Abstract

The incorporation of sustainable construction is essential for minimizing the environmental footprint of cementitious composites. This research examines the mechanical behavior and microstructural features of alternative mortars in which pumice acts as a partial cement replacement. By applying the Taguchi methodology, nine mortar mix variations were assessed at different pumice replacement rates (15%, 25%, and 50%), and their mechanical strength was compared against a control mixture without substitution. Additionally, an X-ray diffraction (XRD) analysis identified the mineral components in the pumice to evaluate their performance and durability. Based on a statistical variance analysis (ANOVA), mortars with up to 25% substitution are suggested as they attain mechanical strength values comparable to those of a control mixture. This study contributes to the advancement of environmentally sustainable construction materials and provides valuable insights into the viability of using pumice in sustainable infrastructure developments.

1. Introduction

Mortars are mixtures of water, sand, and some conglomerating component (cement, lime, or gypsum), made manually or mechanically, which are moldable in the paste state and are mainly used to join surfaces, protect them, and provide strength when acting as coatings [1]. The most used conglomerate material is Portland cement (PC), which, due to its properties and composition, is the most resistant, with low permeability and load support [2].

However, cement production reaches an annual global output of over four billion tons [3], resulting in a significant environmental impact, particularly during clinker production [4]. For every metric ton of clinker manufactured, between 600 and 800 kg of CO2 is released, positioning the cement sector as among the highest contributors to pollution worldwide, accounting for 8% of global CO2 emissions [5,6,7]. Given this situation, sustainable construction practices are increasingly focusing on reducing the environmental footprint of cementitious materials through the incorporation of supplementary cementitious materials (SCMs) and bio-based additives.

Recent studies have explored various SCMs—such as clay, fly ash, and steel slag—as partial replacements for Portland cement to enhance both sustainability and thermophysical properties [8]. For instance, Drissi et al. [9] examined the use of raw red clay as an SCM, reporting that substituting up to 5% of Portland cement improved its thermal conductivity and reduced its environmental impact, while sustaining an acceptable mechanical performance. Similarly, bio-based additives like date palm fibers (DPFs) and mint stem aggregates (MSAs) have been investigated for their potential to enhance the thermal insulation of mortars. Benmansour et al. [10] showed that incorporating up to 15% DPF decreased thermal conductivity without significantly compromising compressive strength, while Horma et al. [11] found that MSA additions notably lowered thermal conductivity, albeit with a slight reduction in compressive strength. These findings underscore the increasing interest in developing sustainable cementitious composites that strike a balance among mechanical performance, environmental sustainability, and energy efficiency.

In this context, pumice, a natural pozzolanic material, has been widely used as a supplementary cementitious material (SCM) in the production of mortars and concrete [12,13,14]. In the development of alkali-activated materials, pumice of volcanic origin serves as an alternative precursor to industrial by-products due to its significant aluminosilicate composition [15,16,17,18,19]. Additionally, its use contributes to reducing pollutant gas emissions, as it does not require heat treatment like other precursors. Furthermore, it significantly enhances the compressive strength of mortars [20,21]. Similarly, pumice can be used as a partial replacement for Portland cement in mortar production, demonstrating favorable performance in terms of mechanical strength [22,23].

Despite its potential, research on pumice as a cement substitute has primarily focused on broad applications, with limited studies addressing region-specific materials and their unique properties. This study aims to bridge this gap by analyzing the mechanical performance and microstructural characteristics of mortars incorporating pumice stone from Perote, Veracruz. This region has an abundant supply of pumice, much of which is considered waste, presenting an opportunity for its valorization in sustainable construction. By assessing the mechanical strength and durability of pumice-based mortars through X-ray diffraction (XRD), this research contributes to the advancement of environmentally friendly construction materials while promoting the efficient use of local resources.

The novelty of this study lies in its comprehensive evaluation of Perote pumice stone as a viable alternative to Portland cement, emphasizing its mechanical and microstructural performance at different replacement levels. This research provides valuable insights into the potential of pumice as a sustainable binder, supporting the transition toward greener construction materials and reducing dependence on conventional cement-based composites.

2. Materials and Methods

2.1. Materials

2.1.1. Sand

The sand used in this study was sampled according to ASTM D75/D75M [24], ensuring that it consisted entirely of excavated material extracted from a depth of less than one meter. Prior to testing, the raw sand underwent a preparation process involving drying, disaggregation, and quartering, in accordance with ASTM C702/C702M—18 [25].

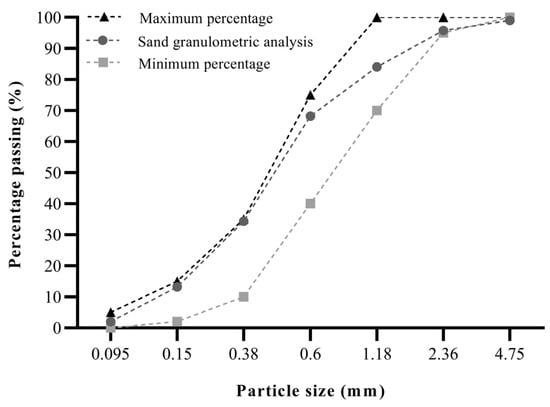

A granulometric analysis was then performed to determine the particle size distribution. This procedure was conducted on a 500 g sample, with the material sieved through meshes No. 4, No. 8, No. 16, No. 30, No. 50, No. 100, and No. 200, following the ASTM C136-14 standard [26]. The results allowed for the classification of particles by size, as illustrated in Figure 1.

Figure 1.

Sieve analysis of sand.

2.1.2. Pumice (PM)

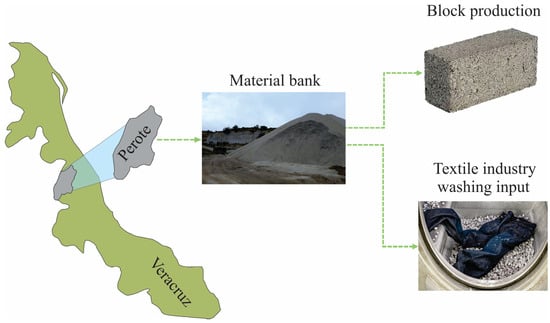

The pumice used in this research was obtained from mining operations in Perote, Veracruz, a region in central Mexico. Locally, this material is commonly used in brick manufacturing and as an abrasive in the textile industry for denim treatment. These applications often generate waste pumice, which offers an opportunity for valorization as a supplementary cementitious material (SCM) (see Figure 2).

Figure 2.

Pumice mine located in Perote, Veracruz, Mexico.

The pumice was initially available in various particle sizes. To ensure consistency, the material was first dried in an electric furnace at 60 °C. It was then ground to reduce particle size and sieved using a No. 200 mesh (0.075 mm), as specified by ASTM C136-14. The processed pumice exhibited a real density of 2358 kg/m3 in accordance with ASTM C188-17 [27] and a specific surface area of 600 m2/kg [28,29].

2.1.3. Alkaline Activator (NaOH)

Pozzolanic materials containing partially amorphous aluminosilicate phases can significantly increase their reactivity through alkaline activation, which enables their effective use as supplementary cementitious materials (SCMs). In this study, pumice was activated using sodium hydroxide (NaOH) [30] to promote the dissolution of silica and alumina species, a process that facilitates the formation of calcium-alumino-silicate-hydrate (C-A-S-H) gels—phases that contribute to the mechanical performance of alkali-activated systems [31].

The activator solution was prepared by dissolving sodium hydroxide flakes in distilled water to achieve a specific molar concentration [32]. This compound was selected due to its strong alkalinity, wide availability, and lower cost compared to other alkaline agents such as potassium hydroxide (KOH), magnesium hydroxide [Mg(OH)2], or borax [33]. Additionally, NaOH allows for the straightforward preparation of solutions with controlled molarity, ensuring consistent and efficient activation of the pumice material.

2.2. Design of Experiments

To establish the mixture proportions, the Taguchi method was employed using an L9 (32) orthogonal array, which enables the evaluation of two factors at three levels with a reduced number of experimental runs. A total of nine experimental conditions were generated, each conducted in triplicate to ensure statistical reliability. The experimental matrix is presented in Table 1.

Table 1.

Design of experiments.

The two main factors selected for this study were as follows: pumice replacement percentage (by weight of binder): 15%, 25%, and 50%; and sodium hydroxide (NaOH) concentration: 1.0 N, 0.5 N, and 0.25 N, where N denotes normality, expressing the chemical concentration of the alkaline solution.

This experimental design enables a systematic evaluation of the influence of both the levels at which pumice is incorporated and the alkalinity of the activator on the mechanical performance of the resulting binder.

2.3. Preparation of Specimens

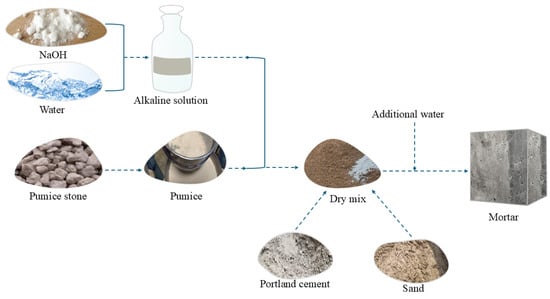

The mixtures for testing were prepared using the geopolymer mortar preparation method in two parts [33], following the procedure outlined below: first, NaOH is mixed with water to obtain the alkaline solution, then the pozzolanic material is activated with the alkaline activator, after which it is mixed with the cement. For the mortar mixture, the binder materials are homogenized with sand, and finally, additional water is added to achieve the desired workability, as shown in Figure 3.

Figure 3.

Mortar preparation.

Specimens for strength testing were prepared according to the conditions specified in the experimental design. The inner surfaces and the base of the cubic molds (50 mm × 50 mm × 50 mm) were lightly coated with mineral oil or fine grease to ensure a proper seal. After assembling the molds, any excess oil or grease was removed from the interior surfaces and the top of the mold.

The materials were mixed thoroughly to create a uniform blend, using a spatula to minimize material loss. To evaluate fluidity, a sample of the mortar mixture was placed on the flow table. After 25 taps, the diameter of the spread mortar was measured in two perpendicular directions to determine the flow index.

Once the desired fluidity was achieved, the cubic molds were filled by placing a 25 mm thick layer of mortar in each compartment. The mortar was compacted using a bullet-tipped rod with 32 taps distributed evenly across the surface. Sufficient pressure was applied during compaction to ensure uniform filling. After compacting the first layer, the remaining mortar was added to fill the molds, and compaction was repeated in the same manner. Any excess mortar was leveled off with a spatula.

After the specimens were filled and compacted, their surfaces were leveled, and the molds were covered with plastic bags. The samples were kept in the molds for 20 to 24 h. Once demolded, the specimens were cured in water until reaching the required testing age for compressive strength.

2.4. Compressive Strength

The compressive strength of the mortar samples was evaluated using a hydraulic compression testing machine at the Quality Control Laboratory in Boca del Río, Veracruz. This equipment ensured even force distribution across the sample surface. Testing was conducted at 7, 14, and 28 days in accordance with ASTM C109/C109M—20 [34], which outlines the procedure for determining the mechanical strength of hydraulic cement mortars with 50 mm (2-inch) cubic specimens. The load was applied at a rate that induced a stress increase of 0.9 ± 0.2 MPa/s, and this rate was maintained until specimen failure to guarantee result consistency and reliability.

3. Results

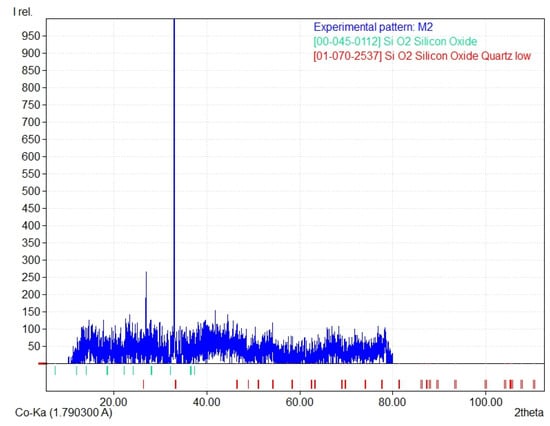

3.1. X-Ray Diffraction (XRD)

To determine the structural and mineralogical composition, the pumice samples were analyzed using X-ray diffraction (XRD). This technique employs cobalt (Co) radiation at a two-theta angle, allowing for the identification of the chemical structure of aluminosilicate materials. The primary phases detected in the pumice, as illustrated in Figure 4, include silicon oxide (SiO2) in both its amorphous and crystalline forms (low-reactivity quartz). The presence of amorphous silica is particularly significant in alternative mortars, as it reacts with Portlandite (Ca(OH)2) during cement hydration, promoting the formation of calcium silicate hydrate (C-S-H) gels and contributing to enhanced mechanical strength. On the other hand, crystalline quartz, despite being less reactive, can function as a mineral aggregate that improves the material’s thermal stability and resistance to aggressive environments. As a natural pozzolan rich in amorphous silica, pumice plays a key role in increasing the mechanical performance and durability of mortars [35,36,37,38,39].

Figure 4.

X-Ray diffraction of pumice used in this study.

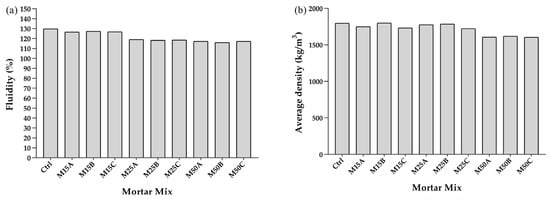

3.2. Average Density and Fluidity

Figure 5 presents data on the properties of mortar mixtures incorporating pumice as an alternative cementitious material, with replacement levels ranging from 0% to 50%. Figure 5a shows the results of the fluidity test, in which the control sample exhibits the highest fluidity, followed by the M15A, M15B, and M15C mixtures, which retain relatively high fluidity levels compared to the other formulations. In contrast, the M25A, M25B, and M25C mixtures exhibit a decrease in fluidity compared to the 15% substitution mixtures, suggesting that a higher pumice content negatively impacts the workability of the mortar. Finally, the M50A, M50B, and M50C mixtures demonstrate the lowest fluidity values, indicating an increase in viscosity and a reduction in ease of handling due to the higher proportion of alternative cementitious material.

Figure 5.

Properties of mortar mixes: (a) fluidity (%) and (b) average density (kg/m3). The recorded values are presented.

Figure 5b presents the average density measurements of the mortar mixtures. The analysis reveals that mixtures M15A, M15B, and M15C (15% pumice), along with M25A, M25B, and M25C (25% pumice), show a slight decrease in average density compared to the control sample. This indicates that at these replacement levels, the material’s density remains relatively stable, suggesting that the pumice can be incorporated without significantly affecting the mortar’s compactness. Conversely, mixtures M50A, M50B, and M50C (50% pumice) show a substantial decrease in average density, with values ranging from 1550 to 1600 kg/m3. This reduction may be attributed to increased porosity resulting from the higher proportion of alternative cementitious material and its interaction with the alkaline solution. These findings underscore the critical role of mix design in determining mortar density, directly impacting its structural performance and applicability in construction. Consequently, optimizing pumice utilization in mortar formulations is essential for enhancing sustainability in construction materials.

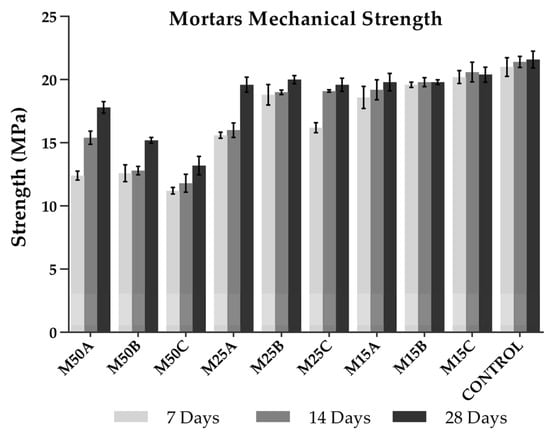

3.3. Mortar Mechanical Strength

Figure 6 illustrates the development of mechanical strength in mortars over 7, 14, and 28 days of curing, showing a consistent increase aligned with the cement hydration process. At early stages, mixtures with higher levels of pumice replacement (M50A, M50B, and M50C) exhibit lower strength values compared to the control mix, indicating delayed strength development due to the nature of these supplementary materials. In contrast, mixtures with lower replacement levels (M15A, M15B, and M15C) show strength values closer to those of the control mix, suggesting minimal impact at early curing ages.

Figure 6.

Evolution of mechanical strength of mortars. The recorded values are presented with the mean ± standard error.

By 14 days, the strength difference between the modified mixtures and the control mix begins to diminish, reflecting continued cement hydration and the gradual contribution of the supplementary materials. This indicates that the use of replacement materials can mitigate the initial strength loss, improving performance over time.

At 28 days, the strength values stabilize, with certain mixtures (M25A, M25B, and M25C) reaching levels comparable to the control mix. These results suggest that moderate pumice replacement can be an effective alternative without significantly compromising the mortar’s long-term structural integrity, highlighting its potential for use in construction.

These findings emphasize the influence of replacement level on strength development, confirming the viability of incorporating pozzolanic materials without notably affecting the mortar’s structural performance.

3.4. Analysis of Variance

A two-way analysis of variance (ANOVA) was performed on the mean mechanical strength data measured at 28 days to assess the interaction effects between the two factors under study. The results, presented in Table 2, show that the percentage of pumice substitution independently influences the mechanical strength of the mortars. The ANOVA yielded an F value of 33.62, which exceeds the critical F value of 3.259, indicating a statistically significant effect (p < 0.05).

Table 2.

Two-way analysis of variance for the design of experiments of mortars.

Additionally, the interaction between the percentage of pumice substitution and the concentration of the alkaline solution also has a significant impact on the mechanical strength. The interaction effect showed an F value of 3.49, surpassing the critical F value of 2.634, with a p-value of 0.0165, further confirming its significance.

The concentration of the alkaline solution, however, showed a lower impact, with an F value of 2.25, not exceeding the critical F value (3.259), and a p-value of 0.121, suggesting that it does not significantly influence the mechanical strength within the parameters of this study.

Furthermore, Table 3 summarizes the mean mechanical strength and variance of the mortars at 28 days, which were formulated by varying the pumice substitution percentage and the concentration of the alkaline solution. The results show minimal variation in the mean mechanical strength for samples with 25% and 15% pumice substitution, whose strength values range from 19.6 MPa and 20.4 MPa.

Table 3.

Mean mechanical strength and variance for mortars at 28 days.

Although the two-way ANOVA indicates significant interaction effects, a one-way analysis of variance (ANOVA) was conducted to assess the independent effects of each factor. This analysis helps to identify the optimal pumice substitution percentage and alkaline solution concentration ratio to maximize the mechanical strength of the mortar.

Table 4 presents the results of the analysis of variance (ANOVA) conducted on mortars with varying pumice substitution percentages and different activating agent concentrations. The findings indicate that for mortars with 50% pumice substitution, significant variations in mechanical strength are observed across different activator concentrations (p < 0.05).

Table 4.

Analysis of variance for each percentage of pumice substitution.

Based on Figure 6, it can be concluded that mortars with 50% pumice substitution and an activator concentration of 1N (A) exhibit a significantly greater variation in strength compared to other samples with the same substitution percentage. This is reflected in the F value of 7.900901, which exceeds the critical value of 3.8852938 (p < 0.05).

For samples with 25% and 15% substitution, no significant differences in strength are observed due to variations in activator concentration. In these cases, the F value remains below the critical threshold (F = 3.8852938, p > 0.05).

Table 5 presents the analysis of variance (ANOVA) results for each activating solution concentration, considering the substitution percentage as the variable of interest.

Table 5.

Analysis of variance for each activating solution concentration.

For mortars with an activating concentration of 1 N (A), no significant differences in mechanical strength were observed with the variations in the pumice substitution per-centage, as the F value of 1.978 is lower than the critical value of 3.885 (p > 0.05).

For mortars with an activating concentration of 0.5 N (B), significant differences in mechanical strength were observed, as evidenced by an F value of 12.427 (p < 0.05). Figure 6 shows that the mortar with 50% pumice substitution and an activating solution concentration of 0.5 N exhibited the lowest mechanical strength.

Similarly, for mortars with an activating concentration of 0.25 N (C), significant differences were found, with an F value of 26.928 (p < 0.05). Figure 6 indicates that the mortar with 50% pumice substitution and an activating solution concentration of 0.25 N showed the lowest mechanical strength.

4. Discussion

The present study on alternative mortars incorporating pumice as a substitute for Portland cement has yielded significant results in terms of mechanical strength and micro-structural properties. By analyzing the influence of various percentages of pumice substitution and concentrations of activating solutions, we have obtained data that facilitate comparisons with prior research regarding sustainable building materials.

The findings in this study align with those of Rahman et al. [22], who also identified that the use of pumice as a cement substitute can result in an acceptable mechanical performance, particularly at substitution rates of up to 25%. In our research, samples with 15% and 25% pumice substitution exhibited mechanical strength values comparable to those of the control mortar, suggesting that these proportions are optimal for maintaining the structural integrity of the material. This behavior is consistent with reports by Zhang et al. [23], which indicated that the addition of pumice in moderate quantities may enhance, or at least not significantly degrade, the strength of the mortar.

Furthermore, the observed trend of decreasing mechanical strength with increasing pumice substitution percentage (50%) is a phenomenon documented in the literature. Previous studies, such as that of Nars et al. [21], have demonstrated that the inclusion of large amounts of pumice may lead to a reduction in strength, attributed to the diminished availability of cement for forming the load-bearing matrix of the mortar. In this context, the evidence suggests that there exists an optimal substitution threshold that should be considered to maximize the mechanical properties of the mortar.

The alkaline activation of pumice, conducted using NaOH at varying concentrations, revealed that a concentration of 0.25 N was the most effective, achieving superior results in terms of mechanical strength. This finding is consistent with the work of Balun et al. [12], which reported that the concentration of the activator significantly affects the properties of the activated mortar, and that excessive concentrations may be counterproductive. In our investigation, samples with 50% substitution and 1 N NaOH exhibited lower strengths, reinforcing the notion that a balance in activation chemistry is crucial for material property optimization.

From an environmental perspective, the use of pumice as a substitute material not only contributes to the reduction in Portland cement consumption but also provides a viable alternative for industrial waste management. Karthika et al. [13] emphasize the potential of pumice as a lightweight aggregate, highlighting its availability and desirable properties for sustainable construction. In this regard, our study supports the ongoing trend toward the incorporation of eco-friendly building materials and the development of technologies within the cement industry aimed at mitigating environmental impact.

The results obtained in this study validate the feasibility of pumice as an alternative material in mortar formulations, particularly at substitution rates of up to 25% and with an activator concentration of 0.25 N. The similarities observed with previous studies reinforce the idea that the development of sustainable mortars represents a promising direction for civil engineering. Future research should continue to explore the optimization of formulations and the practical applications of these mortars under real construction conditions.

5. Conclusions

The results from the analysis of variance in Table 2, Table 4 and Table 5, along with the average values of mechanical strength for the mortars at 28 days, lead to the conclusion that mortars with 25% and 15% pumice substitution and activating solutions at concentrations of 0.5 N and 0.25 N show mechanical strength values comparable to those of the control sample, which contains neither pumice nor an activating solution. These findings demonstrate that partial cement substitution with pumice, in combination with diluted activating solutions, does not compromise mortar strength, thus making these mixtures suitable for potential use in structural applications without affecting performance.

However, it is evident that a mortar with 50% pumice substitution exhibits a lower mechanical strength than the control and mortars with 25% and 15% pumice substitution. This trend indicates a practical limit to the amount of pumice that can be incorporated without negatively impacting the material’s mechanical properties. The practical implication of this finding is that optimizing the proportion of pumice in mortar mixes should be a key consideration to balance sustainability with structural performance, ensuring that the mechanical strength does not fall below required standards.

Regarding the concentration of the activating solution, the mortars with 15% pumice substitution and a 0.25 N activator concentration showed the highest mechanical strength. However, the difference between this formulation and the mortar with 25% pumice substitution and the same concentration of activator is not significant. Therefore, it is recommended to use a 25% pumice substitution with a 0.25 N concentration of the activating solution. This option not only achieves a strength comparable to conventional mortars but also offers a lower environmental impact, as reducing the concentration of the activating solution results in a decreased demand for chemical products, particularly sodium hydroxide. This translates into a reduced consumption of resources and enhances the overall sustainability of construction processes.

Pumice, with its high reactive silica content, serves as a crucial pozzolanic material. This property is essential for maintaining the compressive strength of alternative mortars, particularly when aiming to reduce the clinker content in Portland cement. In practical terms, the use of pumice in mortars offers a valuable strategy for the construction industry’s transition toward more sustainable materials. By incorporating pumice, it is possible to reduce the carbon footprint of mortars, a critical step in addressing the global challenge of CO2 emissions from conventional cement production.

Therefore, the practical implications of this study are clear: partial cement replacement with pumice provides a more eco-friendly and cost-effective alternative that can be used to manufacture mortars with mechanical properties comparable to traditional materials. These findings offer essential guidelines for optimizing mortar compositions for sustainability in construction, contributing to the reduction in environmental impacts associated with the production of conventional cement.

Author Contributions

Conceptualization, writing—review and editing, P.J.L.-G., D.R.-G. and R.V.-O.; validation, data curation, J.S.-L.; supervision, H.R.G.-M. and S.A.Z.-C.; methodology, O.M.-V. and E.M.-R. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

The data that support the findings of this study are available from the corresponding author P.J.L.-G. and J.S.-L, upon reasonable request.

Acknowledgments

We express our sincere gratitude to the Laboratory and Quality Control team, whose collaboration and dedication were essential to the successful execution of the compression test in this study.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- del Río-Merino, M.; Vidales-Barriguete, A.; Piña-Ramírez, C.; Vitiello, V.; Santa Cruz-Astorqui, J.; Castelluccio, R. A review of the research about gypsum mortars with waste aggregates. J. Build. Eng. 2022, 45, 103338. [Google Scholar] [CrossRef]

- Nie, S.; Zhou, J.; Yang, F.; Lan, M.; Li, J.; Zhang, Z.; Chen, Z.; Xu, M.; Li, H.; Sanjayan, J.G. Analysis of theoretical carbon dioxide emissions from cement production: Methodology and application. J. Clean. Prod. 2022, 334, 130270. [Google Scholar] [CrossRef]

- Bhat, R.; Han, T.; Sant, G.; Neithalath, N.; Kumar, A. A comprehensive analysis of hydration kinetics and compressive strength development of fly ash-Portland cement binders. J. Build. Eng. 2024, 88, 109191. [Google Scholar] [CrossRef]

- Martinez-Molina, W.; Chavez-Garcia, H.L.; Perez-Lopez, T.; Alonso-Guzman, E.M.; Arreola-Sanchez, M.; Navarrete-Seras, M.A.; Borrego-Perez, J.A.; Sanchez-Calvillo, A.; Guzman-Torres, J.A.; Perez-Quiroz, J.T. Effect of the Addition of Agribusiness and Industrial Wastes as a Partial Substitution of Portland Cement for the Carbonation of Mortars. Materials 2021, 14, 7276. [Google Scholar] [CrossRef]

- Rosewitz, J.A.; Wang, S.; Scarlata, S.F.; Rahbar, N. An enzymatic self-healing cementitious material. Appl. Mater. Today 2021, 23, 101035. [Google Scholar] [CrossRef]

- Cerchione, R.; Colangelo, F.; Farina, I.; Ghisellini, P.; Passaro, R.; Ulgiati, S. Life cycle assessment of concrete production within a circular economy perspective. Sustainability 2023, 15, 11469. [Google Scholar] [CrossRef]

- Huang, Z.; Zhou, H.; Miao, Z.; Tang, H.; Lin, B.; Zhuang, W. Life-cycle carbon emissions (LCCE) of buildings: Implications, calculations, and reductions. Engineering 2024, 35, 115–139. [Google Scholar] [CrossRef]

- Giergiczny, Z.; Król, A.; Tałaj, M.; Wandoch, K. Performance of concrete with low CO2 emission. Energies 2020, 13, 4328. [Google Scholar] [CrossRef]

- Drissi, M.; Horma, O.; Mezrhab, A.; Karkri, M. Exploring Raw Red Clay as a Supplementary Cementitious Material: Composition, Thermo-Mechanical Performance, Cost, and Environmental Impact. Buildings 2024, 14, 3906. [Google Scholar] [CrossRef]

- Benmansour, N.; Agoudjil, B.; Gherabli, A.; Kareche, A.; Boudenne, A. Thermal and Mechanical Performance of Natural Mortar Reinforced with Date Palm Fibers for Use as Insulating Materials in Building. Energy Build. 2014, 81, 98–104. [Google Scholar] [CrossRef]

- Horma, O.; El Hammouti, A.; El Hassani, S.; Kırgız, M.S.; Channouf, S.; Moussaoui, M.A.; Mezrhab, A. Sustainable Approach to Mortar Production Using Mint Stem Aggregates: Investigating the Thermal, Mechanical, and Physical Performance. J. Mater. Civ. Eng. 2024, 36, 04024330. [Google Scholar] [CrossRef]

- Balun, B.; Karataş, M. Influence of curing conditions on pumice-based alkali activated composites incorporating Portland cement. J. Build. Eng. 2021, 43, 102605. [Google Scholar] [CrossRef]

- Karthika, R.B.; Vidyapriya, V.; Sri, K.N.; Beaula, K.M.G.; Harini, R.; Sriram, M. Experimental study on lightweight concrete using pumice aggregate. Mater. Today Proc. 2021, 43, 1606–1613. [Google Scholar] [CrossRef]

- Wei, S.; Zheng, K.; Chen, W.; Chen, L.; Zhou, J.; Mi, T. The correlation between Al incorporation and alkali fixation by calcium aluminosilicate hydrate: Observations from hydrated C3S blended with and without metakaolin. Cem. Concr. Res. 2023, 172, 107249. [Google Scholar] [CrossRef]

- Zhang, W.L.; Yuan, Z.J.; Li, D.Q.; Zhang, K.; Zhao, L.Y. Mechanical and vegetation performance of porous concrete with recycled aggregate in riparian buffer area. J. Clean. Prod. 2022, 332, 130015. [Google Scholar] [CrossRef]

- Tanyıldızı, M.; Gökalp, İ. Utilization of pumice as aggregate in the concrete: A state of art. Constr. Build. Mater. 2023, 377, 131102. [Google Scholar] [CrossRef]

- Wang, Y.; Liu, Z.; Fu, K.; Li, Q.; Wang, Y. Experimental studies on the chloride ion permeability of concrete considering the effect of freeze–thaw damage. Constr. Build. Mater. 2020, 236, 117556. [Google Scholar] [CrossRef]

- Alqarni, A.S. A comprehensive review on properties of sustainable concrete using volcanic pumice powder ash as a supplementary cementitious material. Constr. Build. Mater. 2022, 323, 126533. [Google Scholar] [CrossRef]

- Tran, Q.; Ghosh, P. Influence of pumice on mechanical properties and durability of high performance concrete. Constr. Build. Mater. 2020, 249, 118741. [Google Scholar] [CrossRef]

- Antunes, M.; Santos, R.L.; Pereira, J.; Rocha, P.; Horta, R.B.; Colaço, R. Alternative Clinker Technologies for Reducing Carbon Emissions in Cement Industry: A Critical Review. Materials 2022, 15, 209. [Google Scholar] [CrossRef]

- Nasr, M.S.; Shubbar, A.A.; Abed, Z.A.A.R.; Ibrahim, M.S. Properties of eco-friendly cement mortar contained recycled materials from different sources. J. Build. Eng. 2020, 31, 101444. [Google Scholar]

- Rahman, F.; Adil, W.; Raheel, M.; Saberian, M.; Li, J.; Maqsood, T. Experimental investigation of high replacement of cement by pumice in cement mortar: A mechanical, durability and microstructural study. J. Build. Eng. 2022, 49, 104037. [Google Scholar] [CrossRef]

- Zhang, M.; Peng, Z.; Li, B.; Monteiro, S.N.; Soman, R.; Hwang, J.Y.; Kalay, Y.E.; Escobedo-Diaz, J.P.; Carpenter, J.S.; Brown, A.D.; et al. Characterization of Minerals, Metals, and Materials 2023. Johns. Matthey Technol. Rev. 2024, 68, 275. [Google Scholar]

- ASTM D75/D75M; Standard Practice for Sampling Aggregates. ASTM International: West Conshohocken, PA, USA, 2021.

- ASTM C702/C702M—18; Standard Practice for Reducing Samples of Aggregate to Testing Size. ASTM International: West Conshohocken, PA, USA, 2018.

- ASTM C136-14; Standard Test Method for Sieve Analysis of Fine and Coarse Aggregates. ASTM International: West Conshohocken, PA, USA, 2014.

- ASTM C188-17; Standard Test Method for Density of Hydraulic Cement. ASTM International: West Conshohocken, PA, USA, 2017.

- Cabrera Luna, K.; Escalante García, J.I.; Nieves Mendoza, D.; Maldonado Bandala, E.E. Compressive strength and microstructure of concretes manufactured with supersulfated cement based on materials of volcanic origin exposed to a sulfate environment. Rev. ALCONPAT 2019, 9, 106–116. [Google Scholar]

- Cabrera-Luna, K.; Perez-Cortes, P.; Garcia, J.I.E. Pumice-based supersulfated cements in mortars: Effects of pumice fineness and activator ratio on physical and environmental characteristics. Constr. Build. Mater. 2022, 342, 127947. [Google Scholar] [CrossRef]

- Jwaida, Z.; Dulaimi, A.; Mashaan, N.; Othuman Mydin, M.A. Geopolymers: The Green Alternative to Traditional Materials for Engineering Applications. Infrastructures 2023, 8, 98. [Google Scholar] [CrossRef]

- Shi, X.; Zha, Q.; Li, S.; Cai, G.; Wu, D.; Zhai, C. Experimental Study on the Mechanical Properties and Microstructure of Metakaolin-Based Geopolymer Modified Clay. Molecules 2022, 27, 4805. [Google Scholar] [CrossRef]

- Oti, J.; Adeleke, B.O.; Anowie, F.X.; Kinuthia, J.M.; Ekwulo, E. Mechanical Properties of a Sustainable Low-Carbon Geopolymer Concrete Using a Pumice-Derived Sodium Silicate Solution. Materials 2024, 17, 1792. [Google Scholar] [CrossRef]

- Ghazy, M.F.; Abd Elaty, M.A.; Mostafa, S.M. Properties of One-Part versus Two-Part Geopolymer Composites—A Review. Am. J. Eng. Res. 2022, 11, 1–14. [Google Scholar]

- ASTM C109/C109M—20; Standard Test Method for Compressive Strength of Hydraulic Cement Mortars. ASTM International: West Conshohocken, PA, USA, 2020.

- Pérez, S.P.M.; Carrasco, J.J.B.; Guerrero, R.C.; Palma, J.A.C.; Bances, K.E.B.; Castillo, S.E.R. El Uso del aditivo mineral como modificador de las propiedades mecánicas en el concreto: Una revisión. Métodos Mater. 2021, 11, 10–19. [Google Scholar] [CrossRef]

- Mobasheri, F.; Shirzadi Javid, A.A.; Mirvalad, S.; Azizi, S.; Mowlaei, R. Durability and mechanical properties of pumice-based geopolymers: A sustainable material for future. Iran. J. Sci. Technol. Trans. Civ. Eng. 2022, 46, 223–235. [Google Scholar] [CrossRef]

- Becerra-Duitama, J.A.; Rojas-Avellaneda, D. Pozzolans: A review. Eng. Appl. Sci. Res. 2022, 49, 495–504. [Google Scholar]

- Pavlík, Z.; Vyšvařil, M.; Pavlíková, M.; Bayer, P.; Pivák, A.; Rovnaníková, P.; Záleská, M. Lightweight pumice mortars for repair of historic buildings–Assessment of physical parameters, engineering properties and durability. Constr. Build. Mater. 2023, 404, 133275. [Google Scholar] [CrossRef]

- Szabó, R.; Kristaly, F.; Nagy, S.; Singla, R.; Mucsi, G.; Kumar, S. Reaction, structure and properties of eco-friendly geopolymer cement derived from mechanically activated pumice. Ceram. Int. 2023, 49, 6756–6763. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).