Improving Fabrication and Performance of Additively Manufactured RF Cavities by Employing Co-Printed Support Structures and Their Subsequent Removal

Abstract

1. Introduction

2. Materials and Methods

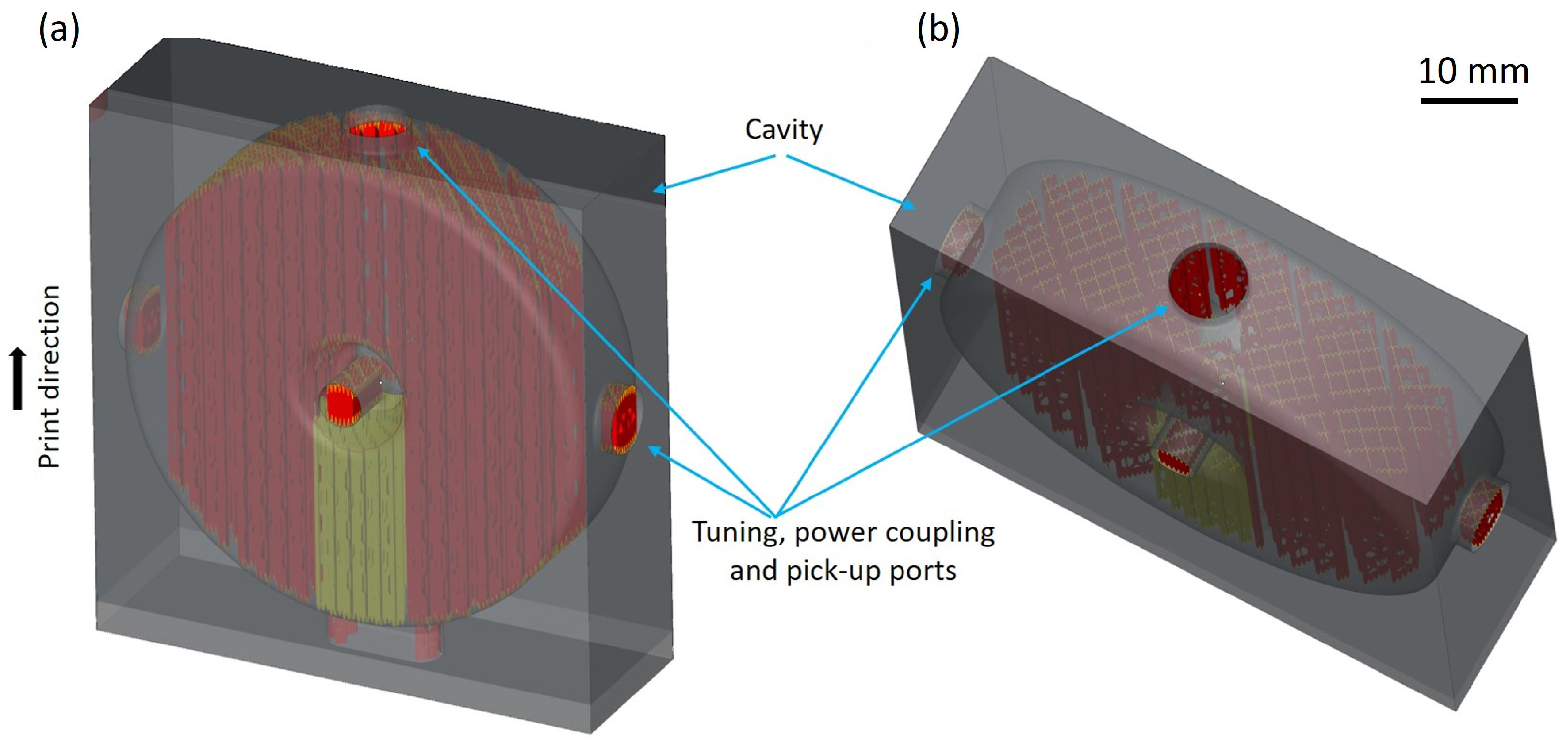

2.1. Cavity Design and Electromagnetic (EM) Simulation

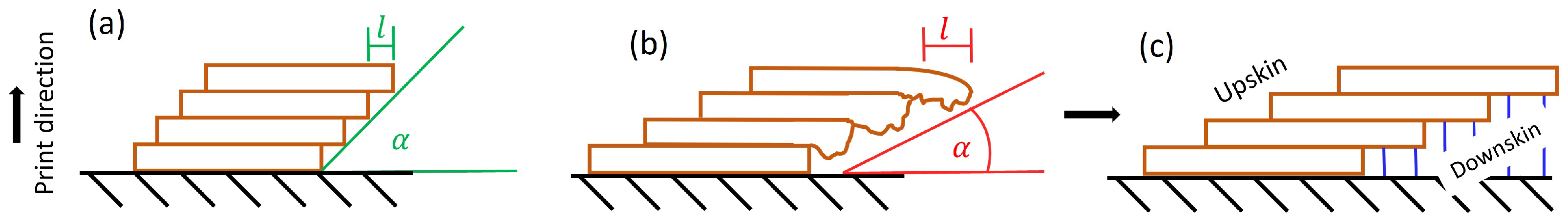

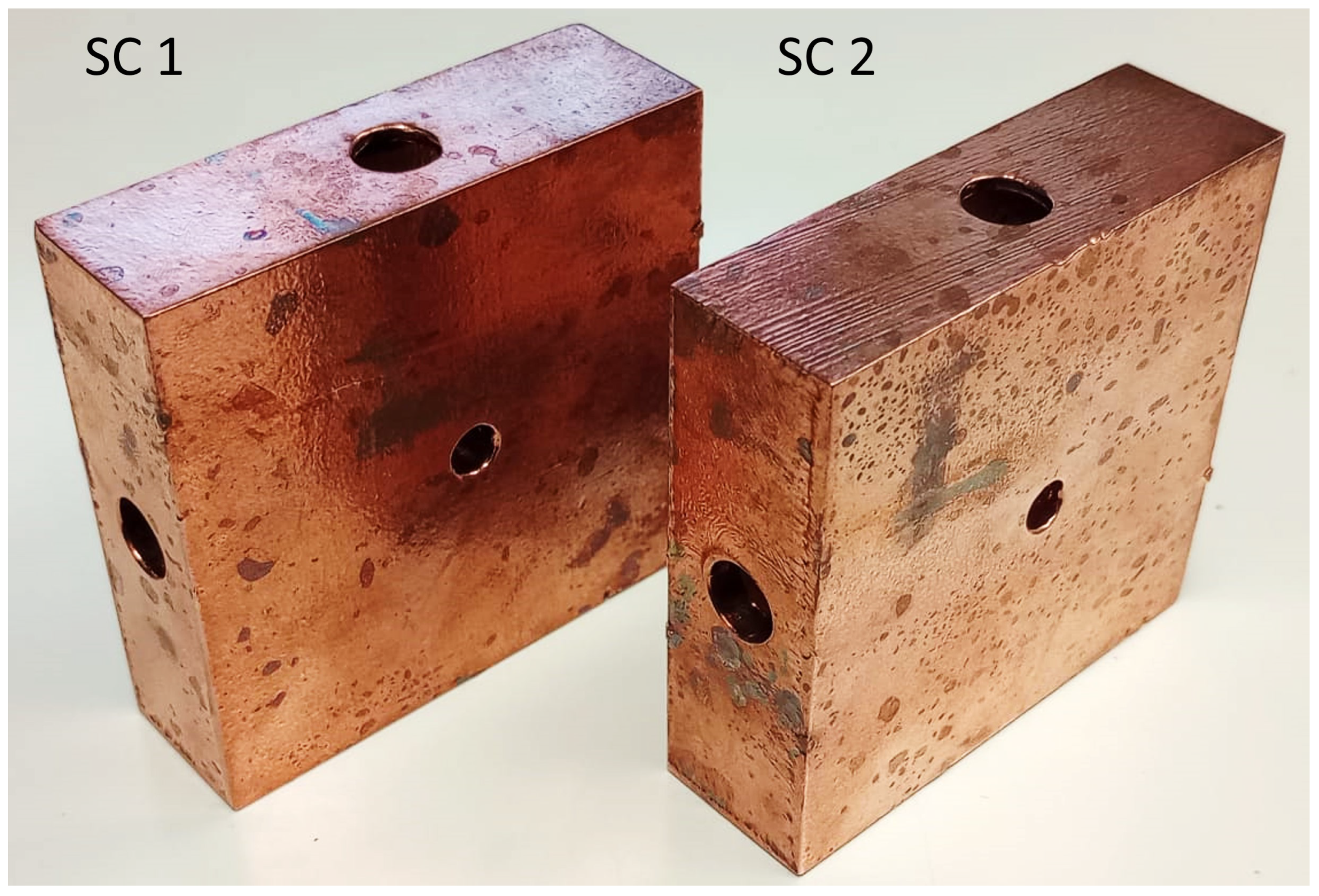

2.2. Additive Manufacturing

2.3. Post-Processing Procedure

- PPS 1: Co-printed support structures are completely dissolved in a first Hirtisation (R) step.

- PPS 2: After step 1, is determined, allowing the calculation of how much material removal (MR) is still required to reach 2997.9 MHz. This MR is then realized by a second Hirtisation (R) step. In addition, PPS 2 further reduces the surface roughness and thus increases .

2.4. RF Measurements

2.5. Evaluation of Inner Geometry and Surface Roughness

3. Results

3.1. Resonance Frequency and Tuning Process

3.2. Unloaded Quality Factor

3.3. Inner Geometry and Surface Roughness

4. Discussion

4.1. Inner Geometry

4.2. Resonant Frequency and Tuning Process

4.3. Unloaded Quality Factor and Surface Roughness

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Wangler, T.P. RF Linear Accelerators, 2nd ed.; John Wiley & Sons: Hoboken, NJ, USA, 2008; pp. 98–121. [Google Scholar]

- Witman, S. Ten Things You Might Not Know about Particle Accelerators. Symmetry Magazine, Fermi National Accelerator Laboratory. 2014. Available online: https://www.symmetrymagazine.org/article/april-2014/ten-things-you-might-not-know-about-particle-accelerators (accessed on 1 December 2023).

- Kutsaev, S.V. Advanced technologies for applied particle accelerators and examples of their use. Tech. Phys. 2021, 66, 161–195. [Google Scholar] [CrossRef]

- Lung, H.; Cheng, Y.C.; Chang, Y.H.; Huang, H.W.; Yang, B.B.; Wang, C.-Y. Microbial decontamination of food by electron beam irradiation. Trends Food Sci. Technol. 2015, 44, 66–78. [Google Scholar] [CrossRef]

- Do Huh, H.; Kim, S. History of radiation therapy technology. Korean Soc. Med. Phys. 2020, 31, 124–134. [Google Scholar]

- Amaldi, H.; Braccini, S.; Puggioni, P. High frequency linacs for hadrontherapy. Rev. Accel. Sci. Technol. 2009, 2, 111–131. [Google Scholar] [CrossRef]

- Wilson, I.H. Cavity construction techniques. Cern Accel. Sch. Eng. Part. Accel. 1991, 2, 92–103. [Google Scholar]

- Nassiri, A.; Chase, B.; Craievich, P.; Fabris, A.; Frischholz, H.; Jacob, J.; Jensen, E.; Jensen, M.; Kustom, R.; Pasquinelli, R. History and technology developments of radio frequency (RF) systems for particle accelerators. IEEE Trans. Nucl. Sci. Inst. Electr. Electron. Eng. 2016, 63, 707–750. [Google Scholar] [CrossRef]

- Ghodke, S.R.; Barnwal, R.; Mondal, J.; Dhavle, A.S.; Parashar, S.; Kumar, M.; Nayak, S.; Jayaprakash, D.; Sharma, V.; Acharya, S.; et al. Machining and brazing of accelerating RF cavity. In Proceedings of the 2014 International Symposium on Discharges and Electrical Insulation in Vacuum (ISDEIV), Mumbai, India, 28 September–3 October 2014; pp. 101–104. [Google Scholar]

- Pagani, C.; Bellomo, G.; Pierini, P. A high current proton linac with 352 MHz SC cavities. arXiv 1996, arXiv:acc-phys/9609004. [Google Scholar]

- Mickat, S.; Barth, W.; Clemente, G.; Groening, L.; Schlitt, B.; Ratzinger, U. The Status of the High-Energy Linac Project at GSI. GSI Sci. Rep. 2014, 306. [Google Scholar]

- Brinkmann, R.; Andruszkow, J.; Agababyan, A.; Ageyev, A.; Andruszkow, J.; Antoine, C.; Aseev, V.; Aune, B.; Ayvazyan, V.; Baboi, N.; et al. TESLA Technical Design Report—PART II The Accelerator; DESY: Hamburg, Germany, 2001; Available online: https://tesla.desy.de/ (accessed on 1 December 2023).

- Calignano, F.; Manfredi, D.; Ambrosio, E.P.; Biamino, S.; Lombardi, M.; Atzeni, E.; Salmi, A.; Minetola, P. Overview on Additive Manufacturing Technologies. Inst. Electr. Electron. Eng. IEEE 2017, 105, 101–104. [Google Scholar] [CrossRef]

- Attaran, M. The rise of 3-D printing: The advantages of additive manufacturing over traditional manufacturing. Bus. Horizons 2017, 60, 677–688. [Google Scholar] [CrossRef]

- Torims, T.; Cherif, A.; Delerue, N.; Pedretti, M.F.; Krogere, D.; Otto, T.; Pikurs, G.; Pozzi, M.; Tatkus, A. Evaluation of geometrical precision and surface roughness quality for the additively manufactured radio frequency quadrupole prototype. J. Phys. Conf. Ser. 2023, 2420, 012089. [Google Scholar] [CrossRef]

- Torims, T.; Pikurs, G.; Gruber, S.; Vretenar, M.; Ratkus, A.; Vedani, M.; Lopez, E.; Bruckner, F. First proof-of-concept prototype of an additive manufactured radio frequency quadrupole. Instruments 2021, 5, 35. [Google Scholar] [CrossRef]

- Hähnel, H. Update on the first 3D printed IH-type linac structure-proof-of-concept for additive manufacturing of linac RF cavities. Proc. LINAC 22 2022, 22, 170–173. [Google Scholar]

- Hähnel, H.; Ateş, A.; Dedić, B.; Ratzinger, U. Additive Manufacturing of an IH-Type Linac Structure from Stainless Steel and Pure Copper. Instruments 2023, 7, 22. [Google Scholar] [CrossRef]

- Frigola, P.; Agustsson, R.B.; Faillace, L.; Murokh, A.Y.; Gianluigi, C.; William, A.C.; Pashupati, D.; Frank, M.; Robert, A.; Joshua, K.S.; et al. Advance additive manufacturing method for SRF cavities of various geometries. In Proceedings of the Thomas Jefferson National Accelerator Facility (TJNAF), Newport News, Whistler, BC, Canada, 13–18 September 2015. [Google Scholar]

- Creedon, D.L.; Goryachev, M.; Kostylev, N.; Sercombe, T.B.; Tobar, M.E. A 3D printed superconducting aluminium microwave cavity. Appl. Phys. Lett. 2016, 109, 032601. [Google Scholar] [CrossRef]

- Riensche, A.; Carriere, P.; Smoqi, Z.; Menendez, A.; Frigola, P.; Kutsaev, S.; Araujo, A.; Matavalam, N.G.; Rao, P. Application of hybrid laser powder bed fusion additive manufacturing to microwave radio frequency quarter wave cavity resonators. Int. J. Adv. Manuf. Technol. 2023, 124, 619–632. [Google Scholar] [CrossRef]

- Mayerhofer, M.; Mitteneder, J.; Dollinger, G. A 3D printed pure copper drift tube linac prototype. Rev. Sci. Instrum. 2022, 93, 023304. [Google Scholar] [CrossRef] [PubMed]

- Mayerhofer, M.; Mittenender, J.; Wittig, C.; Prestes, I.; Jägle, E.; Dollinger, G. First High Quality Drift Tube Linac Cavity additively Manufactured from Pure Copper. In Proceedings of the 14th International Particle Accelerator Conference (IPAC23), Venicem, Italy, 7–12 May 2022; p. 43. [Google Scholar]

- Tran, T.Q.; Chinnappan, A.; Lee, J.K.Y.; Loc, N.H.; Tran, L.T.; Want, G.; Kumar, V.V.; Jayathilaka, W.A.D.M.; Ji, D.; Doddamani, M.; et al. 3D printing of highly pure copper. Metals 2019, 9, 756. [Google Scholar] [CrossRef]

- Gruber, S.; Stepien, L.; Lopez, E.; Brueckner, F.; Leyens, C. Physical and geometrical properties of additively manufactured pure copper samples using a green laser source. Materials 2021, 14, 3642. [Google Scholar] [CrossRef] [PubMed]

- Mayerhofer, M.; Dollinger, G. Manufacturing method for radio-frequency cavity resonators and corresponding resonator. Patent No. EP3944725A1, 2020. [Google Scholar]

- Mayerhofer, M.; Brenner, S.; Helm, R.; Gruber, S.; Lopez, E.; Stepien, L.; Gold, G.; Dollinger, G. Additive Manufacturing of Side Coupled Cavitiy Linac Structures from Pure Copper—A First Concept. Instruments 2023, 7, 56. [Google Scholar] [CrossRef]

- Rena Technologies GmbH. Surface Treatment of 3D-Printed Metal Parts. 2023. Available online: https://www.rena.com/en/technology/process-technology/hirtisation (accessed on 1 December 2023).

- Dassault Systèmes; CST Microwave Studio. 2023. Available online: https://www.3ds.com/de/produkte-und-services/simulia/produkte/cst-studio-suite/ (accessed on 1 December 2023).

- Menzel, M.T.; Stokes, H.K. Users Guide for the POISSON/SUPERFISH Group of Codes; Technical Report; Los Alamos National Lab.: Los Alamos, NM, USA, 1987. [Google Scholar] [CrossRef]

- Ronsivalle, C.; Picardi, L.; Ampollini, A.; Bazzano, G.; Marracino, F.; Nenzi, P.; Snels, C.; Surrenti, V.; Vadrucci, M.; Ambrosini, F. First acceleration of a proton beam in a Side Coupled Drift tube Linac. Europhys. Lett. 2015, 111, 14002. [Google Scholar] [CrossRef][Green Version]

- Degiovanni, A.; Stabile, P.; Ungaro, D. LIGHT: A linear accelerator for proton therapy. In Proceedings of the NAPAC2016, Chicago, IL, USA, 9–14 October 2016; p. 32. [Google Scholar]

- Robinson, J.; Munagala, S.P.; Arjunan, A.; Simpson, N.; Jones, R.; Baroutaji, A.; Govindaraman, L.T.; Lyall, I. Electrical conductivity of additively manufactured copper and silver for electrical winding applications. Materials 2022, 15, 7563. [Google Scholar] [CrossRef] [PubMed]

- EOS GmbH. EOS Copper CuCP. In Material Datasheet; Electro Optical Systems (EOS GmbH): Munich, Germany, 2023. [Google Scholar]

- Verdú, A.S. High-Gradient Accelerating Structure Studies and Their Application in Hadrontherapy. Ph.D. Thesis, Universitat de Valencia, Valencia, Spain, 2013. [Google Scholar]

- Gold, G. A Physical Surface Roughness Model and Its Applications. IEEE Trans. Microw. Theory Tech. Inst. Electr. Electron. Eng. IEEE 2017, 65, 3720–3732. [Google Scholar] [CrossRef]

| —SC 1 | —SC 2 | |

|---|---|---|

| After PPS 1 | (2972.0 ± 0.2) MHz | (2970.8 ± 0.2) MHz |

| After PPS 2 | (2997.7 ± 0.2) MHz | (2996.9 ± 0.2) MHz |

| —SC 1 | —SC 2 | |

|---|---|---|

| After PPS 1 | 5340 ± 100 | 5270 ± 100 |

| After PPS 2 | 8410 ± 100 | 8160 ± 100 |

| Measurement Location | —SC 1 | —SC 2 | Orientation |

|---|---|---|---|

| 1 | 0.49 µm | 0.44 µm | upskin |

| 2 | 0.31 µm | 0.36 µm | parallel |

| 3 | 0.57 µm | 0.50 µm | downskin |

| 4 | 0.46 µm | 0.45 µm | upskin |

| 5 | 0.28 µm | 0.26 µm | parallel |

| 6 | 0.58 µm | 0.50 µm | downskin |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mayerhofer, M.; Brenner, S.; Doppler, M.; Catarino, L.; Girst, S.; Nedeljkovic-Groha, V.; Dollinger, G. Improving Fabrication and Performance of Additively Manufactured RF Cavities by Employing Co-Printed Support Structures and Their Subsequent Removal. Instruments 2024, 8, 18. https://doi.org/10.3390/instruments8010018

Mayerhofer M, Brenner S, Doppler M, Catarino L, Girst S, Nedeljkovic-Groha V, Dollinger G. Improving Fabrication and Performance of Additively Manufactured RF Cavities by Employing Co-Printed Support Structures and Their Subsequent Removal. Instruments. 2024; 8(1):18. https://doi.org/10.3390/instruments8010018

Chicago/Turabian StyleMayerhofer, Michael, Stefan Brenner, Michael Doppler, Luis Catarino, Stefanie Girst, Vesna Nedeljkovic-Groha, and Günther Dollinger. 2024. "Improving Fabrication and Performance of Additively Manufactured RF Cavities by Employing Co-Printed Support Structures and Their Subsequent Removal" Instruments 8, no. 1: 18. https://doi.org/10.3390/instruments8010018

APA StyleMayerhofer, M., Brenner, S., Doppler, M., Catarino, L., Girst, S., Nedeljkovic-Groha, V., & Dollinger, G. (2024). Improving Fabrication and Performance of Additively Manufactured RF Cavities by Employing Co-Printed Support Structures and Their Subsequent Removal. Instruments, 8(1), 18. https://doi.org/10.3390/instruments8010018