1. Introduction

Every year, around 45% of road accidents on European roads involve only one vehicle, so-called ‘single-vehicle-accidents’. These road accidents are categorised as ‘run-off-road accidents’, in which a motor vehicle leaves the carriageway and ends up on the roadside. Many of these types of accidents involve motorcyclists.

Riding through horizontal curves requires a great deal of skill from motorcyclists due to the dynamic behaviour of single-track vehicles. Many studies indicate that horizontal curves are spots where the highest frequency of motorcyclist crashes [

1] occur and where the consequences are most severe. This is mainly due to the fact that motorcyclists need specific riding skills, and they can easily lose control over the motorcycle when steering through curves [

2]. Moreover, in horizontal curves, motorcyclists have reduced roadway perception and visibility [

3]. This is especially evident on rural roads [

4]. Studies [

5,

6] show that crash frequency increases as the radius of the horizontal curve decreases. All these facts lead to motorcyclists being far more prone to steering errors in horizontal curves than in other road sections. There are at least two reasons for this. The first relates to the inherent characteristics of motorcycles. Motorcycles are single-track vehicles with only two small contact areas between the road surface and tyres and, as such, a particular riding skill is required, especially when riding through horizontal curves. The second reason for the problem motorcyclists encounter in horizontal curves relates to the perception and visibility of the environment.

When riding through curves, all longitudinal and lateral forces must be in balance [

7]. If the balance is disrupted, two situations occur: (a) a motorcyclist may fall on their side and slide out of the curve (sliding crash), or (b) a motorcyclist may not fall on their side but continues to ride out of the curve (upright-posture crash) [

8]. Experience from many countries, including Slovenia [

9], show that left-hand curves are more dangerous than right-hand ones.

In a right-hand curve, a motorcyclist can fall to the right side and slide into the oncoming lane. The motorcyclist’s chance of survival depends on whether a vehicle is approaching at that moment from the opposite direction as well as on the safety of the roadside on the left side of the road. The exact same situation occurs if a motorcyclist does not fall onto their side but instead falls directly into the opposite lane in a right-hand curve [

7]. There are no technical solutions for a right-hand curve that would prevent a motorcyclist from crossing into the opposite lane, as the traffic is coming from the opposite direction and therefore it is not possible to implement any physical measures to separate the traffic between the two lanes.

In a left-hand curve, however, the situation is somewhat different. A solution already exists for a situation in which a motorcyclist falls onto their left side and slides out of the left curve—the so-called ‘motorcyclist-friendly barrier’. It has two purposes: to prevent a motorcyclist’s body from hitting the SSB post, whilst also preventing it from sliding between the two SSB posts into a dangerous roadside. However, there are no established solutions for the case where, in a left-hand curve, a motorcyclist does not fall onto the carriageway and slide towards an SSB but rather crashes directly into one.

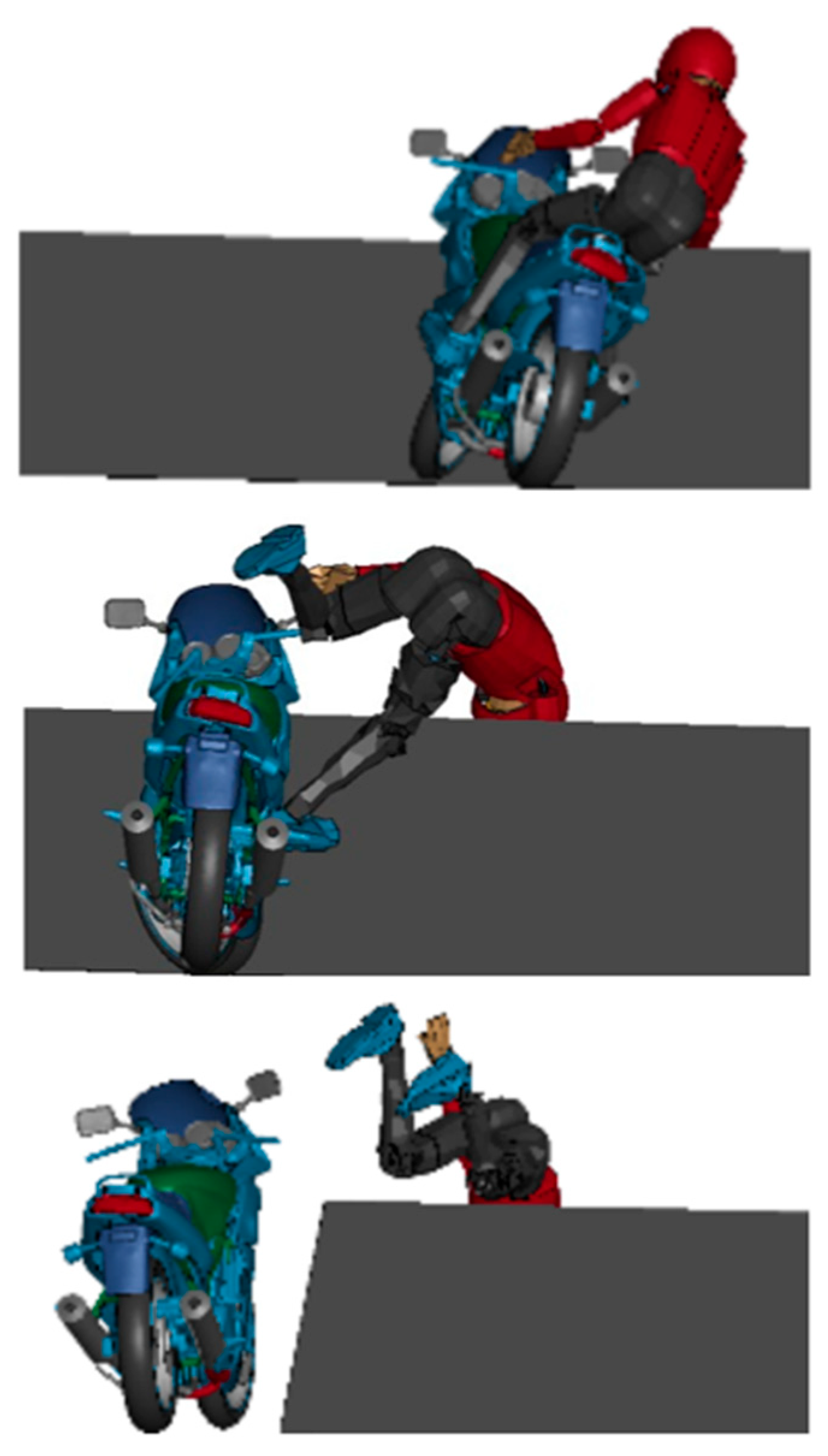

In such a case, due to inertia, the upper part of the motorcyclist’s body bends over the upper sharp edge of the SSB guardrail (

Figure 1). Which part of the motorcyclist’s body bends over the upper edge of the SSB guardrail depends on the height of both the motorcycle and the motorcyclist. As a rule, the motorcyclist’s body bends over the lower ribs or internal organs, where injuries are most dangerous. In addition, motorcyclists’ heads are protected by a helmet; their hands by gloves; and their shoulders, elbows, and knees by protectors, but the ribs and internal organs have no protection.

Methodologically, the analysis was conducted in such a way that detailed reviews were carried out for all available patents and patent applications (13 in total) addressing protection against impact with a post, the upper edge of the SSB guardrail, or a combination of both. The authors of this research identified these solutions through online browsing and targeted queries in the Worldwide Espacenet patent database [

10], using keywords such as motorcyclist barriers, steel safety barriers, and upper guardrail protection for motorcyclists.

It should be noted that all patents available in the Espacenet database are either originally in English or include an English translation provided by the database itself. Therefore, no additional language filtering was necessary. Furthermore, no explicit temporal limitations were applied in the search strategy, as the Espacenet platform does not offer a structured or reliable filtering option by publication date. Consequently, all relevant patents available at the time of the search were considered regardless of their publication year.

In this document, we analysed the patents and patent applications specifically offering upper guardrail protection for motorcyclists. A selection of the most relevant and technically distinctive solutions—four patents and one patent application—is described in more detail below.

This article consists of the following sections: Introduction; The Importance and Role of Steel Safety Barriers; Upper Guardrail Protection for Motorcyclists; Discussion; and Conclusions. The section on upper guardrail protection is the main and most important part of this article.

2. The Importance and Role of Steel Safety Barriers

Because riding through curves represents a major danger to all vehicles, curves are the most common location for the installation of road safety barriers on rural roads.

Road safety barriers are intended to prevent a vehicle from leaving the roadway and protect it from traffic driving in the opposite direction [

11]. Taking into consideration strength and deflection, the most common classification of road safety barriers concerns rigid barriers (typically concrete), semi-rigid barriers (typically guardrail systems), and flexible barriers (typically cable or wire–rope systems) [

12].

Although conventional road safety barriers perform well for occupants of passenger cars and lorries, their effects on other road user groups, especially motorcyclists, usually result in more severe injuries [

13]. In a study conducted in the USA [

14], it was also found that barrier crashes were at risk of being more severe than all other single-motorcycle crashes. According to Roque and Cardoso [

11], in all motorcycle crashes, the upper and lower extremities sustain the most injuries. Motorcyclists involved in road safety barrier crashes are 2.15 times more likely to suffer a severe injury to the thoracic region than those not engaged in that type of crash [

11]. The results of the study conducted by Grzebieta et al. [

15], wherein both sliding and upright-posture crash configurations were evenly represented, showed that the thorax region had the highest incidence of injury and the highest incidence of maximum injury in fatal motorcycle-to-barrier crashes. Other studies found that the risk of injury slightly increases for SSBs due to the stiffness of the steel barrier posts and a lack of absorption of kinetic energy from the motorcycle during the crash [

16]. Ferko et al. [

8] investigated how the traditional approach to safety barriers impacts the severity of motorcycle crashes on typical European two-way rural roads. Their analysis showed that more than half of single-motorcycle crashes resulted in fatalities or severe injuries. This is primarily due to inappropriate riding speeds, since speeding significantly affects the severity of an injury. They found that implemented road safety barriers, designed primarily for cars, did not significantly benefit motorcyclists when they crashed compared to a situation whereby there were no barriers at all. Moreover, no statistically significant differences between individual types of barriers were found.

It is clear that SSBs are not always considered fully satisfactory for motorcyclists’ safety, especially when there is only one guardrail without an additional motorcycle protection system. Furthermore, it is an undeniable fact that SSBs were invented with only two-track vehicles in mind, while powered two wheelers (PTWs) were disregarded. Although the primary purpose of SSBs is to protect users of motorised vehicles, they currently represent one of the greatest dangers for PTWs.

3. Upper Guardrail Protection for Motorcyclists

Road restraint systems (e.g., steel safety barriers, cable barriers, etc.) are the third most dangerous roadside obstacles, after the most dangerous, which are tree lines and electric lighting poles [

17].

Although barrier terminals and transitions are hit more frequently, the barrier guardrails themselves can also be considered roadside hazards, especially for motorcyclists. Safety barriers are, therefore, a special case, as they can be both hazards and forgiving roadside treatments for safety.

Researchers at the Texas A&M Transportation Institute (TTI) [

12], in collaboration with the Texas Department of Transportation (TxDOT), have developed and tested a retrofit containment system aimed at improving motorcyclist safety when impacting rigid concrete barriers. The system consists of a chain-link fence installed atop concrete barriers, designed to prevent motorcyclists from vaulting over the barrier in upright crashes. This innovation addresses one of the primary risks associated with concrete barriers: ejection into opposing traffic or off bridges due to the limited height and rigid structure of traditional barriers.

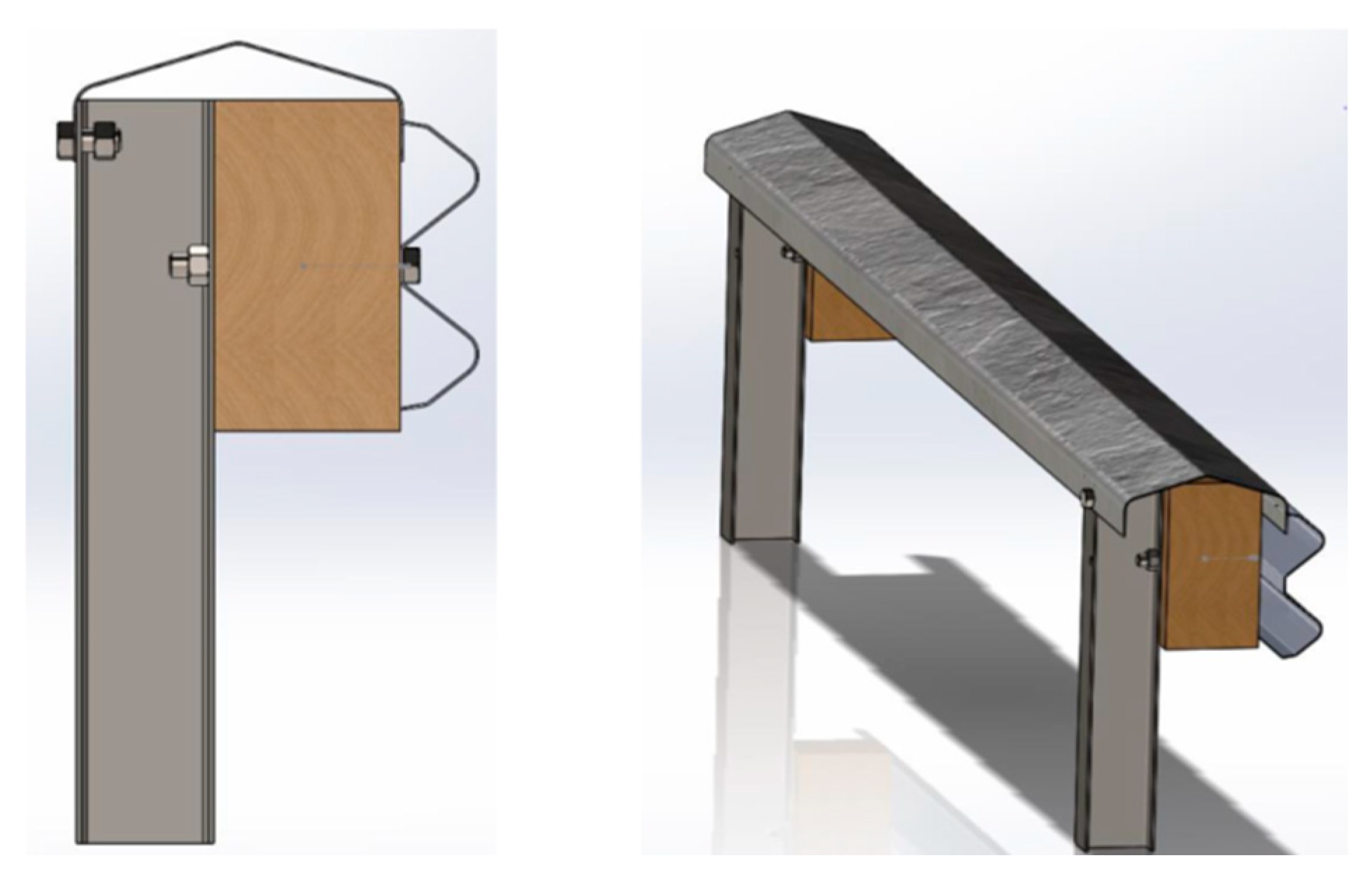

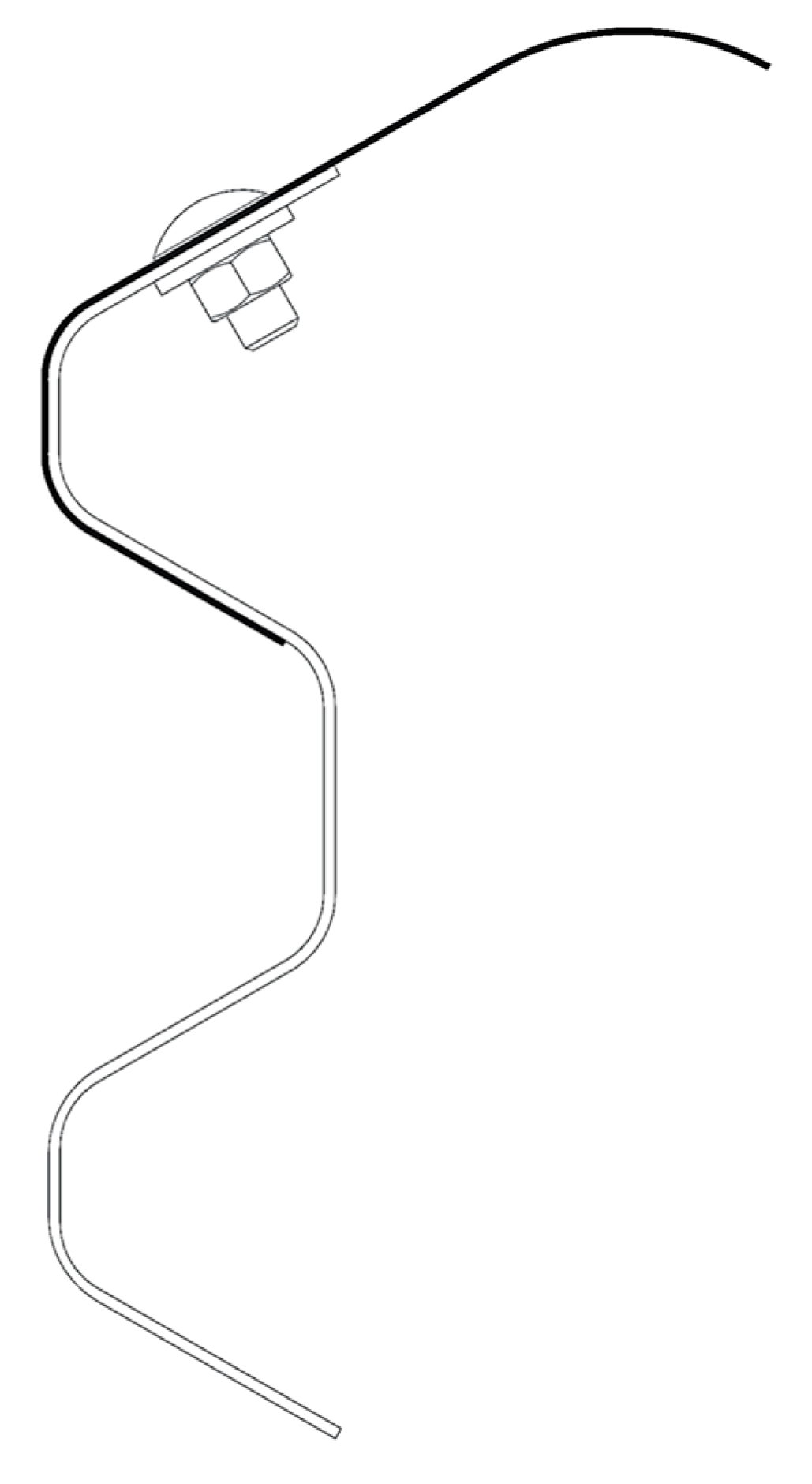

The research involved pendulum tests and full-scale crash simulations using an anthropomorphic test device (ATD) to assess rider interaction with the system. A U-shaped offset post (seen in

Figure 2) was employed to mount the chain-link fence without introducing new impact hazards. Simulation and test results showed successful containment of the rider without interaction with the structural posts, suggesting a significant safety improvement for upright crashes.

Figure 3 shows an example of a simulated motorcyclist impact with a concrete barrier.

This system is notable as one of the first motorcycle-specific containment solutions developed in the U.S. for rigid barriers, and it contributes to closing the gap in testing protocols and safety designs for vulnerable road users.

At the Texas A&M Transportation Institute, researchers also developed three other solutions for upper guardrail protection. First is a retrofit solution called the bent plate top protection (

Figure 4), which is attached to the top of an existing MGS guardrail. The plate is bent to form a smooth vertex that slopes outward and downward and is affixed with minimal effort using standard materials (same as a W-beam rail). The main advantages of this solution include its cost-effectiveness, ease of installation without dismantling existing structures, energy dissipation during impact through controlled deformation, and minimal impact on the original guardrail geometry. Moreover, it allows for better deflection control by not connecting to the front W-beam or blockout. However, its disadvantages include the need to drill or re-galvanise the post in retrofit cases, or the increased cost and complexity if pre-punched holes are used [

18].

Figure 5 shows sequential images of an upright motorcyclist impact with the barrier.

Second is flat plate top protection (

Figure 6), which integrates a flat plate—vertically bent at one end and sloped at the other—into a standard MGS system with steel posts and 8-inch blockouts. The system is attached to the rail with bolted connections and offers a continuous surface along the post and blockout, reducing snagging risks and providing effective shielding during crashes. The design minimises debris dispersion, retains key geometric characteristics of the guardrail, and allows for on-site installation, though the W-beam rail must be replaced. While it demands more installation time and additional post preparation (drilling), this configuration enhances motorcyclist safety during impacts and facilitates better energy dissipation [

18].

Third is the top cap protection (

Figure 7)—aimed at enhancing motorcyclist safety with minimal intervention. This solution consists of individual caps fitted on top of the steel posts of a standard MGS system. It is a low-cost, retrofit-friendly option that preserves the geometric characteristics of the barrier and requires minimal installation effort. However, due to the lack of continuous shielding and energy dissipation, this solution leaves the sides of the posts exposed, presenting a risk of severe injury during side impact. While efficient in cost and installation time, it provides limited protection compared to other options [

18].

However, there are also other solutions, but they are currently still in the patent application or established patent phases.

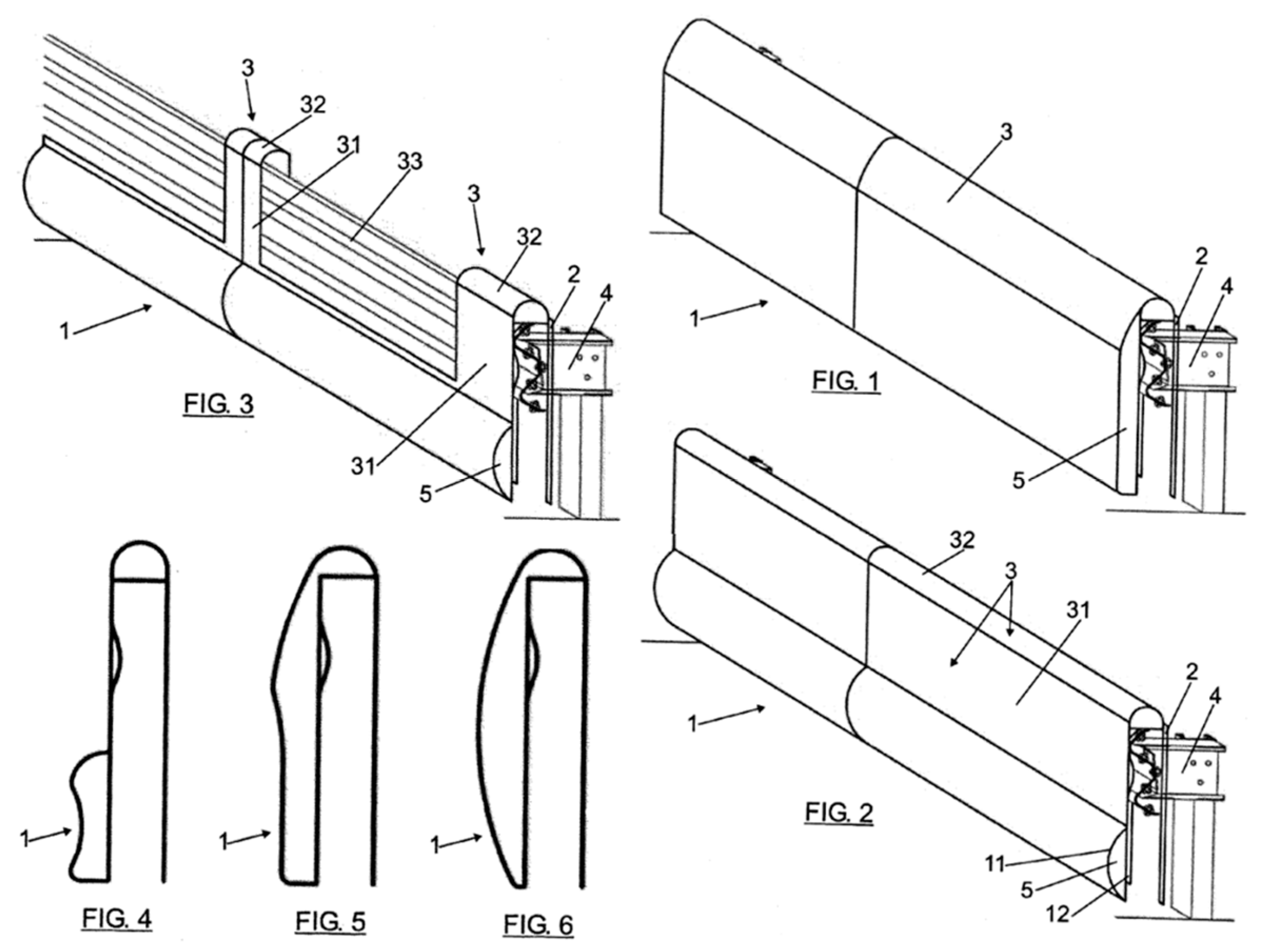

Patent WO2020058935A1 [

19]—named ‘guardrail protection device’ (

Figure 8)—is one of the few solutions that solves the problem of hitting the upper edge of an SSB post. This protection device comprises a longitudinal barrier with an outer surface facing a lane that is delimited at the top and the bottom by flaps, a supporting element that can be anchored to the ground and connected to the barrier on the opposite side of the outer surface, and a protective body connecting with the barrier to cover at least one portion of the barrier. The guardrail cover is made of a polymer material (expanded polyurethane).

One of the disadvantages of this solution is that a separate cover must be made for each type of guardrail (two-wall, three-wall, and beta). However, the same problem applies to all kinds of additional forms of protection. There is a high probability that the outer covering, in the event of a strong impact by a motorcyclist and with high friction, would easily detach. The connecting elements between the individual additional elements (covering) are also problematic. This could be a poor solution during times of winter road maintenance, as snow ploughing can ‘scrape’ the outer surface.

Patent ES2332553A1 [

20]—named ‘protection device on road safety barriers’ (

Figure 9)—is also one of the few solutions that solves the problem of hitting the upper edge of an SSB post. This protection device includes at least a front part, a back part, an upper part, and a chamber (located between the first exterior wall and second interior wall of the front part). All these parts are required in order to safeguard the problems derived from the direct impact of a human body.

This device is designed to solve the characteristics of frontal impact or an angular deviation. Similarly, the shaped design allows the body to be guided along the line after braking. The protective device is made of polymers and/or other recycled synthetic materials. The entire holding post fence is covered and hidden.

However, this is a measure that can (according to the applicant) only be installed on SSBs on motorways. No reason is given for such restrictions/limitations. Similarly, there are no explanations given anywhere as to how these elements of the protective device are connected to each other longitudinally. The patent description does not contain an explanation as to whether the rear part of the protective device needs to be cut out where the spacer is.

This solution does not permit snow ploughing between the SSB posts, nor does it allow for grass mowing between the posts or beneath the protection. Additionally, there is a significant risk that snow ploughing could result in damage, potentially tearing the entire system apart.

This solution does not allow small animals to pass through or rainwater to run under the device (does not avoid flooding the roadway). Lastly, this solution is somewhat expensive.

Patent EP1484448A2 [

21]—named ‘cover element for motorway barriers or guardrails’ (

Figure 10)—is another solution that solves the problem of hitting the upper edge of an SSB post. This cover element for motorway barriers or guardrails comprises a first portion (located on the front part of a guardrail, having a height sufficient to cover the front part of the guardrail), a second portion (located above the upper part of the guardrail and having a width sufficient to cover at least the entire width of the upper part of the guardrail), and a means for affixing the cover element in position relative to the guardrail.

The cover element is made in two layers, from two different materials: the first layer is made of a material that partially absorbs shocks (e.g., recycled rubber or worn tyres), and the second is made of composite materials.

Sections of tread are cut from radial tyres. The resulting strips have very little curvature along their length, which allows them to be laid flat easily. This ensures that the entire width of the strips can be used effectively without causing any flatness issues in the following layer or in the final assembled sheet. Cover element 1 (and consequently relative module 8) can be assembled very easily. This solution is designed to be affixed to reinforced concrete (e.g., on bridges and viaducts). This solution is not intended to be used in cases when SSB posts are driven into the ground. It does not allow for snow ploughing between SSB posts or for grass to be mowed under the protection. In addition, when snow ploughing, there is a strong possibility the plough would rip the solution to shreds. This solution does not allow small animals to pass through. Furthermore, it does not allow rainwater to run under the device and thus does not prevent roadway flooding.

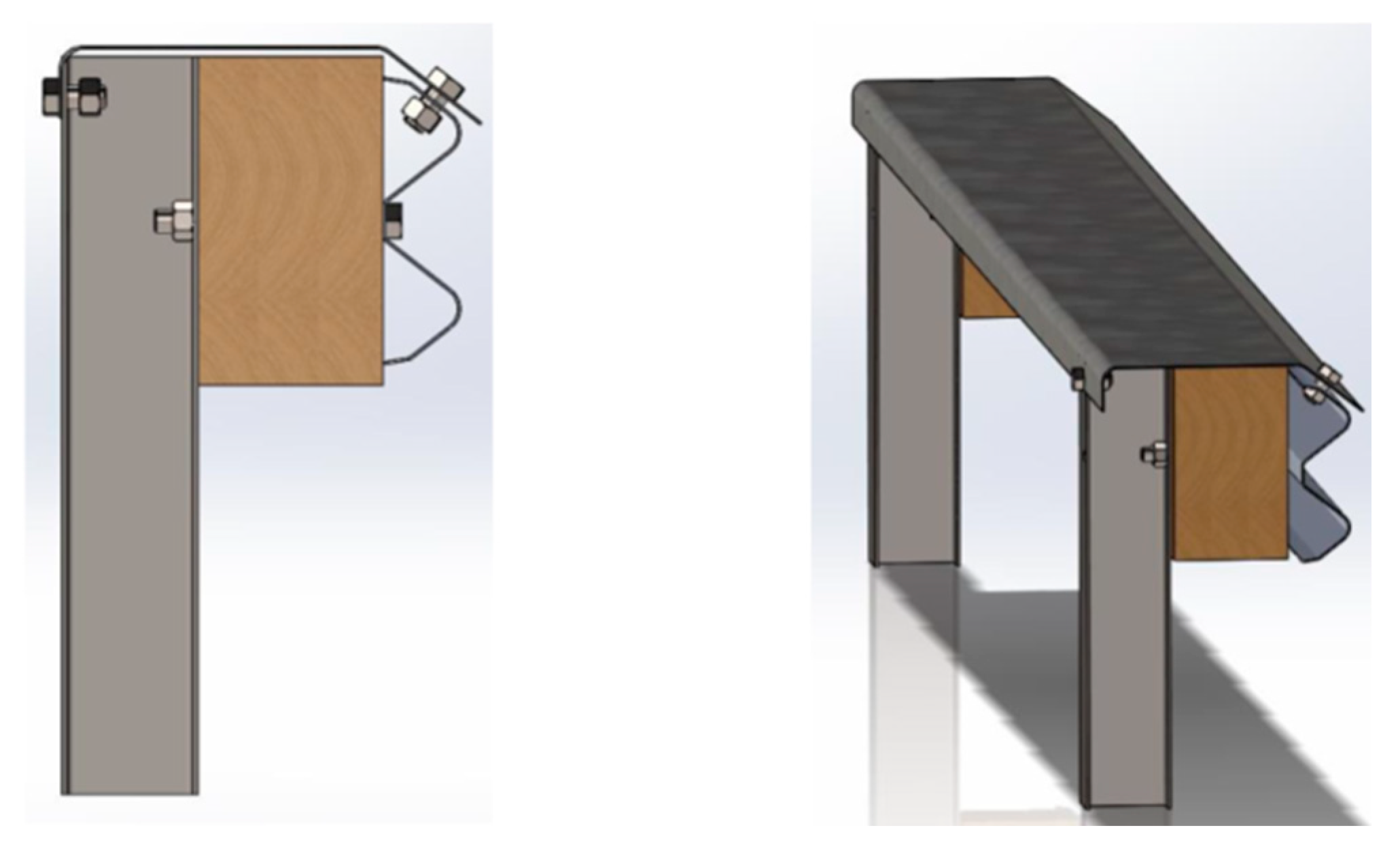

Patent application P2025012 [

22]—named ‘motorcycle protection element and steel safety barrier with cover element’—is another solution that addresses the problem of motorcyclist impact with the upper edge of an SSB post. The invention introduces an additional curved element intended to reduce the severity of surface and internal injuries caused by the sharp edges of the SSB. The upper part of the protective element extends beyond the post and is rounded and sloped downward to shield sharp or protruding parts.

The element (darker one) is installed on the guardrail of the existing SSB, as shown in

Figure 11. The lower part of the protective element matches the shape of the guardrail profile, while the upper bevelled part is attached using screws, similarly to how standard SSB rails are connected. This installation method ensures compatibility with existing systems and ease of retrofitting.

The additional element is mounted very quickly and easily onto the existing guardrail. The existing bolts are used to mount the additional element (the bolts that attach the base guardrail to the SSB post). The additional element is made of galvanised steel sheet. The solution is also cost-effective.

Since one of the patent applicants is also one of the authors of this article, the authors have refrained from drawing conclusions and commercials.

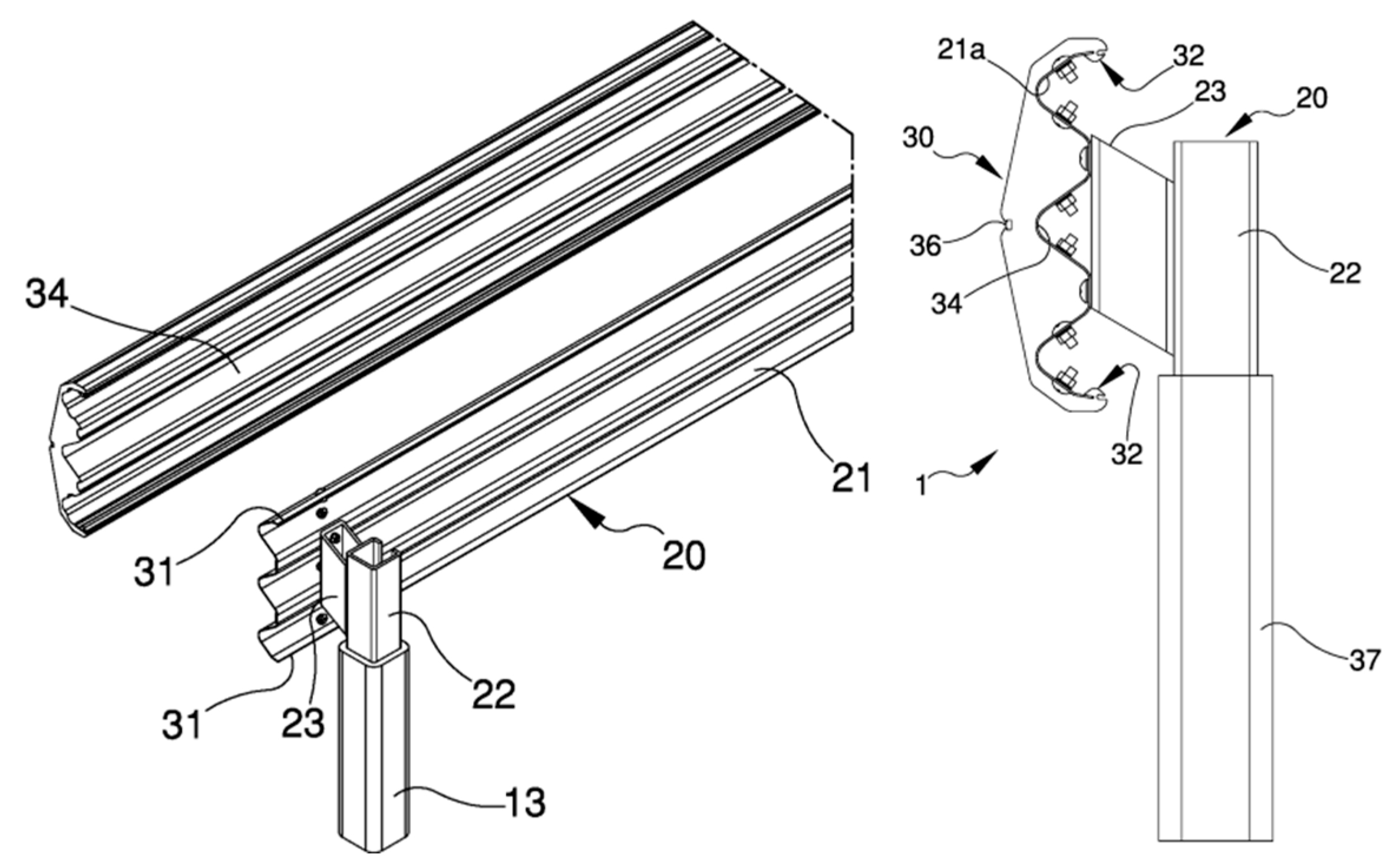

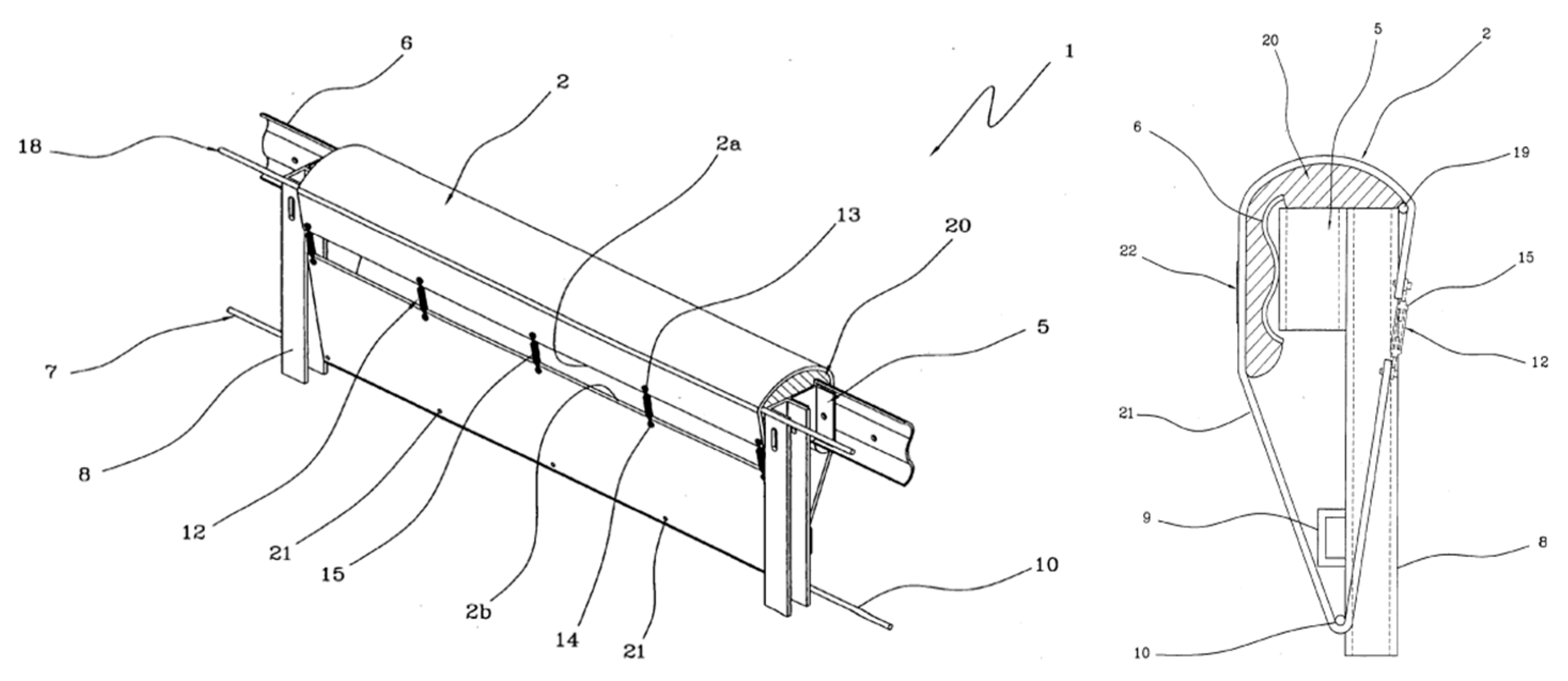

US2006083588A1 [

23]—named ‘method for making a protective device for guardrails, and a protective device for guardrails’ (

Figure 12)—is another solution that solves the problem of hitting the upper edge of an SSB post. The protective device comprises at least one flexible sheet (wrapped between two zones of a guardrail). In particular, the first zone of a guardrail around which the flexible sheet is wrapped is at least one portion of a guardrail longitudinal rail. The second zone around which the flexible sheet is wrapped is at least one portion of a lower longitudinal element located between at least two guardrail uprights.

The lower longitudinal element is normally part of the guardrail structure and is called an anti-intrusion element. In this case, the flexible sheet may be wrapped around the aforementioned anti-intrusion element.

Advantageously, if the anti-intrusion element is not present or is positioned at an unsuitable height, the device comprises at least one first rod-shaped element, which can be firmly bound to at least two uprights on the guardrail at a predetermined height, other than zero, from the ground.

The device comprises adjustable tensioning means operating on the flexible sheet to adjust the tension of the flexible sheet wrapped on the guardrail.

The protective device for guardrails can easily and rapidly be applied to existing guardrails, requiring minimal and marginal installation work.

A comparative table (

Table 1) for the analysed patents and patent applications is shown at the end of this section. The comparison is based on criteria the authors consider important, as in the scientific and professional literature, they did not find any other criteria for comparing different solutions. Each of the selected criteria addresses a key aspect that is critical for real-world implementation and long-term performance of these protective systems. These include the following:

Cost: Affordability is crucial for widespread adoption and implementation on existing road infrastructure.

Use of recycled materials: This reflects environmental responsibility and contributes to sustainable road design.

Drainage: The solution must not obstruct water runoff, as this could lead to road surface degradation and increased risk of aquaplaning.

Passage of small animals: Environmental concerns include maintaining ecosystem connectivity, especially in rural areas.

Installation complexity: Many of these elements are mounted on existing or newly installed steel safety barriers, often under live traffic. Therefore, fast and simple installation is vital to minimise road closures and ensure worker safety.

These criteria were selected to reflect a balance between safety performance, environmental impact, and practical feasibility, in the absence of established evaluation frameworks specific to upper guardrail protection.

To enable an objective and structured comparison, the selected criteria were assigned weights based on their relevance to real-world implementation, sustainability, and functional performance (

Table 2):

Cost (30%): Due to the importance of economic efficiency in implementation decisions, this criterion carries the highest weight. Cost is often the decisive factor in selecting a solution, especially in large-scale infrastructure projects with budget constraints.

Complexity of installation (25%): Solutions that are easier to install tend to be more feasible in practice, reducing both time and labour costs and minimising on-site complications.

Drainage capability (20%): This is a key functional characteristic that affects traffic safety, particularly in wet conditions, and contributes to the long-term durability and maintenance of the infrastructure.

Permeability for small animals (15%): This ecological criterion is increasingly important in modern infrastructure planning, as it helps prevent habitat fragmentation and supports biodiversity conservation. However, it is often considered secondary to core technical and safety requirements.

Use of recycled materials (10%): While the use of environmentally friendly materials adds value in terms of sustainability, it is typically not the primary factor in final decision-making compared to performance and cost-related aspects.

Each patent was assessed using a scoring system where lower values indicate better performance with respect to a given criterion. For instance, a score of 0 represents an optimal or desirable condition (e.g., low cost and simple installation), while higher values (up to 1) reflect less favourable characteristics (e.g., high cost and complex). The final score for each patent was calculated as a weighted sum of all criteria. Consequently, patents with lower total scores are considered more favourable overall (

Table 3).

4. Discussion

There are currently no established solutions on the market for cases where a motorcyclist continues to ride out of the curve and strikes the upper (sharp) part of an SSB guardrail—upper guardrail protection for motorcyclists. Furthermore, the authors’ analysis of patent applications and granted patents indicates that such solutions are exceedingly rare.

One of the primary reasons for this situation is the lack of standards. In Europe, the CEN/TS 17342:2019 standard (‘Road restraint systems—Motorcycle Road restraint systems which reduce the impact severity of motorcyclist collisions with safety barriers’ [

24]) addresses motorcycle-friendly barrier design, but it does not cover upper guardrail protection. Similarly, the U.S. Manual for Assessing Safety Hardware [

25] makes no mention of such systems. As a result, the proposed solutions cannot currently be tested or validated either through crash testing or simulation, which presents a major barrier to innovation, manufacturing, and implementation.

For the purposes of this article, 13 patent documents related to the protection of motorcyclists from impacts with the posts or upper edges of SSB guardrails were reviewed, and 5 representative solutions were selected for in-depth presentation. The authors developed a set of comparative evaluation criteria, as no such framework currently exists in the scientific or technical literature.

The findings indicate that the proposed solutions address the problem of motorcyclists colliding with the upper edge of an SSB with varying levels of effectiveness. The designs use different materials, which absorb impact forces in distinct ways. Some patents propose the use of recycled materials, which is considered an added environmental and economic benefit. Furthermore, the methods of attachment vary in complexity and implementation time. Some include rigid elements that could alter the structural behaviour of SSBs and potentially increase costs.

This study also highlights a broader systemic issue: the absence of harmonised testing protocols for upper guardrail protection systems. In contrast to the standards that exist for lower-body protection, no regulatory framework currently supports the evaluation of these upper-level solutions. To address this gap, future research should prioritise two key steps. First, numerical simulation studies (e.g., using LS-DYNA) should be conducted to assess the dynamic behaviour and biomechanical safety of proposed designs under realistic crash scenarios. This approach offers a cost-effective alternative to expensive full-scale crash tests. Second, based on insights from such simulations, new test protocols should be developed and proposed to standard-setting bodies. Defining test parameters and performance criteria would allow for an objective assessment and could ultimately lead to the standardisation and adoption of these innovative safety features.

Addressing these gaps would significantly contribute to improved road infrastructure design for motorcyclists and support the broader goal of reducing motorcycle crash severity on curves involving SSBs.

Although the focus of this study was on the review of patented solutions for upper guardrail protection, it is important to recognise that the effectiveness of such systems ultimately depends on how well they mitigate injury risks during a motorcyclist impact. To achieve this, future research should define and quantify design loads specific to upright-posture motorcycle crashes, including impact angles, body kinematics, and velocity profiles. Similarly, relevant occupant injury criteria—such as the Head Injury Criterion (HIC), Thoracic Trauma Index (TTI), or abdominal compression thresholds—should be identified and standardised. These metrics would enable more rigorous evaluation of new designs, both through numerical simulations and physical crash testing. Moreover, the geometry, stiffness, and energy absorption capacity of protective elements should be optimised to ensure that these injury thresholds are not exceeded. Currently, the lack of such biomechanical and engineering benchmarks represents a major barrier to advancing upper guardrail protection systems beyond conceptual or patent stages.