The 5W’s for Control as Part of Industry 4.0: Why, What, Where, Who, and When—A PID and MPC Control Perspective

Abstract

:1. Introduction: Why

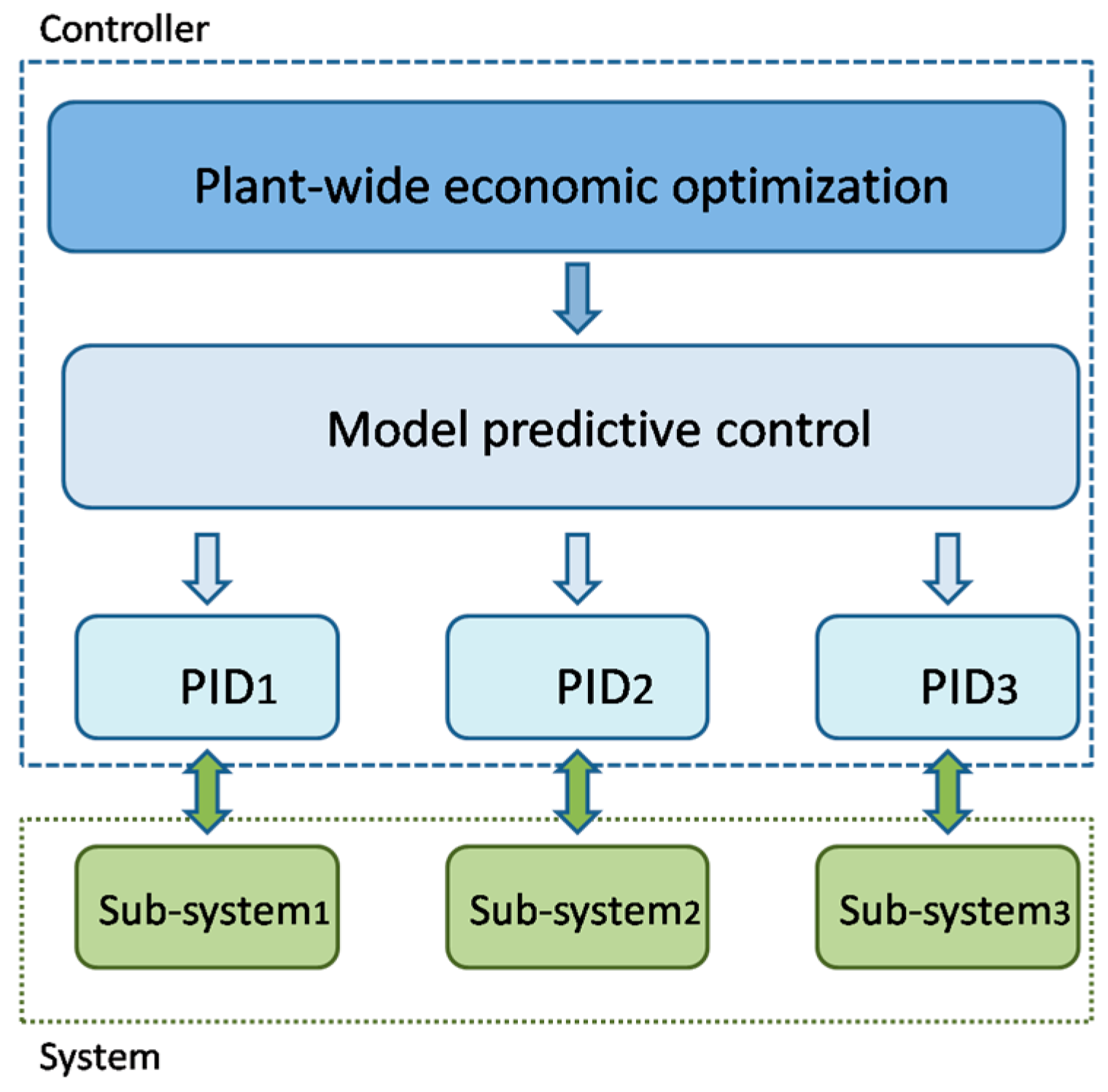

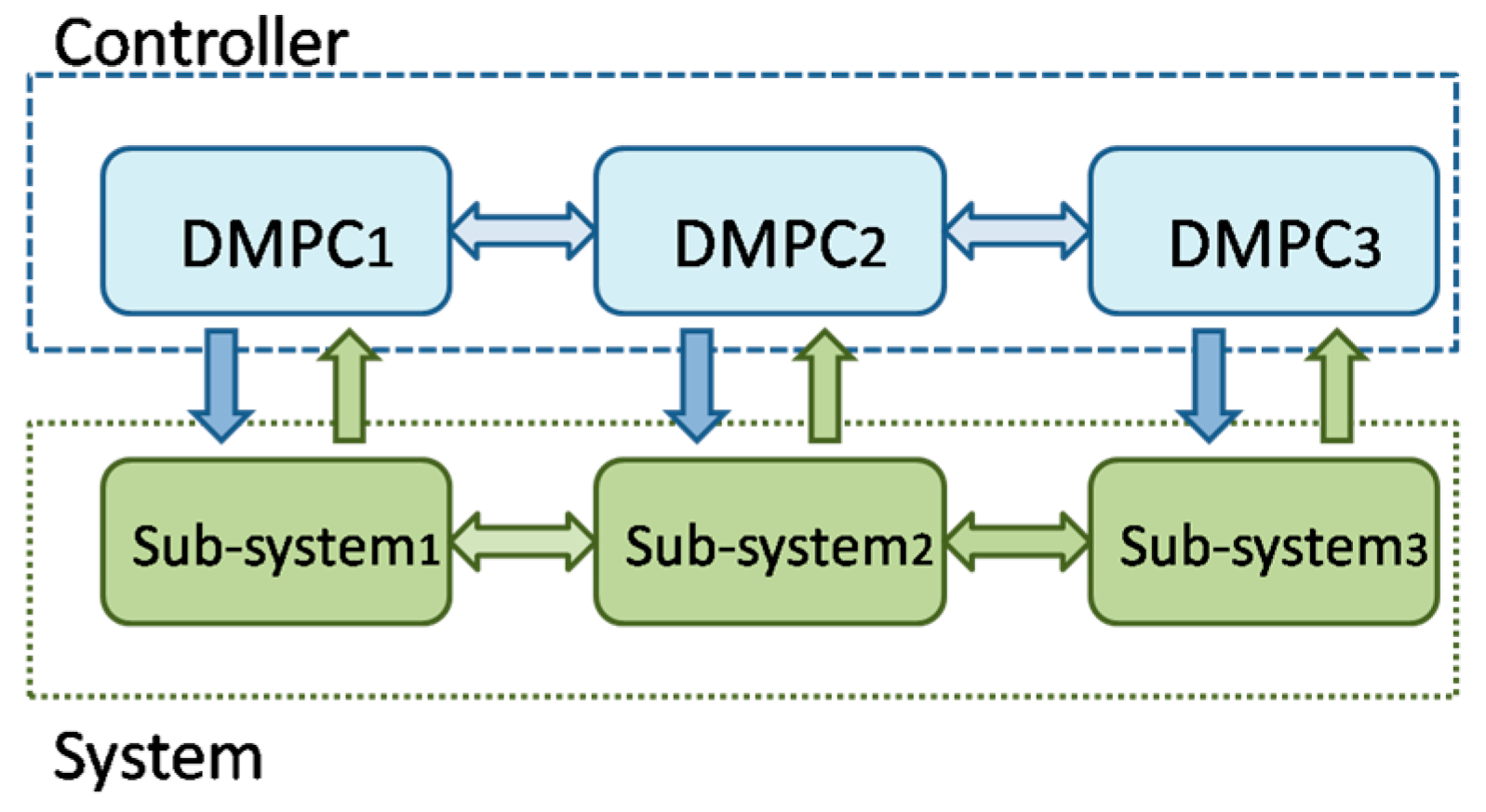

2. On the PID and MPC Control Duality: What

- System integrators have to deal with the creation of interoperable digital models in the scope of their services;

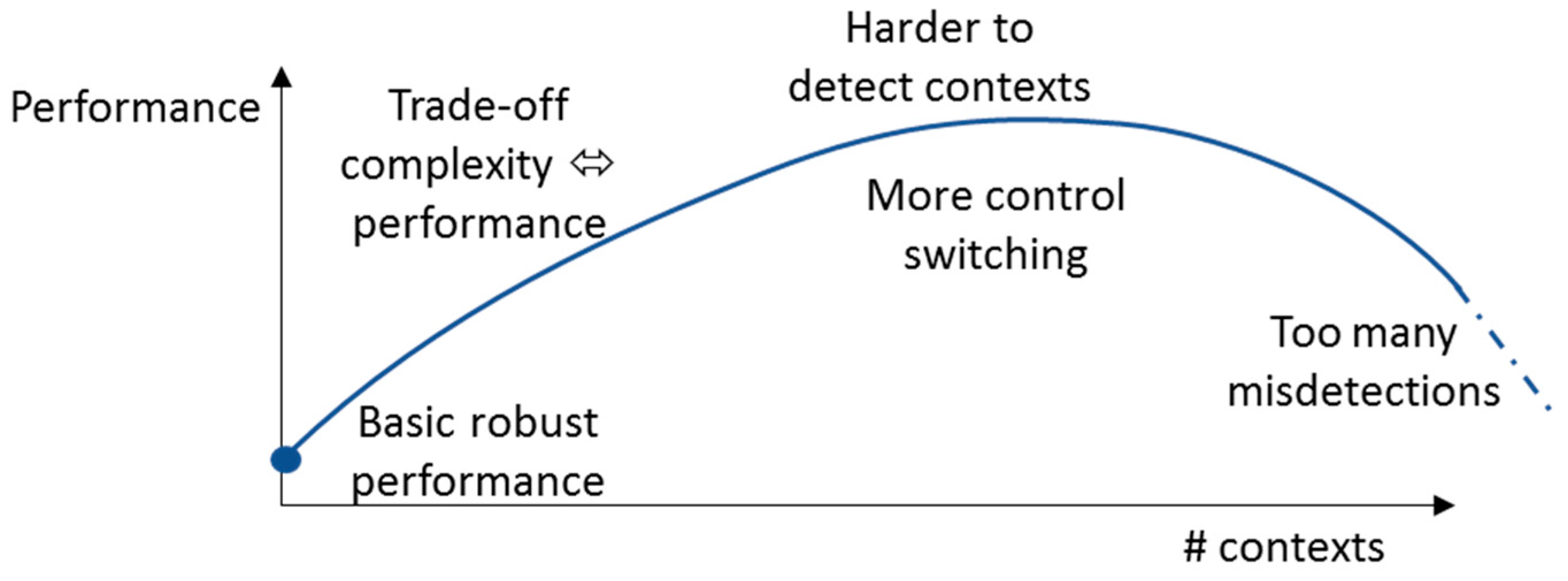

- Device manufacturers need to develop and provide digital libraries of their devices including their I4.0 interfaces;

- Plant operators need to demand the use of standardized I4.0-ready components in their call for tenders.

3. Where Can We Use These Tools?

- Organizational: controller parameter determined automatically; results to be represented as Key Performance Indicators (KPIs) for non-expert evaluation.

- Technological: truly distributed control in the form of simple, cheap control algorithms, based on multiple measurements that can communicate with each other.

- Technological: wireless communication that requires no equidistant sampling and no measurement available for extended periods of time.

- Technological: cloud storage with increased computational power available for historical data analysis as well as available and exchangeable data from other sources.

- Business drivers: increased need for auto-tuning for changing operating conditions.

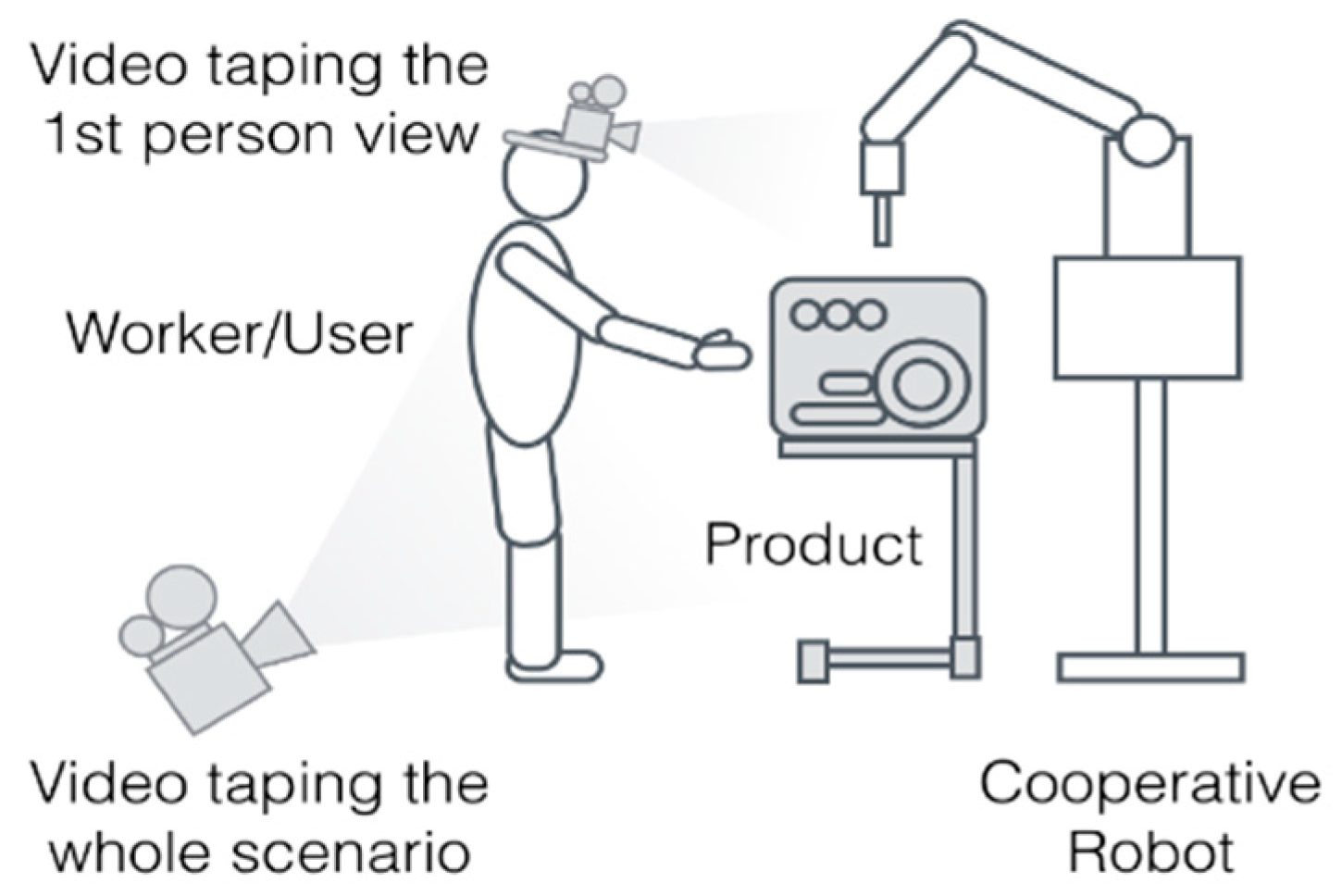

4. The Leaders and Followers: Who

- To simplify implementation by performing computationally intensive optimization offline.

- To develop tools that are generic and can be used for many different types of controllers.

- To develop controllers that adapt to variations in context; however, we cannot assume in advance that we know what context variables are relevant.

5. A Matter of Tuning: When

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Perez Olaya, S.S.; Wollschlaeger, M. Control as an Industrie 4.0 Component. In Proceedings of the 22nd IEEE International Conference on Emerging Technologies and Factory Automation (ETFA), Limmasol, Cyprus, 12–15 September 2017. [Google Scholar] [CrossRef]

- Leva, A. PID-based controls in computing systems: a brief survey and some research directions. In Proceedings of the 3rd IFAC Conference on Advances in Proportional-Integral-Derivative Control, Ghent, Belgium, 9–11 May 2018; pp. 805–810. [Google Scholar]

- Tepljakov, A.; Alagoz, B.B.; Yeroglu, C.; Gonzalez, E.; HosseinNia, S.H.; Petlenkov, E. FOPID controllers and their industrial applications: a survey of recent results. In Proceedings of the 3rd IFAC Conference on Advances in Proportional-Integral-Derivative Control, Ghent, Belgium, 9–11 May 2018; pp. 25–30. [Google Scholar]

- Samad, T. A survey on industry impact and challenges thereof. IEEE Control Syst. Mag. 2017, 37, 17–18. [Google Scholar] [CrossRef]

- Åström, K.; Hägglund, T. Advanced PID Control; ISA: Fort Belvoir, VI, USA, 2006; ISBN 9781556179426. [Google Scholar]

- Skilton, M.; Hovsepian, F. The 4th Industrial Revolution; Palgrave Macmillan: Basingstoke, UK; Springer Nature: Basingstoke, UK, 2018; ISBN 9783319624785. [Google Scholar]

- Alfaro, V.M.; Vilanova, R. Model-Reference Robust Tuning of PID Controllers; Advances in Industrial Control; Springer International Publishing: Basel, Switzerland, 2016; ISBN 9873319282114. [Google Scholar]

- Johnson, M.; Moradi, M. PID Control; Springer: London, UK, 2005; ISBN 9781852337025. [Google Scholar]

- Visioli, A. Practical PID Control; Advances in Industrial Control; Springer: London, UK, 2006; ISBN 9781846285851. [Google Scholar]

- Boiko, I. Non-Parametric Tuning of PID Controllers: A Modified Relay-Feedback Test Approach; Advances in Industrial Control; Springer: London, UK, 2013; ISBN 9781447144649. [Google Scholar]

- Wang, Q.-G.; Ye, Z.; Cai, W.-J.; Hang, C.-C. PID Control for Multivariable Processes; Lecture Notes in Control and Information Sciences 373; Springer: Berlin/Heidelberg, Germany, 2008; ISBN 9783540784814. [Google Scholar]

- Kinoshita, T.; Yamamoto, T. Design of a data-oriented PID controller for a two degree of freedom control system. In Proceedings of the 3rd IFAC Conference on Advances in Proportional-Integral-Derivative Control, Ghent, Belgium, 9–11 May 2018; pp. 412–415. [Google Scholar]

- Hägglund, T.; Guzman, J.L. Development of basic process control structures. In Proceedings of the 3rd IFAC Conference on Advances in Proportional-Integral-Derivative Control, Ghent, Belgium, 9–11 May 2018; pp. 775–780. [Google Scholar]

- Grimholt, C.; Skogestad, S. Should we forget the Smith Predictor? In Proceedings of the 3rd IFAC Conference on Advances in Proportional-Integral-Derivative Control, Ghent, Belgium, 9–11 May 2018; pp. 769–774. [Google Scholar]

- Papadopoulos, K. PID Controller Tuning Using the Magnitude Optimum Criterion; Springer International Publishing: Basel, Switzerland, 2015; ISBN 9783319072623. [Google Scholar]

- Bauer, M.; Auret, L.; le Roux, D.; Aharonson, V. An industrial PID data repository for control loop performance monitoring (CPM). In Proceedings of the 3rd IFAC Conference on Advances in Proportional-Integral-Derivative Control, Ghent, Belgium, 9–11 May 2018; pp. 823–828. [Google Scholar]

- Dietrich, S.; May, G.; Wetter, O.; Heeren, H.; Fohler, G. Performance indicators and use case analysis for wireless networks in factory automation. In Proceedings of the 22nd IEEE International Conference on Emerging Technologies and Factory Automation (ETFA), Limmasol, Cyprus, 12–15 September 2017. [Google Scholar] [CrossRef]

- Alagoz, B.; Tepljakov, A.; Yeroglu, C.; Gonzalez, E.; HosseinNia, H.; Petlenkov, E. A numerical study for plant-independent evaluation of fractional-order PID controller performance. In Proceedings of the 3rd IFAC Conference on Advances in Proportional-Integral-Derivative Control, Ghent, Belgium, 9–11 May 2018; pp. 539–544. [Google Scholar]

- Monje, C.A.; Chen, Y.Q.; Vinagre, B.M.; Xue, D.; Feliu, V. Fractional-Order Systems and Controls; Advances in Industrial Control Series; Springer: London, UK, 2010; ISBN 9781849963343. [Google Scholar]

- Padula, F.; Visioli, A. Advances in Robust Fractional Control; Springer International Publishing: Basel, Switzerland, 2015; ISBN 9783319109299. [Google Scholar]

- Ito, S.; Sato, T.; Araki, N.; Konishi, Y. Two-loop design for dual-rate cascade system. In Proceedings of the 3rd IFAC Conference on Advances in Proportional-Integral-Derivative Control, Ghent, Belgium, 9–11 May 2018; pp. 581–585. [Google Scholar]

- Kurokawa, R.; Sato, T.; Vilanova, R.; Konishi, Y. Closed-loop data-driven trade-off PID control design. In Proceedings of the 3rd IFAC Conference on Advances in Proportional-Integral-Derivative Control, Ghent, Belgium, 9–11 May 2018; pp. 244–249. [Google Scholar]

- Wagner, C.; Grothoff, J.; Epple, U.; Drath, R.; Malakuti, S.; Grüner, S.; Hoffmeister, M.; Zimmerman, P. Performance indicators and use case analysis for wireless networks in factory automation. In Proceedings of the 22nd IEEE International Conference on Emerging Technologies and Factory Automation (ETFA), Limmasol, Cyprus, 12–15 September 2017. [Google Scholar] [CrossRef]

- Qin, S.J.; Badgwell, T.A. A survey of industrial model predictive control technology. Control Eng. Pract. 2003, 11, 733–764. [Google Scholar] [CrossRef]

- Scattolini, R. Architectures for distributed and hierarchical Model Predictive Control—A review. J. Process Control 2009, 19, 723–731. [Google Scholar] [CrossRef]

- Brdys, M.A.; Grochowski, M.; Gminski, T.; Konarczak, K.; Drewa, K. Hierarchical predictive control of integrated wastewater treatment systems. Control Eng. Pract. 2008, 16, 751–767. [Google Scholar] [CrossRef]

- Tatjewski, P. Advanced control and on-line process optimization in multilayer structures. Annu. Rev. Control 2008, 32, 71–85. [Google Scholar] [CrossRef]

- Rawlings, J.B.; Stewart, B.T. Coordinating multiple optimization-based controllers: New opportunities and challenges. J. Process Control 2008, 18, 839–847. [Google Scholar] [CrossRef]

- Christofides, P.D.; Scattolini, R.; Muñoz de la Peña, D.; Liu, J. Distributed model predictive control: A tutorial review and future directions. Comput. Chem. Eng. 2013, 51, 21–41. [Google Scholar]

- Maestre, J.M.; Negenborn, R.R. Distributed Model Predictive Control Made Easy; Intelligent Systems, Control and Automation: Science and Engineering; Springer: Dordrecht, The Netherlands; Heidelberg, Germany; New York, NY, USA; London, UK, 2014; Volume 69, ISBN 9789400770058. [Google Scholar]

- Chilin, D.; Liu, J.; Davis, J.F.; Christofides, P.D. Data-based monitoring and reconfiguration of a distributed model predictive control system. Int. J. Robust Nonlinear 2012, 22, 68–88. [Google Scholar] [CrossRef]

- Bauer, M.; Schlake, J.C. Changes to the automation architecture. In Proceedings of the 22nd IEEE International Conference on Emerging Technologies and Factory Automation (ETFA), Limmasol, Cyprus, 12–15 September 2017. [Google Scholar] [CrossRef]

- Schmitter, C.; Ma, Z.; Ruprechter, T.; Aldrian, A. Practical safe, secure and reliable machine-to-machine connectivity for cyber-physical-production systems. In Proceedings of the 22nd IEEE International Conference on Emerging Technologies and Factory Automation (ETFA), Limmasol, Cyprus, 12–15 September 2017. [Google Scholar] [CrossRef]

- Ustundag, A.; Cevikcan, E. Industry 4.0: Managing the Digital Transformation; Springer Series in Advanced Manufracturing; Springer International Publishing: Basel, Switzerland, 2018; ISBN 9783319578699. [Google Scholar]

- Thames, L.; Schaefer, D. Cybersecurity for Industry 4.0, Analysis for Design and Manufacturing; Springer Series in Advanced Manufacturing; Springer International Publishing AG: Basel, Switzerland, 2017; ISBN 9783319506593. [Google Scholar]

- Villani, V.; Sabattini, L.; Czerniak, J.N.; Mertens, A.; Vogel-Heuser, B.; Fantuzzi, C. Towards modern inclusive factories: a methodology for the development of smart adaptive human-machine interfaces. In Proceedings of the 22nd IEEE International Conference on Emerging Technologies and Factory Automation (ETFA), Limmasol, Cyprus, 12–15 September 2017. [Google Scholar] [CrossRef]

- Dorofeev, K.; Cheng, C.H.; Guedes, M.; Ferreira, P.; Profanter, S.; Zoitl, A. Device adapter concept towards enabling plug & produce production environments. In Proceedings of the 22nd IEEE International Conference on Emerging Technologies and Factory Automation (ETFA), Limmasol, Cyprus, 12–15 September 2017. [Google Scholar] [CrossRef]

- Eisenmenger, W.; Meßmer, J.; Wenger, M.; Zoitl, A. Increasing control application reusability through generic device configuration model. In Proceedings of the 22nd IEEE International Conference on Emerging Technologies and Factory Automation (ETFA), Limmasol, Cyprus, 12–15 September 2017. [Google Scholar] [CrossRef]

- Ericsson, N.; Lennvall, T.; Åkerberg, J.; Björkman, M. Custom simulation of industrial wireless sensor and actuator network for improved efficiency during research and development. In Proceedings of the 22nd IEEE International Conference on Emerging Technologies and Factory Automation (ETFA), Limmasol, Cyprus, 12–15 September 2017. [Google Scholar] [CrossRef]

- Brusa, E.; Cala, A.; Ferretto, D. Systems Engineering and Its Application to Industrial Product Development; Studies in Systems, Decision and Control 134; Springer International Publishing AG: Basel, Switzerland, 2018; ISBN 9783319718361. [Google Scholar]

- Bihani, P.; Drath, R. Concept for AutomationML-based interoperability between multiple independent engineering tools without semantic harmonization. In Proceedings of the 22nd IEEE International Conference on Emerging Technologies and Factory Automation (ETFA), Limmasol, Cyprus, 12–15 September 2017. [Google Scholar] [CrossRef]

- Gutermuth, G.; Hoernicke, M. Automatic generation of plant topologies by analyzing operations data. In Proceedings of the 22nd IEEE International Conference on Emerging Technologies and Factory Automation (ETFA), Limmasol, Cyprus, 12–15 September 2017. [Google Scholar] [CrossRef]

- Amaro, A.; Nixon, M. Towards IEC62439-3: Implementing Linux based (ZHAW-InES) PRP stack with non-PRP passthrough on Ethernet networks in QNX. In Proceedings of the 22nd IEEE International Conference on Emerging Technologies and Factory Automation (ETFA), Limmasol, Cyprus, 12–15 September 2017. [Google Scholar] [CrossRef]

- Rossiter, J.A. Evaluation of student software tools for supporting an understanding of PID tuning. In Proceedings of the 3rd IFAC Conference on Advances in Proportional-Integral-Derivative Control, Ghent, Belgium, 9–11 May 2018; pp. 322–327. [Google Scholar]

- Rossiter, J.A. A First Course in Predictive Control, 2nd ed.; CRC Press: London, UK, 2018; ISBN 9781138099340. [Google Scholar]

- Wang, L. Model Predictive Control System Design and Implementation Using MATLAB®; Advances in Industrial Control Series; Springer: London, UK, 2009; ISBN 9781848823303. [Google Scholar]

- Kouvaritakis, B.; Cannon, M. Model Predictive Control, Advanced Textbooks in Control and Signal Processing; Springer International Publishing: Basel, Switzerland, 2016; ISBN 9783319248516. [Google Scholar]

- Bauer, M.; Horch, A.; Xie, L.; Jelali, M.; Thornhill, N. The current state of control loop performance monitoring—A survey of application in industry. J. Process Control 2016, 38, 1–10. [Google Scholar] [CrossRef]

- Li, Y.; Lin, Z. Stability and Performance of Control Systems with Actuator Saturatio; Birkhäuser, Springer International Publishing AG: Basel, Switzerland, 2018; ISBN 9783319642444. [Google Scholar]

- Soltesz, K.; Cervin, A. When is PID a good choice? In Proceedings of the 3rd IFAC Conference on Advances in Proportional-Integral-Derivative Control, Ghent, Belgium, 9–11 May 2018; pp. 250–255. [Google Scholar]

- Vasquez, M.; Katebi, R. New constrained predictive PID controller for packet dropouts in wireless networked control systems. In Proceedings of the 3rd IFAC Conference on Advances in Proportional-Integral-Derivative Control, Ghent, Belgium, 9–11 May 2018; pp. 811–816. [Google Scholar]

- Liu, T.; Gao, F. Industrial Process Identification and Control Design; Step-Test and Relay-Experiment Based Methods, Advances in Industrial Control; Springer: London, UK, 2012; ISBN 9780857299765. [Google Scholar]

- Berner, J.; Soltesz, K. Short and robust experiments in relay autotuners. In Proceedings of the 22nd IEEE International Conference on Emerging Technologies and Factory Automation (ETFA), Limmasol, Cyprus, 12–15 September 2017. [Google Scholar] [CrossRef]

- Sanchez, J.; Guinaldo, M.; Visioli, A.; Dormido, S. Identification of process transfer function parameters in event-based PI control loops. ISAT 2018, 75, 157–171. [Google Scholar] [CrossRef] [PubMed]

- Sanchez, J.; Guinaldo, M.; Visioli, A.; Dormido, S. Enhanced event-based identification procedure for process control. Eng. Chem. Res. 2018, 57, 7118–7231. [Google Scholar]

- Merigo, L.; Beschi, M.; Padula, F.; Visioli, A. A noise-filtering event generator for PIDPlus controllers. J. Franklin Inst. 2018, 355, 774–802. [Google Scholar] [CrossRef]

- Monje, C.A.; Vinagre, B.M.; Feliu, V.; Chen, Y. Tuning and auto-tuning of fractional order controllers for industry applications. Control Eng. Pract. 2008, 16, 798–812. [Google Scholar]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Maxim, A.; Copot, D.; Copot, C.; Ionescu, C.M. The 5W’s for Control as Part of Industry 4.0: Why, What, Where, Who, and When—A PID and MPC Control Perspective. Inventions 2019, 4, 10. https://doi.org/10.3390/inventions4010010

Maxim A, Copot D, Copot C, Ionescu CM. The 5W’s for Control as Part of Industry 4.0: Why, What, Where, Who, and When—A PID and MPC Control Perspective. Inventions. 2019; 4(1):10. https://doi.org/10.3390/inventions4010010

Chicago/Turabian StyleMaxim, Anca, Dana Copot, Cosmin Copot, and Clara M. Ionescu. 2019. "The 5W’s for Control as Part of Industry 4.0: Why, What, Where, Who, and When—A PID and MPC Control Perspective" Inventions 4, no. 1: 10. https://doi.org/10.3390/inventions4010010

APA StyleMaxim, A., Copot, D., Copot, C., & Ionescu, C. M. (2019). The 5W’s for Control as Part of Industry 4.0: Why, What, Where, Who, and When—A PID and MPC Control Perspective. Inventions, 4(1), 10. https://doi.org/10.3390/inventions4010010