Apparatus Development for the Measurement of the Thermal Conductivity of Geothermal Backfill Materials

Abstract

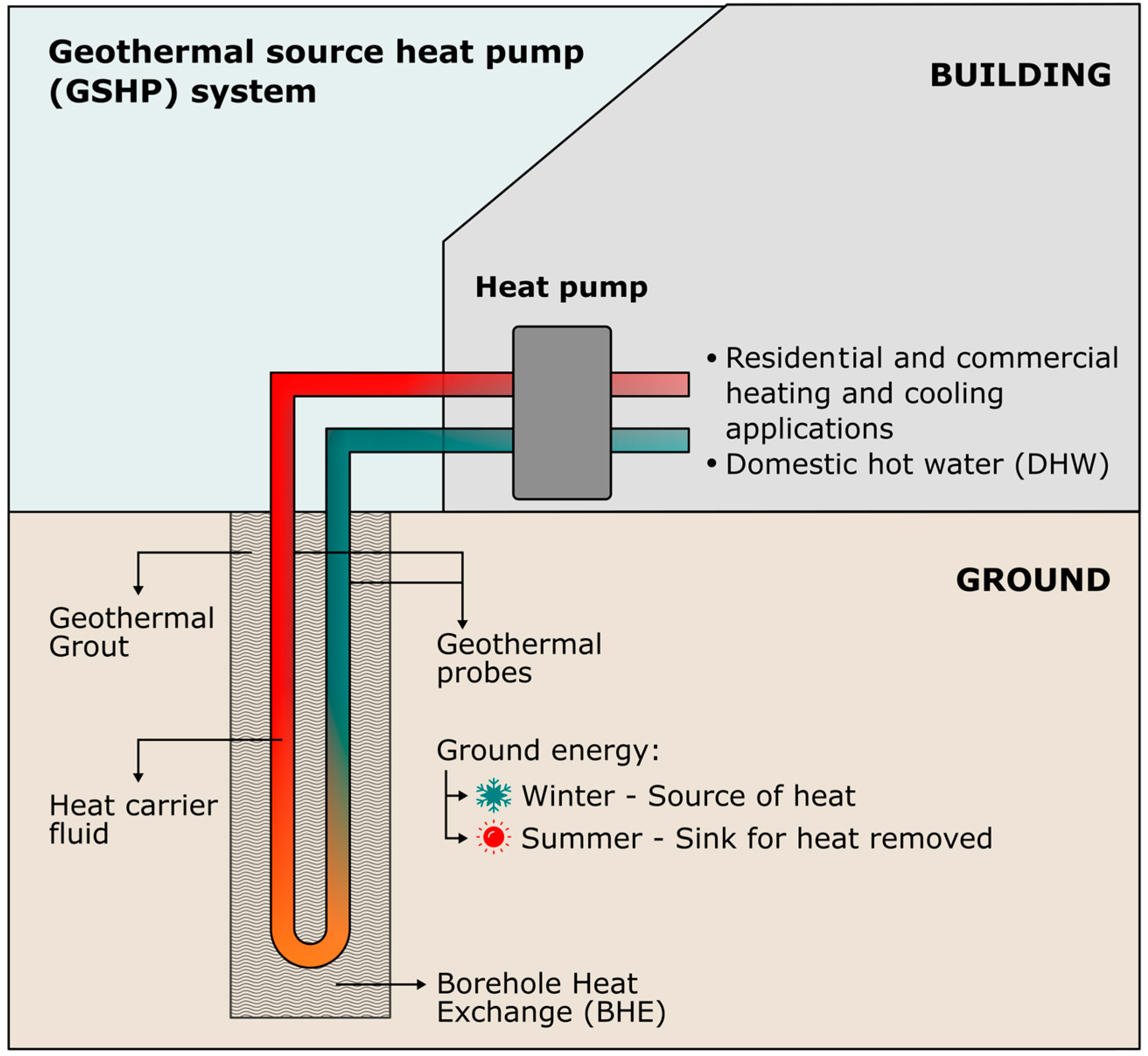

1. Introduction

- 🗸

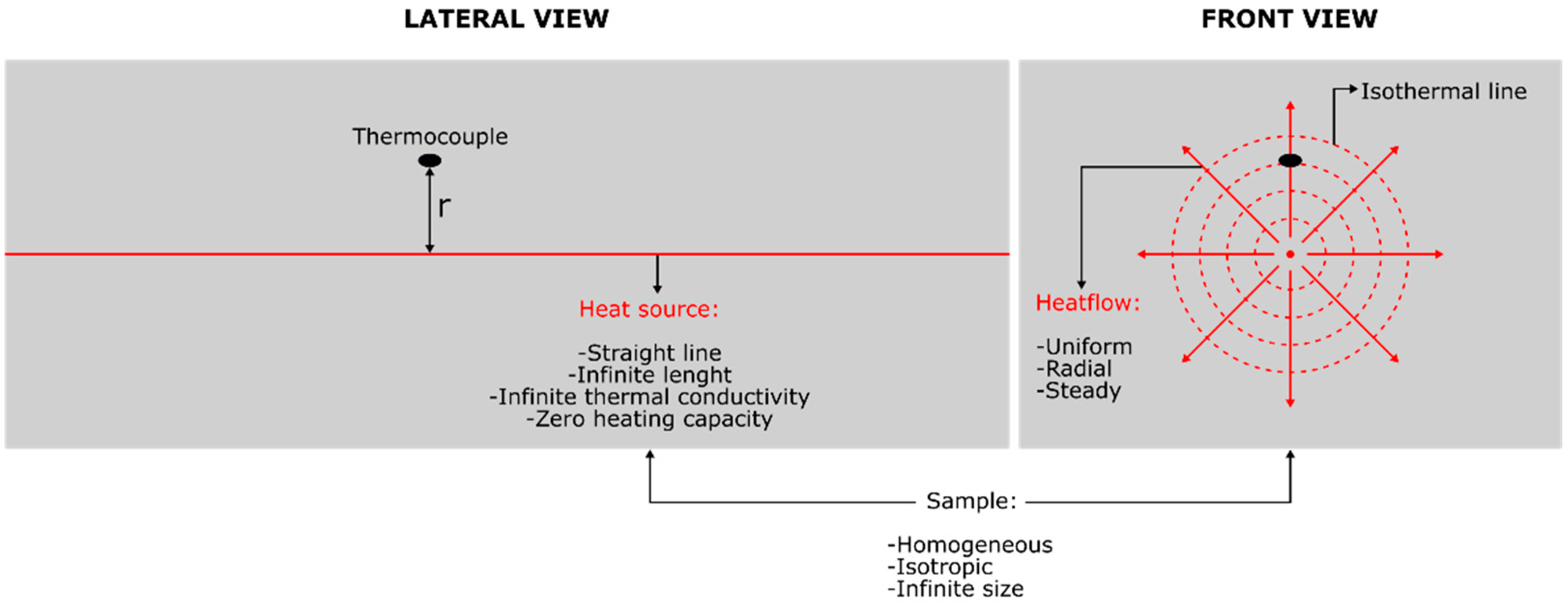

- The heat source is a straight line with an infinite length and infinite thermal conductivity. It also has zero heating capacity that dissipates a steady heat flow, which is radial and uniform;

- 🗸

- The sample is homogeneous, isotropic and it has an infinite size;

- 🗸

- When the trial is initiated, the sample temperature is in balance with the room temperature.

- 🗸

- Regarding the samples:

- ○

- The size: parallelepiped shape briquettes of mortar had been made with different additives. These briquettes might have the size of the sample pattern;

- ○

- The state, compact or powder;

- ○

- The expected thermal conductivity is relatively small, lower than 3 W/m·K, given the composition of the samples.

- 🗸

- Regarding the test:

- ○

- Repeatability;

- ○

- Precision;

- ○

- Heating power control;

- ○

- Duration.

- 🗸

- Regarding the apparatus:

- ▪

- Size;

- ▪

- Prize.

2. Materials and Methods

2.1. Theoretical Basis

- heat flow per unit length; .

- Where:

- ○

- Electrical Intensity; A.

- ○

- Voltage; V.

- ○

- Hot wire length; m.

- initial temperature, matching with environmental temperature at the beginning of the essay; °C.

- temperature in time and distance ; °C.

- distance between the heat source and the temperature sensor, m.

- thermal conductivity, .

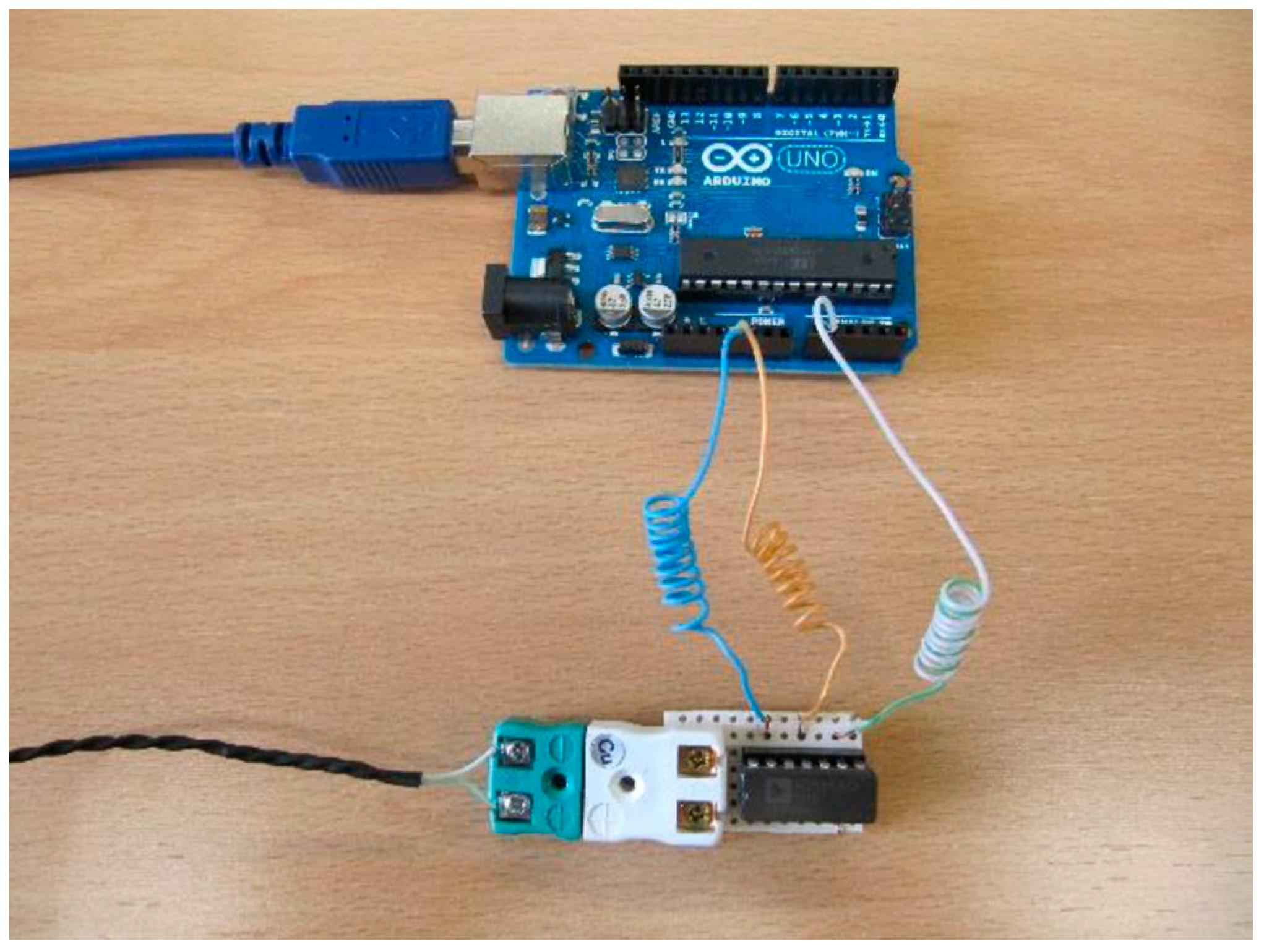

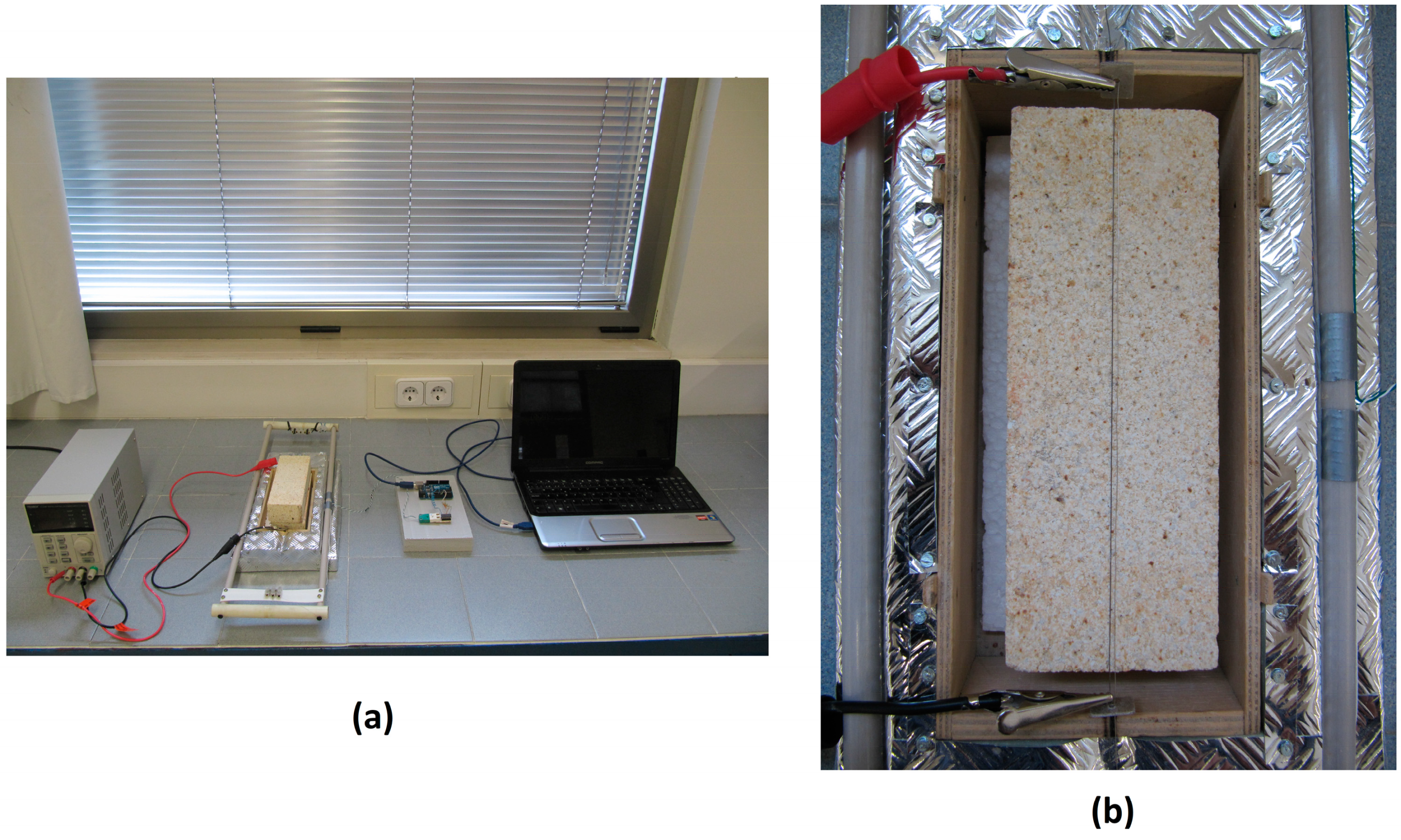

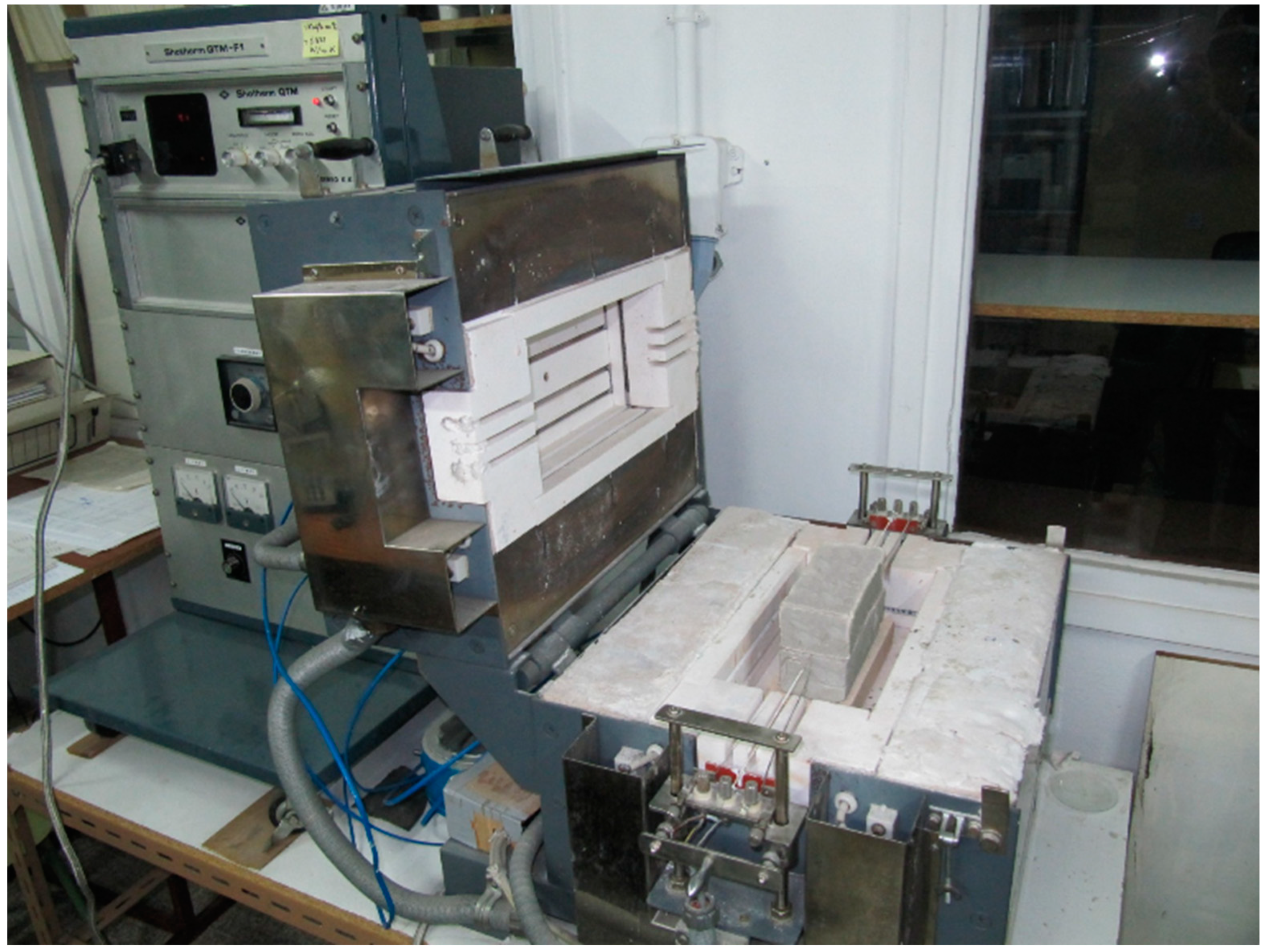

2.2. Experimental Set-Up

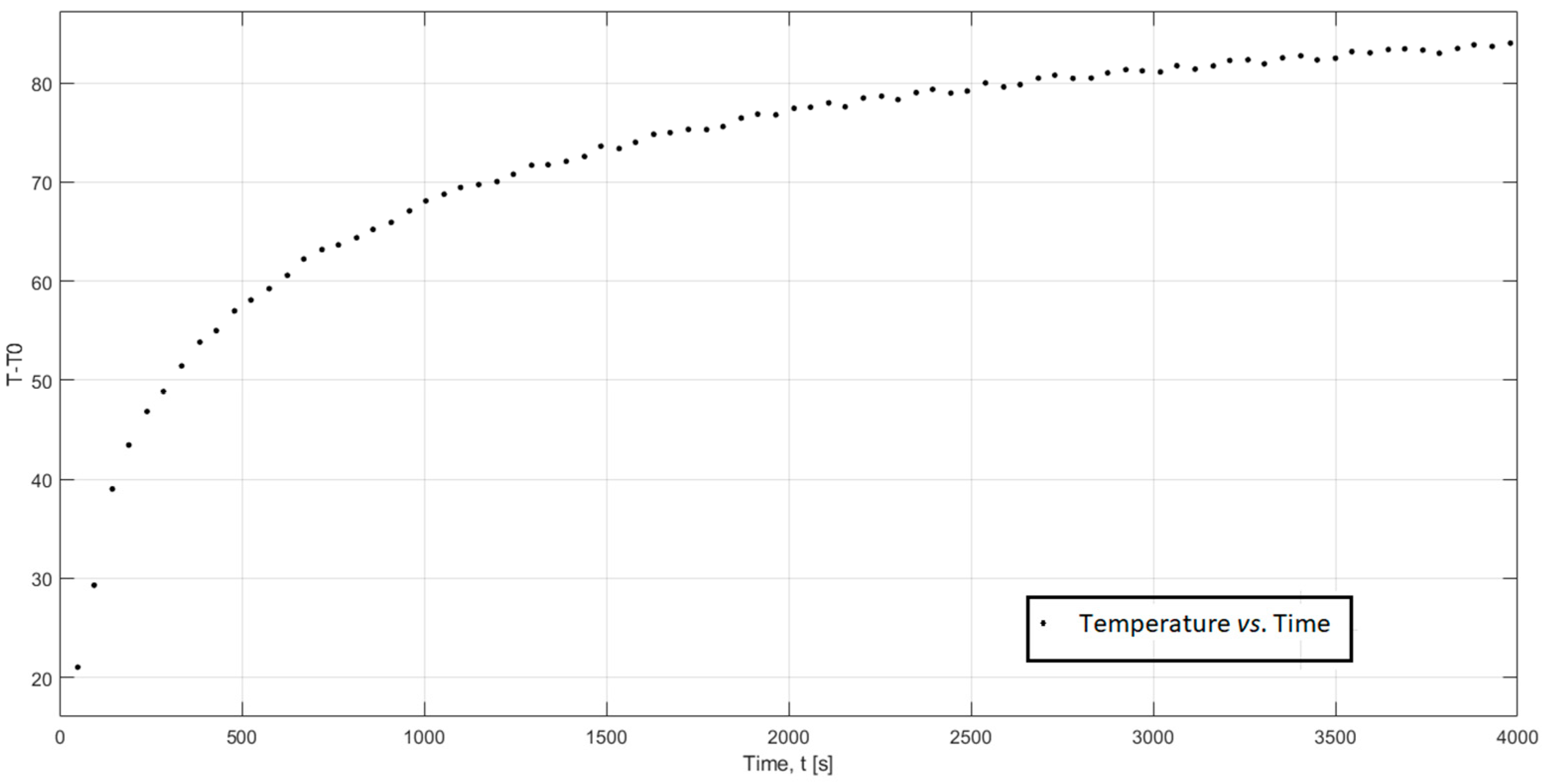

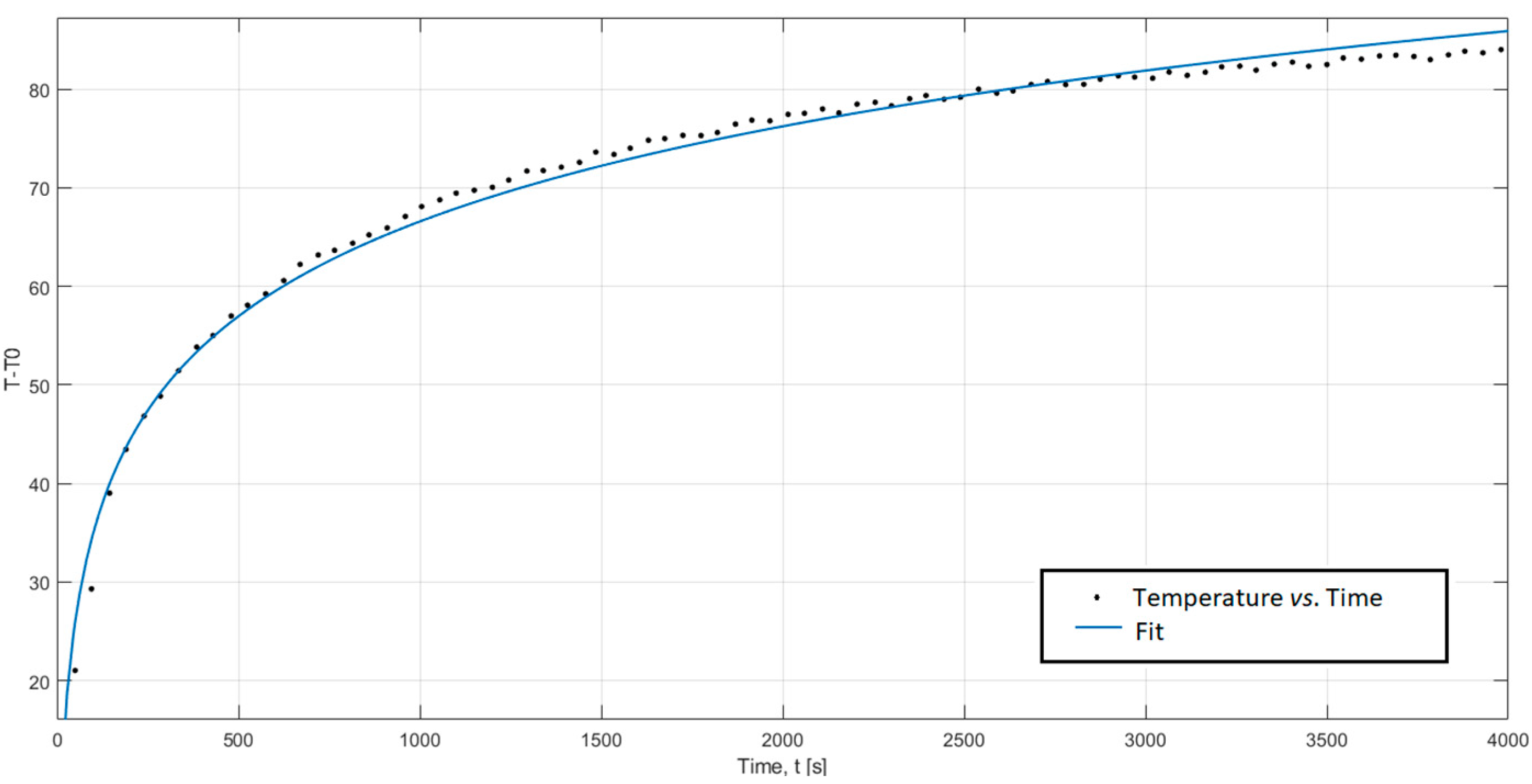

2.3. Thermal Conductivity Calculation and Experimental Procedure

- 1.

- Placement of the measuring unit sample, setting hot wire and temperature sensor between both test specimens;

- 2.

- Placement of the 2 crocodile clips over the hot wire, with a separation equal to the length of the sample for testing;

- 3.

- Selection of the electrical current to apply to the hot wire on the power supply. Intensity value had been estimated previously to ensure that the temperature does not exceed a maximum;

- 4.

- Simultaneous start of the heating and data logging;

- 5.

- Hot wire voltage drop measurement with the multimeter;

- 6.

- Hot wire length measurement between the two crocodile clips with the flexometer;

- 7.

- Completion of the test after 15 min of heating and data logging;

- 8.

- Heating curve plotting;

- 9.

- Sample thermal conductivity obtaining via Equation (4).

2.4. Validation and Calibration

- Skamol SM-65 (Skamol A/S);

- Macizo M5R (Cerámica La Espina S.L.);

- MAXIAL 310 (RHI) y;

- CN-90BA (Cerámica del Nalón S.A.).

3. Results and Discussion

3.1. Sample Minimum Size and Appropriate Electrical Current

- Italicized λexp values are those that deviate more than 10% from the reference values (λref), or those with a coefficient of determination, R2, lower than 0.95;

- Underlined values λexp are those with a deviation lower than 10%, and value R2 is greater than or equal to 0.95, but the time window is so small that the least squares fitting is executed with less than 10 values;

- Values λexp in red bold are those that deviate less than 10%, the value of R2 is greater or equal to 0.95, and the least squares fitting is executed with at least 10 values.

- In which if thermal conductivity is lower than 0.70 W/m∙K the minimum sample size is 110 × 50 × 35 mm and electrical current is considered appropriate both in 0.5 A and in 1 A;

- When thermal conductivity is greater or equal to 0.70 W/m∙K the named minimum size is 180 × 70 × 50 mm, in which case, if thermal conductivity is between 0.70 and 1.20 W/m∙K, the electrical currents of 1 A, 1.5 A and also 2 A are considered appropriate;

- Ultimately, if thermal conductivity is higher than 1.20 W/m∙K it is considered that an electrical current of 1.5 A as of 2 A is appropriate.

3.2. Comparison of Thermal Conductivity Values of the Samples

3.3. Calibration Correction and Estimation of Expanded Uncertainty

3.4. Summary of the TCMA Technical Specifications

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Directiva 2009/28/CE del Parlamento Europeo y del Consejo, de 23 de Abril de 2009, Relativa al Fomento del uso de Energía Procedente de Fuentes Renovables y por la que se Modifican y se Derogan las Directivas 2001/77/CE y 2003/30/CE. Available online: https://www.idae.es/tecnologias/energias-renovables/uso-termico/biocarburantes/sostenibilidad/directiva-europea-de (accessed on 18 October 2022).

- Castán-Fernández, C.; Marcos-Robredo, G.; Castro-García, M.; Rey-Ronco, M.; Alonso-Sánchez, T. Development of a dry mortar with nanosilica and different types of industrial waste for the application in borehole heat exchangers. Constr. Build. Mater. 2022, 359, 129511. [Google Scholar] [CrossRef]

- Kim, D.; Kim, G.; Kim, D.; Baek, H. Experimental and numerical investigation of thermal properties of cement-based grouts used for vertical ground heat exchanger. Renew. Energy 2017, 112, 260–267. [Google Scholar] [CrossRef]

- Shrestha, D.; Rizvi, Z.H.; Wuttke, F. Effective thermal conductivity of unsaturated granular geocomposite using lattice element method. Heat Mass Transf. 2019, 55, 1671–1683. [Google Scholar] [CrossRef]

- Liang, B.; Chen, M.; Guan, J. Experimental assessment on the thermal and moisture migration of sand-based materials combined with kaolin and graphite. Heat Mass Transf. 2022, 58, 1075–1089. [Google Scholar] [CrossRef]

- Frąc, M.; Szudek, W.; Szołdra, P.; Pichór, W. Grouts with highly thermally conductive binder for low-temperature geothermal applications. Constr. Build. Mater. 2021, 295, 123680. [Google Scholar] [CrossRef]

- Kim, D.; Oh, S. Relationship between the thermal properties and degree of saturation of cementitious grouts used in vertical borehole heat exchangers. Energy Build 2019, 201, 1–9. [Google Scholar] [CrossRef]

- Cardoso de Freitas Murari, M.; de Hollanda Cavalcanti Tsuha, C.; Loveridge, F. Investigation on the thermal response of steel pipe energy piles with different backfill materials. Renew. Energy 2022, 199, 44–61. [Google Scholar] [CrossRef]

- Dong, S.; Liu, G.; Zhan, T.; Yao, Y.; Ni, L. Performance study of cement-based grouts based on testing and thermal conductivity modeling for ground-source heat pumps. Energy Build. 2022, 272, 112351. [Google Scholar] [CrossRef]

- Wang, S.; Li, Y.; Wu, L.; He, X.; Jian, L.; Chen, Q. Investigation on thermal conductivity property and hydration mechanism of graphene-composite cement for geothermal exploitation. Geothermics 2022, 104, 102477. [Google Scholar] [CrossRef]

- Hammerschmidt, U.; Sabuga, W. Transient Hot Wire (THW) method: Uncertainty assessment. Int. J. Thermophys. 2000, 21, 1255–1278. [Google Scholar] [CrossRef]

- Franco, A. An apparatus for the routine measurement of thermal conductivity of materials for building application based on a transient hot-wire method. Appl. Therm. Eng. 2007, 27, 2495–2504. [Google Scholar] [CrossRef]

- Zhang, T.; Shen, R.; Lin, C.; Yin, J.; Wang, S. Measuring moisture content in a porous insulation material using a hot wire. Build. Environ. 2015, 84, 22–31. [Google Scholar] [CrossRef]

- Coquard, R.; Baillis, D.; Quenard, D. Experimental and theoretical study of the hot-wire method applied to low-density thermal insulators. Int. J. Heat Mass Transf. 2006, 49, 4511–4524. [Google Scholar] [CrossRef]

- Dos Santos, W.N. Thermal properties of melt polymers by the hot wire technique. Polym. Test. 2005, 24, 932–941. [Google Scholar] [CrossRef]

- Assael, M.J.; Antoniadis, K.D.; Wakeham, W.A. Historical evolution of the transient hot-wire technique. Int. J. Thermophys. 2010, 31, 1051–1072. [Google Scholar] [CrossRef]

- Van der Held, E.F.M.; van Drunen, F.G. A method of measuring the thermal conductivity of liquids. Physica 1949, 15, 865–881. [Google Scholar] [CrossRef]

- Haupin, W.E. Hot wire method for rapid determination of thermal conductivity. Am. Ceram. Soc. Bull. 1960, 39, 139–141. [Google Scholar]

- Beziat, A.; Dardaine, M.; Gabis, V. Effect of compaction pressure and water content on the thermal conductivity of some natural clays. Clays Clay Miner. 1988, 36, 462–466. [Google Scholar] [CrossRef]

- Allan, M.L.; Philippacopoulos, A.J. Performance characteristics and modelling of cementitious grouts for geothermal heat pumps. In Proceedings of the World Geothermal Congress, Tohoku, Japan, 28 May–10 June 2000. [Google Scholar]

- Demirboǧa, R. Influence of mineral admixtures on thermal conductivity and compressive strength of mortar. Energy Build. 2003, 35, 189–192. [Google Scholar] [CrossRef]

- Esen, Y.; Yilmazer, B. Investigation of some physical and mechanical properties of concrete produced with barite aggregate. Sci. Res. Essays 2010, 5, 3826–3833. [Google Scholar] [CrossRef]

- Liu, K.; Wang, Z.; Jin, C.; Wang, F.; Lu, X. An experimental study on thermal conductivity of iron ore sand cement mortar. Constr. Build. Mater. 2015, 101, 932–941. [Google Scholar] [CrossRef]

- Ishido, Y.; Kawamura, M.; Ono, S. Thermal conductivity of magnesium-nickel hydride powder beds in a hydrogen atmosphere. Int. J. Hydrog. Energy 1982, 7, 173–182. [Google Scholar] [CrossRef]

- Liu, Z.Y.; Cacciola, G.; Restuccia, G.; Giordano, N. Fast simple and accurate measurement of zeolite thermal conductivity. Zeolites 1990, 10, 565–570. [Google Scholar] [CrossRef]

- Zhang, X.; Degiovanni, A.; Maillet, D. Hot-wire measurement of thermal conductivity of solids: A new approach. High Temp.-High Press. 1993, 25, 577–584. [Google Scholar]

- Griesinger, A.; Spindler, K.; Hahne, E. Measurements and theoretical modelling of the effective thermal conductivity of zeolites. Int. J. Heat Mass Transf. 1999, 42, 4363–4374. [Google Scholar] [CrossRef]

- Wallwork, A.; Mummery, P.; Gregório Filho, R.; dos Santos Wilson, N. Método de fio quente na determinação das propriedades térmicas de polímeros. Polímeros Ciência E Tecnol. 2004, 14, 354–359. [Google Scholar] [CrossRef]

- Mounanga, P.; Khelidj, A.; Bastian, G. Experimental study and modelling approaches for the thermal conductivity evolution of hydrating cement paste. Adv. Cem. Res. 2004, 16, 95–103. [Google Scholar] [CrossRef]

- Peralta, M.V.; Assael, M.J.; Dix, M.J.; Karagiannidis, L.; Wakeham, W.A. A novel instrument for the measurement of the thermal conductivity of molten metals. Part 1: Instrument’s description. Int. J. Thermophys. 2006, 27, 353–375. [Google Scholar] [CrossRef]

- Daouas, N.; Fguiri, A.; Radhouani, M. Solution of a coupled inverse heat conduction-radiation problem for the study of radiation effects on the transient hot wire measurements. Exp. Therm. Fluid Sci. 2008, 32, 1766–1778. [Google Scholar] [CrossRef]

- Ortiz de Zárate, J.M.; Hita, J.L.; Khayet, M.; Legido, J.L. Measurement of the thermal conductivity of clays used in pelotherapy by the multi-current hot-wire technique. Appl. Clay Sci. 2010, 50, 423–426. [Google Scholar] [CrossRef]

- Sales, A.; Rodrigues de Souza, F.; dos Santos, W.N.; Mendes Zimer, A.; do Couto Rosa Almeida, F. Lightweight composite concrete produced with water treatment sludge and sawdust: Thermal properties and potential application. Constr. Build. Mater. 2010, 24, 2446–2453. [Google Scholar] [CrossRef]

- Rixing, H.; Aichun, M.; Yahui, W. Transient hot wire measures thermophysical properties of organic foam thermal insulation materials. Exp. Therm. Fluid Sci. 2018, 98, 674–682. [Google Scholar] [CrossRef]

- Jannot, Y.; Degiovanni, A. An improved model for the parallel hot wire: Application to thermal conductivity measurement of low density insulating materials at high temperature. Int. J. Therm. Sci. 2019, 142, 379–391. [Google Scholar] [CrossRef]

- Rottmann, M.; Beikircher, T.; Ebert, H.P. Thermal conductivity of evacuated expanded perlite measured with guarded-hot-plate and transient-hot-wire method at temperatures between 295 K and 1073 K. Int. J. Therm. Sci. 2020, 125, 106338. [Google Scholar] [CrossRef]

- Jannot, Y.; Degiovanni, A.; Schick, V.; Meulemans, J. Apparent thermal conductivity measurement of anisotropic insulating materials at high temperature by the parallel hot-wire method. Int. J. Therm. Sci. 2021, 160, 106672. [Google Scholar] [CrossRef]

- Carslaw, H.S.; Jaeger, J.C. Conduction of Heat in Solids, 2nd ed.; Oxford University Press: London, UK, 1959. [Google Scholar]

| Sample | Composition | Size [mm] | λ [W/m∙K] | [W/m∙K] |

|---|---|---|---|---|

| Skamol SM-65 | Diatomite | Small: 110 × 50 × 35 | 0.13 | 0.00 |

| Macizo M5R | Red clay | Small: 110 × 50 × 35 Medium: 180 × 70 × 50 Large: 240 × 120 × 60 | 0.70 | 0.01 |

| MAXIAL 310 | Chamotte | Medium: 180 × 70 × 50 | 1.20 | 0.02 |

| CN-90BA | Alumina | Small: 110 × 50 × 35 Medium: 180 × 70 × 50 Large: 240 × 120 × 60 | 2.80 | 0.04 |

| Sample | Materials | |||

|---|---|---|---|---|

| Cement | Aggregate | Addition | Admixture | |

| c | s | b | r | |

| M 01 | --- | --- | BS | --- |

| M 02 | CEM II | --- | --- | sp |

| M 03 | CEM II | AS | --- | sp |

| M 04 | CEM II | --- | BS | sp |

| Sample | Mix Proportions | ||||

|---|---|---|---|---|---|

| s/c | b/c | w/b | w/c | r/c | |

| --- | --- | 4 | --- | --- | |

| M 01 | --- | --- | --- | 0.25 | 0.02 |

| M 02 | 2 | --- | --- | 0.45 | 0.02 |

| M 03 | --- | 0.20 | --- | 0.52 | 0.02 |

| M 04 | |||||

| Standard Samples | λexp [W/m∙K] | |||||

|---|---|---|---|---|---|---|

| Sample | λref [W/m∙K] | Size [mm] | Electrical Current Heating Power per Unit Length | |||

| 0.5 A 6 W/m | 1 A 25 W/m | 1.5 A 56 W/m | 2 A 100 W/m | |||

| Skamol SM-65 | 0.13 | 110 × 50 × 35 | 0.13 | 0.13 | 0.14 | 0.14 |

| Macizo M5R | 0.70 | 110 × 50 × 35 | 0.75 | 0.68 | 0.67 | 0.67 |

| 180 × 70 × 50 | 0.64 | 0.75 | 0.73 | 0.69 | ||

| 240 × 120 × 60 | 0.65 | 0.66 | 0.70 | 0.65 | ||

| MAXIAL 310 | 1.20 | 180 × 70 × 50 | 0.90 | 1.23 | 1.23 | 1.25 |

| CN-90BA | 2.80 | 110 × 50 × 35 | 1.67 | 2.03 | 2.74 | 2.97 |

| 180 × 70 × 50 | 3.91 | 2.05 | 2.93 | 2.85 | ||

| 240 × 120 × 60 | 3.48 | 3.52 | 2.97 | 2.76 | ||

| λ [W/m∙K] | Sample Minimum Size [mm] |

|---|---|

| <0.70 | 110 × 50 × 35 |

| ≥0.70 | 180 × 70 × 50 |

| λ [W/m∙K] | Appropriate Electrical Current [A] |

| <0.70 | 0.5/1 |

| 0.70–1.20 | 1/1.5/2 |

| >1.20 | 1.5/2 |

| Sample | λLiterature [W/m∙K] | λQTM-F1 [W/m∙K] | λTCMA [W/m∙K] | λTCMA | |

|---|---|---|---|---|---|

| Deviation to λLiterature | Deviation to λQTM-F1 | ||||

| M 01 | 0.70 | 0.71 | 0.70 | 0% | −1% |

| M 02 | 0.80 | 0.79 | 0.82 | +3% | +4% |

| M 03 | 1.53 | 1.63 | 1.58 | +3% | −3% |

| M 04 | 0.80 | 0.84 | 0.81 | +1% | −4% |

| TCMA | |||||

|---|---|---|---|---|---|

| [W/m·K] | (%) | ||||

| Standard Samples | sc | Relative Precision | Relative Accuracy | ||

| Skamol SM-65 | 0.13 | 0.007 | 0.00 | 5 | 0 |

| Macizo M5R | 0.72 | 0.034 | −0.02 | 5 | 3 |

| MAXIAL 310 | 1.24 | 0.034 | −0.04 | 3 | 3 |

| CN-90BA | 2.87 | 0.077 | −0.07 | 3 | 3 |

| Method | THW |

|---|---|

| Range | 0.13–2.80 W/m∙K |

| Samples minimum size | (110 × 50 × 35) mm3 (≤0.70 W/m∙K) (180 × 70 × 50) mm3 (>0.70 W/m∙K) |

| Material for testing | Solid dielectric materials |

| Relative accuracy | 3% |

| Relative precision | 5% |

| Test duration | <15 min |

| Hot wire material | Nichrome |

| Hot wire length | Variable: (0–510) mm |

| Hot wire diameter | 0.2 mm |

| Power supply amperage | (0–3) A |

| Temperature sensor | K-type thermocouple |

| Temperature sensor diameter | 0.1 mm |

| Distance hot wire–temperature sensor | 1 mm |

| Dimensions | 600 × 500 × 260 mm |

| Weight | 10 kg |

| Operating Environment | (0–45) °C and (30–80)% RH |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Castán-Fernández, C.; Marcos-Robredo, G.; Castro-García, M.P.; Rey-Ronco, M.A.; Alonso-Sánchez, T. Apparatus Development for the Measurement of the Thermal Conductivity of Geothermal Backfill Materials. Inventions 2023, 8, 30. https://doi.org/10.3390/inventions8010030

Castán-Fernández C, Marcos-Robredo G, Castro-García MP, Rey-Ronco MA, Alonso-Sánchez T. Apparatus Development for the Measurement of the Thermal Conductivity of Geothermal Backfill Materials. Inventions. 2023; 8(1):30. https://doi.org/10.3390/inventions8010030

Chicago/Turabian StyleCastán-Fernández, C., G. Marcos-Robredo, M. P. Castro-García, M. A. Rey-Ronco, and T. Alonso-Sánchez. 2023. "Apparatus Development for the Measurement of the Thermal Conductivity of Geothermal Backfill Materials" Inventions 8, no. 1: 30. https://doi.org/10.3390/inventions8010030

APA StyleCastán-Fernández, C., Marcos-Robredo, G., Castro-García, M. P., Rey-Ronco, M. A., & Alonso-Sánchez, T. (2023). Apparatus Development for the Measurement of the Thermal Conductivity of Geothermal Backfill Materials. Inventions, 8(1), 30. https://doi.org/10.3390/inventions8010030