An IoT-Enabled System for Monitoring and Predicting Physicochemical Parameters in Rosé Wine Storage Process

Abstract

1. Introduction

2. Materials and Methods

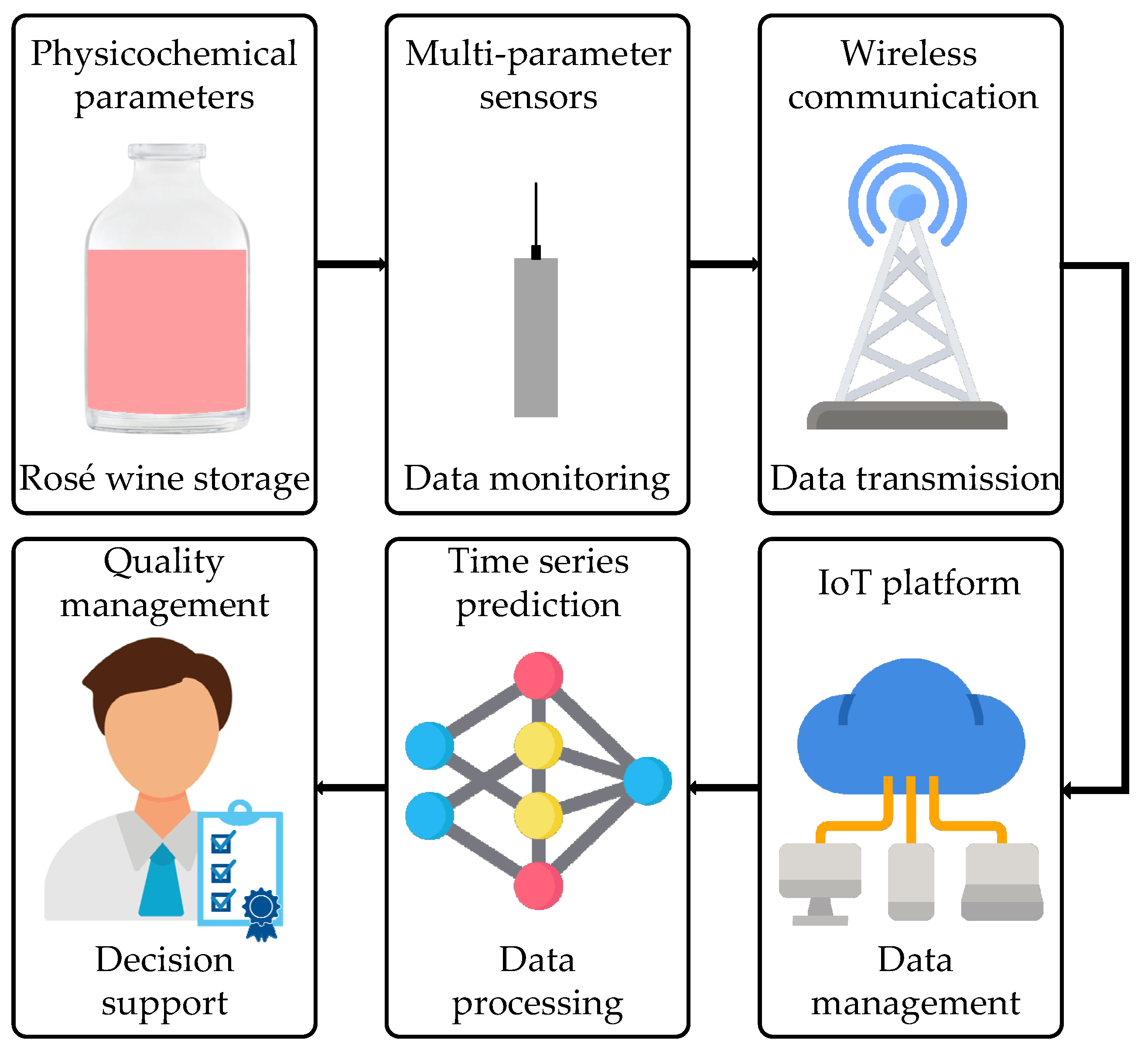

2.1. Design of the Monitoring Device for Physicochemical Parameters in Rosé Wine

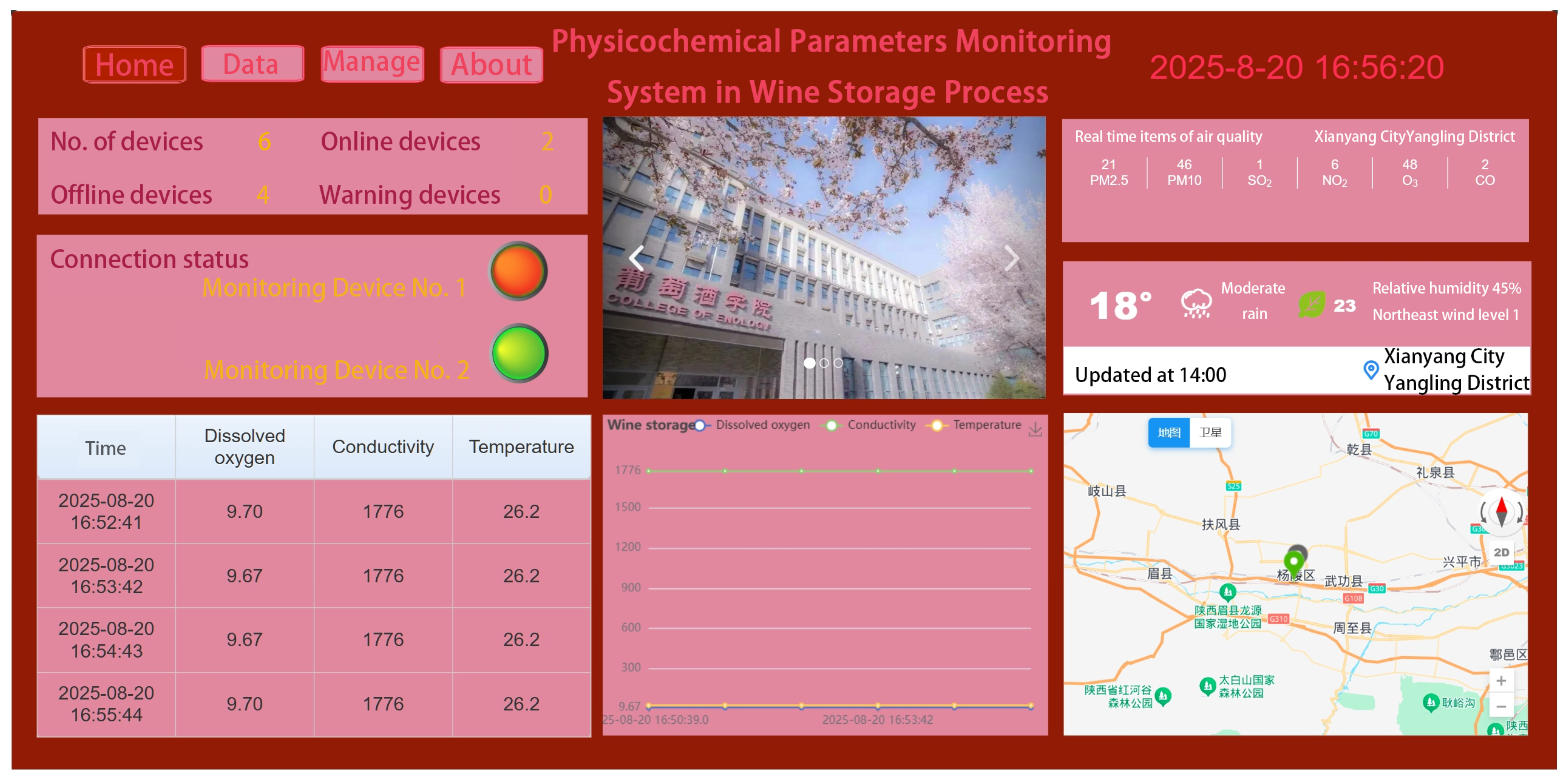

2.2. IoT Cloud Configuration Design

2.3. Monitoring Test of Physicochemical Parameters During Rosé Wine Storage

2.4. Time-Series Prediction Models

2.4.1. Data Preprocessing

2.4.2. Model Construction

2.4.3. Model Training and Evaluation Indicators

3. Results

3.1. IoT Cloud Configuration

3.2. The Changes in Physicochemical Parameters in Rosé Wine During Storage

3.3. The Time-Series Prediction Results of Physicochemical Parameters in Rosé Wine Based on Deep Learning Models

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| IoT | Internet of Things |

| LSTM | Long Short-Term Memory |

| GRU | Gated Recurrent Unit |

| TCN | Temporal Convolutional Networks |

| RNN | Recurrent Neural Network |

| DTU | Data Transfer Unit |

| MSE | Mean Squared Error |

| Coefficient of Determination for the Training Set | |

| Coefficient of Determination for the Test Set | |

| Root Mean Square Error for Training Set | |

| Root Mean Square Error for Test Set | |

| eSIM | Embedded Subscriber Identity Module |

| 4G | 4th-generation |

| ARIMA | AutoRegressive Integrated Moving Average |

Appendix A

References

- Iazzi, A.; Scorrano, P.; Rosato, P.; Grandhi, B. Millennial generation preferences for rosé wine. Br. Food J. 2019, 122, 2443–2461. [Google Scholar] [CrossRef]

- Peres, S.; Giraud-Heraud, E.; Masure, A.; Tempere, S. Rose Wine Market: Anything but Colour? Foods 2020, 9, 1850. [Google Scholar] [CrossRef] [PubMed]

- Medina-Plaza, C.; Dubois, A.; Tomasino, E.; Oberholster, A. Effect of storing conditions (lighting, temperature and bottle color) on rosé wine attributes. Food Chem. 2024, 439, 138032. [Google Scholar] [CrossRef] [PubMed]

- Benucci, I.; Cerreti, M.; Esti, M. Dosing oxygen from the early stages of white winemaking: Effect on oxidation–reduction potential, browning stability, volatile composition, and sensory properties. Food Chem. 2024, 432, 137243. [Google Scholar] [CrossRef]

- Dai, L.; Sun, Y.; Liu, M.; Cui, X.; Wang, J.; Li, J.; Han, G. Influence of Oxygen Management during the Post-Fermentation Stage on Acetaldehyde, Color, and Phenolics of Vitis vinifera L. Cv. Cabernet Sauvignon Wine. Molecules 2022, 27, 6692. [Google Scholar] [CrossRef]

- Deshaies, S.; Cazals, G.; Enjalbal, C.; Constantin, T.; Garcia, F.; Mouls, L.; Saucier, C. Red Wine Oxidation: Accelerated Ageing Tests, Possible Reaction Mechanisms and Application to Syrah Red Wines. Antioxidants 2020, 9, 663. [Google Scholar] [CrossRef]

- Bai, X.; Chen, X.; Li, X.; Tan, F.; Sam, F.E.; Tao, Y. Wine polyphenol oxidation mechanism and the effects on wine quality: A review. Compr. Rev. Food. Sci. Food Saf. 2024, 23, e70035. [Google Scholar] [CrossRef]

- Newair, E.F.; Al-Anazi, A.; Garcia, F. Oxidation of Wine Polyphenols by Electrochemical Means in the Presence of Glutathione. Antioxidants 2023, 12, 1891. [Google Scholar] [CrossRef]

- Chen, X.; Ma, Y.; Diao, T.; Leng, Y.; Lai, X.; Wei, X. Pulsed electric field technology for the manufacturing processes of wine: A review. J. Food Process Preserv. 2022, 46, e16750. [Google Scholar] [CrossRef]

- Amrita, C.M.; Babiyola, D. Analysing the water quality parameters from traditional to modern methods in aquaculture. Int. J. Sci. Environ. Technol. 2018, 7, 1954–1961. [Google Scholar]

- Di Gennaro, S.F.; Matese, A.; Mancin, M.; Primicerio, J.; Palliotti, A. An Open-Source and Low-Cost Monitoring System for Precision Enology. Sensors 2014, 14, 23388–23397. [Google Scholar] [CrossRef]

- Zhang, W.; Skouroumounis, G.; Monro, T.; Taylor, D. Distributed Wireless Monitoring System for Ullage and Temperature in Wine Barrels. Sensors 2015, 15, 19495–19506. [Google Scholar] [CrossRef] [PubMed]

- Morais, R.; Peres, E.; Boaventura-Cunha, J.; Mendes, J.; Cosme, F.; Nunes, F.M. Distributed monitoring system for precision enology of the Tawny Port wine aging process. Comput. Electron. Agric. 2018, 145, 92–104. [Google Scholar] [CrossRef]

- Zhang, Q.; Shen, Y.; Fan, X.; Yan, Y.; García Martín, J.F. Online monitoring of electrical conductivity of wine induced by ultrasound. CYTA J. Food 2016, 14, 496–501. [Google Scholar] [CrossRef]

- Liu, Z.; Zhu, Z.; Gao, J.; Xu, C. Forecast Methods for Time Series Data: A Survey. IEEE Access 2021, 9, 91896–91912. [Google Scholar] [CrossRef]

- Su, Y.; Wang, M.C.; Liu, S. Automated Machine Learning Algorithm Using Recurrent Neural Network to Perform Long-Term Time Series Forecasting. CMC-Comput. Mat. Contin. 2024, 78, 3529–3549. [Google Scholar] [CrossRef]

- Algieri, B.; Iania, L.; Leccadito, A.; Meloni, G. Message in a bottle: Forecasting wine prices. J. Wine Econ. 2024, 19, 64–91. [Google Scholar] [CrossRef]

- Li, W.; Law, K.L.E. Deep Learning Models for Time Series Forecasting: A Review. IEEE Access 2024, 12, 92306–92327. [Google Scholar] [CrossRef]

- Ahmed, D.M.; Hassan, M.M.; Mstafa, R.J. A review on deep sequential models for forecasting time series data. Appl. Comput. Intell. Soft Comput. 2022, 2022, 6596397. [Google Scholar] [CrossRef]

- Li, W.; Zhao, Y.; Zhu, Y.; Dong, Z.; Wang, F.; Huang, F. Research progress in water quality prediction based on deep learning technology: A review. Environ. Sci. Pollut. Res. 2024, 31, 26415–26431. [Google Scholar] [CrossRef]

- Wang, X.; Li, Y. Prediction of mine water quality by the Seq2Seq model based on attention mechanism. Heliyon 2024, 10, e37916. [Google Scholar] [CrossRef] [PubMed]

- Udayakumar, K.; Subiramaniyam, N.P. Deep learning-based production assists water quality warning system for reverse osmosis plants. H2Open J. 2020, 3, 538–553. [Google Scholar] [CrossRef]

- Jan, F.; Min-Allah, N.; Düştegör, D. IoT Based Smart Water Quality Monitoring: Recent Techniques, Trends and Challenges for Domestic Applications. Water 2021, 13, 1729. [Google Scholar] [CrossRef]

- Zhang, T.; Liao, Z.; Li, Z.; Liu, Y.; Liu, Y.; Song, Y.; Qin, Y. Dynamic changes in dissolved oxygen concentration, microbial communities, and volatile compounds during industrial oak-barrel fermentation of Sauvignon Blanc wine. Food Res. Int. 2024, 197, 115250. [Google Scholar] [CrossRef]

- Roussey, C.; Colin, J.; Du Cros, R.T.; Casalinho, J.; Perré, P. In-situ monitoring of wine volume, barrel mass, ullage pressure and dissolved oxygen for a better understanding of wine-barrel-cellar interactions. J. Food Eng. 2021, 291, 110233. [Google Scholar] [CrossRef]

- Giuseppina Paola, P.; Matteo, M.; Arianna, R.; Andrea, V. Effect of Different Glass Shapes and Size on the Time Course of Dissolved Oxygen in Wines during Simulated Tasting. Beverages 2018, 4, 3. [Google Scholar] [CrossRef]

- Yan, Y.; Zhang, Q.; Li, E.; Zhang, Y. Ions in Wine and Their Relation to Electrical Conductivity Under Ultrasound Irradiation. J. AOAC Int. 2017, 100, 1516–1523. [Google Scholar] [CrossRef]

- Oliveira, C.M.; Barros, A.S.; Silva Ferreira, A.C.; Silva, A.M.S. Influence of the temperature and oxygen exposure in red Port wine: A kinetic approach. Food Res. Int. 2015, 75, 337–347. [Google Scholar] [CrossRef]

- Echave, J.; Barral, M.; Fraga-Corral, M.; Prieto, M.A.; Simal-Gandara, J. Bottle Aging and Storage of Wines: A Review. Molecules 2021, 26, 713. [Google Scholar] [CrossRef]

- Shewalkar, A. Performance evaluation of deep neural networks applied to speech recognition: RNN, LSTM and GRU. J. Artif. Intell. Soft Comput. Res. 2019, 9, 235–245. [Google Scholar] [CrossRef]

- Zuo, C.; Wang, J.; Liu, M.; Deng, S.; Wang, Q. An Ensemble Framework for Short-Term Load Forecasting Based on TimesNet and TCN. Energies 2023, 16, 5330. [Google Scholar] [CrossRef]

- Zamani, M.G.; Nikoo, M.R.; Jahanshahi, S.; Barzegar, R.; Meydani, A. Forecasting water quality variable using deep learning and weighted averaging ensemble models. Environ. Sci. Pollut. Res. 2023, 30, 124316–124340. [Google Scholar] [CrossRef]

- Fu, Y.; Hu, Z.; Zhao, Y.; Huang, M. A long-term water quality prediction method based on the temporal convolutional network in smart mariculture. Water 2021, 13, 2907. [Google Scholar] [CrossRef]

| Module | Model | Size | Price (USD) |

|---|---|---|---|

| Sensor module | GD52-RS500A | 246.5 mm × Φ 44 mm | 348.00 |

| Data transmission module | DR154 DTU | 74 mm × 24 mm×22 mm | 14.60 |

| Power module | T60D | 159 mm × 97 mm × 38 mm | 6.40 |

| Parameters | Detection Range | Resolution | Accuracy | Detection Principle |

|---|---|---|---|---|

| Conductivity | 1.0~2000 μS/cm | 1 μS/cm | ±2.5%FS | Two-electrode |

| Dissolved oxygen | 0~20 mg/L | 0.01 mg/L | ± 0.4 | Ultraviolet fluorescence |

| Temperature | 0 °C~40 °C | 0.1 °C | ±0.3 °C | Thermistor |

| Parameter | LSTM | GRU | TCN |

|---|---|---|---|

| Input features | 3 | 3 | 3 |

| Time steps | 24 | 24 | 24 |

| Hidden units | 64 | 64 | 64 |

| Number of layers | 2 | 2 | 3 |

| Kernel size | - | - | 3 |

| Number of channels | - | - | [64, 64, 64] |

| Batch size | 32 | 32 | 32 |

| Learning rate | 0.001 | 0.001 | 0.001 |

| Optimizer | Adam | Adam | Adam |

| Loss function | MSE | MSE | MSE |

| Epochs | 100 | 100 | 100 |

| Early stopping patience | 12 | 12 | 12 |

| Model | Parameter | ||||

|---|---|---|---|---|---|

| LSTM | Conductivity | 0.973 | 2.489 | 0.946 | 0.718 |

| Dissolved oxygen | 0.983 | 0.102 | 0.956 | 0.012 | |

| Temperature | 0.985 | 0.167 | 0.960 | 0.045 | |

| GRU | Conductivity | 0.974 | 2.413 | 0.947 | 0.712 |

| Dissolved oxygen | 0.984 | 0.100 | 0.957 | 0.012 | |

| Temperature | 0.985 | 0.167 | 0.961 | 0.045 | |

| TCN | Conductivity | 0.977 | 2.297 | 0.951 | 0.695 |

| Dissolved oxygen | 0.988 | 0.085 | 0.964 | 0.011 | |

| Temperature | 0.990 | 0.134 | 0.966 | 0.042 | |

| ARIMA | Conductivity | 0.958 | 3.109 | 0.930 | 0.830 |

| Dissolved oxygen | 0.971 | 0.133 | 0.944 | 0.014 | |

| Temperature | 0.975 | 0.207 | 0.946 | 0.052 |

| Model | Parameter | ||||

|---|---|---|---|---|---|

| LSTM | Conductivity | 0.978 | 2.251 | 0.950 | 0.724 |

| Dissolved oxygen | 0.987 | 0.089 | 0.962 | 0.011 | |

| Temperature | 0.989 | 0.136 | 0.965 | 0.042 | |

| GRU | Conductivity | 0.979 | 2.184 | 0.951 | 0.724 |

| Dissolved oxygen | 0.989 | 0.082 | 0.963 | 0.011 | |

| Temperature | 0.990 | 0.136 | 0.965 | 0.042 | |

| TCN | Conductivity | 0.984 | 1.912 | 0.955 | 0.705 |

| Dissolved oxygen | 0.994 | 0.060 | 0.968 | 0.011 | |

| Temperature | 0.996 | 0.080 | 0.971 | 0.039 | |

| ARIMA | Conductivity | 0.965 | 2.819 | 0.936 | 0.778 |

| Dissolved oxygen | 0.977 | 0.116 | 0.948 | 0.013 | |

| Temperature | 0.979 | 0.192 | 0.951 | 0.050 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, X.; Yang, J.; Zhao, R.; Qin, Z.; Xie, Z. An IoT-Enabled System for Monitoring and Predicting Physicochemical Parameters in Rosé Wine Storage Process. Inventions 2025, 10, 84. https://doi.org/10.3390/inventions10050084

Zhang X, Yang J, Zhao R, Qin Z, Xie Z. An IoT-Enabled System for Monitoring and Predicting Physicochemical Parameters in Rosé Wine Storage Process. Inventions. 2025; 10(5):84. https://doi.org/10.3390/inventions10050084

Chicago/Turabian StyleZhang, Xu, Jihong Yang, Ruijie Zhao, Ziquan Qin, and Zhuojun Xie. 2025. "An IoT-Enabled System for Monitoring and Predicting Physicochemical Parameters in Rosé Wine Storage Process" Inventions 10, no. 5: 84. https://doi.org/10.3390/inventions10050084

APA StyleZhang, X., Yang, J., Zhao, R., Qin, Z., & Xie, Z. (2025). An IoT-Enabled System for Monitoring and Predicting Physicochemical Parameters in Rosé Wine Storage Process. Inventions, 10(5), 84. https://doi.org/10.3390/inventions10050084