur-containing expanded clay concrete (Figure 10). For both types of lightweight iron-sulfur-containing concrete, creep strains reached, depending on the curing time, values exceeding the elastic strains by two to three times. In all samples, a rapid increase in creep strain was observed just after loading, and then the growth of strains gradually slowed down. It was revealed that the rate of creep growth in time depends not only on the magnitude of stress but also on the time elapsed since the moment of loading. As the tests showed, the creep change rate of lightweight iron-sulfur concrete depends on the rate of strength growth, reflecting the curing process of concrete. It was found that compared to iron-sulfur-containing expanded clay concrete, the creep of iron-sulfur-containing arbolite appears to be significantly lower (Figure 9 and Figure 10).

Figure 9.

Creep strains of iron-sulfur arbolite as a function of curing time and by the time of loading from 4 to 90 days. ♦—Series I; ■—Series II; ▲—Series III.

Figure 10.

Creep strains of iron-sulfurized clay concrete as a function of curing time and by the moment of loading from 4 to 90 days ▲—series I; ■—series II; ♦—series III.

The character of deformation changes is somewhat peculiar. Immediately after load application, its value increases, reaching its maximum in 2–4 days after loading, and then decreases in limit to values equal to 0.11–0.13 at σ = 0.15 Rnp, 0.14–0.17 at σ = 0.44 Rnp, and 0.21–0.25 at σ = 0.74 Rpr, remaining lower than the value of the elastic-moment deformation coefficient ν1(τ) found at lower stress levels (Figure 9 and Figure 10). The table below summarizes the average values of creep strain ratio ν2(t, τ) and elastic-momentum strain ratio ν1(τ) obtained from the results of the compression experiments (Table 7).

Table 7.

Values of transverse deformation coefficients.

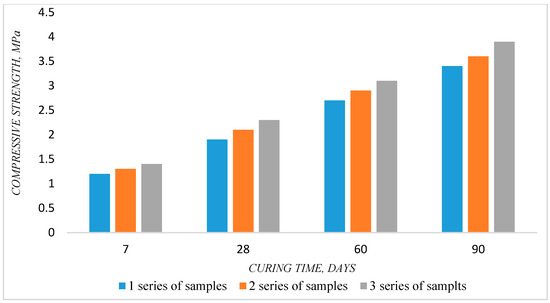

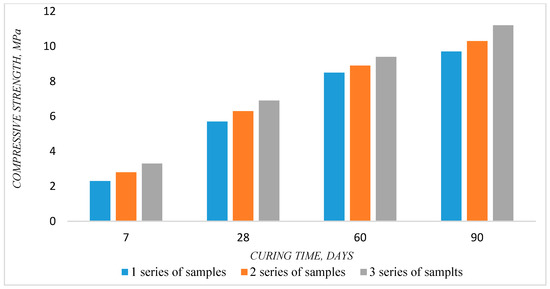

It was revealed that at 7 days of age, the deformability of the iron-sulfur-containing mortar part is the lowest; this period can be attributed to the first phase of hardening of arbolite. The character of the deformations slightly changes by 28 days of age. There is a decrease in the deformation of the mortar part due to the growth in the strength characteristics of iron-sulfur-containing arbolite (Figure 9). According to the theory in [21,25,27], starting from the moment when the deformability of the mortar component is less than the deformability of the organic aggregate, the strength of lightweight concrete should not increase because the destruction of the aggregate prevents it. However, as the results showed, the strength of iron-sulfur-containing arbolite continues to increase even by 90 days of age, despite the excess of deformability of the mortar component over the deformability of the organic aggregate. Apparently, the increase in the strength of iron-sulfur-containing material in the second phase of curing is explained by the change in the deformation modulus of the constituent components of sulfur-containing arbolite under loading with different stress levels. The graph (Figure 9) shows that the deformation modulus of the iron-sulfur-containing mortar component and the material decreases with increasing stress, while it increases for the organic aggregate in a certain range of relative stress. It can be assumed that the organic aggregate in the form of shredded reed is strengthened in the stressed state and can take more load than in the unstressed state. Strengthening of the cellulose organic aggregate in the studied stress range up to 0.8R3 (R3–the strength of organic aggregate) occurs due to the reduction in intra-stem porosity in the fibers of shredded reed and the appearance of the “shell” effect in the structure of this material. It was also found that the reason for the greater strength of iron-sulfur-containing arbolite, compared to low-strength organic aggregate, is the ringing of its pores iron-sulfur-containing cement mortar, for which hardening causes an increase in the strength of shredded cane. These effects were observed in sulfur-containing arbolites of a dense structure in sulfur-containing materials of porous and large porous structure (with a density of 450–500 kg/m3) are manifested to a lesser extent or almost not at all. Changes in the compressive strength of iron-sulfur-containing arbolite concrete and expanded clay concrete depending on the curing conditions are shown in Figure 11 and Figure 12. It was revealed that the strength of iron-sulfur-containing arbolite continued to increase even to 90 days of age, despite the excess deformability of the mortar component over the deformability of organic aggregate. The results gave grounds to assert that the growth of sulfur-containing material strength in the second phase of curing is explained by the change in the deformation modulus of the components of sulfur-containing arbolite during prism sample loading. We also found that the destruction of sulfur-containing arbolite in the second phase occurs stepwise (aggregate-mortar). It has been determined that the increase in the strength of sulfur-containing lightweight concrete over time in some cases cannot be described by a single logarithmic dependence, and at the early stage, the pattern is different than in the subsequent period. It was found that with the increase in the content of iron-sulfur components in the range of 10–12% in arbolite concrete composites and lightweight expanded clay concrete accepted for comparison of the results, the strength of all three series of specimens with curing time increased and reached 3.4, 3.6, and 3.9 MPa and 9.7, 10.3, and 11.2 MPa, respectively (Figure 11 and Figure 12). It is pertinent to note here that the presence of iron-sulfur components in all cases leads to an increase in mechanical properties in the specimens.

Figure 11.

Change in compressive strength of iron-sulfur-containing arbolite composites depending on curing time.

Figure 12.

Variation in compressive strength of sulfur-containing expanded clay concrete specimens depending on curing time.

3.3. Strength and Fracture Results of Iron-Sulfur-Containing Arbolite Concrete Composites

The experiments allowed us to give an exhaustive answer to the statements that appeared in recent years that in lightweight concrete, including iron-sulfur-containing arbolite concrete, the ratio between cubic and prismatic strength is close to unity and even exceeds it (Table 5).

The experimental studies have given the following results:

- Strain gauges located in the mortar component of the material record the moment of its destruction and the achievement of the ultimate tensile strength of iron-sulfur arbolite in the prisms perpendicular to the acting load of the press. In this case, the arrow of the press pressure gauge falls; that is, the initial destruction of the material can always be observed.

- Strain gauges fixed on 4–5 mm shredded reed fibers oriented along and across the acting load continue to show strain growth, and the press pressure gauge arrow continues to show stress growth.

- The described effect is not observed in iron-sulfur arbolite of porous (500 kg/m3) or coarse-porous structure (450 kg/m3) of low volumetric mass.

- In the tests of iron-sulfur-containing arbolite of dense structure (650 kg/m3), the simultaneous destruction of the iron-sulfur-containing mortar component and organic aggregate did not occur. Usually, there was sequential destruction associated with organic filler based on shredded reed fibers, then with the iron-sulfur-containing mortar component, but only in the second phase of curing. The failure of the material by the iron-sulfur-containing mortar component occurred only in the first curing phase.

When testing iron-sulfur-containing arbolite density across both porous and large porous structures, the surface of adhesion of crushed reed fiber with iron-sulfur-containing mortar component is of significant importance. For dense material, the strength of adhesion of the mortar component Rcohesion of the mortar is less than that of the organic filler based on crushed reed Rfiller (Rcohesion of the mortar < Rfiller). For porous and coarsely porous material, the bond strength of the mortar component Rcohesion of the mortar is greater than the bond strength of the organic aggregate Rfill (Rcohesion of the mortar > Rfill). This fact was noticed at the destruction of porous and coarsely porous iron-sulfur-containing arbolite and corresponds to the observed clogging of pores of crushed reed fiber with iron-sulfur-containing cement mortar. This study provides a basis for the clarification of the hypothesis of strength formation of iron-sulfur-containing arbolite (Table 8).

Table 8.

Bond strengths of the iron-sulfur-containing mortar component and bond strength of organic aggregate.

The theory in [17] is entirely acceptable to explain the process of increasing strength of the material during curing, that is, when the deformability of the mortar component is less than the deformability of clogged fibers of shredded reed. To explain the increase in the strength of iron-sulfur-containing arbolite of dense structure in the second phase of curing, the above curing theory requires clarification, as follows: the simultaneous destruction of crushed reed fibers and iron-sulfur-containing mortar component in iron-sulfur-containing arbolite of a dense structure is not observed. The destruction of the material in the second phase of curing occurs stepwise (aggregate-mortar).

The final strength of iron-sulfur-containing arbolite of dense structure in all tested samples was determined by the strength of the iron-sulfur-containing mortar component as follows:

- -

- When Rmortar < Raggregate, one-phase solidification and one-stage fracture occurs due to the mortar;

- -

- When Rsolution > Raggregate, two-phase solidification and two-stage failure occur.

The strength of iron-sulfur-containing arbolite of the porous structure is formed in one phase, one-stage fracture occurs due to the clogging organic filler, and the material of dense structure associated with organic filler based on shredded reed fibers was observed to sequentially fracture, and then that with the iron-sulfur-containing mortar component, but only in the second phase of curing. The nature of the fracture of specimens from iron-sulfur-containing arbolite at different ages clearly illustrates the expressed additions to the hypotheses of strength formation of iron-sulfur-containing arbolite and its fracture mechanism (Table 9).

Table 9.

Curing phases and fracture sequences of iron-sulfur-containing arbolite concretes depending on the bonding of the mortar component and the strength of bonding of the organic aggregate.

Using the obtained experimental data, it is possible to recommend obtaining iron-sulfur arbolite of different strengths depending on the fraction and size of the organic aggregate fiber. Of course, they cannot fully explain the processes of formation of the strength of iron-sulfur arbolite, and the mechanism of its deformation and fracture need further study and clarification.

The novelty of the research work is that the proposed method of structure formation and strength formation of arbolite concrete composites under long-term loading on the basis of activated iron-sulfur binders led to the following statements:

- Adopted methods of mutual neutralization and detoxification by their mechanochemical treatment allowed us to reduce the consumption of expensive cement by replacing it partly with cheap industrial waste.

- The growth of the strength of iron-sulfur-containing material depending on the curing period and changes in the modulus of deformation, and especially the great extensibility of organic aggregate based on shredded cane in the composition of iron-sulfur-containing arbolite under loading with different stress levels.

- The nature of fracture and strength formation of iron-sulfur arbolite samples at different ages depend on the fraction and size of the crushed reed fiber.

The practical significance of this study relates to the obtained results, which can be recommended for application in the construction industry for the construction of civil buildings, especially in regions of seismic activity.

Although the study covers important aspects of the topic, it only addresses a limited area of the building industry for low-rise construction.

Despite the significance of the findings, more extensive research is needed to set up additional experimental work to investigate the strength and deformability of arbolite concrete products.

4. Conclusions According to the Results of the Study

- Mutual neutralization of toxic iron-sulfur-containing waste and using the method of mechanochemical processing developed compositions of iron-sulfur-containing binders with compressive strength up to 73.5 MPa for their further use in the composition of arbolite-concrete composites. Moreover, the adopted methods reduce the consumption of expensive cement by replacing part of it with cheap industrial waste.

- The growth of the strength of iron-sulfur-containing material in the second phase of curing is explained by the change in the deformation modulus of the constituent components of sulfur-containing arbolite under loading with different stress levels. It was found that the deformation modulus of the iron-sulfur-containing mortar component and the material decreases with increasing stress from σ = 0.15 Rbn to σ = 0.74 Rbn, while it increases for the organic aggregate in a certain range of relative stress. In the stressed state, the organic aggregate based on shredded reed with 4–5 mm size is strengthened and can be more loaded than in the unstressed state.

- The nature of fracture and strength formation of samples from iron-sulfur-containing arbolite at different ages depends on the fraction and size of crushed reed fiber and the average density of lightweight concrete. The strength of iron-sulfur-containing arbolite of porous structure (400–500 kg/m3) is formed in one phase, with the one-stage destruction due to clogging by organic aggregate. For the material of dense structure (650–700 kg/m3), there is sequential destruction associated with the organic aggregate based on shredded reed fibers and then with iron-sulfur-containing mortar component, but only in the second phase of hardening.

The conducted studies allow for planning to obtain effective wall bearing and enclose structures based on iron-sulfur-containing arbolite composites with different strengths, depending on the grain fraction or length of organic aggregate fibers. Also, according to the indicators of two-stage sequential failure, iron-sulfur-containing arbolite concrete composites can be recommended for the construction of buildings in seismic regions of Kazakhstan.

Author Contributions

Conceptualization, B.I. and A.I.; methodology, B.I.; validation, A.I. and A.D.; formal analysis, B.I.; research, B.I. and A.I.; resources, B.I.; data processing, A.I.; writing—initial draft preparation, B.I.; writing—reviewing and editing, A.D.; visualization, B.I.; guidance, B.I.; obtaining funding, B.I. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Science Committee of the Ministry of Science and Higher Education of the Republic of Kazakhstan (AP25794879-Recycling of plastic film waste as a binder for the production of reed-layered building material).

Data Availability Statement

The data presented in this study are available in the article.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Slizneva, T.E.; Akulova, M.V.; Razgovorov, P.B. Influence of mechanomagnetic activation of solutions Cacl2 and Na2S2O3 on phase structure of cement stone. Izv. Vyss. Uchebnykh Zaved. Seriya Khimiya Khimicheskaya Tekhnol. 2019, 62, 101–107. [Google Scholar] [CrossRef]

- Vyshar, O.; Stolboushkin, A.; Rakhimova, G.; Stanevich, V.; Rakhimov, M. Study of the properties of overburdened rocks from coal mining: Overburden—As a raw material in the production of ceramic bricks. Int. J. GEOMATE 2023, 25, 86–94. [Google Scholar] [CrossRef]

- Sokolova, Y.A.; Akulova, M.; Isakulov, B.; Sokolova, A.G.; Isakulov, A. The Study of the Impact of Iron and Sulfur Containing Additives on the Strength Properties of Sulfur Containing Binders. Solid State Phenom. 2022, 334, 195–201. [Google Scholar] [CrossRef]

- Sokolova, Y.A.; Akulova, M.V.; Isakulov, B.R.; Kul’sharov, B.B.; Isakulov, A.B. The Study of Creep and Deformation Properties of Sulfur-Containing Arbolit Exposed to Various Compression Stresses. Key Eng. Mater. 2021, 899, 137–143. [Google Scholar] [CrossRef]

- Sokolova, Y.; Akulova, M.; Isakulov, B.; Sokolova, A.; Tukashev, Z.; Konysbaeva, Z. Improvement of Strength Properties of Arbolite Concrete Composites by Impregnation with Sulfur—By-Products of Oil and Gas Industry. Lect. Notes Civ. Eng. 2023, 282, 1–8. [Google Scholar] [CrossRef]

- Stanevich, V.T.; Bulyga, L.L.; Vyshar, O.V.; Girnis, S.R.; Rakhimova, G.M. Analysis of energy efficiency of building envelopes of JSC “station EGRES-2”. AIP Conf. Proc. 2022, 2559, 050006. [Google Scholar] [CrossRef]

- Isakulov, B.; Abdullaev, H.; Mukasheva, A.; Akishev, U.; Ordabayeva, G. Investigation of the formation of microstructure and strength characteristics of slag-alkaline arbolite. EUREKA Phys. Eng. 2023, 2, 209–221. [Google Scholar] [CrossRef]

- Isakulov, B.R.; Dzhumabaev, M.D.; Abdullaev, K.T.; Konysbaeva, Z.O.; Shalabaeva, S.I. Detoxication and neutralization of toxic industrial waste components for production of sulfur-containing binding construction materials. Int. J. Eng. Res. Technol. 2020, 13, 4880–4884. [Google Scholar]

- Rakhimova, G.; Stolboushkin, A.; Vyshar, O.; Stanevich, V.; Rakhimov, M.; Kozlov, P. Strong Structure Formation of Ceramic Composites Based on Coal Mining Overburden Rocks. J. Compos. Sci. 2023, 7, 209. [Google Scholar] [CrossRef]

- Tazhentayeva, E.; Vighio, A.A.; Saha, K.M.; Rakhimov, M.; Zakaria, R.; Wen, T.J.; Rakhimov, A.; Rakhimova, Z.; Imanov, Y.; Maikotova, K.A. Renovation Framework for Energy Efficient Dilapidated Building Retrofitting in Kazakhstan. Chem. Eng. Trans. 2024, 113, 613–618. [Google Scholar] [CrossRef]

- Isakulov, B.R.; Akulova, M.V.; Kulsharov, B.B.; Sartova, A.M.; Isakulov, A.B. Formation of strength and phases of sequence of destruction of arbolite composites at various long loads. Ser. Geol. Tech. Sci. 2020, 4, 28–34. [Google Scholar] [CrossRef]

- Kairakbaev, A.K.; Abdrakhimova, E.S.; Abdrakhimov, V.Z.; Tukashev, Z. Rheological characteristics of the ceramic mixture and physical mechanical properties of acid-resistant materials based on man-made waste and pyrophyllite. AIP Conf. Proc. 2023, 2999, 020011. [Google Scholar] [CrossRef]

- Omarov, A.; Sarsembayeva, A.; Zhussupbekov, A.; Nurgozhina, M.; Tleulenova, G.; Yeleussinova, A.; Isakulov, B. Bearing Capacity of Precast Concrete Joint Micropile Foundations in Embedded Layers: Predictions from Dynamic and Static Load Tests according to ASTM Standards. Infrastructures 2024, 9, 104. [Google Scholar] [CrossRef]

- Beysenbayev, O.K.; Umirzakov, S.I.; Tleuov, A.S.; Smaylov, B.M.; Issa, A.B.; Dzhamantikov, K.; Zakirov, B.S. Obtaining and research of physical and chemical properties of chelated polymer-containing microfertilizers on the basis of technogenic waste for rice seed biofortification. Ser. Geol. Tech. Sci. 2019, 1, 80–89. [Google Scholar] [CrossRef]

- Sokolova, Y.; Akulova, M.; Isakulov, B.; Sokolova, A.; Kul’Sharov, B.; Isakulov, A. Detoxication of by-products of oil and gas industry accompaniied by obtaining iron and sulfur-containing binders for structural building materials. Ser. Chem. Technol. 2020, 6, 65–72. [Google Scholar] [CrossRef]

- Sadieva, K.R.; Massalimova, B.K.; Abisheva, R.D.; Tsoy, I.G.; Nurlybayeva, A.N.; Darmenbayeva, A.S.; Ybraimzhanova, L.K.; Bakibaev, A.A.; Sapi, A.K. Preparation of carbon nanocomposites on the basis of silicon-tin containing substances. Ser. Geol. Tech. Sci. 2019, 4, 158–166. [Google Scholar] [CrossRef]

- Isakulov, B.R.; Jumabayev, M.D.; Abdullaev, H.T.; Akishev, U.K.; Aymaganbetov, M.N. Properties of slag-alkali binders based on industrial waste. Period. Tche Quim. 2019, 16, 375–387. [Google Scholar] [CrossRef]

- Zhiv, A.S.; Isakulov, B.R. Resource-saving technologies for the production and research of the properties of wood concrete based on a sulfur-containing binder. Scientific Herald of the Voronezh State University of Architecture and Civil Engineering. Constr. Archit. 2014, V, 61–74. [Google Scholar]

- Abdykalykov, A.; Bolotov, T.; Kurbanbaev, A.; Matyeva, A.; Zhumabaev, R. Optimisation of composition and strength properties of slag-alkali binders based on fuel slags. Arch. Stud. 2024, 10, 125–135. [Google Scholar] [CrossRef]

- Abdul, F.; Adachi, K.; Ho, H.-J.; Iizuka, A.; Shibata, E. Magnesium recovery from ferronickel slag by reaction with sodium hydroxide. J. Environ. Chem. Eng. 2024, 12, 112516. [Google Scholar] [CrossRef]

- Athira, V.; Charitha, V.; Athira, G.; Bahurudeen, A. Agro-waste ash based alkali-activated binder: Cleaner production of zero cement concrete for construction. J. Clean. Prod. 2021, 286, 125429. [Google Scholar] [CrossRef]

- Akhtar, M.N.; Alotaibi, A.; Shbeeb, N.I. River Sand Replacement with Sustainable Sand in Design Mix Concrete for the Construction Industry. Civ. Eng. J. 2025, 11, 201–214. [Google Scholar] [CrossRef]

- Shults, R.; Seitkazina, G.; Annenkov, A.; Demianenko, R.; Soltabayeva, S.; Kozhayev, Z.; Orazbekova, G. Complex Geodetic Monitoring of the Massive Sports Structures by Terrestrial Laser Scanning. Civ. Eng. J. 2025, 11, 884–909. [Google Scholar] [CrossRef]

- Chen, J.; Xing, Y.; Wang, Y.; Zhang, W.; Guo, Z.; Su, W. Application of iron and steel slags in mitigating greenhouse gas emissions: A review. Sci. Total Environ. 2022, 844, 157041. [Google Scholar] [CrossRef]

- Cheng, Y.; Awan, U.; Ahmad, S.; Tan, Z. How do technological innovation and fiscal decentralization affect the environment? A story of the fourth industrial revolution and sustainable growth. Technol. Forecast. Soc. Chang. 2021, 162, 120398. [Google Scholar] [CrossRef]

- Cristelo, N.; Castro, F.; Miranda, T.; Abdollahnejad, Z.; Fernández-Jiménez, A. Iron and Aluminium Production Wastes as Exclusive Components of Alkali Activated Binders—Towards a Sustainable Alternative. Sustainability 2021, 13, 9938. [Google Scholar] [CrossRef]

- Dai, X.; Ren, L.; Gu, X.; Yilmaz, E.; Fang, K.; Jiang, H. Strength Analysis and Optimization of Alkali Activated Slag Backfills Through Response Surface Methodology. Front. Mater. 2022, 9, 844608. [Google Scholar] [CrossRef]

- Deepak, M.; Reddy, Y.R.; Nagendra, R. Investigating the mechanical strength, durability and micro-structural properties of slag-based concrete. Innov. Infrastruct. Solut. 2023, 8, 272. [Google Scholar] [CrossRef]

- Kombayev, K.; Muzdybayev, M.; Muzdybayeva, A.; Myrzabekova, D.; Wieleba, W.; Leśniewski, T. Functional Surface Layer Strengthening and Wear Resistance Increasing of a Low Carbon Steel by Electrolytic-Plasma Processing. Stroj.-Vestnik-J. Mech. Eng. 2022, 68, 542–551. [Google Scholar] [CrossRef]

- Gao, Y.; Zhao, W.; Zhou, A.-N.; Han, R.; Li, Z.; Zhang, N.-N.; Wang, J.-Z.; Ma, C. Study on the composition and structure characteristics and dry decarbonization separation of coal water slurry gasification fine slag. J. Fuel Chem. Technol. 2022, 50, 954–965. [Google Scholar] [CrossRef]

- Krivenko, P.; Helevera, O.; Rudenko, I.; Rohozina, N. Structure formation and optimization of compositions of decorative alkali-activated slag cements. AIP Conf. Proc. 2023, 2684, 040012. [Google Scholar] [CrossRef]

- Manjunatha, M.; Preethi, S.; Malingaraya; Mounika, H.; Niveditha, K. Ravi Life cycle assessment (LCA) of concrete prepared with sustainable cement-based materials. Mater. Today Proc. 2021, 47, 3637–3644. [Google Scholar] [CrossRef]

- Zhukov, A.; Stepina, I.; Sodomon, M.; Bazhenova, S. Preliminary optimization of composite compositions based on modified Sosnowsky’s Heracleum. BioResources 2024, 19, 5731–5740. [Google Scholar] [CrossRef]

- Stepina, I.; Sodomon, M.; Semenov, V.; Kononov, G.; Petukhov, V. Compatibility of modified heracleum sosnovskyi cellulose-based material with some polymers. Cellul. Chem. Technol. 2022, 56, 815–826. [Google Scholar] [CrossRef]

- Turkoglu, M.; Bayraktar, O.Y.; Benli, A.; Kaplan, G. Effect of cement clinker type, curing regime and activator dosage on the performance of one-part alkali-activated hybrid slag/clinker composites. J. Build. Eng. 2023, 68, 106164. [Google Scholar] [CrossRef]

- Wang, Y.; Cao, Y.; Ma, Y.; Xiao, S.; Hu, J.; Wang, H. Fresh and hardened properties of alkali-activated fly ash/slag binders: Effect of fly ash source, surface area, and additives. J. Sustain. Cem. Mater. 2021, 11, 239–262. [Google Scholar] [CrossRef]

- Yakovkin, I.; Katrich, G.; Loburets, A.; Vedula, Y.; Naumovets, A. Alkaline-earth overlayers on furrowed transition metal surfaces: An example of tailoring the surface properties. Prog. Surf. Sci. 1998, 59, 355–365. [Google Scholar] [CrossRef]

- Mehta, V. Sustainable approaches in concrete production: An in-depth review of waste foundry sand utilization and environmental considerations. Environ. Sci. Pollut. Res. 2024, 31, 23435–23461. [Google Scholar] [CrossRef]

- Akhtar, J.N.; Akhtar, M.N. Enhancement in properties of concrete with demolished waste aggregate. GE-Int. J. Eng. Res. 2014, 2, 73–83. [Google Scholar]

- Singh, G.B.; Prasad, V.D. Environmental impact of concrete containing high volume fly ash and ground granulated blast furnace slag. J. Clean. Prod. 2024, 448, 141729. [Google Scholar] [CrossRef]

- Akhtar, M.N.; Jameel, M.; Ibrahim, Z.; Bunnori, N.M. Assessment of structural concrete made by sustainable sand at high temperatures: An experimental research. Ain Shams Eng. J. 2024, 15, 103108. [Google Scholar] [CrossRef]

- Stepina, I.; Sodomon, M.; Semenov, V.; Dorzhieva, E.; Titova, I. Modifying heracleum sosnowskyi stems with monoethanolamine (N→B)-trihydroxyborate for manufacturing biopositive building materials. Lect. Notes Civ. Eng. 2022, 170, 45–52. [Google Scholar] [CrossRef]

- Turan, C.; Javadi, A.A.; Vinai, R.; Russo, G. Effects of Fly Ash Inclusion and Alkali Activation on Physical, Mechanical, and Chemical Properties of Clay. Materials 2022, 15, 4628. [Google Scholar] [CrossRef] [PubMed]

- Vázquez-Rodríguez, F.; Elizondo, N.; Montes-González, M.; Gómez-Rodríguez, C.; González-Carranza, Y.; Guzmán, A.M.; Rodríguez, E.A. Microstructural and Mechanical Characteristics of Alkali-Activated Binders Composed of Milled Fly Ash and Granulated Blast Furnace Slag with µ-Limestone Addition. Materials 2023, 16, 3818. [Google Scholar] [CrossRef]

- Zhumadilova, A.; Zhigitova, S.; Turalina, M. The impact of greenhouse gases on climate change. Sci. Horiz. 2023, 26, 97–109. [Google Scholar] [CrossRef]

- Zhang, T.; Zhu, Q.; Liu, H.; Gao, S. Utilization of coal gangue sand in structural concrete as fine aggregate towards sustainable production. Constr. Build. Mater. 2024, 417, 135264. [Google Scholar] [CrossRef]

- Akhtar, M.N.; Bani-Hani, K.A.; Malkawi, D.A.; Albatayneh, O. Suitability of sustainable sand for concrete manufacturing—A complete review of recycled and desert sand substitution. Results Eng. 2024, 23, 102478. [Google Scholar] [CrossRef]

- Saini, A.; Soni, H.; Yadav, J.S. Utilization of recycled construction and demolition waste to improve the bearing capacity of loose sand: An integrated experimental and numerical study. Géoméch. Geoengin. 2024, 19, 444–461. [Google Scholar] [CrossRef]

- Mistri, A.; Bhattacharyya, S.K.; Dhami, N.; Mukherjee, A.; Barai, S.V. A review on different treatment methods for enhancing the properties of recycled aggregates for sustainable construction materials. Constr. Build. Mater. 2020, 233, 117894. [Google Scholar] [CrossRef]

- Panghal, H.; Kumar, A. Recycled Coarse Aggregates in Concrete: A Comprehensive Study of Mechanical and Microstructural Properties. Iran. J. Sci. Technol. Trans. Civ. Eng. 2024, 49, 115–1131. [Google Scholar] [CrossRef]

- Luo, H.; Aguiar, J.; Wan, X.; Wang, Y.; Cunha, S.; Jia, Z. Application of Aggregates from Construction and Demolition Wastes in Concrete: Review. Sustainability 2024, 16, 4277. [Google Scholar] [CrossRef]

- Monish, M.; Srivastava, V.; Agarwal, V.C.; Kumar, R. Utilization of demolished waste as fine aggregate in Concrete. J. Acad. Ind. Res. 2012, 1, 398–400. [Google Scholar]

- Ju, M.; Jeong, J.-G.; Palou, M.; Park, K. Mechanical Behavior of Fine Recycled Concrete Aggregate Concrete with the Mineral Admixtures. Materials 2020, 13, 2264. [Google Scholar] [CrossRef] [PubMed]

- Akhtar, M.N.; Jameel, M.; Ibrahim, Z.; Bunnori, N.M.; Bani-Hani, K.A. Development of sustainable modified sand concrete: An experimental study. Ain Shams Eng. J. 2024, 15, 102331. [Google Scholar] [CrossRef]

- Wang, C.-Q.; Cheng, L.-X.; Ying, Y.; Yang, F.-H. Utilization of all components of waste concrete: Recycled aggregate strengthening, recycled fine powder activity, composite recycled concrete and life cycle assessment. J. Build. Eng. 2024, 82, 108255. [Google Scholar] [CrossRef]

- Akhtar, M.N.; Ibrahim, Z.; Bunnori, N.M.; Jameel, M.; Tarannum, N.; Akhtar, J. Performance of sustainable sand concrete at ambient and elevated temperature. Constr. Build. Mater. 2021, 280, 122404. [Google Scholar] [CrossRef]

- Kazmi, S.M.S.; Munir, M.J.; Wu, Y.-F. Development of sustainable high-performance desert sand concrete: Engineering and environmental impacts of compression casting. Resour. Conserv. Recycl. 2025, 212, 108002. [Google Scholar] [CrossRef]

- Issakulov, B.R.; Zhiv, A.S.; Zhiv, Y.A.; Strelnikova, A.S. Light concrete on the base of industrial and agricultural waste. In Proceedings of the 2nd International Conference on Sustainable Construction Materials and Technologies, Ancona, Italy, 28–30 June 2010; Available online: http://www.scopus.com/inward/record.url?eid=2-s2.0-84861395964&partnerID=MN8TOARS (accessed on 8 April 2018).

- Sokolova, Y.; Akulova, M.; Isakulov, B.; Sokolova, A.; Kul’sHarov, B.; Isakulov, A. The study of the properties and structure of cement binding composition on electrolyte acqueous solutions activated by mechanomagnetic method. Ser. Chem. Technol. 2021, 2, 86–91. [Google Scholar] [CrossRef]

- Samchenko, S.; Ushkov, M.; Erofeev, V.; Ushkov, V.; Stepina, I. The Flammability and Thermal Stability of Filling Epoxy Foam Plastics for Construction Purposes. Materials 2024, 17, 5268. [Google Scholar] [CrossRef]

- GOST 31108-2020; General Construction Cements. Specification. Standardinform: Moscow, Russia, 2020. (In Russian)

- GOST 127.1-93; Technical Sulfur for Industrial Use. Specification. IPK Publishing House of Standards: Minsk, Belarus, 1996. (In Russian)

- GOST 30515-97; Cements. General Specifications. Standardinform: Moscow, Russia, 1998. (In Russian)

- GOST 7473-2010; Concrete Mixtures. General Specifications. Standardinform: Moscow, Russia, 2018. (In Russian)

- GOST 19222-84; Arbolit and Its Products. General Specifications. Publishing House of Standards: Moscow, Russia, 1984. (In Russian)

- GOST 25820-2000; Lightweight Concretes. General Specifications. Standardinform: Moscow, Russia, 2008. (In Russian)

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).