Automatically Monitoring, Controlling, and Reporting Status/Data for Multiple Product Life Test Stands

Abstract

:1. Background

2. Materials and Methods

3. Results

3.1. Life Test Durations

Number of Life Test Cycles = Product field life number of year(s) × 1.5 duration factor × Number of cycles/year

3.2. Implementations

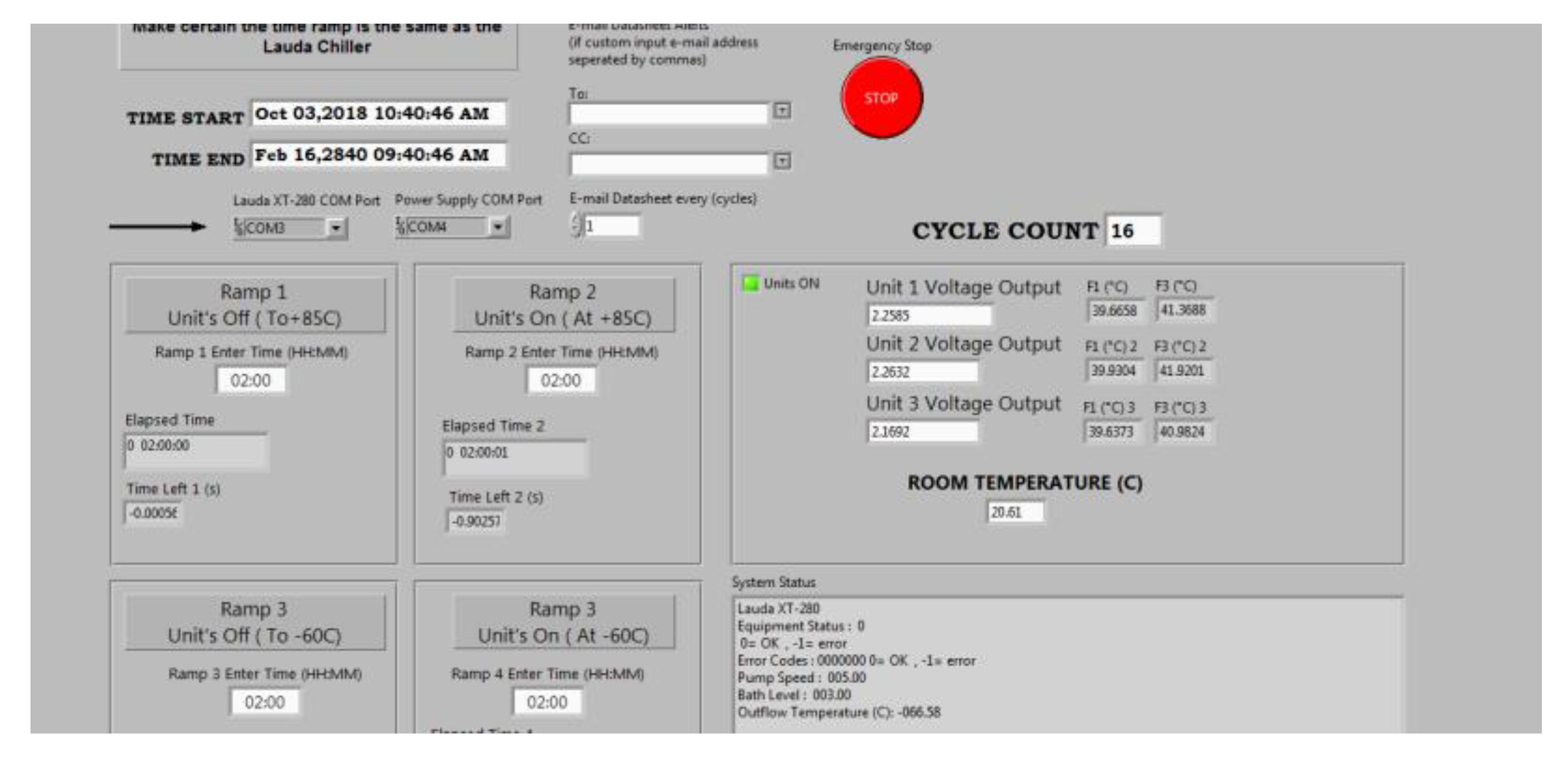

3.2.1. Multiple, Simultaneous Test Protocols on the Same Equipment

3.2.2. Fluid Level & Purity

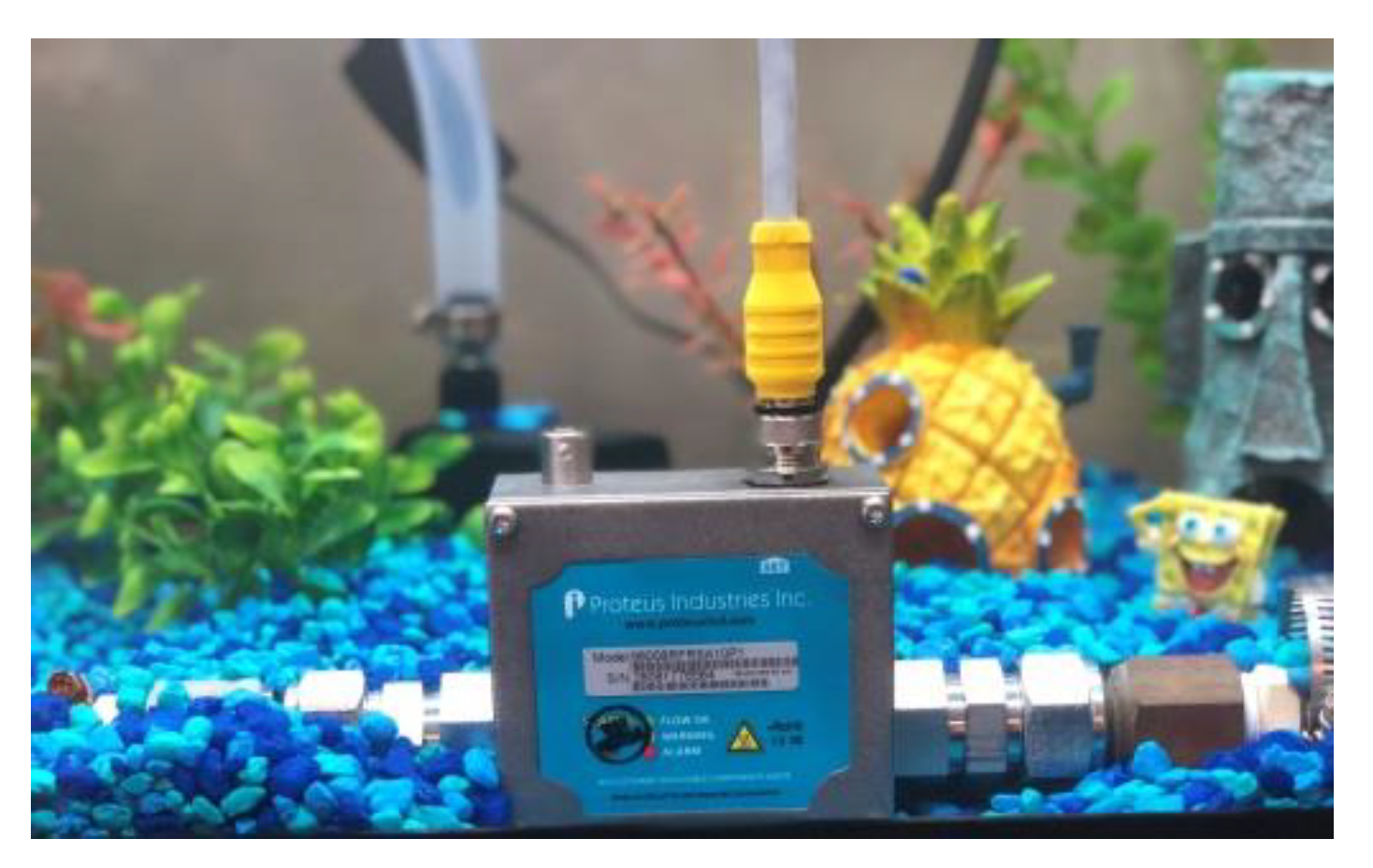

Fluid Level

Purity

3.2.3. Monitoring

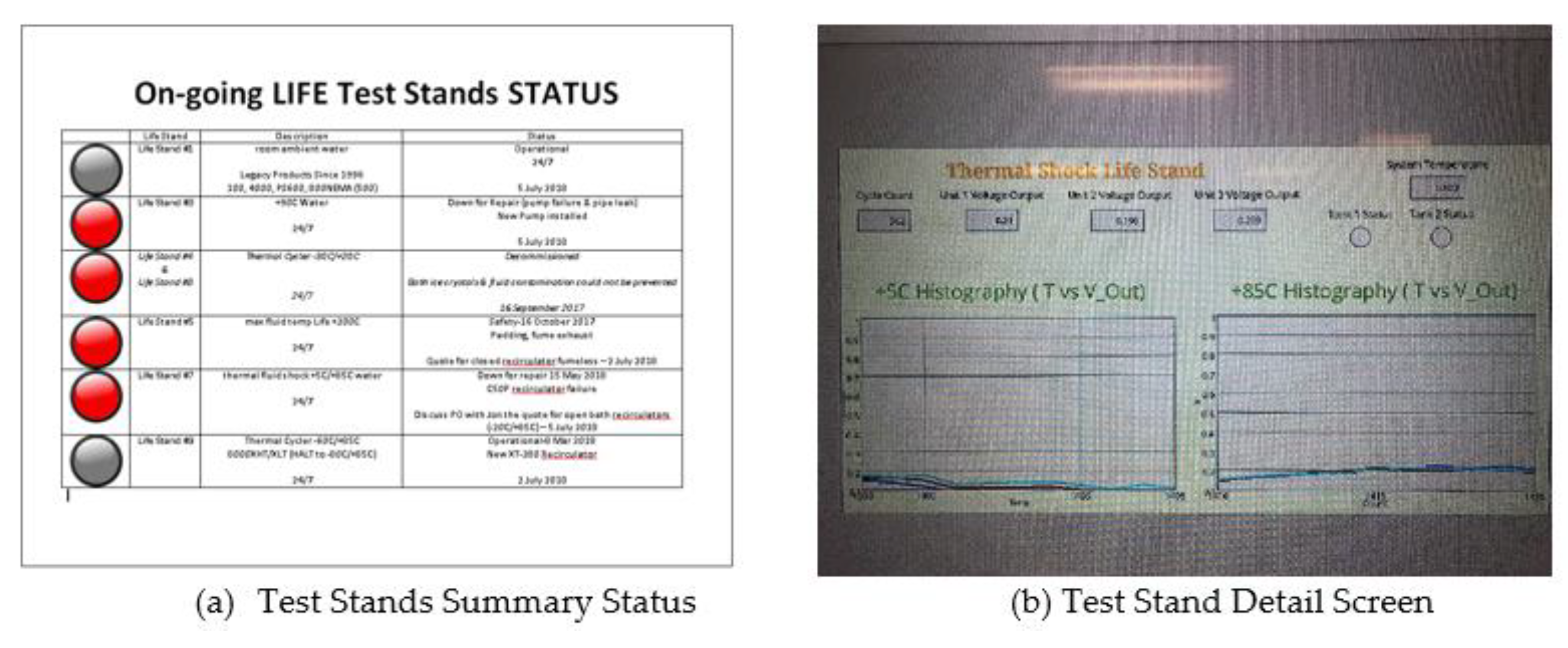

Executive Summary and Individual Summary

Local Monitoring and Control Status

4. Discussion

4.1. Efficient Use of Resources, Local Monitoring, and Control for Safety at Product Testing Stands

4.2. Inter-Relationship Between Tests, Product Reliability Estimations, and Customer Applications

4.3. Possible Solutions to Test Specification Issues

4.4. Remote Automation Monitoring for Status and Safety

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- National Electrical Manufacturers Association. NEMA 250-2014; Enclosures for Electrical Equipment (1000 Volts Maximum); National Electrical Manufacturers Association: Rosslyn, VA, USA, 2014. [Google Scholar]

- International Electrotechnical Commission. IEC 60529; Degrees of Protection Provided; International Electrotechnical Commission: Geneva, Switzerland, 2001. [Google Scholar]

- University of Wisconsin-Madison College of Engineering, Plasma Etching Outline. Available online: https://wcam.engr.wisc.edu/Public/Reference/PlasmaEtch/Etching.pdf (accessed on 19 September 2018).

- Lifetime Reliability Solutions | World Class Reliability. Available online: http://www.lifetime-reliability.com/tutorials/reliability-engineering/Do_Timeline_Before_Weibull_Analysis.pdf (accessed on 6 November 2018).

- MTBF and Product Reliability. Available online: https://ftp.automationdirect.com/pub/Product%20Reliability%20and%20MTBF.pdf (accessed on 10 November 2018).

- A Closer Look at MTBF, Reliability, and Life Expectancy. Available online: https://www.cui.com/blog/mtbf-reliability-and-life-expectancy (accessed on 10 November 2018).

- Reliability Prediction Basics. Available online: http://www.reliabilityeducation.com/ReliabilityPredictionBasics.pdf (accessed on 10 November 2018).

- Mean Time Between Failures. Available online: https://en.wikipedia.org/wiki/Mean_time_between_failures (accessed on 10 November 2018).

- Evaluating FMEA, FMECA and FMEDA. Available online: https://www.controlglobal.com/articles/2018/evaluating-fmea-fmeca-and-fmeda/ (accessed on 7 November 2018).

- International Electrotechnical Commission. IEC 60812; Analysis Techniques for System Reliability—Procedure for Failure Mode and Effects Analysis (FMEA); International Electrotechnical Commission: Geneva, Switzerland, 2006. [Google Scholar]

- International Electrotechnical Commission. IEC 61010-1; Safety Requirements for Electrical Equipment for Measurement, Control, and Laboratory Use—Part 1: General Requirements; Edition 3.1 2017-01 Document; International Electrotechnical Commission: Geneva, Switzerland, 2017. [Google Scholar]

- Factor of Safety. Available online: https://en.wikipedia.org/wiki/Factor_of_safety (accessed on 7 November 2018).

- National Instruments, Data Dashboard Update Rates. Available online: http://digital.ni.com/public.nsf/allkb/DF058CF63BC25E29862579EB0062E828 (accessed on 5 October 2018).

- Shi, Y.; Liang, X.; Yuan, B.; Chen, V.; Li, H.; Hui, F.; Yu, Z.; Yuan, F.; Pop, E.; Wong, H.-S.P.; Lanza, M. Electronic synapses made of layered two-dimensional materials. Nat. Electron. 2018, 1, 458–465. [Google Scholar] [CrossRef]

- Knowling, G.; Foster, J. Low Temperature Etching of Silicon Nitride Structures Using Phosphoric Acid Solutions. U.S. Patent 8716146 B2, 6 May 2014. [Google Scholar]

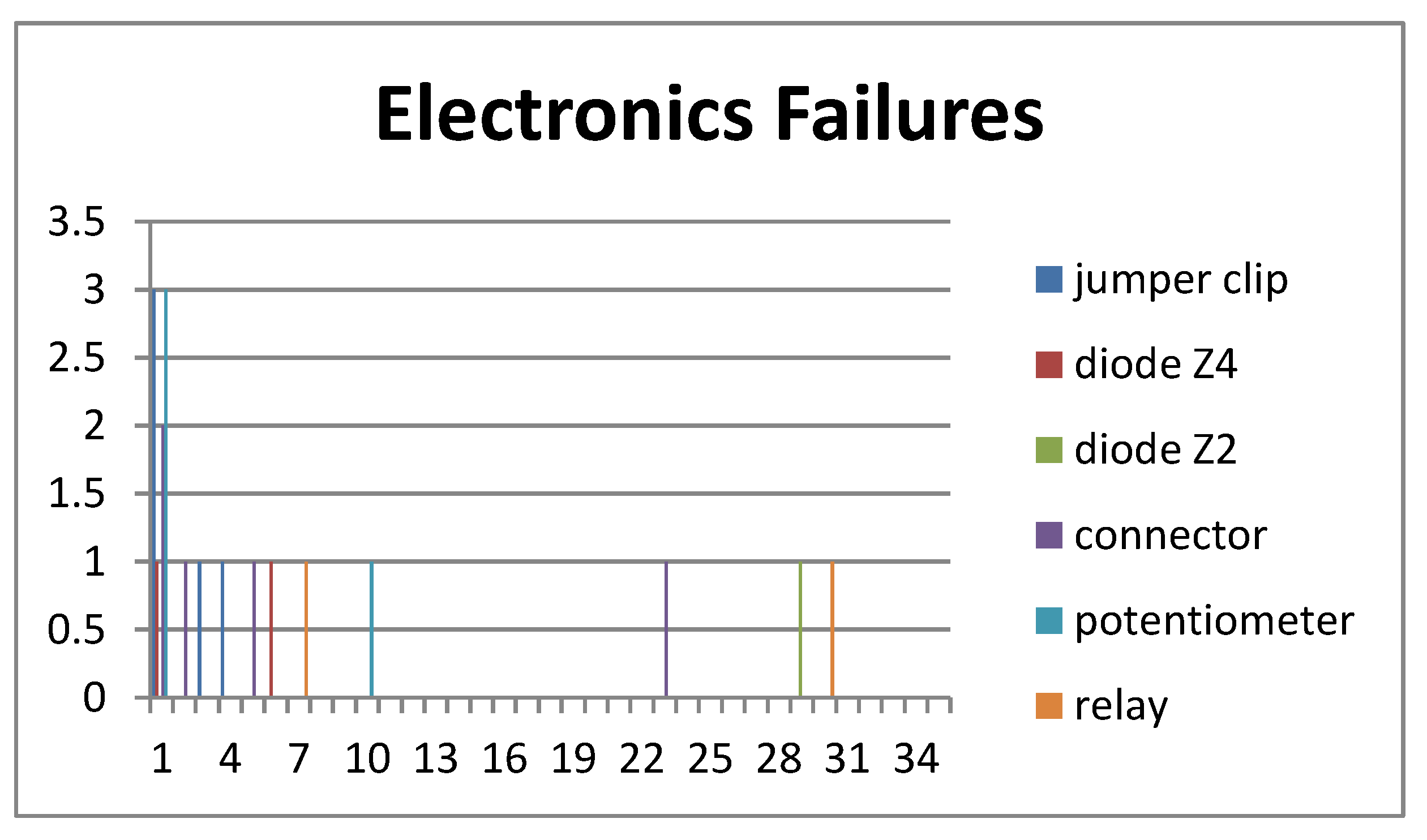

| Electronics | Jumper Clip | Diode Z4 | Diode Z2 | Connector | Potentiometer | Relay | Total |

|---|---|---|---|---|---|---|---|

| Number of failures | 5 | 2 | 1 | 5 | 4 | 2 | 19 |

| Number of failures/72 units | 0.069444444 | 0.027778 | 0.013889 | 0.069444444 | 0.055555556 | 0.027778 | 0.263889 |

| Failures per unit/78,840 h in field | 8.80828 × 10−7 | 3.52 × 10−7 | 1.76 × 10−7 | 8.80828 × 10−7 | 7.04662 × 10−7 | 3.52 × 10−7 | 3.35 × 10−6 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fertell, R.; Ershad, H. Automatically Monitoring, Controlling, and Reporting Status/Data for Multiple Product Life Test Stands. Inventions 2019, 4, 7. https://doi.org/10.3390/inventions4010007

Fertell R, Ershad H. Automatically Monitoring, Controlling, and Reporting Status/Data for Multiple Product Life Test Stands. Inventions. 2019; 4(1):7. https://doi.org/10.3390/inventions4010007

Chicago/Turabian StyleFertell, Richard, and Hamed Ershad. 2019. "Automatically Monitoring, Controlling, and Reporting Status/Data for Multiple Product Life Test Stands" Inventions 4, no. 1: 7. https://doi.org/10.3390/inventions4010007

APA StyleFertell, R., & Ershad, H. (2019). Automatically Monitoring, Controlling, and Reporting Status/Data for Multiple Product Life Test Stands. Inventions, 4(1), 7. https://doi.org/10.3390/inventions4010007