Two-Scale Topology Optimization with Isotropic and Orthotropic Microstructures

Abstract

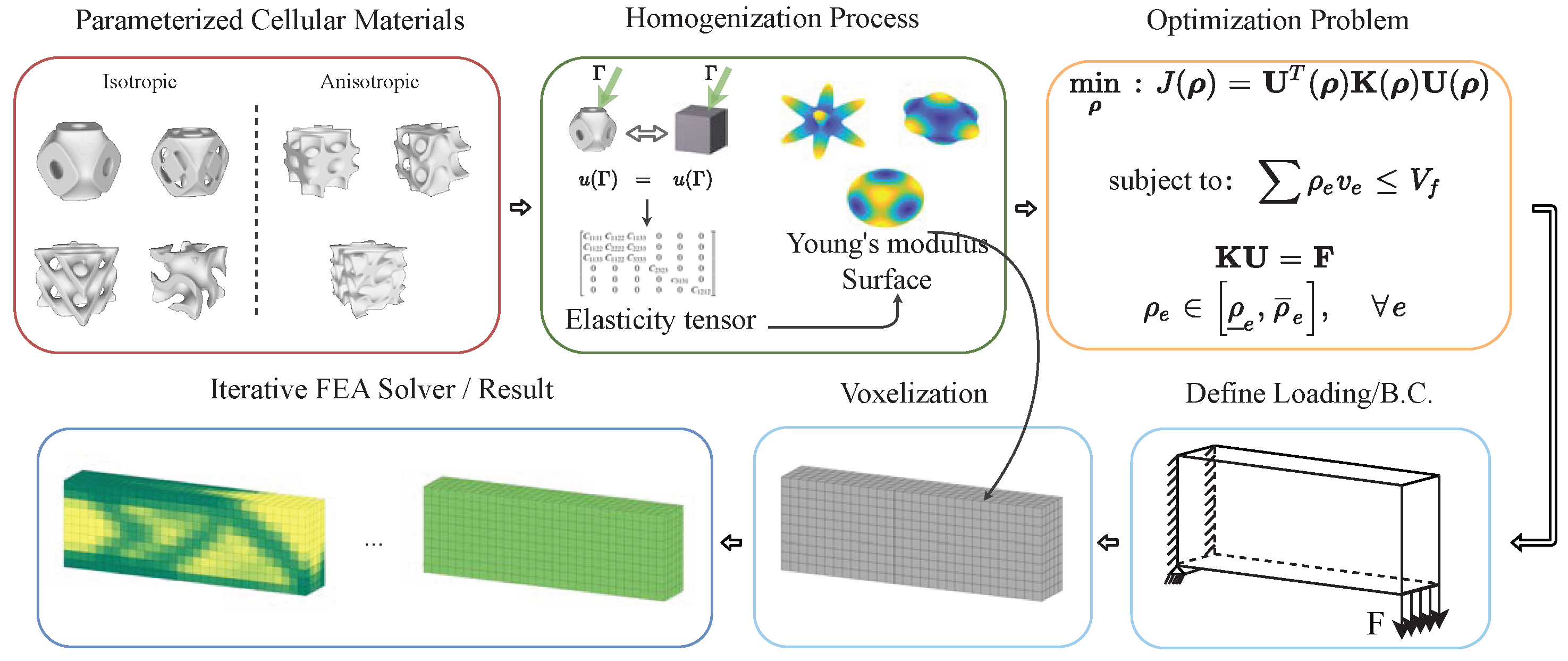

:1. Introduction

- −

- Scaling laws of the relative density and elastic tensor of FSF and TPMS microstructures are derived, which approximates the mechanical properties of the microstructures based on their relative densities with high accuracy;

- −

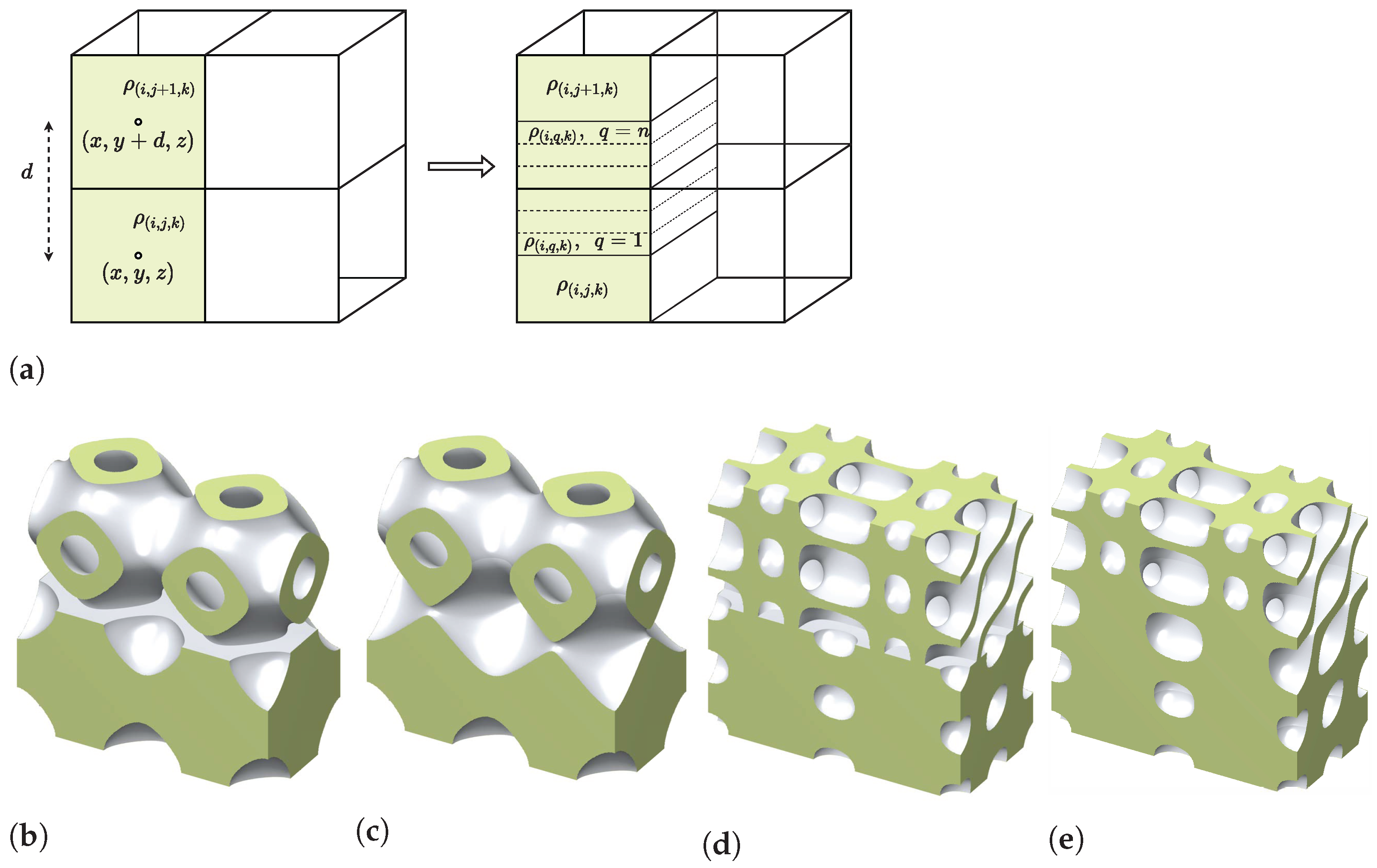

- A high-quality connection between adjacent unit cells with different densities is ensured by utilizing a smoothing operator;

- −

- Set of benchmark cases in mega-voxel are used for validating the results and demonstrating its versatility to various design problems of practical interest;

- −

- Up to decrease in structural compliance by utilizing orthotropic microstructures instead of isotropic ones is achieved, and up to increase in structure stiffness compared to SIMP and other multi-scale TO methods.

2. Overview

2.1. Mathematical Representation

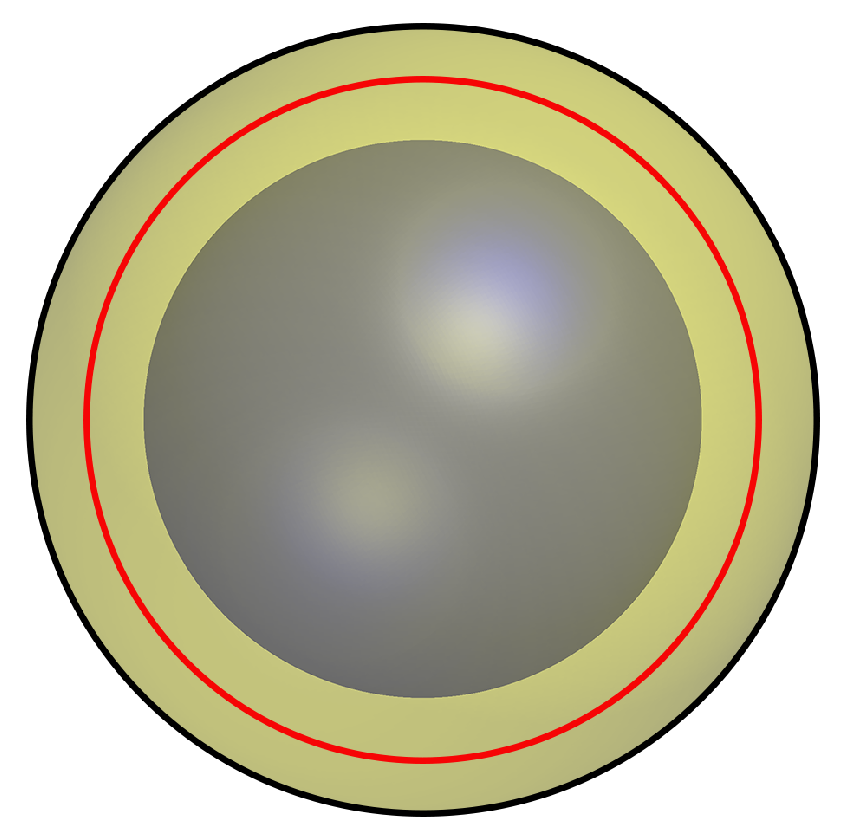

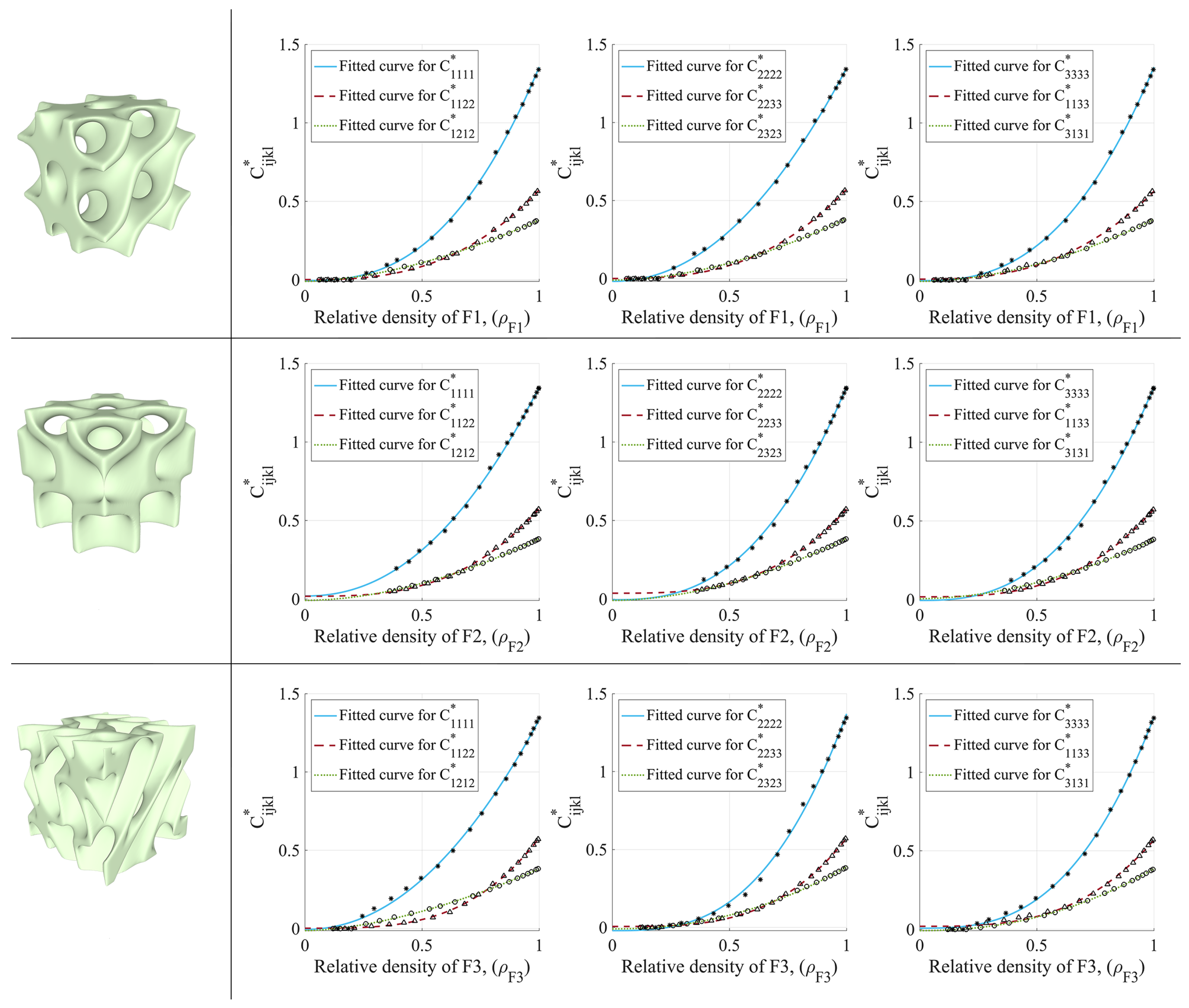

2.2. Homogenized Model of Microstructure

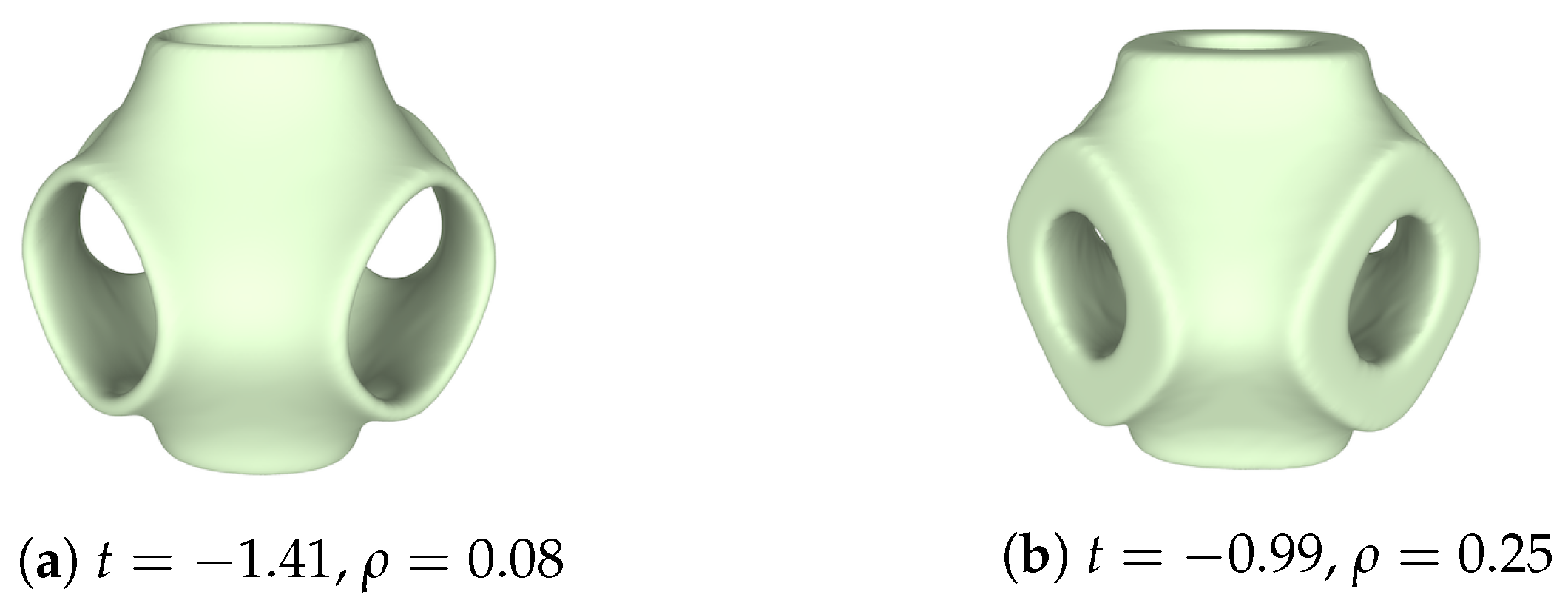

2.2.1. Scaling Laws of the Elasticity Tensors

2.2.2. Isotropic Cellular Materials

2.2.3. Orthotropic Cellular Materials

3. Two-Scale Topology Optimization

3.1. Optimization Problem Formulation

3.2. Elementary Stiffness Matrices

3.3. Optimization Algorithm

| Algorithm 1: Pseudo-code of the proposed optimization algorithm |

|

3.4. Post Processing

Minimum Feature Size

4. Numerical Results

4.1. Benchmark Problems

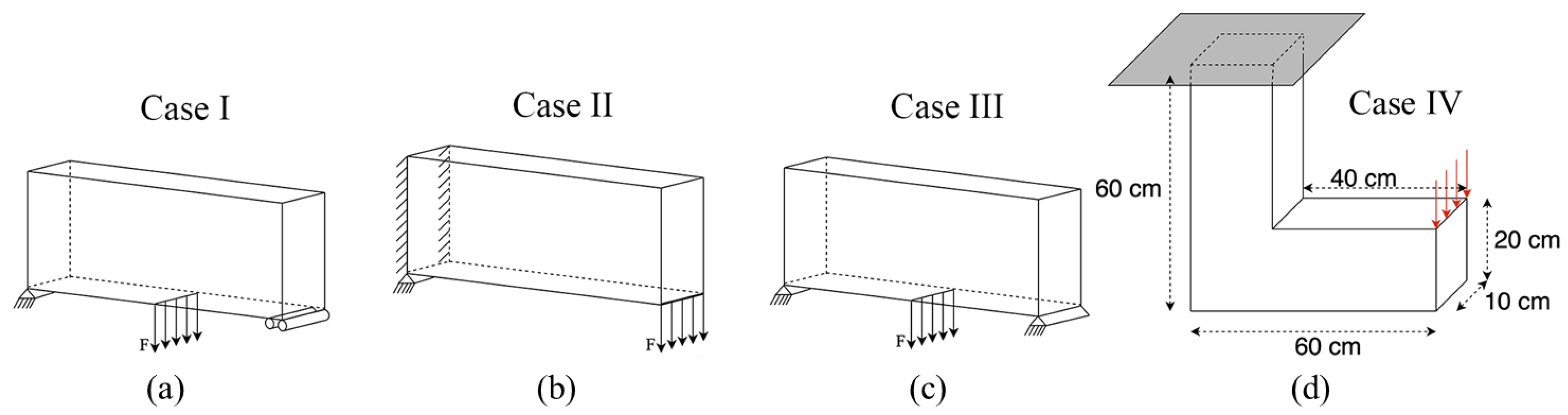

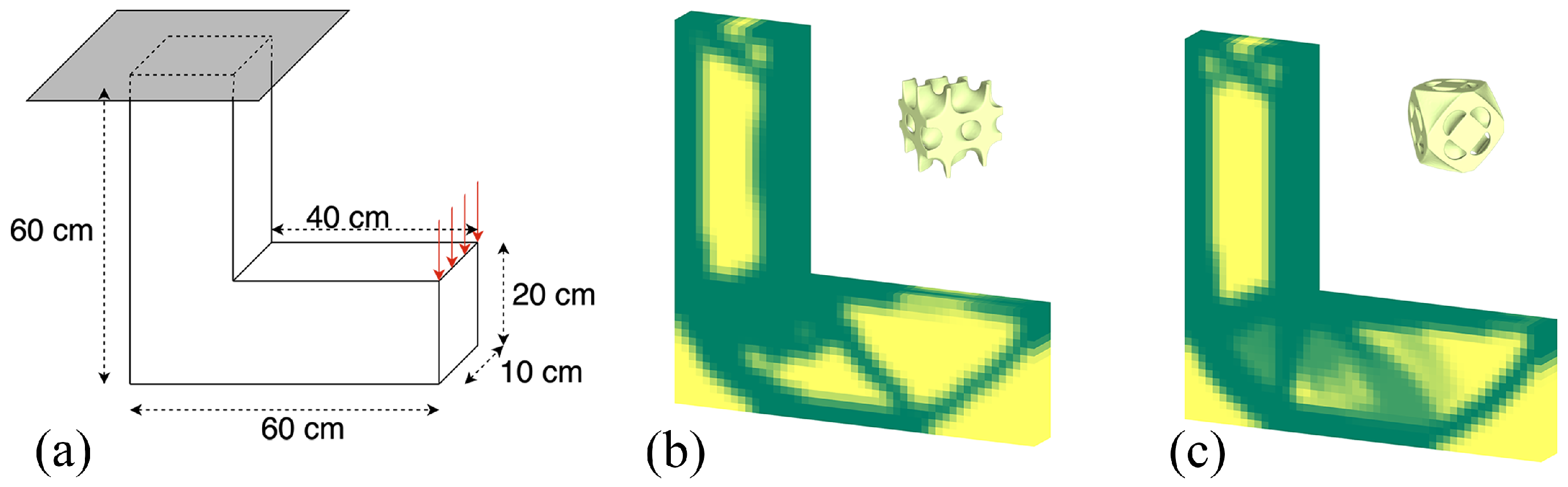

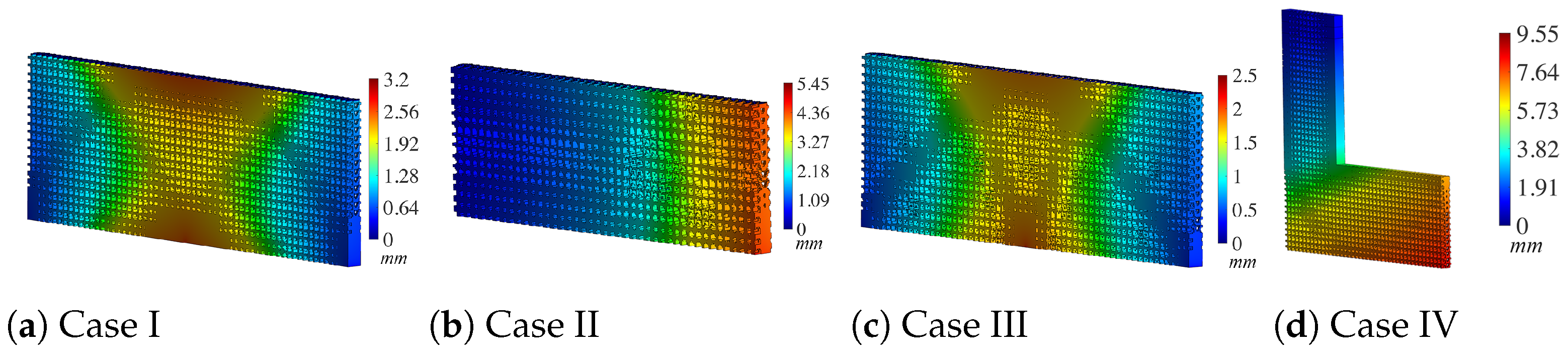

- Case I: This problem is a bending beam with a rectangular cross-section, bottom left edge hinged, roller support for the bottom-right edge, and a uniform load applied to the bottom middle of the beam. The graphic illustration of the boundary condition is presented in Figure 8a;

- Case II: The second problem is a classic cantilever beam problem. In which the beam has a rectangular cross-section, left face fixed, and a uniform load applied to the bottom-right edge of the beam as shown in Figure 8b;

- Case III: This case is an alternative version of the bending beam, and the problem has been configured as follows: both the bottom-left and the bottom-right edge of the beam are hinged, and a uniform load is applied to the bottom middle of the beam shown in Figure 8c;

- Case IV: The fourth problem is an L-shaped structure, clamped from the top surface of the structure, and a uniform downward load is acting on the right top edge of the structure, as shown in Figure 8d.

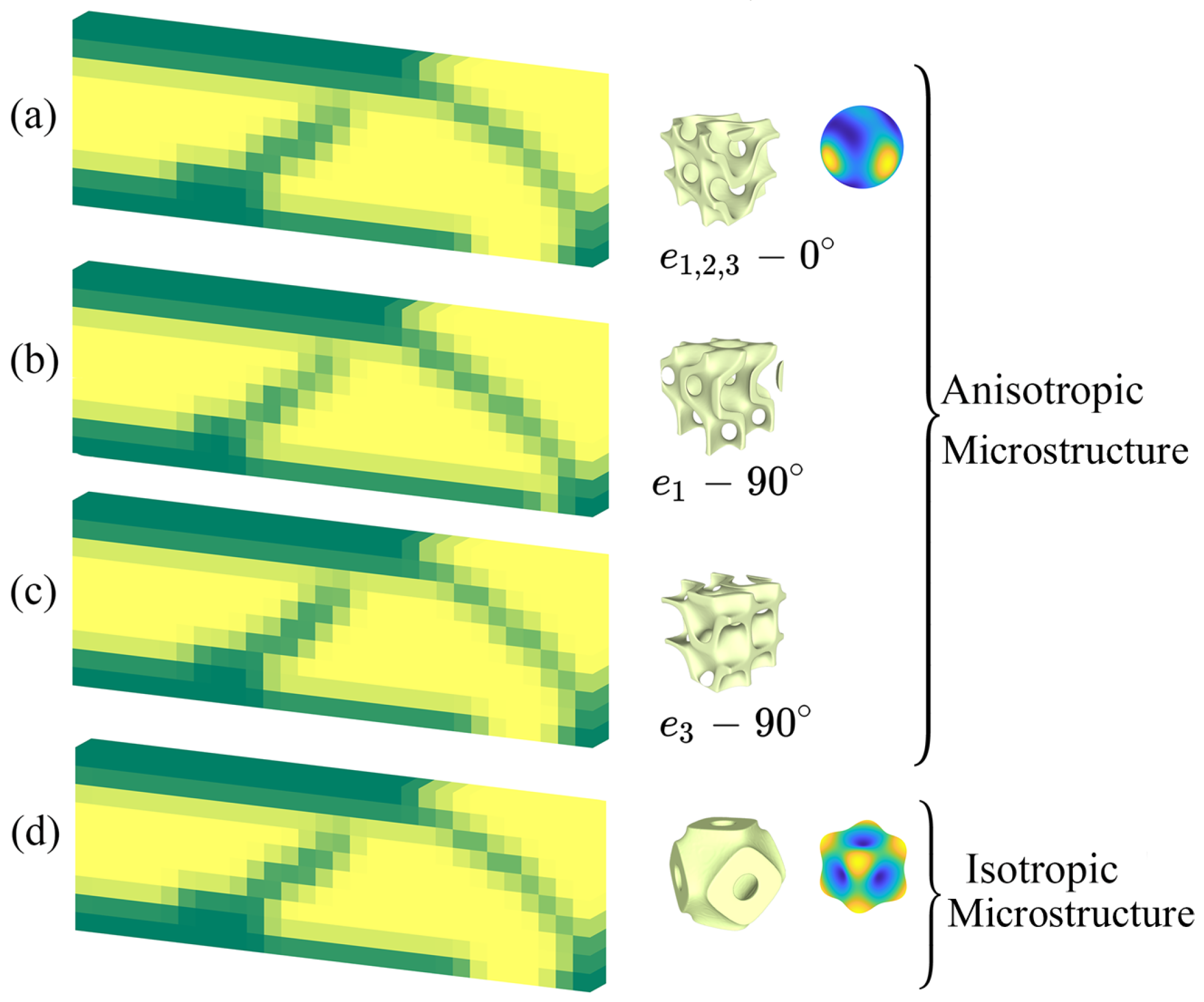

4.2. Isotropic versus Orthotropic Cellular Materials

Directional Tunability

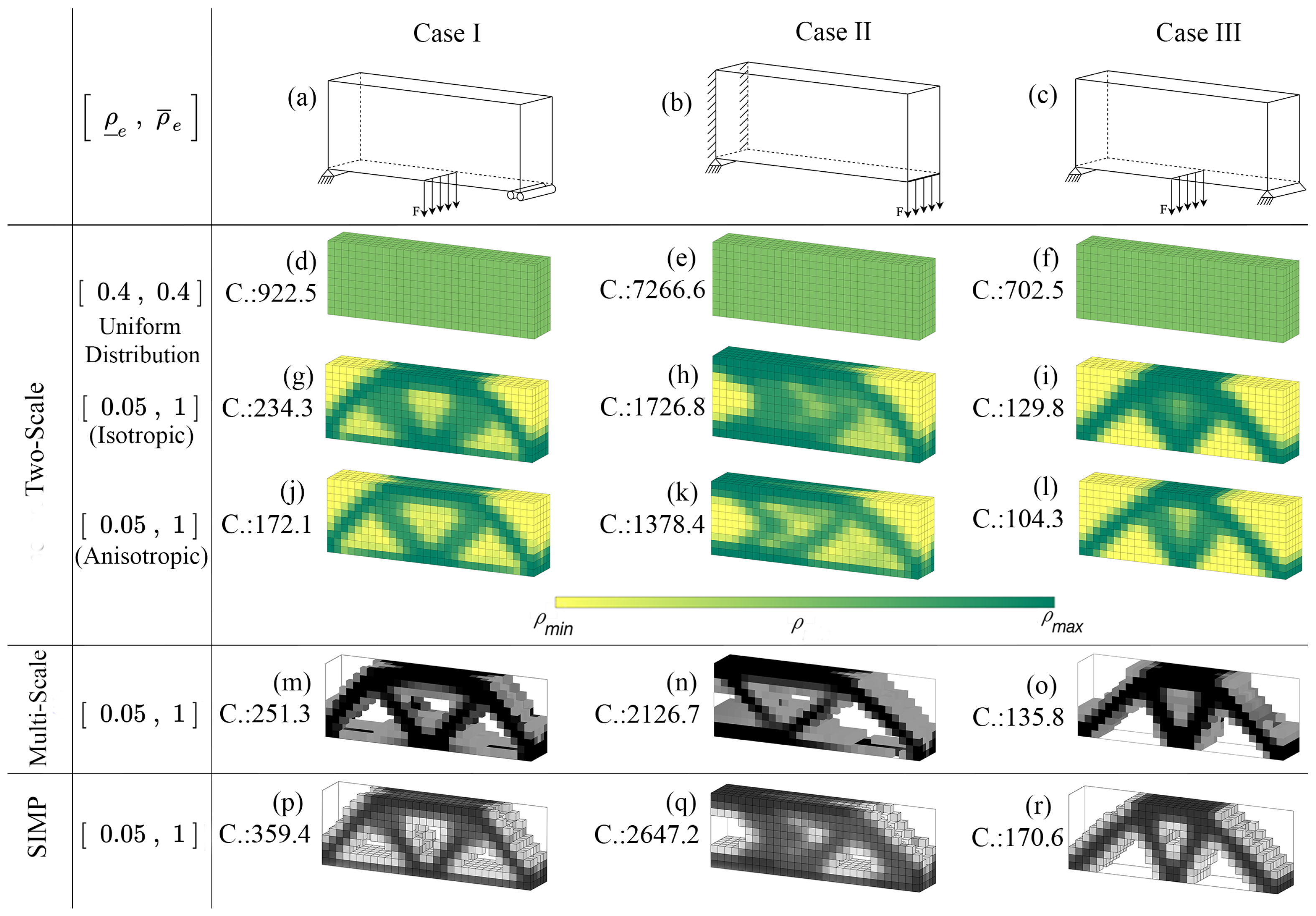

4.3. Performance Evaluation

4.3.1. Computational Performance

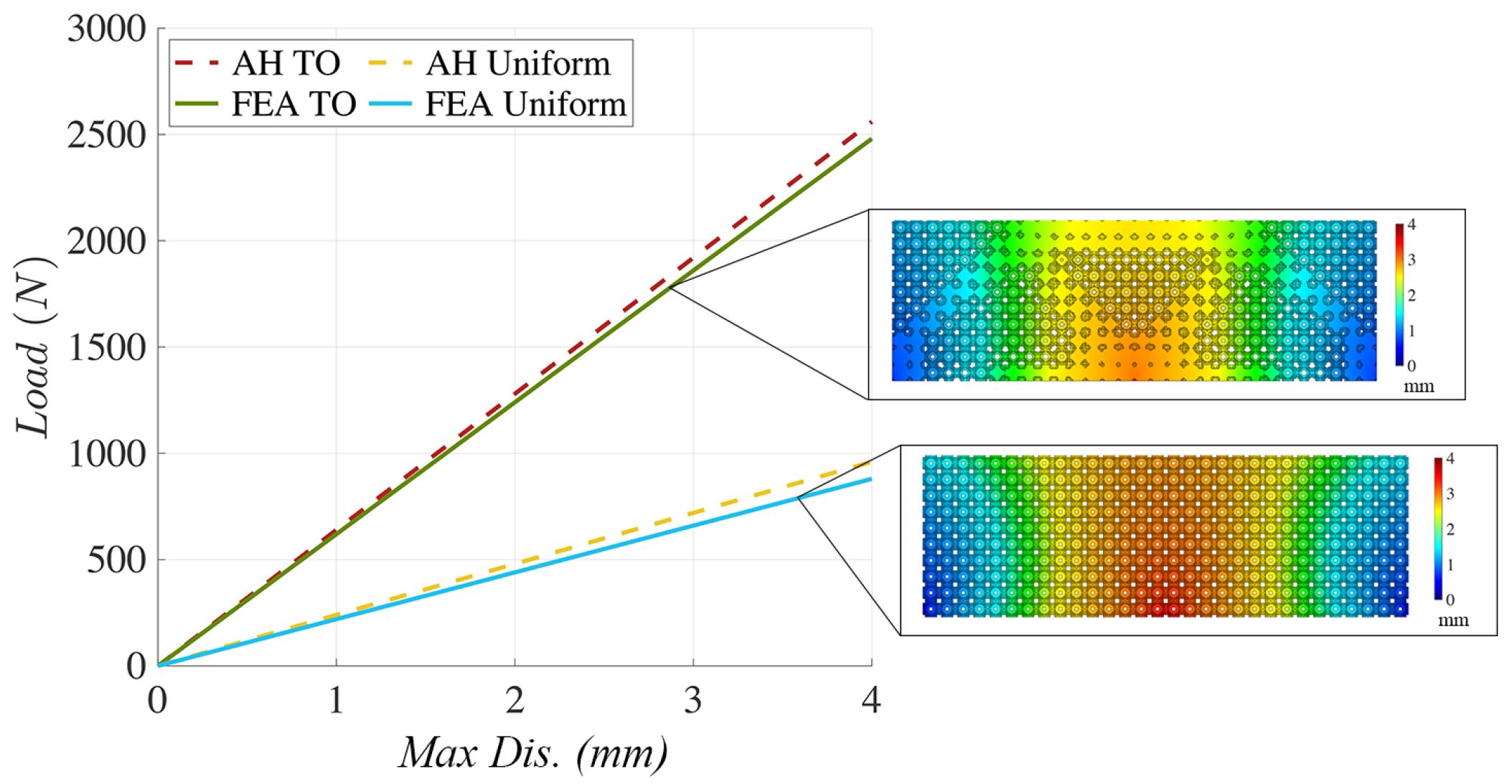

4.3.2. Structural Performance

4.3.3. Level Parameter Effect

4.3.4. Comparison with Multi-Scale and SIMP

4.3.5. Homogenization Result versus Full-Scale FEA Simulation

4.4. Applications

5. Discussions

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Sigmund, O. A 99 line topology optimization code written in Matlab. Struct. Multidiscip. Optim. 2001, 21, 120–127. [Google Scholar] [CrossRef]

- Sigmund, O.; Maute, K. Topology optimization approaches. Struct. Multidiscip. Optim. 2013, 48, 1031–1055. [Google Scholar] [CrossRef]

- Sigmund, O. Topology optimization: A tool for the tailoring of structures and materials. Philos. Trans. R. Soc. Lond. Ser. A Math. Phys. Eng. Sci. 2000, 358, 211–227. [Google Scholar] [CrossRef]

- Sigmund, O.; Torquato, S. Design of smart composite materials using topology optimization. Smart Mater. Struct. 1999, 8, 365. [Google Scholar] [CrossRef]

- Zhu, J.H.; Zhang, W.H.; Xia, L. Topology optimization in aircraft and aerospace structures design. Arch. Comput. Methods Eng. 2016, 23, 595–622. [Google Scholar] [CrossRef]

- Fernández, E.; Ayas, C.; Langelaar, M.; Duysinx, P. Topology optimisation for large-scale additive manufacturing: Generating designs tailored to the deposition nozzle size. Virtual Phys. Prototyp. 2021, 16, 196–220. [Google Scholar] [CrossRef]

- Fu, Y.F.; Rolfe, B.; Chiu, L.N.; Wang, Y.; Huang, X.; Ghabraie, K. Parametric studies and manufacturability experiments on smooth self-supporting topologies. Virtual Phys. Prototyp. 2020, 15, 22–34. [Google Scholar] [CrossRef]

- Wu, J.; Sigmund, O.; Groen, J.P. Topology optimization of multi-scale structures: A review. Struct. Multidiscip. Optim. 2021, 197–224. [Google Scholar] [CrossRef]

- Zheng, L.; Kumar, S.; Kochmann, D.M. Data-driven topology optimization of spinodoid metamaterials with seamlessly tunable anisotropy. Comput. Methods Appl. Mech. Eng. 2021, 383, 113894. [Google Scholar] [CrossRef]

- Schury, F.; Stingl, M.; Wein, F. Efficient two-scale optimization of manufacturable graded structures. SIAM J. Sci. Comput. 2012, 34, B711–B733. [Google Scholar] [CrossRef]

- Xia, L.; Breitkopf, P. Concurrent topology optimization design of material and structure within FE2 nonlinear multiscale analysis framework. Comput. Methods Appl. Mech. Eng. 2014, 278, 524–542. [Google Scholar] [CrossRef]

- Hassani, B.; Hinton, E. A review of homogenization and topology opimization II—Analytical and numerical solution of homogenization equations. Comput. Struct. 1998, 69, 719–738. [Google Scholar] [CrossRef]

- Andrews, E.; Gibson, L.J. The influence of cracks, notches and holes on the tensile strength of cellular solids. Acta Mater. 2001, 49, 2975–2979. [Google Scholar] [CrossRef]

- Portela, C.M.; Greer, J.R.; Kochmann, D.M. Impact of node geometry on the effective stiffness of non-slender three-dimensional truss lattice architectures. Extrem. Mech. Lett. 2018, 22, 138–148. [Google Scholar] [CrossRef]

- Mateos, A.J.; Huang, W.; Zhang, Y.W.; Greer, J.R. Discrete-continuum duality of architected materials: Failure, flaws, and fracture. Adv. Funct. Mater. 2019, 29, 1806772. [Google Scholar] [CrossRef]

- Latture, R.M.; Rodriguez, R.X.; Holmes, L.R., Jr.; Zok, F.W. Effects of nodal fillets and external boundaries on compressive response of an octet truss. Acta Mater. 2018, 149, 78–87. [Google Scholar] [CrossRef]

- Gandy, P.J.; Bardhan, S.; Mackay, A.L.; Klinowski, J. Nodal surface approximations to the P, G, D and I-WP triply periodic minimal surfaces. Chem. Phys. Lett. 2001, 336, 187–195. [Google Scholar] [CrossRef]

- Meeks, W., III; Pérez, J. The classical theory of minimal surfaces. Bull. Am. Math. Soc. 2011, 48, 325–407. [Google Scholar] [CrossRef]

- Hsieh, M.T.; Endo, B.; Zhang, Y.; Bauer, J.; Valdevit, L. The mechanical response of cellular materials with spinodal topologies. J. Mech. Phys. Solids 2019, 125, 401–419. [Google Scholar] [CrossRef]

- Khaderi, S.; Deshpande, V.; Fleck, N. The stiffness and strength of the gyroid lattice. Int. J. Solids Struct. 2014, 51, 3866–3877. [Google Scholar] [CrossRef] [Green Version]

- Kumar, S.; Tan, S.; Zheng, L.; Kochmann, D.M. Inverse-designed spinodoid metamaterials. npj Comput. Mater. 2020, 6, 1–10. [Google Scholar] [CrossRef]

- Gibiansky, L.; Cherkaev, A.V. Microstructures of composites of extremal rigidity and exact bounds on the associated energy density. In Topics in the Mathematical Modelling of Composite Materials; Birkhäuser: Cham, Switzerland, 2018; pp. 273–317. [Google Scholar]

- Groen, J.P.; Wu, J.; Sigmund, O. Homogenization-based stiffness optimization and projection of 2D coated structures with orthotropic infill. Comput. Methods Appl. Mech. Eng. 2019, 349, 722–742. [Google Scholar] [CrossRef]

- Wu, J.; Wang, W.; Gao, X. Design and optimization of conforming lattice structures. IEEE Trans. Vis. Comput. Graph. 2019, 27, 43–56. [Google Scholar] [CrossRef] [PubMed]

- Watts, S.; Arrighi, W.; Kudo, J.; Tortorelli, D.A.; White, D.A. Simple, accurate surrogate models of the elastic response of three-dimensional open truss micro-architectures with applications to multiscale topology design. Struct. Multidiscip. Optim. 2019, 60, 1887–1920. [Google Scholar] [CrossRef]

- Zhou, Y.; Nomura, T.; Zhao, E.; Zhang, W.; Saitou, K. Large-Scale Three-Dimensional Anisotropic Topology Optimization of Variable-Axial Composite Structures. In Proceedings of the International Design Engineering Technical Conferences and Computers and Information in Engineering Conference, American Society of Mechanical Engineers, Virtual, Online, 17–19 August 2020; Volume 84003, p. V11AT11A055. [Google Scholar]

- Mirzendehdel, A.M.; Rankouhi, B.; Suresh, K. Strength-based topology optimization for anisotropic parts. Addit. Manuf. 2018, 19, 104–113. [Google Scholar] [CrossRef]

- Wang, J.; Rai, R.; Armstrong, J.N. Investigation of compressive deformation behaviors of cubic periodic cellular structural cubes through 3D printed parts and FE simulations. Rapid Prototyp. J. 2019, 26, 459–472. [Google Scholar] [CrossRef]

- Wang, J.; Callanan, J.; Ogunbodede, O.; Rai, R. Hierarchical combinatorial design and optimization of non-periodic metamaterial structures. Addit. Manuf. 2021, 37, 101710. [Google Scholar] [CrossRef]

- Wang, J.; Huang, J. Functionally Graded Non-Periodic Cellular Structure Design and Optimization. J. Comput. Inf. Sci. Eng. 2022, 22, 031006. [Google Scholar] [CrossRef]

- Allaire, G.; Cavallina, L.; Miyake, N.; Oka, T.; Yachimura, T. The homogenization method for topology optimization of structures: Old and new. Interdiscip. Inf. Sci. 2019, 25, 75–146. [Google Scholar] [CrossRef]

- Li, K.; Zhan, J.; Yang, T.; To, A.C.; Tan, S.; Tang, Q.; Cao, H.; Murr, L.E. Homogenization timing effect on microstructure and precipitation strengthening of 17–4PH stainless steel fabricated by laser powder bed fusion. Addit. Manuf. 2022, 52, 102672. [Google Scholar] [CrossRef]

- Ntintakis, I.; Stavroulakis, G.E. Infill Microstructures for Additive Manufacturing. Appl. Sci. 2022, 12, 7386. [Google Scholar] [CrossRef]

- Park, S.I.; Rosen, D.W. Homogenization of mechanical properties for material extrusion periodic lattice structures considering joint stiffening effects. J. Mech. Des. 2018, 140, 111414. [Google Scholar] [CrossRef]

- Bendsøe, M.P.; Kikuchi, N. Generating optimal topologies in structural design using a homogenization method. Comput. Methods Appl. Mech. Eng. 1988, 71, 197–224. [Google Scholar] [CrossRef]

- Zhu, B.; Skouras, M.; Chen, D.; Matusik, W. Two-scale topology optimization with microstructures. AACM Trans. Graph. (TOG) 2017, 36, 1. [Google Scholar] [CrossRef]

- Chen, W.; Tong, L.; Liu, S. Concurrent topology design of structure and material using a two-scale topology optimization. Comput. Struct. 2017, 178, 119–128. [Google Scholar] [CrossRef]

- Wu, J.; Wang, C.C.; Zhang, X.; Westermann, R. Self-supporting rhombic infill structures for additive manufacturing. Comput. Aided Des. 2016, 80, 32–42. [Google Scholar] [CrossRef]

- Li, D.; Dai, N.; Tang, Y.; Dong, G.; Zhao, Y.F. Design and optimization of graded cellular structures with triply periodic level surface-based topological shapes. J. Mech. Des. 2019, 141, 071402. [Google Scholar] [CrossRef]

- Von Schnering, H.; Nesper, R. Nodal surfaces of Fourier series: Fundamental invariants of structured matter. Z. für Phys. B Condens. Matter 1991, 83, 407–412. [Google Scholar] [CrossRef]

- Engquist, B.; Souganidis, P.E. Asymptotic and numerical homogenization. Acta Numerica 2008, 17, 147–190. [Google Scholar] [CrossRef]

- Sánchez-Palencia, E. Non-homogeneous media and vibration theory. Lect. Notes Phys. 1980, 127. [Google Scholar]

- Lopes, B.; Arruda, M.; Almeida-Fernandes, L.; Castro, L.; Silvestre, N.; Correia, J. Assessment of mesh dependency in the numerical simulation of compact tension tests for orthotropic materials. Compos. Part C: Open Access 2020, 1, 100006. [Google Scholar] [CrossRef]

- Ashby, M.F. The properties of foams and lattices. Philos. Trans. R. Soc. A: Mathematical. Phys. Eng. Sci. 2006, 364, 15–30. [Google Scholar] [CrossRef] [PubMed]

- Chandrupatla, T.R.; Belegundu, A.D.; Ramesh, T.; Ray, C. Introduction to Finite Elements in Engineering; Cambridge University Press: Cambridge, UK, 2002; Volume 10. [Google Scholar]

- Shiakolas, P.; Nambiar, R.; Lawrence, K.; Rogers, W. Closed-form stiffness matrices for the linear strain and quadratic strain tetrahedron finite elements. Comput. Struct. 1992, 45, 237–242. [Google Scholar] [CrossRef]

- Wu, J.; Dick, C.; Westermann, R. A system for high-resolution topology optimization. IEEE Trans. Vis. Comput. Graph. 2015, 22, 1195–1208. [Google Scholar] [CrossRef] [PubMed]

- Bruns, T. A reevaluation of the SIMP method with filtering and an alternative formulation for solid–void topology optimization. Struct. Multidiscip. Optim. 2005, 30, 428–436. [Google Scholar] [CrossRef]

- Rastegarzadeh, S.; Wang, J.; Huang, J. Two-Scale Topology Optimization with Parameterized Cellular Structures. In Proceedings of the International Design Engineering Technical Conferences and Computers and Information in Engineering Conference, American Society of Mechanical Engineers, Virtual, Online, 17–19 August 2020; Volume 84003, p. V002T02A046. [Google Scholar]

- Maas, S.A.; Ellis, B.J.; Ateshian, G.A.; Weiss, J.A. FEBio: Finite elements for biomechanics. J. Biomech. Eng. 2012, 134, 011005. [Google Scholar] [CrossRef] [Green Version]

| Printer | - Res. (mm) | Max. Res. | n-Range | Feature Size (mm) |

|---|---|---|---|---|

| ANYCUBIC (Photon Mono X) | 100 | |||

| 150 | ||||

| 200 | ||||

| Creality (Halot-One Plus) | 100 | |||

| 150 | ||||

| 200 |

| Orthotropic () | Isotropic () | |||

|---|---|---|---|---|

| Rotation | x- | z- | ||

| Comp. | 1884 | 1441 | 1793 | 1844 |

| Imp. | - | |||

| Two-Scale | Multi-Scale [25] | |||

|---|---|---|---|---|

| No. of Elements (Total) | ||||

| No. of Elements (Micro) | ||||

| No. of Elements (Macro) | 1500 | 1500 | 1500 | 1500 |

| Compliance | ||||

| Time to Converge (s) | 141 | 140 | 141 | 386 |

| Case I | Case II | Case III | Case IV | |

|---|---|---|---|---|

| No. of Elements (Total) | ||||

| SIMP Compliance | 359.4 | 2647.2 | 170.6 | 2204.4 |

| multi-scale [25] Compliance | 251.3 | 2126.7 | 135.8 | 2017.9 |

| Two-Scale (isotropic ) Compliance | 234.3 | 1726.8 | 129.8 | 1895.1 |

| Two-Scale (orthotropic ) Compliance | 172.1 | 1378.4 | 104.3 | 1623.4 |

| Improvement to SIMP |

| Bunny | Armadillo | |

|---|---|---|

| No. of Elements (Total) | ||

| No. of Elements (Micro) | ||

| No. of Elements (Macro) | 83,942 | 106,260 |

| Time to Converge (min) | 44 | 64 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rastegarzadeh, S.; Wang, J.; Huang, J. Two-Scale Topology Optimization with Isotropic and Orthotropic Microstructures. Designs 2022, 6, 73. https://doi.org/10.3390/designs6050073

Rastegarzadeh S, Wang J, Huang J. Two-Scale Topology Optimization with Isotropic and Orthotropic Microstructures. Designs. 2022; 6(5):73. https://doi.org/10.3390/designs6050073

Chicago/Turabian StyleRastegarzadeh, Sina, Jun Wang, and Jida Huang. 2022. "Two-Scale Topology Optimization with Isotropic and Orthotropic Microstructures" Designs 6, no. 5: 73. https://doi.org/10.3390/designs6050073

APA StyleRastegarzadeh, S., Wang, J., & Huang, J. (2022). Two-Scale Topology Optimization with Isotropic and Orthotropic Microstructures. Designs, 6(5), 73. https://doi.org/10.3390/designs6050073