Acoustic Energy Harvested Wireless Sensing for Aquaculture Monitoring

Abstract

1. Introduction

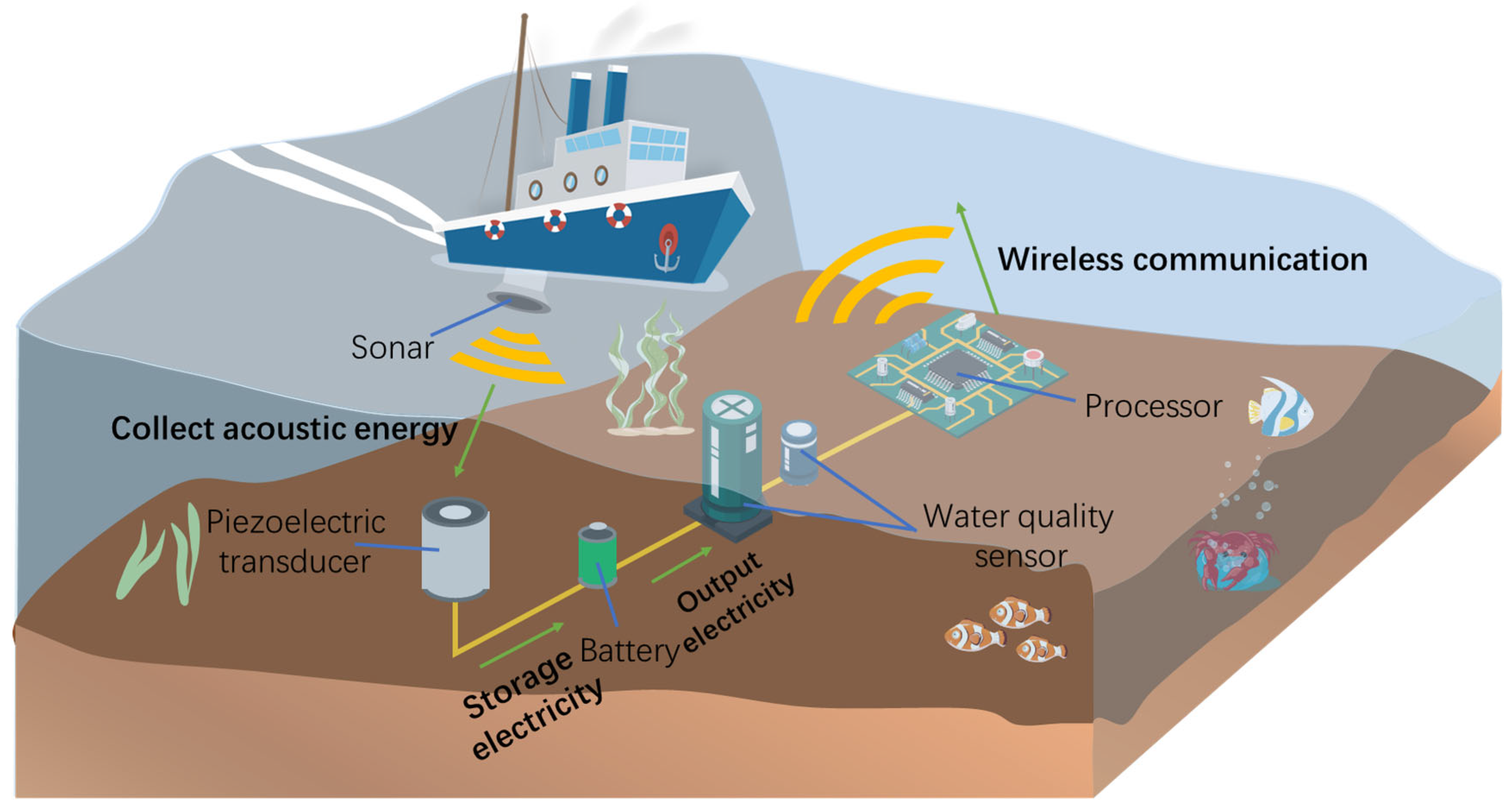

2. Acoustic Energy Harvested Wireless Sensing Principle

2.1. Overall Architecture

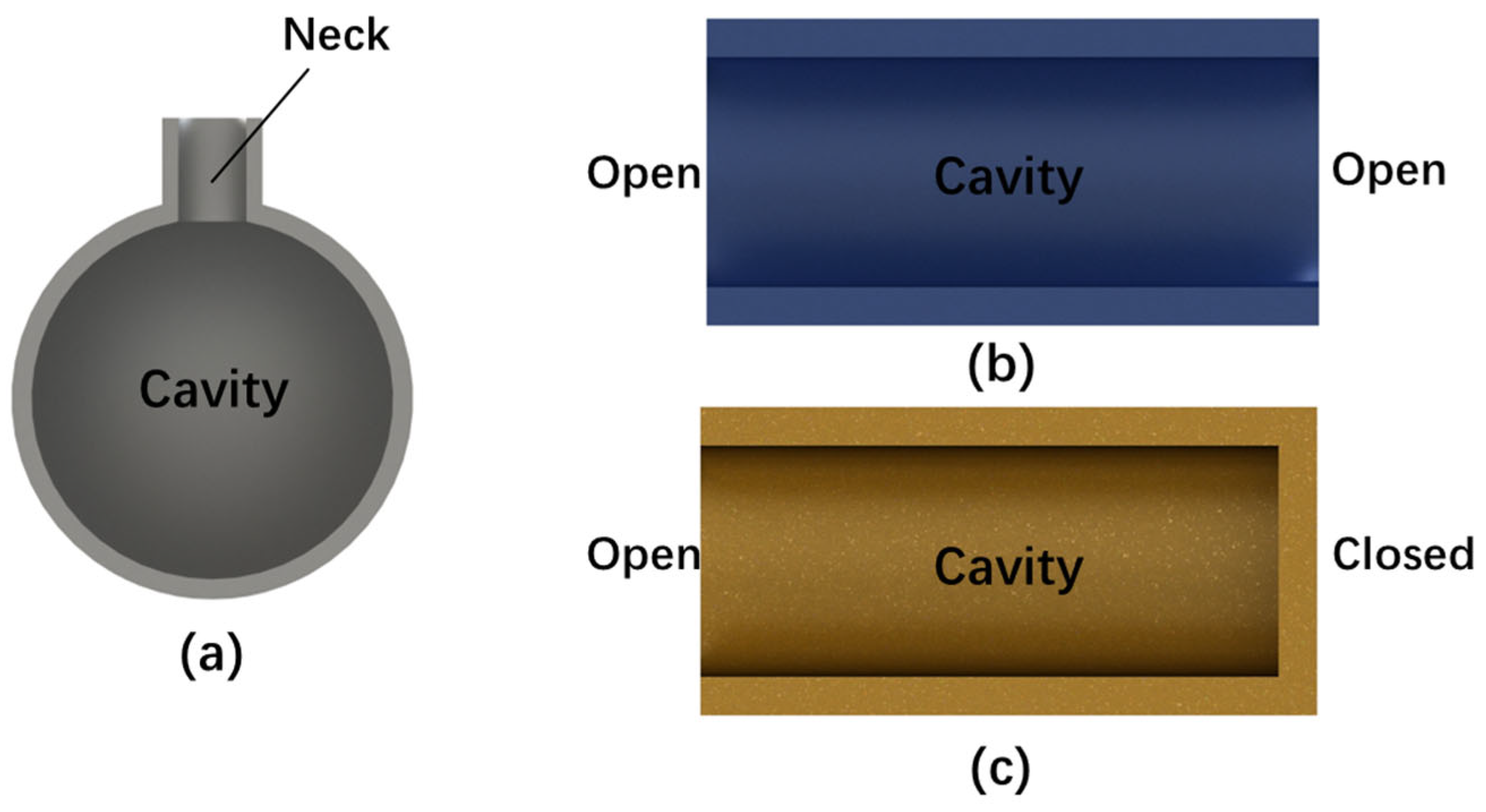

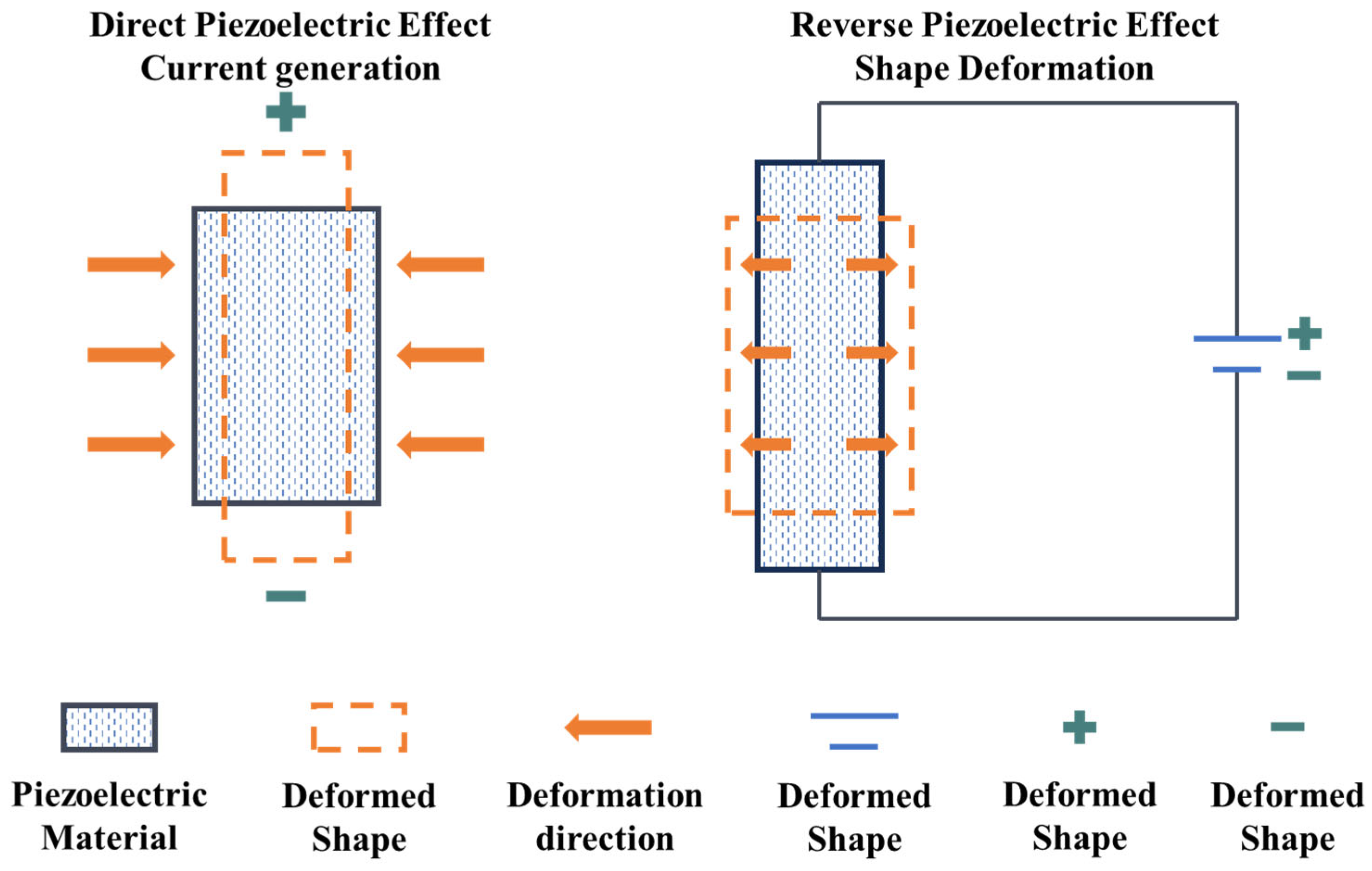

2.2. Acoustic Energy Harvesting Principle

2.3. Materials for Acoustic Energy Harvesting

2.4. Wireless Sensing in Aquaculture Monitoring

3. Applications in Aquaculture Monitoring

3.1. Dissolved Oxygen (DO)

| Monitoring the Water Quality Index | Design Content | Based on | Advantages | Applications | References |

|---|---|---|---|---|---|

| Dissolved Oxygen (DO) | Three dissolved oxygen prediction models for Multi-layer perceptron neural networks | Multi-universe Optimizer, Black Hole Algorithm, and Complex Evolutionary Algorithm | High stability | The weight and bias of the MLP neural network are optimized by algorithms to predict the level of DO. | [105] |

| The DO concentration in coastal water was estimated by combining satellite remote sensing data and measured DO data. | Satellite remote sensing data and field DO data | Large-scale water quality monitoring is more cost-effective | Extensive water quality monitoring | [106] | |

| By collecting dissolved oxygen data, combined with the information coefficient, the dissolved oxygen level is predicted. | Based on the wavelet transform (WT) | High accuracy | Water quality management and early warning system construction | [107] | |

| New flexible array dissolved oxygen sensor. | Multi-cell array structure and flexible materials | High sensitivity, Stability Wearability | Robot integration, Water environment monitoring | [108] | |

| Turbidity | An Internet of Things turbidity sensor based on the principle of light attenuation. | Optical attenuation principle, Calibration model | Stable performance, Strong adaptability | As part of the Internet of Things monitoring platform, to achieve dynamic monitoring of water quality. | [109] |

| Turbidity monitoring of the San Francisco estuary using satellite data. | Satellite remote sensing technology | High accuracy, large range | Turbidity monitoring designed for large areas of water. | [110] | |

| Integrating remote sensing technology and machine learning methods to monitor turbidity anomalies. | Remote sensing technology, Machine learning | Timeliness | It can generate turbidity anomaly maps under different hydrological conditions. | [111] | |

| pH | Low-cost virtual pH sensor | Electromagnetic field variation | High accuracy | PH monitoring designed for coastal waters. | [112] |

| Self-referencing fiber-optic pH sensor | Evanescent wave absorption principle | High stability, reliability, and longevity | Optical pH sensors designed for marine environments. | [113] | |

| Fast and stable optical pH sensor material | B-O bond covalently coupled indicator | Dynamic range and response time are optimized | PH monitoring designed for sea water. | [114] | |

| Salinity | Conical plastic multi-mode fiber optic sensor | Based on the change in refractive index of the optical fiber | High linearity and sensitivity | It is suitable for continuous monitoring of water salinity changes. | [115] |

| Low-cost graphene salinity sensor | Changes in the resistance and capacitance characteristics of the solution | High linearity and sensitivity | Salinity measurement designed for the ocean. | [116] |

3.2. Turbidity

3.3. pH

3.4. Salinity

4. Discussion

4.1. Advantage

4.2. Disadvantage

4.3. Prospects

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Terence, S.; Purushothaman, G. Systematic review of Internet of Things in smart farming. Trans. Emerg. Telecommun. Technol. 2020, 31, e3958. [Google Scholar] [CrossRef]

- Mizuta, D.D.; Froehlich, H.E.; Wilson, J.R. The changing role and definitions of aquaculture for environmental purposes. Rev. Aquac. 2023, 15, 130–141. [Google Scholar] [CrossRef]

- Ahmed, S.F.; Kumar, P.S.; Kabir, M.; Zuhara, F.T.; Mehjabin, A.; Tasannum, N.; Hoang, A.T.; Kabir, Z.; Mofijur, M. Threats, challenges and sustainable conservation strategies for freshwater biodiversity. Environ. Res. 2022, 214, 113808. [Google Scholar] [CrossRef] [PubMed]

- Yadav, N.K.; Patel, A.B.; Singh, S.K.; Mehta, N.K.; Anand, V.; Lal, J.; Dekari, D.; Devi, N.C. Climate change effects on aquaculture production and its sustainable management through climate-resilient adaptation strategies: A review. Environ. Sci. Pollut. Res. 2024, 31, 31731–31751. [Google Scholar] [CrossRef] [PubMed]

- Wang, C.; Li, Z.; Wang, T.; Xu, X.; Zhang, X.; Li, D. Intelligent fish farm—The future of aquaculture. Aquac. Int. 2021, 29, 2681–2711. [Google Scholar] [CrossRef]

- Prapti, D.R.; Mohamed Shariff, A.R.; Che Man, H.; Ramli, N.M.; Perumal, T.; Shariff, M. Internet of Things (IoT)-based aquaculture: An overview of IoT application on water quality monitoring. Rev. Aquac. 2022, 14, 979–992. [Google Scholar] [CrossRef]

- Farouk, M.I.H.Z.; Jamil, Z.; Latip, M.F.A. Towards online surface water quality monitoring technology: A review. Environ. Res. 2023, 238, 117147. [Google Scholar] [CrossRef]

- Islam, M.; Kashem, M.A.; Alyami, S.A.; Moni, M.A. Monitoring water quality metrics of ponds with IoT sensors and machine learning to predict fish species survival. Microprocess. Microsyst. 2023, 102, 104930. [Google Scholar] [CrossRef]

- Cuthbert, R.N.; Diagne, C.; Hudgins, E.J.; Turbelin, A.; Ahmed, D.A.; Albert, C.; Bodey, T.W.; Briski, E.; Essl, F.; Haubrock, P.J.; et al. Biological invasion costs reveal insufficient proactive management worldwide. Sci. Total Environ. 2022, 819, 153404. [Google Scholar] [CrossRef]

- Van Geest, M.; Tekinerdogan, B.; Catal, C. Design of a reference architecture for developing smart warehouses in industry 4.0. Comput. Ind. 2021, 124, 103343. [Google Scholar] [CrossRef]

- Luo, Y.; Abidian, M.R.; Ahn, J.-H.; Akinwande, D.; Andrews, A.M.; Antonietti, M.; Bao, Z.; Berggren, M.; Berkey, C.A.; Bettinger, C.J.; et al. Technology roadmap for flexible sensors. ACS Nano 2023, 17, 5211–5295. [Google Scholar] [CrossRef] [PubMed]

- Navarro-Segarra, M.; Tortosa, C.; Ruiz-Díez, C.; Desmaële, D.; Gea, T.; Barrena, R.; Sabaté, N.; Esquivel, J.P. A plant-like battery: A biodegradable power source ecodesigned for precision agriculture. Energy Environ. Sci. 2022, 15, 2900–2915. [Google Scholar] [CrossRef] [PubMed]

- Vasudevan, S.K.; Baskaran, B. An improved real-time water quality monitoring embedded system with IoT on unmanned surface vehicle. Ecol. Inform. 2021, 65, 101421. [Google Scholar] [CrossRef]

- Huang, Y.; Wang, X.; Xiang, W.; Wang, T.; Otis, C.; Sarge, L.; Lei, Y.; Li, B. Forward-looking roadmaps for long-term continuous water quality monitoring: Bottlenecks, innovations, and prospects in a critical review. Environ. Sci. Technol. 2022, 56, 5334–5354. [Google Scholar] [CrossRef]

- Zhao, T.; Xu, M.; Xiao, X.; Ma, Y.; Li, Z.; Wang, Z.L. Recent progress in blue energy harvesting for powering distributed sensors in ocean. Nano Energy 2021, 88, 106199. [Google Scholar] [CrossRef]

- Chen, X.; Wang, J.; Wang, Z.; Xu, H.; Liu, C.; Huo, B.; Meng, F.; Wang, Y.; Sun, C. Low-frequency mechanical energy in the environment for energy production and piezocatalytic degradation of organic pollutants in water: A review. J. Water Process Eng. 2023, 56, 104312. [Google Scholar] [CrossRef]

- Qin, W.; Liu, Q.; Wang, Y.; Xie, Z.; Zhou, Z. Increase output of vibration energy harvester by a different piezoelectric mode and branch structure design. J. Phys. D: Appl. Phys. 2022, 56, 034001. [Google Scholar] [CrossRef]

- Ali, M.; Bathaei, M.J.; Istif, E.; Karimi, S.N.H.; Beker, L. Biodegradable piezoelectric polymers: Recent advancements in materials and applications. Adv. Healthc. Mater. 2023, 12, 2300318. [Google Scholar] [CrossRef]

- Iqbal, M.; Khan, F. Hybrid acoustic, vibration, and wind energy harvester using piezoelectric transduction for self-powered wireless sensor node applications. Energy Convers. Manag. 2023, 277, 116635. [Google Scholar]

- Li, M.; Wang, M.; Ding, R.; Deng, T.; Fang, S.; Lai, F.; Luoi, R. Study of acoustic emission propagation characteristics and energy attenuation of surface transverse wave and internal longitudinal wave of wood. Wood Sci. Technol. 2021, 55, 1619–1637. [Google Scholar] [CrossRef]

- Ghosh, A. A comprehensive review of water based PV: Flotavoltaics, under water, offshore & canal top. Ocean Eng. 2023, 281, 115044. [Google Scholar]

- Li, J.; Li, Z.; Jiang, Y.; Tang, Y. Typhoon resistance analysis of offshore wind turbines: A review. Atmosphere 2022, 13, 451. [Google Scholar] [CrossRef]

- Zeng, F.; Wang, T. In-situ wave energy harvesting for unmanned marine devices: A review. Ocean Eng. 2023, 285, 115376. [Google Scholar] [CrossRef]

- Zou, H.X.; Li, M.; Zhao, L.C.; Gao, Q.H.; Wei, K.X.; Zuo, L.; Qian, F.; Zhang, W.M. A magnetically coupled bistable piezoelectric harvester for underwater energy harvesting. Energy 2021, 217, 119429. [Google Scholar] [CrossRef]

- Jean, F.; Khan, M.U.; Alazzam, A.; Mohammad, B. Advancement in piezoelectric nanogenerators for acoustic energy harvesting. Microsyst. Nanoeng. 2024, 10, 197. [Google Scholar] [CrossRef]

- Wu, D.; Guo, J. Optimal design method and benefits research for a regional integrated energy system. Renew. Sustain. Energy Rev. 2023, 186, 113671. [Google Scholar] [CrossRef]

- Sanislav, T.; Mois, G.D.; Zeadally, S.; Folea, S.C. Energy harvesting techniques for internet of things (IoT). IEEE Access 2021, 9, 39530–39549. [Google Scholar] [CrossRef]

- Rahman, A.; Farrok, O.; Haque, M.M. Environmental impact of renewable energy source based electrical power plants: Solar, wind, hydroelectric, biomass, geothermal, tidal, ocean, and osmotic. Renew. Sustain. Energy Rev. 2022, 161, 112279. [Google Scholar] [CrossRef]

- Yao, Y.; Pan, Y.; Liu, S. Power ultrasound and its applications: A state-of-the-art review. Ultrason. Sonochem. 2020, 62, 104722. [Google Scholar] [CrossRef]

- Xu, J.; Ye, Y.; Dong, T.; Yang, Z.; Pires, N.M.M.; Zhou, Y.; Tao, F.; Wang, J.; Zhang, J.; Luo, G.; et al. State of the Art of Low-Frequency Acoustic Modulation: Intensity Enhancement and Directional Control. Adv. Sci. 2025, 2410695. [Google Scholar] [CrossRef]

- Choi, J.; Jung, I.; Kang, C.Y. A brief review of sound energy harvesting. Nano Energy 2019, 56, 169–183. [Google Scholar] [CrossRef]

- Mir, F.; Mandal, D.; Banerjee, S. Metamaterials for acoustic noise filtering and energy harvesting. Sensors 2023, 23, 4227. [Google Scholar] [CrossRef] [PubMed]

- Magliacano, D.; Catapane, G.; Petrone, G.; Verdière, K.; Robin, O. Sound transmission properties of a porous meta-material with periodically embedded Helmholtz resonators. Mech. Adv. Mater. Struct. 2024, 31, 6748–6756. [Google Scholar] [CrossRef]

- Valière, J.C.; Prax, C. Dependence of the internal geometry for the calculation of the Helmholtz frequency in an axisymmetrical acoustic resonator. J. Acoust. Soc. Am. 2021, 150, 4053–4063. [Google Scholar] [CrossRef]

- Mahesh, K.; Ranjith, S.K.; Mini, R.S. A deep autoencoder based approach for the inverse design of an acoustic-absorber. Eng. Comput. 2024, 40, 279–300. [Google Scholar] [CrossRef]

- Zhou, S.; Jia, C.; Shu, G.; Guan, Z.; Wu, H.; Li, J.; Ou-Yang, W. Recent advances in TENGs collecting acoustic energy: From low-frequency sound to ultrasound. Nano Energy 2024, 129, 109951. [Google Scholar] [CrossRef]

- Li, B.; Zhou, Q.; Yuan, X.; Su, H.; Guo, Q. Influence of back pressure adjustment of porous media on cavity flow noise control. Phys. Fluids 2024, 36, 106115. [Google Scholar] [CrossRef]

- Liao, G.; Luan, C.; Wang, Z.; Liu, J.; Yao, X.; Fu, J. Acoustic metamaterials: A review of theories, structures, fabrication approaches, and applications. Adv. Mater. Technol. 2021, 6, 2000787. [Google Scholar] [CrossRef]

- Zarastvand, M.R.; Ghassabi, M.; Talebitooti, R. A review approach for sound propagation prediction of plate constructions. Arch. Comput. Methods Eng. 2021, 28, 2817–2843. [Google Scholar] [CrossRef]

- Lee, G.; Lee, S.J.; Rho, J.; Kim, M. Acoustic and mechanical metamaterials for energy harvesting and self-powered sensing applications. Mater. Today Energy 2023, 37, 101387. [Google Scholar] [CrossRef]

- Muhammad Lim, C.W. From photonic crystals to seismic metamaterials: A review via phononic crystals and acoustic metamaterials. Arch. Comput. Methods Eng. 2022, 29, 1137–1198. [Google Scholar] [CrossRef]

- Zhou, X.; Sun, Y.; Yang, S.; Bian, Z. Band gap manipulation on P-wave propagating in functionally graded phononic crystal by periodical thermal field. Int. J. Mech. Sci. 2021, 212, 106817. [Google Scholar] [CrossRef]

- Oudich, M.; Gerard, N.J.; Deng, Y.; Jing, Y. Tailoring structure-borne sound through bandgap engineering in phononic crystals and metamaterials: A comprehensive review. Adv. Funct. Mater. 2023, 33, 2206309. [Google Scholar] [CrossRef]

- Laude, V.; Iglesias Martínez, J.A.; Wang, Y.F.; Kadic, M. Effective anisotropy of periodic acoustic and elastic composites. J. Appl. Phys. 2021, 129, 215106. [Google Scholar] [CrossRef]

- Park, C.S.; Shin, Y.C.; Jo, S.H.; Yoon, H.; Choi, W.; Youn, B.D.; Kim, M. Two-dimensional octagonal phononic crystals for highly dense piezoelectric energy harvesting. Nano Energy 2019, 57, 327–337. [Google Scholar] [CrossRef]

- Chan, V.; Perlas, A. Basics of ultrasound imaging. Atlas of Ultrasound-Guided Procedures in Interventional Pain Management; Springer: New York, NY, USA, 2011; pp. 13–19. [Google Scholar]

- Gao, N.; Zhang, Z.; Deng, J.; Guo, X.; Cheng, B.; Hou, H. Acoustic metamaterials for noise reduction: A review. Adv. Mater. Technol. 2022, 7, 2100698. [Google Scholar] [CrossRef]

- Singh, J.; Kaur, R.; Singh, D. Energy harvesting in wireless sensor networks: A taxonomic survey. Int. J. Energy Res. 2021, 45, 118–140. [Google Scholar] [CrossRef]

- Wen, J.; He, H.; Niu, C.; Rong, M.; Huang, Y.; Wu, Y. An improved equivalent capacitance model of the triboelectric nanogenerator incorporating its surface roughness. Nano Energy 2022, 96, 107070. [Google Scholar] [CrossRef]

- Li, T.; Lee, P.S. Piezoelectric energy harvesting technology: From materials, structures, to applications. Small Struct. 2022, 3, 2100128. [Google Scholar] [CrossRef]

- Nguyen, Q.H.; Ta, Q.T.H.; Tran, N. Review on the transformation of biomechanical energy to green energy using triboelectric and piezoelectric based smart materials. J. Clean. Prod. 2022, 371, 133702. [Google Scholar] [CrossRef]

- Lay, R.; Deijs, G.S.; Malmström, J. The intrinsic piezoelectric properties of materials—A review with a focus on biological materials. RSC Adv. 2021, 11, 30657–30673. [Google Scholar] [CrossRef] [PubMed]

- Zhu, Z.; Rui, G.; Allahyarov, E.; Zhang, H.; Li, R.; Taylor, P.L.; Zhu, L. Mechanisms of direct and converse piezoelectricity in ferroelectric polymers. Polymer 2025, 325, 128290. [Google Scholar] [CrossRef]

- Owusu, F.; Venkatesan, T.R.; Nüesch, F.A.; Negri, R.M.; Opris, D.M. How to make elastomers piezoelectric? Adv. Mater. Technol. 2023, 8, 2300099. [Google Scholar] [CrossRef]

- Chen, L.; Liu, H.; Qi, H.; Chen, J. High-electromechanical performance for high-power piezoelectric applications: Fundamental, progress, and perspective. Prog. Mater. Sci. 2022, 127, 100944. [Google Scholar] [CrossRef]

- Jaffe, H. Piezoelectric ceramics. J. Am. Ceram. Soc. 1958, 41, 494–498. [Google Scholar] [CrossRef]

- Mahapatra, S.D.; Mohapatra, P.C.; Aria, A.I.; Christie, G.; Mishra, Y.K.; Hofmann, S.; Thakur, V.K. Piezoelectric materials for energy harvesting and sensing applications: Roadmap for future smart materials. Adv. Sci. 2021, 8, 2100864. [Google Scholar] [CrossRef]

- Zhang, J.H.; Li, Z.; Liu, Z.; Li, M.; Guo, J.; Du, J.; Cai, C.; Zhang, S.; Sun, N.; Li, Y.; et al. Inorganic Dielectric Materials Coupling Micro-/Nanoarchitectures for State-of-the-Art Biomechanical-to-Electrical Energy Conversion Devices. Adv. Mater. 2025, 2419081. [Google Scholar] [CrossRef]

- Qian, W.; Yang, W.; Zhang, Y.; Bowen, C.R.; Yang, Y. Piezoelectric materials for controlling electro-chemical processes. Nano-Micro Lett. 2020, 12, 149. [Google Scholar] [CrossRef]

- Pan, X.; Wu, Y.; Wang, Y.; Zhou, G.; Cai, H. Mechanical energy harvesting based on the piezoelectric materials: Recent advances and future perspectives. Chem. Eng. J. 2024, 497, 154249. [Google Scholar] [CrossRef]

- Afzal, S.S.; Akbar, W.; Rodriguez, O.; Doumet, M.; Ha, U.; Ghaffarivardavagh, R.; Adib, F. Battery-free wireless imaging of underwater environments. Nat. Commun. 2022, 13, 5546. [Google Scholar] [CrossRef]

- Chen, S.; Patil, S.A.; Brown, R.K.; Schröder, U. Strategies for optimizing the power output of microbial fuel cells: Transitioning from fundamental studies to practical implementation. Appl. Energy 2019, 233, 15–28. [Google Scholar] [CrossRef]

- Boettcher, S.W.; Oener, S.Z.; Lonergan, M.C.; Surendranath, Y.; Ardo, S.; Brozek, C.; Kempler, P.A. Potentially confusing: Potentials in electrochemistry. ACS Energy Lett. 2020, 6, 261–266. [Google Scholar] [CrossRef]

- Jiang, L.; Zhang, H.; Xia, R.; Zhou, J.; Liu, S.; Ding, Y. Research on Identification Method of Cable Cross-Sectional Loss Rates Based on Multiple Magnetic Characteristic Indicators. J. Nondestruct. Eval. 2024, 43, 64. [Google Scholar] [CrossRef]

- Ujah, C.O.; Popoola, A.P.I.; Popoola, O.M. Review on materials applied in electric transmission conductors. J. Mater. Sci. 2022, 57, 1581–1598. [Google Scholar] [CrossRef]

- Nesser, H.; Lubineau, G. Strain sensing by electrical capacitive variation: From stretchable materials to electronic interfaces. Adv. Electron. Mater. 2021, 7, 2100190. [Google Scholar] [CrossRef]

- Huang, X.; Yang, B. Towards novel energy shunt inspired vibration suppression techniques: Principles, designs and applications. Mech. Syst. Signal Process. 2023, 182, 109496. [Google Scholar] [CrossRef]

- Akande, I.; Fajobi, M.; Odunlami, O.; Oluwole, O. Exploitation of composite materials as vibration isolator and damper in machine tools and other mechanical systems: A review. Mater. Today Proc. 2021, 43, 1465–1470. [Google Scholar] [CrossRef]

- Sezer, N.; Koç, M. A comprehensive review on the state-of-the-art of piezoelectric energy harvesting. Nano Energy 2021, 80, 105567. [Google Scholar] [CrossRef]

- Waqar, M.; Wu, H.; Chen, J.; Yao, K.; Wang, J. Evolution from lead-based to lead-free piezoelectrics: Engineering of lattices, domains, boundaries, and defects leading to giant response. Adv. Mater. 2022, 34, 2106845. [Google Scholar] [CrossRef]

- Wei, X.K.; Domingo, N.; Sun, Y.; Balke, N.; Dunin-Borkowski, R.E.; Mayer, J. Progress on emerging ferroelectric materials for energy harvesting, storage and conversion. Adv. Energy Mater. 2022, 12, 2201199. [Google Scholar] [CrossRef]

- Yang, X.; Yang, Z.; Wang, X.; Guo, Y.; Xie, Y.; Yao, W.; Kawasaki, H. Piezoelectric nanomaterials for antibacterial strategies. Appl. Mater. Today 2024, 40, 102419. [Google Scholar] [CrossRef]

- Safaei, M.; Sodano, H.A.; Anton, S.R. A review of energy harvesting using piezoelectric materials: State-of-the-art a decade later (2008–2018). Smart Mater. Struct. 2019, 28, 113001. [Google Scholar] [CrossRef]

- Yang, Z.; Zu, J. Comparison of PZN-PT, PMN-PT single crystals and PZT ceramic for vibration energy harvesting. Energy Convers. Manag. 2016, 122, 321–329. [Google Scholar] [CrossRef]

- Baidya, K.; Roy, A.; Das, K. A review of polymer-matrix piezoelectric composite coatings for energy harvesting and smart sensors. J. Coat. Technol. Res. 2024, 21, 55–85. [Google Scholar] [CrossRef]

- Wu, H.; Zhuo, F.; Qiao, H.; Kodumudi Venkataraman, L.; Zheng, M.; Wang, S.; Huang, H.; Li, B.; Mao, X.; Zhang, Q. Polymer-/ceramic-based dielectric composites for energy storage and conversion. Energy Environ. Mater. 2022, 5, 486–514. [Google Scholar] [CrossRef]

- Zak, A.K.; Yazdi, S.T.; Abrishami, M.E.; Hashim, A.M. A review on piezoelectric ceramics and nanostructures: Fundamentals and fabrications. J. Aust. Ceram. Soc. 2024, 60, 723–753. [Google Scholar]

- Chen, Z.; Liang, R.; Zhang, C.; Zhou, Z.; Li, Y.; Liu, Z.; Dong, X. High-performance and high-thermally stable PSN-PZT piezoelectric ceramics achieved by high-temperature poling. J. Mater. Sci. Technol. 2022, 116, 238–245. [Google Scholar] [CrossRef]

- Zhang, Z.; Li, Z.; Li, Q.; Liu, X.; Gong, J.; Li, H. A PVDF/PU-based composite 3D flexible piezoelectric nanofiber aerogel for acoustic energy harvesting and noise reduction. Chem. Eng. J. 2025, 507, 159836. [Google Scholar] [CrossRef]

- Zhou, S.; Hou, L.; Wang, G.; Zhou, Y.; Li, G.; Jiang, Y. Ultrasound vibration energy harvesting from a rotary-type piezoelectric ultrasonic actuator. Mech. Syst. Signal Process. 2023, 197, 110337. [Google Scholar] [CrossRef]

- Jiang, L.; Yang, Y.; Chen, R.; Lu, G.; Li, R.; Li, D.; Humayun, M.S.; Shung, K.K.; Zhu, J.; Chen, Y.; et al. Flexible piezoelectric ultrasonic energy harvester array for bio-implantable wireless generator. Nano Energy 2019, 56, 216–224. [Google Scholar] [CrossRef]

- Bell, A.J.; Comyn, T.P.; Stevenson, T.J. Expanding the application space for piezoelectric materials. APL Mater. 2021, 9, 010901. [Google Scholar] [CrossRef]

- Zhang, S.; Malič, B.; Li, J.-F.; Rödel, J. Lead-free ferroelectric materials: Prospective applications. J. Mater. Res. 2021, 36, 985–995. [Google Scholar] [CrossRef]

- Wang, Q.; Zhang, Y.; Xue, H.; Zeng, Y.; Lu, G.; Fan, H.; Jiang, L.; Wu, J. Lead-free dual-frequency ultrasound implants for wireless, biphasic deep brain stimulation. Nat. Commun. 2024, 15, 4017. [Google Scholar] [CrossRef]

- Al-Sulaifanie, A.I.; Al-Sulaifanie, B.K.; Biswas, S. Recent trends in clustering algorithms for wireless sensor networks: A comprehensive review. Comput. Commun. 2022, 191, 395–424. [Google Scholar] [CrossRef]

- Eitzinger, A.; Cock, J.; Atzmanstorfer, K.; Binder, C.R.; Läderach, P.; Bonilla-Findji, O.; Bartling, M.; Mwongera, C.; Zurita, L.; Jarvis, A. GeoFarmer: A monitoring and feedback system for agricultural development projects. Comput. Electron. Agric. 2019, 158, 109–121. [Google Scholar] [CrossRef]

- Rao, A.S.; Radanovic, M.; Liu, Y.; Hu, S.; Fang, Y.; Khoshelham, K.; Palaniswami, M.; Ngo, T. Real-time monitoring of construction sites: Sensors, methods, and applications. Autom. Constr. 2022, 136, 104099. [Google Scholar] [CrossRef]

- Chen, L.K.; Shao, Y.; Di, Y. Underwater and water-air optical wireless communication. J. Light. Technol. 2022, 40, 1440–1452. [Google Scholar] [CrossRef]

- Aman, W.; Al-Kuwari, S.; Muzzammil, M.; Rahman, M.M.; Kumar, A. Security of underwater and air–water wireless communication: State-of-the-art, challenges and outlook. Ad Hoc Netw. 2023, 142, 103114. [Google Scholar] [CrossRef]

- Yu, J.; Wu, Y. High-speed optical fiber communication in China. ACS Photonics 2022, 10, 2128–2148. [Google Scholar] [CrossRef]

- Ali, M.F.; Jayakody, D.N.; Chursin, Y.A.; Affes, S.; Dmitry, S. Recent advances and future directions on underwater wireless communications. Arch. Comput. Methods Eng. 2020, 27, 1379–1412. [Google Scholar] [CrossRef]

- Islam, K.Y.; Ahmad, I.; Habibi, D.; Waqar, A. A survey on energy efficiency in underwater wireless communications. J. Netw. Comput. Appl. 2022, 198, 103295. [Google Scholar] [CrossRef]

- Zhao, Y.; Chen, Y.; Huang, J.; Zhou, Z.; Zhang, F. Photoacoustic communication system based on detecting laser-generated sound by optical fiber underwater acoustic sensor. Opt. Lasers Eng. 2024, 177, 108134. [Google Scholar] [CrossRef]

- Noufal, K.; Sanjana, M.; Latha, G.; Ramesh, R. Influence of internal wave induced sound speed variability on acoustic propagation in shallow waters of North West Bay of Bengal. Appl. Acoust. 2022, 194, 108778. [Google Scholar] [CrossRef]

- Azeez, A.; Revichandran, C.; Muraleedharan, K.R.; John, S.; Seena, G.; Nair, R.C.; Manju, K.G. Sound speed variation in the coastal waters off Cochin and signature of subsurface maxima. Ocean Dyn. 2021, 71, 923–933. [Google Scholar]

- Zhu, S.; Zhang, G.; Wu, D.; Jia, L.; Zhang, Y.; Geng, Y.; Liu, Y.; Ren, W.; Zhang, W. High Signal-to-Noise Ratio MEMS Noise Listener for Ship Noise Detection. Remote Sens. 2023, 15, 777. [Google Scholar] [CrossRef]

- Su, X.; Sutarlie, L.; Loh, X.J. Sensors, biosensors, and analytical technologies for aquaculture water quality. Research 2020, 2020, 8272705. [Google Scholar] [CrossRef]

- Kwon, D.Y.; Kim, J.; Park, S.; Hong, S. Advancements of remote data acquisition and processing in unmanned vehicle technologies for water quality monitoring: An extensive review. Chemosphere 2023, 343, 140198. [Google Scholar] [CrossRef]

- Zhang, M.; Guo, W.; Chen, Y.; He, D.; Isaev, A.B.; Zhu, M. Dissolved oxygen in aeration-driven piezo-catalytic for antibiotics pollutants removal in water. Chin. Chem. Lett. 2023, 34, 108229. [Google Scholar] [CrossRef]

- Hallinan, B.D.; Tettelbach, S.T.; Volkenborn, N.; Doherty, O.W.; Allam, B.; Gobler, C.J. Warming and hypoxia reduce the performance and survival of northern bay scallops (Argopecten irradians irradians) amid a fishery collapse. Glob. Change Biol. 2023, 29, 2092–2107. [Google Scholar]

- Wang, B.; Guo, Q.; Luo, Z.; Zhuang, J.; Wang, C.; Li, Z.; Li, H.; Han, Q.; Cao, J.; Wang, H.; et al. The effect of varying dissolved oxygen levels on Cryptocaryoniasis in cage-farmed Larimichthys crocea. Aquaculture 2025, 594, 741373. [Google Scholar] [CrossRef]

- Anconi, A.C.S.A.; Brito, N.C.S.; Nunes, C.A. Determination of peroxide value in edible oils based on Digital Image Colorimetry. J. Food Compos. Anal. 2022, 113, 104724. [Google Scholar] [CrossRef]

- Wolfbeis, O.S. Luminescent sensing and imaging of oxygen: Fierce competition to the Clark electrode. BioEssays 2015, 37, 921–928. [Google Scholar] [CrossRef] [PubMed]

- Grasso, G.; Onesto, V.; Forciniti, S.; D’amone, E.; Colella, F.; Pierantoni, L.; Famà, V.; Gigli, G.; Reis, R.L.; Oliveira, J.M.; et al. Highly sensitive ratiometric fluorescent fiber matrices for oxygen sensing with micrometer spatial resolution. Bio-Des. Manuf. 2024, 7, 292–306. [Google Scholar] [CrossRef]

- Yang, F.; Moayedi, H.; Mosavi, A. Predicting the degree of dissolved oxygen using three types of multi-layer perceptron-based artificial neural networks. Sustainability 2021, 13, 9898. [Google Scholar] [CrossRef]

- Kim, Y.H.; Son, S.; Kim, H.C.; Kim, B.; Park, Y.G.; Nam, J.; Ryu, J. Application of satellite remote sensing in monitoring dissolved oxygen variabilities: A case study for coastal waters in Korea. Environ. Int. 2020, 134, 105301. [Google Scholar] [CrossRef]

- Xu, C.; Chen, X.; Zhang, L. Predicting river dissolved oxygen time series based on stand-alone models and hybrid wavelet-based models. J. Environ. Manag. 2021, 295, 113085. [Google Scholar] [CrossRef]

- Xu, X.; Wang, B.; Du, Z.; Bai, Z.; Wang, S.; Wang, C.; Li, D. A novel nonplanar multi-chamber flexible array dissolved oxygen sensor for aquaculture robotic fish. Comput. Electron. Agric. 2025, 230, 109903. [Google Scholar] [CrossRef]

- Trevathan, J.; Read, W.; Sattar, A. Implementation and calibration of an IoT light attenuation turbidity sensor. Internet Things 2022, 19, 100576. [Google Scholar] [CrossRef]

- Lee, C.M.; Hestir, E.L.; Tufillaro, N.; Palmieri, B.; Acuña, S.; Osti, A.; Bergamaschi, B.A.; Sommer, T. Monitoring turbidity in San Francisco Estuary and Sacramento–San Joaquin delta using satellite remote sensing. JAWRA J. Am. Water Resour. Assoc. 2021, 57, 737–751. [Google Scholar] [CrossRef]

- Souza, A.P.; Oliveira, B.A.; Andrade, M.L.; Starling, M.C.V.; Pereira, A.H.; Maillard, P.; Nogueira, K.; dos Santos, J.A.; Amorim, C.C. Integrating remote sensing and machine learning to detect turbidity anomalies in hydroelectric reservoirs. Sci. Total Environ. 2023, 902, 165964. [Google Scholar] [CrossRef]

- Natkunarajah, K.; Masilamani, K.; Maheswaran, S.; Lothenbach, B.; Amarasinghe, D.; Attygalle, D. Analysis of the trend of pH changes of concrete pore solution during the hydration by various analytical methods. Cem. Concr. Res. 2022, 156, 106780. [Google Scholar] [CrossRef]

- Li, H.; Cui, Z.; Cui, H.; Bai, Y.; Yin, Z.; Qu, K. A review of influencing factors on a recirculating aquaculture system: Environmental conditions, feeding strategies, and disinfection methods. J. World Aquac. Soc. 2023, 54, 566–602. [Google Scholar] [CrossRef]

- Chen, H.; Luo, D. Application of haematology parameters for health management in fish farms. Rev. Aquac. 2023, 15, 704–737. [Google Scholar] [CrossRef]

- El-Khoury, M.; Roziere, E.; Grondin, F.; Cortas, R.; Chehade, F.H. Experimental evaluation of the effect of cement type and seawater salinity on concrete offshore structures. Constr. Build. Mater. 2022, 322, 126471. [Google Scholar] [CrossRef]

- Yue, G.H.; Ma, K.Y.; Xia, J.H. Status of conventional and molecular breeding of salinity-tolerant tilapia. Rev. Aquac. 2024, 16, 271–286. [Google Scholar] [CrossRef]

- Zhang, K.; Ye, Z.; Qi, M.; Cai, W.; Saraiva, J.L.; Wen, Y.; Liu, G.; Zhu, Z.; Zhu, S.; Zhao, J. Water quality impact on fish behavior: A review from an aquaculture perspective. Rev. Aquac. 2025, 17, e12985. [Google Scholar] [CrossRef]

- Sun, R.; Zhou, S.; Cheng, L. Ultra-low frequency vibration energy harvesting: Mechanisms, enhancement techniques, and scaling laws. Energy Convers. Manag. 2023, 276, 116585. [Google Scholar] [CrossRef]

- Lone, S.A.; Lim, K.C.; Kaswan, K.; Chatterjee, S.; Fan, K.P.; Choi, D.; Lee, S.; Zhang, H.; Cheng, J.; Lin, Z.H. Recent advancements for improving the performance of triboelectric nanogenerator devices. Nano Energy 2022, 99, 107318. [Google Scholar] [CrossRef]

- Matos, T.; Martins, M.; Henriques, R.; Goncalves, L. A review of methods and instruments to monitor turbidity and suspended sediment concentration. J. Water Process Eng. 2024, 64, 105624. [Google Scholar] [CrossRef]

- Guo, Z.; Ouyang, W.; He, M.; Peng, S.; Hu, J.; Lin, C. Involving degradation products provides a new perspective of diffuse pollution assessment of atrazine with a modified mass balance approach. J. Hazard. Mater. 2025, 487, 137169. [Google Scholar] [CrossRef]

- Chen, K.; Wang, X.; Wang, C. High-Precision monitoring system for turbidity of drinking water by using scattering method. IEEE Sens. J. 2023, 23, 29525–29535. [Google Scholar] [CrossRef]

- Safar, Z.; Chassagne, C.; Rijnsburger, S.; Sanz, M.I.; Manning, A.J.; Souza, A.; van Kessel, T.; Horner-Devine, A.; Flores, R.; McKeon, M.; et al. Characterization and classification of estuarine suspended particles based on their inorganic/organic matter composition. Front. Mar. Sci. 2022, 9, 896163. [Google Scholar] [CrossRef]

- Saha, A.; Yermembetova, A.; Mi, Y.; Gopalakrishnan, S.; Sedaghat, S.; Waimin, J.; Wang, P.; Glassmaker, N.; Mousoulis, C.; Raghunathan, N.; et al. Temperature self-calibration of always-on, field-deployed ion-selective electrodes based on differential voltage measurement. ACS Sens. 2022, 7, 2661–2670. [Google Scholar] [CrossRef] [PubMed]

- Viciano-Tudela, S.; Parra, L.; Sendra, S.; Lloret, J. A low-cost virtual sensor for underwater ph monitoring in coastal waters. Chemosensors 2023, 11, 215. [Google Scholar] [CrossRef]

- Chen, W.H.; Dillon, W.D.; Armstrong, E.A.; Moratti, S.C.; McGraw, C.M. Self-referencing optical fiber pH sensor for marine microenvironments. Talanta 2021, 225, 121969. [Google Scholar] [CrossRef]

- Staudinger, C.; Strobl, M.; Breininger, J.; Klimant, I.; Borisov, S.M. Fast and stable optical pH sensor materials for oceanographic applications. Sens. Actuators B Chem. 2019, 282, 204–217. [Google Scholar] [CrossRef]

- Rahman, H.; Harun, S.; Yasin, M.; Phang, S.; Damanhuri, S.; Arof, H.; Ahmad, H. Tapered plastic multimode fiber sensor for salinity detection. Sens. Actuators A Phys. 2011, 171, 219–222. [Google Scholar] [CrossRef]

- Nag, A.; Mukhopadhyay, S.C.; Kosel, J. Sensing system for salinity testing using laser-induced graphene sensors. Sens. Actuators A Phys. 2017, 264, 107–116. [Google Scholar] [CrossRef]

- Moyano, D.B.; Paraiso, D.A.; González-Lezcano, R.A. Possible effects on health of ultrasound exposure, risk factors in the work environment and occupational safety review. Healthcare 2022, 10, 423. [Google Scholar] [CrossRef]

- Maridevaru, M.C.; Lu, H.; Roy, S.; Yan, Y.; Wang, F.; Soe, S.K.; Ullah, Z.; Sang, H.; Shang, J.; Guo, B. Development of Polymer-Based Piezoelectric Materials for the Bone Tissue Regeneration. Macromol. Biosci. 2025, 2500031. [Google Scholar] [CrossRef]

- Ali, M.F.; Jayakody, D.N.K.; Li, Y. Recent trends in underwater visible light communication (UVLC) systems. IEEE Access 2022, 10, 22169–22225. [Google Scholar] [CrossRef]

- Abaei, M.M.; Kumar, S.; Arzaghi, E.; Golestani, N.; Abdussamie, N.; Garaniya, V.; Salehi, F.; Asadnia, M.; Hunter, T.S.; Pichard, A.; et al. Developing offshore renewable energy systems in Australia: Existing regulatory challenges and requirements for reliability assurance. Ocean Coast. Manag. 2024, 257, 107316. [Google Scholar] [CrossRef]

- Choi, J.; Son, Y. Effect of dissolved gases on sonochemical oxidation in a 20 kHz probe system: Continuous monitoring of dissolved oxygen concentration and sonochemical oxidation activity. Ultrason. Sonochem. 2023, 97, 106452. [Google Scholar] [CrossRef] [PubMed]

- Roszkiewicz, A.; Garlińska, M.; Pregowska, A. Advancements in Piezoelectric-Enabled Devices for Optical Communication. physica status solidi (a) 2025, 222, 2400298. [Google Scholar] [CrossRef]

- Liu, T.; Mao, Y.; Dou, H.; Zhang, W.; Yang, J.; Wu, P.; Li, D.; Mu, X. Emerging Wearable Acoustic Sensing Technologies. Adv. Sci. 2025, 12, 2408653. [Google Scholar] [CrossRef]

- Hagelauer, A.; Ruby, R.; Inoue, S.; Plessky, V.; Hashimoto, K.Y.; Nakagawa, R.; Verdu, J.; de Paco, P.; Mortazawi, A.; Piazza, G.; et al. From microwave acoustic filters to millimeter-wave operation and new applications. IEEE J. Microw. 2022, 3, 484–508. [Google Scholar] [CrossRef]

- Turner, B.L.; Senevirathne, S.; Kilgour, K.; McArt, D.; Biggs, M.; Menegatti, S.; Daniele, M.A. Ultrasound-powered implants: A critical review of piezoelectric material selection and applications. Adv. Healthc. Mater. 2021, 10, 2100986. [Google Scholar] [CrossRef]

- Chen, J.; Qiu, Q.; Han, Y.; Lau, D. Piezoelectric materials for sustainable building structures: Fundamentals and applications. Renew. Sustain. Energy Rev. 2019, 101, 14–25. [Google Scholar] [CrossRef]

- Fan, J.; Wang, F. Review of ultrasonic measurement methods for two-phase flow. Rev. Sci. Instrum. 2021, 92, 091502. [Google Scholar] [CrossRef]

- Casali, J.G. Sound and noise: Measurement and design guidance. In Handbook of Human Factors and Ergonomics; John Wiley & Sons: Hoboken, NJ, USA, 2021; pp. 457–493. [Google Scholar]

- Ahmed, R.; Mir, F.; Banerjee, S. A review on energy harvesting approaches for renewable energies from ambient vibrations and acoustic waves using piezoelectricity. Smart Mater. Struct. 2017, 26, 085031. [Google Scholar] [CrossRef]

- Motaei, F.; Bahrami, A. Acoustic energy harvesting using phononic crystal fiber with conical input. Sci. Rep. 2024, 14, 12354. [Google Scholar] [CrossRef] [PubMed]

- Li, T.; Wang, Z.; Xiao, H.; Yan, Z.; Yang, C.; Tan, T. Dual-band piezoelectric acoustic energy harvesting by structural and local resonances of Helmholtz metamaterial. Nano Energy 2021, 90, 106523. [Google Scholar] [CrossRef]

- Lee, J.H.; Cho, K.H.; Cho, K. Emerging trends in soft electronics: Integrating machine intelligence with soft acoustic/vibration sensors. Adv. Mater. 2023, 35, 2209673. [Google Scholar] [CrossRef] [PubMed]

- Mayer, P.; Magno, M.; Benini, L. Self-sustaining acoustic sensor with programmable pattern recognition for underwater monitoring. IEEE Trans. Instrum. Meas. 2019, 68, 2346–2355. [Google Scholar] [CrossRef]

- Wang, X.; Gao, Y.; Liu, C.; Wang, Y.; Liu, A.; Yang, W. Cordless Miniature Robots from Centimeter to Nanometer Scale: Recent Progress and Future Challenges in Biomedicine Field. Adv. Mater. Technol. 2024, 10, 2401223. [Google Scholar] [CrossRef]

- Li, D.; Du, Z.; Wang, Q.; Wang, J.; Du, L. Recent advances in acoustic technology for aquaculture: A review. Rev. Aquac. 2024, 16, 357–381. [Google Scholar] [CrossRef]

| Type | Materials | Advantage | Disadvantage | Ref |

|---|---|---|---|---|

| Single-crystal material | Quartz lithium niobate (LiNbO3) Lithium tantalate (LiTaO3) | Low loss; The electromechanical coupling coefficient is large; Excellent piezoelectric properties | Production is difficult and expensive; Brittleness height | [73] |

| Polycrystalline materials (piezoelectric ceramics) | PZT | Easy to manufacture and low cost; High coupling; High energy conversion rate | Easy to age, performance declines with time; Very brittle, unable to absorb large strains without damage; The performance is slightly lower than that of single-crystal materials | [74] |

| Relaxation ferroelectric materials | PVDF | High dielectric constant; High electromechanical coupling coefficient; Strong electrostrictive effect; | High temperature sensitivity; Preparation complexity | [75] |

| Polymer materials | Polyvinylidene fluoride (PVDF) | Good flexibility, light weight; Easy to process, strong adaptability; High flexibility; | The piezoelectric properties are low; Poor thermal stability; The electromechanical coupling coefficient is low | [76] |

| Composite material | Epoxy matrix composite; PVDF-based composite | Can combine the advantages of a variety of materials; Specific performance requirements can be achieved by changing material composition and structural design | The preparation process is complex; It is difficult to optimize all desired performance simultaneously | [77] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, Z.; Ma, L.; Zhang, R.; Zhang, J.; Liu, F.; Xiao, X. Acoustic Energy Harvested Wireless Sensing for Aquaculture Monitoring. Inventions 2025, 10, 41. https://doi.org/10.3390/inventions10030041

Yang Z, Ma L, Zhang R, Zhang J, Liu F, Xiao X. Acoustic Energy Harvested Wireless Sensing for Aquaculture Monitoring. Inventions. 2025; 10(3):41. https://doi.org/10.3390/inventions10030041

Chicago/Turabian StyleYang, Zhencan, Longgang Ma, Ruihua Zhang, Jiawei Zhang, Feng Liu, and Xinqing Xiao. 2025. "Acoustic Energy Harvested Wireless Sensing for Aquaculture Monitoring" Inventions 10, no. 3: 41. https://doi.org/10.3390/inventions10030041

APA StyleYang, Z., Ma, L., Zhang, R., Zhang, J., Liu, F., & Xiao, X. (2025). Acoustic Energy Harvested Wireless Sensing for Aquaculture Monitoring. Inventions, 10(3), 41. https://doi.org/10.3390/inventions10030041